17 minute read

Trailer Building Materials/Components

In safe hands

FAMILY OWNED AND OPERATED SINCE 1944, FRASERS LIVESTOCK TRANSPORT HAS A LENGTHY HISTORY OF RELIABLE, SAFE AND EFFICIENT ANIMAL HUSBANDRY. FOR THE LAST TWO DECADES OR MORE THE COMPANY HAS RELIED ON RINGFEDER COUPLINGS SUPPLIED BY BPW TRANSPEC TO MAINTAIN THE VITAL LINK BETWEEN THE TRAILERS IN VARIOUS CONFIGURATIONS OF MULTI COMBINATIONS.

Said to be Australia’s oldest family owned and operated livestock haulage business, Frasers has been transporting cattle, sheep, pigs and goats across Queensland, New South Wales and the Northern Territory for nigh on 80 years. With a goal of maintaining a best-in-class fleet, Frasers has for many years standardised on Australian made Kenworth trucks and Byrne trailers – both products built to exacting specifications in order to provide the highest levels of animal and human welfare, along with optimum levels of durability and safety. Frasers’ fleet is highly versatile with the ability to accommodate any combination of cattle, sheep, goats or pigs. The company’s capacity entails 250 decks located at strategic depots in the eastern states, comprising single trailer, A-double, B-double, B-triple, Type 1 and Type 2 road trains. The Frasers fleet includes a large proportion of 4.5 deck B-triples which are said to be regarded by the CSIRO and MLA (Meat & Livestock Australia) as industry-best following exhaustive research carried out by Meat Standards Australia (MSA) focussed on animal welfare and journey comfort/ shrink. Specialised features of Frasers’ trailers that enable them to meet these high standards include airbag suspension, specialist effluent management systems and a range of side-, rear- and cross-loading options to meet the diverse requirements of on-farm, saleyard, port, abattoir and feedlot loading and deliveries. BPW Transpec products play a big part in the operation with the trailers featuring BPW landing legs and BPW ECO Plus 3 axles and air suspension which provide the best possible standard of ride for the animals, while also being suitably robust to stand up well to the typically harsh road conditions often encountered when hauling livestock. Furthermore, when it comes to trailer coupling, the ubiquitous Ringfeder (popularly known as Ring-Feeder) brand sold by BPW Transpec has also firmly cemented itself in the Frasers psyche.

The new Ringfeder generation provides unparalleled reliability according to BPW Transpec

While Ringfeder is by far the most popular trailer coupling on the market in this country, BPW Transpec has never been an organisation to rest on its laurels; on the contrary, the company continues to develop and improve its products in synch with the ever-changing market demands. Hence the company has just introduced the New Generation Ringfeder RF50 to replace the existing 303AUS and 303AUS AM/RL models. The new Ringfeder RF50 coupling is the product of years of development and rigorous field testing right here in this country; and has also benefited from extensive customer feedback on product ameliorations, many of which have been adopted in the final product. This has resulted in an overall improvement on the existing robust coupling design and means customers can continue to rely on superior product performance from Ringfeder, backed up by BPW Transpec’s comprehensive Australia-wide product support network. BPW Transpec cites a number of advantages of the new RF50, starting with the important fact that it retains the same mounting bolt hole pattern as earlier Ringfeder models, meaning retrofitting it to older vehicles is a simple exercise. It also includes a quick-change coupling body which has been redesigned to make it more resistant to impacts, as well as faster and easier to replace. The more compact design lowers coupling height by 7.0mm. Stronger return springs ensure the funnel – which features flush mounted screw heads on the bottom to avoid damage – always returns to centre; and a new ergonomically designed release handle makes for easier manual uncoupling. Daemon Cross, Workshop Manager at Frasers, has been with the company for 19 years and he says that over this period the company has relied solely on Ringfeder couplings for its road train trailer and dolly connections. “The Ringfeder is simply a solid and reliable product that does what it’s meant to do without giving us any dramas – which is what we expect from every piece of equipment we use,” Daemon says. “Apart from regular maintenance and the occasional overhaul to replace the parts that eventually wear out through normal use, we just don’t touch them.” He attributes this longevity and product integrity to the uncomplicated, tried and proven design. “And when it does come time for an overhaul the parts such as rebuild kits are readily available through the comprehensive nationwide BPW Transpec network and don’t cost an arm and a leg, making it a worthwhile exercise to give them a second or third life.” Daemon says the most important maintenance items that need to be replaced when worn are the bush in the drawbar eye and the triangle shaped nylon wear pad that

