107 minute read

Prime Mover News

> Isuzu introduces innovative technology on new N Series range

The new N Series from Isuzu.

The best-selling Isuzu N Series lightduty range has been given a significant update by the Japanese commercial vehicle manufacturer. In what is now regarded as its safest Isuzu truck ever developed for the Australian market, the new N Series, on sale 1 November, introduces a new Advanced Driver Assistance System (ADAS). It complements the existing safety suite found in all Isuzu N Series 4×2 trucks. Cleverly designed to keep Isuzu truck drivers, as well as other road users, safe and secure on Australian roads, the new ADAS observes changing traffic conditions and assists drivers in maintaining a safe distance from other road users, pedestrians, cyclists, and objects. This all works to help avoid collisions with a combination of warning alerts and automations that activate when an imminent crash or potentially dangerous change in driving environment is detected. The eyes behind Isuzu’s new ADAS is the highly effective Hitachi Stereo 3D Camera, proven to be incredibly accurate in object detection, as well as speed and depth perception (regardless of day or night operation). Unlike other trucks in the market that offer a single camera attached to the windscreen (usually at the top) and a radar sensor mounted lower on the cabin face or bumper, Isuzu has mounted the dual-lens Hitachi camera inside the cabin in a central dashboard position that does not obstruct driver view and is not attached to the windscreen. This gives the camera a superior field of vision to detect lower-height objects while in motion (small children for example)—a critical advantage for those working in established and built-up areas. Isuzu’s Advanced Emergency Braking system with Forward Collision Warning (FCW) works by way of the dual optical sensor camera, which monitors the environment in front of the truck. It can detect and determine the distance of three-dimensional objects such as vehicles, pedestrians, bicycles and other objects that appear in front of the truck. If the FCW system determines a collision is likely and depending on the circumstances and severity of the situation, the system will respond with either audible and visual alerts, or autonomous activation of the vehicle’s brakes. Under normal operating conditions the system is designed to avoid a collision with a speed difference up to 50 km per hour and can reduce the risk of a collision impact for higher speed differentials, even at night. Similar to systems found in many modern passenger cars, Isuzu’s Lane Departure Warning works via sensors that detect and monitor the vehicle’s trajectory in relation to lane markings on roads or the road edge itself, providing audible and visual alarms for the driver if the vehicle begins to wander out of the lane marking or over the road edge. Isuzu has also introduced the Distance Warning System (DWS). This is designed to ensure the truck operator is travelling at a safe distance from the vehicle ahead. Allowing drivers to pre-set a desired minimum distance (depending on application or environment), the DWS will alert drivers with a subtle visual warning on the dash when an unsafe distance is detected. The system has been intuitively programmed to only activate when speeds exceed 30 km per hour, which is particularly useful for highway driving and prevents spurious warnings in situations such as traffic jams. Operators who do face those unavoidable traffic conditions, or who are operating in metro settings will also appreciate the Traffic Movement Warning (TMW) system, another feature unique to Isuzu’s N Series ADAS. The TMW system monitors stationary vehicles ahead and will alert the driver with a clear but subtle warning sound when forward traffic movement is detected more than five metres from a truck’s stopped position. Isuzu Australia Limited National Sales Manager, Les Spaltman said the new N Series trucks were built to support operators across a gamut of applications, but that urban operators would find particular benefit in Isuzu’s ADAS. “We are incredibly pleased to offer our customers the next generation of safety in light-duty trucking with our updated N Series range,” said Spaltman. “With confidence, we can say these are the safest, most advanced, diesel-powered light-duty Japanese trucks in the Australian market. “In terms of work-smart features to keep drivers safe and comfortable, and capacity to get the job done, we believe operators will see a huge difference between owning a new Isuzu N Series truck compared with any other similar truck out there.”

> Simon National Carriers upgrades fleet in latest safety quest

Freight and haulage specialist Simon National Carriers has further bolstered its fleet with four new prime movers. Its Brisbane fleet recently welcomed four new Euro 6 Mercedes-Benz Actros 2653 units featuring the latest generation active safety technology that can automatically perform emergency braking for vehicles and people. Just like all Simon National Carriers trucks, the 2653 Mercedes-Benz units have been limited to 90km/h to reduce the risk of accidents in addition to providing fuel efficiency gains. Simon National Carriers has long been at the forefront of safety in the freight industry and was the first major operator to instigate a 90km/h limit on Australia’s East Coast in the 1980s. Mercedes-Benz was the first to introduce its Advanced Emergency Braking System (AEBS), which it calls Active Brake Assist, more than ten years ago in Australia and it has been standard on its trucks ever since. Now in its fifth iteration, this AEBS system uses both radar and camera technology to automatically bring the truck to a complete stop to avoid a collision or to mitigate an impact with vehicles or moving pedestrians if the driver does not respond. The Actros is also standard with the Lane Departure Warning System, which sounds an audible alert if the vehicle is drifting out of its lane. Mercedes-Benz offers driver training with all Actros models sold, while Simon National Carriers invests heavily in extensive training for every one of its drivers to ensure they are familiar with its trucks. Simon National Carriers Executive CEO, David Simon, said safety is paramount in the family-owned operation, which operates across all Australian states and territories as well as New Zealand. “One of our drivers died after stopping and crossing the road to help a lady change a tyre in the early 1990s and that hardened my resolve for us to do everything we can within our control to avoid losing another person,” he said. “At Simon National Carriers we will do everything we can to protect our drivers, so it makes sense that we select the safest equipment we can and limit the speed limit to 90km/h.” The Actros models, delivered by the team at Daimler Trucks Brisbane, also align with the Simon National Carriers focus on emission reduction with advanced six-cylinder engines that meet strict Euro 6 emission standards, well ahead of the currently mandated Euro 5 standards. The 530hp 13-litre six-cylinder Mercedes-Benz engine features an asymmetrical turbocharger and latest generation variable pressure fuel injection in order to maximise drivability and minimise fuel consumption. It is designed to work seamlessly with the Mercedes-Benz 12-speed Automated Manual Transmission to optimise fuel efficiency. “Simon Nation Carriers has always looked at ways to reduce our fuel consumption and lower emissions. We were one of two early adopters of engines with electronic controls in the late ’80s, and as well as testing and operating early Euro 2 and 3 engines, we also purchased the first Euro 4 production truck in Australia,” said Simon. “We know that our 90km/h speed limiting delivers 10 to 12 per cent fuel consumption savings, but an efficient truck like the Actros delivers further gains. The Euro 6 rating is also something that we appreciate.” Driver comfort was also central to the decision to choose Actros and minimise driver fatigue. All Actros trucks feature a recently upgraded interior that now features the Multimedia Cockpit as standard, which is made up of two new highresolution tablet-style display screens on the dashboard, replacing the centre screen and speedo and tacho cluster.

xxx The four new Euro 6 MercedesBenz Actros 2653s.

> NHVR reappoints board, backs borderless operations in new document

Key features of the modern, regulatory approach promoted, as part of the NHVR’s future vision, will be to deliver borderless operations and increasing flexibility for safe operators. These have been outlined in the National Heavy Vehicle Regulator’s Strategic Directions 2021-2026 document. NHVR Chair Duncan Gay said the release of the NHVR’s long term Strategy (first released in 2016) came at a critical time for industry, as the regulator pursues ambitious and relevant industry reform to the Heavy Vehicle National Law, currently under the spotlight. “We know the majority of industry want

Consistent regulation is expected across the eastern part of Australia.

to do the right thing – our job is to leverage this through data sharing and tailored regulatory approaches to lift safety standards right along the supply chain,” Gay said. “We have learnt a lot over the last five years, for example, the importance of driver physical and mental wellbeing and its impacts on road safety, and we have increased our capability to share safety insights with industry to collectively pursue better outcomes. “We are also going back to basics to develop a national understanding of freight infrastructure, ensuring consistent assessments that open up productive networks which are critical to the success of our road transport task.” As part of the Strategy, a key priority for the NHVR is completing the transition of regulatory services from the final HVNL participating jurisdictions. “Transitioning operations from New South Wales and Queensland will provide consistent regulation right across the eastern part of the country, ensuring industry experience and the same on-road interactions regardless of where people are working,” added Gay. Recently reappointed Chair of the NHVR Board, Gay welcomed the reappointment of current Board Members Ken Lay and Robin StewartCrompton for a further three years. “The reappointment of Ken and Robin at this critical time for our industry will enable continuity in pursuing the opportunities ahead of us,” he said. “They join Board members Julie Russell and Catherine Scott, who both bring a wealth of practical industry experience to the table.” The NHVR’s Strategy Directions will be reviewed in another five years, following the completion of transition of services.

