26 minute read

A GLASS HALF FULL

RECYCLED ROADS – A GLASS HALF FULL

SUSTAINABILITY AND BETTER RECYCLING OUTCOMES ARE NOW INFORMING AUSTRALIA’S ONGOING “BIG BUILD” OF INFRASTRUCTURE, WRITES THE AUSTRALIAN ROAD RESEARCH BOARD.

Turning waste streams into responsible road construction materials is something the Australian Road Research Board (ARRB) has led research and development in for more than 30 years. ARRB has a strong, trusted reputation in the sustainability and resilience space when it comes to road construction.

From our work with crumb rubber bitumen to researching the use of plastics and organics in road building, ARRB has been at the forefront of finding solutions

Testing of the recycled crushed glass/ crushed concrete blend has been carried out in ARRB’s state-of-the-art labs facility in Port Melbourne, Victoria.

to using more recyclables and less virgin materials for superior, better performing roads.

Recently, we have been working with the City of Canterbury Bankstown in NSW to put more recycled crushed glass into road infrastructure.

The objective of this project is to maximise the use of recycled crushed glass– the glass you put in your recycling bin – in granular subbase materials for roads.

The project has an additional sustainability benefit. It uses another recycled material, crushed concrete, as the preferred granular subbase material.

Crushed concrete is the control material to measure our progress against. The performance of blends of RCG and crushed concrete is being evaluated to ensure the optimal blend is fit for purpose.

Testing in ARRB’s state-of-the-art labs facility in Victoria has found that combining glass with crushed concrete improves performance, compared with crushed concrete alone.

“Blending with recycled crushed glass was found to improve the grading and lead to improved compaction capabilities,” says Dr James Grenfell, ARRB Principal Professional.

“This has meant that the incorporation of high levels of RCG can improve the performance of crushed concrete in subbase applications.”

The 12-month ARRB/City of Canterbury Bankstown project is a multi-stage effort, which includes reviewing current standards worldwide, the lab testing, finding the optimum blend and then establishing a trial site on a road in the CanterburyBankstown area, and assessing the performance of the road.

ARRB is currently involved in many sustainability-focused road projects including: • developing national and state guidelines and standards for the use of recycled materials in road pavements and transport infrastructure • developing new and innovative pavement design mixes incorporating recycled or marginal materials in a safe and appropriate manner • conducting specialised trials, testing and performance monitoring in collaboration with key industry sectors, road agencies, local government, environmental and sustainability agencies and producers of recycled and reclaimed products • assessing engineering performance and technical constraints of recycled and alternative materials (e.g. crumb rubber, plastics, glass, bottom ash, organics, reclaimed asphalt pavement, crushed construction and demolition waste and other emerging waste streams) in different applications and climatic areas. As all levels of government, industry and the community demand the increased use of recycled materials in roads, less waste and a sustainable circular economy, ARRB can help.

Talk to our Sustainability and Resilience team for assistance in recycled and alternative materials use, life cycle analysis and economic evaluation, and environmental management of your infrastructure projects at sustainability@arrb.com. au. Or visit our website at www.arrb.com.au/sustainability.

Blending crushed concrete and recycled crushed glass as a subbase was found to improve the grading and lead to improved compaction capabilities.

Strategising a zero-waste future

WASTE MANAGEMENT REVIEW SPEAKS WITH GUADA LADO, WESTERN SYDNEY REGIONAL ORGANISATION OF COUNCILS’ REGIONAL WASTE COORDINATOR, AHEAD OF HER WASTE STRATEGY SUMMIT 2021 PRESENTATION.

With an estimated 67 million tonnes of waste generated by Australians every year, public and private sector waste strategies are critical to environmental and economic health.

As such, the imperative to modernise infrastructure, technology and operations while bringing industry and community together has never been greater.

Enter Waste Strategy Summit 2021, which will bring together key stakeholders in the waste sector, from local councils and government authorities to private enterprise and academics, to examine what collaboration, investment and technology is necessary to ensure an efficient, sustainable future for public and private sector waste management.

