NEW FRONTIERS

The PNG Expo is back and bigger than ever THE NICKEL MINING BOOM

PNG is gearing up to produce more nickel PLANNING FOR THE FUTURE

Exploring PNG’s future in the renewable energy space VOLUME 2 NO. 1 | FEBRUARY–MARCH 2025

The PNG Expo is back and bigger than ever THE NICKEL MINING BOOM

PNG is gearing up to produce more nickel PLANNING FOR THE FUTURE

Exploring PNG’s future in the renewable energy space VOLUME 2 NO. 1 | FEBRUARY–MARCH 2025

Inside Wake Goi’s vision for the PNG mining sector

Deep dive into two of the most well-known underground mines in PNG

How mining companies foster better lives for those living around their projects

for Aust ralia, Papua N ew Guine a and South East Asia

IMS have added the new BP1200-48TB track electric twin power blender to its impressive collection of blenders and pugmills, the new BP1200-48TB has four separate feed hopper each five meters long holding 12m3 each. All feed hopper conveyors are fitted with belt scales and controlled by a PLC control and recording system that can be operated from an iPad or phone from its own Wi-Fi system from a loader or

COO

Christine Clancy

GROUP MANAGING EDITOR

Paul Hayes

T: +61 3 9690 8766

E: paul.hayes@primecreative.com.a

EDITOR

Alexandra Eastwood

T: +61 3 9690 8766

E: alexandra.eastwood@primecreative.com.au

JOURNALIST

Kelsie Tibben

T: +61 3 9690 8766

E: kelsie.tibben@primecreative.com.au

CLIENT SUCCESS MANAGER

Janine Clements

T: +61 2 9439 7227

E: janine.clements@primecreative.com.au

RESOURCES GROUP LEAD

Jonathan Duckett

M: +61 498 091 027

PNG Mining takes a look into the world of renewable energy, discussing the key trends emerging in the year ahead.

E: jonathan.duckett@primecreative.com.au

BUSINESS DEVELOPMENT MANAGER

Tom Scott

M: +61 411 188 322

E: thomas.scott@primecreative.com.au

ART DIRECTOR

Michelle Weston

SUBSCRIPTION RATES

Australia (surface mail) $140.00 (incl GST) New Zealand A$148.00 Overseas A$156.00

For subscriptions enquiries please call +61 3 9690 8766

COVER IMAGE: Mineral Resources Authority PRIME CREATIVE MEDIA 379 Docklands Drive Docklands, VIC 3008 Australia www.primecreative.com.au

© Copyright Prime Creative Media, 2016

All rights reserved. No part of the publication may be reproduced or copied in any form or by any means without the written permission of the publisher.

AS THE INDUSTRY EVOLVES, new frontiers are opening up on the ground. Renewable energy is a key area of growth and innovation in Papua New Guinea (PNG), with advanced technologies making it easier than ever to create.

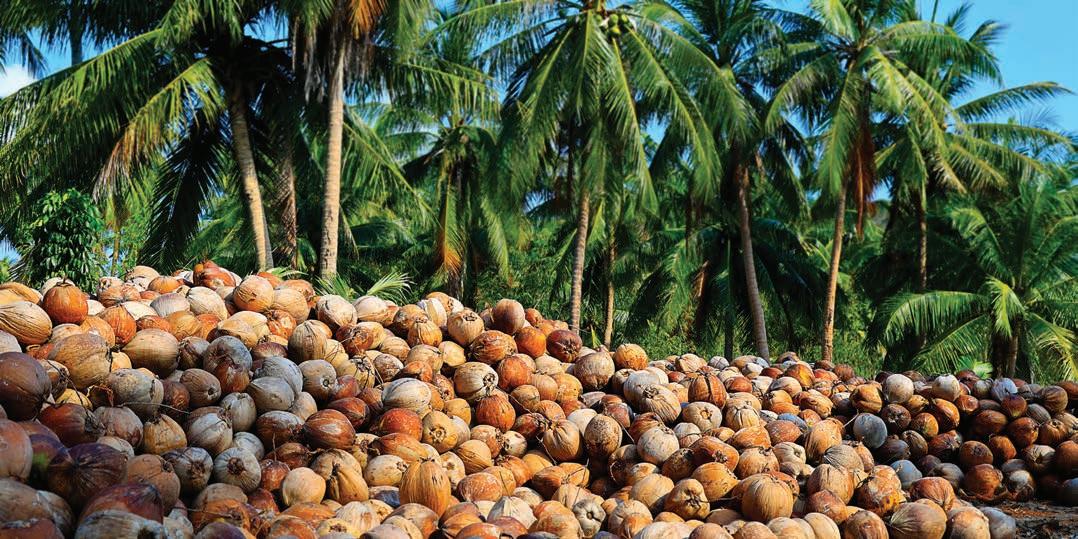

The February–March issue of PNG Mining delves into the latest developments in renewable energy, highlighting how the humble coconut has emerged as a potential substitute for diesel fuel.

In this issue, we also recap the highlights from MINExpo 2024. Held from September 24–26 in Las Vegas, MINExpo saw a some of the key minds from the PNG resources sector gather to discuss challenges and breakthroughs.

The event showcased an impressive roster of global companies and cutting-edge technologies, reinforcing the importance of collaboration and innovation for the sector’s future.

As PNG prepares for the 2025 PNG Expo, we look ahead to what promises to be a landmark event for the industry.

Silver sponsor TriCab is back on board for another year, and PNG Mining sat down with TriCab Queensland state manager Shane Plumridge to discuss what the company is looking forward to at this premier event.

“Events like the PNG Expo are vital in bringing like-minded consumers and suppliers together in the one space where it is mutually beneficial to all parties, in a relaxed and safe environment,” Plumridge said.