> New notice guarantees PBS access ahead of vehicle builds

A new notice delivered by the NHVR will give eligible Performance-Based Standards (PBS) vehicles immediate network access when they receive a vehicle approval with a Tier 1 bridge assessment. South Australia’s Minister for Infrastructure and Transport Corey Wingard said all PBS vehicles must pass various safety and infrastructure standards, such as acceleration capability, turning space, pavement wear, and mass and dimension limits. “Previously operators of these approved PBS combinations would have to apply for a permit after receiving their vehicle approval,” he said. “This National Class 2 Performance-Based Standards (Tier 1) Authorisation Notice 2021 eliminates the requirement of a permit application and allows operators automatic access to approved networks. “This is another example of governments and the regulator reducing red tape and providing increased access for the heavy vehicle industry, which has continued to keep Australia moving during the pandemic.” NHVR CEO Sal Petroccitto said the Notice establishes a platform to provide operators with guaranteed PBS access before they build their vehicle. “Operators have told us that knowing they have immediate network access would be a big factor in deciding whether to invest in a PBS vehicle or expand their PBS fleet,” Petroccitto said. “It will certainly encourage the take-up of these smarter, safer and more-productive PBS vehicles in the Australian heavy vehicle fleet. We will continue to build on this Notice by starting to roll out a higher productivity PBS notice later this year.” The National Class 2 Performance Based Standards (Tier 1) Authorisation Notice 2021 applies in South Australia, the Australian Capital Territory, New South Wales, Tasmania and Victoria. Each network – as shown in the Notice’s jurisdictional schedules – has a maximum mass cap and a specified length limit for eligible vehicles. Operators must ensure they check their vehicle approvals against the conditions of this Notice.

> BlueScope joins as highway sponsor of Healthy Heads

Healthy Heads in Trucks & Sheds Foundation (HHTS) has attracted BlueScope as a National Highway sponsor it has announced. Through this sponsorship, BlueScope is committed to embedding the Healthy Heads Roadmap, playing a role in raising awareness and building cultures where workers, employers, managers and leaders know they can reach out for support when they need it the steel producer said. “At BlueScope, we know how vital this industry is, we want to play our part in driving awareness and change, building greater resilience across the workforce and ensuring people feel heard when it comes to the challenges they may face. We respect and value the work our Driver-Partners do,” said Jeff Moore, BlueScope Australian Steel Products Supply Chain Manager. “The important initiatives and projects carried out by HHTS are pivotal to building better work cultures and breaking down the stigma that exists around mental health. We are committed to working closely with HHTS and taking the necessary steps to make sure everyone across the road transport, warehousing and logistics industries have access to the information, tools and resources they need.” Earlier this year the Foundation launched the three-year National Mental Health and Wellbeing Roadmap (the Roadmap), providing all operators with access to the tools and resources needed to build healthier and thriving working environments. HHTS CEO Naomi Frauenfelder extended a warm welcome to BlueScope in joining HHTS as a sponsor. “We are delighted to work with organisations like BlueScope who are committed to taking steps toward better mental health and physical wellbeing of the wider industry,” she said. “The need to address key industry mental health risk factors is well overdue, with 38.2 per cent of workers diagnosed with a mental health condition saying that their workplace caused or exacerbated it, according to SuperFriend. With the support of BlueScope, we are able to continue delivering on key initiatives and projects nationally.” HHTS is an industry umbrella body specifically created to improve mental health and physical wellbeing across the road transport, warehousing and logistics sector. Recognising that it is vital to take action to ensure the industry is one where all people feel supported in what they do, HHTS is aligned with BlueScope in its vision.

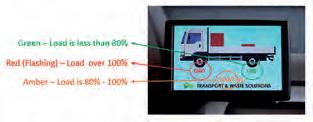

CHAIN OF RESPONSIBILITY LEGISLATION GOT YOU WORRIED? RELAX!

With TWS and Axtec there is no longer any reason or excuse for your vehicles to be overloaded

ONBOARD AXLE LOAD INDICATOR

DISPLAYS AXLE AND GROSS WEIGHTS SIMPLE COLOURCODED DISPLAY

Visual and audible warnings alert drivers to load errors Side and rear cameras Single touch-screen displays all functions - less driver distraction

WITH AXTEC ONBOARD

You can: • Load vehicle to capacity every time • Avoid fi nes and threats to Operating License • Avoid excessive wear and tear to associated with overloads • Reduce environmental impact • Receive real-time notifi cations via GPS / telematics system • Connect cameras to improve safety to pedestrians and cyclists ph: 02 9623 1800 e: chris.coleman@twsaust.com.au www.twsaust.com.au

> QLD horse carrier invests in user-friendly truck technology

To transport precious equine cargo, ‘Dippy’s Horse Transport’ insists on horseman rather than drivers. As a consequence the fleet must be easyto-use. “Our drivers are horsemen first, so the trucks we have can’t be complicated to drive, and this is one of the areas where the IVECOs are really good,” said ‘Dippy’ Dipzal. Born and bred on a Queensland cattle station, Dipzal has been around horses and livestock his entire life. Based in Toowoomba, Dippy’s Horse Transport began in 2010 and has a strong history with the IVECO brand. The company has owned six over the years, most recently a Stralis ATi prime mover and a Eurocargo ML160. It also operates INTERNATIONAL ProStar on fleet for B-Double float jobs. Servicing all areas of Queensland, New South Wales and beyond, the business has regular routes as far south as Victoria, northwest to Darwin and to far north Queensland. The Stralis is predominantly used for the Townsville run, while the Eurocargo travels to Melbourne. It’s a busy schedule that results in both trucks accruing over 5,000 kilometres per week. Prior to starting his business, Dipzal drove for another carrier of prized thoroughbreds for 20 years, and it’s here where he first began to appreciate the benefits of IVECO, primarily around the key performance measures of safety, driver comfort and low total cost of ownership. The operation transports race, stock and quarter horses so that safety and comfort is important, and not just for the driver. “When I was working for another carrier, one of my co-workers was involved in a serious accident and they came away with only minor injuries – they were driving an earlier IVECO Stralis,” Dipzal said. “This stayed in my mind, and when the time came to buy my own trucks I knew I wanted them to be IVECO.” The ML160 Eurocargo is fitted with a stock body that allows Dipzal to comfortably transport up to ten horses at a time, with the model also selected for its rear electronically-controlled air suspension which helps smooth out the bumps. “I go for an airbag suspension set-up where possible as it takes a lot of the jarring out of the ride, particularly over the rough tracks that we often have to cover,” Dipzal said. “Both the Stralis and Eurocargo also provide good accommodation for the drivers for when they need to rest-up on the road. “We install 24V air conditioning in our trucks to keep drivers cool when they’re resting.” The Stralis ATi features a 460hp / 2100Nm engine that’s matched to the 12-Speed Eurotronic II AMT, providing more than enough power for the single trailer application, which allows Dipzal to cater for a maximum of 15 animals. In the Eurocargo, power comes courtesy of a 5.9 litre power plant which produces 280hp and 950Nm of torque, with the engine coupled to a 9-speed manual. A common feature of both vehicles according to Dipzal is their impressive fuel efficiency. “Both these trucks are brilliant on fuel and are cost effective to maintain,” he said. “In some of our earlier IVECOs we covered up to 1.5 million kilometres before upgrading, nothing’s really gone wrong with them, all they’ve needed is replacement of the usual wear and tear items,’ Dipzal explained. “With the new trucks, we go back to the selling Dealership IVECO Brisbane for major servicing but do oil changes ourselves every 20,000 kilometres, just for that extra protection because of the high kilometres and tough conditions we cover.”

