seven seas, five oceans, one voice

seven seas, five oceans, one voice

An introduction to the leisure marine sector, with special reports on sustainability at famous yacht shows and the life of crew on a superyacht, plus a review of superyachts in film and a selection of news items.

An overview of sustainability at yacht shows.

Yacht shows feature some of the world's most advanced vessel designs and iconic brands all in one space. As the demand for sustainability has grown in the industry, yacht shows around the world have applied their innovative spirit to advancing environmental preservation. Report by Antonia Cole.

The world’s yacht shows allow visitors to explore the latest innovations in yacht design and discuss cuttingedge technologies with leading shipyards. Facilitating conversations between industry professionals, these festivals drive the future of yachting forward.

As spaces full of innovation and collaboration, yacht shows pioneer environmental development in the industry. From the organisation of the show to creating a platform to exchange ideas, these shows present a great opportunity to accelerate sustainability.

The Cannes Yachting Festival, the Southampton International Boat Show and the Monaco Yacht Show are all major yachting events that are incorporating sustainability into exhibitions. With these events working to inspire positive change, the future of the yachting industry is transforming environmentally.

The Cannes Yachting Festival

Located across Cannes’ two ports, the Vieux Port and the Port Canto, the Cannes Yachting Festival offers visitors the opportunity to see the latest innovations from the coast of the French Riviera. Presenting almost 700 boats, the festival brings together industry leaders and passionate yachters from around the world.

The festival has now developed an innovation route, aimed at promoting sustainable solutions. Vessels and equipment that pro vide a minimised environmental impact are identified with specific signage, increasing sustainability awareness for visitors. From alternative power engines to environmentally friendly materials, all the latest sustainable innovations are highlighted.

Additionally, the festival has also adjusted its structure to become more sustainable. To reduce paper use, the show has imple -

mented paperless tickets and environmentally friendly maps. For the press village’s furniture and the majority of the festival’s signage, recycled cardboard has been used to limit environmental impacts. Waste sorting practices, as well as aisle carpet recycling have been implemented to encourage sustainability in the festivals take-down. There is also wastewater treatment and environmentally friendly boat tank emptying to minimise pollutants entering the water.

In terms of festival services, the Cannes Yachting Festival has optimised transportation fuel use and has worked with caterers to create sustainable options. This includes using local products as much as possible, as well as reducing waste like excess food and single-use plastics.

As Britain’s largest boating festival, the Southampton International Boat Show is leading the industry in showcasing sustainable innovations. With everything from paddleboards to superyachts from a variety of major global brands, the show offers visitors the opportunity to explore the world’s best vessels and more.

The show is committed to reducing its carbon footprint and driving industries towards more sustainable practices. The event operates as a platform to uplift environmentally-friendly technologies and innovations. Visitors can learn about the latest market developments and how to implement them for more sustainable operations.

Exhibitors and contractors for the show are encouraged to sign an environmental pledge, focusing on marine conservation and reducing carbon footprint. When

signing the pledge, exhibitors promise to make as much of their stand reusable, promote sustainability, travel responsibly and encourage others to be more environmentally conscious too.

By signing up to the pledge, exhibitors are able to demonstrate their commitment to sustainability. With their stand highlighted on the event map, a special display for their stand and a digital pledge logo to share online, exhibitors can attract visitors and engage in environmental conversations. The exhibitors are also encouraged to participate in the Exhibitor Sustainability Award, in which the event recognises the environmental efforts of participants.

The festival has additionally implemented mandatory sustainable requirements for exhibitors. This includes reducing single use plastics and only using compostable, recyclable or reusable plates, cups, glasses and cutlery. Exhibitors can only offer sustainable

promotional giveaways and must nominate a sustainability champion to oversee waste reduction at the show.

Sustainability has been a part of the Monaco Yacht Show since 2005. Since then, the event has taken great steps to promote environmental awareness throughout the industry. In 2022, the show signed the Mission for the Energy Transition of Monaco pact, aiming to reduce emissions, waste and energy use.

Some initiatives include minimising journeys and encouraging the use of public transport, like electric shuttles. Efficient waste recycling systems have been added, as well as implementing more sustainable materials into the festivals set-up.

The show also only uses green electricity and has committed to producing energy and carbon assessments of events in order to set a standard for improvement.