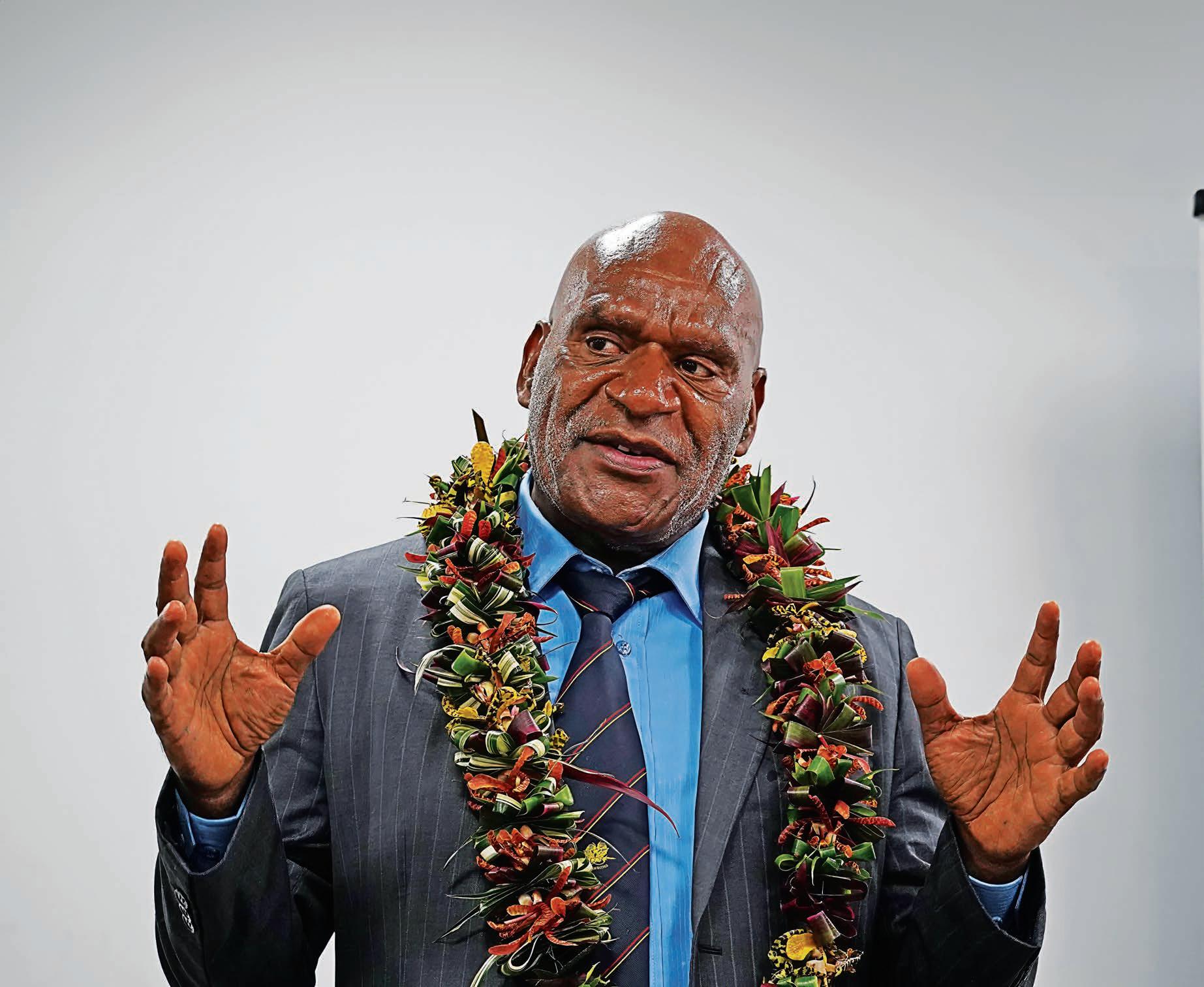

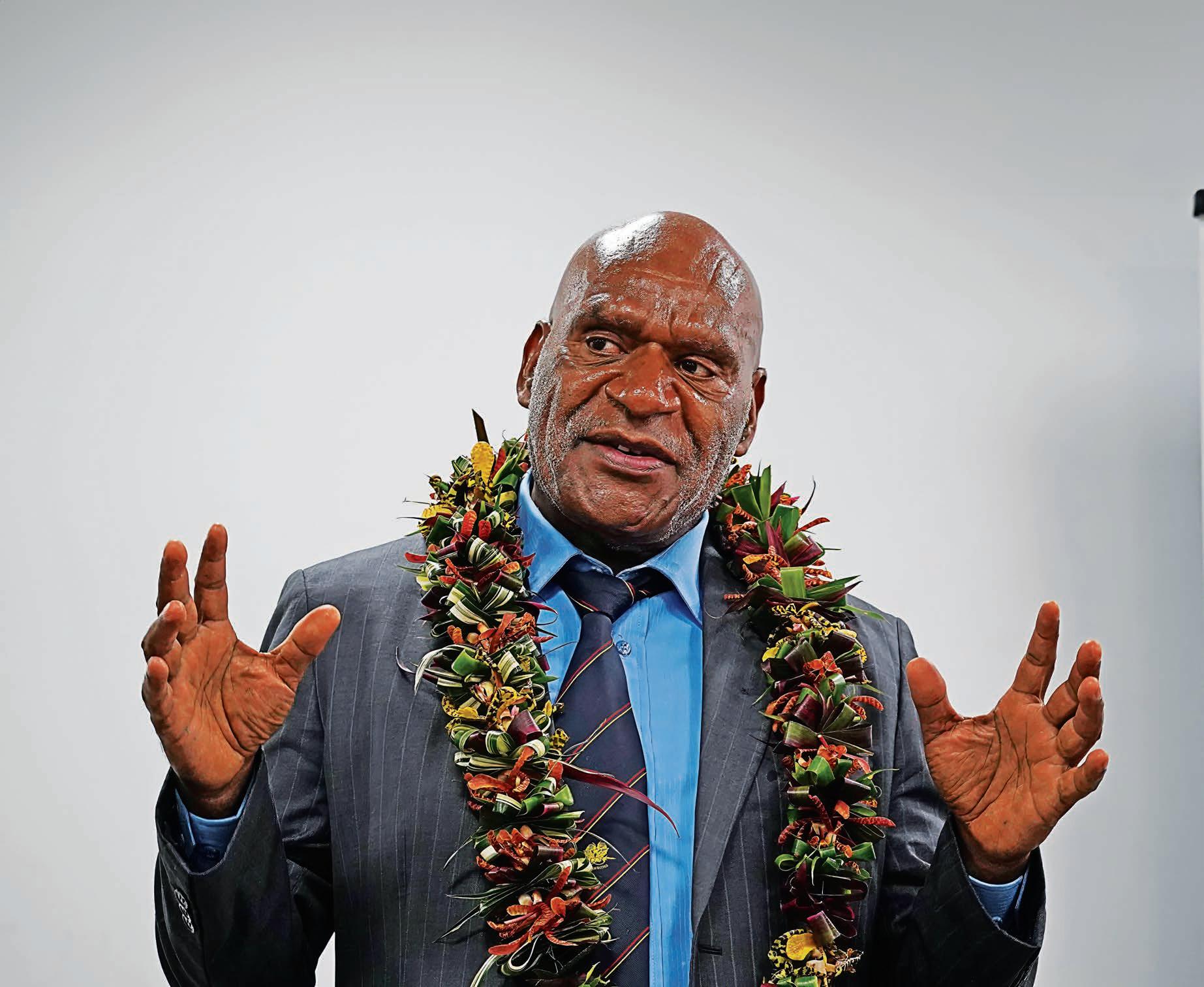

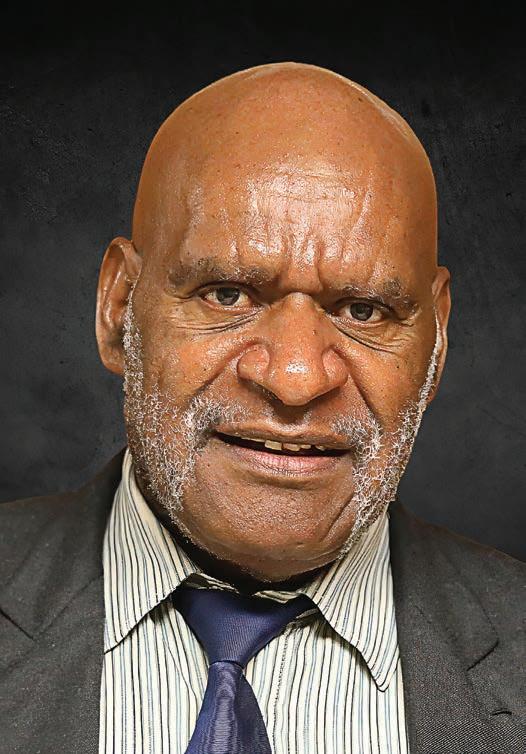

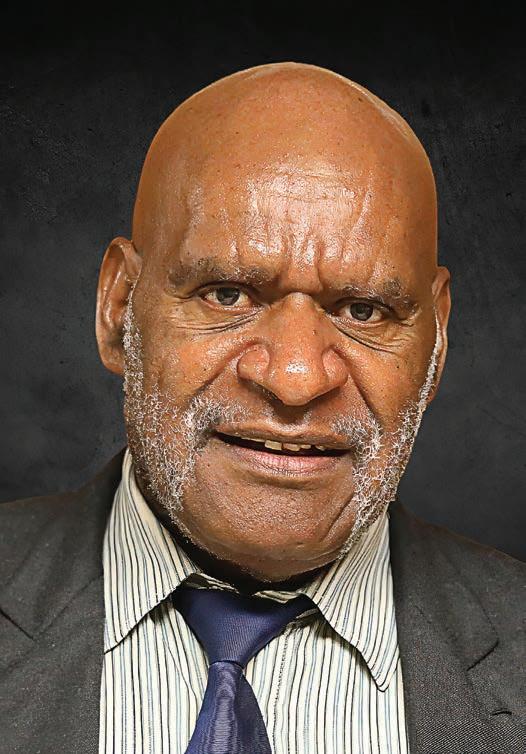

Elsewhere in this issue, we profile PNG’s new Mining Minister Wake Goi. Goi will be a crucial figure in shaping the country’s mining landscape in the years to come.

The new minister’s vision for the sector aligns closely with the evolving needs of the industry, and his years of experience will surely see PNG’s mining industry guided safely into the future.

As the industry faces both opportunities and challenges, the role of renewable energy international collaboration and strong leadership will be instrumental in the year ahead.

Happy reading.

Alexandra Eastwood Editor

8 Equipment

Blending with precision Crusher Screen Sales & Hire has produced a game-changing piece of equipment for accuracy in road base production, blending of materials, rehabilitation and slurry mixing.

10 Mining

Introducing the new Mining Minister PNG Mining profiles Wake Goi, PNG’s new Mining Minister.

18 Community Driving change

PanAust is a communityminded organisation keen to foster better lives for those living around its Frieda River mine.

24 Commodity spotlight

The nickel mining boom PNG is gearing up to produce more nickel than ever before, and is constantly on the look out for ways to boost its production capabilities.

32 Health Healthier, happier communities

Health initiatives have become one of the key ways resources companies in PNG give back to their communities.

40 Community Dedicated to care PNG Mining sat down with QueenPads founder AnneShirely Korave to learn more about the mission behind her menstrual health company.

42 MINExpo 2024

Mining’s glittering mecca MINExpo brought together mining’s key industry players in Las Vegas.

48 Renewable energy

From the ground up Wind and solar power

While the environmental permit application for the Frieda River copper-gold project advances, women from the Wabia community within the lease are gearing up to participate in the project’s activities.

PanAust, the parent company of Frieda River Limited (FRL), is progressing with its four-pillar development initiative to boost economic growth in East and West Sepik Provinces with the aim to bring economic benefits to the whole of PNG.

The projects include the mine, the Frieda River hydroelectric project, the Sepik power grid project, and the Sepik infrastructure project.

FRL is committed to working closely with government agencies and landowner leaders as the projects progress.

“The company has made us aware of both the positive and negative impacts of the mine,” landowner leader Martina Aki said. “As women, we need to be prepared. We must educate ourselves to maximise the opportunities the mine presents.”

FRL has already provided Adult Literacy Level 1 training to communities around the mine and is now working with other development partners to further support the pursuit of financial literacy, including skills in governance, banking, and budgeting.

“We need to learn how to market our garden produce and manage our finances so we can take care of ourselves and our children, educate our children, and develop our community,” Aki said.

“We recognise that Frieda River is in a remote location. It needs a well-developed road network and a dam before mining can start. We are supportive of this major development.” PNG

The Simberi gold mine will remain pivotal to St Barbara’s success as it looks to the 2024–25 financial year (FY25).

St Barbara’s strategy at Simberi is to continue sustaining its operations at break-even of near break-even operating cashflow.

Gold production at the site is sitting at 65,000–75,000 ounces, and St Barbara is forging ahead with a 9000m sulphide drilling program targeting the SorowarPigiput Trend.