Now in its fourth year, the Waste Strategy Summit aims to deliver connection and solutions that will positively impact public and private sector operations, environmental impact, and corporate social responsibility. Set to take place 20 to 22 July, the summit is designed for executives working within waste management, recycling, resource recovery and environmental sustainability.

The event will explore real life case studies with presenters from governments and organisations leading the way in waste strategy innovation, cost-savings and sustainability.

Guada Lado, Western Sydney Regional Organisation of Councils’ Regional Waste Coordinator, is one such presenter, with her session, ‘Tried and Tested: Strategies from a 5-year Regional Litter Plan that Really Work’, set to explore best practice litter reduction initiatives.

“We have been on a journey from unveiling the $14 million litter problem in our region to delivering best practice litter-reduction initiatives across Western Sydney,” she says.

“Littering behaviours can be quite complex and even sensitive, but utilising all four pillars – engagement, infrastructure, enforcement, monitoring and evaluation – proved successful for driving behavioural change in a variety of settings.

“The benefit of multi-agency projects, central delivery and local and targeted community engagement were also consistently proven.”

Guada Lado continues to support waste strategies throughout Western Sydney.

Lado explains that when she was a recent graduate starting out in the industry at Cleanaway, the career advice given to her was that waste, like taxes, was unavoidable, but meant there would always be work.

“Since then, this notion of waste has become the challenge that so many of us here are addicted to trying to solve,” she says.

Over the past six years, Lado has worked with nine councils to deliver the Western Sydney Regional Waste Strategy, working on issues that are common challenges to councils across the region.

A key challenge, she says, had been the changing urban landscape of the region and increasing population growth, which highlight systemic problems due to the lack of recognition of waste as an essential service.

“I will be sharing the most effective strategies and practical learnings for those interested in driving community engagement and litter prevention in public places at a local, regional, or wider scale,” Lado says.

She adds that the key takeaway from her presentation will be that partnerships and collaboration with other agencies, understanding the community and positive engagement were key to the success of WSROC’s programs.

In addition to Lado’s presentation, Waste Strategy Summit 2021 attendees will hear from an extensive range of speakers including Soko Made, San Francisco Zero Waste Senior Coordinator, Julie Morgan, Transport for NSW Environment and Sustainability Executive Director, and Ryan Collins, Planet Ark Head of Circular Economy programs.

Attendees will also gain insights into the landfill crisis facing Australia and hear how others are reducing upstream waste through sensible material management. The power of big data in transforming waste management and recycling processes will also be explored, alongside a deep dive into product stewardship and the importance of a zero-waste mindset.

“The Waste Strategy Summit brings forward-thinking leaders and innovators from diverse backgrounds to inspire us and to collaborate with – vital for solving our fascinating waste challenge,” Lado says.

To register for the Waste Strategy Summit 2021, go to ww.wastestrategysummit.com.au. Waste Management Review readers receive a 15 per cent discount on registration. Use code ‘WMR15’ when booking.