IVECO Stralis ATi (right) with real horsepower (left).

> ETR Haulage turns heads with new T909 flagship

Kenworth T909 powered by 600hp Cummins.

ETR Haulage has taken delivery of a new Kenworth T909 that raises the bar to the highest echelon for the company. The new T909 features a 50” sleeper and Kentweld Bullbars – AJ’s Total Truck Gear Bronco Bar, mirror polished stainless steel work by RC Metalcraft, Custom Air bunk air conditioning, Groeneveld auto greasing system and scrollwork completed by Grant Fowler. Power comes from a 600hp Cummins turning out 2,050ft/lb of torque driving through an 18-speed manual transmission to Meritor 46-160 diffs with a ratio of 4.3:1. ETR Haulage is owned by Bob and Fiona Fuchs, based at Gladysdale in Victoria’s Yarra Valley. The couple started Eastern Truck and Earthmoving Repairs (ETER) in 2014 with Bob having been a diesel mechanic since 2003. Starting as a sole trader business, ETER now has more than ten employees including diesel mechanics, an apprentice mechanic and MC heavy vehicle drivers who have experience in the transportation of a wide variety of products. In 2017 ETER put its first truck on the road hauling logs and ETR Haulage was born. “My family had trucks so for me it was a natural step to become a diesel mechanic and then start my own heavy vehicle repair business,” said Fuchs. “A friend whose trucks I worked on helped me get into log haulage – we bought a Kenworth SAR and did one 12-month season on the logs then branched out into other types of transport.” The company went into hay carting, selling the SAR and buying an K200 Aerodyne and hauled hay to NSW as part of the drought relief effort. “We did that for a year and it started to slow down so we then got into milk cartage,” said Fuchs. “That’s been our bread and butter since then.” Today the company has three trucks pulling milk tankers and two semi-tippers, with the new T909 pulling a double roadtrain for this year’s grain harvest. “All my trucks are Kenworths – I like the big bangers because the drivers treat them better and you can always find a good driver to operate them,” said Fuchs.

> DGL acquires Shackell Transport in deal worth $8.9M

Specialist chemical business, DGL, has announced the strategic acquisition of Shackell Transport. Shackell Transport is a freight carrier service that specialises in bulk liquid haulage. The acquisition price of $8.9 million includes Shackell Transport’s fleet, consisting of 28 primer movers, 22 bulk liquid tankers and 31 trailers that cater for specialised products and services. As DGL manufactures, transports, stores and processes chemicals and hazardous waste, the purchase makes for a natural fit enabling it to expand upon its interstate fleet. Shackell Transport has been operating for over 40 years, offering regional and interstate distribution and linehaul services across Australia to customers in the food, mining, chemical, agricultural, building and construction industries. As the first acquisition for DGL’s Warehousing and Distribution division it will complement existing fleet, bringing synergies and greater control over the distribution of chemicals, while also enhancing the Company’s visibility and access to the bulk chemical industry. “Through the acquisition of Shackell Transport we are significantly expanding our transport fleet, adding 71 quality vehicles to the Group. Shackell Transport further enhances our service offering to our customers, providing them with additional services and capabilities to align with their needs,” said DGL Founder and CEO Simon Henry. “We are seeing more of our customers seeking efficiency in their supply chains and moving towards consolidating suppliers. By expanding our interstate transport and bulk tanker fleet, we are cutting out the need for multiple suppliers, saving on transport costs and offering our customers all services in the sphere of chemical management.” Investing in equipment, according to a statement issued by DGL, is a core part of its growth strategy to achieve further economies of scale, driving growth through organic opportunities and greater operating efficiencies. “Investing in quality equipment sets us up for the long-term and ensures we are able to keep up with the demand the industry requires,” said Henry. “Expanding our inter-state transport fleet brings synergies between our three divisions and connects our Australiawide network of facilities, giving us greater control over distribution and the customer service experience.” The favourable acquisition price is considered equal to the asset value alone. It consists of a cash payment of $7.8M in addition to the issue of 506,912 fully paid ordinary shares in the capital of DGL. At the time the parties negotiated the conditional commercial terms in September 2021, the consideration represented a valuation of 7 x FY21 normalised Earnings Before Interest, Taxes, Depreciation, and Amortisation, and based on the current market price of DGL shares, a valuation of 7.3 x FY21 normalised EBITDA.

Simon Henry, DGL Founder and CEO.

> Hino-Connect rolled out for 500 Series customers

Hino 500 Series will feature HinoConnect as standard fitment.

Hino Australia has announced that all 500 Series customers will benefit from the standard fitment of Hino-Connect on all vehicles plated from 1 January 2022. Currently available as standard on the all-new Hino 700 Series, Hino-Connect is the next-generation of business intelligence that provides customers with real-time performance data tracking, remote diagnosis of vehicle faults and dedicated Hino-Connect specialist support. Built and designed in Australia by Directed Electronics, Hino-Connect allows direct communication with the driver through the truck’s Multimedia unit, which is an Australian-first. A unique element of Hino-Connect is the case-management provided by the Sydney-based team of Hino-Connect Specialists that support the customer, driver and dealer and monitor the progress of the repair to get the truck back on the road quickly. “At Hino, we are committed to placing our customers at the centre of our operations, by providing them with experienced specialists within the walls of our head office in Caringbah and, with Hino-Connect, we provide a complete support solution that minimises their downtime,” said Gus Belanszky, Hino Australia General Manager – Service and Customer Support. Meanwhile, Fleet and Business Managers can use an online portal and mobile app to access business intelligence and real-time insights into their fleet including live vehicle performance data such as fuel usage, the cause and effect of driving performance, and safety alerts. Other features include live GPS tracking and detailed trip reports plus useful tools such as ‘movement without ignition’ alerts and geo-fencing. “Another feature Hino-Connect offers our customers is an API (Application Programming Interface) data feed, which is rFMS compatible,” said Belanszky. “For our multi-brand fleets, this allows them to plug the data from the HinoConnect module straight into their own third party fleet management system.” 500 Series Standard Cab, Wide Cab, and 4×4 customers will join 700 Series customers in receiving five years of complimentary remote diagnostics and Hino-Connect Specialist support including vehicle engine control monitoring; severe fault alerts; and case management of fault rectification. In addition, they will also receive 12 months of complimentary business intelligence access, which will provide in-depth operational management of their fleet including live tracking and trip analysis; fuel consumption and forecasting; vehicle performance monitoring; and maintenance support. After 12 months, customers can choose to extend the business intelligence access and API integration for up to an additional 48 months. A modified version of Hino-Connect featuring the business intelligence elements will also be available as an accessory on 300 Series light-duty trucks from January 2022. “Hino-Connect is a natural evolution of the decade-long partnership between Hino Australia and Directed Electronics, which has been made possible by the high level of support provided by the team at Hino Motors, Ltd. in Japan,” said Belanszky. “Directed Electronics has built the hardware and firmware to suit the current market – their high level of expertise and capability allows us to deliver the right ‘plug and play’ solution for the Australian market, and provides flexibility to adapt the system for the future needs of our customers.” Built from the ground up in Australia, including the local manufacture of the Hino-Connect telematics hardware, the program is customised around the unique dataset available from the Hino vehicle and the capabilities of the multimedia unit. Directed Electronics Executive Director Brent Stafford said he was proud of the partnership with Hino and the opportunity it occasioned for the two companies to work together in the development of the Hino-Connect program. “Hino customers care about digital services that keep their trucks operating efficiently while reducing downtime and operating costs,” said Stafford. “In developing Hino-Connect, we set out to build a system that would achieve this – it is more than technology, it’s about making a difference in the lives of Hino customers.”