“Importantly the metallurgical testwork has allowed early selection of

the final flowsheet and the company will now focus on optimisation of saleable concentrate flowsheet ahead of commencement of an updated feasibility study,” St Barbara head Andrew Strelein and independent nonexecutive chair Kerry Gleeson said in an announcement.

In FY24, St Barbara’s exploration team recorded another full twelve months free of reportable injuries, marking five years of reportable injury free-operations.

The broader St Barbara team also farewelled non-executive director Stef

Loader from the board on June 30, thanking her for her almost six years of service.

With three new directors already serving from 2023, the board has decided not to replace Loader.

Looking to financials, St Barbara ended the year with $191 million in total cash at bank and no debt and is well funded to complete the next phases of work and beyond.

Simberi achieved the midpoint of revised guidance with gold production of 54,705 ounces. PNG

Santos and TotalEnergies Gas & Power Asia have signed a new mid-term liquified natural gas (LNG) supply contract.

The contract includes the supply of 20 LNG cargoes, or up to 0.5 million tonnes of LNG per annum over three years.

Commencing in the fourth quarter of 2025, the LNG will be supplied from Santos’ global portfolio of LNG assets,

including the PNG LNG Project, on a delivered ex-ship basis.

“This oil indexed contract, along with the recently executed long-term LNG sales and purchase agreement with Hokkaido Gas in Japan, and the mid-term contract with Glencore, demonstrates Santos’ strong LNG portfolio position and customer relationships in the region,” Santos managing director and chief executive officer Kevin Gallagher said.

“There continues to be extremely strong demand for high heating value LNG from projects such as Barossa and PNG LNG as countries focus on reducing their carbon emissions.

“Santos is committed to supporting the energy security of our valued customers across Asia, where gas will play an essential role in decarbonisation efforts across the region.” PNG

Barrick Gold’s strong operating cash flow is providing the financial flexibility it needs to fund its growth projects.

President and chief executive Mark Bristow said Barrick has managed to reduce net debt by $3.5 billion, investing $11.2 billion in plans that promise over 10 years of mine life. This should return more than $5 billion to shareholders.

With six Tier 1 gold mines in its portfolio – and more in the pipeline –Bristow said Barrick’s long-term plans are based on quality orebodies with industry-leading grades that drive rising cost profiles.

The Goldrush mine in Nevada, Barrick’s latest project, is on track to hit the targeted 400,000 ounces per annum by

2028. Goldrush is Barrick’s fully-owned Fourmile project.

Fourmile is returning grades double those of Goldrush and is on its way to becoming another Tier 1 mine.

The Leeville project in Nevada is producing 14 million ounces, developing into a major growth driver that could double or triple the reserves of the nearby Carlin gold mine.

“Five years ago, we set out to build a sustainable, profitable gold and copper business focused on world-class assets,” Bristow said.

“We did not have to buy them at a premium. They were embedded in the merged portfolio of Barrick and Randgold and we just had to unlock their value.”

Copper business is another growing sector for Barrick. This strategic metal is said to enhance the company’s growth optionality to include coppergold porphyries.

Copper porphyry deposits are one of the most valuable types. Expansion into this business offers more than 30 years of mine life. Barrick already has two transformative projects on track to commence in 2028.

The Reko-Diq copper-gold project in Pakistan is expected to produce 400,000 tonnes of copper as well as 500,000 ounces of gold per year in phase two of development. PNG

Crusher Screen Sales & Hire has produced a game-changing piece of equipment for accuracy in road base production, blending of materials, rehabilitation and slurry mixing.

THE IMS PM1200-20TB track pugmill blender from Crusher Screen Sales & Hire (CSSH) has been bringing high-precision material processing to quarries, major construction projects and mine remediation since it was introduced in early 2024.

CSSH manager John Andersen said the PM120020TB pugmill has been a hit with the mining and quarrying industries thanks to its high accuracy, blending options and reliability.

“Crusher Screen Sales & Hire is the Australian distributor for IMS from Ireland and both companies have worked together to create pugmills and blenders offering solutions for accurate processing of products, powders and liquids of blended material in the quarry, construction and mining industries,” Andersen said.

“Some quarries have difficulty meeting road base standards without blending fines into the product. There is also increased use of blending recycled products into virgin quarry products to reduce the amount of raw material being used, reduce the amount of waste being taken to landfill and reduce the amount of transport movements on the road.”

This is where the PM1200-20TB pugmill can provide significant benefits to customers, due to its large-scale throughput and ability to handle several raw materials and additives at once.

“The new IMS PM1200-20TB track pugmill blender has two 5m-long feed hoppers holding 10m3 each with the option of fitting vibrating hydraulic tipping grids,” Andersen said.

“Each separate hopper conveyors are fitted with belt scales enabling the blending of two products with accuracy.

“The pugmill has the option of one or two powder hoppers and the ability to add two liquids. This is fully automated with a PLC (programmable logic controller) and recording system that can be operated with an iPad in a loader or site office.”

The PM1200-20TB has a longer 3m pugbox to ensure a quality mix when blending high percentages of powder – like rollercompacted concrete.

A four-sided access platform with stairs gives complete access around the cement hoppers for maintenance and visibility of the feed.

The IMS-PM1200-20TB pugmill twin feed hopper blender provides accuracy to mine and quarry operations.

A series of IMS PM1200-20TB pugmills, along with the single-hopper IMS PM1050-16TB tracked pugmill, are working in quarries across Australia, blending road base for major new infrastructure projects.

Andersen said the ability of the IMS-PM120020TB pugmills to blend two raw materials with the option of adding two powders and liquids has been a major draw for his customers.

“These machines also offer great serviceability, and the improved PLC control and recording system increases both safety and ease of maintenance,” he said.

The PM1200-20TB has an improved Australiandesigned PLC with a reporting program showing the percentages of each product, along with a supporting graph for each batch. If the blend is not meeting the programmed percentages, the pugmill will automatically stop.

It also shows daily totals of different products used on a particular day, which helps with the management of stock materials and ordering.

Alongside the IMS PM1200-20TB pugmill, IMS has also released the new BP1200-48TB track blender with four 5m-long feed hoppers, each holding 12m3 and powered by a Cat C7 generator that can be connected to mains power.

The BP1200-48TB blender can also work in conjunction with the IMS modular electric pugmill.

“The PM1200-20TB pugmill stands out as it’s the only pugmill blender on the market that has two separate conveyors on both feed hoppers,” Andersen said.

“Others have a dividing wall on the feed hopper, but only one conveyor belt, so you can only adjust the percentage of product from both sides with a front-ofhopper flow gate.

“The PM1200-20TB has a front-of-hopper adjustable flow gate plus a variable speed conveyor belt fitted with belt scales and a PLC control system, making it more accurate.”

Meet Wake Goi, PNG’s new Mining Minister.

PAPUA NEW GUINEA’S (PNG) mining portfolio has seen some changes in the past year.

Prime Minister James Marape most recently filled in the role, taking on the duties of outgoing Minister for Mining Muguwa Dilu until a replacement could be found.

Now, Wake Goi has been sworn into the role and has hit the ground running as he works to ensure PNG gets a “fair share” of the resources found under its soil.

Goi is a Member of Parliament in the Jimi electorate of Jiwaka Province and has previously served as PNG’s Minister for Community Development, Youth and Religion.

He completed tertiary education at Nazarene College of Nursing in 1990 and went on to become the Evangelical Brotherhood Church (EBC) Health Services general secretary after graduation.

Upon swearing Goi into the role of Mining Minister, Marape said he would be “a leader of high ethics and standards”.

“[Mining is] an important sector,” Marape said. “We’ve got the Porgera community benefit sharing agreement (CDA) that needs to be concluded. We have the Wafi gold project that needs to be progressed.

“[Goi has] strong experience on the ground. He’s been [a] minister for some time … I will assist him and offer my help to bring to conclusion the work

The Porgera mine will be a primary focus for Goi.

in moving our mining regimes to [be] legitimate, fair, equitable and beneficial to our country, giving respect to the constitutional laws and its resources in the first instance. Goi brings to the table his own experience as a leader of our country.”

In early October, Goi met with Mineral Resources Authority of PNG (MRA) managing director Jerry Garry at Mining Haus in Port Moresby to discuss future plans for the sector.

Garry said Goi’s appointment will bring the sector integrity, maturity and experience.

“Minister, I want to assure you that the MRA team has a pool of mining expertise [if] you require, to give

The Porgera CDA is set to become a focus for Goi as the government continues to speak with New Porgera Limited and the Enga Provincial Government (EPG) on obtaining their signatures on the agreement.

“It [is] the government’s wish to see that the

A CDA is a legal agreement or commitment entered into by the mining company and affected community or communities and approved pursuant to

Gold Fields’ Agnew mine in WA is setting a new standard in efficiency, increased throughput and operational safety thanks to a new crushing and screening plant from Sandvik.

THE AGNEW GOLD MINE is one of four Australian gold mines operated by Gold Fields Limited, one of the world’s largest gold mining companies with nine operating mines located in Australia, South Africa, Ghana, Peru and Chile.

Nestled firmly in the prolific Western Australian Goldfields, Agnew makes its home approximately 375km north of Kalgoorlie, where it has enjoyed a long history of gold production dating back to the late 1970s.

The mine is best known for its underground operations, primarily targeting the Agnew and Lawler gold deposits. The ore is extracted using a combination of underground and surface mining and is then processed on-site.

