9 minute read

Trailer Building Materials/Components

Brown and Hurley’s impressive showcase of trailer brands.

The complete package

THE BROWN AND HURLEY GROUP HAS EXPANDED ITS CABOOLTURE DEALERSHIP BY BUILDING A DESIGNATED TRAILER WORKSHOP. THIS COINCIDES WITH THE GROUP RECENTLY BEING APPOINTED DEALERS FOR SEVERAL WELL-ESTABLISHED TRAILER BRANDS.

A family-owned Australian company, the Brown and Hurley Group has a long and proud history dating back to 1946 when it was founded in Kyogle, NSW. Today, Brown and Hurley has nine branches strategically located throughout Queensland and northern New South Wales from Tamworth to Townsville. Brown and Hurley began selling trailers back in 1992 when the company opened a new purpose-built larger branch at Coffs Harbour. Late last year work was started at the Caboolture facility to build a stand-alone six-bay trailer workshop surrounded by a vast amount of concrete hardstand area to cater for the company’s growing trailer sales division. Critically, the Brown and Hurley Trailer division now offers four key trailer types from four different manufacturers; including Krueger trailers, Hercules tippers, Schmitz Cargobull refrigerated vans and Pumpa moving floor and specialised trailers. According to Dylan Hurley, Group Trailer Manager for Brown and Hurley, each of the trailer brands the company represents designs and manufactures top quality products within its specific area of expertise. This is a prerequisite for Brown and Hurley, a company that prides itself on providing quality products and an unparalleled level of after sales service that is fully backed by the manufacturers, suppliers and the company’s own parts and service divisions. “In choosing Krueger, for example, we were looking to partner with an Australian family

A new purpose-built six-bay trailer workshop has been recently constructed.

business with values and ideals that align with our own,” Dylan says. “Both companies are committed to their staff; with extensive training conducted across all facets of their operations and a consistent focus on providing innovative solutions and exceptional service to our customers. “Brown and Hurley now offers Krueger Transport Equipment’s full range of skels, flat tops, curtainsiders and dry vans.” Already, Dylan explains, the relationship is bearing fruit with a good number of trailers on order and many already out to work. He adds that the Krueger range of trailer types is comprehensive and complements the Kenworth and DAF product lines exceptionally well. “The fact that they’re Australian made, have their own RFS (road friendly suspension) and have a comprehensive parts network is important to us,” Dylan says. The beginning of this year also saw the Brown and Hurley Group dealerships stocked with Schmitz Cargobull fully-imported shortchassis reefers and the company’s locally assembled full chassis B-double refrigerated semi-trailer range. “The Australian reefer market demands skilled, dedicated customer service coupled with a reliable aftersales service and repair network to ensure minimal downtime and optimal profitability for operators,” Dylan explains. “Schmitz Cargobull’s Ferroplast technology offers premium thermal efficiency so it’s exciting to see these benefits being delivered into some of Australia’s hottest regions where the resultant fuel savings can significantly improve the operator’s bottom line,” he says. Both Schmitz Cargobull Australia and Brown and Hurley share a passion for providing dedicated customer service and quality road transport equipment.

Fast Fact

Brown and Hurley Trailers is ramping up its numbers in new trailer sales. Having taken on Hercules tippers in 2011, early this year the company added Krueger, Pumpa and Schmitz Cargobull to its new trailer sales portfolio.

The modern facility features an overhead crane to facilitate the heavy lifting.

Most recently, the Brown and Hurley Group has partnered with Swan Hill-based trailer builder, Pumpa Manufacturing. According to Dylan, “The Pumpa moving floor range and the Xtreme Wide Belt™ live bottom trailers complement the trailer models already offered by Brown and Hurley. “We can also offer custom trailers covering all configurations, with Performance-Based Standards (PBS) combinations being one of our specialties.” The Australian tipper manufacturer Hercules Engineering is another long-time partner of Brown and Hurley. “Hercules designs and continually develops its range of tipper bodies and trailers with a view to exceeding customer expectations in terms of quality, reliability and value,” Dylan says. “With a range of aluminium and steel truck bodies, dog trailers and semi-tipper combinations available, Hercules trailers deliver maximum payload advantages thanks to their durable designs and quality build materials.” This year, in particular, has been a huge year for growing the trailer business after Krueger, Schmitz Cargobull and Pumpa all joined the Brown and Hurley fold. The company now has an exclusive sales and service network for these brands stretching all the way from Newcastle to North Queensland. Dylan goes on to elaborate that Brown and Hurley has invested a lot of resources into building up its workshop and parts facilities over the years to ensure everyone who buys trailers from the company has the backup and service support to suit their business. “We needed more partners that are specialist