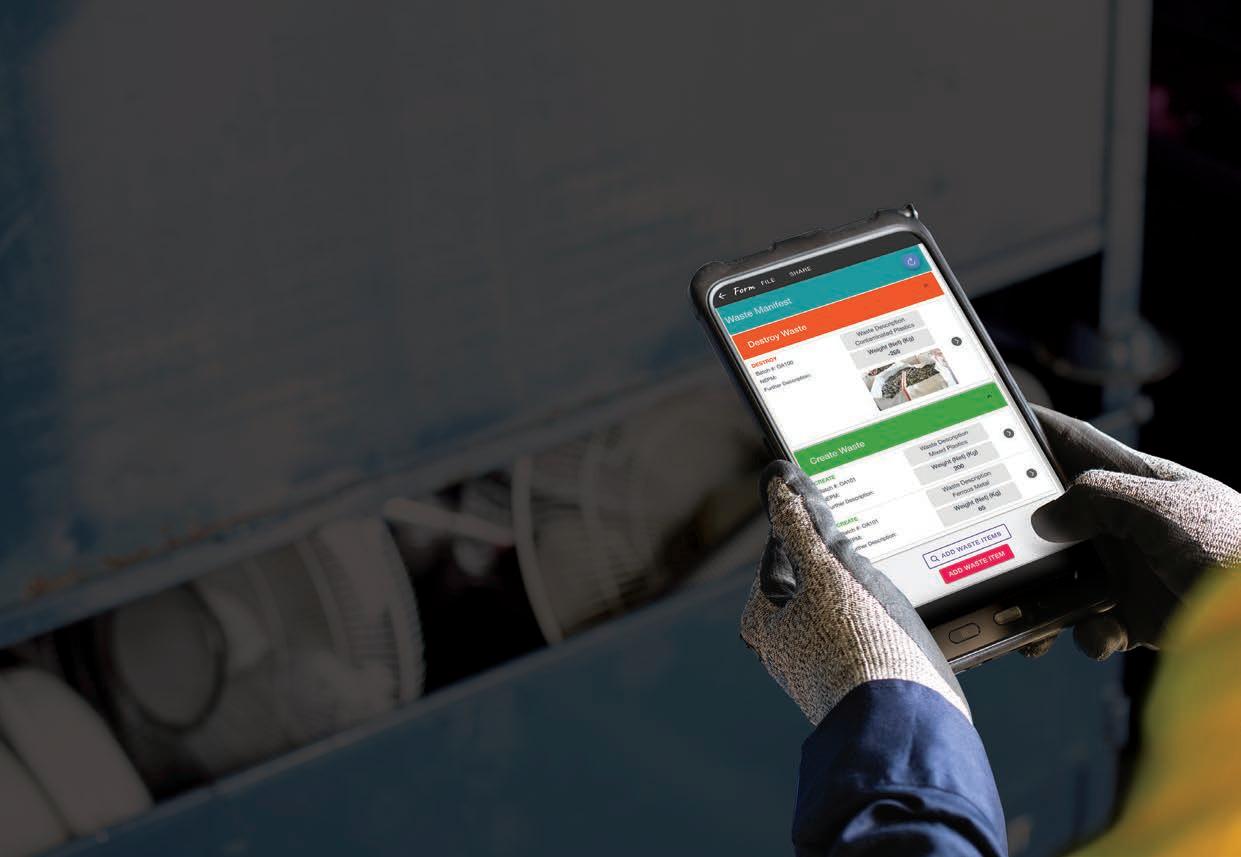

Our Management Software

AN INTEGRATED OPERATIONS PLATFORM

A suite of powerful, easy-to-use waste management tools designed specifi cally to meet Australia’s growing regulatory, certifi cation and customer reporting requirements.

Waste Tracking

ISO and Compliance Management System

Corrective Action Management System

Training and License Management System

Customer and Supplier Portals

Bespoke Business Process Applications

Grinding on the front-line

JAMES READ, BULLMORE DIRECTOR, SPEAKS WITH WASTE MANAGEMENT REVIEW ABOUT ELIMINATING DOWNTIME WITH KOMATSU FOREST.

Every year, millions of tonnes of organic waste is disposed of in landfills, shortening landfill lifespans and contributing to greenhouse gas emissions.

Greenhouse gas emissions resulting from the decomposition of organic wastes in landfills have been identified as a significant source of emissions contributing to global climate change.

Significant environmental resources are also lost, prompting governments across Australia to set diversion targets. In Victoria, for instance, the state government is seeking to cut the volume of organic material sent to landfill by 50 per cent by 2030.

To achieve those targets, however, organics operators rely on support in the form of high-powered equipment, such as that offered by leading equipment manufacture and supplier Komatsu Forest.

In addition to Komatsu Forest’s own extensive range of forestry equipment, the company distributes

Peterson Horizontal Grinders. The grinders are an ideal tool for quickly and effectively reducing green waste into mulch or compost products. This is a fact well known to James Read, Bullmore Director, who has been operating a 2710C Peterson Grinder for the last four years.

