PROCESS OPTIMISATION

The Role of Thinking and Master Data

BEYOND THE BOTTLE

Amcor: Replenishing the world through sustainable packaging

PROCESS OPTIMISATION

The Role of Thinking and Master Data

BEYOND THE BOTTLE

Amcor: Replenishing the world through sustainable packaging

AND INNOVATION

SailPoint’s SD of Global Procurement Linda Siegert on using culture, sustainability and transparency in procurement to drive strategic success

Join the must-see virtual event disrupting procurement and supply chain on the 28th of June 2023.

This year, we are bringing you a solely virtual event, Procurement & SupplyChain LIVE Virtual will highlight the innovators changing the industry. Brought to you by BizClik, Procurement & SupplyChain LIVE Virtual will be held on 28th June 2023, streaming remotely to virtual audiences around the world.

The unmissable event will feature expert keynote speakers, interactive fireside and panel discussions, and more. Do not miss this 1-day deep dive into the disruption and the future of procurement, supply chain and logistics.

Do you want to position your brand in front of thousands of innovators, decision-makers and influencers?

Sponsor Procurement & SupplyChain LIVE to unlock the future of your business, access thousands of potential partners and influence businesses at the highest level.

Both global giants and innovative start-ups alike can discover the ideal platform with easy access to an engaged and active audience.

Contact a member of our team today to discuss sponsorship opportunities.

See you on 28th June 2023.

It’s time for DISRUPTION. GET YOUR PASS SPONSORSHIP

Innovators are paving the way for a more resilient, sustainable, and efficient future. The rules have changed. It’s time for disruption.▶ Watch our showreel from PROCUREMENT & SUPPLY CHAIN LIVE London 2022

Procurement magazine is an established and trusted voice with an engaged and highly targeted audience of 70,000 global executives

Digital Magazine

Website Newsletters

Industry Data & Demand Generation

Webinars: Creation & Promotion

White Papers & Research Reports

Lists: Top 10s & Top 100s

Events: Virtual & In-Person

WORK WITH US

EDITOR-IN-CHIEF

ILKHAN OZSEVIM

CHIEF CONTENT OFFICER

SCOTT BIRCH

MANAGING EDITOR

NEIL PERRY

PROOFREADER

JESS GIBSON

CHIEF DESIGN OFFICER

MATT JOHNSON

HEAD OF DESIGN

ANDY WOOLLACOTT

LEAD DESIGNER

JULIA WAINWRIGHT

FEATURE DESIGNERS

MIMI GUNN

SOPHIE-ANN PINNELL

HECTOR PENROSE

SAM HUBBARD

REBEKAH BIRLESON

ADVERT DESIGNERS

JORDAN WOOD

DANILO CARDOSO

CALLUM HOOD

VIDEO PRODUCTION MANAGER

KIERAN WAITE

SENIOR VIDEOGRAPHER

HUDSON MELDRUM

DIGITAL VIDEO PRODUCERS

MARTA EUGENIO

ERNEST DE NEVE

THOMAS EASTERFORD

DREW HARDMAN

JOSEPH HANNA

SALLY MOUSTAFA

JINGXI WANG

PRODUCTION DIRECTORS

GEORGIA ALLEN

DANIELA KIANICKOVÁ

PRODUCTION MANAGERS

JANE ARNETA

MARIA GONZALEZ

CHARLIE KING

YEVHENIIA SUBBOTINA

MARKETING MANAGER

ANDREW STUBBINGS

PROJECT DIRECTORS

CRAIG KILLINGBACK

MEDIA SALES DIRECTOR

JAMES WHITE

MANAGING DIRECTOR

LEWIS VAUGHAN

CEO

GLEN WHITE

Ahlsell's CPO, Karolina Hagberg Chinell, shares their transformation journey at IvaluaNow EMEA and how digitalisation helped strengthen supplier relationships amid the pandemic, while committing to building a more sustainable society

Amid the chaos of a world that falls apart, procurement and supply chains are examples of processes that can adapt and thrive.

One critical component of Ahlsell’s transformation was the realisation that digitalisation was essential to optimise procurement processes and build stronger supplier relationships. COVID-19 created an environment where prices were skyrocketing, and there were shortages of supply and difficulties in transportation, intensifying the need for strong partnerships with suppliers.

Ahlsell engaged with both employees and suppliers in a stakeholder survey to identify opportunities for process optimisation and digitalisation. The survey revealed that employees wanted better product data, while suppliers indicated that everything worked fine, highlighting complacency and a lack of innovation. Chinell recognised the need for change, and through process optimisation, digitalisation and changes in thinking about the issue at hand, they recreated their business and turbocharged their supplier relationships. This is how you optimise your processes…

ilkhan.ozsevim@bizclikmedia.com

“Everything is about change. You need to prepare, communicate, and repeat. It's not enough to create awareness: You need to create desire”

Amid disruptions, process optimisation is analogous to mycelium reconfiguring their roots around collapsing structures

