This month’s Procurement Magazine issue looks at the dilemma of surviving in uncertain times. Most companies will fail to adapt, transform and, therefore, succeed; but there are those who have been successful, and within these pages is exactly how…

There’s an ongoing arms race in procurement. Though the battle is no longer about the acquisition of the greatest number of things – which included tossing aside people and planet amid an insatiable appetite for more – it increasingly tilts instead towards the stockpiling of newly-forged armouries of sustainability.

The future of procurement is today, and the changes that we are seeing are clear. They reveal that, in a flash, the whole world is set to transform. Only the adaptable and agile will survive the vicissitudes.

From shifting work cultures and progressively peoplecentric organisational ethoses to innovations in technology, Procurement Magazine delves into the companies and executives that are making it happen.

ILKHAN OZSEVIMilkhan.ozsevim@bizclikmedia.com

“It will fall to procurement to take the leading role in ESG initiatives”

Effective procurement rests on data, and the more data, the better the procurement processes in potentia…

To analyse mountains of information; to make meaningful connections that would have, in all likelihood, been missed by human calculation, requires advanced Artificial Intelligence – and the rate of development in AI is about to open up an era that will transform procurement at its most fundamental level.

Efficiency is about to become much more efficient…

Adapting to change is no easy feat, here's how procurement is responding

Jag Lamba CFounder and CEO of

“Mature

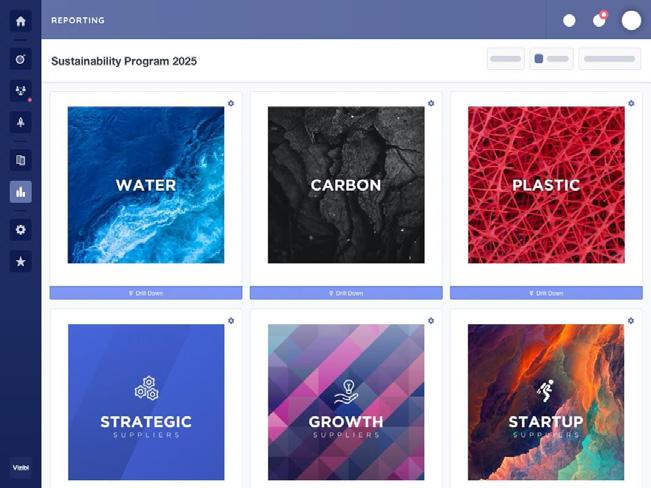

Mark Perera is CEO and Co-Founder of Vizibl, the company behind the world’s leading supplier collaboration and innovation platform.

As CEO, a large part of Perera’s role involves speaking directly to Vizibl’s customers and prospects to learn more about their challenges, gaining an understanding of how Vizibl can work alongside them to iterate on and expand existing offerings to meet those needs.

Procurement’s sustainability progress

Perera feels that “there has been an overall lack of real progress in sustainability”, though he emphasises that “this isn’t something that can be landed at the door of procurement alone”, with “some mitigating factors at play that have also prevented things from moving forward at the pace that they need to”.

He says procurement has had more “immediate” issues to deal with in the supply chain, mainly caused by the hangover from COVID-19, the ongoing Russian war in Ukraine, and – for people in the UK – Brexit-related supply problems. Therefore, ways to reduce scope 3 emissions in the value chain, for example, have once again had to take a back seat.

Sustainable sourcing is growing, and Oceanum is exploring the many uses of sea plants to transform numerous industries from packaging to textiles

As sustainability efforts grow globally, Owens Corning – the world's largest manufacturer of fibreglass composites –seeks a circular economy

Recent survey finds netzero 2050 targets being thwarted by lack of skills, robust reporting standards, and costs of procuring materials. TAIWAN

Procuring semiconductors from Taiwan may be exposing fragility across the semiconductor supply chain, with Taiwan being responsible for nearly 65% of global semiconductor supply. Single-supplier dependencies fail to spread the risks.

Once upon a time, procurement was merely about driving profits. Get stuff, sell stuff, make money, repeat. The emergence of extra-material cultural values has galvanised the drive to transform procurement from the ground up. The future of procurement will concentrate on ‘triple-bottom lines’, incorporating ‘people’, ‘planet’ and ‘profit’ into the same framework.

Even when procurement was wholly concerned with the bottom line, efficiency was key. ‘Time is money’ – you know the crack. But time is foremost a resource; the foundation of all the rest – and so productivity and efficiency are crucial, thus growing concerns for procurement. Simply put: the more that’s digital, the less wastage.

If the past is anything to go by, change is the only constant – and the past 3 years have brought about more change to procurement than the last 30 combined.

Here are our top 6 predictions for the future of procurement:

Teleportation will revolutionise procurement forever

Ok. So this one’s a bit of a fantastical indulgence. For now. All science was once science-fiction. Take an iPhone back a mere century and the planet would bow at your feet in subservience.We’ve already achieved teleportation in the quantum world, and perhaps it will be AI that helps us bridge the gap between the micro and macro. Think Amazon ‘Time’, with “Rightnow delivery”.

Procurement’s role will keep gaining traction

You’re sick of hearing it, but perk up your ears: ‘Pandemic’. This single event brought about so many changes in the way the world itself is organised, let alone the procurement world (and they are intimately connected), that procurement went from a lowly background function to a board-room-level, I’m-here-to-save-your-life critical service, in the twinkling of an eye. Procurement will inevitably continue to rise in its prestige.

The rise of AI will redefine the function

At the upper echelons of digitalisation is AI. Our greatest procurement gripes are due to our shortcomings in prediction – predicting pandemics, predicting wars, economic collapses and the rest. Advanced AI will be able to make predictions that we cannot even fathom. They are unknown, unknowns. What is known is that AI will transform the very nature of procurement itself. Watch this space.

ESGs, DE&I & ethical standards will take hold Environmental, Social, (and Corporate) Governance, Diversity and Inclusion, Ethics – my, my, how far we’ve come since the days when we just wanted ‘to get stuff’. Ethical value systems related to people and planet, now in their infancy, will subsume procurement entirely, and procurement itself will play a central role in ethical movements.

Joining IBM in 1978, Chief Procurement Officer Bob Murphy has witnessed fundamental procurement transformations from the very beginning, dexterously adapting in tandem – and transforming both himself and IBM in the process.

Bob Murphy, Chief Procurement Officer of IBM, is a true career veteran. Murphy joined IBM in 1978, going on to earn a Master’s degree in Manufacturing Sciences and Engineering in 1983. Until the late 90s, he held various engineering and management positions at IBM Greenock (Scotland).

In the 2000s, Murphy developed his skills to hold various roles in procurement and moved from Scotland to North Carolina until 2014, when he became IBM’s Vice President of Supply Chain and Chief Procurement Officer.

Since taking up this role, Murphy’s focus has been on improving the way IBM approaches procurement, by enhancing processes and applying technologies to help IBM “listen for need and act with speed” in support of its stakeholders.

In both procurement and supply chain, Murphy is still focused on this goal of working smarter and faster; in improving productivity; in reducing costs; in optimising cash and innovating – all aimed towards providing a better stakeholder experience.

At IBM, Murphy works with technologies and processes to handle crises such as natural disasters and pandemics. He also works with suppliers across the globe to source new products and services from new suppliers that, once upon a time, IBM couldn't have anticipated.

Murphy was instrumental in helping implement dedicated freight carrier lanes to maintain delivery routes throughout the

pandemic, as well as with pre-booking flight spaces to secure shipping capacity as part of his role.

He helped execute urgent accountspayable supplier setups, expediting payments for business-critical requirements.

As IBM CPO, a large part of Murphy’s role is to actively support IBM’s clients in achieving business objectives as well as increasing the marketability of procurement offerings. This includes continual transformation, employing leading edge technologies and empowering a skilled team of professionals to improve their clients’ experience.

The rate and pace of change in his industry is faster today than at any other time during his long and fruitful career. The seemingly constant advancements in tech are certainly a goldmine of opportunity but, at the same time, create challenges for business across every industry, with all working to stay ahead of this extraordinary technological curve.

For this reason, Murphy finds that his role entails the buying of commodities that are different to what they were five years ago – even to those just one year ago – as new products are continually entering the market. Teams need to be immersed in the businesses of IBM’s clients from end-toend to ensure they are providing value at every level.

Murphy feels that it is absolutely critical that procurement and finance operate together as one team, as the CFO function has the responsibility for ensuring the fidelity and operations of the company, as well as in achieving its objectives in terms of things such as free cash flow, profit margin and all of those critical revenue metrics; in IBM, they moved procurement under the CFO function.

Murphy wants to ensure that IBM has strong employee engagement to keep their procurement professionals happy and moving forward in their careers, despite the challenges of working remotely.

IBM is now far more visible and increasingly focused on achieving Environmental, Social and Corporate Governance (ESG) goals.

IBM also took a further step, moving Accounts Payable from finance to procurement’s remit.

The changing role of the CPO has led to Murphy saying that he is out there looking for ways to keep improving and adding value. He spends 25% of his time speaking with other CPOs, in addition to leaders from industry and technology companies, to discover how they’re thinking around challenges and motivating their teams.