Bullmore, a modern and progressive contracting company, has been operating since 2009. Read explains that the company started out in almond hull processing around Mildura, using highly modified grinders to process almond hulls for the stock feed industry.

That said, Bullmore has diversified in recent years – expanding into green and timbre waste processing after purchasing a second-hand Peterson Grinder from Komatsu Forest four years ago.

The 2010, 2710C Peterson Grinder is now Bullmore’s front-line machine, with in excessive of 7300 hours on it.

Since 1981, Peterson has specialised in the development and delivery of processing equipment that turns lowgrade organic materials into high value products. Komatsu Forest has been a dealer for Peterson products since 2010, selling their Horizontal Grinders, Disc and Drum Chippers and Flails into the Australian market.

“I started talking to Komatsu Forest five years ago when I was looking for a grinder. I then took a trip to the US and had a look at the machines being built at the Peterson factory,” Read says.

“I then made the decision to buy an older machine and since then have worked very closely with Komatsu Forest to keep the machine going.”

The 2710C is designed for operators requiring high production and frequent moves between jobs. At 26,762 kilograms, it is among the lightest of Peterson’s grinder series.

The 2710C is powerful, with a choice of a Caterpillar C13 Tier III, 475 horsepower engine, or a C15 Tier III, 580 horsepower engine. Heavy duty and mobile, the 2710C’s large feed

Peterson’s three-stage grinding process provides a consistent product and sound fracturing of material.

opening can readily reduce a wide range of materials.

Peterson’s three-stage grinding process provides a consistent product and better fracturing of material, while its patented impact release system airbags provide uniform grinding.

“Like any high impact machine, you have breakdowns and damage from contamination like steel – it doesn’t matter what machine you have. But because Komatsu Forest understand forestry, and that if one machine goes down another five go down, they understand the importance of time frames,” Read says.

He explains that prior to the COVID-19 pandemic and its associated effect on global supply chains, he could ring the Komatsu Forest team on a Thursday and get parts flown out of the US by the following Monday.

Komatsu Forest is one of the world’s largest manufacturers and distributors of forest machines. It operates in all important forestry markets and has a comprehensive range of machines, services, servicing and spare parts for modern forestry.

“Komatsu Forest understands the need to get machines up and going, and I couldn’t get that with any other brand of machine in Australia,” Read says.

“I hear from competitors that they have machines go down for months while they’re waiting on parts. I’ve never had that problem.”

The 2710C is designed for operators requiring high production and frequent moves between jobs.

Contact - Komatsu Forest

P +61 2 9647 3600 W www.komatsuforest.com.au/

ShowHello!

THE PHOENIX HAS LANDED IN AUSTRALIA

The Phoenix is an extraordinary mythical creature. At the end of its life when just ashes remain, something magical happens. New life merges out of something that seems lifeless. What we consider to be the end, suddenly transforms into a new beginning. We give ash a new life in the real world.

What we do

The ash in our line of business comes from the new Energy-from-Waste facility Avertas Energy. Incineration of municipal solid waste (MSW) is an effective way to reduce waste volume and reduce our reliance on fossil fuels for energy.

How we do it

We process the remaining ash and extract valuable resources. With our state-of-the-art technology we recover metals to produce a secondary aggregate used for civil construction work. Environmental protection is at the forefront of our day-to-day operations. We assure the proper use of aggregates, limiting the impact on the environment.

Why we do it

We believe our work is only valuable if it contributes to a better future. We prevent landfilling and the negative impacts associated with the extraction of virgin raw materials by producing a secondary aggregate that contributes to the circular economy.

THE ELDAN POWDER SYSTEM

ELDAN Recycling’s Powder System for tyre recycling is used to turn rubber granulate from any type of tyre into rubber powder, with sizes down to 50 Mesh, according to ASTM D 5603-96.

It is used to meet demands for very fine rubber powder and can be added to existing tyre recycling plants.

Key features of the system include a low power consumption to horsepower ratio, with a high capacity ranging from 2000 to 500 kilograms depending on output size.