014 BIG PICTURE CPOs hold the key to helping construction decarbonise and improve profitability

016 FIVE MINUTES WITH Sunder Balakrishnan, LatentView Analytics’ Supply Chain Analytics Leader

022 LIFE TIME ACHIEVEMENT Deloitte’s Global Chief Procurement Officer Rhonda England

6 - 7 September 2023

Business Design Centre, London

SPONSORSHIPS GET YOUR PASS

JUNE

CONTENTS

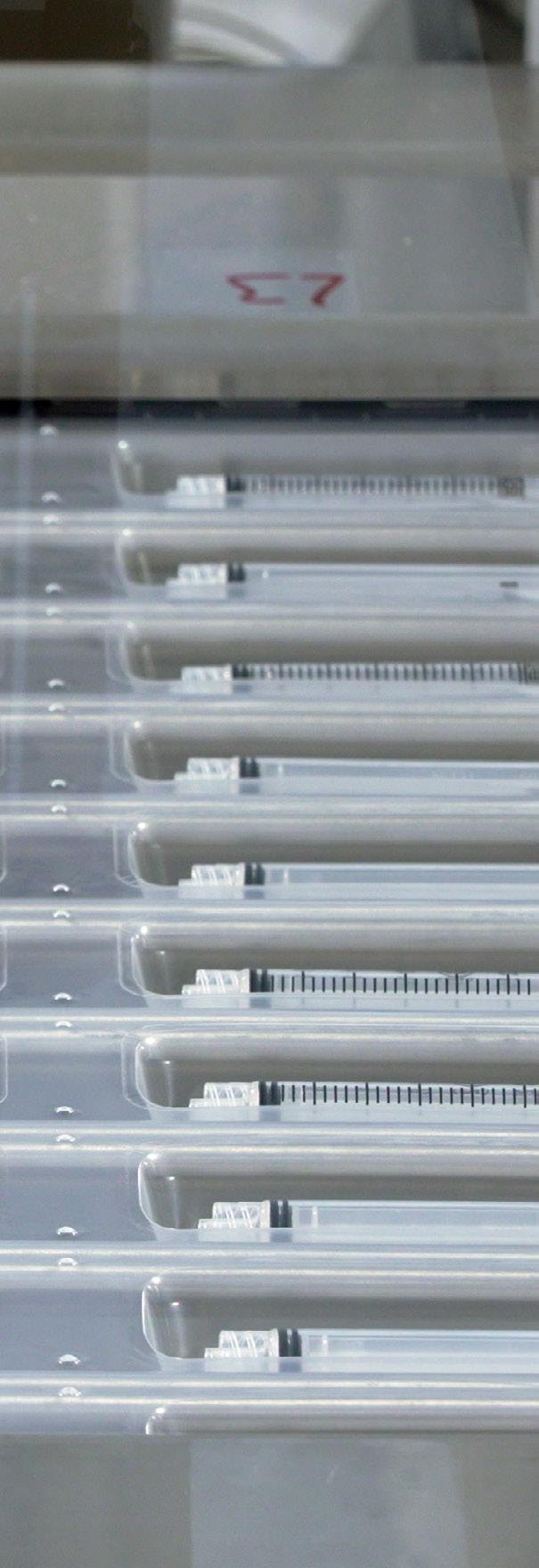

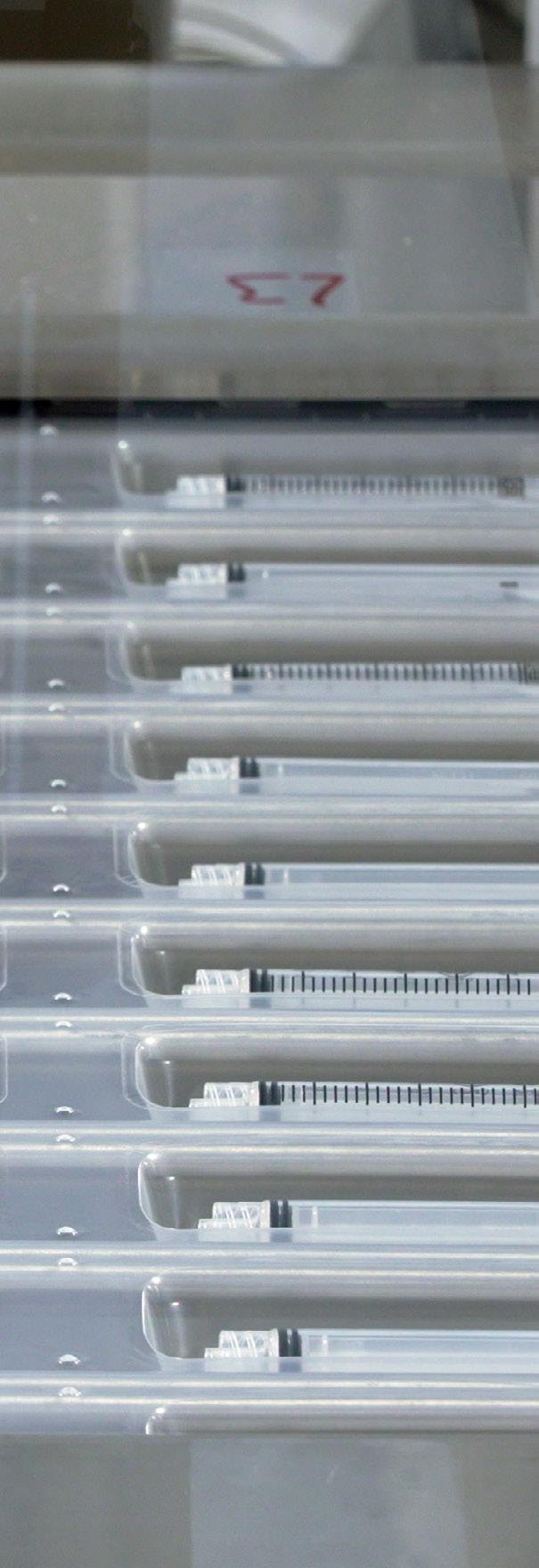

050 BECTON DICKINSON

Ensuring a resilient, responsible & agile supply chain

090 SUSTAINABLE PACKAGING

Innovators are paving the way for a more resilient, sustainable and efficient future. The rules have changed. It’s time for DISRUPTION.

Tech LIVE Virtual returns to highlight the innovators changing the industry through expert keynote speakers, interactive fireside and panel discussions. This exclusive 1-day virtual event will bring together the greatest voices in the industry for an essential deep dive into the future of Technology, AI and Cyber.

Brought to you by BizClik, Technology, AI and Cyber Magazines, the event will shine a light on essential topics such as the AI revolution, quantum computing, the virtual workplace, technology’s place in sustainability and much more.

It’s time for DISRUPTION.

Position your business as a pioneer in Technology and showcase your values, products and services at Tech LIVE Virtual.

This is your chance to share your innovations with the technology community by making an impact in front of fellow decision-makers and influencers as well as accessing potential partners via an active and engaged audience.

See you on the 8th June 2023.

Despite being the world’s largest ecosystem, Construction typically yields slim margins and low productivity improvement. Coupled with the pressures presented by COVID-19 and its crucial role in achieving global sustainability, construction must lean on its CPOs to decarbonise and become a source of competition. Typically accounting for 40-70% of a construction company’s total spend, procurement is stepping into the light as a trusted partner to better navigate uncertainty. Key areas for improvement:

• Create transparency for CO2

• Gain a granular perspective on materials and suppliers

• Help manage trade-offs

Balakrishnan explains how data and analytics have the power to penetrate supply chain obscurities and allow insight into demand and supply variance

Q. PLEASE INTRODUCE YOURSELF AND YOUR ROLE…

» My name is Sunder Balakrishnan, and I’m a Supply Chain Analytics Leader at LatentView Analytics, where I focus on helping global organisations build resilient supply chains by helping drive a “connected supply chain” vision using the power of analytics, AI, and supply chain consulting.

Q. WHAT ARE SOME OF THE MOST SIGNIFICANT CHALLENGES THAT PROCUREMENT PROFESSIONALS ARE CURRENTLY FACING AMIDST THE GLOBAL SUPPLY CHAIN CONCERNS, AND HOW CAN THEY OVERCOME THEM?

» Procurement professionals live in a world of a constantly oscillating supply chain that swings between supply shortages and excesses. There is an ever-growing need for resilience required to deal with disruptions to global supply chains from the pandemic, natural disasters, geopolitical tensions, and other factors.

“The companies that took the step years ago to invest in data analytics are reaping these benefits today”

These events have led to increased costs, supply shortages, and regulatory compliance concerns. A traditionally cost-minimisation focused function is now shifting its operating principles to think about the balance between cost and supply performance.

The dependency on China has called on enterprises to think about a China-plus-one / alternate sourcing strategy and nearshoring opportunities. These challenges point to procurement being at the cusp of a transformation from a cost reduction philosophy to service-level maximisation lever.

The first step in this transformation journey has to be a thorough supply-side visibility using a quantitative approach to supply availability risk assessment, and the associated cost analysis.

“The role of data+analytics+AI and technology paired with good old supply chain thinking will help organisations unlock their true procurement potential”WATCH NOW

LatentView Analytics — Corporate Video

Proactive steps to diversify their supply chain, renegotiate contracts, find alternative suppliers, and implement cost-saving measures such as automation and process improvements would be subsequent phases of this transformation based on every organisation’s unique situation and needs.

The role of data+analytics+AI and technology paired with good old supply chain thinking will help organisations unlock their true procurement potential.

Q. CAN YOU SHARE ANY REAL-LIFE EXAMPLES OF HOW SUPPLY CHAIN ANALYTICS HAVE HELPED COMPANIES TO MANAGE DEMAND VOLATILITY AND IMPROVE THEIR PROCUREMENT PROCESSES?

» A leading toy manufacturer had an interesting problem where new product demand was highly unpredictable with poor accuracy leading to high demand planning bias, and excess finished goods inventory.

For a toy to be launched 6 months from now, the procurement order for parts had to go out today, and the process was entirely based on heuristics. The power of supply chain analytics with internal and external data factors, coupled with our consulting prowess, helped the organisation bring down the predicted demand variance, provide improved explainability to the factors affecting demand, and allowed the procurement team to have higher level of confidence in the BOM volumes required.

Q. HOW HAS THE PANDEMIC AFFECTED THE SUPPLY CHAIN, AND WHAT STRATEGIES CAN PROCUREMENT PROFESSIONALS ADOPT TO MITIGATE ITS IMPACT ON THEIR OPERATIONS?

» The pandemic has caused disruptions to global supply chains, leading to shortages of critical goods and services. These disruptions, as a consequence, led to increased costs for raw materials, transportation and logistics.

As the pandemic caused a wave of remote work, consumer behaviour and demand patterns changed significantly, making it a challenge for procurement professionals to truly assess and anticipate these new patterns.

However, procurement professionals, if they develop data-driven contingency plans, can achieve insights into factors that can impact the supply chain. Again, it goes back to that connected view approach that we have developed for our clients.

Q. WITH THE SUPPLY CHAIN BECOMING INCREASINGLY DISCONNECTED, WHAT STEPS CAN COMPANIES TAKE TO ENSURE TRANSPARENCY AND VISIBILITY ACROSS THEIR SUPPLIERS AND PARTNERS?

» Companies need to be able to view demand forecasting, supplier management and logistics management

in a single-pane-of-glass view, understanding how they work together to achieve a full supply chain picture. By bringing together data insights from these pieces, which rely on data individually, companies can experience more connectivity between these individual hubs of data.

This requires data engineering and an infrastructure that supports this mission. It’s important for leaders to think about the future and not a matter of if, but when, the next major supply chain disruption will occur. So a capital expenditure today will save money and contribute to customer satisfaction in the future. The companies that took this step years ago to invest in data analytics are reaping these benefits today.

Every event or risk in the supply chain has a cascading impact on some other event downstream, but due to organisational silos, lack of visibility, sub-optimal processes and technology

silos, modern supply chains lack a good way to understand the impact of these risks on the eventual on-shelf availability. This is a disconnected supply chain.