“Ultimately, it comes down to revenue and growth, improving speed and productivity and selecting suppliers that provide a competitive advantage, all while protecting the brand. To do those things effectively, procurement processes need to be digitised from source to pay to provide visibility.”

“Some people refer to AI as ‘Artificial Intelligence’, but we at IBM refer to it as ‘Augmented Intelligence’. The whole point around AI is to help our human workers to make better decisions, to make them faster, to give them better insights and therefore to deliver better outcomes.”

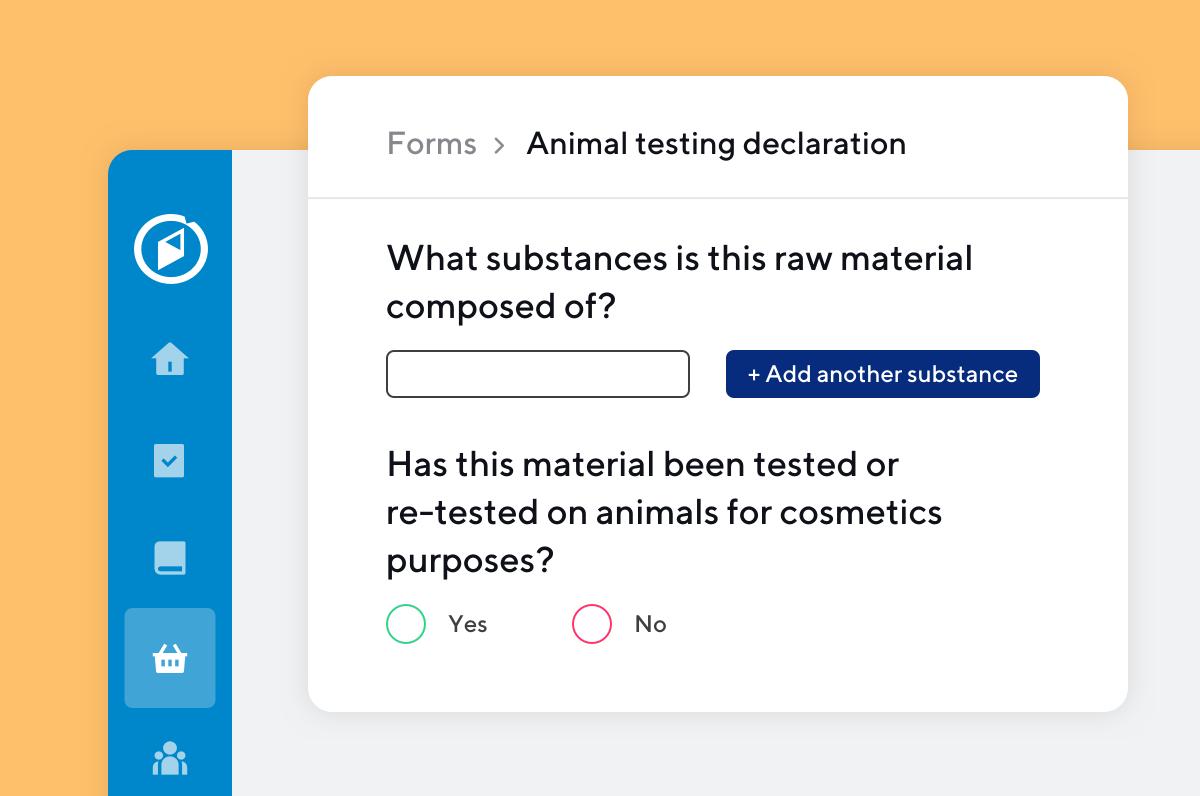

I’m James Butcher, CEO at Supply Pilot. I am passionate about supplier engagement, which is achieved when companies work in collaboration with suppliers to accelerate change.

» At Supply Pilot, our mission is to help companies transform the way they work with their suppliers to become more successful –with more sustainable products and brands at pace, and achieving measurable results within weeks, not years.

I have worked across the manufacturing industry, as well as many household name retailers, on best practice for many years, so I understand that much of what manufacturers do is driven by the requirements of the brands they manufacture for.

There is often a disconnect between brand and supplier – and this sparked a passion in me for improving supplier collaboration. When applied correctly, it is a win-win for both brand owner and supplier.

The opportunity to achieve benefits through collaboration with suppliers is often ignored or, at best, underestimated. Right now, brands need to be responding to environmental and social challenges, and they can do this best by focusing on their supply chain.

Effective supplier collaboration can empower suppliers to do more on time

and, in turn, deliver accelerated results against brand and retailers’ sustainability commitments, in addition to their commercial goals.

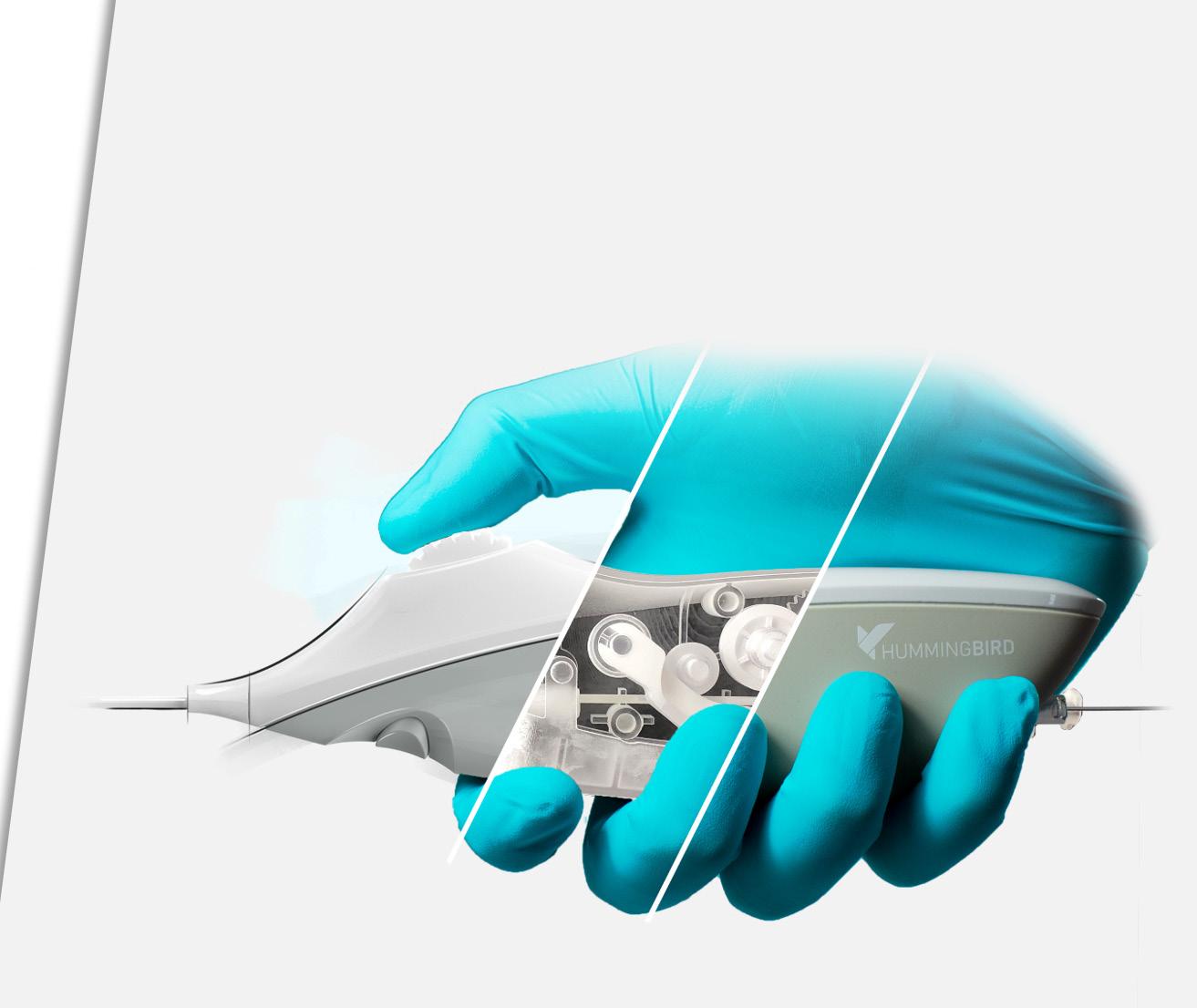

Supply Pilot’s proven process and cloud platform are perfectly suited to driving this type of transformation.

» I’d worked part-time for my dad’s engineering company from a young age, and I think that experience helped my engineering mindset and problemsolving skills, as well as encouraging an entrepreneurial spirit.

My first role after graduating in engineering was as a software developer, which led me to becoming a solutions’ consultant, implementing product control systems for the likes of Boots and Bayer.

I spent an enjoyable 20 years dealing with data, lot and barcoding equipment in factories, working with global customers and partners on a wide range of projects –from aerospace to potato crisps – before moving into software control as the founder of Claricom.

Our aim was to help ensure accurate barcoding and date coding to increase traceability in the supply chain, thereby reducing food waste. That led to my next step in retail: working with the likes of Asda, M&S and Tesco to develop best practice. From here, my eyes were opened to the opportunities available through successful collaborations.

