6 minute read

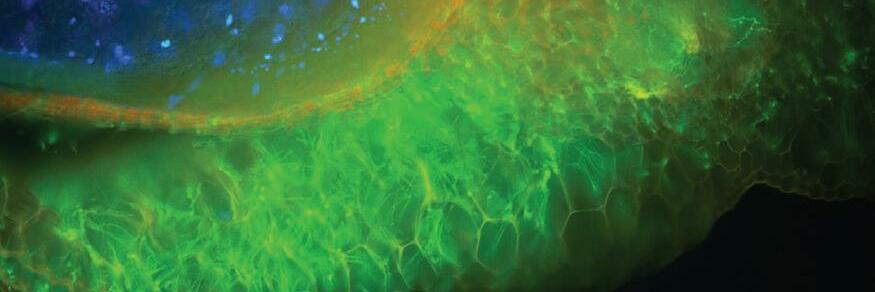

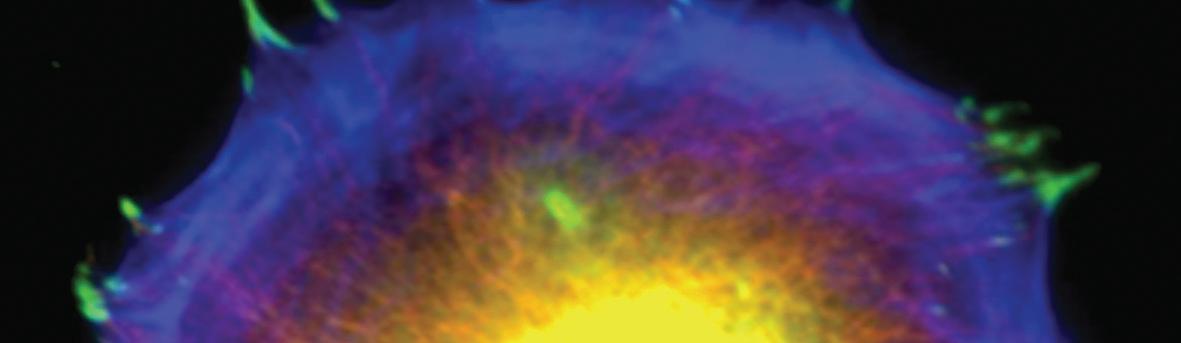

WHERE MATERIALS MEET BIOLOGY

Wound-healing bandages? Germ-repelling doorknobs?

Advertisement

Think of doorknobs that repel bacteria, bandages that heal wounds, home test kits for cholesterol, and contact lenses that rarely need changing.

These are the kinds of technologies being developed at the McMaster Biointerfaces Institute, which offi cially opened its doors in April, 2013.

The $22 million institute – the fi rst of its kind in Canada, and among the fi rst in the world – will use high-throughput synthesis and screening technologies coupled with advanced surface characterization methods to provide a new understanding of the nature of the biological/material interface, or biointerface for short.

Investigators at the lab will test millions of combinations of biological agents and complex surfaces, in pursuit of rapid solutions to stubborn health, safety and other problems.

Leading researchers from a variety of disciplines will use the sophisticated, biosecure facilities to effectively sift through entire haystacks at a time in search of the proverbial needle.

Work that had taken weeks in the past can now be done in hours.

John Brennan, Canada Research Chair in Bioanalytical Chemistry and Biointerfaces, and the Director of the Institute, can’t hide his enthusiasm when talking about the potential outcomes.

“We already have researchers working on more comfortable contact lenses and ondemand diagnostic tools for just about (any condition) you might want … We are looking at a lot of exciting things along those lines,” he said.

Simply put, Brennan and other researchers at the Biointerfaces Institute are able to make both materials that have biology built into them and materials that resist interactions with biology.

His colleague, Fred Capretta, an associate professor of chemistry at McMaster and a principal investigator at the Biointerfaces Institute, echoes Brennan’s enthusiasm. He estimates the lab’s robotic systems and advanced microarray printing and assaying tools can test the reactions of tens of thousands of biological samples against a variety of materials every single day, allowing them to “look for multiple needles in multiple haystacks at the same time.”

Capretta explains it like this. “Traditionally, you’d take a biological sample and surface that you think might work, put them together and study them. If that doesn’t work, you discard that surface and you move on to your next surface.”

But that was then and this is now.