The system’s control and soft touch panel shows operators the friction ratio, overall mill speed, Amps, bearing and output temperature.

Mill rolls are powered by two electrical motors, and due to the high ratio, production is significantly higher than traditional mills.

The cast mill rolls are interchangeable and specially treated and machined for optimum quality. The rolls are also water cooled, with the cracker mill including a water cooler developed for this purpose.

The system’s solid construction also ensures smooth production, while the controlled drive friction ratio system is adjustable at all times including during operation.

The Powder System’s bearings are lubricated by means of PLC-controlled grease pumps, which ensures long life.

The electrical system is designed to regenerate large volumes of electrical power resulting in energy savings.

The automated process requires only occasional operator control for surveillance and supervision, making the Powder System a turn-key solution that includes everything needed for high quality powder production.

THE BEHEMOTH SINGLE-SHAFT SHREDDER

Applied Machinery’s BH Series heavy-duty single shaft shredder can be considered a “behemoth.”

The heavy-duty size reduction machine is designed for shredding a wide variety of materials with the powerful, wear resistant machine structure well suited to demanding recycling applications.

Applications include municipal solid, industrial and demolition waste, wood waste, plastics, alternative fuels and a range of other items.

Its v-cutting rotor design allows for staggered cutter positioning alongside heat treated and adjustable counter knives ensuring cutter clearance can be maintained.

A classifier screen enables accurate particle size control while a force feeding ram supports a precision machined chamber base with adjustable/replaceable brass guides.

The machine’s powerful electric drive motors, heavy duty oversized gearboxes and shock absorption system ensure smooth processing with improved performance.

Its bearings, hydraulic opening design and electrical control panel mean the machine is robust and intuitive.

Other equally capable machines include GC Series Granulators, ideal for a range of materials such as plastics, rubber and fibres and K Series high performance single shaft shredders suitable for processing a wide range of materials.

Applied Machinery works with its customers to find the right machine for them, with a number of Genox shredders and granulators also available for niche applications.

ELDAN Recycling’s tyre recycling electrical system.

The BH Series single shaft shredder is built to service a range of applications.

Contact - ELDAN Recycling

E cn@eldan-recycling.com W www.eldan-recycling.com

Contact - Applied Machinery

P 03 9706 8066 W www.appliedmachinery.com.au

Adam Krajewski of GCM vouches for the E520 Compactor’s effectiveness.

Fewer pass

compaction

RESOURCE RECOVERY POWERHOUSE BINGO INDUSTRIES RECENTLY PURCHASED A GCM ENVIRO TANA E520 COMPACTOR TO MANAGE WASTE SAFELY AND EFFICIENTLY.

Strong compactor teeth can be the difference between excellent or average traction and manoeuvrability on a landfill site, as they break, grind and compact their way through refuse efficiently.

The result is increased efficiencies, allowing operators to boost profitability and focus their efforts on other crucial areas of the business. Additionally, when it comes to landfill compaction, a smooth surface is key to ensuring daily cover is applied in a safe and cost-effective manner.

This is well understood by BINGO Industries, which in April 2021, purchased a TANA E520 landfill compactor through GCM Enviro – the third E520 handover for the leading distributor of waste management equipment in the last six months.

According to BINGO Industries representative Phillay, the reason for the purchase was simple.

“My big boss told me that TANA was the best, so we went with TANA,” he says.

Phillay adds that the machine has been performing well, backed up by GCM’s high-level of pre and after sales support.

“The TANA compactor is a great machine. It gets the job done and is simple to use,” he says.

FROM WASTE TO VAULE

The TANA E520 features a unique design with twin drums, which according to GCM’s Adam Krajewski, means fewer passes. This in turn produces a smooth and dense surface – making the E520 one of the most productive compactors on the market.

A rigid frame maximises the crushing force of up to 50 per cent of the total compactor weight, compared to 25 per cent for an oscillating frame, Krajewski says. He adds that the rigid frame also means waste spreads in level layers, which maximises uniform compaction, instead of being spread unevenly along the surface through an oscillating frame.