The festival partners with environmental organisations such as the Prince Albert II of Monaco Foundation, in which it supported the preservation of glacial ice samples to study climate change. Also, the show

promotes Blue Marine Foundation’s London2Monaco cycling race to raise funds for marine conservation projects.

With the Water Revolution Foundation, the show has created a sustainability hub, bringing together sustainable projects from industry experts. In 2024, the event saw the announcement of the Yacht Safety and Environmental Consortium from leading global classification societies Lloyd’s Register, RINA, DNV, Bureau Veritas and ABS.

The consortium will drive forward safety and environmental standards for yachts, Shiptype Manager Yachts at Bureau Veritas Marine & Offshore Dubravka Zaja said: “By leveraging our combined strengths, we are well-positioned to advise on operational practices and contribute to a more sustainable maritime future.”

Yacht shows from all over the world are responding to the demand for more sustainable events, but many are also taking the extra steps to promote environmental awareness through industry partnerships. These shows create an opportunity for both experts and visitors to connect and share ideas, driving the yachting industry towards a more sustainable future. n

Behind the luxurious experience of a Superyacht charter is a dynamic crew working to deliver unforgettable memories. From morning preparations to cleaning and maintenance, crew members see to guests’ every need. Antonia Cole explored what a day in the life looks like on board one of these premium vessels.

3am – T he day of a superyacht deckhand begins shortly after the previous day’s end. The passerelle connecting the yacht to the dock is raised and decks must be cleaned. Facilities such as jacuzzis and water sports rooms are prepared alongside the addition of finishing touches like replacing cooler bags and towels. This time is used to com plete all the necessary jobs out of the sight of guests.

6am – This is when the chef sets up for breakfast. Typical offerings may include pastries, fruit, eggs, bacon or cereals. A crew member will set the table and assist the chef, making sure all breakfast items are ready. Meanwhile, the rest of the yacht is arranged for when the guests wake up. Tasks include uncovering seating, laying out sun loungers, putting out sun cream and water bottles, and wiping down surfaces.

7am – The chef will write the menu for the day, which is printed by the stewardess for the guests to see. Breakfast is served according to the guests’ requests and the chef moves on to preparing lunch.

9am – Once the guests are all awake, a crew member will see to the cabins. Linens will be replaced with fresh ones , laundry is collected and bathrooms are cleaned. At this point a stewardess will usually confirm the day’s itinerary.

10am – Lines are brought up, fenders deflated and fender hooks put away as the yacht prepares to leave the dock. The yacht captain will assess weather conditions and routes to ensure safe and smooth travel. Once at the destination of the day, activities are set up for the guests to enjoy, such as a swim platform, jet skis

and slides. Crew members carry out regular checks, tidying the decks to keep the yacht looking untouched. This involves clearing glasses, straightening cushions and polishing finger marks.

12pm – Lunch is served to the crew, whilst the guests decide what time they would like to eat. Guest lunch usually includes fresh bread and a meal suited to their individual preferences. Some guests choose their own meals and others leave it up to the chef.

4pm – All water sports equipment is now brought back and cleaned. The anchor is lifted and the yacht sets sail to its next destination. Around this time, the chef begins dinner preparation and makes some canapés for the guests to enjoy.

6pm – Canapés and drinks are served, and the guests decide when they would

like to have dinner. Usually, dinner will have three courses followed by petit fours and cheeses. Crew members will create a unique table setting and serve each course to the guests, attending to any extra requirements.

8pm – Deckhands will prepare the yacht for docking and organise a passerelle-watch rota. This involves taking note of who is on the vessel and preventing any unwelcome guests from entering.

10pm – The guests have finished eating and are enjoying their evening. Crew will spend the rest of the day attending to guests’ needs before cleaning, sanitising and preparing everything to start again the next morning.

Inside Marine explores superyachts on film.

When it comes to th From awe-inspiring budget to go big. An there’s a strong pos Here at Inside Marine taken a deep dive in

he big screen, glitz and glam is often served up by the boatload. costumes to star-studded casting, the latest blockbusters have the nd with the phenomenon of superyachts spreading across the globe, ssibility that you may spot one next time you’re streaming on Netflix. e, we have found some great examples of superyacht screentime and nto what exactly makes these yachts so super. Report by Imogen Ward.