At Supply Pilot, our clients are typically the brand owner, whether this is a large manufacturer, consumer packaged goods customer or retail own-brand.

Change is most typically driven through procurement. This can range from the need to source products that meet certain responsible sourcing standards, or working with suppliers to deliver transformational processes, such as increased sustainable packaging or removing materials of concern.

» My favourite aspect is the ability to drive positive change, empowering brands and suppliers to enable this change. When done well, a more collaborative approach is the quickest way to deliver sustainability improvements that result in winning products. This defines success for the brands, as well as for the companies

that manufacture for or supply those brands.

What we do at Supply Pilot is to enable the ‘conversations’ that would otherwise only be had with a small number of strategic suppliers. Our work enables this to be had with all suppliers, quickly and effectively, to scale the positive impact.

» The biggest issue is often the sheer scale and complexity involved in procurement. The increasing number of suppliers, products and materials is often compounded by limited internal resources, which can leave clients feeling overwhelmed and with no option but to focus on the few.

What the industry needs is a simplified system of supplier collaboration, with clear, measurable and actionable communications on what is needed and why, to help inform and empower them.

» In the current uncertain economic climate, focus will be on cost and supplier consolidation. However, this can be a false economy. It can stifle innovation. Necessity is the mother of invention, and therefore I predict the ‘winners’ will be those that seize on the current conditions to not stifle innovation, but encourage and empower those that deliver lower cost and more sustainable, winning products.

“THEREFORE I PREDICT THE ‘WINNERS’ THAT SEIZE ON THE CURRENT CONDITIONS INNOVATION, BUT ENCOURAGE THAT DELIVER LOWER COST AND WINNING PRODUCTS"”

‘WINNERS’ WILL BE THOSE CONDITIONS TO NOT STIFLE

AND EMPOWER THOSE AND MORE SUSTAINABLE,

Vodafone was among the first organisations to see procurement as something more than a mere cost control centre – eleven years before the supply chain shocks of the pandemic prompted organisations the world over to follow suit.

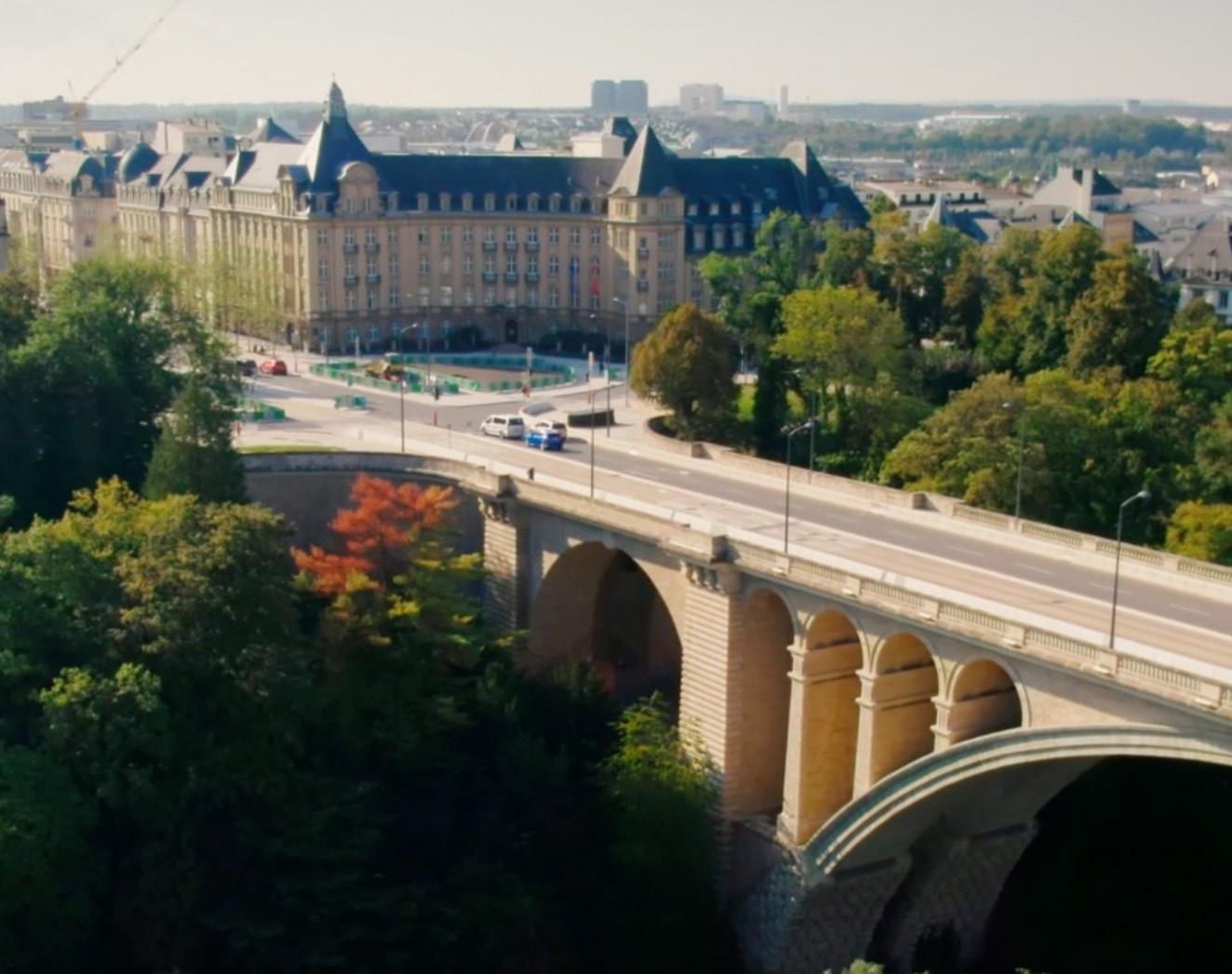

It was back in 2008 that Vodafone established Vodafone Procurement Company (VPC) in Luxembourg, aiming to service the procurement needs of all Vodafone entities across the group. The motive for the move was to bring the company’s scale to bear.

“Prior to VPC, Vodafone’s supplier partners had to negotiate with every single operating company and tell them that they had the best procurement deal on the planet,” says Ninian Wilson, who is both CEO of VPC and also Vodafone Director of Supply Chain Management. “They don't do that anymore. Now, they negotiate once for our suppliers, and we hold the price books for the whole company.”

Today, Ninian Wilson and his team manage a spend of around €24bn across the company, and, as well as marshalling spending with suppliers worldwide, it supports the needs of its operating companies and group functions, in addition to selling procurement services to third parties.

Ninian Wilson, Global Supply Chain Director & CEO of Vodafone Procurement Company, on why problems are an opportunity to create competitive advantage

Huawei green energy solutions aim to drive technology revolution for a better, greener future. Together with global customers and partners, by end of Jun 2022 Huawei energy solution has achieved:

Green Energy Generation: 588.5 billion kWh

CO2 Emission Reduction: 290 million tons

Equivalent to Plant: 390 million trees

Learn More

Huawei is using innovative solutions, including the development of solar panels and energy storage solutions, to help significantly reduce carbon emissions

With the help and support of Huawei, Vodafone has been a pioneer in implementing its net zero strategy.

To support its ambitious goals, Huawei has used a number of innovative solutions, including the development of solar panels and energy storage solutions in a number of countries, including Egypt and South Africa, in a move to significantly reduce Vodafone’s carbon emissions.

“Apart from its European networks achieving 100% electricity supply from renewable sources in 2021, Vodafone is also committed to making all its African networks 100% powered by renewable energy by 2025,” says Huawei’s Senior Vice President, Vincent Pang.

“The current energy crisis in Europe has resulted in sharp increase in electricity bills and energy shortage, which is severely impacting telcos’ operations,” adds Pang. “To overcome the challenge, we have developed innovative solutions at the equipment, site, and network levels to

support telcos reducing energy consumption throughout the life cycles of their networks.”

Huawei has been continuously working with the Carbon Disclosure Project (CDP) and has achieved industry-leading scores for consecutive years in scope 3 carbon emissions: indirect emissions that occur in a company’s value chain. And with the globalisation of supply chains in recent years, Huawei has managed key supply chain issues to support Vodafone’s requirements, maintaining steady operations and remained determined to invest for the future.

To maintain supply chain resilience against pressure and to ensure both business continuity and cost advantages, Huawei works closely with suppliers and partners, Pang says.“We do not rely on any single country or supplier, and all of our key products have alternative sources within our supply chain,” he adds. “Vodafone and Huawei are long-term strategic partners,” Pang concludes. “We are absolutely confident in our ability to continue providing Vodafone with high-quality products and services.”

Wind River discusses its work with Vodafone, to help in its efforts to build Europe’s first commercial Open Radio Access Networks.

Wind River – a global leader in intelligent edge software – is in the vanguard of businesses driving the digital transformation of mission-critical systems and advancing the new intelligent machine economy.

One of the areas where the company is helping usher customers into an everchanging future is telecommunications. “We’re constantly strategising operations for the future,” says Kevin Dallas, Wind River President and CEO.