manufacturers in their own field and, importantly, that don’t overlap the other brands in our portfolio,” Dylan says. “We are pleased with the way it’s all panning out and look forward to working with our customers in selling and supporting these great products.” The Brown and Hurley group also offers trailer rentals through its PacLease division. Trailers can be rented from one day to 12 months and can be leased for periods of over 12 months. The Brown and Hurley PacLease trailer fleet is suitable for most applications and includes A and B curtainsiders (with options for hanging gates or load restraint curtains), curtainside mezzanine floor A and B trailers as well as flat-tops (road train ready with three-way container pins), road train dollies, moving floor trailers and drop-deck trailers with ramps. In addition, a number of new Krueger 22-pallet Kurtainer B trailers have recently joined the rental fleet. All of the Brown and Hurley PacLease trailers feature tri-axle groups, except for the dollies which sport tandem axles. The Brown and Hurley Group prides itself on providing quality products, services and facilities to the Australian road transport industry. The company offers a full package of prime movers, trailers and finance solutions to suit the needs of every customer.

Contact Brown and Hurley Trailers 16 Motorway Drive Burpengary Qld 4505 Ph: 07 3385 4800 Web: www.brownandhurley.com.au

Staying on the ball

SLOANEBUILT TRAILERS HAS BEEN DESIGNING AND MANUFACTURING TRAILERS AND TIPPER BODIES IN SOUTHWESTERN SYDNEY FOR OVER 30 YEARS. WHEN IT COMES TO BALLRACES, FIFTH WHEELS AND LANDING LEGS, THE COMPANY INSISTS THAT ONLY JOST WILL DO.

The founders of Sloanebuilt Trailers, Fred and Helen Marano, have developed their family owned and run business from humble beginnings in the 1980s to the impressive operation it is today. The company remains owned and operated by Fred and Helen along with their four children Tim, Freddy, Daniel and Kate. Tim is Production Manager in the workshop and Kate is the Administration Manager. Sloanebuilt Trailers is located in Smeaton Grange, on Sydney’s southwestern rim, in a brand new $52 million production facility set on nine acres in one of Australia’s fastest growing industrial estates. The modern factory is fully equipped with drive-through bays, a state-of-the-art heated spray booth, mixing room, wash bay and grit blasting facility. This has enabled the company to further build on its solid reputation for manufacturing custom built trailers

renowned for their strength, reliability, longevity and high-quality finish. In addition to serving its core customers in the tipper market, Sloanebuilt Trailers is also developing some new and innovative transport solutions, including an upcoming all-aluminium flat-top trailer. “We have around 100 people working in the business and we design and

