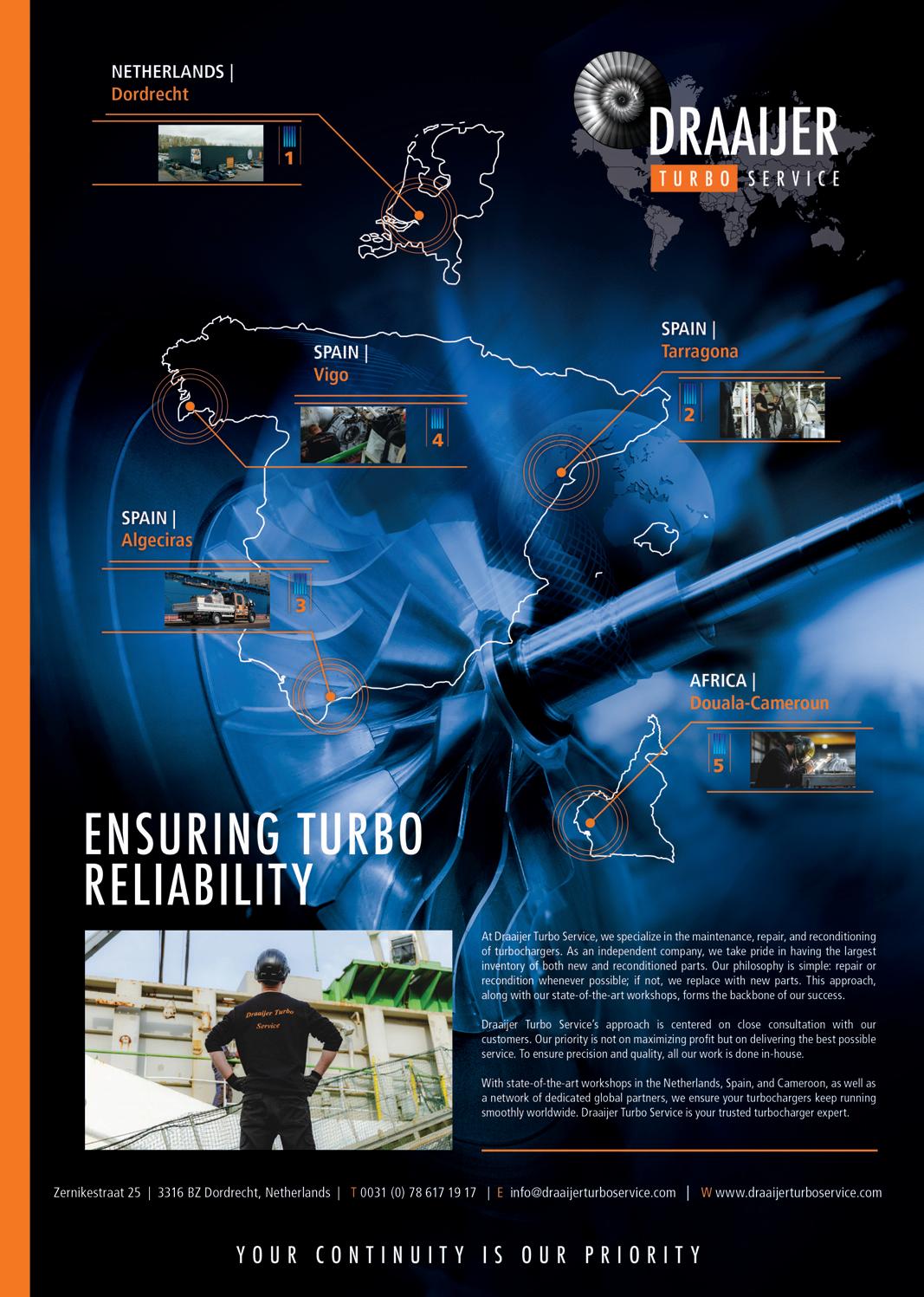

DRAAIJER TURBO SERVICE

At Draaijer Turbo Service, we specialise in the maintenance, repair and reconditioning of turbochargers. We have the largest inventory of new and reconditioned parts. Our philosophy is to repair or recondition whenever possible and replace with new parts only when necessary.

We prioritise close consultation with customers, focusing on the best service rather than profit. All work is handled in-house to ensure quality. With state-ofthe-art workshops in the Netherlands, Spain and Cameroon, plus a network of global partners, we keep your turbochargers running smoothly worldwide.