With the first known reference dating all the way back to 1912, the idea of a superyacht has evolved significantly over the years. Growing bigger, bolder and more technologically advanced, these boats often exemplify the cutting-edge of boat building. Now, more popular than ever, these vessels take centre stage at many world-renowned boat shows and have even made it to the big screen on more than one occasion.

But have you ever wondered why exactly these vessels are chosen? Well, wonder no more, as we take you on a tour of true craftmanship.

When thinking of superyachts in film, perhaps the most famous franchise that comes to mind is James Bond. Known for sporting

the crème de la crème of cars and boats, this multi-billion-dollar film series is one of the highest grossing franchises in history, and with 27 films spanning 60 years, it continues to draw in crowds, young and old.

These films have even inspired several pivotal superyacht builds, including Octopussy, which is currently the fastest superyacht in the world.

Our first contender took up the role of Chimera in one of the more recent Bond movies (Skyfall). Superyacht ARIA 1 was built by Med Yachts in 2011 and can host up to 12 guests thanks to six-bedroom suites that sit comfortably within the 184ft-long boat. Guests can look forward to making the most of the aft amenities, thanks to a wet-feet bar capable of hosting all 12 occupants and a pop-up TV perfect for rewatching ARIA 1’s big debut.

Jumping further back in time to 1995, another stellar ship made its way onto movie screens everywhere. Featured in the seventeenth Bond film, GoldenEye, the Northern Cross is a 141-foot luxury superyacht built by Swedish shipyard Marinteknik Verkstads AB in 1991.

This boat features two CAT 3512 DITA engines, which ensure a top speed of 24 knots – making it the perfect getaway vehicle for the Xenia Onatopp. Capable of hosting 10 people in five separate cabins, this superyacht is maintained by eight crew members, who make sure to keep all areas of the boat shipshape.

Whether you want to dine alfresco in the convertible aft area or lounge on the sundeck, the Northern Cross guarantees a luxury yachting experience.

Of course, James Bond isn’t the only on-screen character enjoying the finer things in life.

The 2019 film Murder Mystery features the 197-foot superyacht Sarastar. Built in 2017 for charter, this eye-catching example features the finest marble floors and back-lit

onyx staircases, ensuring a truly memorable break. There are also tonnes of amenities to enjoy, including a helipad turned dancefloor, glass-panelled sundeck (which provides an abundance of natural light to the beach club below) and enough cabins to comfortably house 12 guests. And no need to worry about getting your cardio game on as Sarastar comes fully equipped with its own state-of-the-art gym.

As part of the €364,000 p/week charter price, guests can also enjoy an array of activities, thanks to the numerous water toys on board. Whether you want to swoosh around on a pair of three-seater Yamaha VX DELUXE waverunners or take a relaxing float in the two-person inflatable kayak, Sarastar is equipped to keep you entertained until the sun goes down.

Stepping away from the suspense and intrigue of spy thrillers and murder mystery movies, we explore the world of Greek sun and Swedish pop groups, through the 2008 hit Mamma Mia!

Haida 1929 is one of the oldest yachts sailing the seas today, and she recently underwent an extensive renovation. The 218-foot superyacht was given a full-blown makeover that was reflective of the era from which she was launched. Of course, modern additions were made to bring her into the 21st century, including new exterior staircases, a shallow paddling pool and a hammam spa featuring a massage room and hairdressing parlour.

Inside Marine explores superyachts on film.

All in all, the refit saw more than 100 tonnes of steel replaced within the ship’s

hull, ensuring Haida 1929 was in peak condition for her maiden voyage as a freshly renovated superyacht.

The impressive vessel also still operates with her original twin diesel engines, which are said to be some of the oldest of their kind still operating in the vessel they were intended for.

Who’s to say when another superyacht will end up in film, but with such a luxurious legacy, it’s surely only a matter of time before we find out. n

YachtWave®, the leading provider of innovative solutions for the boating industry, announced the official release of the YachtWave Delivery Platform, a groundbreaking tool designed to revolutionise how boat manufacturers and dealers manage the boat delivery process. The YachtWave Delivery Platform debuted at IBEX 2024 in Tampa, Florida.

The platform streamlines the complex and paper-heavy process of delivering boats to customers. It provides a seamless, digital-first approach that significantly enhances customer satisfaction while improving operational efficiency for manufacturers and dealers. The platform offers innovative features that address many of the long-standing challenges in the boat delivery process.