> LINX Cargo Care Group names new CEO

Brett Grehan will resume the role of CEO at LINX Cargo Care Group following Anthony Jones’ resignation. He joins the Group following 28 years with McKinsey & Company, most recently as a Senior Partner. Having built his career with McKinsey & Company, Grehan’s extensive working history, combined with his commercial and strategic expertise, has enabled him to accumulate strong sector experience in industrials including rail and steel, logistics, telecommunications and private equity. In these sectors, Grehan has worked overseas in cities like London, Atlanta and Mumbai, as well as delivering projects for clients in New Zealand, south east Asia, Hong Kong and China. The LINX Cargo Care Group Board is pleased to have Grehan join LINX CCG in this crucial leadership position where he will, together with the LINX CCG Senior Leadership Team, lead and guide the Group sustainably forward amidst the ever-changing operational and economic landscape. Grehan’s broad cross-sector experience and valuable insights and perspectives from his many years with McKinsey & Company, will benefit our Group and our position in Australia’s and New Zealand’s logistics supply chains. While Grehan officially commenced on Monday, 25 October he has already begun working with the Group Senior Leadership Team to ensure a smooth transition to the role in advance of Anthony Jones departing at the end of the month. In other news, the Griffith-based fleet of LINX Cargo Care Group has invested in another 13 new Kenworth K200s.

> Woolworths Group has announced an executive appointment for its supply chain business.

Annette Karantoni has been appointed Chief Supply Chain Officer and Managing Director of Primary Connect. Currently Woolworths’ Director of B2C eCommerce, Karantoni will formally transition to the new role in February 2022 and also join the Woolworths Group Executive Committee. “We’re delighted to appoint Annette to what is an important leadership role in our business,” said Woolworths Group CEO, Brad Banducci. “Annette has done an outstanding job rapidly expanding our eCommerce business to meet the surge in demand we’ve seen for online shopping over the past 18 months. As we continue to expand our retail ecosystem, our supply chain network will be critical to both the foundations and future aspirations of our business. “Our distribution centres are an essential link in the nation’s food and grocery supply chains and we’re continuing to invest in our network to improve range, service levels and resilience. “Annette joins a very strong team at Primary Connect, who have demonstrated safety and service leadership throughout the pandemic. I look forward to seeing them build our next generation supply chain in the years ahead.” Karantoni has spent the last 20 years working in a wide range of roles across Woolworths Group. Most recently, Annette has been the Director of B2C eCommerce – overseeing the significant acceleration in eCommerce demand over the last 18 months. Woolworths’ Australian Food eCommerce sales have more than doubled since the start of the pandemic. Prior to working in eCommerce, Annette led the development and investment roadmap for the Woolworths supply chain network. Annette has also held senior roles in supermarkets buying, marketing and replenishment. Woolworths Group’s current Acting Chief Supply Chain Officer, Chris Brooks, will remain in the role until February 2022. WooliesX Managing Director, Amanda Bardwell will continue to maintain overall responsibility for Australian Food eCommerce. In other news, refrigerated freight company Eades Transport has grown its national footprint thanks in part to its association with Primary Connect.

Annette Karantoni.

> Australia Post adds trucks, staff, forecasts hectic finish to year

One of the 4,000 vehicles in the national Australia Post fleet.

Delivery drivers and posties are set to deliver as many as 350,000 parcels across Victoria each and every weekend for the rest of the year. Despite delays and ongoing supply chain difficulties being felt around the globe, Australia Post reports that its facilities in Melbourne are processing on average a million parcels each day, enough to fill the seats of the MCG ten times. Around 1000 additional team members are also being recruited in Victoria to help sort parcels and mail, drive trucks, forklifts and delivery vans, and to help customers with their queries. The impacts of COVID have been particularly challenging in Melbourne, with hundreds of Australia Post team members having been forced to isolate. Even so facilities, subject to COVID-safe restrictions, posties and drivers have continued to deliver record numbers of parcels for Victorians, including each Saturday and Sunday. Australia Post has also added six additional pop-up sites to process parcels- at Dandenong, Somerton, Tottenham, Thomastown and two at Derrimut. The national mail delivery service confirmed its two biggest permanent facilities at Sunshine West are processing more than 450,000 parcels a day. To counter a significant reduction in passenger flights, Australia Post has also doubled its weekly freighter flights into Victoria to 60, to help carry more than 340 tonnes of parcels a week, with another 32 tonnes arriving via extra weekly Express Post trucks. Australia Post General Manager Corporate Affairs Michelle Skehan said the difficult decision to pause parcel collections from eCommerce retailers in Greater Melbourne had been vital in returning volumes in Victorian facilities to safe levels, with 4.5 million parcels processed during that time, while deliveries continued across the city. “We haven’t stopped delivering and have broken delivery records throughout the pandemic even as we’ve been faced with challenges like having large numbers of our Melbourne people in isolation,” said Skehan. “We recognise that people want their parcels to arrive as quickly as possible, especially as we head into Christmas, and that means on weekends too, and our people really are doing all they can to meet the huge demand under challenging times.” Weekend deliveries will remain across Melbourne and major regional centres for the rest of the year, and where volumes are high in other regional areas.

> Better bridges to eliminate heavy vehicle detours: Transport for NSW

Hundreds more timber bridges will be replaced across regional New South Wales, Transport for NSW has announced. Applications are now open for the next round of the NSW Government’s $500 million Fixing Country Bridges program. Deputy Premier and Minister for Regional Transport and Roads, Paul Toole, said the Government had already invested $282 million to replace more than 400 timber bridges across 53 Local Government Areas in round one. “This program has been an absolute game changer for councils right across the state, allowing them to replace some of their oldest and mostly costly to maintain timber bridges with safer, stronger structures that are more resilient to natural disaster and better equipped to meet the needs of the community,” said Toole. “Right across the State, we’re hearing the success stories of this program – from bridges that will now be able to support their RFS trucks in the event of a bushfire, to a new structure that will eliminate a detour of more than 260 kilometres for heavy vehicles moving to nearby farms. “Replacing these bridges will help drive economic growth, create jobs and build stronger connections in our bush communities for generations to come.” Toole said the unprecedented funding commitment to replace the State’s worst timber bridges was on top of the $500 million being invested by the NSW Government through Fixing Local Roads to help regional councils repair, maintain and seal priority roads in their communities. “Together, this $1 billion investment will ensure we build a safer, modern and more resilient road and bridge network for years to come in NSW,” he said.

A heavy vehicle enters NSW across the Murray River.

> Daimler Trucks Huntingwood sale completed

Velocity Vehicle Group Australia (VVGA) has announced the fulfillment of the transaction to acquire the Daimler Trucks Huntingwood dealership from Daimler Truck and Bus Australia Pacific. The ownership change took effect on 16 October 2021. “We are excited to have Daimler Trucks Huntingwood join the VVGA family,” said VVGA Executive Vice President, Richard Higgins. “The dealership has a 30-plus year history of providing exceptional support to a large and diverse customer base and the experienced and dedicated team of circa 125 people are an important and welcome addition to the VVGA network.” Higgins said the team had been leaders in Daimler’s Elite Support program which he said aligns well with the VVGA pillars of Speed, Value and Trust. “With our focus on these values, we aim to continue to grow and develop the Huntingwood dealership to provide service that meets the ongoing needs of our customers,” he said. In addition to this latest acquisition, VVGA operates 15 dealerships across Australia, exclusively selling Daimler truck, bus and van products across its network. The company purchased these dealerships from Eagers Automotive (Adtrans) on 1 May 2021. Daimler Truck and Bus Australia Pacific Aftersales and Network Operations Director, Greg Lovrich, said VVGA knows what good customer service looks like and understands the expectations of commercial vehicle customers. “We are confident Daimler Trucks Huntingwood customers will benefit from VVGA’s commitment to build capabilities across its network to ensure it can consistently deliver an excellent experience,” said Lovrich. Daimler Trucks Huntingwood is located in one of the main transport and distribution regions in western Sydney and has a strong reputation and presence within the industry. Its location, culture and customer base make it an important and complementary addition to VVGA’s nationwide network.