Around 2018, with the mine expanding into a third underground source, there was a need to increase plant throughput. The 21-year-old tertiary crushing circuit, which was suffering from poor reliability, was unable to meet the demand.

Gold Fields metallurgy manager Reg Radford is the company’s technical expert in the field of processing metallurgy. He works with process managers across all Gold Fields sites in Australia to assist in optimising the operations.

Radford could see that the crushing and screening circuit was not in keeping with the broader standards of the company.

“It was working to its limits, and if you compared it to other Gold Fields sites, it was not to the standard that would be accepted elsewhere,” he said. “It didn’t meet our criterion for a well-organised, safe, professional gold processing operation.

“The equipment was old, and there was little or no spare parts availability. From a metallurgical perspective, it was being pushed to its limits to deliver the tonnage required. At best it was giving us an 8–10mm output, which was putting pressure on the downstream grinding circuit.”

The age and complexity of the existing plant also meant that access for operation and maintenance was difficult, presenting potential safety concerns.

Seeking a complete solution

The existing crushers were reaching end-of-life, and rather than just replacing them, it was decided to build an entirely new crushing and screening circuit.

To do this, a comprehensive upgrade project known as the Agnew Stage 1 upgrade was conceived.

A new crushing and screening plant at Agnew Gold is delivering financial rewards.

The initiative examined bespoke and modular designs that could replace the existing plant. The project aimed to improve site water drainage and dust management (by installing a fine ore bin) while minimising disruptions during construction and commissioning.

Gold Fields manager – processing Tristan Freemantle was appointed as project director for the upgrade at Agnew. A veteran of the gold and copper industry, Freemantle originally worked for Barrick Gold and then transferred to Gold Fields around 12 years ago.

Since then, he has worked across several of Gold Fields’ Australian sites and is currently based at Gruyere, a joint venture project with Gold Road Resources located in the Yilgarn area of Western Australia.

“Agnew’s mine life had been extended for a further eight years, so upgrading the crushing and screening circuit was important to increase our processing capabilities: we needed to be in a position to process more ore from the new third mine coming online,” Freemantle said.

Gold Fields has enjoyed a longstanding relationship with Sandvik, with the company having Sandvik crushers installed at both their St Ives and Granny Smith operations. After considering a bespoke solution, the Gold Fields team chose to go with a Sandvik modular plant.

“We needed a circuit that was simple, low maintenance and reliable, but we also wanted the best crushers and screens that we could get,” Freemantle said.

“Sandvik showed a willingness to work with us within our parameters. Initially, it was just the crushers and screens, but in the end, they presented a complete plant design, which was modular and comparable with the bespoke designs that we were considering.

“Sandvik was also able to accommodate our desire to manage our own electrical and process control design.”

Key to the successful implementation was Sandvik’s expertise in crushing and modular plant design combined with the screening know-how of Schenck Process.

The scope of supply included a Sandvik reciprocating plate feeder, grizzly screen, jaw crusher, and two cone crushers, as well as a Schenck Process doubledeck banana screen fitted with Screenex screening media. Sandvik also provided bins, chute work, associated wear protection and conveyors.

The innovative plant design eliminated the need for two screening stations and associated conveyors when compared with other proposed designs.

“Having a single vendor was an advantage,” Radford said. “Sandvik’s initial designs and 3D models were quite detailed and comprehensive,

which was encouraging. It gave us confidence in the circuit because we knew exactly how the proposed layout would interact with the existing plant.”

A significant challenge for the project team was that Gold Fields needed the new plant to be installed in parallel with the old one so that, ideally, there would be zero downtime.

“Agnew can’t afford to be down for two or three weeks,” Radford said. “The mill is pushed to its limits, so it has little ability to catch up.

“Solving this problem – where we could build the new circuit and how to tie it in – was a good part of the success story. Commissioning on-time and within budget, with limited downtime, was a very important part of the brief.”

To accommodate this requirement, the team decided to move the run-of-mine (ROM) pad and build the new circuit on the site of the old ROM pad. While this achieved the brief of zero downtime, it introduced a new challenge.

The geology of the ROM pad was untested, and some contractors argued that a substantial concrete foundation would be required to support the crushing and screening plant, greatly increasing both the build time and cost.

In the end, working with Gold Fields geotech consultants, Sandvik’s design team resolved this problem by delivering a support structure for the

A control room centralises all Agnew crushing and screening functions.

new circuit that was strong and rigid enough to reduce the concrete foundations required.

The new crushing and screening plant has been running for more than 12 months, and the Gold Fields team is very happy with its performance.

“It is going very well,” Freemantle said. “The Schenck screen is performing well, and the Sandvik crushers have an intuitive automation system that was easy to integrate with our process control.

Solving this problem –where we could build the new circuit and how to tie it in – was a good part of the success story.

Gold Fields metallurgy manager Reg Radford

“The new plant was designed for a two-million-tonne-per-annum (Mtpa) throughput, which is oversized for the current throughput of 1.3Mtpa.

“This means the crushers can be run tighter, producing smaller product.

During the design stage, the crusher output was set at 8mm, but it is now regularly producing less than 6.5mm.

“The finer feed has improved downstream mill performance, increasing the maximum throughput rate from 155 to 170 tonnes per hour.”

A comminution crushing and grinding survey completed in October 2023 indicates that the new circuit is around 18 per cent more energy efficient.

“Also, we were able to centralise the control room duties, where we now have one operator in one

control room, and the crushers run pretty much automatically with extensive CCTV around the circuit,” Freemantle said.

“Previously, the crushers had their own control room, and the operator relied heavily on visual line of site monitoring.”

Safety has also improved considerably with the simpler design, modern instrumentation, and improved automation. The new circuit effectively addressed safety concerns associated with the old plant, exemplifying Gold Fields’ commitment to providing a safe workplace for its employees.

“Access to the new circuit is much easier and safer, with better, wider walkways, chutes that are accessible, and more room for cranes.” Radford said.

According to Radford, the design of the new circuit has reduced dust generation and improved water drainage around the plant.

“The new circuit has fewer conveyors and transfer chutes, and improved water sprays and belt scrapers,” he said. “We aimed to improve housekeeping and access to make things easier forour maintenance and operations staff. Comparing the two plants is like comparing chalk and cheese.”

Including a fine ore bin seamlessly tied into the main mill feed conveyor reduced dust emissions, reduced freshwater consumption from sprinklers, and improved site drainage through an improved plant layout.

Schenck Process’ (now a Sandvik company) double-deck multislope vibrating screen at Agnew.

Replacing the crushing and screening circuit has also led to financial improvements for the company.

The new modular crushing and screening circuit has delivered minimum annual savings of $1.5 million by increasing throughput at a reduced crushed product size, improving downstream efficiencies, and introducing a fully centralised control room. This has eliminated the need for a permanent second crusher control process technician.

Finer crusher output has improved grinding circuit efficiency and throughput at Agnew.

Combined with capital savings, this led to an impressive three-year payback period.

The Agnew gold mine’s transformative upgrade not only eliminated long-standing challenges but also ensured a more efficient, cost-effective, and profitable operation.

The Gold Fields team feels that the teamwork between all those involved has greatly contributed to the success of the project.

“Overall, working with Sandvik has been quite stress-free,” Radford said.

“There have been challenges on both sides, but we were always able to meet in the middle and find solutions.

“Once the concrete civil issues were solved, the whole thing came together very quickly.

“Sandvik’s ability to work with multiple teams was a highlight, delivering a project to spec, and always listening. The Sandvik team really pushed themselves to deliver the project and helped us achieve what we needed despite the challenges –many of which were out of their control.”

PNG Mining takes a look at the leadership changes from various resources companies across PNG.

SOME OF PAPUA NEW GUINEA’S (PNG) most well-known resources companies underwent significant leadership changes in late 2024.

Great Pacific Gold (GPAC) welcomed two new leaders to its board.

The first was Ron Gawi, who took on the role of country manager – Papua New Guinea in October 2024.

Gawi worked for the PNG Department of Minerals and Energy – which later became the Mineral Resources Authority (MRA) – for 20 years. During his tenure, he served in the roles of assistant director mining and manager –project coordination.

While working with the MRA, Gawi provided leadership and guidance to the team, overseeing seven operating mines. He has also overseen mining operations at the Porgera and Lihir gold mines.

Following his tenure at the MRA, Gawi took on the role of country manager – PNG at Highlands Pacific, developing vast experience in government and diplomatic relations.

“With the focus of the company’s exploration activity now in Papua New Guinea, we are very pleased to welcome Ron Gawi to our executive team,” GPAC chief executive officer (CEO) Greg McCunn said.

“His extensive background in permitting, obtaining and managing social license to operate in PNG is critical for the long-term success of Great Pacific Gold. With an exciting maiden drill program just getting underway at Kesar, Ron is joining the team at an ideal time.”

Previous country manager – PNG Benjamin Trotsky has moved to an advisory role within GPAC, assisting the company to ensure a smooth transition.

GPAC also welcomed Callum Spink as its new vice president – exploration at the end of October.

Spink brings 15 years of dedicated expertise in mining, exploration and resource development, marked by a record of success across complex geological terrains, particularly in PNG.

Spink has excelled in high-level exploration roles, including in his recent position as senior exploration geologist at Porgera for Barrick Gold.