This includes build project status timelines, task management for customers and dealers, digital document delivery, anytime access to orientation training, AI Mechanic™ support, and maintenance logs and parts inventory.

“YachtWave is revolutionising how manufacturers and dealers deliver boats to buyers,” said CEO of YachtWave Captain John O'Keefe. “Our platform not only simplifies the process for manufacturers and dealers, but also provides an enhanced, stress-free experience for the customer.

“The days of unwieldy paper manuals and delayed communication are over. With YachtWave, everything is digital, streamlined and designed with the customer in mind.” n

Cummins and Beneteau unveiled a new star at Cannes

Leading boatbuilder Beneteau unveiled its Cummins-powered SWIFT Trawler 54 at the Cannes Boat Show. The latest sleek and sophisticated addition to the Swift Trawler range, which now includes five models ranging from 35 to 62 feet, is designed for leisurely long-range cruising in a serene environment laden with new technology and home comforts.

The new vessel is a statement of seafaring luxury from Beneteau, the world’s leading marine brand, which has been working in partnership with Cummins for almost 20 years.

The Swift Trawler 54 (17.13m) is powered by two Cummins QSB 6.7 engines, each delivering 550hp. The QSB 6.7 is a proven winner for Beneteau, featuring on the Swift Trawler 48 (2 x 425hp versions) and Swift Trawler 35 (single 425hp). With the refined power of the twin Cummins engines, the Swift Trawler 54 has a cruising speed of 8-12 knots and a maximum speed of 20 knots.

It offers a range of 700 nautical miles at nine knots, maintaining a 10% fuel reserve. Handling is enhanced by the ‘Fusion’ hull shape from the drawing board of Dixon Yacht Design.

“The QSB 6.7 550hp has excellent power density and gives Beneteau the right balance of power, fuel efficiency and smoothness, with low levels of noise and vibration,” said Patrick Leroux, Recreational Marine Sales Manager at Cummins France, based in Nantes, not far from Beneteau’s manufacturing base.

The Swift Trawler 54 can accommodate up to six people, with an option for an additional crew berth. The living spaces are spacious and bright, thanks to panoramic glazing offering a 360-degree view, and a staircase connects the flybridge to the wheelhouse. n

Viareggio in northern Tuscany, Italy, is easily the boatbuilding capital of the country, with over a dozen yacht builders located in the town. One of those is Rossinavi, a family-owned builder of bespoke superyachts. Richard Hagan met with COO & Co-owner Federico Rossi, to find out how engineering breakthroughs at Rossinavi, including advanced AI and hybrid propulsion, are blazing a new path in sustainable yachting.

Viareggio’s picturesque seaside, gourmet restaurants and various cultural attractions make it a mustvisit destination for both tourists and locals alike. The town is also the perfect backdrop for Rossinavi, a superyacht builder specialising in the production of custom one-off superyachts ranging in length from 40 to 70 metres. The headturning, eye-catching yachts that have left its sheds over the years have made the yard famous worldwide as the top destination for the most discerning and demanding clients.

The company’s ability to cater confidently to high-profile clients seeking the most specific, luxurious and revolutionary yachts, has guaranteed its place amongst the world’s elite yacht builders. And for good reason: not just any yard is capable of undertaking the complex projects routinely demanded by Rossinavi’s clients.

This complexity is perfectly encapsulated by Rossinavi’s successful 2015 launch of its flagship project, Taransay, a 38.55m modern replica of a classic motor yacht of the same name that was originally built in 1930. With only a few pictures of the original vessel to go by, in 2013 Rossinavi set out to design and build the new Taransay for an enthusiastic German client.

In addition to the lack of source material to inform the new vessel’s design, Rossinavi had to contend with the combined challenges of incorporating modern materials, modern safety regulations and modern equipment into a classic design. Consequently, highly creative engineering solutions can be found throughout the yacht, with one example being removable teak cladding that allows for easy maintenance of Taransay’s decks.

“Taransay perfectly demonstrates our ability to build highly complex, full-custom vessels,” said Rossinavi’s COO & Co-owner Federico Rossi. “It required that we replicate parts and structures that no longer exist on the market, as well as old construction techniques using new technology. It was a real milestone project for us.”

A familial foundation

Rossinavi began life in the early 1980s as a small metal fabrication company with only a handful of employees - all Rossi family members - supplying workboat components to nearby shipyards. Eventually, the company began producing entire vessels on contract for other shipyards until, after having successfully built over 100 such vessels over the years, the company made the major decision to rebrand and begin producing its own vessels. Thus in 2008, Rossinavi was born.