> MAN readies for self-driving truck production

MAN Truck & Bus has successfully completed the joint project Hamburg TruckPilot along with partner Hamburger Hafen und Logistik AG (HHLA). It’s considered an important milestone by the two companies involved for the use of self-driving trucks in port terminals for container transport. The objective of the three-year project, which was also part of the strategic mobility partnership between the City of Hamburg and Volkswagen AG, included the development and practical testing of an autonomous truck in container handling at the HHLA Container Terminal Altenwerder (CTA). During the practical trips, the logistics partner, Spedition Jakob Weets e.K. from Emden, first transported 40-foot containers controlled by a driver on behalf of Volkswagen Group Logistics to the CTA terminal in the Port of Hamburg. There, the truck drove autonomously across the terminal area and moved smoothly in mixed traffic with other road users. It drove to its destination in the block storage lane and also manoeuvred itself backwards with high precision into the parking position. After container handling, the return journey to the check gate was just as autonomous, and beyond the terminal grounds, the driver of the Jakob Weets e.K. haulage company once again took full command. The results were presented by MAN Truck & Bus together with HHLA at the ITS World Congress in October. “Pilot projects like Hamburg TruckPilot prove that the use of self-driving trucks is technologically feasible and can be efficiently integrated into logistics processes,” said Dr. Frederik Zohm, MAN Board Member for Research and Development. “In close cooperation with customers and partners, we are testing practical automation solutions with the aim of getting self-driving trucks ready for series production from 2030,” he said. HHLA CEO Angela Titzrath said cooperation with MAN remains an important and necessary step in shaping the future of freight transport. “Autonomous driving is coming. We at HHLA are preparing for this. Logistics 4.0 offers opportunities on a global scale,” she said. “To use them, we have to be open to change and show the courage to change. Autonomous driving and Hamburg TruckPilot are good examples of transformative processes that we want to actively shape.” The HHLA Container Terminal Altenwerder was considered an ideal test environment for trying out promising technologies as the facilities operate 24/7 around the clock, 360 days a year. That being said, the safe integration of autonomous trucks into the terminal processes is a major challenge, given autonomous and classic transports are intermingled. Under the conditions of the Hamburg TruckPilot, both parties were able to show that the application is possible and promising in practice. Satisfied with the results of the practical tests in the Port of Hamburg, Sebastian Völl, MAN Truck & Bus Project Manager — Hamburg TruckPilot, called it an important milestone for autonomous driving. “When our prototype manoeuvred independently into a block storage lane for the first time, we saw that it worked and that we can meet the high accuracy requirements. And even driving across the terminal site with many other manually controlled trucks, sensor technology, environment detection and automation systems have mastered the interaction perfectly,” he said. “When the first container with a real load lifted off the chassis during the practical drives, I was super proud of the entire team! We can build on this experience for future projects.”

MAN TGX Self-driving truck.

Frank Sandy

Frank Sandy, CEO of TWUSUPER has been with the fund since 2005. His previous roles have involved managing both finance and human resources. Frank is a CPA and has a Degree in Business Studies in accounting as well as a wealth of experience in finance and superannuation.

TRUCKING ANGELS

Commercial vehicle operators are bringing compassion, so often sorely missed, to the side of our roads.

Ruth Oakden, Group Manager Wellbeing at Toll Group tells a story about her mum, who was driving at night on a country road in rural Victoria. Her car windscreen and headlights were blownout by rocks from an overtaking vehicle. “My mum was forced to stop on the side of the road in her little 500cc Suzuki car in a dangerous section where she could have been back-ended – it was a dark night – she was frightened, and not sure what to do,” Ruth recalls. Who should pull over? A truck driver of course – offering help. The driver radioed his mate coming down the highway in another heavy vehicle. “The two trucks escorted Mum with her little Suzuki between them providing forward and rear cover and lighting her way right to the end of her suburban street,” says Ruth. “They went way out of their way to make sure she got safely home.” It’s a story that makes a powerful point about the people who deliver more than just goods. And another true story to make the point. One of our managers recently stopped at a serious single vehicle accident in Sydney on the way to work. The driver had a serious medical emergency in his car and had lost control, driving into a barrier on the side of the road. Two other vehicles pulled over to help — you guessed it - both truck drivers. Not skilled in medical help, but willing nevertheless to do what they could to help a man in a medical crisis until an ambulance arrived. The man unfortunately later passed away. Every Prime Mover reader would relate to these stories and likely have their own about truck drivers and it could be a theme for a future series. (Better talk to the editor). We know first responders – fire and rescue, ambulance, police – come under immense stress due to what they will see on their jobs but forget that regular road-users such as truck drivers are often among the first in the scene and share in the mental trauma. The broader community probably don’t have much understanding of this aspect of transport – after all, not only are truck drivers first to pull over in a serious accident, they also shun recognition. As Ruth Oakden puts it: “They see someone in distress in their patch, they are likely to pull over – it’s the compassion shown by truck drivers on the side of our roads. The road is their workplace or their office, and they do stop” Most truck drivers are highly experienced transport professionals, out there on our roads 24/7, keeping the nation running

even in a pandemic, but some can witness horrific scenes in their working lives, and the stress this causes is huge. A 2020 Monash University study of nearly 1400 heavy vehicle drivers found half of the respondents reported having some level of psychological distress. Ruth talks to a lot of people involved as first responders and she believes, truck drivers deal with it in their own way often, quietly and between mates, and that can help a lot, but the trauma can last and show itself in different ways such as gambling or self-medicating. Our own insurance statistics at TWUSUPER show mental health claims last year for Total and Permanent Disability were the second highest of any medical category. A high proportion of these would be related to PTSD conditions as a result of being first responders. At transport conferences we have heard people talk about this topic with great emotion. It would be good if the wider community understood the image they may have of transport doesn’t reflect the professionalism in the main and the people who work in it. The same survey also found one in five drivers under 35 years reported having severe psychological distress compared to the national average of one in nine in that age group. We understand a number of transport companies have programs and initiatives in place such as the work that Ruth does at Toll Group, as well as broader emerging industry initiatives like Steering Healthy Minds and Healthy Heads in Trucks and Sheds. At TWUSUPER we are trying to play our part. We take insurance seriously and will pay claims for those people suffering serious conditions relating to mental health issues, including posttraumatic stress trauma stemming from road accidents. And unlike many super funds, we pay benefits for people working in what are classed as ‘hazardous occupations’. You may be surprised to know a number of jobs in transport are considered hazardous. Not just truck driving and loading, but also mechanics, and almost anything of a physical nature. We are urging people who work in the transport industry, including your people to check the insurance they have in their super. As more people join the transport industry, many may be stapled to super funds with insurance cover that is not fit for purpose – such as excluding their occupation at claim time or preventing them access to additional insurance. These new employees will assume they are insured, only to find out later – at possibly the worst time in their lives – that a vital insurance claim has been refused by their insurer. It’s essential that we do as much as we can to alert people to this easily avoidable problem. As transport business owners and managers, you can remind your valued people via newsletters and the like to check if their super fund insurance covers their occupation. We will also be raising this issue via a Parliamentary submission, and education at transport events, forums and with help from the VTA, TTA, QTA and other industry bodies. Like you, we are proud to stand behind the people who may attend road accidents every day. We just wish it didn’t have to happen.

Truck drivers are often first to respond to an emergency situation on our roads.

THEY DRIVE BY

IVECO Highway B-double on the move in Melbourne.

Multi-faceted freight specialist, Datspares Transport, runs IVECO commercial vehicles interstate and locally including the new Highway B-double spec from the Italian truck manufacturer.

