19 minute read

Trailer Building Materials/Components

from Trailer Mag Apr 2022

by Prime Group

Forging ahead with Allison

HEAVY HYDRAULICS HAS SEEN A CONTINUOUS SURGE IN POPULARITY OF OMFB PRODUCTS SINCE INTRODUCING THE ITALIAN RANGE TWO YEARS AGO.

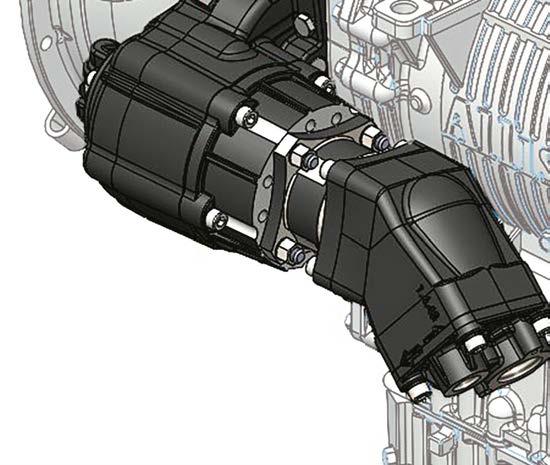

Rubbish trucks are loud enough anyway, without being woken up at 5am by the raucous whine of one fitted with an inferior power take-off (PTO). That’s just one example of the thousands of ways that Allison transmissions service the transport industry daily and, where fitted with an unrefined PTO, they have been known to be noisy in operation. Engineers at OMFB set out to overcome this aspect and in 2020 the manufacturer released its Precision range of low-noise units. The performance exceeded all expectations, with the company now being confident in claiming the product to be the quietest on the market. OMFB’s latest development is a range of heavy-duty units – offering up to a whopping 700Nm of torque – with units already working in the field and showing promising results. Heavy Hydraulics offers an unbeatable selection of OMFB PTOs to suit Allison transmissions. One of the fastest growing hydraulic transport solution providers in Australia, Heavy Hydraulics is also known for its expert knowledge of Allison transmissions and the PTO options that exist for them. It also has a wide range of other highly engineered and innovative transport hydraulic products from OMFB, to offer across its branches in Sydney, Adelaide and Perth. Heavy Hydraulics’ parent company, Heavy Automatics, has been operating for over 30 years and is the largest Allison Transmission distributor in the Asia Pacific region. The Heavy Hydraulics arm was co-founded by Michael Applebee and Danny Guthrie six years ago, creating a unique combination of experience and expertise across transmission and power take-off products alike. It’s this winning formula that saw the business grow into other regions within a short space of time. Today, Heavy Hydraulics is known as a national distributor of quality manufactured hydraulic transport products that are globally recognised. It offers an extensive range of products to suit all types of applications, including PTOs, gear pumps, piston pumps, control valves, hydraulic tanks, cylinders and control systems. For Heavy Hydraulics, having OMFB products in its catalogue is an ace up the sleeve that may have something to do with its growing success. The same can be said for the OMFB range in Australia. “OMFB and Heavy Hydraulics have together created a trusting team that is mutually beneficial. Since we’ve come onboard with OMFB, they have added more to our product portfolio than we originally had. We’ve also been able to focus on areas that we traditionally hadn’t,” Michael says. “We offer hydraulic solutions from OMFB for all types of applications within the transport industry. We would have the biggest Allison PTO range in the country. We have complete knowledge of the product range, and also service the product nationally.” Michael, who has worked in the truck hydraulics side of the industry for over 25 years, has extensive knowledge of the Allison product range. “I’ve been in the industry long enough to know all the different brands and I knew that OMFB has a very solid reputation for making quality products. Therefore I was really humbled to be approached by them to become a national distributor in 2020. Having local support in Australia, and support from the manufacturing team in Italy, we get best of both worlds.” OMFB’s product range covers all transport industry applications from waste and concrete trucks and tippers to truckmounted cranes and vacuum trucks. “One

of the unique features of the Allison transmission is the ability to control the hydraulic system while the vehicle is in motion. The fully automatic transmissions have a global reputation for quality and reliability, which is why they’re the most popular transmission used in the market today. “OMFB offers some of the best-quality products in the industry. The Allison PTO units are quite compact and lightweight. They are very versatile in being able to adapt to different requirements. There are various options covering different ratios, outputs, and power requirements, to suit a range of applications. It is also important for our customers that these products are quiet in operation. This is a huge plus compared to some other PTOs that can be quite noisy. They cover everything the market expects in the PTO range.” Heavy Hydraulics’ customers rate the OMFB range very highly. In the past two years, Michael and his team have recommended OMFB products to many customers, who have been happy with the performance. “We’ve had great experience working with OMFB. As a national distributor we look forward to further developing our working relationship to capture the full potential of the Australian market.”