“What we’ve decided to do in this lab is high throughput, and that means doing things many times, very quickly, hundreds and thousands of samples at a time,” he said.

Another McMaster colleague, biomaterials engineer Heather Sheardown, is using the Institute’s high-tech capabilities to experiment with materials designed to improve eye health, including how the eye reacts to contact lenses.

Sheardown confi rms that bioengineered lenses could eventually allow people to wear their invisible glasses for longer periods of time, more comfortably. That could eventually mean “the end to eye dryness” associated with contact lenses, she said.

The Institute received funding from multiple sources – the Canadian Foundation for

Innovation, Ontario’s Ministry of Research & Innovation, and support from a number of industry partners, including Bruker Canada, Tecan, Physical Electronics, Scienion, Air Liquide and Pro-Lab Diagnostics.

The provincial and federal investments were based on the knowledge that the facility’s research will ultimately improve the health and economy of Ontario and Canada.

This message was loud and clear at the offi cial opening of the Institute at McMaster University.

“This is the sort of progress the world needs more of,” said Reza Moridi, Ontario’s Minister of Research & Innovation.

“The Ontario government is proud to support McMaster’s new Biointerfaces Institute,” he said. “The world-class research being conducted here could lead to a new generation of medical devices and diagnostics that work with the human body, strengthening Ontario’s innovation economy and improving our quality of life.”

It was a similar sentiment from the Government of Canada, represented by MP David Sweet. “Our investments helped establish this state-of-the-art facility and set up a unique training program in the development of biointerfaces that will create jobs and longterm economic prosperity for all Canadians.”

Canada Foundation for Innovation’s president and CEO, Gilles Patry, added that, “without world-class research and access to state-of-the-art equipment, we simply can’t do the research that attracts the world’s attention.”

Attracting that attention will come easier as the Institute begins to commercialize its technologies.

While it’s still early days, Brennan – who has kept a watchful eye over the centre he envisioned and has seen grow from concept to completion – is certain that commercializing some of the Institute’s technologies is not far off.

“We’ve got test strip technology for E. coli and pesticides that we’ve brought to a fairly advanced stage and we’re working with a number of industry partners to move that out of the lab,” he said. “I expect that will be among our fi rst success stories.”

While doing his own research and conversing with colleagues from other disci-

plines, Brennan recognized the need for this kind of facility – a one-stop biointerface shop, if you will, where industrial and academic researchers have both the equipment and data at their fi ngertips.

That equipment includes dozens of machines, but among them are two robots and two advanced microarray printers that are considered to be “the heart” of the lab. Specifi cally, these robots and printers will help the researchers to test surfaces in parallel and, very quickly, tell them if it has the components or the reaction for which they are looking.

The data, however, is much more farreaching.

“One of the main things we’re working on right now is creating the global Database of Biointerface Interactions, or DBI, and to link this in with all the big standard databases, like PubMed, GenBank, and Swiss-Prot,” said Brennan.

“Our intent is to mine all of the biointerface literature that’s ever been written and catalogue it. On top of that, all of the data that we generate at the Institute will also go into the database.”

Brennan, recognized as a global leader in his fi eld, is also working with clinicians to develop a strip that will rapidly identify the cause of respiratory exacerbation, separating asthma patients from patients with infection in mere seconds.

He believes that the new facility gives McMaster University the opportunity to become the global leader in biointerfaces research and a place that will be accessed equally by industry and academics alike.

“We want this project to be the basis for a much larger set of initiatives,” he said. “We want to be able to spin companies out of it. We want to create a national centre for biointerfaces. We want academics and industry researchers in Ontario and beyond to be

using it. We want, and we very much plan, to be the global leader.”

Brennan estimates that, in fi ve years or so, several hundred students will have gone through and graduated on into groups that are affi liated with the Institute. He expects they should have several hundred papers published, dozens of patents, several licenses and more than a few spinout companies.

To learn more about McMaster’s Biointerfaces Institute, please visit: www.biointerfaces.mcmaster.ca

Fred Capretta (right), a principal investigator in the Biointerfaces Institute talks about the state-of-the-art lab with Ontario’s Minister of Research & Innovation, Reza Moridi (far left), and McMaster University’s president, Patrick Deane (centre).

— John Brennan

To see this story online visit http://biotechnologyfocus.ca/ mcmaster-university-opens22m-biointerfaces-institute/