Ringfeder automatic coupling oiler released

Hot off the press is the latest innovation by Ringfeder designed to automatically supply much-needed lubrication to the coupling on a regular basis. Proper lubrication ensures the pin moves easier which means less effort is required to lift the handle when releasing the coupling – a significant OH&S benefit. It also makes the coupling less prone to wear and corrosion which increases longevity and life-tooverhaul times. The automatic oiler unit weighs just 0.6kg and has a reservoir capacity of 120ml. It’s filled with special Ringfeder coupling oil which has a high viscosity for superior adhesion and corrosion protection for the critical components.

is located on the lower boss and which prevents metal-to-metal contact between the drawbar eye and the boss. “If these are replaced religiously, the Ringfeder unit should be good for at least five years before needing an overhaul,” Daemon explains. In the final wrap-up, Daemon says the bullet-proof nature of the Ringfeder and other BPW Transpec products such as landing legs and axles gives Frasers peace of mind that its trailers will go the distance under the demanding operating conditions prevalent in the livestock transport realm.

Contact

BPW Transpec 1-11 Cherry Lane Laverton North VIC 3026 Ph: 03 9267 2434 Web: www.bpwtranspec.com.au

Seal the deal

SCOTSEAL WAS ORIGINALLY DEVELOPED AND PATENTED BY US SEAL SPECIALIST, CHICAGO RAWHIDE, WHICH WAS ACQUIRED BY SKF IN 1990. THE COMPANY CONTINUES TO SHOW ITS QUALITY THROUGH ITS RELIABLE SERVICES – SUPPLYING TRUCK MANUFACTURERS AND HEAVY VEHICLE WORKSHOPS WITH COMPONENTS THAT INCREASE RELIABILITY, PERFORMANCE FLEET UPTIME.

Up to 90 per cent of premature wheel bearing failures are reportedly due to poor bearing adjustment, improper seal installation and subsequent leakage of lubricant. However, quality sealing solutions can eliminate the risk of these leaks as they are designed to retain oil and grease. Scotseal offers sealing solutions that are proven to be dependable and long-lasting, in a variety of different styles and sizes for applications in steer, drive or trailer axles. The redesigned Scotseal range manufactured by SKF has been tested and proven in both on-and-off road applications in Australia and the US, and it is ideal for the wheel end sealing needs of trucks and trailers. The SKF Scotseal Classic has proven its quality and long-life service in the trucking industry over the last three decades. SKF Scotseal Longlife, based on the Classic version, is designed to last longer intervals between services. It seals in and out with four sealing lips, including: spring-loaded primary sealing lip that is factory pre-lubed, radial dirt lip, axial dirt lip, and outer bumper lip that acts as preliminary dirt excluder. The SKF Longlife has superior tolerance and resistance to high temperatures. The special formulated polymer is compatible with all known synthetic lubricants, this combined with advanced seal design makes it suitable for extreme conditions and extends seal life. SKF Scotseal Plus offers the same advantages as well as easy, hand installation. The SKF Scotseal Plus XL has been the consumer’s primary wheel seal of choice

since 2002. Its Hydrogenated Nitrile Butadiene Rubber (HNBR) features a handinstallable design and is ideal for frequent braking applications. It also has a high heat tolerance, is compatible with synthetic lubricants, and has excellent exclusion properties, even in harsh conditions. The Scotseal Plus XL offers maximum sealing life under virtually any and all driving conditions, including frequent braking applications and heat generating environments. It is the standard seal in preassembled hubs, and is preferred by many OE truck and trailer manufacturers due to its proven history of high performance. The advanced HNBR material provides heat resistance up to 149 degrees Celsius as well as broad compatibility with synthetic lubrication fluids. Its unique design provides fresh running surface for sealing lips and keeps out road contaminations for better protection. Its ‘fat footprint’ with adhesive type properties locks onto the spindle, making a perfect seal even on a worn spindle. Similar to Scotseal Longlife, the Plus XL seals in and out with four sealing lips, including the spring-loaded primary sealing lip with its Waveseal design that sweeps oil back to the bearings. Plus XL is easily installed without the need for special tools, which eliminates costly do-overs and extending wheel end life. Scotseal’s Plus XL seals are designed by highly trained wheel end SKF engineers. Elastomeric formulation along with the high tolerances, finishes and manufacturing quality controls put together with the design features produce a seal that cannot be duplicated. With extended life capabilities, the most recent product, SKF Scotseal X-Treme, brings improved reliability and extended service life under the harshest operating conditions for the vehicle service market, as well as OE truck and trailer manufacturers. Contact SKF for genuine, premium quality SKF Scotseals.