Catena-X is a great example of auto OEMs in Europe coming together to build a supplier data hub for greater visibility and transparency to the supply ecosystem. With everything being intelligent today - from watches and glasses to swimsuits and toothbrushes, supply chains have converged and connected more than we realise.

SUPPLY CHAIN OPERATIONS AND MITIGATE RISKS?

» Companies today can use AI algorithms to analyse data from various sources, including social media, news outlets and even weather reports to

“These challenges point to procurement being at the cusp of a transformation from a cost reduction philosophy to service-level maximisation lever”

identify potential disruptions, including natural disasters, political instability and future pandemics.

Additionally, these tools can help procurement professionals identify the right suppliers based on their capabilities, performance and compliance with a variety of regulations.

AI and ML can also be leveraged to extract vital information from contracts, including terms and conditions, pricing and performance. These measures can help procurement professionals to develop contingency plans and mitigate the impact of these risks.

with if one of your suppliers is experiencing challenges.

Leverage technology to help streamline the procurement process with automation tools that can help reduce manual processes. This should include using predictive analytics to anticipate and prevent supply chain disruptions and have a connected view of your suppliers.

Foster collaboration with suppliers by building strong relationships with them to both understand their challenges and to communicate your needs.

An F&B giant with annual revenue of US$70bn dollars faced a significant revenue loss owing to a 27%

drop in their OSA. Through LatentView’s ConnectedView Transformation program, they were able to help the business service

» Diversify your supplier base so you have ample backups to work

US$81m per annum of additional orders

Conduct regular risk assessments to identify potential risks and disruptions and then develop contingency plans to mitigate them.

Unsilo data and prioritise transparency both with suppliers and internal stakeholders. Monitor market trends, including news, regulatory changes and other factors that can impact your procurement process.

Companies today can use AI algorithms to analyse data from various sources, including social media, news outlets and even weather reports to identify potential disruptions, including natural disasters, political instability and future pandemics

Q. WHAT ACTIONABLE INSIGHTS CAN YOU PROVIDE TO PROCUREMENT PROFESSIONALS TO HELP THEM NAVIGATE THE CURRENT CHALLENGES IN THE SUPPLY CHAIN AND ENSURE A SEAMLESS PROCUREMENT PROCESS?

The role of a CPO has never been more important. Procurement and supply chains sit at the heart of response and must remain resilient against the threat of global events and day-to-day challenges.

As the current Global CPO for one of the top four consulting firms (Deloitte), Rhonda England has been spearheading the field of procurement for more than 30 years, championing its value.

In her role, England leads a talented team of procurement, supplier sustainability, and diversity experts to work alongside strategic suppliers to deliver superior cost savings and return on investment (ROI).

Passionate about the strategic value of procurement, England and her team proactively engages with business partners through intelligent analytics to drive enhanced value, as well as drive meaningful impact to Deloitte’s global WorldClimate strategy and commitment to developing a diverse, inclusive supplier base.

Mindful of the opportunities and development she herself has received to advance her career, England is committed

“Rhonda is an incredibly talented individual” Lysenko

to ensuring diversity, equity, and inclusion across her organisation, with a particular interest in empowering and developing future women leaders.

England is spoken highly of among her peers, described as intelligent, inspiring and thoughtful with Danny Lysenko, Senior Vice President at PetIQ commenting: “Rhonda is an incredibly talented individual. She has a tremendous knowledge of the retail industry and demonstrates a deep level of commitment to any task she takes. In addition, she is a wonderful leader, teacher, and team player. I would recommend Rhonda with no hesitations.”

Prior to joining Deloitte in January 2020, England spent the rest of her procurement career in the retail industry working for May Merchandising Company, Abercrombie & Fitch and JCPenney.

England spent her longest time at JCPenney, starting as a senior

30+

buyer and climbing through the ranks to Vice President of Procurement.

England holds two degrees, a BS in Retailing and Retail Operations from Indiana University Bloomington and a Graduate Certificate in Finance from Southern Methodist UniversityCox School of Business.

She also featured at number three in Procurement Magazine’s 2023 Top 100 Women in Procurement.

Number of years working in the industry

2020

Year joined Deloitte #3

Position in Top 100 Women in Procurement

“It is an honour to be recognised along with this cohort of amazing leaders. I am mindful that this accolade has been made possible by the efforts of the outstanding team I lead, as well as the mentors and sponsors who have supported me throughout my career,” said England.

“I am committed to paying it forward by developing and empowering the next generation of women leaders. Thank you for this recognition – I am truly humbled.”

“It is an honour to be recognised along with this cohort of amazing leaders” England

PRODUCED BY: MIKE SADR

PRODUCED BY: MIKE SADR

As technology accelerates at near-exponential rates, invariably bound up with the internet and big data, security considerations explode in accordance with this growth. A very large part of these security concerns is around ‘identity’.

PwC’s recent Global Economic Crime and Fraud Survey found that of 1,296 executives surveyed across 53 countries and regions, 51% of organisations said they had experienced fraud in the previous two years – the highest level in PWC’s 20 years of research.

We interviewed Linda Siegert, the Senior Director of Global Procurement for SailPoint Technologies, to find out how they leverage culture in procurement to influence the future.

SailPoint is the leading provider of identity security for the modern enterprise. They help organisations discover, manage and secure all identities across all environments.

As Senior Director of Global Procurement, Siegert began her career in accounting and quickly found that while she was good at the numbers, she more enjoyed the working relationships and the stories that the numbers could tell. Siegert transitioned into an HR role and then HR leadership, which further solidified how much she enjoyed “empowering people for success”.

TITLE: SENIOR DIRECTOR OF GLOBAL PROCUREMENT

TITLE: SENIOR DIRECTOR OF GLOBAL PROCUREMENT

INDUSTRY: SOFTWARE DEVELOPMENT

LOCATION: UNITED STATES

SailPoint is a leading provider of identity security for the modern enterprise, empowering organisations worldwide to put identity security at the core of their business. With a foundation of artificial intelligence and machine learning, SailPoint identity security delivers the right access to the right identities and resources at the right time.

Linda Siegert, Senior Director of Global Procurement“Procurement is really the brilliant marriage of the two: the numbers and the people. It enables me to do what I'm passionate about — giving me a unique perspective and approach to our strategic goals.”

“Today, I have the privilege of leading an incredibly talented procurement team with a focus on sustainable strategic procurement that stretches beyond simple spend management, but also includes risk in contractual management, supplier lifecycle management, compliance and audits and sustainability throughout the entire lifecycle. It allows us to be on a continual growth track. The exciting part is the continual maturity road on which I get to lead the team.”

Now at SailPoint, Siegert has set her sights on the intersection between culture, sustainability in procurement activity. These aspects mesh more naturally than one would expect.

“ We don't view the buying landscape as just a numbers game – because numbers are only a part of our overall success”

LINDA SIEGERT SENIOR DIRECTOR OF GLOBAL PROCUREMENT, SAILPOINT

SailPoint's unique procurement philosophy: the four ‘I’s Siegert says that SailPoint sets itself apart in that the company “lives and breathes culture” through the Four ‘I’s of Innovation, Impact, Individuals and Integrity.

Within procurement, these values are cornerstones to every interaction. They inform buying approach and allow the procurement team to look past dollars to drive ROI deeper into the business.

“Our dollars shouldn't just buy things, they should grow things,” Siegert says. “We don't view the buying landscape as just a numbers game - because numbers are only a part of our overall success.

“There really is no single way to solve a problem, and just because it’s worked ten other times already, that doesn't mean it's going to work for an eleventh”

LINDA SIEGERT SENIOR DIRECTOR OF GLOBAL PROCUREMENT, SAILPOINT

“When two companies interact, it's relational, and if we're to achieve long-term strategic success, we can't only focus on the numbers. We need to look deeper, expect higher values from our suppliers, and ensure that our suppliers’ company goals align with SailPoint's goals for spend sustainability.”

SailPoint utilises its core values to maximise the value of its supplier interactions because, says Siegert, “within this structure, success can always be found.”

Core message as it relates to procurement Siegert says that what separates SailPoint is its ability to think outside of the box.

“We don't have to think like mainstream procurement,” she says. “Let's think from a human perspective; let's think from a creative perspective and use organisational values to provide a natural foundation for procurement strategic thinking.

“There really is no single way to solve a problem, and just because it's worked ten other times doesn't mean it's going to work for an eleventh. It’s important to always be thinking of a better way to do it. When it comes to our foundational core values for innovation within the procurement team, we're developing real solutions for challenges and solving problems.