Datspares Transport, based in Clayton, a semi-industrial area in Melbourne’s southeast, moves an array of dissimilar goods for many customers in different industries. Its services include metropolitan depot to depot operations using rigid and light commercial vehicles and interstate B-doubles — 12 of them to be exact. The business is owned by Brian Murphy who arrived in Australia 30 years ago having grown up in Wexford, on a farm, in the southeast corner of Ireland. Around a decade ago the business, which originally specialised as a scrap metal yard, transitioned to a dedicated road transport outfit as demand for shipping spare parts on pallets escalated under the agency of a long-term customer contract. The company, whose General Manager Laura Murphy, Brian’s daughter, has been doing its best to keep up with a surging workload ever since. A second office for the business is located in Sydney while it also makes use of regular distribution points in both Brisbane and Adelaide. That is, to put it another way, just the tip of the iceberg. Then last year the iceberg — more commonly known as COVID — arrived and operational provisions have intensified to accommodate the frenetic regime of PCR testing, the chaos of waiting for containers to pass through customs, sudden border closures and the inconvenience of mandates that have exacerbated the dearth of experienced truck drivers plaguing an industry desperate for them. Into this mix, Datspares Transport, which runs on its linehaul a fascinating mingling of IVECO heavy vehicles, namely PowerStars and Stralis series vehicles, took on a pair of the new IVECO Highway B-double trucks for an extended trial run. The immediate results, of which there have been much to evaluate, culminated in the order of four more units, the first two are due to arrive in Q1 next year. It was a long time coming as the new trucks had been hyped, according to Brian, by Darren Cann, General Sales

Manager at Melbourne Truck Centre for the best part of two years. “They’re absolutely brilliant. The safety features are smack on, making it basically idiot-proof,” Brian says. “All the other European trucks might offer 600 horsepower and above, but they only run with a 12-speed gearbox.” That’s a problem for a company that regularly runs B-doubles into Wollongong over Mount Ousley and the steep and sustained descent in and out of Adelaide. Pulling 60 plus tonnes with a 12-speed gearbox demands every bit of RPM available in the engine. Datspares Transport assessed as many truck brands as possible at different horsepower ratings to see if it could deliver on the task. Not only did the suspension, gearbox and Euro 6 Cursor engine on the IVECO Highway B-double all feel improved but it also surprised in its fuel consumption, performing ahead of the other models. “I’d originally heard the new IVECO Highway B-double was meant to have 575 horsepower and when it had been dropped down to 550 it worried me as we do a lot of heavy loads coming out of Wollongong,” Brian says. “Coming back up that hill she’s also on max weight as we carry back out to a furnace in Melbourne. On that route the IVECO Highway, with the 16-speed box, is leaving every other truck we’ve tried for dead. In both the speed coming up the hill it does it with ease and going down the hills the retarder holds back the full loads so we’re not wearing out brakes. Even though IVECO tell me the engine is the same after you drive it you wonder that there’s nothing the same about it.” Datspares Transport still conducts manual checks to verify its fuel consumption rates though it will adopt the onboard IVECO telematics including IVEConnect, a driving style evaluator, on the newest vehicles, for more granular reporting on gear changes, braking, fuel economy and other crucial data points as it learns more about the system. “As you get bigger as a company you have to have access to that kind of information,” Brian says. “You’re able,

Bags of shredded plastic await to be shipped on the new IVECO Highway B-double.

with the telematics coming through it, to bring everything back to a much safer working place. That’s where I think the IVECO Telematics are going to be a huge advantage for our business. But we are only really at the beginning of that journey at the moment.” Servicing and diagnostic checks are also scheduled through IVECO Telematics. While the new IVECO Highway B-double has a millionkilometre warranty bumper-to-bumper, Datspares Transport conducts all of its own inhouse servicing when it comes to maintenance. A majority of the interstate trucks, it should be noted, run up 1000kms minimum every night. The driver, at the end of the shift, will go to a motel and someone else will operate the same vehicle all day. That evening the drivers will swap over again, with the first driver responsible for the return leg. On average, a Datspares Transport commercial vehicle travels 1500km every 24 hours. “When you take that mileage into account this is where the back-up service you have is so important,” says Brian. “The back-up service from IVECO is second-to-none at the moment and it was one of the big factors in us buying the new Highway B-double IVECO. They have improved with back-up parts and servicing dramatically.” It’s seldom that Brian will wait longer than 24 hours for a part. IVECO’s distribution warehouse in Sydney is well stocked, ensuring its customers are rarely at the mercy of import schedules, especially during the ongoing debacle of global supply chains. According to Brian it’s not the big things that bring operations to a halt — it’s the little things. Keeping engines tuned the right way; adhering to COVID protocols; maintaining experienced staff and close relationships with the likes of Darren at Melbourne Truck Centre, who is, per Brian, “worth his weight in gold.” With a minimum of ten B-doubles on the road every single night of the week, Brian estimates he wouldn’t have any more than three breakdowns a year. “No matter what truck you have if you

don’t have confidence in the back-up service when the little things go wrong it’s pretty pointless,” he says. “That’s where the reliability comes into it.” Datspares Transport won’t entertain using aftermarket parts. Every part, whether it is an oil filter or nuts and bolts, is always a genuine IVECO. “When you’re doing the kilometres that we do you can’t afford little variations,” Brian says. “Running with a genuine part, you know what’s right for the job and you’re going to get a certain number of kilometres.” Every certainty in an industry beleaguered over the past two years by uncertainties, counts. Between February and May, the business transports seedlings from Sydney to Melbourne. On hot days cool air moving over the trailer keeps the plants from frying inside. Any breakdown, on such an application, would remove the very shield that mitigates against direct sun from belting down on the roof of the trailer. “You literally can’t afford that. It would only take an hour to lose your whole load,” Brian says. “There wouldn’t be a point in going any further with it.” Most of his existing highway fleet has clocked between 1.3 million and 2.7 million kilometres. Until the first IVECO Stralis models were introduced in late 2015, Datspares Transport had been transporting everything and anything from batteries bound for recycling plants, concrete products and spare parts on IVECO PowerStars matched with a Cummins ISX engine. These, in turn, were paired with the EuroTronic II 16-speed transmission. “They don’t fall apart,” Brian says. “They are put together very well.” The IVECO PowerStars are also, from a maintenance perspective, easy to work on. As well as having a degree in horticulture, Brian, among his many talents, is a qualified mechanic. “With the IVECOs you don’t have to have special spanners to get into things. I don’t have to send mechanics out to spend a week with Benz or Scania or Volvo so as to learn how to change the eyelet in it,” he explains. “It’s still, at its core, a truck, which is a huge advantage for small operators like myself. We can work on our own truck and keep up with everything that way. IVECO has stood by me with the warranties.” If a truck comes in from Sydney at 6am, two mechanics will get “stuck into it” on a service so that it is ready by 10am. Because everything can be done without delay, as a consequence it empowers the operator. “I need trucks that have to get up around the two million-kilometre mark. And if you can’t do two million kilometres than you have the wrong models,” Brian says. “There’s not many operators who run the highways with trucks over a million kilometres because they are not able to stand up to it.” In 2015 the IVECO ASL Stralis was introduced into city operations and proved a nimble addition, accessing locations the bonneted PowerStars found more difficult. The Stralis was eventually given some of the same depot to depot tasks and have been just as effective in Brian’s estimation. Changes in the industry including kneejerk government edicts, sporadic border enforcements and a deficit of veteran, expert drivers, have placed a burden on OEM designers and engineers to deliver user-friendly vehicles to increase safety and awareness, especially for untried drivers coming into the game. This is where IVECO’s new truck comes into its own. “The visibility out of the cabin is absolutely brilliant. Some of these checkpoints, like entering into South Australia, on a miserable wet night when your ability to see is cut so short and trucks are backed up out on the highway can make it dangerous,” Brian says. “From a user experience you can’t ask for anything more. The IVECO Highway B-double has everything like the Driver Attention Support, Advanced Emergency Braking, lane keeping and a rollback system. When you have trucks like that in your fleet your insurance premiums go down. It pays for that as well.” Mindful that most of his interstate drivers are big men, egress to the cabin is important and the IVECO Highway B-double excels in this area, so it is less like scaling a ladder according to Brian. “The steps are very easy to use and they need to be when you have men who weigh 100 kilos,” he says. “No one wants anyone to get hurt. Who wants to have a WorkCover claim? I’m finding its very safe to send lads out in it.” On maximum weight loads, the new trucks are recording an average of 2kms/ litre. With a light load it improves to 2.2 to 2.4kms/litre, depending on the conditions and load. “I had one max weight single run to Sydney the other night and between Melbourne and Sydney she averaged 2.7km/litre. That’s a huge saving,” Brian says. “Every point of fuel you save, depending on the price of fuel, equates to a saving of $25,000 to $30,000 a year. If you can get two points up on fuel then that’s pretty much the repayments on your truck. That’s why we’re running two of those new trucks at the moment and why there will be another four coming next year.” The Hi-Tronix 16-speed transmission is equipped with ‘Rocking’ and ‘Creeping’ modes while a hydraulic retarder is essential for the type of miles required of Datspares Transport’s trucks. At 14.5 kilometres in length, the Mount Ousley climb is, for 6.6 of those kilometres, steeper in incline than 5 per cent. For another 1.2 kms the grade is steeper in incline than ten per cent. On this run Brian has got no need for exhaust brakes. “The new retarder system with the new 16-speed gearbox is exceptional. When you’re running on a hill she will hold it back within two or three kilometres of the speed that you set so if you’ve set it at 100 k/p/h it will run out to 102 or 103 going down one of those hills. That’s without touching the brake,” he explains in his lilting Irish brogue. “So you have a lot less wear and tear on your truck and trailers and you don’t have the highway patrol on your back or the RMS. That’s where those things really do come into