An important area for Wind River in telecoms is its work with Open RAN (O-RAN). This is a new approach to building mobile networks. Traditional RAN solutions required telecoms operators to work with single suppliers, an approach that works against smaller vendors, who lack the financial muscle to build and manage RAN solutions.

Wind River is embracing O-RAN in its work with telecoms customers, and as a result of its contributions to O-RAN including the contribution of key open-source technology, the company has been selected by customers such as Vodafone for production deployment of 5G.

“We were thrilled to be selected by Vodafone, to help in its efforts to build Europe’s first commercial O-RAN, which will be one of the largest in the world,” says Dallas. “Vodafone believes this will be the catalyst for other large-scale O-RAN deployments, and spearhead the next wave of digital transformation across Europe.”

But as well as opportunities, new technologies also bring challenges, most of which concern system integration. Vodafone recently published a white paper on the challenges of O-RAN system integration, with a call to action for ecosystem providers to integrate much earlier.

“Instead of buying a single box from a traditional vendor multiple vendors in the ecosystem need to work together,” Dallas explains.

“Distributed networks are complex,” adds Dallas. “This is why our focus is on “providing ease of deployment, increased levels of automation and operational efficiency.”

VPC is also a joint partner (with the Luxembourg government) in Tomorrow Street, a technology incubator with which it shares the same office and whose successes help grow the Vodafone tech ecosystem with scale-up businesses on the leading edge of telecoms tech solutions.

VPC helps Vodafone leverage scale on procurement “The rationale of VPC was strong from the outset,” Ninian Wilson adds. “Not only did it save vendors money because they no longer had as many account managers, but it also leveraged our scale as a company and provided a focal point for the whole of Vodafone.”

The Vodafone Procurement Company’s team operates across four areas, including IT, Networks, Commercial & Services, and Devices. “In all of these we leverage scale

and hands-on expertise,” Ninian Wilson says. “The vision is to create the future of procurement with digital and pioneering practices, connected to experts worldwide.”

“

CEO, VODAFONE PROCUREMENT COMPANY AND GLOBAL SUPPLY CHAIN DIRECTOR OF SUPPLY CHAIN MANAGEMENT

TITLE: CEO OF VODAFONE PROCUREMENT COMPANY AND GLOBAL SUPPLY CHAIN DIRECTOR OF SUPPLY CHAIN MANAGEMENT

INDUSTRY: TELECOMMUNICATIONS

LOCATION: LUXEMBOURG

Ninian Wilson is CEO of Vodafone Procurement Company and Director of Supply Chain Management. He joined Vodafone on 1 June 2009 as IT procurement director and was appointed to the board of Vodafone Procurement Company in November 2009. From 2014 to 2016 he held the role of SCM Technology Director and was responsible for all technology sourcing in the company, including Networks, IT and new product development. In March 2016, he was appointed director of group SCM and CEO of Vodafone Procurement Company.

MarketPlace brings structural change to the way telecom operators SOURCE & MAINTAIN their networks by putting the CIRCULAR ECONOMY at the core of their business, resulting in efficiencies, cost savings & planet benefits. Our MarketPlace technology moves networks towards NET ZERO.

Shields CEO Daniel Jones explains how his company’s MarketPlace software platform helps telecom operators of all sizes save money - and the planet

The global telecoms industry faces critical challenges in the fight against climate change and the drive to introduce a more circular economy. Reducing greenhouse gas (GHG) emissions has become a global goal to mitigate climate change, and telecom operators have an important role to play.

Drawing on four decades of experience working in the telecoms sector, UKheadquartered Shields has developed MarketPlace, a cloud-based platform which allows telecom operators to realise financial, environmental and social benefits.

“The telecoms world is now only 8.6 per cent circular,” says Shields CEO Daniel Jones. “The contribution network equipment can make to achieve a circular economy is enormous.”

MarketPlace has been adopted by the leading international telecom operator Vodafone, active in more than 25 local markets. To date, the Shields platform has enabled at least €30 million of CAPEX saving from reusing refurbished equipment and more than €5 million of additional revenue generated from the resale of surplus network equipment. It has also saved more than 7,000 tons of greenhouse gas emissions during the process.

Shields had been offering circular economy services for a range of operators when they were first introduced to Vodafone UK in 1998.

The telecom giant was in the process of modernising network equipment, and Shields formed a relationship with Vodafone UK that enabled them to introduce a 3R principle: 1) optimise Reuse back to Vodafone UK,

2) Resell surplus Vodafone UK assets globally and 3) Recycle the delta with a zero landfill policy. This 3R policy adopted with Vodafone UK is the foundation of MarketPlace which has introduced a fourth ‘R’ and explores Group Reuse after local needs have been catered for.

“MarketPlace creates significant financial savings (avoidance) and generates new revenue streams, whilst at the same time reducing long lead times compared to new equipment. There is a positive business case that also saves the planet. It is a win-win-win for all telecom operators that embrace our MarketPlace solution, which they need in this highly competitive market,” says Jones.

Find out more

Open RAN provides an exciting opportunity for Operators and Vendors to collaborate in a more harmonious manner. While Operators get an opportunity to pick the sub-system components from different vendors aiming towards efficient technology, cost modelling and operability, vendors see this as an area to enhance their individual products or components, instead of building end-to-end traditional RAN models.

While Open RAN has led to a more open environment and expansion across vendors and ecosystems, it also has certain challenges, such as procurement. There are different models that operators are using to procure networks; the single-vendor model, in which all the risk is managed by a single entity that manages all the risks of multiple eco-system vendors, is one such model. The other model is procuring individual sub-systems, taking the responsibility to stitch the solution together and procuring professional services with limited liability. Each model has different implications on accountability, risk profile and commercial/ contractual conditions. From the seller’s

perspective, a risk premium is often defined to manage unknowns depending on the model. However, this can lead to Open RAN losing out as comparisons are often made with traditional RAN procurement models –a comparison that unfairly de-emphasizes the enormous benefits of Open RAN.

NEC has collaborated closely with Vodafone to contribute in the field of Open RAN; together we will build one of the largest commercial Open RAN networks in the world. The future of Open RAN is promising and challenging at the same time. To allow innovation to foster, we need to move forward steadfastly and with patience. In the short term, an investment led approach needs to be taken that doesn’t measure TCO on Day 0 and that doesn’t default to the vertically integrated solutions the market is accustomed to. This will give time for the benefits of virtualisation and cloudification to be realized, which will be the basis of building next generation networks.

Internally, its job is to support Vodafone, and, in so doing, it is also indirectly supporting Vodafone’s consumer and business customers around the world, whether these be large corporates or small companies.

Ninian Wilson says the Vodafone Procurement Company also has external customers to whom it provides procurement services.

“This is through what we call our Partner Markets Division,” he explains, adding that this team sells Vodafone products and services, including third-party procurement and supply chain support. “Our primary role is to make Vodafone successful and to provide it with competitive advantage,” Ninian Wilson goes on to remind us.

Ninian Wilson helps deliver competitive advantage to Vodafone Part of that competitive advantage is ensuring it works with the kind of suppliers who not only help the company mitigate

against supply disruption, but who also perform strongly on ESG requirements.

Before rubber-stamping suppliers to provide Vodafone with products or services, VPC vets them closely, assessing their commitment and performance on diversity and inclusion, the environment, and health and safety in areas where there is risk.

On ESG, Ninian Wilson says VPC has taken “a very strong and forward-looking position”, adding that Vodafone doesn’t just recognise diversity “but celebrates it”.

“We take every opportunity to ensure we create an inclusive environment for all and provide opportunities for thousands more across our supplier base,” he says.

“Diverse suppliers bring a huge positive impact to our businesses and, ultimately, to our customers. This is why we identify partners who embrace diversity in their workforce, and who influence companies in their supply chain to do the same.”

As a company, Vodafone says it believes that “the promise of a better digital future should be accessible to all” and is committed to “ensuring the more vulnerable are not left behind on that journey”.

“We help support Vodafone in this,” says Ninian Wilson. “We help it use technology to bridge divides in society, and to ensure people can contribute equally and fully to society. Our employees come from 50 nations, and we employ 36,500 women globally, so we understand what it means to have a diverse workforce.”

Prior to Vodafone, Ninian Wilson was Chief Procurement Officer with Cable and Wireless, as well as also being Operations Director at Royal Mail.

How did those challenging positions help shape him professionally?

“I learned a lot in the Cable and Wireless role,” he says. “It was my introduction not only to telecoms, but also to international procurement.” He enjoyed some of the

locations, too. “Most of our operations were in the Caribbean, so it was clearly a good job to have.”

At Royal Mail, Ninian Wilson says he had 158,000 people working with him or for him. “I learned a lot about what it takes to work with a huge workforce. It showed me the pros of my management style, but also the limitations.”

“Vodafone

DIRECTOR OF SUPPLY CHAIN MANAGEMENT

As a key partner of Vodafone Procurement Company, Netcracker is preparing the supply chain for a digital world.

etcracker’s portfolio of digital products is designed to help businesses, like Vodafone Procurement Company, innovate and automate their operations. By tracking data such as inventory levels and client payment history, companies can better understand their operational needs and ensure they are running as efficiently as possible.