The end plates on the drums of the TANA machine eliminate any waste extrusion experienced in the eight points of four-wheel compactors. The drum design concentrates pressure directly under the frame, providing a smooth and level compaction.

Stability is also ensured through a maximum sideways tilt angle of more than 50 degrees and minimum cabin sway due to a rigid frame. It’s particularly important for safety, preventing the risk of rollover for the operator.

Krajewski says that with fewer passes, simplified maintenance and good drivability, the TANA E520 works to save expensive landfill airspace.

“The TANA E520 offers easy access for maintenance, has a safe walkaround design and the operator and machine are well-protected from random debris,” he says.

“The cabin also has a roll-over protection structure, or ROPS, and falling-over protection structure for the safety of the operator.”

Furthermore, the compactor’s TANA Control System improves driveability with a user-friendly interface with a simple operating menu and four-colour display. The monitoring system helps the operator determine any faults and prevent damage from occurring.

“GCM’s philosophy is to maintain constant dialogue between manufacturers and clients to ensure equipment design is governed by market requirements, particularly in the harsh climatic conditions we experience,” Krajewski says.

“Ultimately, our objective is to enable customers to increase revenue with cutting edge technology, allowing them to generate value from waste.”

Ease of maintenance and operation are key components of the E520.

Contact - GCM Enviro

P +61 2 9457 9399 E sales@gcmenviro.com.au W www.gcmenviro.com

Adjusting to industry: Palfinger’s PH T22A DINO SLD5 Hookloader

AS STEVE LLYOD TELLS WASTE MANAGEMENT REVIEW, THE NEW MODEL PALFINGER PH T22A DINO SLD5 HOOKLOADER IS SET TO OFFER THE FLEXIBILITY NEEDED FOR MODERN PROJECTS.

Flexibility has never been more important in the waste industry, with operators now requiring machines which can be used for multiple applications. The Palfinger PH T22A DINO SLD5 Hookloader was developed purely for this purpose.

As General Manager Sales Steve Lloyd explains, the PH T22A DINO SLD5 Hookloader was manufactured to help operators adapt to the changing waste landscape.

“In Australia there are no standards for critical dimensions on containers or bins and as such rail widths and hook heights can differ greatly between products. The Palfinger PH T22A DINO SLD5 Hookloader was re-designed specifically for Australian applications,” Lloyd says.

While international waste sites and containers feature universal measurements, the Australian market can differ from bin to bin. As such, the uniquely Australian product mix required a uniquely Australian solution.

The PH T22A DINO SLD5 Hookloader aims to ease the difficulty of the differing sized bins, featuring a new fully adjustable three position (four optional) manual adjust hook height which is universal across model range.

Bins with pin heights from 1410 to 1610 millimetres are able to be collected with the one Hookloader, making for increasingly efficient and effective projects for waste operators. A unique hydraulic adjustable hook height option, controlled from inside the cab, is available on selected models.

The wider bin rail range of the Hookloader also supports multiple bin widths, fitting bin widths measuring between 660 and to 1200 millimetres.

“We have a machine that has multiple functions in different situations, that is the core strength of the PH T22A DINO SLD5 Hookloader,” Lloyd says.

The newly introduced ‘X Frame’

The PH T22A DINO SLD5 Hookloader offers the flexibility needed for projects.

concept enables the rear of the chassis design to face less stress during operation, an essential aspect when operating in difficult environments.

The flexibility comes in the chassis front bin locks and support brackets, which are now bolt-on components including three position fittings for the main valve bodies.

The chassis component is uniquely designed for the PH T22A DINO SLD5 models and allows a level of customisation for different operatives, as Lloyd explains.

“The way we attach the mounting system for the chassis is distinctive and we have a wide range of dedicated truck brand and model specific chassis mounting kits which are tailor made and specifically designed for different chassis,” he says.

All Palfinger Hookloaders are manufactured to meet Machinery Directive 2006/42/EC and all welding is defined by the ISO 3834-2 certification.