“When we engage with suppliers, we are solving a need. Our suppliers and all those we have relationships with understand our challenges. They know there's a bottom-line impact – and they want to make us better. When we combine our knowledge with our suppliers to create a truly successful relationship, both parties win.”

Asked about overarching goals, Siegert says: “Our goal always is impact.” She points out that for SailPoint procurement, success

is based on measurable results, and this takes the form of KPIs, in-depth due diligence and clear standards for excellence and engagement.”

“We value individuals and both the work they do and the roles they serve. We treat people with integrity and deliver on the commitments that we make - and we expect others to deliver on the commitments that they themselves make.”

“We base our relationships on trust and offer honest solutions. We want our suppliers to do the same for us. If there are issues that need to be resolved, we do it with transparency. Achieving and maintaining strong, healthy relationships is foundational.”

Transparent supplier engagements Siegert says that SailPoint procurement approaches its supplier engagements

“When it comes to our foundational core values for innovation within the procurement team, we’re developing real solutions for challenges and solving problems”

LINDA SIEGERT SENIOR DIRECTOR OF GLOBAL PROCUREMENT, SAILPOINT

with transparency and deeply holds company strategy at the forefront of her team’s goals. “We partner closely with our business areas to understand their objectives and walk alongside them as partners so we can help them drive strategy and corporate vision in a sustainable way.

“Culture impacts the dollars we spend. It drives the talent and positioning of the team beyond just a job title. It empowers the procurement team to do what they love and creates healthy partnerships while making a long-term impact,” Siegert says.

“I encourage my team to be relationship driven with a focus on strategic partnerships and lifecycle sustainability. When coupled with spend management, that's impactful for everyone.”

Her team also offers its expertise and innovations to SailPoint’s suppliers. “We're all on an innovation journey and we regularly collaborate with our suppliers to innovate and find new and creative ways of solving SailPoint goals. For us, depth is key,” she says. “We don't want to wade in the pond when we can really swim in the ocean.”

When asked about SailPoint’s procurement partner ecosystem Siegert says that they have a number of really amazing procurement partners and strategic supplier partnerships, and of course, that it's difficult for her to list them all, “but I'll mention a couple of examples from two opposite sides of business support,” she says.

“Since we are a global company and we're providing support in all areas, we hold events all over the world. We wouldn't be able to robustly serve the business without the partnership of companies like Prestige Global Meeting Source (Prestige), who support us globally through sourcing our

company event locations with their intimate knowledge of the global meeting and event landscape.

“Prestige just outshines any other company I've worked with in this area. They are strategic, hands-on, and truly a genuine pleasure to work with. Prestige emulates our core values, placing our success as their top goal.

“On the operational side of the business, we partner with companies like ServiceNow who have a passion for innovation and value the individuals they work with inside of our company. This is highly important for us, as we provide for employee self-service and operational efficiencies at an enterprise level.”

SailPoint’s procurement focus is on managing the current market and the fluctuations that we're all continuing to see – while better positioning the company over the next three to five years.

“We're doing that by continuing to drive depth within the company through our supplier and business stakeholder relationships. We work smart, which means we're always innovating and optimising how the procurement team works, interacts and how we accomplish our goals.

“We don't ever settle for, 'it's working today, so why fix it?' We are always looking for ways to work smarter and automate activities that don't bring long-term value.”

“My team is strategic in nature, so eliminating transactional churn really allows me to focus their talents on the procurement activities that matter and provides SailPoint with the most impact.”

Things fall apart – that’s the law of entropy; it’s woven into the very fabric that makes everything up. In 1958, Chinua Achebe entitled his debut novel, now a classic, with the phrase.

It’s always been a serendipitous paradox that, as physics slouches towards disorder, it simultaneously throws up systems that organise in the most sophisticated ways, and procurement and supply chains are a striking example of these optimising processes.

Think of it, the world falls into disarray through pandemic, war – unwanted and unforeseeable vicissitudes – and procurement and supply chains rearrange their operations like mycelium reconfiguring their roots around collapsing structures, and somehow, they find a way.

It’s late March, and to get at this ‘somehow’, I’m at IvaluaNow EMEA in Paris, where procurement and supply chain leaders from across the region have gathered to understand how to digitally transform their organisations in such tumultuous times.

As the brightly fuschia-lit stage booms its bass at the attendees, Karolina Hagberg Chinell, CPO of Ahlsell, steps out and announces that she’s going to share Ahlsell’s transformation journey with the audience. She establishes that a key element of it revolves around how they engage closely

An award-winning collaborative supplier relationship platform

Suppeco leverages the potential in relationships to solve key challenges within the value chain

A practical solution built for the real world

with their suppliers – one of their core stakeholders alongside their customers and employees – and how they have used digitalisation to do so. But this is just a small piece of the puzzle.

Ahlsell is, as Chinell reveals, strongly committed to building a more sustainable

society: “That is our mission and also our reason to be.”

In terms of the company itself, they are the leading distributor of technical installation products, tools, and supplies to industry, installers, energy companies, and the public sector throughout the Nordics. These are all important branches of society, as well as of business.

Ahlsell has a turnover of approximately 50bn SEC (which is equivalent to about €5.5bn), and approximately 7,500 employees and 300 branches throughout the Nordics –“and we’re also present with an omnichannel approach to business-to-business, businessto-consumer, and do-it-yourself,” she says.

Just a few more figures: Ahlsell offers more than 1.5mn SKUs to their 250,000+ customers, coming from more than 10,000 suppliers. 30% of all their orders are placed on the web, and so it’s a strongly digital company.

Use more image captions as often as possibleKAROLINA HAGBERG CHINELL CPO, AHLSELL

“You need to be able to swap between the logical left side and the more creative right side of your brain to really solve problems”

Ahsell’s digital journey: Setting out Chinell reiterates a well-known theme: During COVID, everyone worked in an environment where prices were skyrocketing alongside increasing supply shortages, difficulties in transportation and so on, and that this undeniably increased the focus on creating strong

supplier relationships and risk management across industries.

Everyone wanted to create strong partnerships with suppliers. “They wanted to tie them up. They were looking for secondary sources of supply, and they were doing all this during a period where you could not actually meet or travel with new suppliers.

Use more image captions as often as possible

“Therefore, you needed to use ‘digitalisation’,” Chinell emphasises, “and this is also something that is demonstrated in research.”

If you look at the procurement survey run globally among 800 respondents last year by PWC, it showed that besides cost reduction, digitalisation was of increasing importance, and came in as the third most important strategic priority for procurement departments.

KAROLINA HAGBERG CHINELL CPO, AHLSELL

“Ahlsell is strongly committed to building a more sustainable society. That is our mission and also our reason to be”Between us construction professionals

“And this will not be less important in the future,” she says. “At Ahlsell we had been very manual, especially in the source-tocontract part of the procurement process. So, when I joined the company pre-COVID (approximately four-and-a-half years ago), I was convinced that we need to start to digitalise our procurement organisation to be attractive towards our suppliers and invest in our supplier relationships the way that we’re investing in our customer relations. It’s crucial that we can communicate, embrace, and relate to our top suppliers.

Equally important is the internal perspective. “Things are changing all the time so we need to increase speed, efficiency, and accuracy to simply create better business – and digitalisation is definitely a measure to do so,” she says. “And I’m convinced – and I’m sure you’ll agree – that digitalisation has not only revolutionised your personal life, but also your working life.”

Chinell thinks that it’s crucial to understand your stakeholders. To gain more of a perspective on this, Ahlsell began with a survey into their suppliers and employees, and asked: ‘What do you want more of?’, ‘What can we do differently?’, ‘How can we digitalise to make it easier for you to do business with us – or make it easier for you to do your job within Ahlsell?’

Employee demand for better product data? The survey revealed that internal employees wanted better product data. According to Chinell, good product data is extremely important to execute good business, as well as crucial to being able to digitalise. She says that, since it was also an ongoing project in the company, their employees were already aware of it.

“That can also symbolise that it could be hard to imagine what digitalisation can actually do for you. It’s easy to answer in terms of what you already see.”

This is another important point. To risk a metaphor, those born blind don’t know –and can’t really know – what they are missing in the world of sight. Digitalisation may be the light.

Supplier demand for nothing?

Digging deeper

The survey results into supplier demand served as a major catalyst for Ahlsell’s next move. They said that everything worked perfectly fine, and they didn’t want anything new from Ahlsell.