Netcracker Digital Platform is made for the transformation to a digital world. With Netcracker Digital Platform, an open, modular digital-native solution, businesses can adapt quickly to changes in the market, stimulate innovation internally and maximize profitability from their investments.

“As we see an increasingly digital society, Netcracker is proud to be on the front lines of development for products that help businesses achieve automation,” said Bob Titus, CTO of Netcracker. “We want to enable Vodafone Procurement Company to fulfill its goals of autonomous procurement and reducing its carbon footprint as it takes the next step of its digital transformation.”

With cutting-edge data and analytics, Netcracker provides Vodafone Procurement Company with a competitive advantage in the marketplace. Netcracker Digital Platform automates every aspect of the operations environment within and across domains with embedded intelligence for zero-touch and self-management.

Netcracker addresses the digital transformation through:

outcomes

agility

collaboration

cloud operations

“In summary, Netcracker Digital Platform provides the tools and practices needed to deliver the digital future,” Titus said. “Our software accelerates business agility and stimulates innovation, enabling our customers to succeed in their automation goals.”

NINIAN WILSON CEO, VODAFONE PROCUREMENT COMPANY AND GLOBAL SUPPLY CHAIN DIRECTOR OF SUPPLY CHAIN MANAGEMENT

NINIAN WILSON CEO, VODAFONE PROCUREMENT COMPANY AND GLOBAL SUPPLY CHAIN DIRECTOR OF SUPPLY CHAIN MANAGEMENT

“I like to be on first-name terms with everyone though, obviously, it's difficult to remember everybody's name. But you meet some wonderful people from very diverse backgrounds; I think you bring all that knowledge and those experiences with you when you take on a role like mine at a multinational company like Vodafone.”

Vodafone Procurement Company has seen many changes Ninian Wilson joined Vodafone in June 2009, and he has seen many changes in the years since. “Back then, the procurement team in

“Diverse suppliers bring a huge positive impact to our businesses and, ultimately, to our customers”

Luxembourg numbered 150 people, whereas today it is more than 400 people,” he says. “We've scaled operations in that time, but I also think its role is now more than being about just managing procurement activity. We're also managing physical logistics activity, such as warehousing distribution and supply chain for our network equipment. Obviously, we're also managing risk and building a more-resilient supply chain.”

The focus of VPC may have shifted over the years but the core of the business remains procurement, “making sure we get the right requirements from our

internal clients and that we have the right engagement with our supply partners”, Ninian Wilson says. “The core is the same but everything else around it, in terms of context, has changed.”

When asked what is his biggest challenge currently, Ninian Wilson replies by saying he sees challenges as opportunities, and adds with a wry grin: “Let’s just say there have been far more opportunities over the past three years than I expected.”

He adds: “But certainly I'm hugely proud of the work the team has done to get us through two years of pandemic. I think

the pandemic for us has been a defining moment for teamwork, collaboration, and getting things done together. Although, during that time we had never been physically further apart from one another, we had never felt closer. I felt it pooled the entire company together.”

It also changed the way VPC works, with hybrid working now the norm – something Ninian Wilson feels is “good for our people and good for our company”.

The pandemic also saw Vodafone offer staff the ability to work abroad for periods of time “which a number of our employees and colleagues have taken advantage of this year” according to Ninian Wilson, who then states how it has “changed the dynamic of working”. He does admit that, as part of this changing dynamic, hybrid working asks different questions of his managerial style.

“Managing people remotely is different to bumping into them at the coffee machine and having an informal chit chat,” he says. “I do miss that, but we're working hard to make sure we make hybrid working as productive for both the person and the company as possible. We've just about got the balance right but we're still learning.”

The Vodafone Procurement Company’s team has done ‘amazing work’

As well as his team’s sterling efforts during lockdown, Ninian Wilson says that his team has done “amazing work” battling microchip shortages across Vodafone’s operations, in the face of demand for microprocessors massively outstripping supply.

And supply problems continue apace, with geopolitical turbulence and inflation compounding pandemic woes.

“We've now got the impact of the Ukraine War, and yet more uncertainty in supply chains,” Ninian Wilson says. “I would say the biggest challenge we face today is creating more agile supply chains, which can flex as they meet ongoing challenges.”

“Supply as a sector takes a long time to change and ways of working tend to be quite embedded. So, making them more agile is certainly a challenge, but it also provides us with opportunity if we get it right.”

Asked what he feels VPC’s defining strategy is, Ninian Wilson says that no procurement or supply chain team can have a separate approach to the overriding company strategy.

“As a company, Vodafone’s strategy is to help society digitise, to be a more inclusive employer and to work really hard on sustainability,” he says. “This is a very

purpose-driven approach, and we’re strongly aligned to this, in that we’re adopting and driving a purpose-driven approach as a procurement organisation.”

Achieving this, he says, comes down to “how VPC builds relationships” with key partners and key suppliers “as well as how we transform our physical logistics and supply chain activity, and how we utilise all our great people to bring that strategy to life over the coming years”.

As Solution Engineering and Customer Engagement Principal at Aera Technology, Jennifer Chaplain not only implements Aera’s core technologies, she also designs decision intelligence workflows for global companies. Aera Technology was founded in 2017 with a vision to transform the future of work through decision intelligence. The company’s cloud platform integrates with existing systems to automate business decisions in real time, enabling global enterprises to gain agility and respond to disruption.

Among many other accomplishments at Aera, Chaplain led the implementation of the first-ever operational procurement solution on a decision intelligence platform.

A passionate evangelist of data science and machine learning in enabling predictive, self-healing supply chains, Chaplain guides

WRITTEN BY: ILKHAN OZSEVIM Jag Lamba, Founder of Certa, & Jennifer Chaplain, Solution Engineering & Customer Engagement Principal at Aera, on the Intelligent Procurement Revolution

customers in transformational projects so their systems can react to supply issues autonomously and in real time – including communication with n-tier suppliers and contract manufacturers.

Digital transformation and rise of intelligent procurement

Intelligent procurement solutions are the future because, to put it simply, there will always be more decisions to be made. And those decisions will continue to grow more complex while the window of opportunity in which to make them shrinks.

Chaplain says: “Procurement teams are on the front lines, protecting companies from supply chain risk in addition to reducing

costs. Yet, today, we see many procurement teams in continual ‘triage’ or ‘firefighting’ mode – dealing with disruptions and challenges to the extent that they lack time for strategic planning or collaboration.

“Planners react to shifts in demand that happen more rapidly than before; buyers react to more frequent disruptions, while finance guards against purchase price variances (PPVs) and impacts on revenue. The number of decisions that must be made daily force these professionals to be reactive rather than proactive.”

In this environment, dashboards and traditional methods of monitoring trends and making decisions aren’t enough. Procurement teams need intelligent solutions that can augment and automate day-to-day decisions. This will allow not only the team, but the entire enterprise, to be more responsive and strategic in a fasterpaced business environment.

Jag Lamba, Founder and CEO of Certa, agrees. Certa is a supplier and risk management software provider that takes the complexity and opacity out of working with third parties. According to Lamba, “procurement needs to have its hands in a number of different systems for these various functions”.

“It will fall to procurement to take the leading role in ESG initiatives”

JAG LAMBA, FOUNDER AND CEO, CERTA E

“To prevent being bogged down by the inefficiencies of disparate software and systems, intelligent procurement capabilities can integrate and automate all of these non-spend functions in a way that creates transparency and efficient workflows.”

The many benefits of Intelligent procurement Intelligent procurement solutions capture the causes of deviations between budgeted and actual spend, the decisions made and the outcomes of those decisions – in context and in real time. This technology reduces risk by helping procurement teams

make informed decisions more quickly in the face of changing conditions.

Chaplain says: “An ideal solution leverages data science as well as digital technologies to understand the business, recommend actions, predict outcomes and take action by writing back to source systems.

“Technologies that leverage decision intelligence enable procurement teams to harness the data inside their enterprise systems across the business to predict deviations, notify buyers, and automate important decisions – such as changes to supplier mix – within defined parameters.”

Companies that have implemented these solutions have revealed opportunities to cut costs while also improving visibility and facilitating collaboration among suppliers, contractors, and customers.

“Another big advantage that is worth focusing on,” says Lamba, “is the benefit intelligent procurement platforms can bring to companies' ESG (environmental, social, and governance) initiatives.

“With up to two-thirds of a company’s emissions coming from its supply chain, procurement will be crucial in gathering, analysing and reporting emissions data across units.

As Solution Engineering and Customer Engagement Principal at Aera Technology, Jennifer Chaplain implements Aera’s core technologies and designs decision intelligence workflows for global companies.

- Jennifer Chaplain, Solution Engineering & Customer Engagement Principal at Aera

My role is to guide our organisation as we help our customers do good business –by which we mean being able to be confident that the suppliers you work with are quality organisations that align with your values and mission – and manage our suppliers with transparency

- Jag Lamba, Founder and CEO of Certa

“That process will be even more difficult and time-consuming if procurement doesn’t have an integrated, intelligent platform letting them collect emissions from multiple sources and store them efficiently.”