Contact

SKF Australia 17-21 Stamford Road Oakleigh Vic 3166 Ph: 03 92690700 Web: www.vsm.skf.com

Passing the test

WHEN IT COMES TO BRAKE SHOES, AUSTRALIAN AND NEW ZEALAND VEHICLE STANDARDS ARE FOR THE FULLY DRESSED AXLE, SO IT IS IMPORTANT THAT INDUSTRY USE A RECOGNISED STANDARD LIKE FMVSS 121 TO TEST THE PERFORMANCE OF THE FRICTION MATERIAL.

It’s no secret that Australia offers a huge range of seasonal challenges for road transport operators. Temperatures vary between the high 40s and high humidity to sub-zero Alpine conditions, from fine desert dust to cyclonic rainstorms. And through it all, operators want to keep their rigs running and hauling freight. When drivers hit the brakes, they can generally tell if the truck’s going to pull up smoothly and without drama. Tyres play a big part in this, as does the road surface, weather conditions, the load being hauled, how well maintained the truck is and the skill and experience of the driver – but at the core of braking performance are, unsurprisingly, the brakes themselves. The brake activation system is designed and engineered to deliver fast, safe stops under all types of conditions, time after time over the operating life of the vehicle, however one of the main variables is the brake shoes and the kind of friction material used. Sadly, some operators may seek to cut costs by using inferior replacement brake shoes which may inevitably affect overall braking performance. Inferior linings on brake shoes can result in premature wear and ruinous overheating. Brake fade, costly repairs down the track and damage to other brake components are very real risks of this shortsighted brake shoe choice. What might surprise operators and experienced truckies alike is that to achieve a recognised standard on brake shoe quality, TRP® needed to look across the pond to North America to find a recognised standard. TRP brake linings are tested to stringent the U.S. Federal Motor Vehicle Safety Standard 121 (FMVSS 121). This is not a competitive ranking of rival products but an evaluation of compliance with the Standard’s own benchmarks. TRP also conducted FMVSS 121 tests on other aftermarket and OEM-equivalent linings which showed the TRP lining offered comparable performance to the OEM product. When comparing the recovery performance, for example, the TRP lining is comparable to the OEM performance on PSI performance and stays cooler than OEM during the recovery period. A cooler lining means less fade and better braking performance. In addition, TRP brake shoes are also tested and certified where applicable, to comply with the widely respected European quality Standard, ECE R90. This Standard is recognised by Australian Design Rules (ADR) and requires brake shoes to perform within 15 percent of the Original Equipment Manufacturer (OEM) equipment. All TRP brake shoes certified to ECE R90 have exceeded this requirement; making TRP one of the only suppliers in the Australian market to offer product tested to both standards. TRP Brake Shoes are available in either 21,000lb (9.6 tonnes) gross axle weight rating (GAWR) or 23,000lb (10.5 tonnes). All TRP brake linings exceed the maximum GAWR limit in Australia. That said, fitting a 23k rated lining doesn’t mean it’s right for every application, or that it will give any service life advantage. What’s most important in the choice of lining is the operational environment the brakes will face. Brake linings certified at 23,000lb could be too aggressive and cause premature brake drum wear or ‘grabby’ brakes, while the 21,000lb versions may not give enough braking power to stop some vehicles. Most on-highway trucks and trailers can use a 21k lining, which can be identified via a green edge on the TRP lining. Vehicles used in construction, refuse collection, stop-start and heavy-haul should use a gold-edged 23k lining. As detailed in the graphs opposite, the results of the FMVSS 121 testing are revealing.

All TRP® brake shoes come with a 2 year, unlimited kilometre warranty and are available at the ten dedicated TRP stores or from the 48 PACCAR Parts dealerships across the country.