Draaijer Turbo Service is your trusted turbocharger expert.

vessels there. In 2008, the company brought its large graving dock into service. The 400 metres long by 50 metres wide dock was previously nonoperational and sunk in seawater. Its refurbishment proved a key milestone.

“After that, Cernaval started making noise abroad,” said Mr Perez. “We are very well located, but we were mainly serving ferries between Morocco and Spain. But after the graving dock opened, we escalated our presence into the international market.”

To meet the increasing size of the vessels passing through the shipyard, the company invested in a new floating dock in 2018. It was transported from South Korea to Algeciras in 2019 and took almost a year to install. The first vessel was serviced in the new floating dock in April 2020.

The company was thus able to unify the floating dock and the graving dock. “That means that we have now 40 years in the contract and can be here until 2057,” Mr Perez reflected. “That was the main target, though from my point of view, the biggest step was developing the graving dock.”

The shipyard offers repairs, maintenance, retrofits and upgrades to all commercial ships. And Cernaval is singular in its purpose. “We just focus on repairs,” Mr Perez explained. “We don’t get involved in new buildings or the super yacht sector. We service commercial ships of all sizes and can carry out repairs afloat and in drydock.”

These services include standard dry dockings, emergency repairs and planned repairs. The state-of-the-art facilities are

spread across four quays, totalling 270,000 square metres, and include more than one kilometre of layby berth. With 150,000 ships transiting through the Strait of Gibraltar each year, Cernaval’s location is undoubtedly a desirable one. “We are at one of the best points in the globe and can offer all kinds of services demanded by any kind of fleet,” said Mr Perez. “The world’s main container players, Maersk and CMA CGM, are established in Algeciras Port in their own container terminals and send plenty of work our way.”

Going green

Following new regulations from the IMO, ship owners are striving to reduce emissions from their vessels wherever possible. This means projects that focus on upgrades and retrofits are becoming ever more common at Cernaval.

“The next step is working with the gas carriers,” said Mr Perez. “So many vessels are now using dual engines, powered by electric or gas. And the gas carriers have a very specialised system to manage the loading of gas as cargo. So, we need a specific certification, a special isolated workshop and people accredited to work on this type of job.”

The company is also retrofitting to meet AMP standards, an air quality programme that focuses on reducing emissions from container vessels. Instead of running on diesel power while at berth, AMPequipped ships plug in to shoreside electrical power.

“There are only two ports in the world, New York and Shanghai, where the vessels need to be disconnected when they are in port to reduce noise and emissions,” said Mr Perez. “But there are an uncountable number of vessels that need

to be retrofitted to accommodate this.

Maersk has at least 700 ships in its fleet, it’s a huge number. So, customers need to adapt for when they go to these ports, otherwise a vessel is not allowed to enter.

“For us, this is a very good move. But all these retrofits can only be done in drydock, because it’s the only long period when the vessel stops in five years. When they are in charter, they cannot afford to stop for 20 days for the retrofit. So, the ship owners try to match the drydock period with the retrofit job to save money by doing everything at once.”

Cernaval has also recently invested in mobile cranes for removing and refitting hatch covers, adaptable to the capacity of a vessel, particularly container ships. “We have agreements with the major players and have invested millions in

these mobile cranes which allow us to be very competitive,” said Mr Perez. “We externalised this service until 2020, when we purchased a big mobile crane, which is able to remove and refit the biggest hatch covers on the biggest vessels we are capable of taking.”

Powering ahead

As the shipping industry matures and develops, Cernaval does so alongside it. The main goal for the company is a continued focus on the modifications and upgrades of its facilities in order to accommodate the increase in gas carrier traffic.

“We are entering a new era in the life of gas carriers,” said Mr Perez. “It’s really demanding. We have been approached from some very big shipowners that we

have not worked with before who are now moving gas carriers. The trading is from the United States to the Mediterranean or the Middle East, passing through the Strait of Gibraltar. And now fuel costs are racing up it makes sense to save money by deviating course as little as possible. So, we are using our strategical location to adapt to what these customers need. This is the future.”

Shipping may be a demanding business to work in, but Mr Perez has been in the industry since 1987 and would not have it any other way.

“If someone doesn’t like shipping, they don’t work in shipping,” he concluded.

“There are no days off here, every day is Monday. I tell job candidates: ‘You have to wake up very early and you don’t know what will happen that day, there is no routine,’ to emphasise the point.

“But I like working with people and I get to meet a lot of very important and interesting people. Ultimately, we are a service company, so we must give a good service. That means being available to customers 24/7, I don’t even wear a watch anymore because it doesn’t matter what the time is, I will answer the phone. Because if we don’t do that, there are others that will.” n