His previous experience spans superintendent and principal geologist roles with companies like Newcrest, Northern Star Resources and Pacgold, underscoring his ability to drive strategic project generation and deliver sustainable value through rigorous geological assessment.

Specialising in project management, 3D modelling and advanced geostatistical analysis, Spink brings a refined skill set in subsurface interpretation, drill program design, and high-priority target identification to the role.

His geological exploration expertise has enabled him to lead complex exploration programs from inception through to discovery. Spink leverages his technical proficiencies and strategic vision to drive

discovery and optimise resource growth, ensuring impactful exploration outcomes and shareholder value creation.

“Attracting someone of Callum’s caliber to the team is a testament to the quality of our assets, particularly Kesar and Wild Dog,” McCunn said.

“His extensive experience in PNG including recently as senior exploration geologist at Porgera and at Lihir will be invaluable as we unlock shareholder value with our 5000m diamond drill program that is currently underway at Kesar, and with our plans for Wild Dog for 2025.”

Spink will oversee all of the company’s exploration programs in both PNG and Victoria, Australia. He will be instrumental in setting the Wild Dog exploration program for 2025 over a transition period in November and December and will start full-time in the role on January 1, 2025.

The International Council on Mining and Metals (ICMM) announced Tom Palmer, president and CEO of Newmont, as its new chair back in October 2024.

Palmer succeeded Iván Arriagada, CEO of Antofagasta Minerals, who led the ICMM for the past two years.

ICMM is governed by a council made up of the CEOs from its 24 member companies, with the chair appointed from within the group. The chair’s term lasts for approximately two years.

“I am delighted to welcome Tom as our new chair as we embark on our strategy to drive responsible mining practices under a consolidated standard while enhancing dialogue and engagement with our stakeholders,” ICMM president and CEO Rohitesh Dhawan said.

“Tom has led by example in this regard, having chaired ICMM’s Social Performance Advisory Group and through his genuine sustainability leadership within our industry.”

Palmer said he is excited to be working with ICMM in the new role.

“Newmont is a founding member of ICMM, sharing its vision for a safe, just and sustainable mining industry,” he said.

“I look forward to working closely with ICMM leadership, council members, and the wider mining industry. My focus will be on building

“I

support across the sector for a consolidated mining standard.”

Arriagada welcomed Palmer into the fold.

“It has been an honour to lead the ICMM council, and I am proud of the progress we have made, especially on the issues of tailings management, nature, diversity, equity and inclusion and better engagement with Indigenous Peoples,” he said.

Palmer’s appointment marks a new chapter in ICMM’s efforts to promote responsible mining practices worldwide.

In September, Santos welcomed Sherry Duhe to the role of chief financial officer (CFO) as outgoing CFO Anthea McKinnell began retirement.

am delighted to welcome Tom (Palmer as Newmont president) as our new chair as we embark on our strategy to drive responsible mining practices under a consolidated standard.

ICMM president and CEO Rohitesh Dhawan

Duhe was most recently interim CEO at Newcrest, where she worked with the company to negotiate and complete its sale to Newmont.

She was also CFO at Woodside Energy until early 2022, coming off the back of a 13-year career with Shell.

Santos managing director and CEO Kevin Gallagher thanked McKinnell for her time at the company, welcoming Duhe into the fray.

“Anthea joined Santos more than five years ago and has steered the finance function through a period of significant inorganic and organic growth,” he said.

“Anthea has been a valued member of the Santos executive leadership team and I wish her all the very best for the future as she returns to Perth for family reasons.

“Sherry’s demonstrated financial capability, knowledge of the complex and dynamic energy and financial markets in which Santos operates, and experience in engaging with investors, capital markets and governments, positions her well to support the Santos management team and board of directors in delivering superior value for our shareholders into the future.”

Duhe holds a Bachelor of Science in Accounting from Louisiana State University and an International Master of Business Administration from the University of South Carolina. She is also a certified public accountant. PNG

PanAust is a community-minded organisation keen to foster better lives for those living around its Frieda River mine.

PANAUST, the operator of the Frieda River coppergold project in Papua New Guinea’s (PNG) West Sepik Province, doesn’t do things by halves.

As the company ramps up its exploration and development at Frieda River, it continues to take steps to ensure communities in the area are looked after.

With a particular focus on healthcare, PanAust and its subsidiary Frieda River Limited have been driving change across the region, making essential health services more accessible and providing help where it’s needed most.

PanAust inked an important deal back in February 2024; one that would change the lives of people living in the East and West Sepik Provinces.

PanAust sat down with Interplast to sign on to a new three-year partnership to deliver a range of farreaching health benefits to the country.

Interplast Australia is a not-for-profit that regularly partners with local organisations to send teams of specialists to 17 countries across the Asia Pacific region.

“In Papua New Guinea our focus is on improved health, education services and capacity-building with an emphasis on the maintenance and establishment of infrastructure to support these services,” PanAust managing director and chief executive officer Daling Zheng said.

“We are here for the long haul and acknowledge our responsibility to support current and future generations. We believe that access to health is a fundamental right, and we are proud to play a role in ensuring that right is upheld in remote communities near the Frieda River project.”

The agreement sees PanAust commit $120,000 per year for three years to sponsor teams from Interplast; the first of which touched down in East Sepik Province in June 2024.

During one week in June, the five-person team performed almost 20 surgeries during their stay in East Sepik Province and conducted various consultations at Great Chief Somare Memorial Hospital, one of PNG’s most remote hospitals.

“We know how difficult it is for remote communities to access specialist healthcare and I’ve witnessed first-hand how transformative the surgeries can be for patients and their families,” Frieda River project director Phil McCormack said.

“It’s a powerful reminder of how we can deliver immediate change in a way that benefits local

PanAust committed $120,000 per year for three years to sponsor surgical teams from Interplast.

communities and provincial governments. PanAust and Frieda River Limited are proud to be able to offer these surgeries to the people of Papua New Guinea and to continue a long-standing partnership with Interplast.”

In addition to performing surgeries, the Interplast team conducted training sessions with local medical staff to enhance their capacity to deliver lifesaving healthcare.

Members of the plastic surgery team from Port Moresby General Hospital also joined the surgeons as part of their own professional development, including head of plastic and reconstructive surgery Dr. Jackson Nuli.

“This program was such a great opportunity for me and for my registrar Dr. Amoko to build our reconstructive surgical skills,” Nuli said.

“The patients who received surgery this visit have had significant improvements in their function. Thank you to Interplast and the team for making this happen.”

Interplast director of international programs Jess Hill thanked the sponsors for making the visit a reality.

“Interplast is thrilled to have a specialist volunteer Australian plastic and reconstructive surgical team returning to Wewak, thanks to the support of PanAust,” Hill said.

“Our thanks to the team at the Great Chief Somare Memorial Hospital and the East Sepik Provincial Health Authority for hosting this visit, and for arranging for patients from the communities in East and West Sepik to access much-needed specialised reconstructive surgical care which would not otherwise be available.’’

Altogether, the Interplast team performed 17 surgeries, conducted 50 consultations and provided clinical training to 18 surgeons, nurses and anaesthetic support staff throughout the visit.

“Whether it’s providing helicopter and fixedwing medivacs or offering support during natural disasters, we want the people of the Sepik Provinces to know we are here for them and will continue to be a good neighbour,” McCormack said.

“This is our way of meaningfully giving back to the community. By providing free surgeries and training local medical staff, we aim to leave a legacy of

improved healthcare in the Sepik Provinces that will benefit generations to come.”

Plans are already underway for future Interplast visits to the region, with PanAust continuing to work closely with community leaders and organisations to identify those most in need.

“We look forward to continuing to deliver this important work in Papua New Guinea, and in doing so, building the capacity of the excellent Papua New Guinea clinicians to deliver these services independently,” Hill said.

But it’s not just specialist surgeries that PanAust sponsors.

The company has long been a staunch supporter of women’s health, partnering with non-governmental organisation Queenpads to ensure access to menstrual products and resources for villages around the Frieda River project, with a particular emphasis on respecting dignity and human rights.

“These communities are remote and we consider this program an opportunity to address the silent needs of women and girls in hard-to-reach locations and give them choices through education,” Queenpads founder Anne-Shirley Korave said.

“We’re proud to have worked with Frieda River Limited on improving the wellbeing of the many local women and girls who attended one of our sessions.

“While we were there, we saw how closely the company worked with the community and the respect and trust the company has earned.”

PanAust also collaborated with PNG’s Ambunti Drekikier and Pacific Island Ministries to open a maternity ward in Papua Village Clinic.

The ward is located near the Frieda River base camp and provides a safe and supportive environment for expectant mothers.

Frieda River Limited contributed support equivalent to $15,200, covering the cost of transporting construction materials by road and casual labour hire to construct the eight-bed clinic.

Clean water is a vital part of ensuring the health and wellbeing of villages near the Frieda River project.

So, when an earthquake hit the village of Kamanimbit on April 3, 2023, and contaminated the only clean water source, PanAust stepped in to help.

Responding to a social media appeal for alterative access to cooking and drinking water, Frieda River Limited provided two 5000L water tanks as well as tarpaulin canvases.

villages healthy.

Then, in August 2024, Frieda River Limited donated a 5000L water tank to the Wombun Community Health Post in Chambri Lakes in an effort to secure a safe and stable water supply for those affected by natural disasters.

McCormack said the donation was part of Frieda River Limited’s continuing commitment to, and investment in, healthcare, education and infrastructure.