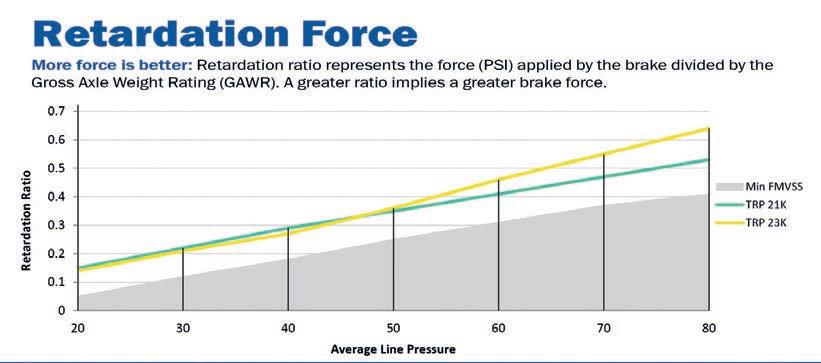

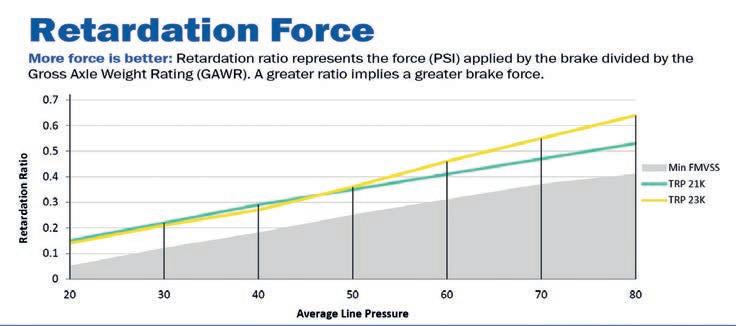

Retardation comparisons

Retardation is the force measured in pounds per square inch applied by the brake, divided by the Gross Axle Weight Rating. A greater ratio implies greater friction generated at the brake drum. Both TRP linings comfortably exceed the FMVSS standard and the 23k lining offers more braking at higher pressures; both compounds are satisfyingly linear – there’s more braking available with more pressure, with no sudden dips or spikes in bite.

Retardation Force

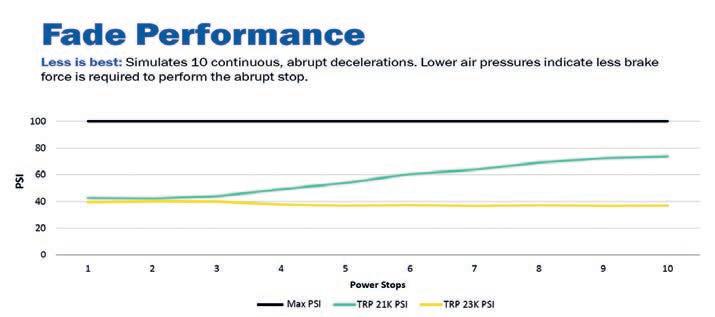

Fade Performance

Fade is tested in 10 abrupt stops from a consistent speed of 60mph (100km/h); to achieve the benchmark, trucks and trailers must stop in less than 250 feet (80 metres) when loaded to their GAWR and 235 feet (72m) when lightly loaded, and not demand more than the 100psi minimum rating of pneumatic brake systems. As linings get hotter, more brake pressure is required to produce the required stopping power. It is clear the 23k linings required only 40psi to complete the abrupt 10 stops with remarkable consistency, which will be very reassuring to drivers. The 21k linings did require more brake air pressure to achieve the consecutive stops, exactly as might be expected from a lining intended for highway use.

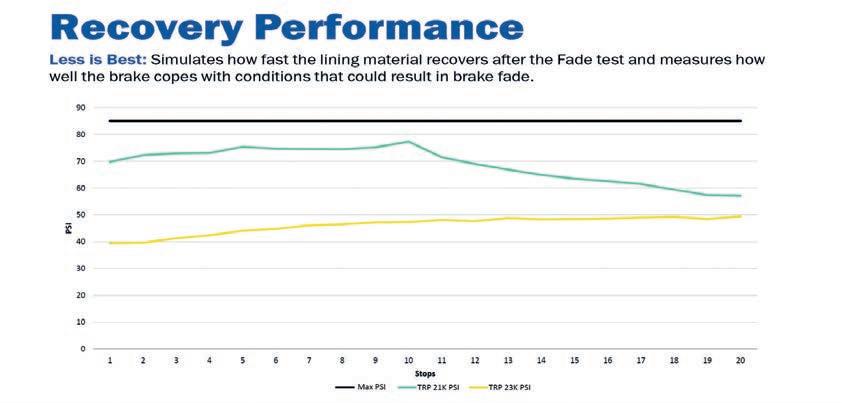

Recovery

Linked to Fade performance is the rate at which linings recover from heat application by abrupt repeated braking over a further 10 stops. As can be seen, the 23k remained consistent, while the 21k linings recovered quickly and required less air-pressure to pull the test rig to a halt.