Maintenance cost reduction was of upmost importance for the Palfinger team resulting in yet another inclusion in the new design of the PH T22A DINO SLD5 – the installation of Tipping Cylinder Bend Protection. The addition provides safer operation in the case of misuse by operators.

In addition to the bend protection, a newly designed fuse-bolt connection not only prevents overloading on cylinders, but also averts significant damage occurring to the Hookloader.

Multiple control options for both in-cab and radio remote operation are available on the new range of Palfinger Hookloaders including the PH T22A DINO SLD5.

In standard configuration the tried and proven PAD control sets the industry standard for ease of use and feedback to the operator. The up-spec TEC5 units encompass the latest PAD Touch single joystick control process and a loading camera, both are optional with radio remote control.

Aside from the fresh face of an all-new control system, Palfinger also offers multiple automatic load, automatic unload, automatic tipping, fast tipping and soft stop options tailored to suit each operators’ individual requirements.

With 37 service partners nationally, operators can be assured they will receive full parts, repairs and Palfinger factory trained service specialists for Hookloader components.

Contact - Palfinger

W www.palfinger.com/en-au

shredders for every product, business & budget. That’s Applied Thinking.

UNCAPPED

INSTANT ASSET WRITE-OFF

One of Australia’s most popular brands of shredders and granulators Safe, efficient, cost effective size reduction of your bulky, or sensitive waste streams Perfect for reprocessing your waste material for closed loop manufacturing Huge range available to suit practically all waste streams; plastic, wood, metals, tyres, e-waste & more

Machines in stock in Melbourne

appliedmachinery.com.au

Waste Management Contractors Showcase 2021

The Waste Management Contracts Showcase will be a go-to-list for finding contractors, big or small, that are playing a part in Australia’s circular economy transition.

Whether you collect it, process it, or transport it – register your business and be part of an essential resource for the industry.

Chelsea Daniel-Young

Business Development Manager, Waste Management Review (+61) 425 699 878 chelsea.daniel@primecreative.com.au

Scan the code to list your business:

Material specifications a stepping stone to increasing recycled content

DEVELOPING AND PROMOTING A SET OF PUBLICLY AVAILABLE NATIONAL RECOVERED MATERIAL SPECIFICATIONS TO ENABLE GREATER UPTAKE OF RECYCLED MATERIALS IN DOMESTIC MANUFACTURING AND CONSTRUCTION HAS BECOME A PRIORITY PROJECT FOR NWRIC, WRITES CEO ROSE READ.

The development and promotion of up-to-date specifications for recovered materials along the supply chain is key to providing certainty and confidence to both recyclers and manufacturers, as they look to increase recycled content in Australia’s domestic construction and manufacturing sectors in the wake of the waste export bans.

The export bans of waste plastic, paper, tyres and glass sent a clear message that Australia needs to increase the quality of recycled materials and take responsibility for its own waste through greater domestic reuse.

There was also the outcome of last year’s National Plastics Summit, where the Federal Government committed to the procurement of recycled materials and recycling market development as a priority.

These two critical activities impacting the waste and resource recovery sector, along with direction in the National Waste Policy Action Plan to “establish nationally consistent definitions and specifications for waste and recycled commodities to define the scope of export bans” and, “build industry capacity and infrastructure to collect, separate, recycle and remanufacture recycled materials”, were key drivers in the need to update existing and develop new national recovered material specifications.

NWRIC is committed to making available a clear set of recovered material specifications that will assist Australian recyclers in meeting market demands for recovered materials locally and overseas, as well as give manufacturers and construction companies greater confidence in the quality of recovered materials being put on to the market.

We also consider that to stimulate domestic reuse of recovered materials we need to improve the information available about the physical and chemical characteristics of recycled materials, and encourage independent certification or quality assurance of these secondary raw materials against mutually recognised specifications.

Effectively, through these specifications, we are taking steps for industry to become a reliable provider of quality secondary raw materials for manufacturing and construction rather than just a manager of waste.