their own value.” The other driver aids, which include Tyre Pressure Monitoring System, Electronic Braking System (EBS) with Brake Assistance System (BAS), Electronic Stability Program (ESP), Hill Holder, Adaptive Cruise Control (ACC) and Advanced Emergency Braking System (AEBS) all make the truck idiot-proof as Brian puts it. “For anything on the Eastern seaboard and as far as Adelaide, no matter what industry you are in, I reckon she’s probably the best suited truck that you could possibly get,” he says. “It’s foolproof. I can’t find any other fault. The truck has the pulling power to keep the experienced lads happy.” The finance process was made a breeze by Alex Charilaou at Finlease according to Laura, who notes the drivers have told her they love the truck and the way it handles the workload. “The saving on fuel and wear and tear have a direct effect on our bottom line,” she says. “This means we can grow our business faster and continue expanding our fleet. Our customers choose us because we are on time and reliable, so I need our trucks to be the same.” The eldest of three daughters, Laura is the brains of the operation according to her father. Her siblings, like their mother, work in the medical field. “As kids we would come into work with dad every Saturday,” Laura recalls. “I have learned almost everything I know about this industry and business in general from him. Spending so much time in a wrecking yard and being one of the guys had an enormously positive effect on us all.” One of her favourite quotes, — attributed to Thomas Edison — “opportunity is missed by most people because it’s dressed in overalls and looks like work,” says much of the values instilled by Brian in his girls. “I love working with my dad. We both think in a similar way,” Laura says. “On difficult days, and there are many in this business, we are able to figure out the best cause of action together. We trust each other to make the right call, no matter the situation.” Some of Brian’s staff have been with Datspares Transport for 30 years. The big joke among the team is that if you last two weeks then you’re up for long service leave. “It means you know how to do your job and there’s no reason we’d be getting rid of you,” Brian notes. “I don’t have a high turnover of staff.” He says it not to brag, but rather out of admiration for an accomplishment that is, especially in this day and age, hard to ignore.

A sample of the IVECO fleet on show at the Datspares Transport home base in Clayton.

BIG A DEAL

Vehicle reliability and value for money are as important to operators transporting bulk products for the agricultural industry as in any other category.

Based in Bolwarrah near Ballarat in Central Victoria, Mark Rix transports grain and fertilisers primarily throughout Victoria and Southern New South Wales. Depending upon the season, Mark’s trucks will occasionally travel as far as the NSW New England district. A local for most of his life, Mark was born just five kilometres away in the town of Wallace. After earning his trade qualifications as a spray painter, Mark transitioned to transport, driving as an employee before establishing his own operation with his wife Kaye, following the familiar path of buying one truck, then two years later buying another, then another. Mark bought his first Freightliner in 2000 and has stayed with the brand ever since other than adding a Kenworth T610 in 2019. Mark recently took delivery of his third Freightliner Cascadia which is a 126 model fitted with a 60-inch sleeper cab. “I’ve bought some Freightliner Coronados over the years and had a good run out of them,” says Mark of his decision to become an early adopter of the latest from Freightliner. “So I moved on to Cascadia when they came out.” Asked what is important to him in a truck and Mark has a quick and straightforward answer: “Value for money.” Much of the grain transport is performed on behalf of the giant agribusiness operation Grain Corp. Fertiliser transport is also seasonal, and only occurs over a few months each year. Much of the fertiliser product is picked up in Geelong and transported direct to farms. Fertiliser and lime account for frequent loads to the Benalla area on behalf of Benalla Bulk Fertilisers. Mark and his son Ben perform all the maintenance, other than full rebuilds of engines or gearboxes. Their strict maintenance routines are likely the main factors contributing to the impressive reliability and longevity the Rix family extracts from its vehicles. “We don’t have a lot of days off,” says Mark. “The trucks are out during the week and we do all our maintenance on the weekend, so they are always on the road.” Proof that good maintenance pays dividends is embodied by the 2005 Freightliner Columbia, which Mark has only recently sold, although he had some regrets due to an almost emotional attachment to the vehicle. At the time of its sale the truck had covered more than two million kilometres, the engine being rebuilt twice and the transmission once. Other components such as the diffs were not touched in all that time. The current boom in the sales of new trucks has also

Freightliner Cascadia 126.

had an effect on the used truck market, with the value for quality second-hand vehicles on the rise. “I was never going to sell that truck,” says Mark of the C12 Columbia. “But when I got a good offer on it, I thought if I don’t sell it I would be an absolute fool. I’d rebuilt the motor last year so mechanically it was A1. We put in in for roadworthy inspection and only had to replace the torque rod bushes on the rear and put two windscreens in it. That’s not bad for two million ‘k’s’.” Mark’s maintenance and servicing regimes contributed to the longevity of two of his Coronados, with a 2013 model covering 1.1million kilometres before the engine was rebuilt and a 2012 model as still performing well at 1.2 million kilometres before its engine was overhauled even though it was not exhibiting any problems up to that point in its working life. Having a truck in the fleet which has similar specifications to the Freightliners provides the opportunity for some operational comparisons. “Fuel wise the Detroit engine is probably a smidgen in front of the Cummins in the T610, but I’m not talking huge amounts,” he says. “It may be 1.85 kilometres per litre compared to about 1.9, but the Detroit does use less AdBlue.” As the business has expanded Mark doesn’t get to perform as much driving himself as he used to, a situation for which he harbours a little regret. Travelling to different locations, particularly in the country, results in meeting new people and expanding his network. “What I used to like about what we do is getting out and about to different places all the time. You meet some good people, and you meet some not so good people, but overall you mostly meet a lot of good people and you see plenty of the country and you’re not stuck in the city,” he says. “Getting out and about is very enjoyable.” The latest Cascadia is connected to a ‘stag’ trailer set from Chris’s Body Builders, the first tri-tri stag combination manufactured by the Melbourne based body and trailer builder. Mark has specified automated manual transmissions since he bought the Columbia back in 2005. “I tried running them way back then and I’ve stuck with the auto path ever since,” he says. “Over the years they have got better, but this new 12-speed in the Cascadia’s is second to none and is super smooth. It’s just like going for a drive in my RAM pickup.” Mark genuinely appreciates the evolution of the Freightliner brand and how it has improved its suitability for his type of operation. “When I bought the first Coronado I thought it was so much better than the old trucks. I bought three of them in three years and yet the new Cascadia makes the Coronado look almost ancient,” Mark says. “It’s nothing like any Freightliner anyone has ever experienced before. It’s the ultimate.” Consequently, Mark has acquired three Cascadias during the past 12 months

The New Freightliner Cascadia on show in the western district of Victoria.