TITLE: CPO

COMPANY: AHLSELL

LOCATION: STOCKHOLM, SWEDEN

An experienced Director of Purchasing with a demonstrated history of working in the retail industry. Skilled in Negotiation, Food & Beverage, Fast-Moving Consumer Goods (FMCG), P&L Management, and Sales Management. A strong purchasing professional, she has a Bachelor of Science focused in Economics and Business Administration from Stockholms universitet.

“And, of course, I was not satisfied with that,” says Chinell. This outcome induced an understanding of what they really wanted “beyond the outspokenly expressed.

“So it triggered us to be more suppliercentric, and that’s how we try to work nowadays. That’s my mission within the company. I’m always the one taking the interest of the supplier into account because we have so many others doing it for the customer. And since we buy and sell products, suppliers are absolutely crucial for us.

Based on the findings of their survey, Ahlsell created their first digital roadmap – which determined that strong supplier relationships would be at their core – and decided to approach them in the same way that their customer relationships were approached. “And the reason for that is, of course, that for suppliers, the routes to market are infinite.

“We as Ahlsell simply need to be easier to work with: less costly, better at driving their revenue, and better at reinforcing their brand values to make sure that they choose us as their primary collaborative partner. And, once again, digitalisation is the way to achieve this.”

Based on the survey, Ahlsell clearly defined their needs.

Chinell says: “We put together an RFI and RFQ, went out to scan the supply landscape, and executed a tender to find the best service solution provider for our needs.”

As a result, the company created the Ahlsell Supplier Portal, the objectives of which are to:

• Make it easier for suppliers to do business with Ahlsell

• To ‘automise’ administration and improve efficiencies

• To make sure that Ahlsell could actively collaborate with more suppliers at the same time

The keys to process optimisation: From master data to supplier onboarding Chinell says that the first area that they looked into to achieve these objectives was master data, to allow Ahlsell to have a more

automised onboarding and maintenance of products with increased automisation; with automatic integration of different data pools, industry databases and so on.

Secondly, they looked into supplier negotiations, which is all about Ahlsell’s approach to strengthening supplier relationships. Then they looked at traditional contract management and risk management – “both increasingly important”, according to Chinell.

“So we digitalised all the self-assessments that we would traditionally send out to our

PWC’s global procurement survey showed that besides cost reduction, digitalisation was of increasing importance, and it came in as the third most important strategic priority among procurement departments

KAROLINA HAGBERG CHINELL CPO, AHLSELL

“Procurement specialists love the left brain because they’re noticed based on the logical skills concerned with numbers, structure and order”

suppliers manually. We also looked into traditional supplier relationship management (SRM), and that is actually the main driver to get the supplier into our portal because it’s about what’s in it for them. Through the SRM module, we can actually exchange information and data. Suppliers are able to look at their sales figures or at their delivery positions whenever they want.”

The last area that Ahlsell looked into was supplier onboarding, so that they could have all the financial and sustainability checks automised.

7,500 Employees

300 branches throughout the Nordics

1.5mn+ Offered SKUs

250,000+ Customers

“And all this functionality was not necessarily provided by one supplier, but could be different suppliers behind the scenes. The key for us was that it should all be accessible via the portal with a single sign on,” she says.

10,000+

comes to optimising processes, any organisation that doesn’t have its master data under control will run into problems and difficulties. So it acts like the trunk of a tree, supporting all ensuing ramifications, and therefore, needs to be robust.

Change management: Changing thinking, changing feeling

Concluding, Chinell says: “And lastly, you need to work with change management. Everything is about change. You need to prepare, communicate, and repeat. It’s not enough to create awareness; you need to create desire

“And once you’re created awareness and desire, you need to make sure that there is the knowledge and ability to actually embrace these new technologies. Digitalisation is a transformative journey. It demands a lot of energy and it can be fun, but it’s also challenging.

Looking out at the crowd, Chinell rhetorically asks:

“And what, among all of these processes, was the key success enabler?”

“If I had to point to one key driver for success,” she answers, “It’s master data.” Chinell explains that when it

“It demands that you are swapping back and forth between your logical left-brain and your creative right-brain. Procurement specialists love the left-brain because they’re noticed based on the logical skills concerned with numbers, structure, order, and so on.

“But,” she says, “you need to be able to swap between the logical left side and the more creative right side of your brain to really solve problems, to rethink, and to do new things – because digitalisation is about changing the way you do things, which means changing the way you think about things.”

WRITTEN BY: HELEN ADAMS

PRODUCED BY: MIKE SADR

WRITTEN BY: HELEN ADAMS

PRODUCED BY: MIKE SADR

Kevin Nelson is the Chief Procurement Officer at BD (Becton, Dickinson and Company), a medical technology company based in Franklin Lakes, New Jersey. His responsibilities include overseeing all third-party spend, including direct and indirect.

“I’ve been in the procurement profession for a number of years, starting my career in the high-tech industry and evolving into roles within the biotechnology arena before leading strategic sourcing at C. R. Bard, a medical device company that BD acquired about six years ago,” he says.

BD is one of the world’s largest medical technology companies. Its purpose is ‘advancing the world of health’ by improving medical discovery, diagnostics and the delivery of care.

“Roughly 90% of patients coming into a clinical setting in the United States are going to use a BD product,” says Nelson.

Products vary from well-known medical devices such as needles, syringes and blood collection tubes to sophisticated electromechanical devices, diagnostic instruments and reagents.

COVID-19 changed the world foreverhybrid working is the new normal, face masks are as common as earrings and you never leave your house without your keys,

how his team mitigates supply chain risks and delivers innovative solutions in an ethical way

Gainfront’s AI driven technology platform is designed to increase procurement efficiency while solving the unique procurement process challenges that arise from today’s remote and hybrid work environments and increased focus on corporate social responsibility around supplier diversity, ethical compliance, and reducing green house gas emissions

Gainfront’s highly customisable, modular, procure-to-pay powerhouse platform for Diversity, ESG, and collaboration

Gainfront is a platform that meets the procurement needs of today’s business landscape, focusing on mandates related to diversity, supplier diversity, workforce diversity, as well as ESG tracking. Led by Hetal Mehta, CEO of Gainfront, the company provides organisations with an innovative way to achieve compliance to preferred buying while offering powerful workflow automation, which is essential in today’s hybrid work environment.

Gainfront enables customers to easily configure their workflows, whether in sourcing, finance, or HR, granting them full control over the process through team collaboration and audit trails. As a complete Procure-to-Pay platform, Gainfront fully embraces diversity, ESG, and workflow automation requirements, providing a comprehensive solution for procurement professionals.

Gainfront recognises the pressing need for finding new, diverse, and environmentally conscious suppliers on a global scale. With current supply chain challenges, customers often struggle to identify and source from new suppliers. Gainfront addresses this issue by offering their customers access to a strong and robust global Discovery database. Mehta highlights the importance of this database, stating that it resolves the problem of customers being unable to replace suppliers due to a lack of viable alternatives.

In the context of today’s hybrid work environment, there is a growing need to find qualified suppliers while managing risk profiles. Gainfront introduces the RFX Concierge service, which allows customers to source suppliers easily by providing preliminary criteria. By leveraging this service, Gainfront identifies qualified suppliers and connects them, significantly reducing customers’ search time by almost 60%.

“Gainfront recognises the importance of collaboration in today’s hybrid work environment,” says Mehta. “The company’s horizontal approach to workflow automation provides customers with team collaboration capabilities, allowing for efficient communication and tracking of audit trails. By gathering all decision-making processes in a team-collaboration environment, individuals are held accountable, mitigating the risk of miscommunication or lost information.”

Gainfront’s Partnership with Becton Dickinson (BD) Becton Dickinson (BD) has been a customer of Gainfront for the past three years. Mehta and her team have been instrumental in helping BD manage supplier diversity, spend management, and tracking, thereby assisting them in achieving their BDR goals. Through Gainfront’s database, BD gains access to new suppliers, enabling them to meet their sourcing and diversity goals successfully.

wallet, phone and hand sanitiser. The postpandemic planet changed the procurement process too, especially for those dealing with medical equipment.

“The world has changed and our supply chains need to adapt,” said Nelson. “When we look at the environment, or the world around us right now, we are continuing to see more disruptions every year. We’ve been tracking this, not only within BD, but also within the healthcare and the life sciences industry.”

More frequent disruptions in the supply chain are happening year over year, which include plant shutdowns, supplier shutdowns, supplier insolvency, port strikes, geopolitical tensions and more.

