Elastec, a US-based leader in environmental solutions, has transformed oil spill cleanup with its cutting-edge innovations. From highly efficient drum skimmers to advanced firebooms, the company has built a worldrenowned portfolio that is making a significant impact in safeguarding the environment. Senior VP of Sales & Marketing Shon Mosier explored the company’s journey, during an in-depth interview with Imogen Ward.

Elastec’s journey began all the way back in the ‘90s when Founders Donnie Wilson and Jeff Cantrell happened upon a solution that would change the game completely.

“The two founders came from the Southern Illinois oil basin where a lot of oil production took place,” explained Senior VP of Sales & Marketing Shon Mosier. “With the market being very cyclical, the two entrepreneurs were looking for new opportunities that would provide a steady income. At the same time, new EPA regulations came into effect that left a lot of berms in need of cleaning.”

The two Founders began offering vacuum and disposal services from the back of their truck. However, they soon moved on to a weir skimmer after seeing how much

water was being recovered during the vacuuming process.

“The weir skimmer was working better, but it still wasn’t as efficient as they wanted it to be,” continued Mr Mosier. “Then, one day while experimenting with a bucket, they noticed that the oil stuck to the side of it, and it gave them an idea.”

This was the starting point for Elastec’s drum skimmer, which would later become a game changer for the oil spill industry. These skimmers are still in action today and are just one of the many innovative solutions Elastec has developed.

Over the years, Elastec has developed some top tier solutions with the help of its long-term suppliers. Each one of these businesses has been pivotal to the company’s operations, especially when

it comes to emergency response – thanks to their ability to provide high-quality components with short lead times.

One of the lines that have benefited from these partnerships is Elastec’s grooved disc skimmers, which were created off the back of a major competition.

In 2011, the XPRIZE™ Foundation challenged industry innovators to create an oil skimmer that could clear water of 2,5000 gallons of oil per minute. Around 350 companies took part, all vying to win the top prize of $1 million.

“The industry standard at the time was for oil skimmers to remove 1,100 gallons of oil per minute,” explained Mr Mosier. “XPRIZE™ wanted to see if anyone could achieve 2,500 gallons per minute, while still being 70 percent efficient.

“XPRIZE™ narrowed down the 350 entrants to a top 10 who were encouraged

to compete for three prizes. Our unit underwent testing and surpassed the goal by over 2,000 gallons and achieved 4,670gpm, an efficiency rating of 89.5 percent, winning us the top prize.”

Out of the ten competing, only one other company achieved the impressive feat, proving just how difficult a task it was.

Following its success in the Oil Cleanup X Challenge, Elastec went on to adapt and scale down the design to make it a more practical and affordable solution.

“We have developed a number of different skimmers from that initial technology, some of which we have successfully adapted to fit boats that aren’t designed to skim, while others are being used to supplement skimmers on existing skimming vessels”

Senior VP of Sales & Marketing

continued Mr Mosier. “Using these skimmers, we have proven that we can clean up light to medium viscosity oils very well, which is an increasingly important requirement for modern vessels.”

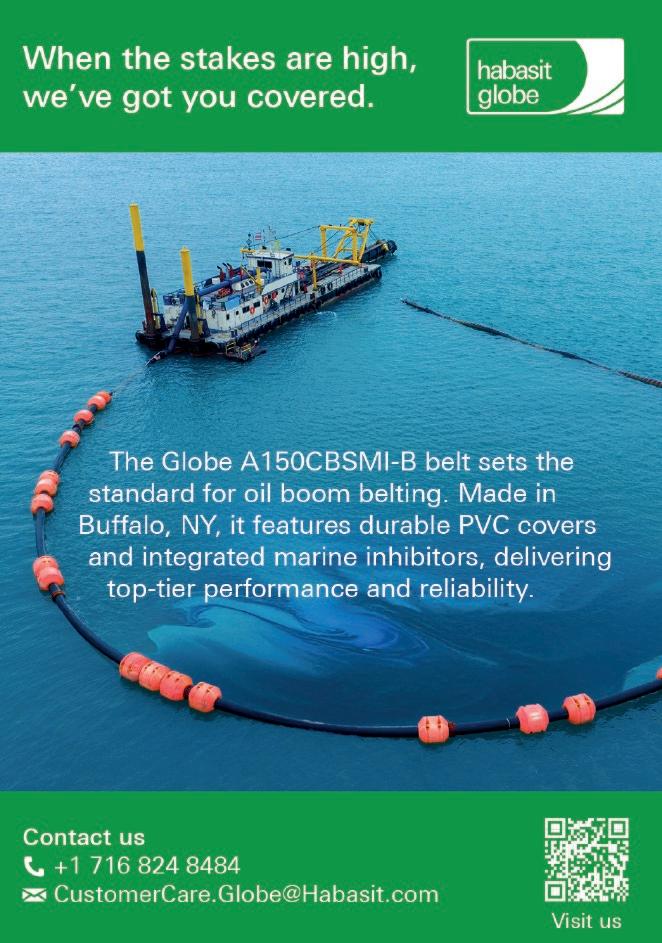

Not only does Elastec offer the best skimmers on the market for diesel collection, but it also owns several leading-edge firebooms.

In the early 2000s, Elastec acquired American Marine, which at the time was a significantly larger company. American Marine was also the developer of the American Fireboom. This acquisition led to developing the Hydro-Fire® Boom alongside oil spill response expert, Al Allen. This move would become an important stage in the company’s journey to becoming a market leader.

“Our firebooms have been a pivotal part of our success through the years,” said Mr Mosier. “They even played a prominent role in the 2010 Deepwater Horizon oil spill, during which we proved that the Hydro-Fire® Boom could last longer than any other product on the market.”

The American Fireboom and Hydro-Fire® Boom remain the top two world-leading products of their kind and are joined by

other environmentally friendly solutions such as the Trash and Debris Boom, Oil Spill Containment Boom, and Sargassum and Invasive Aquatic Plant Boom.

Some of Elastec’s booms have even been involved in major crowdfunding projects by companies such as The Ocean Cleanup and 4Ocean.

“We take pride in every one of our products, because we know that they aren’t just another wasteful widget; they are actually helping improve the environment and keeping our waterways clean,” remarked Mr Mosier. “And its not just our booms or our skimmers, we also build incinerators for medical waste and drug paraphernalia, which are currently aiding police departments across the country.”

Having already spent years adapting its products to fit on various vessels and workboats, Elastec made the strategic decision to add vessel construction to its capabilities.

“There are fewer spills today than there were 20 years ago, which is a great thing,” explained Mr Mosier. “But it does also mean that we need to adapt our business

to reflect these changes. The move into aluminum workboats was a smart one for us as we were already building aluminium frames for our skimmers and would often sell them alongside a boat as part of a package deal.

“We have successfully developed several different models typically within the 18 to 32-foot range, and these have been very popular– not just in the oil spill market either; we have worked with a wide variety of sectors, and even some governmental projects too.”

As the company continues to look forward, it expects to see more of these projects coming into play.

“We want to continue operating in the oil spill market, because that is where the majority of our knowledge is, but at the same time, we intend to continue applying our experience to different applications,” said Mr Mosier, in conclusion. “We see good growth potential in aluminium work boats, especially as we continue to refine what we are doing and find our niche.

“Above all, we have a great customer base, and we look forward to serving them more in the future.” n