“We’re invested in meeting the demand for resources in a socially responsible way and looking after the diverse needs of local communities,” he said.

“From supporting infrastructure projects to providing fresh water, we remain deeply committed to helping communities in need, especially during times of crisis.

“We know this water tank will make a huge difference to a community that has been affected by two natural disasters in one year and we are proud to be a part of the community’s rebuilding efforts.”

Between 2017 and 2022, PanAust injected more than $US1.6 million ($2.4 million) into the local economy by way of its community development fund.

The company’s selfless drive to make a difference to villages around the Freida River project is ongoing, with PanAust keen to change lives well into the future. PNG

As Australia’s longest running mining show, Asia-Pacific’s International Mining Exhibition (AIMEX) has a long, established history of showcasing and supporting the latest trends and developments in the industry.

AIMEX is relocating and will call South Australia home for the next 10 years, following market feedback and strong support from the local government and key mining players.

The move marks an exciting new chapter for the event and the region’s resource sector, with the state leading the way in future-focused mining.

AIMEX offers unparalleled opportunities to connect with Australia’s largest community of mining suppliers and professionals in an environment that stimulates innovation and collaboration.

Often dubbed ‘Mining Island’, Misima has seen more than 130 years of mining activity, with no signs of slowing down.

JUST A SHORT two hour flight from Papua New Guinea’s (PNG) capital of Port Moresby lies Misima Island, a stretch of land known for its stores of gold beneath the surface.

Tiny but mighty, the whole of Misima measures only 40km by 10km – but this island has a historic mining past much larger than its size.

Gold was first discovered on Misima in late 1888 by a group of explorers making their way to PNG from Queensland, Australia.

The island did not provide the crew with a hospitable welcome. The foliage was dense, and the elevation of the land meant the team had to work for more than half a day just to clear enough space for a tent.

It took five months for the new arrivals to begin mining at Misima, but once they did, there was no stopping them. The island’s wealth of gold, copper and silver made the hard journey worth it.

Mining continued on Misima until World War II began in September 1939. With many of the wouldbe miners away fighting in the war, Misima wasn’t mined again until Canadian mining company Placer Dome commenced exploration there in 1977.

Placer opened and operated the Misima gold-silver mine from 1989 until 2004. During that time, the mine produced 3.7 million ounces (Moz) of gold and 22.2Moz of silver.

Eventually, the low price of gold in 1999 was the catalyst for the Misima mine shutting its doors, officially ceasing production in 2004.

Major miner Barrick Gold, who had acquired Placer in 2006, relinquished the licence for the site, which was in turn granted to Gallipoli Exploration, a whollyowned subsidiary of Pan Pacific Copper (PPC).

Gallipoli Exploration was the sole owner of the licence until 2011, when WCB Resources signed an exploration farm-in agreement with PPC to earn up to 70 per cent interest in the site.

From 2011 until 2017, WCB spent $6.8 million on the site before the company was acquired by Kingston Resources in November 2017.

Kingston then completed the farm-in agreement in August 2018, giving the company a 70 per cent of the mine – and the ability to allow it to shine once more.

The process of reestablishing operations at Misima kicked off for Kingston in June 2022 when the company reported the results of the project’s definitive feasibility study (DFS).

The DFS confirmed Misima as a large scale, longlife, low-cost operation with compelling project economics such as a $956 million net present value and a 20-year mine life. In February 2024, Kingston managing director Andrew Corbett said the company remains committed to the project.

“The past three months have continued to be a period of significant achievement for us,” he said.

The price of gold has historically been the decider of Misima’s mining future.

“With the successful milestones achieved and ongoing efforts, Kingston Resources is optimistic about the future and the opportunities that lie ahead.”

Kingston’s current focus at Misima is prioritising environmental and social impact assessment reports, strategic funding and development strategies.

“Placer Pacific operated Misima as a profitable open pit mine between 1989 and 2001, producing over 3.7 million ounces before it was closed when the gold price was below $US300 per ounce,”

Kingston said.

“The Misima project also offers great potential for additional resource growth through exploration success targeting extensions and additions to the current resource base.”

A 2024 strategic review at Misima continued to maximise project value for Kingston, with interest driven by favourable gold prices of $US2400 per ounce.

The company is also partnering with representatives from the PNG Government and related financial institutions to deliver a women in business program, aiming to increase the financial literacy of women on the island.

Kingston has seen high engagement in the program, with groups in the broader community also expressing interest in being involved. There are hopes that community engagement will further prolong the life of mine.

“Misima continues to represent an outstanding investment opportunity with strong economics and a long mine life,” Kingston non-executive chair Mick Wilkes said.

“We continue to pursue strategic options that will lead to growth in shareholder value and realisation of significant social benefits to the people of Misima and the people of PNG more broadly.” PNG

PNG is gearing up to produce more nickel than ever before while looking for ways to boost its production capabilities.

PAPUA NEW GUINEA’S (PNG) large stockpiles of nickel have dazzled the international mining sector since the mid-1950s.

Although the country is well-known for its quantities of gold, copper and silver, nickel sits proudly as one of PNG’s dominating exports, helping the country achieve the title of the world’s 12thlargest nickel producer in 2023.

Nickel production in PNG is only expected to rise in the years leading up to 2027, and miners are gearing up to extract more of this critical mineral in the decades to come.

in PNG

The $US2.1 billion ($3.1 billion) Ramu nickel-cobalt project is perhaps the most well-known nickel project in PNG.

Located near Madang on the north coast of PNG, Ramu is one of the largest mining and processing projects in the country.

The site is composed of laterite open-pit mining, a 135km slurry pipeline, deep sea tailings placement and a number of supporting facilities.

Ramu produces an astonishing quantity of ore, including 31,000 tonnes of nickel per year. The mine is often on the radar of Prime Minister James Marape,

who has called the site “historically significant” for the country.

Construction at Ramu began in 2008 and was completed by 2011. The project is managed by Ramu NiCo Management (MCC), who is fully responsible for its construction, development and operation.

In January 2024, MCC and Kumul Minerals Holdings signed an agreement to encourage Chinese involvement in downstream processing in PNG, particularly in the nickel and cobalt spaces.

Unsurprisingly, Ramu was the main drawcard.

“Our government has been resolute in its desire to transition from being a raw produce exporter to an exporter of finished products,” Marape said on the signing.

Marape met with Chinese President Xi Jinping in October 2023 to discuss opportunities for China to invest in various sectors across PNG, including agriculture, fisheries and forestry.

“I thank the Chinese Government and Chinese companies for recognising the imperative for Papua New Guinea to build a robust and diversified economy through downstream processing,” Marape said.

“I extend an invitation to more Chinese companies to come and partner with us in the downstream processing space.”

Nickel is widely used in power generation.

While Ramu might be the most famous PNG nickel mine, there is one up-and-comer that could eventually give it a run for its money.

Perth-based LCL Resources’ PNG Nickel Project has been gearing up to full-scale mining since early 2023, when LCL acquired 100 per cent of the project.

To date, four prospects have been identified within a 20km strike: Veri Veri, Iyewe, Doriri and Olei Creek. These four prospects make up the project’s 3400km2 area.

LCL has regularly found high-grade nickel within the project. In July 2023, the company announced it had found 45.8 per cent nickel concentrations in boulders within the project’s river, a find that managing director Jason Stirbinskis said was encouraging.

“We currently don’t know the extent and number of nickel-bearing shear zones within the identified structural corridor nor the presence of nickel sulphides separate from the boudin structures, however the scale of the shear zones in the small area we have mapped suggests they are part of a large nickel mineralised system,” he said.

In October 2023, LCL announced it had defined its project exploration model, using reviews of previous exploration completed as far back as the 1960s.

LCL worked with leading nickel expert Dr Martin Gole to develop a distinct exploration model at the project. Gole’s work came back showing the PNG Nickel Project has a rare type of mineralisation, with the closest similar geological setting in Tasmania.

“Our evolving nickel sulphide story is showing great promise,” Stirbinskis said.

stockpiles of nickel.

“Results and the input of nickel experts are giving us confidence that we could be onto something of global interest.”

Throughout the remainder of 2023 and the beginning of 2024, LCL continued to find new high-grade nickel sulphide outcrops throughout the project, culminating in the discovery of extensive nickel laterite mineralisation in October 2024.

While the PNG Nickel Project gears up, the PNG Government has been looking further afield to bolster its nickel reserves.

PNG Minister for International Trade and Investment Richard Maru announced in September 2024 that the country would focus on attracting Indonesian investments following high-level engagements between the two nations.

Indonesia is the largest nickel producer in the world, with reserves of 21 million tonnes. This accounts for 20.6 per cent of the global nickel total.

“Downstream processing has been highly successful in Indonesia, creating thousands of jobs, transferring higher-value skills, and introducing advanced technological processes,” Maru said at the time.

“The nickel special economic zone at Weda Bay alone created 80,000 direct jobs and 12,000 indirect jobs – more jobs than PNG’s entire mining and petroleum industries combined.”

According to Maru, the Indonesian Government has recommended that PNG implement a ban on raw material exports.

“Our government has already declared its intention to pursue downstream processing, and we don’t have to reinvent the wheel,” Maru said. “Indonesia is right next door, ready to share its experience and offer support.”

PNG Deputy Prime Minister John Rosso said PNG would look to implement special economic zones like in Indonesia.

A special economic zone is a designated area of a country that is subject to more favourable economic regulation, like tax incentives and lower tariffs.