“BD has taken this ‘moment’ to lead a ‘movement’ to create the supply chain of the future, and that all starts with enhanced procurement visibility and agility”

KEVIN NELSON SENIOR VP & CPO, BD

TITLE: SENIOR VP & CPO

COMPANY: BD

INDUSTRY: MANUFACTURING

LOCATION: NEW JERSEY, US

Kevin Nelson has served as BD’s SVP and Chief Procurement Officer for the past five years focused on applying advanced Procurement strategies to help BD navigate supply chain disruptions and inflationary challenges during the pandemic. Kevin created BD’s Responsible Sourcing Program which strives to develop an ethical, agile supply chain capable of sustaining external pressures.

Prior to B, Kevin was VP of Global Strategic Sourcing C.R. Bard where he introduced an advanced sourcing methodology that delivered solid yearover-year savings as well as additional value through innovative supplier relationship management, revenue generation, reduced backorder and a supplier risk management program.

“All these things result in some sort of disruption to the supply chain,” says Nelson. “We have continued to see that and experience it. That has led us to asking, what do we need to do differently? Because we’re probably not going to get back to this ‘normal’ that everyone’s been waiting for. BD has taken this ‘moment’ to lead a ‘movement’ to create the supply chain of the future, and that all starts with enhanced supply chain visibility and agility.”

This “movement” at BD has resulted in multiple initiatives to evolve procurement strategies to be more resilient, agile and socially responsible.

Kevin received his B.A. from the University of North Dakota and MBA from Boston University. Kevin is a member of the Healthcare Transparency Institute, Strategic Marketplace Initiative, National Minority Supplier Development Committee, Institute for Supply Management and sits on multiple advisory boards in the medical device industry.

Enhanced visibility via AI & ML

“To start building our supply chain of the future, we mapped our product lines to identify which ones are considered critical to healthcare,” Nelson explains. “These are products that the healthcare industry has

deemed essential to care for the patients, and if they aren’t on the market, there’ll be a problem around meeting basic or routine healthcare needs.”

BD identified over a hundred different product lines that are critical to healthcare. Nelson and his team conducted an assessment on every product line, looking at every item in the bills of materials and ensured remediation is in place for the critical high-risk materials.

“A product line may have a few items in the bill of materials, or it may have a few hundred items. We do an assessment on every item in that bill of materials and on every supplier, to see where potential risks are.”

BD creates a composite score that allows them to plot product lines to see which ones are in a high-risk quadrant.

“We’re looking at how we can help a community where our customers are living”

BD: Ensuring a resilient, responsible and agile supply chain

KEVIN NELSON SENIOR VP & CPO, BD

“We can take that back to our business units and work with them to create mitigation plans to dual source, adjust inventory levels, and/or regionally source some of the material or components.”

90%

As part of the work to de-risk high-priority products, BD uses discovery technology that employs AI and machine learning ML to map subtier supply chains for critical products and leveraged that visibility to uncover hidden risks in its suppliers’ extended supply chains.

“During COVID-19, 80% of BD’s supply chain disruptions didn’t come from our direct suppliers,” Nelson adds. “They came from our suppliers’ suppliers or even three or four levels down the chain. Unless you have mapped your entire supply chain and employ

very sophisticated technology, it is very hard to know how a disruption at a third or fourth-tier supplier will impact your product.”

An example of the payoff of this work was a recent paper strike in Finland. Because BD mapped the supply chain, the procurement team knew that pulp from Finland was used in medical grade labels the company uses and that there were very few alternate suppliers. BD received early warning signals from the risk intelligence partner along with the visibility to understand the issue early on, work with its partners to find alternate sources and secure inventory of labels well in advance of other companies or industries that would be vying for the same label stock.

Roughly 90% of patients coming into a clinical setting in the United States are going to use a BD product

The life sciences industry continues to experience unparalleled innovation as investment and talent flow into the sector and breakthrough discoveries happen at a rapid pace.

Named the 2021 BD Sustainability Supplier of the Year, JLL helps life sciences companies create compelling real estate and facilities strategies that improve efficiency, mitigate risk and deliver a sustainable workplace. Lay the groundwork for rapid growth →

Creating a socially & environmentally responsible supply chain BD knows its customers want them to provide high-quality products at a fair price and that they expect more than the basics. Improved resiliency, visibility and agility are adding value, but the company is also focusing on sustainable business practices that are environmentally, ethically and socially responsible.

“At BD, we stay true to our values, including doing what is right. We set up the Responsible Sourcing Program to ensure we embed supplier responsibility and sustainability in every purchasing decision we make,” Nelson explains.

This includes partnering with ethical and diverse suppliers, helping protect human rights and working to ensure environmental stewardship.

“Our customers want to understand the bigger picture, too,” Nelson explains. “Are they buying a product from us that is sourced from an ethical and responsible supplier paying fair wages to its workers?”

BD ensures compliance in these areas through ongoing assessments, desktop and face-to-face audits and close partnerships across its supply base. This is all to ensure that suppliers understand exactly what BD

“Unless you have mapped your entire supply chain and employ very sophisticated technology, it is very hard to know how a disruption at a fifth-level supplier will impact your product”

expects when doing business with them, while also making sure risks are anticipated and managed effectively.

Like most companies, Nelson and his team have certainly found some areas of concern in their network that need to improve.

“Instead of moving away from that supplier and letting it be someone else’s problem, we’ve tried to see how we can work with them to identify an area they need to improve in. If they’re able to, that’s great. If not, then we’d have to move away. So far, we’ve been successful in mitigating issues. We’re working to help improve human rights around the world while ensuring important medical products get to those who need them.”

Another focus area of BD’s Responsible Sourcing Program is supplier sustainability. This examines where suppliers are driving reductions in greenhouse gases, diverting waste away from landfills and understanding how much renewable energy they use. The Responsible Sourcing team is also working internally with product stewardship and category management to develop and implement strategies to eliminate materials of concern where possible.

“The partnership is that three-legged stool: our customer, our internal stakeholders and our suppliers”

KEVIN NELSON SENIOR VP & CPO, BD

How well do you know your suppliers?

Or even your suppliers’ supplier?

Get clear visibility and unmatched intelligence to make faster, smarter supply chain decisions. Everstream reveals supplier, material, and revenue risk before anyone else. With the world’s most accurate and reliable data, network graphing, and human analysis, Everstream empowers supply chain leaders to build strong, agile, and sustainable supply chains.

Take control of your supply chain with Everstream everstream.ai

everstream.ai/demo

KEVIN NELSON SENIOR VP & CPO, BDsustainable sterilisation technologies, and addressing materials of concern (MOC).

The third area of focus of the Responsible Sourcing Program is supplier diversity, which has gained a lot of momentum in the US.

“We pivoted our supplier diversity focus from one that historically assessed our spend with small businesses and diverse suppliers, which was more of a reactive approach. Today, we are looking at economic impact in terms of how we’re helping different regions and local economies by using diverse and small businesses that are truly making an impact. We’re looking at how we can help a community where our customers are living,” explains Nelson.

“The Supplier Sustainability pillar includes working alongside our R&D team and business units to identify products, materials and components that are ‘greener’ in nature while also making products that are more effective, efficient and economical,” Nelson explains. “This might be a packaging component that uses less energy to make or is recyclable.”

In 2022, BD launched the Sustainable Medical Technology Institute, a model of practice within the organisation that brings together BD researchers and engineers, as well as quality, regulatory, policy, sourcing and operational expertise, to focus on reducing the environmental impact of the company’s product portfolio in three areas: adopting sustainable product design strategies, developing and deploying

Finally, there’s end-to-end transparency, which is connecting back to the customer and providing enhanced visibility to them. “The key is providing this information proactively and transparently to the customers, to the patients, before it’s a problem, so they have the ability to do something in advance.”

As with any medical manufacturer, BD’s partner ecosystem is vast.

“Partnering with our customers upfront is a key priority for BD. We aim to identify the customer requirements and expectations and build those into our long term strategies and initiatives,” he explains.

From day one, BD’s style has been to collaborate and work with its partners, which was essential during the pandemic.

“We came in working together, wanting to figure out a solution with our supplier partners, as opposed to demanding, ‘Shift this or I’m going to move away from you’.

“Instead of moving away from that supplier, we’ve tried to see how we can work with them to identify how they can improve”

“The partnership is a three-legged stool: our customer, our suppliers and our internal stakeholders that includes business units, Quality and Regulatory, among others.”

This work is further strengthened through strategic collaboration and public-private partnerships with government agencies, including the FDA, HHS, POTUS/White House – and industry collaboratives like Advamed – to address supply chain and sourcing issues that plague the broader healthcare industry.