Within the next two to five years, procurement teams will be forced to move from relying on processes and transactional recording systems (which often only show what happened in retrospect) into an environment that demands an ‘always on’ memory of decisions made, their contexts, and their outcomes.

“This digital record will be critical to strategy,” says Chaplain, “particularly as environmental, social, and governance (ESG) mandates require companies to measure and justify the impacts of procurement decisions. When we consider how many organisations still rely on spreadsheets, emails, or phone calls to track decisions and outcomes, the value of this technology is very apparent.

“In addition, decision automation helps procurement teams focus on the high-value, strategic decisions that deliver competitive advantage. Using predetermined rules and predictive logic to automate decisions that a person would have made reduces the team’s operational workload and allows those professionals to focus on their areas

of expertise, such as strategy, contract management, and negotiations. Relieving teams of those ‘firefighting’ responsibilities in turn allows companies to adapt and compete in this new environment.”

Intelligent procurement allows organisations to consider more variables in purchasing and supply chain decisions, allowing them to choose a course of action more quickly.

Optimal procurement decisions must consider data such as customer orders, safety stock, total cost of ownership, and on-time in-full (OTIF) performance. This equips companies with the capability of balancing risk, cost, and quality through the application of AI and machine learning, as well as data harmonised from across enterprise systems.

This allows, for example, a company to choose the best potential supplier for a given sourcing need, while monitoring spend and ensuring adherence to budget. Chaplain says: “Or consider that, with traditional procurement processes, a yearend deviation between budgeted spend and actual spend leaves staff working to understand the cause of the discrepancy. By contrast, today’s technology makes it possible to track performance versus budget on an ongoing basis, record decision outcomes, and make adjustments as needed.

“With this technology, companies can mitigate risks by breaking down the silos that hide process gaps. Moreover, companies can readily adjust strategic sourcing and contracts to consider changing market conditions or supply-chain threats whilst mapping both decisions and outcomes to business objectives.”

What does 2023 hold for intelligent procurement processes?

“In 2023,” says Chaplain, “we expect to see more executives at large organisations adopting decision intelligence platforms; siloed data, slow purchasing processes, and lack of visibility to supplier inventory positions are making it difficult to keep up with the pace of change.

“Despite advances in supplier collaboration tools, too many key communications or decisions still take place in offline channels – phone calls, emails, or occasional faxes. Technologies that leverage AI and machine learning to digitise and automate decision making across business functions and processes allow companies to detect a risk, generate or change purchase orders (POs), monitor for PPV, send approvals to managers, and release POs to suppliers in minutes or seconds, as opposed to hours or even days.”

Lamba adds: “Overall, I expect 2023 to be the year we see a large uptick in the adoption of intelligent procurement platforms –driven largely by the above factors. Those factors introduce a lot of risks, something that intelligent procurement functions are designed to mitigate.”

Future innovations in the intelligent procurement space

Advancements in digitised decisionmaking are not only providing actionable intelligence and measurable results –they’re showing procurement teams that they no longer have to rely on methods that aren’t allowing them to be competitive.

“It’s no longer reasonable for users to interact with multiple systems to process POs, negotiate contracts and analyse data,

then generate all the insights,” Chaplain says. “Realising that there are new ways of doing business is as important as the technology innovations themselves.”

Lamba believes that 2023 will be the year of ESG. “As the procurement function has evolved, those teams don’t just

manage spend, they now manage carbon footprint and more,” he says. “It will fall to procurement to take the leading role in ESG initiatives, or at the very least serve as the central hub for all the data required to tackle ESG initiatives to be sourced, stored and shared with the right parties.”

“Procurement teams are on the front lines, protecting companies from supply chain risk, in addition to reducing costs”

JENNIFER CHAPLAIN, SOLUTION ENGINEERING & CUSTOMER ENGAGEMENT PRINCIPAL AT AERA

PRODUCED BY: CRAIG KILLINGBACK

PRODUCED BY: CRAIG KILLINGBACK

From empty terminals in 2020, to serving over 50 million passengers in 2022, Heathrow Airport has weathered some mighty turbulence in recent years. Now the UK’s hub airport is building back, Heathrow’s procurement team stands ready to ensure the airport’s growth is efficient, responsible and meets the needs of every passenger

From the outside, running a procurement operation with the size and variety of London Heathrow airport is an incredibly complex challenge. For Paul Doherty – the Procurement Director at Heathrow Airport –and his team, their job becomes clearer when they focus on the most important person in the building.

“The passenger is central to everything we do, every decision that we make and every project that we launch. Every operational change or operating procedure that we do has the passenger at the centre of those decisions,” he says.

With passenger numbers steadily climbing back higher, a hundred thousand priorities are walking through the terminal doors every day, each of whom need to be given the best possible travelling experience.

‘It is really important to us that, from the moment the passenger enters the airport, their holiday starts. So we want them to be comfortable, we want them to be enjoying the experience that they have,” he says.

Paul speaks passionately about customer care, about how every member of staff at the airport should support a passenger if

they see them in any form of confusion or discomfort. That mantra permeates right from the very top of the executive team down to all of Heathrow’s colleagues - including the airport's operators via their service signatureswhich provide a framework for the passenger service proposition, to notice and care, share what they know and ensure the passenger’s problem is resolved before they leave.

This is just an example of the variety of tasks that present themselves daily in what Doherty describes as a ‘city of services’, which features an enormous range of diversity regarding what they have to deliver on a huge scale.

“I've just come off of a call talking to someone who is at the party conferences, understanding the political landscape. Later on, I'm going to go and talk about cleaning performance in one of our terminals. This afternoon I'm going to talk about algorithm development and security products.”

Because of the incredible breadth of the services he speaks about, becoming a “specialist at being a generalist” is a given –there are few jobs where you can start your day dealing with politics and end with cleaning regimes, successfully able to pivot between the two as well as engage with everything else within that. It also necessitates having experienced people in post who can cope with operating under the pressures of one of the busiest airports in the world.

PAUL DOHERTY PROCUREMENT DIRECTOR , HEATHROW

“ The passenger is central to everything we do, every decision that we make and every project that we launch”

A world class player in the mobility market, committed to empowering the freedom to move everyday thanks to safe, reliable, sustainable and innovative solutions that serve the common good.

Contact us

Rebecca Mupita, MD of Transdev Airport Services, says the future for the company will be green, and connected to local Heathrow communities

Rebecca Mupita is Managing Director of Transdev Airport Services and CCH Aviation Logistics, both of which are part of the Transdev Group, whose core function is delivering multimodal transportation services.

Mupita and her colleagues are based a stone’s throw away from Heathrow Airport, and provide innovative, sustainable passenger transport and fleet maintenance solutions for the aviation sector. “We deliver solutions that are aimed at providing clients and customers with complete transparency, so that they better understand their operational demands,” she explains. “With this insight, we can identify and tailor the right solutions to support.”

As well as managing and maintaining complex airport fleet and equipment, Mupita and her team provide scheduled and on-demand transportation services and manage airport bus and coach stations. Tailoring its services and solutions is just part of the company’s transformation journey,

as it continues its recovery from a brutally tough pandemic. “Covid hit Transdev very hard,” says Mupita. “It decimated the aviation industry.” In the post-pandemic era Transdev is not just rebuilding, but is “rebuilding green”, says Mupita.

“Reducing emissions is at the heart of our sustainability measures,” Mupita adds. “We are currently planning to deploy a new electric fleet at Heathrow Airport, and through our new technologies we are also designing passenger services that reduce unnecessary transfers, while enhancing the passenger experience.” And, she adds, the company will also continue to extend its outreach initiatives, working with local schools, colleges, and universities, looking to find the next generation of ‘journey makers’.

“We’re increasing our apprenticeship schemes to develop young talent,” says Mupita. “Typically, logistics isn’t a career young people think about going into. But we are looking to change that.”

Doherty speaks on the transformational challenges – caused in part by the pandemic – that Heathrow have undergone while continuously modernising and embracing new security technologies. “Our new security solution means you won't have to take your laptop out of your bag,” he says. “You can go through security and just put your bags through a scanner. It’s a much less intrusive journey.”

“We talk about a frictionless passenger journey, and it's just like a good doctor in the NHS: when you need us, we're there.”

Doherty’s route to being Director of Procurement started in a very different, but also incredibly demanding form of transport.

He worked in operations at the London Underground for seven years, but says he always found getting into the capital space appealing and, ultimately, took on a more junior role at Heathrow to expand his personal skill-set. From there, he progressed through different projects, including the airport's role in hosting London 2012 Olympics arrivals, baggage categories, heading up terminals and, when the pandemic arrived, closing down aspects of the capital portfolio before moving into the operational environment to focus on cost reductions and supplier management.

“We did that as caringly and as responsibly as we could with our capital supply chain partners, many of whom are still with us and working. Following that, I went over

Paul Doherty is the Procurement Director at Heathrow Airport, responsible for Operational, Infrastructure and Technology procurement.

Paul’s accountabilities centre around meeting the airport’s current and future business needs. His teams are focused on delivering value for money, data-driven insights and trusted advice to both internal and external stakeholders. Paul is passionate about empowering his teams to target continuous improvement and delivering results to advance the talent of the procurement team.