Rossinavi remains a privately held business, proudly owned and run by the Rossi family. Since its rebranding,

Rossinavi has launched on average two to three vessels per year from its five modern, high-tech facilities all centred in Viareggio. Though it has the capability to fabricate yachts using any combination of steel, fibreglass and aluminium, Rossinavi specialises in aluminium fabrication, of which it uses approximately 300 tonnes annually.

The company is staffed by 110 skilled employees, evenly split between its workshops and office facilities.

“CGT has been an invaluable strategic partner to us for a significant duration, serving as our trusted engine supplier,”

said Mr Rossi. “Our longstanding collaboration speaks volumes about CGT’s reliability and the integral role this company plays in our operations.”

Seacat and AI

Rossinavi is blazing a new trail in the sustainability of the yachting sector through Seacat, a futuristic new build project that is putting the industry on notice.

“Seacat will be the most innovative vessel in the superyacht market; its launch will take our sustainability efforts to extreme lengths,” Mr Rossi revealed. “Seacat is the result of my conviction that

sustainability is everyone’s responsibility, and it is one of the ways in which we will begin to offer clients more sustainable solutions.”

Powered by Rossinavi’s innovative, eco-friendly BluE technology, Seacat is a futuristic 43m hybrid catamaran. Its design incorporates a diesel-electric drivetrain supplied by Siemens Energy, with whom Rossinavi has a long and close relationship.

“Siemens Energy is able to guarantee worldwide after-sales support, which is especially important for advanced systems like this that are often new for yacht crews,” Mr Rossi explained. “The onboard control room manages 4MW of power, so there’s a whole new level of

knowledge that yacht engineers need to have. Siemens Energy is the perfect partner for us, given our preference for strong collaborations that allow us to combine our technology and knowledge with that of our suppliers.”

Another valuable partner is Videoworks, who supplies Rossinavi with bespoke technology. Solutions from Videoworks enable customers to manage on-board technology through touch screen devices with customised interfaces.

For transatlantic crossings, Seacat’s large onboard solar installation ensures that the yacht can spend 80% of its time in full-electric mode, where CO 2 emissions

are reduced by approximately 40 tonnes compared to a traditional yacht of the same size.

Seacat’s engineering includes an advanced Artificial Intelligence that, with the help of machine learning, monitors all aspects of the yacht’s operations, ensuring that the propulsion and onboard electricity usage is constantly optimised according to the vessel’s location, the time of day and how the yacht is being used.

“In future, we expect that Seacat’s AI will be able to communicate with nearby boats to share information and learn from one another,” said

Mr Rossi. “Sustainability in this industry is a challenge; the technology behind it is a challenge. But with our high-tech design, we can define a new kind of luxury that moves both people and the economy sustainably.”

Rossinavi recently celebrated the opening of its brand-new office in Fort Lauderdale, Florida, where the new Rossinavi USA Corporation will be based.

To mark the occasion, Rossinavi will launch two new catamaran design concepts in 2024. The company hopes that these designs will bring a new generation of American clients to the yard. n