pag.1 O.M.F.B. S.p.A. Hydraulic Components We reserve the right to make any changes without notice. Edition 2021.02 No reproduction, however partial, is permitted. Via Cave, 7/9 25050 Provaglio d’Iseo (Brescia) Italy Tel.: +39.030.9830611

Fax: +39.030.9839207-208 Internet:www.omfb.it e-mail:contatti@omfb.it Contact OMFB Pacific Pty Ltd Ph: 03 9330 2694 Web: www.omfbpacific.com

Primary Connect and SAF lead innovation with e-axle trial

A NEW E-AXLE TRAILER IS HELPING TO REDUCE EMISSIONS AND ENABLE MORE SUSTAINABLE SUPPLY CHAIN OPERATIONS

Electric axle trailers have been undergoing testing around the world and in an Australiafirst move, SAF-Holland is currently testing the success of its new e-axle trailer in partnership with Woolworths’ logistics arm Primary Connect. The aim of the new trailer is to reduce fuel consumption by capitalising on the power created by the movement of the truck on the road. The new trailer has been developed in partnership with trailer builder MaxiTRANS, refrigerated system provider Carrier Transicold that supplied the fridge and battery system, and axle manufacturer SAFHolland. The trailer is currently being trialled in Queensland. If proved successful, Woolworths and Primary Connect plan to scale the new technology across its fleet of over 800 refrigerated trailers. The innovative trailer uses kinetic energy from its own axle and wheels to generate electricity. This electricity feeds a battery, which can run the refrigeration system and reduce the diesel consumption. The removal of both diesel generators and 200 litre fuel tanks means with the use of this trailer, carbon dioxide (CO2) and particulate emissions are significantly reduced. “We’re pleased to have had the opportunity to put the first e-axle trailer on the road in Australia,” Primary Connect General Manager Strategy and Partnerships, Ben Newton, says. “At Woolworths, we want to build a better tomorrow for generations to come, and this is an important step in our path towards reducing emissions in our road transport operations.” Trailers throughout the Primary Connect fleet normally consume two litres of fuel per hour (16 litres per day), with each trailer refrigeration system being used for an average of eight hours per day. Given the minimum life of a trailer is 10 years, the new e-axle trailer would save more than 5,000 litres of fuel per annum equating to 13.2 tonnes of CO2 over that period. “The trial not only helps reduce emissions, but also runs more quietly, meaning less disruption through residential community areas,” Primary Connect National Fleet Manager, Phillip Farrugia, says. “We’ll keep a close eye on the impact of this technology on our emissions profile and look at its potential for broader deployment across the fleet. We’re grateful to Carrier Transicold, SAF-Holland and MaxiTRANS for their assistance in bringing this new and exciting technology to Australia for the first time.” SAF-Holland Australia Sales Director, Stephen Vranesic, is proud to partner with Primary Connect in what is the nation’s first step into

the successful application of energy axles for refrigerated trailing equipment. “This e-axle development is a first for Australia,” he says. “SAF-Holland is delighted to support Primary Connect’s commitment to operate as efficiently and safely as possible through the use of innovative technologies.” Primary Connect operates the largest food and grocery supply chain in Australia, with over 7,500 employees across 18 distribution centres. Working with 86 transport carriers, Primary Connect moves more than 20 million pallets of product to more than 3,000 stores each year. The business supports over 1,200 external customers, including Woolworths. “When it comes to innovation, our ultimate goal is to develop solutions that matter for people and the planet, a value we share with Woolworths Group’s Primary Connect,” says Stephen Elford, Carrier Transicold AustraliaNew Zealand’s Managing Director. “We believe the Vector eCool represents the future of refrigerated trailer technology. This fully electric trailer refrigeration unit operates autonomously without the need for a diesel engine. It’s one of the most exciting new products we have ever brought to market, and we are delighted to have partnered with Woolworths Group to deliver the first unit of its kind in Australia.” The e-axle trailer is one of the many sustainability initiatives across the group, supporting delivery of a 63 percent reduction in Scope 1 emissions by 2030.