“You (Indonesia) have already gone down that path, learned from your mistakes, and you will be able to teach us,” Rosso said.

Maru said Madang would be an ideal location for PNG to establish a special economic zone.

“It can create thousands of new jobs,” he said.

“The Indonesia experience is an eye-opener for PNG on what can be achieved, and best of all, they are willing to help us.”

The PNG Development Strategic Plan outlines the country’s future in renewable energy.

THE MAMMOTH TASK of switching to a renewable energy grid may seem daunting, but for countries like Papua New Guinea (PNG), a well-thought out plan can help tackle the job.

PNG’s Development Strategic Plan 2010–2030 (PNGDSP) aims to not only make the transition to renewables easier, but also help to ensure a high quality of life for all Papua New Guineans.

The PNGDSP was coined by former Prime Minister Michael Somare, who called on the people of PNG to think positively about the future of the country.

“PNG has progressed and is now at the crossroad of economic development,” Somare said. “The people of PNG rightfully expect a policy that has the courage to change the future, and the strength to change and transform things.”

The objectives of the PNGDSP can be narrowed down to five key points:

• Integral human development

• Equality and participation

• National sovereignty and self-reliance

• Natural resources and environment

• Papua New Guinea ways

Altogether, the PNGDSP aims to guide the Pacific nation onto a path of sustainable growth to achieve economic prosperity and a high quality of life – and renewables will feature heavily in this framework.

A key part of the PNGDSP is the building of an ‘electricity super-corridor’.

The corridor would be built to pass through areas where electricity can be generated at the lowest cost, with the wider national grid feeding off it.

This would allow electricity to be allocated efficiently across the country and the possibility of building future interconnection to a regional grid where electricity can be exported.

“As Australia and Indonesia look to reduce their reliance on fossil fuel-powered electricity in the future, buying electricity off the PNG grid may be a competitive option,” the PNGDSP said. “The Purari River alone could generate enough power for the entire Australian state of Queensland.”

Private sector participation is crucial to build the corridor, and to invest more in hydroelectricity power.

Hydroelectricity will become a mainstay of power generation in PNG.

PNG is expecting 52 per cent of its electricity to be generated from hydro by 2030 to meet the fivefold rise in demand. Only two per cent of energy generation is expected to come from diesel.

“Diesel and heavy fuel-generated electricity is expensive and has been a main contributor to the high-cost structure in the energy sector of PNG,” the PNGDSP said. “Under the PNGDSP, diesel generators will be phased out and retained mainly for backup purposes.”

PNG also has a wealth of gas resources.

“Gas is a cheap energy source and easier and cheaper to install than other technologies such as hydro,” the PNGDSP said. “In view of the substantial gas resources, PNG will significantly increase the use of gas during the initial PNGDSP period while plans are made to develop renewable sources.”

The country will continue to pursue other renewable energy sources including geothermal, wind and biomass, with an estimated 25 per cent of PNG’s electricity needs to be generated from these sources by 2030.

Energy distribution and demand

PNG’s energy generation capacity currently sits at approximately 580 megawatts (MW).

Much of this amount is provided by the private sector, and as a result, only 13 per cent of the population has access to electricity.

The PNGDSP is aiming to connect 70 per cent of Papua New Guineans to electricity by 2030.

While the country’s generation capacity is low, the demand remains high. The average daily peak load demand for electricity is approximately 290MW, and this number is projected to grow five times over by 2030.

“This means more sources of power generation must be identified,” the PNGDSP said.

“The benefits to PNG of achieving the 70 per cent electricity coverage target will be the creation of over 100,000 additional jobs and a rise in national income of more than K2.9 billion ($1.1 billion).”

Ensuring 70 per cent of the country has access to electricity in less than six years is no small feat.

In order to reach its target, the PNGDSP has laid out a series of milestones it wants to achieve as it embarks on the path to its 2030 goal:

Step 1: Over 80 per cent of households to use traditional energy sources such as wood

Step 2: Between 10–50 per cent of households to use fuels like kerosene for lighting, cooking, etc.

Step 3: At least 50 per cent of households to use fuels like kerosene, electricity or gas, while less than 10 per cent to use electricity (if connected) or gas

Step 4: Between 10–50 per cent of households to use electricity or gas

The PNGDSP aims to ensure people in PNG have long and fulfilling lives.

Step 5: Between 50–70 per cent of households to use electricity or gas

Step 6: By 2030, over 70 per cent of households and all businesses to have access to reliable, affordable and modern clean energy sources.

Even the most well-laid plans can fall apart without funding.

Recognising this, the PNGDSP has outlined how proposed projects and the country’s mining sector will continue to provide strong revenue for PNG.

“The revenues that are generated from gas, oil and mining belong not just to the current generation but to all future generations,” the PNGDSP said.

“It is therefore important that these revenues are invested judiciously so that future generations will benefit.”

The minerals sector has been the primary source of PNG’s exports over the years and will continue to be important into the future as new and emerging mines come online.

“For the future, the PNGDSP provides direction for government investment of tax revenues in order to turn mining projects into sustainable, broad based economic development,” the PNGDSP said.

PNG is aiming to double its mineral exports between 2010 and 2030 to increase its national economic welfare to K1.9 billion ($761 million).

It is hoped that this will also lead to a substantial increment in tax revenue.

PNG is well on its way to making its plans a reality, with renewable energy and mining projects increasingly making a home in the country.

And as the country continues to work towards its priorities, it’s clear its people will only continue to benefit. PNG

GetincontacttofindoutRegalRexnordIPScanhelp youwithendtoendIndustrialPowertrainSolutions.

At JJ Ship Equip Agencies, supporting mining companies with transportation across the Pacific Ocean is about more than logistics – it’s about connecting a nation.

RELIABLE TRANSPORTATION is crucial for the mining sector, where sites across the world are known for being remote and difficult to access. This is especially true in Papua New Guinea (PNG), where logistical challenges like lack of infrastructure and inaccessible terrain can hinder the growth of new and existing mines.

The only reliable form of access for many locations across PNG is by boat, with maritime experts working with miners to develop pathways from pit to port and beyond.

One such expert is JJ Ship Equip Agencies (JJSEA), which has become a leader in maritime solutions and rural transportation across PNG.

JJSEA managing director and chief executive officer Dinesh Hapuarachchi knows what it takes to ensure the island nation remains a competitive producer of essential metals and minerals.

“Partnering with globally renowned companies like Jotron, JRC, Onwa Marine and Haining, we provide cutting-edge marine safety products, GMDSS equipment, navigation electronics and lifesaving equipment from life rafts, personal flotation devices and advanced radar systems and explosion-proof equipment,” Hapuarachchi told PNG Mining. “Our expertise extends to the mining sector, supporting logistics and the transportation of minerals, equipment and personnel to remote mining sites.”

From its early days, JJSEA has grown into a vital player in PNG’s maritime and industrial sectors,

an upward trajectory supported by the company’s commitment to environmental responsibility and safety, culminating in its acquisition of International Organisation for Standardisation (ISO) 9001, 14001, and 14001 certifications.

With branches in Singapore and Sri Lanka, JJSEA aims to combine global partnerships with local expertise to deliver comprehensive solutions to PNG businesses.

“JJSEA provides tailored marine solutions to ensure the safe and efficient transport of minerals, personnel and equipment,” Hapuarachchi said.

“Our commitment to serving remote and rural areas positions us as a key partner for the sector’s ongoing success.”

In 2024, JJSEA played a pivotal role in the Connect PNG program, a national initiative aimed at improving connectivity across the country’s remote regions.

The program led to the company signing contracts to serve the districts of North Bougainville, East New Britain, Milne Bay and Morobe with its fleets of vessels.

“The project, spearheaded by PNG’s Department of Transport in collaboration with JJSEA, marked a turning point for communities that have long relied on unsafe banana boats for transportation,” Hapuarachchi said.

“This initiative, celebrated by Department of Transport Secretary Mathew Wowoni, underscores JJSEA’s unwavering commitment to bridging gaps

The port of Port Moresby is one of the only reliable access locations in PNG.

and fostering development through accessible and safe maritime solutions.”

Since the program began, JJSEA built the first rollon, roll-off vessel for the North Bougainville district, which was scheduled to set sail in early 2025.

“We also collaborated with Kanematsu Corporation in Japan as their local agent on aluminium rescue boats and fisheries research vessels,” Hapuarachchi said.

“Additionally, our partnerships with the PNG Coffee Board, Cocoa Board and Department of Transport support rural farmers through freight subsidy programs that have improved market access.”

JJSEA was in attendance at last year’s PNG Industrial and Mining Resources Exhibition and Conference (PNG Expo), where the company exhibited its range of ventilators, explosion-proof lights and other essential equipment to the local mining and industrial sectors.

“These products enhance safety and efficiency, particularly in challenging environments,” Hapuarachchi said. “Our ability to provide highquality, globally certified equipment has made us a trusted supplier for both local industries and international vessels.

“Additionally, our in-house life raft servicing, licensed pyrotechnicians and marine survey capabilities ensure we offer comprehensive safety and operational solutions.”

Hapuarachchi emphasised the fact that this trust is what has led to strong partnerships with mining companies across PNG.

“Our customers consistently praise JJSEA for our outstanding after-sales service,” he said.

“Clients also appreciate our responsiveness and the long-term support we provide, from installation and training to maintenance and upgrades.

“These qualities have earned us repeat business and long-standing relationships with customers locally and internationally.”