To undertake this project NWRIC is working collaboratively across the supply chain, bringing together primary sorters and secondary processors with manufacturers to build on existing and develop new specifications for masonry materials, metals, organics, paper and cardboard, plastics, glass, tyres, ash and oil.

Material specifications for these nine material types will cover approximately 90 per cent of all the waste materials generated in the Australian economy, and more than 95 per cent of the embodied energy of production captured. Medical waste, liquids, hazardous waste and contaminated ash are excluded due to the complexity of these material steams.

NWRIC is also keen to see sorters and secondary processors getting their material outputs independently certified or assessed against these specifications

so that buyers have confidence in the material they are receiving, and customers have certainty the waste is being converted into a resource for reuse.

The collaborative approach NWRIC is taking with industry across the supply chain to develop and enhance existing material specifications is an effective way to start the conversation between suppliers and buyers on how to get more recycled content into products and developing those markets.

NWRIC has been working closely with the Australian Packaging Covenant Organisation on specifications for plastic polymer bales from sorters (e.g. MRFs) and flakes from secondary plastic processors so they are input ready for plastic converters.

So far, specifications have been developed for seven material types, for both MRFs, sorters and secondary processors for PET, HDPE, PP and PE.

NWRIC is also working with the CSIRO End Plastics Waste Mission team and the Vinyl Council of Australia on material specifications for plasticised and non-plasticised PVCs coming out of the commercial and industrial, and construction and demolition waste streams.

This project includes undertaking stakeholder interviews across the supply chain to ensure the specifications and associated testing and auditing regimes developed for recycled PVC meet the manufacturers requirements.

One project that demonstrates the importance of developing material specifications and auditing systems with all stakeholders along the supply change is Western Australia’s Roads to Reuse program, where industry and government are working together to drive greater reuse of recycled materials in civil construction works.

The Roads to Reuse program is a WA state government initiative administered by the Waste Authority. Its objective is to encourage state government organisations, local governments, regional councils, and the private sector to use recycled C&D products in civil applications, such as road construction. It does this by supporting the supply of recycled C&D products to market that meet a product specification, to protect human health and the environment.

By having agreed material specifications and a strong quality assurance process in place, recyclers know what quality materials they must deliver, and the construction industry has confidence and certainty in both the quality of the material and its timely supply.

To date, more than 62,000 tonnes of Roads to Reuse material has been used as road base under full depth asphalt in Western Australian roads.

NWRIC hopes to achieve this level of collaboration and success across all nine material types.

A list of current national and international specifications identified can be found online at the NWRIC website, www.nwric.com.au.

NWRIC Project: Development of national recovered material specifications Objectives

Create a current up to date set of national recovered material specifications that will, a) assist Australian recyclers in meeting market demands for recovered materials locally and overseas, b) improve the quality of recovered materials as tradable commodities c) stimulate domestic re-use of recovered materials by improving market information and greater confidence in the quality of recovered materials. Publication of recovered material specifications for following material streams • Masonry materials • Metals • Organics • Paper and cardboard • Plastics • Glass • Tyres • Ash • Oil • Identification of end markets • Industry communications package • Publication and promotion through the NWRIC website, social and industry media.

Outcomes

Industry involvement Material Type Stakeholder Engagement

Masonry materials Construction industry, C&D Recyclers, ARRB,

Metals APCO, AFGC, ACOR, MRFs, Steel manufacturers, Scrap industry

Organics AORA, NFF, Nursery, Forestry, Agriculture, Horticulture

Paper and Cardboard APCO, AFGC, ACOR, MRFs, paper manufacturers,

Plastics APCO, AFGC, ACOR, MRFs, Vinyl Council, Chemistry Australia, paper manufacturers, agriculture,

Glass APCO, AFGC, ACOR, MRFs, Steel manufacturers, Scrap industry

Tyres TSA, Construction industry, C&D Recyclers, ARRB, Cement manufacturers ATRA, ACOR

Ash Oil Construction industry, C&D Recyclers, ARRB, Oil Recyclers Association, End markets