Contact

SAF-Holland 115 High Street Melton VIC 3337 Ph: 03 9971 7900 Customer Support: 1300 131 613 Web: www.safholland.com.au

Boomerang keeps coming back to Capral

FOR A VERY LONG TIME THROUGHOUT ITS 50-PLUS YEARS, PERTHBASED BOOMERANG ENGINEERING HAS TRUSTED CAPRAL’S EXTRUSION CAPABILITIES AND ALUMINIUM SUPPLY TO BUILD QUALITY TRANSPORT, MINING, AGRICULTURAL AND CIVIL CONSTRUCTION EQUIPMENT.

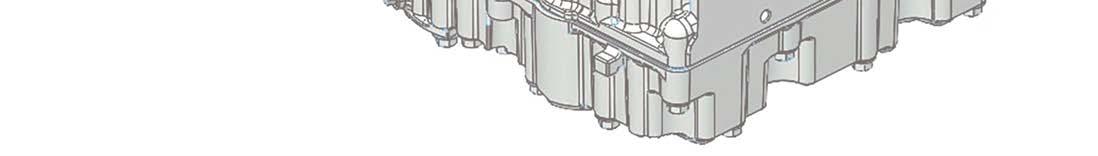

When two Australian heavyweights come together to produce transport equipment, you can be sure it is going to be good. Capral and Boomerang Engineering have been working together to for many decades, enabling Boomerang Engineering to deliver solid trailers, tippers, and other transport and mining equipment to local and international markets. “Boomerang uses a lot of Capral aluminium to build our grain trailers and aluminium side tippers,” Boomerang Sales Technical Support Manager, Daniel Hoschke, says. “The majority of our trailer material is supplied by Capral. Our manufacturing is based in Western Australia, but we sell our products across Australia and to a global market Boomerang Engineering and Capral have been working together for a very long time. Back in the day, Capral used to organise a lot of our aluminium sandcasting moulds, and even now we have custom-made dies and special materials made with Capral material.” Capral has capabilities to produce exactly what customers like Boomerang Engineering require for their manufacturing needs, including cut to length material, long length extrusions up to 17m and long length plate up to 12m. Capral also offers aluminium processing solutions and can provide slotting, routing, drilling, punching, mitre cutting, knurling, de-burring, sheet and plate routing, cutting and bending to streamline customer manufacturing processes. “Capral’s extrusion capabilities are secondto-none,” Daniel says. “Over the years we have had many, many custom-made extrusions with Capral. Boomerang works with Capral to get the specialised material that we need for our manufacturing needs, and they design and deliver these custom-

About Capral

Established in 1936, Capral is Australia’s largest manufacturer and distributor of aluminium products today. It supports a wide range of Australian industries including residential and commercial building, transport, marine, defence and industrial sectors. Capral has manufacturing facilities in Queensland, New South Wales, Victoria, South Australia and Western Australia, employing over 900 people locally. Its eight extrusion presses manufacture over 75,000 tonnes of products every year and deliver them through its six manufacturing plants and seventeen trade centres across the country.

made extrusions to Boomerang exactly how we want them. A lot of our specialised products have very specific materials, their own specific shapes and we source them from Capral. They are always willing to work with us to design our custom material extrusions, which makes our job easier. We are very happy with the service the Capral team provide. They come and see us every couple of weeks to make sure everything is good. They deliver on time, which is a big plus, and we don’t have issues ever.” With worldwide shipping disruptions caused as a result of Covid-19, many manufacturers in Australia that were sourcing materials from overseas saw major delays. However, for Boomerang Engineering having a local aluminium supplier helped to minimise interruptions. Being Boomerang’s main supplier, Capral made sure the manufacturer did not face materials delay. Once the initial restrictions of 2020 lifted, Capral’s operations rebounded, and its Victorian manufacturing and distribution facilities continued to operate at near full capacity through Stage 4 restrictions. “Covid has created a lot of shipping issues and that affected materials supply, but Capral has been quite consistent,” Daniel says. “Certain materials are very hard to come by at the moment, but Capral has kept up to our requirements and met all our needs, which is great for us.” Capral has a wide distribution network across Australia that ensures all its aluminium extrusions and rolled materials are supplied to the customers quickly. Capral also offers next day delivery service that helps customers reduce stock inventory, warehouse space and manufacturing time. The service extends to custom pieces in various lengths and sizes, and even full kits ready for manufacturing refrigerated trailers, tippers, flat tops, recreational vehicles and box trailers. “We have produced more aluminium trailers in the last couple of years than we have done in Boomerang’s history,” Daniel says. “It is one of the biggest growth elements for us. And all of those new builds have been carried out using Capral materials.”