JJSEA endeavours to offer end-to-end support to its clients, including installation, training and maintenance. Hapuarachchi said the company has brought this holistic approach into the new year.

“In 2025, JJSEA aims to expand its footprint through rural jetty developments, advanced vessel acquisitions and increased support for freight subsidy programs,” he said.

“We plan to introduce innovative marine safety products and navigation technologies while continuing to empower rural communities by transporting cocoa, coffee, copra and timber to markets.

“Our weekly schedules from Lae to rural ports in Morobe, Madang and Oro provinces remain a cornerstone of our service.”

Hapuarachchi wants to see more opportunities grown on PNG shores through the connection of rural communities, enriching of livelihoods and driving of economic growth.

“As an equal-opportunity employer, we are committed to empowering diverse talents while maintaining the highest standards of quality, safety and accountability,” he said.

“Our partnerships, innovative solutions and unwavering dedication to PNG’s future make us more than just a maritime service provider – we are a partner in progress.”

Health initiatives have become one of the key ways resources companies in PNG give back to their communities.

As Papua New Guinea’s (PNG) resources companies work to improve the lives of those who live near their mines, the health of these communities has become a key focus.

Each year, some of the country’s largest resources companies donate thousands of dollars to health initiatives in an effort to give back to the communities that have given them so much.

Ok Tedi Mining Limited’s (OTML) most recent health initiative was its rollout of a HPV screening program. HPV, or human papillomavirus, can cause cervical cancer and is spread through intimate contact.

OTML is aiming its HPV screening and treatment program at the prevention of cervical cancer, delivering this essential service to its employees, business partners, government departments and communities across its operations.

The program, made possible through support of the Ok Tedi Women’s Network (OWN), will be administered by the Tabubil Hospital every Tuesday. Those who attend can expect results within 48 hours of screening, with pap smear tests also offered.

“This program is a major milestone and will play a critical role in protecting women’s health by enabling the early detection and prevention of cervical cancer,” OTML manager – health services Raymond Singamis said.

“Apart from the screening process, OTML has added a bonus activity for those women who test positive for high-risk HPV types by providing treatment.”

The HPV screening test takes less than five minutes and requires no hospitalisation or anaesthesia. If the test returns a positive result, it indicates the presence of HPV which can then be easily treated at the hospital.

“OTML has a corporate social responsibility to the people of Western Province and Papua New Guinea to provide lifesaving health interventions for our girls and women,” the company said.

Earlier in 2024, OTML presented OWN with K100,000 ($40,600) to purchase life-saving cervical cancer screening equipment.

Presented during a gala fundraising dinner, the money went towards equipment to aid in the early detection and prevention of cervical cancer.

“Cervical cancer is the second most frequent cancer among PNG women and 1400 women in PNG die from it every year,” OWN chair Jessica Bablis said.

“This equipment will contribute to the reduction in cervical cancer cases in Western Province and PNG, which is an amazing breakthrough.”

OTML managing director Kedi Ilimbit commended OWN for their efforts in advocating for awareness.

resources companies across PNG.

“OWN has demonstrated their unwavering support for the wellbeing of our community,” he said. “They embody the spirit of compassion and solidarity and remind us of the impact that can be made when we come together for a common cause.”

In September, Kumul Petroleum and the Fly River Provincial Government opened a new health centre near the village of Teapopo.

The centre was constructed in an effort to make accessing healthcare easier for residents in the nearby remote villages, who previously had to travel for hours to seek basic medical care.

Kumul Petroleum external affairs executive general manager Luke Liria officiated the opening of the health centre at a ceremony attended by other senior provincial and government ministers.

“Investing in health care facilities such as the Teapopo Health Centre improves the livelihoods of community members and also contributes the development and prosperity of the nation,” Liria said.

The Teapopo Health Centre includes staff housing, six in-patient wards, an antenatal clinic and a month’s supply of medication.

“The facility is solar powered, has rainwater collection and storage as well as a septic system – so it is self-sufficient with regard to support services, very necessary in this location,” Liria said.

The opening of the facility will support the healthcare needs of people in eight nearby villages who now no longer need to take a boat to the larger areas of Daru and Balimo.

“Our support for the construction of this health facility is consistent with our support of major health infrastructure in Port Moresby and elsewhere in the country,” Liria said.

Newmont distributed over $42 million worth of medical supplies and equipment across the globe throughout its two decades of partnership with Project C.U.R.E.

The partnership was bolstered by an additional five years in February 2024, with medical supplies and healthcare training to be delivered to communities near Newmont’s mining operations.

Under the agreement, Newmont will contribute $200,000 over the next five years for a total of $1 million.

Newmont and Project C.U.R.E.’s partnership has created a positive economic ripple effect across 36 countries.

“Creating a positive impact on more than 10 million people globally through our partnership with Project C.U.R.E. is something we are incredibly proud of,” Newmont chief safety and sustainability officer Suzy Retallack said.

“For nearly two decades, our partnership has helped deliver support to host communities near our operations and around the world. We look forward to continuing to leverage our combined global reach to make a strong impact where it is needed most.”

The partnership has seen Newmont fund 108 shipping containers of medical equipment to 36 countries, train more than 440 medical professionals and contribute $5 million to support humanitarian efforts.

“We are proud of our partnership with Newmont,” Project C.U.R.E president and chief executive officer Douglas Jackson said.

“In countries like Ghana, Suriname and others, we have established a figurative gold standard for social responsibility and making our communities healthier, happier and more hopeful.” PNG

Newmont’s 2024 was marked by significant leadership changes, record-breaking results and a drive to give back to the community.

MAJOR MINER Newmont is no stranger to bumper years.

In 2023, the company completed one of the most well-known acquisitions in modern mining when it bought Newcrest Mining for $26.2 billion.

Newcrest brought a wealth of assets to Newmont, including its Lihir gold mine in Papua New Guinea (PNG).

As one of the world’s largest producing gold mines, Lihir is an economic staple for PNG, producing upwards of 600,000 ounces of gold every year.

But as important as Lihir is, it’s not the major’s only asset. PNG Mining takes a look at Newmont’s 2024 and the highlights that came from it.

Leadership changes

Newmont started out 2024 with a big change, appointing Peter Wexler as chief legal officer in January.

Wexler has spent the past year on Newmont’s executive leadership team, responsible for leading the company’s legal, compliance and regulatory affairs.

An experienced legal and risk management leader, Wexler brought with him over three decades of international knowledge in managing legal, risk, compliance, mergers and acquisitions, litigation and corporate governance affairs.

In January, Newmont president and chief executive officer (CEO) Tom Palmer said the team was excited to welcome Wexler into the fold.

“Peter’s appointment further strengthens Newmont’s executive leadership team,” Palmer said.

“Peter brings decades of world-class legal and risk management experience at global organisations, which will be invaluable as Newmont continues to grow.”

Just one month after Wexler’s appointment, Rob Atkinson stepped down from the role of chief operating officer, with the company welcoming Natascha Viljoen in his place.

“Rob Atkinson has played a pivotal leadership role in Newmont in recent years,” Palmer said at the time.

“Rob drove the Fatality Risk Management program, achieving five-year fatality free performance.

“I want to personally thank Rob for his leadership and the many contributions to Newmont’s operational excellence during his leadership tenure and I wish him the very best for the future.”

Viljoen joined Newmont from Anglo American’s platinum business in South Africa where she was the CEO.

“Natascha has shown outstanding leadership transforming technical processing capabilities at Anglo American and we are excited to have her join the Newmont executive leadership team,” Palmer said.

“Natascha will further strengthen our leadership capabilities as we continue to build a resilient and profitable future for the company – safely delivering on our commitments and continuing to differentiate Newmont as the recognised leader for sustainable and responsible gold mining.”

In April, Newmont veteran Francois Hardy stepped into the position of chief technology officer. Having held various roles at Newmont since 2002, Palmer said Hardy was well-placed to take on the role.

“Francois is a strong leader with deep technical experience and a demonstrable track record of improving operating performance,” Palmer said.

“His appointment will further strengthen Newmont’s executive leadership team, adding valuable technological expertise which will be central to our ongoing success as a business.”

Finally, in June, Newmont welcomed Harry (Red) Conger to its board of directors.

With over 45 years of mining and leadership experience, Conger joined the board after retiring from his CEO position at Teck Resources.

“We are pleased to welcome Red Conger to Newmont’s board of directors,” Palmer said.

“Throughout his distinguished career, he has gained a wealth of unparalleled experience in the mining sector and strategic insights. Red brings significant operational leadership to Newmont’s board.”

The second quarter (Q2) of 2024 was a particular highlight for Newmont, as the company produced 2.1 million gold equivalent ounces from its operations.

Other highlights from the quarter included the generation of $594 million in free cash flow and the reduction of nominal debt by $250 million.

“We continued to advance our divestiture program and, to date, have announced $527 million in proceeds this year,” Palmer said in the company’s Q2 financial report.

“With this momentum, we completed $250 million in share repurchases and repaid $250 million in debt.

As we head into the second half of the year, we remain confident in our ability to continue executing on shareholder returns, meet our full year guidance and deliver on our commitments.”

Q2 also saw Newmont repurchase 5.7 million shares at an average price of $43.34 for a total cost of $250 million and deliver $539 million in total returns to shareholders.

Palmer has not been shy about speaking on the company’s copper aspirations, telling the Melbourne Mining Club in June that Newmont would be looking at ways to invest in copper in the future.