Fade performance

Recovery performance

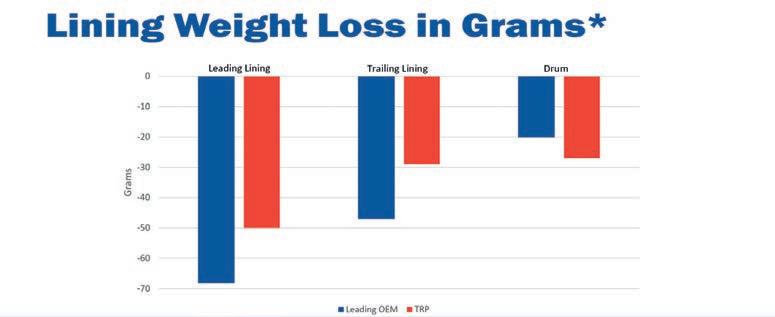

Weight Loss

Effectively a measure of wear, this graph clearly shows the 21k TRP linings wear up to 30 percent less than OEM linings. More force is better: Retardation ratio represents the force (PSI) applied by the brake divided by the Gross Axle Weight Rating (GAWR). A greater ratio implies greater brake force.

Less is best: Simulates 10 continuous, abrupt decelerations. Lower air pressures indicate less brake force is required to perform the abrupt stop.

Less is best: Simulates how fast the lining material recovers after the Fade test and measures how well the brakes cope with conditions that could result in brake fade.

Lining weight loss in grams

No end in sight for Rentco

RENTCO SUPPLIES EQUIPMENT ON A SHORT, MEDIUM OR LONG-TERM BASIS AND BACKS ITS SERVICES WITH HIGHLY SKILLED PERSONNEL TO PROVIDE CUSTOMERS WITH INDUSTRY LEADING SUPPORT ANYWHERE IN AUSTRALIA. DUE TO ITS COMPLIANCE, RELIABILITY AND INVESTMENT IN HIGH QUALITY EQUIPMENT AND TECHNOLOGY, RENTCO LEADS THE WAY IN THE HEAVY DUTY TRUCK AND TRAILER INDUSTRY.

Rentco Transport Equipment Rentals is a prominent equipment rentals company, providing fleet operators Australia-wide with trucks, utility vehicles and trailers along with 24/7 support. Rentco National Business Manager, Paul Scott, says the company’s position in the market is explained through its dedication to its services. “We’re open for business, we’re the largest in the market because we’re good,” he says. “And it’s not been an easy climb to the top, we’ve done it through good management investment and longevity.” Rentco is focused on continuing to service the Australian transport sector through its safe, current and compliant vehicles of varying spec and design, and Paul explains that along with building further efficiencies in technology, tracking and lean leadership, the company aims to draw on the past 25 years and make good business decisions while catering to the market in the next 12 months. “We continue listening louder and more carefully to the market and what it tells us to do,” he says. “The next 10 years will be testament to that. The more the market speaks, the more we listen and the more we change.” The scene in 1994 painted a different picture for Rentco, then located in Kewdale, Western Australia. Paul explains that it was a basic operation, with basic principles and management systems. Clients spoke and acted according to budgets and finance constraints, and yearly growth was very difficult due to the challenges a small new business faces and the large number of competitors in the industry. By expanding locations, adjusting its operations according to the demands of the market and sourcing strategic management teams for each depot, Rentco was able to completely turn the tables and take leadership in the industry, while keeping its long-serving employees. “We’ve got Townsville, Brisbane, Sydney, Victoria, South Australia, Perth and Darwin,” he says. “Many of the founder management personnel are still in place. The founding manager of Adelaide is still in Adelaide, one of the founding managers in Brisbane is still in Brisbane. Each one of these depots has a 10-years-plus employee looking after it.” Paul says the compliance aspect of the job has also grown significantly. “Technology has been a massive change in the business, particularly in the last 10 years,” he says. “It’s been a huge part in our growth and capabilities in terms of operational efficiency, compliance, servicing and reporting, and our electronic platform that we use is integrated and custom, it’s being updated monthly to try and keep step with the times.” Just like how different needs and demands

changed the way Rentco operated back in 1994, similar situations such as the current Covid-19 pandemic and the online purchasing revolution have forced Rentco to re-focus its attention. Paul says that rather than focusing on a single niche in the industry, Rentco listens to the needs of the market. “We don’t focus on a specific industry, we focus on the noise that the entire transport market makes, and right that’s coming from parcel delivery and from import/export businesses. We expect that the food industry will deliver some unexpected additional requirements in the coming months as well.” Paul says Rentco is in an exceptional position in the market and will continue to grow into the unforeseeable future. “Rentco is open for business and continues to grow because it has to – not because it wants to,” he says. “We’re becoming more adaptable every year, and the 25 years of success allows that adaptability. With more than 3,000 vehicles in fleet and most currently out on hire it’s easy to see that much of our nations transport industry is dependent on Rentco to continue to forge forward and we take this challenge head on and we are all totally aware of our responsibility and are committed to do our part in Australia’s supply chain networks.”

Contact

Rentco Transport Equipment Rentals Web: www.rentco.com.au Ph: 08 9353 4171