Contact

Capral Ph: 1800 258 646 Web: www.capral.com.au

High energy products and partnerships

STANDARDISING ON LUCIDITY LIGHTING EQUIPMENT FOR ITS NEW BUILDS IN LATE 2019 WAS A SOUND BUSINESS DECISION ACCORDING TO ALUMINIUM TIPPER AND BODY BUILDING SPECIALIST, BORCAT TRAILERS.

From the earliest days of 1958 right through to the present, Borcat has never stopped searching for better ways to design and build its trailers, as well as seeking the best possible ancillary equipment to fit to them. And so it was that the company started its association with Lucidity in October 2019, thus ensuring its products were from that date forward equipped with the cuttingedge excellence that Lucidity provides with its lighting. All wiring and IDM materials from Lucidity are also made in Australia. “We are very pleased we made the decision to partner with Lucidity and we now use their excellent products on all of our trailer and body builds,” Borcat Trailers owner, Paul Gallagher says. “Our passion for local manufacturing with products designed fit for purpose here is something we are extremely proud of.” According to Paul, the Lucidity products have made the job of installing wiring and lighting on the trailers easier and more efficient. He cites several advantages including the ‘plug-and-play’ configuration which, as the term suggests, involves simply plugging the lights directly into the wiring harness via Deutsch Connectors, providing a watertight and reliable connection. This is in stark contrast to the earlier more time-consuming method of soldering the wires together which, while generally providing a reliable connection, also made the subsequent job of replacing the light due to damage or malfunction a lengthier exercise. Further to this, Paul says the fact that Lucidity supplies its products in kit form with everything necessary for each project is another boon for production efficiency. He also vouches for the quality and longevity of the Lucidity products, remarking that since October 2019 when its partnership with Lucidity started, Borcat is yet to have a single warranty issue. “The circuits are very reliable and designed to withstand the tough working conditions that tipper trailers are exposed to on a daily basis,” Paul says. “We swear by Lucidity’s Integrated Distribution Module (IDM) for electrical connections because it eliminates from the trailer the old-fashioned junction box and all the wire splices that are prone to corrosion and failure. The IDM is a robust and reliable product, and as I mentioned before, we have simply had no issues with them since we first installed them in October 2019.” Borcat uses the Glo Trac 26059 Series of rear combination lamps, which is said to be the first rear combination lamp to introduce the latest Glo Trac lens design in the Australia market. According to Lucidity, its 26059 lamp is an ideal product for the tipper market due to its low profile and lightweight design. The Glo Trac principle is said to increase the illumination area which

Lucidity wiring and lighting is ideal for rugged tipper applications.

significantly improves safety during night driving as the light distribution is even and has no glaring high intensity LEDs visible. Lucidity’s Glo Trac 26275 Series side marker lamps encompass the same features as the taillights in a smaller side marker design. The products are ADR-approved, multi-volt (12/24V), IP67 rated and feature a heavyduty polycarbonate lens with the highest possible resistance to breakage. They are covered by a five-year warranty. Also used by Borcat is the 22809 Series work lamp which has a multi-volt operation of 12 to 36 Volts. All mounting hardware of this series is stainless steel and the lens material is polycarbonate. According to Paul, the distinct advantages of investing in these products are their robust construction and light weight, the fact they are ADR-approved and come with a five-year warranty, and that they are supplied in kit form to suit Borcat-specific trailer builds. “Lucidity products definitely add value to our trailer builds due to these advantages,” Paul says. “Another great benefit is the staff at Lucidity – they are extremely professional and proficient at what they do and are always keen to accommodate our needs.”

Fast Fact

Lucidity’s Glo Trac range of 26059 Series rear combination lamps and 26275 Series side marker lamps are ADR-approved, multi-volt (12/24V), IP67 rated and feature a tough, heavy-duty polycarbonate lens with the highest possible resistance to breakage. The products are covered by a five-year warranty.

Contact

Lucidity Australia 37 Paraweena Drive Truganina VIC 3029 Ph: (03) 9219 4074 Web: www.lucidityaustralia.com.au

Strength Through Innovation

BRUCE ROCK ENGINEERING IS THE EXCLUSIVE DISTRIBUTOR OF TITAN TRAILERS IN AUSTRALIA

Sales Contact East Coast Michael Booker M: 0438 101 673 Freecall: 1300 611 253 E: michael.b@brucerockengineering.com.au brucerockengineering.com.au Sales Contact Southern W.A. & S.A. Lee Maddison M: 0488 083 228 Ph: 089 454 7177 E: lee.m@brucerockengineering.com.au brucerockeengineering.com.au Sales Contact Northern W.A. & N.T. Peter Oliver M: 0429 201 983 Ph: 089 454 7177 E: peter.o@brucerockengineering.com.au brucerockengineering.com.au

Connecting industry with uncompromising performance

GENERAL PNEUMATICS TRADING AS GP TRUCK PRODUCTS IS A SPECIALIST SUPPLIER OF AIR BRAKE FITTINGS AND TRUCK AND TRAILER PARTS. ENSURING TOTAL COMPLIANCE IS EASY WITH ACCESS TO A VAST PORTFOLIO OF PRODUCTS THAT MEET THE GUIDELINES FOR ADR AND VARIOUS INTERNATIONALLY RECOGNISED PERFORMANCE STANDARDS.