Being able to incorporate those areas into BD’s strategy has allowed what Nelson sees as a resilient end-to-end supply chain.

The momentum of BD’s procurement supply chain team has been exciting for Nelson and his team.

“We’ve experienced very little turnover in our function, and I think a big reason for that is that people see the movement we are driving and understand we have become extremely vital to BD, our customers and the patients they serve. We are on the frontlines; we are helping shape strategy as we go forward here.”

Nelson views this as an entirely different kind of mindset and even acumen, from a team perspective.

“I think it’s been refreshing for the team to pivot away from historical firefighting or cost-reduction to facing the bigger opportunity we’re trying to address.”

“We have more engineers on the team now doing more,” says Nelson. “Our engineers look at an existing product line and see what we can do to redesign elements that can meet the needs of our customer and patients, reduce our overall risk exposure and benefit BD as well.”

ResMed’s Director of Procurement operations, Ama-Aidoo Sam, on how to use data to clarify and organise procurement across the board

WRITTEN BY: ILKHAN OZSEVIMTo work efficiently and make effective, informed decisions, procurement professionals rely heavily on data analytics. Insights from data analysis can be used in sourcing to select the supplier best suited to meet the requirements of the organisation.

In supplier management, having performance-related data means proactive management of suppliers to the contractual terms and being able to identify suppliers that are not performing and managing them. Access to risk data means awareness of issues that may impact compliance, quality, or lead to disruptions across the supplier

chain, allowing for proactive management of the identified issues. Access to data analytics therefore allows procurement professionals to make informed decisions across the procurement lifecycle.

Ama Aidoo-Sam is Director of Procurement Operations at ResMed, the innovative medical device and digital health solutions organisation based out of Dan Diego, California. Her role covers all processes and systems from a procurement perspective, while her team works very closely with, and supports, the category and sourcing teams that collectively perform the overall procurement function.

“To leverage data, organisations need the right tools and in-house expertise to effectively interpret the data correctly”

AMA AIDOO-SAM DIRECTOR, PROCUREMENT OPERATIONS

“Challenges to implementing a data-driven procurement strategy can come from people, processes, or from technology,” she says. “From a peopleand-processes perspective, it manifests as resistance to change, with people being stuck in their ways of thinking and doing things.”

Examples of this may include people not following established processes or finding ways to bypass them; an unwillingness to apply new processes; or the application of old mindsets to new ways of working. “Some negative results of these approaches can be

teams pulling data from differing sources, inconsistent data, or impaired data visibility altogether,” she says.

"From a technology perspective, there may be divergent, unintegrated solutions being utilised that are creating data silos. It’s important for organisations to keep processes simple and easy to follow, documented, and easily accessible –and to always do these things with the best interests of the end-user in mind.”

Aidoo-Sam points out that, when choosing new procurement technologies, organisations need to ensure that

requirements and expectations are clearly defined, and that the process for using them is agreed on by all key players.

“Don’t select the technology simply because it’s the new iteration of existing technology. Without getting the process foundation right, organisations will encounter data issues, even when using so-called ‘best-in-class’ solutions.

To overcome these challenges organisations need to consider and balance the management of people, processes, and technology as these all provide input into data.”

“Having a process where anyone in the organisation can report data issues is important to improving the quality of data”

AMA AIDOO-SAM DIRECTOR, PROCUREMENT OPERATIONS

Artificial intelligence (AI) and machine learning (ML) will play a major role in enabling better analysis of data – thus aiding decision making – thanks to their ability to analyse large amounts of data, come up with insights and trends, and provide recommendations.

AI and ML can also be used across the procurement lifecycle – from assisting with supplier selection, based on the information provided in Requests for Tender, and spend analysis, where the two can help identify opportunities for cost savings through to contract management, where they can help analyse the real value from contracts.

Aidoo-Sam says: “This technology can also help with identifying risks. Across all these areas, getting data analysis will help inform decisions. The world of AI/ML is constantly evolving and the utilisation of both in procurement is swiftly progressing. There is room for improvement however, and it will be good to see how this evolution plays out.”

Accurate and reliable data starts at the point of data collection. “Therefore, organisations should ensure that there are rules in place to govern that initial step in the process,” says Aidoo-Sam. “A good data governance policy clearly identifies the data owner, the data steward, the data custodian, and each of their responsibilities and points of interaction.

“The systems used to collect data can also be set up to ensure there is verification at the point of data entry. The process for cleansing and maintaining the data is equally important. Having clear accountability around the collection, storage, and

TITLE: DIRECTOR | PROCUREMENT OPERATIONS

COMPANY: RESMED

LOCATION: SAN DIEGO, CALIFORNIA

A relationship builder and a leader with a record of outstanding results in developing high-performing teams, delivering savings, and meeting the strategic objectives of customers.

An experienced procurement leader whose industry experience covers financial services, consulting, FMCG and consumer electronics. Ama Aidoo-Sam has managed both strategic and operational procurement in the UK, ANZ, and Asia.

processing of the data helps to improve its quality.

“And finally, working with bad data frustrates everyone – especially procurement professionals – so having a process where anyone in the organisation can report data issues is another important step to improving the quality of data.”

There’s a lot of talk about big data –and it’s true that companies have access to more data than ever before. One of the main impacts of big data is better access to insights, trends, and patterns that can assist in making more informed business decisions.

“Having big data is one thing,” says Aidoo-Sam, “but in order to leverage that data, organisations need the right tools and in-house expertise to effectively interpret the data correctly.

“Procurement professionals need to learn the analytical skills that enable them not only to correctly interpret the information that’s gleaned from big data, but also to ask the right questions to get the correct insights in the first place in order to explain data and insights to key stakeholders.”

Aidoo-Sam says that ultimately, data will provide you with facts (spend data, usage trends, or demand trends, for example), but the ability to use that data to make an informed decision rests with the procurement professional.

September 2020

“This is where your experience and intuition become important,” she says. “For example, current and projected spend data doesn’t tell the full story, and it’s not the only factor impacting the dynamics of certain relationships within a business. For instance, there's also high potential value in qualitative

data, like market intelligence gathered from talking to colleagues or partners.”

Ama’s advice to procurement professionals is: “Use a combination of data together with your experience and intuition when it comes to making decisions for your organisation.”

The ProcureCon Australia Summit 2023 took place on May 24th-25th in Sydney. Ama presented a talk on supplier risk assessment, including how to financially vet your suppliers to reduce risk, plan for contingencies, and build resiliency to avoid reputational damage and protect your brand. You can catch her talks online.

Key topics and why ProcureCon Australia was such an important event ProcureCon came to Australia for the very first time, making it even more of an important event. The two-day programme was jam-packed full of industry experts talking through topical content across the industry. It also served as a great networking event. The discussion on the future outlook for procurement and capitalising on procurement digitisation was a particularly great session, with scope for shaping the future of the sourcing space.

“Challenges to implementing a datadriven procurement strategy can come from people, processes, or technology”

AMA AIDOO-SAM DIRECTOR, PROCUREMENT OPERATIONS

WRITTEN BY: ILKHAN OZSEVIM

WRITTEN BY: ILKHAN OZSEVIM

Icaught up with Ian Thompson, Ivalua’s VP for Northern Europe at IvaluaNow in Paris to talk about Source-to-Pay (S2P), ‘supplier’ relationships, and Ivalua’s projects concerning sustainability and beyond –and you’ll understand why the term supplier is contained within quotation marks as you read on.

Thompson has worked his entire career in procurement and supply chain technologies, and has been involved in supply chain integration, major projects and evaluations – always involved in the process of buying and supplying.

“I didn't sit on my father's knee and say, ‘I want to be in procurement technology’,” he says.

“It was a job that I got after college, but now, it's 22 years later, and here I am. I've been involved in project work andon the commercial side, and I’m now in a management and leadership role.”

Thompson says that what he does, is all about trying to create a team that believes in what they are doing, as well as believes in themselves –wanting to engender that through an inclusive and positive atmosphere.

The disruptions that came about following COVID-19 and the war in Ukraine proved to be both a major challenge and offered major opportunities. When asked about S2P in relation to future disruptions in the supply

the way we see our relationships, affects outcomes. All through the lens

The e2open connected supply chain platform provides the end-to-end visibility and collaboration you need to tackle unpredictability. Build trust and confidence with your channel, supply, logistics, and global trade partners. Take control of supply constraints through direct procurement and meet customer commitments in the face of disruptions and scarcity. The connected supply chain. Moving as

TITLE: PROCUREMENT CATEGORY

MANAGER | VP |NORTHERN EUROPE

COMPANY: IVALUA

LOCATION: LONDON, ENGLAND, UK

Ian is a high-integrity technology sales leader who builds long-term, mutually beneficial relationships with both customers, prospects, and team members. He has broad experience in procurement and supply chain technologies.

chain, Thompson says: “What you measure and how you select is the first thing.”