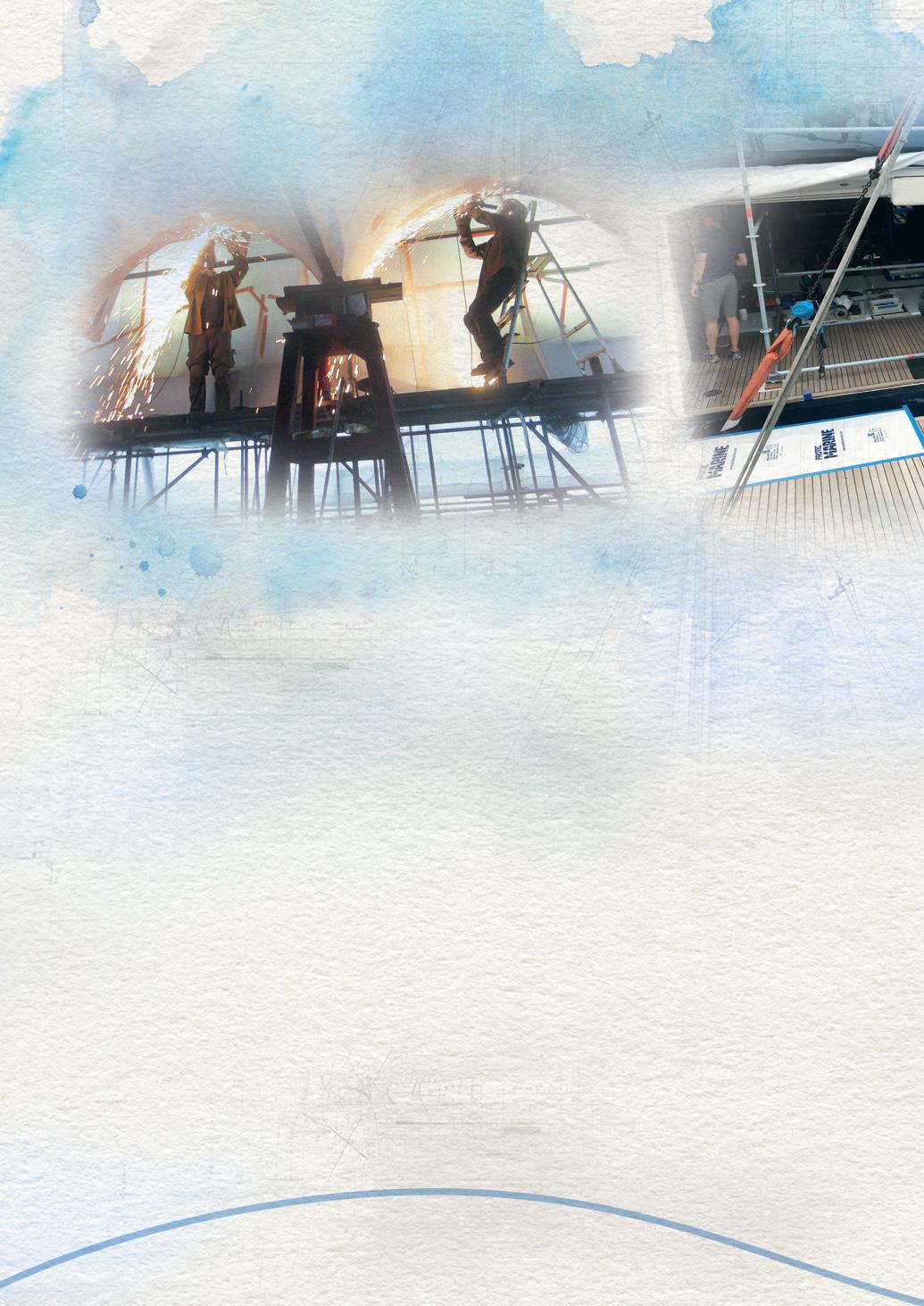

Based in Palma de Mallorca, PURE Superyacht Refit provides professional and specialist superyacht refit management services, tailored to fit clients’ needs. Owner Nic Clarke discussed PURE’s services and innovative business model, in conversation with Hannah Barnett and Antonia Cole.

With over 20 years of experience in professional yacht racing as a team manager, boat captain and sailor, Owner of PURE Superyacht Refit Nic Clarke has an extensive knowledge of the marine industry. Mr Clarke saw the increasing demand for specialist refit services and used his expertise to found PURE in 2007, a leader in the service of superyachts.

The company is based within the open Servicios Técnicos Portuarios (STP) facility in Palma de Mallorca. This means that PURE is able to offer clients a range of highly skilled contractors to fit individual project needs.

STP consists of 102,000m2 of hard standing area for 80 hauled vessels up to 67m & 1000 tonnes and 60,000m2 of berthing area for 60 vessels to a maximum of 110m LOA. There are six travel lifts ranging from 30 to 1000 tonne maximums and seven keel pits accommodating deep-draft sailing yachts of up to 67m.

Despite being a small company with three permanent staff members, PURE accounts for a high percentage of Mallorca’s superyacht refit business. Palma de Mallorca has many skilled nautical professionals and sub-contractors from around the world, giving PURE the ability to provide a high-performance

service, regardless of language barriers or weekly working hour constraints.

Pure also offers refit accounting services, providing detailed status reporting of the refit as it progresses. Thus, allowing captains, owners, management companies etc. to be completely informed.