The new 12-speed Cascadia is hooked to a tri-tri stag combination.

through Brendan Eales who is the Freightliner specialist at the Daimler Trucks dealership located at Somerton in the northern suburbs of Melbourne. It’s a continual challenge to attract and retain good drivers, no more so than in ‘the bush’, so driver acceptance of certain vehicles is an important issue. One of the Cascadias has a 34-inch sleeper and performs five trips a fortnight to Adelaide and the regular driver had driven the renowned Mercedes-Benz Actros prime movers in his previous job. “He can’t find anything wrong with the truck. Towing a single trailer with 600hp it saves half an hour per leg loaded to around 44 tonnes over and back,” he says. “It’s only done 15,000 kilometres but its returning 2.4 kilometres per litre.” The quietness of the Cascadia cabs and advancement of the hardware and the suite of technologies continue to impress Mark and his drivers. “There is a lot of value for money in that truck. It’s got everything on it as standard and for the first 500,000 kilometres I don’t have to worry about them which is a bonus,” he says. “If they can get people to try them they will be quietly surprised at how good they are. If you can get a million ‘k’s’ out of a truck and it hasn’t caused you any grief you haven’t done bad and made a bit of money along the way if you’re doing everything right. But maintenance is the key. That’s the proof with the old 2005 model doing two million ‘k’s’.”

STAND AND DELIVER

Sharing their business name with a famous English firearms and motorcycle manufacturer, Brian and Sharon Anderson have built a successful crane truck business primarily servicing southeast Queensland and utilising a fleet of specialised trucks including three DAFs.

Founded in 1861, the Birmingham Small Arms Company Limited (BSA) was a major British industrial conglomerate manufacturing military and sporting firearms, bicycles, motorcycles, cars, buses and bodies, among other things. Some 143 years later, on the other side of the world, Brian and Sharon Anderson started a company called BSA Transport, where the name lives on but the similarities, on the whole, end there. The couple provides a first class crane truck service to customers primarily in southeast Queensland, having begun in accordance to a plan that they were, quite memorably, promptly forced to abandon. “In 2004 I’d just left a management position with a large taxi truck company and we decided to buy one crane truck so I could semi-retire,” Brian says. “That plan lasted for about three seconds and 36 trucks later here we are today.” Brian says it soon proved impossible for the couple to keep the business at one truck because as word got out about the great service the company offered, they were inundated with requests for their

DAF LF 290 6x2.

Brian Anderson.

services and had no choice but to expand it to meet the demand. “We have built some very strong relationships with several companies over the years and they have been rock solid in their support for us which has formed the mainstay of the business,” Brian says. One such company is a steel frame and roofing manufacturer which BSA Transport has been servicing since 2008 and which currently keeps 10 to 14 of the company’s trucks busy on a daily basis. One of these is a DAF CF single drive prime mover that BSA bought back in 2011 and that has been providing sterling service to both companies. Brian explains that this truck has had an unusual life. After a few years as a prime mover at the customer’s request, it was turned into a 14-pallet rigid curtainsider with the chassis lengthened and a lazy axle added. “Several years later they decided they needed a prime mover again so we removed the body and the lazy axle, shortened the chassis, and it once again became a single drive prime mover which now pulls an 18-pallet tandem axle semi-trailer,” Brian says, adding that the truck has now done over 700,000km and still going strong. The company’s policy is to keep its trucks for around 10 or 11 years, which is to say this prime mover will likely be retired before too long. Brian talks about the excellent reliability of the truck being matched by the outstanding service BSA receives from the dealer Brown and Hurley at Yatala — conveniently located just a 20-minute drive from the company’s depot at Kingston. “You’ve got to have reliability and backup and as far as I’m concerned Brown and Hurley and DAF put a big tick in both these boxes,” he says. “The service is second to none.” Brian explains that there were a couple of minor issues with the “old girl”, (his fond reference to his first DAF), but that the issues were swiftly dispatched by the proficient team at Brown and Hurley. “In the last eight or nine years it’s only been off the road for one or two days,” he affirms. “Virtually nothing goes wrong

Brian Anderson BSA Transport

with them, they’re reliable, comfortable and our drivers love them.” The second DAF Brian purchased is a 510hp CF85 8x4 rigid with a nine-metre tray and rear mounted HMF 32 tonnemetre crane. This versatile unit is set up to pull a tri-axle pig trailer and does a lot of concrete pipe haulage. Meanwhile, the newest DAF in the fleet is a 6x2 LF290 with a nine-metre tray and liftable ‘pusher’ axle that Brian says makes it ideal for delivering steel reinforcing mesh for concrete slabs at domestic building sites. This LF is Euro 6 compliant and has all the safety fruit including Adaptive Cruise Control (ACC), Forward Collision Warning (FCW), Advanced Emergency Braking System (AEBS), Lane Departure Warning System (LDWS), Vehicle Stability Control (VSC), protective cab suspension and construction; driver’s air bag and two seat belt pre-tensioners, reverse warning and engine immobiliser system. The steer axle has parabolic leaf suspension with shock absorbers and a stabiliser bar and a maximum load capacity of 7.5t. Wheelbase, as measured between the steer and Weweler pusher axle, is 6.9m, and the drive axle with a ratio of 4.1:1 rides on air suspension with a maximum load capacity of 20t. Brakes are EBS controlled ventilated discs on all axles while a polished alloy bullbar completes the picture. Power comes from a 6.7 litre six-cylinder diesel engine producing 217kW (295 hp) at 2,300 rpm and peak torque of 1,100Nm (811lb/ft) between 1,000 and 1,700rpm. This feeds into a ZF AS Tronic 12-speed transmission with ratios ranging from a 10.37:1 first gear to an 0.81:1 overdriven top. Other standard features include an exhaust brake, 430-litre capacity aluminium fuel tank, spray suppression, front underrun protection (FUP), 50-litre AdBlue tank and LED rear lights. According to Brian, the pusher lift axle on the LF is far better than a tag axle in terms of not getting hung-up on uneven ground and he says the longer wheelbase doesn’t adversely affect the turning circle. “Delivering into new housing estates and turning around in tight cul-desacs you need a truck that’s highly manoeuvrable and the LF certainly doesn’t disappoint in this respect,” Brian says. “In my experience, the turning circle on the DAFs is superior to that of the Japanese brands.” Brian also has high praise for the ZF 12-speed automated manual transmission (AMT) in the DAFs which he says shifts more smoothly and with more intelligence than the torque converter automatic transmissions in some Japanese trucks. “We spend a lot of time training our drivers to ensure they operate the gear in the required manner and we do our own servicing so we can keep an eye on how the trucks are being driven,” Brian

says. “For example, if we detect excessive clutch wear, we alert the driver and ensure corrective action is taken.” As for the future, Brian says the fourth DAF truck will be joining the fleet next year as part of the standard replacement policy that sees the trucks turned over every 10 to 11 years with around 750,000km on the clock. While his semi-retirement plan didn’t go exactly to plan, Brian says the couple’s son and daughter are now fully involved with running the business, which means he has more time to visit customers and drive one of the trucks when necessary. Further down the track Brian says he and Sharon are looking forward to more trips to various parts of Australia in their custom-built RAM truck and caravan. “With the kids now basically running the show, in a few years’ time I reckon we’ll be ready to see a lot more of what this great country has to offer,” he says. With the reliability and dependability of the DAFs along with the top-notch service from Brown and Hurley, they should have nothing to worry about.

DAF CF85 8x4.

CHANGING LANDS

Last year Centurion Transport began preparing early for dramatic changes to the economy, supply chains and interstate travel likely to impact industry. Through its willingness to adapt it has continued to discover new solutions through ingenuity, team work and key partners.

A Queensland-based Centurion Kenworth T610 roadtrain with Dana system package.

CAPES