A company can, he says, do more than just provide a catalogue of products, so it’s important to begin by considering its capabilities. “During the pandemic for example, there was a company that was providing point-of-sale equipment for a supermarket. Because the supermarket understood that the company was not just providing a catalogue of services –and because they knew that the company had GPS software, vehicles, and so on –they actually brought them in to augment their delivery.

“So understanding what a company can do, its capabilities, and the outcomes that you can bring about through creative innovation will allow you to get a much better performance from the suppliers that you have.”

Thompson then points to assessing risk and resilience. He says that trying to understand the individual supplier and how it's set up to disaster recovery, and

the way it manages risk, will be an important factor in dealing with future supply chain disruptions.

“But, in all likelihood, the best way of managing disruption risk is to have a larger quantity of suppliers in your network. So, even though you may buy all of your products or commodity apps from a certain supplier – because, let’s say that's sufficient, administratively easy, or gives you leverage on your spend, in terms of driving prices – it's also much more risky than buying the same quantity spread between ten different suppliers.”

Managing suppliers, managing friends Thompson highlights that S2P software and technology means that a lot of the traditional downside of dealing with a host of suppliers have largely gone away because of digitisation.

“Fifteen years ago, you would've struggled to manage a hundred friends, but now you’re able to do so because of technology. In many ways, supplier management is a similar affair.”

Although it may seem an odd thing for him to say the above as a procurement professional, Thompson points out that he actually doesn’t like the term ‘supplier’. “The reason,” he says, “is that 'supplier' is actually a way of describing a company – and a company is like a node in the network, which is the economy.

“Take myself, for example: I’m a colleague and a friend, I'm a father and a husband – and I embody all of these different characteristics. But, behind them all, there's actually a person.”

“Companies are considered to be

If, for example, you measure the United Kingdom's carbon output, we're fairly low down on the global stage, representing about 1% of the global total. But if you look at it in terms of what we consume and what impact we have across the chain, it’s far more consequential than many would assume.

composed of customers, innovators, competitors, agents pushing out content and so on, and they've got all of these different characteristics. And of course, it just so happens that when you're a procurement professional, you interact with the supply side of things.

“When it comes to suppliers, I need to squeeze them. I need to get them all to comply with X, Y, Z. What you really need to ask is, ‘how can they help me to innovate?’, ‘what do they know that I don't know?’, ‘what information can they share with me about the reality of our supply chain?’.”

Here, Thompson hits upon the fact that the way in which we approach something changes the very thing we find, and it closely ties into his philosophical,

yet concretely humanistic approach to supplier relationships.

The role of technology in humanising procurement

Thompson says that all of this can't be done without technology, because without it, all of your efforts, and all of “the burn” on your organisation will just be about managing the fact that suppliers exist.

“But,” he says, “you can let technology take care of that side of things, and then you can begin to see your suppliers as an entity; and your connection to them as more than just a commodity-type relationship.”

He says that it’s important to understand your suppliers and to be able to see what they do, and that this has the power to transform ‘supplier’ relationships,

“Don’t let the perfect become the enemy of the good”

IAN THOMPSON VP OF NORTHERN EUROPE, IVALUA

into human relationships that will yield significant outcomes.

Ivalua is doing a lot in the S2P space within supplier relationship management (SRM) at the moment, as well as in sourcing and their environmental impact centre. A lot of Ivalua’s efforts are about providing understanding to Scope 3.

“The environmental impact centre means that you are actually part of a network that is trying to understand the full implications of carbon emissions across the entire value chain – and this is actually quite profound. For example, where an organisation sources its product from

“Do you believe that sourcing decisions will get affected heavily by the carbon impact, or is it still always going to be a financial decision?”

IAN THOMPSON VP OF NORTHERN EUROPE, IVALUA

might surprise them in terms of actual carbon impact and Ivalua can help them to change and innovate to reduce their carbon footprint.

“If, for example, you measure the United Kingdom's carbon output, we're fairly low down on the global stage, representing about 1% of the global total. But if you look at it in terms of what we consume and what impact we have across the chain, it’s far more consequential than many would assume. Companies are no different.

“The big question is: ‘Do you believe that sourcing decisions will get affected heavily by the carbon impact, or is it still

1%

always going to be a financial decision?’. My answer to that is that sustainability is increasingly becoming an unavoidable subject, simply because your investors, your customers, and your employees all care about the impact of carbon emissions.”

When asked about his thoughts on the future of S2P, Thompson replies that structurally, he believes it's going to be the same. He emphasises that many companies can get lost in notions of technology suddenly quantum-leaping, and this becoming a sci-fi world, which he says is “really just not true”.

The United Kingdom’s contribution to the global total carbon output –on the face of it WATCH NOW

“But there are developmental aspects to S2P that will have a great impact,” he says.

“S2P can produce a lot of data, and with machine learning and AI, we'll be able to better understand that data.

“On the payments side of things, there'll be more effective and efficient ways that organisations can provide financing to suppliers, such as helping to receive them in a much faster, more secure manner.”

I ask him what the one message is that he’d like his audience to know. Quoting Voltaire, Thompson replies: “Don’t let the perfect become the enemy of the good. Just because it's difficult to map supply chain emissions, it doesn't mean you shouldn't try. Just because your supplier master data is in a huge mess, it doesn't mean you shouldn't launch a program to try to address that.

“We deal with a lot of people who want to make changes, but they can be overwhelmed and suffer from decision paralysis, so I’d say this: although it sounds simple, the important thing is to just begin.”

Supplier is actually a way of describing a company, and a company is like a node in the network, which is the economy”

IAN THOMPSON VP OF NORTHERN EUROPE, IVALUA

Amcor designs smart, sustainable packaging that weighs and contributes less to greenhouse gases with readily recyclable, in addition to 100%-recycled products that are designed with end-of-life usage and circularity in mind.

Here, procurement plays a very strategic, integrated role in driving corporate ESG strategy through important activities like raw material and strategic vendor selection, creating strategic partnerships across the value chain, driving grassroots recycling efforts, and capacity and supply protection.

Ranga Mulabagula is Global Vice President of Procurement at Amcor Rigid Packaging. He is responsible for US$2.5bn global spend

Amcor's sustainable procurement drives ESG strategy, circularity and industry-wide change towards greater sustainability, overcoming current market challenges

RANGA MULABAGULA GLOBAL VP OF PROCUREMENT, AMCOR

“We work with numerous reputable organisations across North America to achieve appreciable ESG outcomes”

spread across 50+ manufacturing facilities in over 15 countries.

His 27-year global career – of which he has dedicated 10 years to Amcor on top of a previous 17 spent at General Motors – spans the areas of procurement, supply chain, product development, and international operations, helping him to develop into a highly-skilled and wellrounded operations executive in the manufacturing and service industries.

Amcor’s procurement activities tackle everything from supporting Scope 1 endeavours, carbon footprint reduction efforts with Kaizen workshops, and supporting scope 2 renewable energy footprint sourcing and expansion – all the way through to Scope 3 greenhouse emissions reduction.

Mulabagula says, “we recognise the principle that ESGs shouldn’t be a later addition to circularity efforts, but are far more effective when baked into the process from the very outset.”

ESG efforts are, of course, not a solitary endeavour, and the importance of partnerships and supplier relationships is an incontestable part of the enterprise. Such gigantic projects require cooperation, and Amcor has set its sights on significant collaborations to achieve a farreaching and positive environmental impact

It is worth noting that Amcor's focus on ESG aligns with broader trends in the corporate world. Many companies are increasingly recognising the importance of addressing ESG concerns not only for ethical reasons, but also for the potential financial benefits.

Now, it’s widely recognised that addressing ESG concerns can help companies reduce costs, mitigate risks, and improve their reputations – among other benefits.

Amcor's approach in addressing ESG concerns across all three scopes is also notable. Scope 3 emissions in particular, are often overlooked by companies but can be a significant source of emissions and environmental impact. By addressing greenhouse gas emissions in its value chain, Amcor is taking a more holistic approach to ESG, which should help the company achieve its sustainability goals more effectively.

RANGA MULABAGULA GLOBAL VP OF PROCUREMENT, AMCOR