“One of the benefits of working with PURE is that we don’t take every project that comes along,” said Mr Clarke. “We take on projects that are challenging and require the advanced involvement and expertise that we are able to offer.”

PURE determines the scope of work required and establishes a realistic timeframe. The company then organises designs, berthing or haul-out options, suitable skilled contractors, plus work lists and budgeting to meet client and project requirements.

The company’s first project in 2007 took a 52m 650 tonne motor yacht out of the water, before cutting 2m square openings into either side of the hull/engine room, then removing and replacing generators, exhausts and engine management systems. A 1.3m swim platform hull extension was constructed and the project was completed with teak deck replacement and full, four colour paint re-finish, making it a nearly €5 million project.

“Projects like these, that exceed expectations, are what have put us on the map,” explained Mr Clarke. “Our ability and determination to achieve the incredible is what makes our clients confident that PURE will meet and deliver their needs.

“We have no problem cutting holes into the bottom or sides of vessels if required, as it is often more efficient and less intrusive. We go that extra mile to deliver exceptional services as efficiently as possible. Our standards are high and we meet them with every project.”

As a qualified engineer and professional skipper with experience in shipyards world-wide, Mr Clarke has the knowledge to interpret client requirements to a greater degree. This expertise allows PURE to complete all projects to the level of quality that the customer envisions.

“I’ve got very high standards for our work,” said Mr Clarke. “I am confident in the fact that if I accept something, then the client will accept it too. We don’t waste our clients’ time, so we make sure to get it right.”

PURE begins project management around three to six months before the vessel arrives, in a process it calls ‘pre-fitting’. This means that preparations are made so when the vessel does arrive, the company can begin work immediately and clients receive their services quickly and efficiently.

“The initial three weeks after the vessel arrives are critical to the successful completion of works in the allotted time period,” explained Mr Clarke. “Through preparation and access to skilled crews and

sub-contractors, we are able to deliver refit services that are guaranteed to satisfy our clients.

The company operates out of the STP boatyard, a unique public facility that allows independent contractors to deliver works, whilst STP provides berthing, hauling and occupation services. There are no contactor relations through STP, so there are no surcharges for choosing subcontractors as there would be in a private shipyard.

This business model allows clients the freedom to choose contractors that mee t their individual needs without excess charges. Based within STP, PURE is able to provide clients with the best possible contractor options, tailored to suit skill requirements and price points.

“Whether it’s someone from across the world or someone local, our clients have the opportunity to use whichever

contractor they want,” said Mr Clarke. “For example, a lot of our clients have systems in their properties that they want to replicate in their vessel, such as audio-visual set-ups. We can assist in access into STP for the specific company, providing they submit the required documentation, to come and carry out the desired works without any additional surcharges.

“This model means that we can meet specific requirements for our clients and can bring in the specialised skills from a range of industries to develop the vessel into the client’s vision.”

With Palma de Mallorca as PURE’s main location, the company has access to large numbers of highly skilled craftsmen across all superyacht services and trades. With access to a large workforce, PURE is able to complete projects quickly and deliver significant upgrades that exceed expectations. Over the last 17 years, the company has managed painting over 30 vessels.

One of PURE’s recent projects involved transforming an 82m industrial vessel into a leisure vessel/toy carrier with a helicopter pad, a basketball court, a golf simulator room, a bar and more, all within three weeks. This highlights PURE’s capabilities as a company to achieve the almost unachievable.

PURE has built long-standing relationships with partners across the industry, so that it can trust that projects are being completed to a high standard and on time.

“We work with some really good companies,” explained Mr Clarke. “They understand how we work and allow us to succeed. We all see the importance of going out and getting the work done as soon as possible. With our distinctive handson approach, we are well positioned to anticipate client and contractor needs and plan well in advance. Being proactive

instead of reactive allows for a smoothrunning operation.”

PURE often finishes projects ahead of schedule, meaning that clients have the ability to have more works or services added to the project within the original allotted time frame. The company’s focus on efficiency means added convenience for the client, as well as more business for partners and suppliers.

Going forward, PURE hopes to maintain this management system, but to expand into other facilities. The company will be able to create teams and work on vessels in different areas, increasing PURE’s project capacity.

“I like to succeed,” concluded Mr Clarke. “Taking what seems like an impossible project and turning it into a reality is rewarding. I am passionate about the industry and what we do, which shows in the projects that we deliver.” n