A constant focus for Paul is working with our supply chain partners and local community to ensure Heathrow’s strategic sustainability goals and targets are achieved to maintain the airport's licence to operate.

Where our data experts pinpoint where you can make the biggest carbon savings to accelerate your path to net zero.

This is the Science of Service

This is just the star t

mitie.com/scienceofservice

The exceptional, every day

Mitie prioritises decarbonisation and takes a flexible approach to sustainability through its Plan Zero, which supports its partner Heathrow Airport

As the UK’s leading facilities management and professional services company, Mitie is determinedly working on not only its own decarbonisation journey, but also supporting partners including Heathrow Airport. As Mike Sewell, Mitie’s Plan Zero Director, says, “if an organisation wants to drive real change in decarbonisation, it absolutely should be front and centre for their facilities management providers to be the party that’s helping them on that journey”. For partners like Heathrow Airport, Scope 3 includes their supply chain, which includes Mitie. Sewell’s approach to partner support is simple: “Just by operating better ourselves, we’re already helping reduce their Scope 3 emissions— and that applies to every single customer that we work with”.

Mitie has “committed to having net zero, from a Scope 1 and Scope 2 perspective, by 2025 and Scope 3 by 2035”. Mitie’s industry-leading Plan Zero initiative has three key focuses: eliminate carbon emissions from power and transport; eradicate non-sustainable waste; and enhance inefficient buildings.

For example, Sewell says that within Mitie’s operations the majority of emissions sits in our use of vehicles: “We’ve focused our efforts on decarbonisation of our fleet together with connected workplaces where we’re actually looking at better data connectivity, where we can actually monitor sites, understand sites and deal with things remotely.”

Mitie’s latest ESG report highlights its progress, centred around five pillars: Environment, People, Community, Responsible Supply Chain and Innovation. Among its sustainability successes Mitie reports a 33.4% reduction in emissions since the FY19/20 baseline year and how it has cut 11,445 tonnes of CO2 by investing in electric vehicles (EVs).

By prioritising its own decarbonisation journey, Mitie put itself in the best position to support partners and proactively work to reduce its impact.

As Sewell states: “Decarbonisation: it’s not a challenge for one organisation, one customer. It affects us all.”

1944 - Construction of London Airport's runways begins 1946 - London Airport Officially Opens

1955 - Her Majesty The Queen opens the Central Terminal Area and Control Tower 1966 - London Airport renamed ‘Heathrow’ 1969 - Terminal 1 opened 1976 - Concorde makes its first passenger flight 1986 - His Royal Highness Prince Charles and Princess Diana inaugurate Terminal 4 1987 - The British Airports Authority is privatised as BAA plc 2003 - Three Concordes make their final touchdown at Heathrow 2007 - A new air traffic control tower is operational – the tallest in the UK 2008 - Terminal 5 officially opened by Her Majesty The Queen 2009 - Major refurbishment of Terminal 4 2014 - New Terminal 2 re-opens 2015 - Terminal 1 closed 2016 - Heathrow celebrates 70th anniversary

to our operations teams to support them in removing the costs that we needed to be able to continue operating through the pandemic,” he says.

It resulted in him being offered the Director of Procurement in 2021, a role for which Doherty thinks the breadth of his experience across both the capital and operational sides of transportation has positioned him well, as having both pillars of experience gives a better, more holistic outlook on the role.

“I always knew the benefit of broadening my portfolio. I had relative success at quite a young age in the operational space and knew that to actually really understand the business, you need to understand both the capital and the operational side of the company,” he says.

The pandemic presented all sectors with genuinely unprecedented challenges, and Doherty believes that the legacy of that time is the biggest single challenge facing all airports: passenger numbers at Heathrow had consistently climbed in the decade leading up to the pandemic, before dropping to 22.1 million in 2020. This created a situation when scale had to be quickly changed to cope with a 73% decrease compared to 2019, while still keeping planes in the sky and passengers happy.

“Speaking as a Procurement Director, the pandemic is the primary challenge. Aviation took a substantive knock during the pandemic period that we have to take care of over the coming three to four years. It’s not just the debt in terms of commerce, it’s the debt in terms of having had to make difficult decisions around assets, services, our service proposition, our security proposition; having had to slow down pieces of work to make them affordable means that we now need to speed them up to make them deliver.”

“The playbook for the pandemic didn't exist. The thing that makes the UK proud

about Heathrow as a piece of national infrastructure is that we run at a capacity that no other airport, globally, runs at. We run at 98% across our two runways, we have more air traffic movements during the day, we move and turn aircraft around quickly. We have operating procedures for if we have a busy day, we have an operating procedure for if something goes wrong during a day –we have an operating procedure for most things. Yet this isn't operating procedure, this is managing demand in a different way.”

Strategic partners and pillars to posts

With demand fluctuating rapidly during the most acute months of the pandemic –followed by a gradual return to more familiar capacity levels – there has been pressure to scale engagement with suppliers and service providers around the Heathrow

“ We talk about a frictionless passenger journey, and it's just like a good doctor in the NHS: when you need us, we're there”

environment. This operates alongside a project called the Heathrow Partner Balanced Scorecard, which helps the procurement team choose the best strategic partners and convey the strategic aims of the business for prioritisation.

“It focuses on five main pillars: carbon reduction, social value inclusive of accessibility, inclusion and diversity, opportunities for local business, innovative solutions and behaviours. And that’s not just behaviours

“ The thing that makes the UK proud about Heathrow as a piece of national infrastructure is that we run at a capacity that no other airport, globally, runs at”

in terms of business-to-business behaviours, but also the behaviours between our supply chain and our passengers, should they encounter them, and also behaviours towards sustainability. So Heathrow’s role is incredibly influential and important in the supply chain, persuading them to contribute towards our aims.”

He describes the intention of creating a ripple effect with their partner organisations and the supply chains that support them, but making sure that that whole ecosystem is made up of organisations with sustainable practices built into their DNA as a service

provider, rather than simply raising their game to be part of the Heathrow environment.

“We are really keen that companies bring to bear, here at the airport, the best of what they're doing centrally. An account director reporting here at Heathrow, for example, will contribute towards their central numbers as a business.“

Doherty speaks about how the needle has moved rapidly on the subject of sustainability, due to matters such as the London living wage that are now built into contracts, yet wouldn’t even have been a discussion point a decade ago. He describes how sustainability is now a ‘licence to operate’ at an airport and how, if you do not have those strategies in place, it’s difficult to be part of the operation.

“It’s quite exciting how sustainability has kicked on and matured. It's absolutely the case that it is going to grow, not diminish. As an airport, we have to accept that we are historically polluters, so we have to take a responsible view of that. And we have an executive right now passionate about being responsible.”

These advancements in sustainability, and how it is inextricably linked to the supply

At Vanderlande, we’re committed to delivering sustainable solutions in every aspect of our operations. We do not want to do this alone, which is why we seek collaboration with our suppliers and customers like Heathrow Airport to maximise the impact of our efforts throughout the value chain.

When it comes to sustainability, there’s no doubt that close collaboration enriches discussions and allows all partners to learn from each other and align activities that support each other’s sustainability goals.

Want to know more? Read the blog about our partnership for sustainability with Heathrow Airport.

Learn more:

chain and procurement operation, play a pivotal role in Heathrow’s sustainability strategy. Heathrow 2.0 is their plan to connect ‘people and planet’ and to work to build a better, more sustainable airport. The broad strategy includes net-zero aviation, creating a great place to live and work, and having responsible business foundations. It’s a piece of work that shows how far the airport has come since they took the step to publish their first environmental policy back in 1992.

There is a raft of commitments from Heathrow to make them a better neighbour to both their locality and the wider environment. They are committed to cutting carbon in the air by 15% compared to 2019, their ground level emissions by an even more ambitious 45% and an air-side ultra-low emission zone by 2025 for all operational vehicles. The targets also include doing even more for the region in which they operate, providing 10,000 external jobs, apprenticeships and career opportunities for local people, as well as 15,000 workplace experiences.

This strategy also aims to have a positive impact throughout the sprawling sphere of influence the airport achieves via its strategic partners, being part of the London Living Wage Foundation and a good neighbour to other local businesses.

“I also personally have an objective to grow our small to medium-size enterprises from

2019 levels,” he says. “There are a number of initiatives and schemes we are doing both in the local chambers of commerce and through business summits to help us achieve those aims.” A statement that demonstrates Heathrow and its procurement team's passion passion to deliver on the commitments it has made.

Lessons to carry into the future and beyond It is this culture of collaboration that Doherty feels is the best route to building mutuallybeneficial relationships between Heathrow and their strategic partners. If they are working with other organisations who can innovate and deliver more than would normally be expected, they can produce better and wider outcomes than the ceiling setting a defined target could engender. He believes the biggest piece of learning for the whole management team was for them not to mandate but to collaborate, as they do not just want their partners to deliver up to a set limit, but instead to bring the best of what they can deliver to the airport, with a level of quality that is centrally ingrained within the business.

“We go back to the mantra: ‘if you can make it work at Heathrow, you can make it work anywhere’.”