Fast Fact

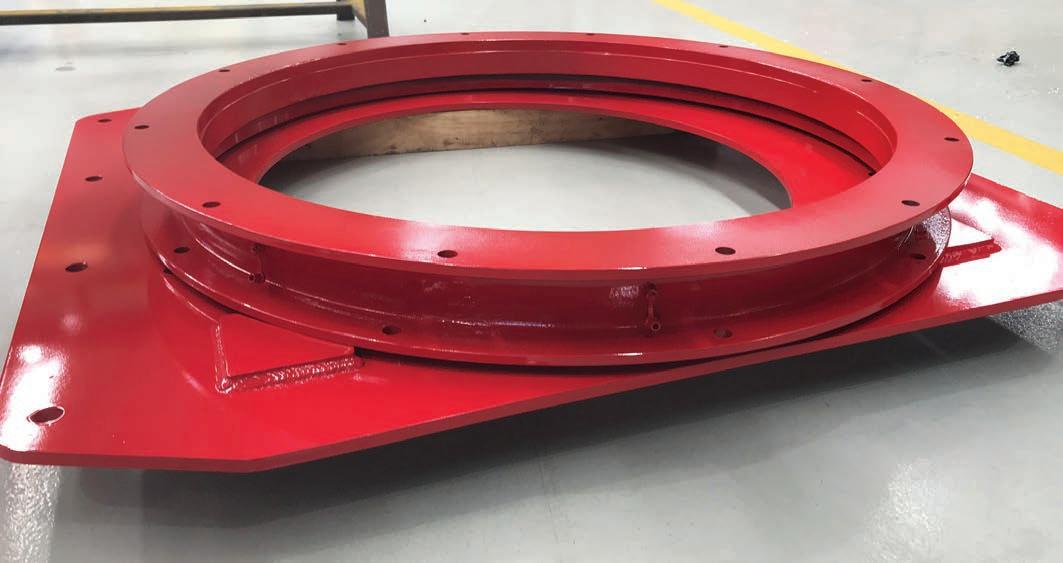

The JOST KLK series of double-row ballrace slew rings has a number of features which make it ideal in harsh and dusty environments such as quarries, including the labyrinth seal and the upper and lower rows of ball bearings that ensure vertical and horizontal forces are evenly distributed throughout the entire component.

The JOST KLK series of double-row ballrace slew rings are designed to handle the extra loads and stresses inherent with PBS-approved combinations.

manufacture as much as we possibly can in-house to ensure the end product meets standards and exceeds expectations,” says Bennett Haberbusch, Business Development Manager at Sloanebuilt Trailers. “Where we need to purchase components from external suppliers, we look to partner with fellow industry-leading companies, and that’s where JOST comes in.” Bennett maintains that one of the hardest working components in a truck and trailer combination is the ballrace, especially in the forms of a slew ring ballrace integral with a dog trailer or a fifth wheel dolly used to connect A-double combinations, for example. Particularly with tippers where off-road work is common, the units must be exceptionally well sealed and greased to prevent the ingress of grit and moisture which over time can cause accelerated wear to the balls and races.

“With the proliferation of PBS (PerformanceBased Standards) combinations allowing ever higher weights to be carried, the ballrace is subjected to tremendous forces day-in, day-out,” Bennett says. “Over the years we’ve established that to meet our high standards in terms of durability and reliability only the JOST range of ballraces suits our applications.” The JOST KLK series of double-row ballrace slew rings has a number of features which make it ideal in harsh and dusty environments such as quarries, including the labyrinth seal and the upper and lower rows of ball bearings that ensure vertical and horizontal forces are evenly distributed throughout the entire component. Thanks to the functional design, the axial loads are ideally supported and the thrust and tractive forces which occur when driving are transmitted in an optimal fashion. Horizontal forces in the pull or push directions, as well as the moment load resulting from braking and centrifugal forces, are supported by the interplay of the two rows of balls. Lifting forces are taken care of by the smaller ring of balls. A particularly large grease reservoir results from the free space between the tracks, ensuring smooth running and optimum lubrication capacity. The units have eight equally spaced lubrication points enabling the best possible distribution of grease within the tracks with minimal rotation (+/- 20°) required during lubrication. Optionally available is a pre-assembled lubrication block which provides convenient access to all lubrication points in the one

JOST slew rings can be optioned with a preassembled lubrication block and automatic lubrication system for more convenient greasing.

central location. This can be also specified in preparation for connection to an automatic lubrication system. With a D-value rating of 275kN, the KLK Series of ballrace slew rings can be optionally fastened using splined bolts which obviates the need for additional welding of thrust plates. When required, Sloanebuilt Trailers utilises the JOST mobile fifth wheel installation and certification service to streamline the delivery process to its end users. “The JOST service and support network is outstanding, and we have always been well taken care of by locally-based Area Managers Joey Coles and John Dreves, both of whom are only ever a phone call away,” Bennett says. In addition to the JOST slew rings, fifth wheels and landing legs, Bennet says the company has recognised a growing trend with customers specifying the newly released JOST EverShine aluminium wheels on their new Sloanebuilt trailers, further strengthening the bonds between the two companies. “We are more than happy to use the full range of JOST products across our trailer builds as we know the quality is always up to our high standards and the aftersales support is fantastic,” Bennett concludes.

Contact JOST Australia Web: www.jostaustralia.com.au Ph: 1800 811 487