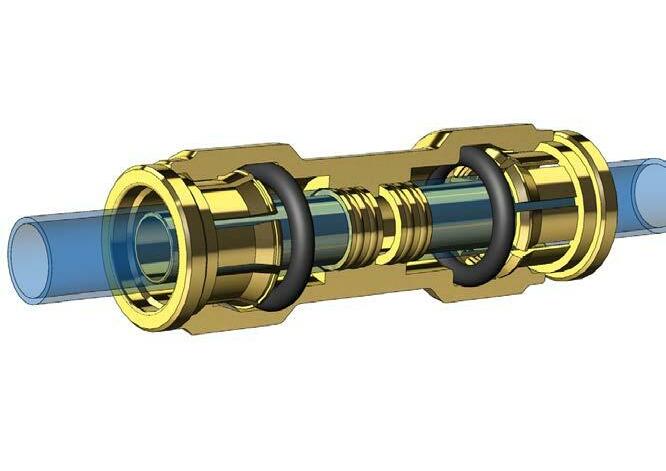

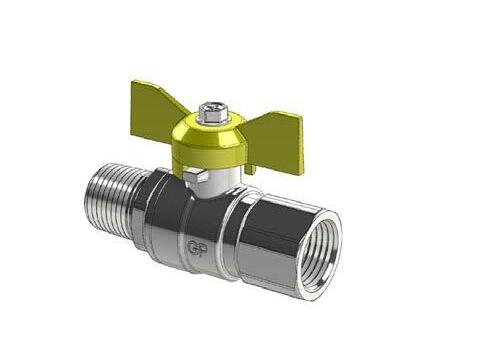

GP Truck Products is a Melbourne-based supplier of road transport components including Air Brake fittings & Tubing, Suzi-coils, trailer couplings, air brake system filtration and associated products. The business has grown from strength to strength to become a major supplier to truck manufacturers, trailer builders, fleet operators, maintenance workshops and the Australian Defence Force. It also boasts one of the largest range of Department of Transport (DOT) air brake fittings for the Australian market. The DOT air brake fittings also comply with US transportation laws and are reported to form an integral part of any braking system as they connect the air brake tubing in all vehicle brake circuits and cabin air control systems. They are also strong, lightweight, impact resistant and leakage-free. They are

Fast Fact

GP Truck Products, a division of General Pneumatics, was formed in 1994 to support the truck and trailer industry by sourcing the best quality products available for Australian truck, trailer manufacturers and aftermarket distributors of truck and trailer parts.

easy to fit and can reduce tube assembly times when compared to traditional compression or swaged brake fittings. With more than 18 years of experience in the fittings niche, GP Truck Products understand the importance of providing equipment that not only performs well but also adheres to strict Australian guidelines for vehicle and operator safety. The requirement for air brake fittings is to meet or exceed appropriate performance standards to minimise possible failures. As a manufacturer and supplier, it is up to GP Truck Products to do its due diligence to uphold user safety by ensuring these fittings conform to the appropriate performance standards as well as provide full testing documentation to the end user that confirms certification. These are matters that must be addressed, especially when fittings are imported. That is the difference when dealing with GP Truck Products. Another observation, it pays to be aware that fittings branded with DOT lettering does not immediately guarantee the part is actually tested and certified for approved use. Again, the team at GP Truck Products reiterate that only documented testing data stating each performance test of the required criteria will certify the fittings for air brake applications. Ultimately, for the most extensive range of air brake fittings for trucks and trailers, contact GP Truck Products today.

Fast Fact

Australian made parts are manufactured by precision components manufacturer Redline Engineering and are made to the highest standards using only the best materials.

Fast Fact

In addition to providing original equipment manufacturers, fleets and workshops with a variety of truck and trailer components, GP Truck Products also supports the Australian Defence Force. The Hawkei light protected vehicle project, for instance, features fittings supplied by GP Truck Products.

Contact

GP Truck Products 29 Hinkler Road Mordialloc VIC 3195 Ph: 03 9580 1811 Web: www.generalpneumatics.com.au