Ultimately, Paul Doherty returns to the key purpose of every operational decision the airport makes, which is the experience of every person who walks through the terminal door with a suitcase in hand.

“The way in which we work with our supply chain is to always make sure that we are listening, collaborating and challenging ourselves to make sure that we don't miss the opportunity to get something even better for ourselves, for our passengers and for our airport community and stakeholders.”

–

–

Ash Finnegan, Digital Transformation Officer at Conga, reveals that most organisations attempting digital transformations

Ash Finnegan is currently digital transformation officer at Conga, which provides end-to-end solutions to help organisations transform their revenue operations (RevOps) and navigate business complexity. In her role, she works directly with customers and partners to execute these programmes in-house.

Drawing upon her 20-year-strong experience as a digital transformation consultant, she has spearheaded the development of a unique framework that empowers organisations to understand the revenue operations’ landscape and successfully tackle their transformation journeys. This assessment ensures organisations implement technology at a pace that they are ready for, only incorporating solutions that drive real business outcomes.

are missing the point entirely

“This is an industry-leading framework, and it is now utilised by Conga’s entire frontline, partner network and global customer base, including 11,000 organisations, such as Accenture, PWC and Adobe,” she says.

Digital transformation maturity landscape for procurement Finnegan says: “The day-to-day supply of goods and services has become increasingly challenging over the past few years. The emergence of new risks and increasing market pressures – such as global supply chain shortages, price increases and inflation – have meant that procurement teams have had to accelerate their digital transformation initiatives to cope. Digital change programmes have become a necessity to overcome the challenges of cost control, supplier relation securitisation and supply chain traceability.

According to PWC’s recent Global Digital Procurement Survey 2022, digital transformation is now considered a top business priority. In fact, 77% of companies

“Employees need to see digital transformation as an opportunity rather than a challenge to be overcome”

are now equipped with source-to-pay digital solutions, while 50% of procurement leaders believe digital transformation will be a major focus for the next few years.

Though digital transformation in procurement offers many benefits such as cost control, supply chain traceability, and risk mitigation, that doesn’t mean it’s easy to implement a company-wide strategy – only 36% are successful.

“While recent events may have accelerated companies’ digital evolution or change programmes,” says Finnegan, “it’s still very much in its infancy. There are plenty of lessons to be learnt, particularly when leaders are looking to harness as much data as possible to make far more accurate

strategic decisions for their organisation.

“Looking ahead, procurement departments will be setting ambitious digitalisation targets for next year. Teams will be looking to maximise their operational efficiency and will need to ensure that they are making the right digital investments for long-term gains.”

Challenges for successful digital transformation Finnegan says: “Too many leaders are focused on the ‘hype’ around digital transformation, prioritising technology over strategy, simply picking the latest digital solution and implementing at speed, in an attempt to keep up with their competitors

ASH FINNEGAN DIGITAL TRANSFORMATION OFFICER, CONGA“Too many leaders are focused on the ‘hype’ around digital transformation, prioritising technology over strategy”

– with no real idea of how this will improve their operations or services. This presents a great risk to their business and any future DX initiatives.

“As the pandemic has proven, most transformation projects are extremely complex and tend to be rushed. There are so many teams, processes and systems involved – many of which are siloed or disconnected, resulting in serious operational complexity, inefficiencies, and data leakage.”

Organisations have to get their data in order before committing to a transformation programme. All systems, data and processes need to be aligned, and leaders need to ensure all workflows are fully optimised

before implementing a solution – especially if hoping to use a specific new tool to make major strategic decisions for, or changes to, their organisation.

Putting people at heart of transformation crucial Digital change programmes fail when organisations treat them as ‘technology change’ projects, rather than ‘people change’ projects.

Effective digital procurement transformation is all about the connections between people, processes and technology. Most falter due to lack of employee and departmental preparedness amid poor communication.

“Change is often made without considering the teams involved and how it will affect their job role,” says Finnegan. “Leaders need to consult and reassure teams that technology is, in fact, their ally and explain how a particular digital solution will help them in their roles.”

It’s often best practice to discuss change programmes across departments prior to implementation – leaders may be unaware of current processes or inefficiencies, while

employees can offer valuable insight into how communication and data-sharing could be improved across teams.”

of company culture and employee buy-in

Putting people first matters. True digital transformation involves rethinking the connection between people, processes and data, establishing a pathway that connects them all together. Moving forward, leaders

“True digital transformation involves rethinking the connection between people, processes and data, establishing a pathway that connects them all together”

ASH FINNEGAN

OFFICER, CONGA

need to consider their employees when establishing their integration plan and approach it in a phased manner.

“They need to ensure that all their employees understand what they’re trying to achieve,” says Finnegan, “but, most importantly, they need to get their buy-in and ensure that they’re on board well before implementation. Company culture is critical to the success of any digital transformation programme.

“Technology exists to make their lives easier; employees shouldn’t feel like their jobs are at risk, or that they are not performing well. Leaders should prioritise re-skilling employees, and clearly defining job roles. Employees need to see digital transformation as an opportunity rather than a challenge to be overcome.”

It’s difficult to accurately measure the value of digital transformation in procurement, since it is a continuous journey. There will always be a new way of working – a new technology or tool – or ways of doing business. Leaders need to be smart and match digital solutions to real strategies that improve procurement performance.

Finnegan says: “Organisations should ideally focus on identifying existing operational issues and reviewing legacy systems before making any serious investments.

“By streamlining their operational models, companies will have far greater insight into data streams and into problems that need to be rectified. They will be able to establish the next stage of their procurement digital transformation journey, but there needs to be measurable impact. Given budget constraints, it’s important that leaders only purchase solutions or services that they can utilise, and that will improve their operational performance.

“The real value here is when procurement teams can establish whether they are leveraging all of the data at their disposal. They should have far greater visibility of their revenue and data streams and be able to identify other areas of improvement. Only then, will they be able to make strategic decisions for their organisations, which leave them far more agile and adaptable to any given outcome.”

Brutally honest. That’s a phrase that springs to mind when talking procurement transformation with Sue Spence – Vice President, Global Sourcing & Procurementat FedEx Corporation.

Drafted in by the shipping and transportation giant a little over nine years ago to build a centralised sourcing and procurement operation from scratch, straight-talking Spence wasted little time in making a big impression.

“One of my favourite phrases is ‘begin with the end in mind’,” she says. “My approach to designing the future state of sourcing and procurement at FedEx was to first define what world-class looked like for our function. We came up with seven characteristics of a bestin-class organisation and then gave ourselves a brutally honest assessment (red, yellow, green) on how close or far apart we were from those characteristics. There was a whole lot of red back in 2013, but by 2018, it was a whole lot of green.”

Let’s just put the scale of the task Spence faced into perspective. In fiscal year 2022, FedEx delivered 3.1 billion packages. That is almost 8.5 million packages per day, delivered globally, by plane, train and truck. Over 550,000 people work for FedEx, literally juggling billions of moving parts, schedules and itineraries.

FedEx Corporation, on driving the organisation’s procurement

SUE SPENCE VICE PRESIDENT, GLOBAL

SUE SPENCE VICE PRESIDENT, GLOBAL

A great deal of that US$17bn annual Spence spend goes on fuel, and when there is disruption in the supply chain, like during the Colonial Pipeline cyber attack, it would be easy for FedEx operations to slowly run out of gas – were it not for robust risk assessment in the organisation’s supply chain. This is where Spence – and the sourcing and procurement team she has shaped – really shows her value.

Prior to joining FedEx, Spence had a 28-year career with United Technologies Corporation, in positions of increasing responsibility at the aerospace divisions of Pratt & Whitney, Hamilton Sundstrand and Sikorsky Aircraft as well as a key leadership role in Sourcing at the UTC Corporate office. She had multiple roles of traditional procurement, strategic sourcing as well as managing continuous improvement for both the assembly and maintenance and repair operations at Pratt & Whitney – experience that has proved invaluable in her FedEx role.

“Take a leap of faith and be more confident in your abilities. There is never a perfect time to go for the big job or challenge”

SOURCING & PROCUREMENT, FEDEX CORPORATION

“My time managing continuous improvement taught me the criticality of the measurement system as well as ‘learning to see’ through process mapping, root cause and corrective action, and especially in business processes where there is so much opportunity to streamline,” she says. Spence brought that methodology to FedEx, which proved an extra challenge as she was an ’outsider’, but also gave her the distance from the company to see a clearer route forward. But when you are tasked with building a world-class procurement team, what are you looking for? Spence is quick to list: demonstrating category expertise; managing effective stakeholder relationships; making decisions based on data, not emotion, and monitored by a robust measurement system; focusing on process improvement to increase productivity; raising the bar on performance for both suppliers and employees; and leveraging spend across the entire book of business you have with your suppliers. Recognising that this is a Herculean task for an organisation as complex and vast as FedEx, it’s also essential to proactively develop and manage the existing talent on your team. And that’s just for starters.

TITLE: VICE PRESIDENT, GLOBAL SOURCING & PROCUREMENT AT FEDEX CORPORATION

INDUSTRY: FINANCIAL PACKAGE FREIGHT DELIVERY

LOCATION: UNITED STATES