64 minute read

Announcements/Releases

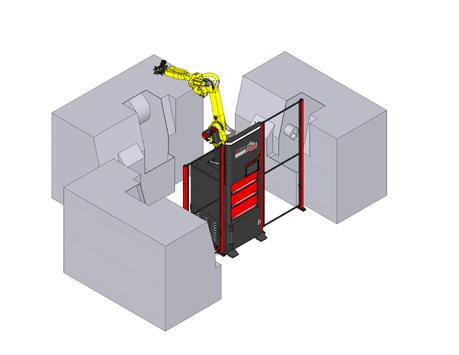

Mobile Collaborative Robot Increases Shop Capacity Fast

Pre-engineered for delivery in as quickly as ONE WEEK.

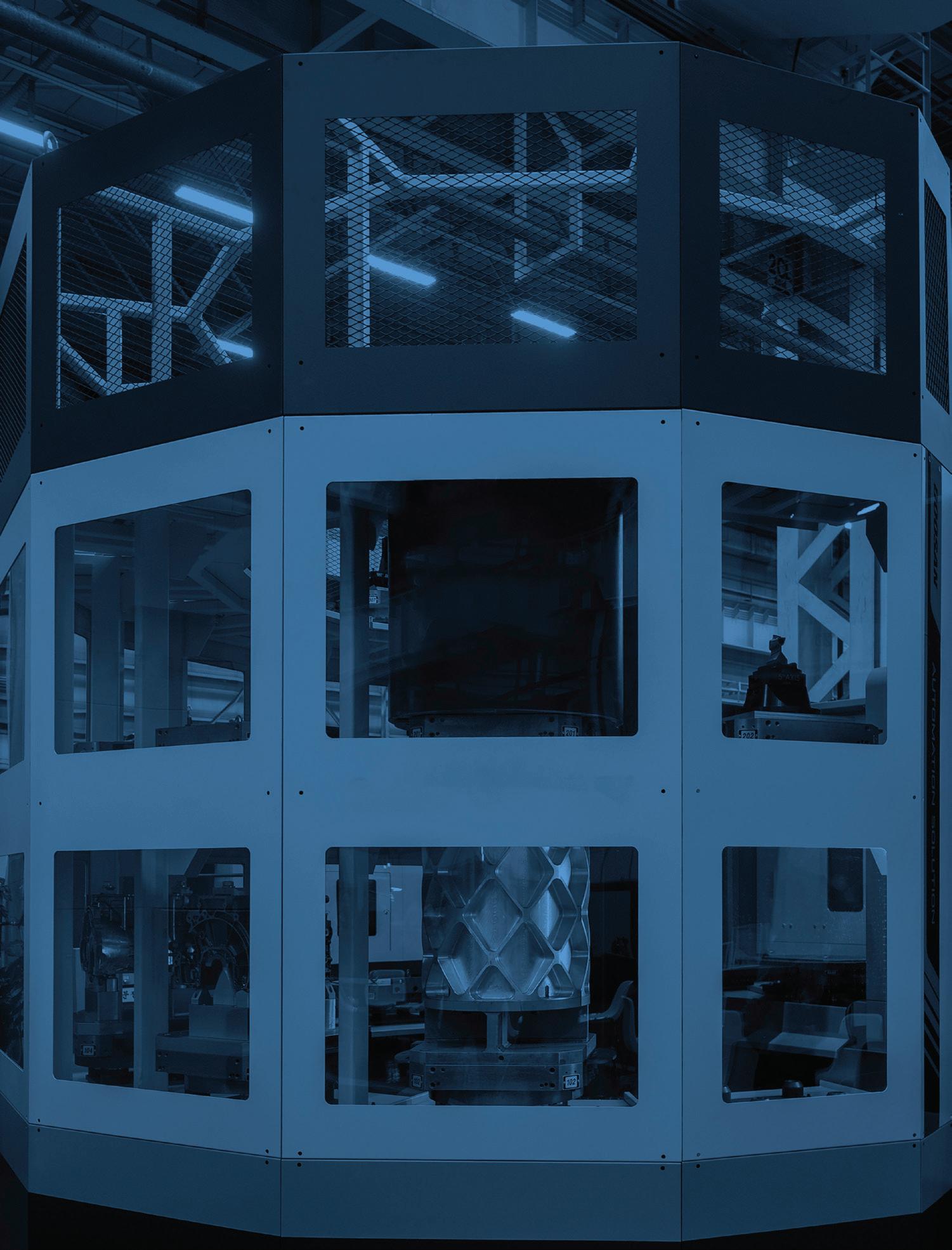

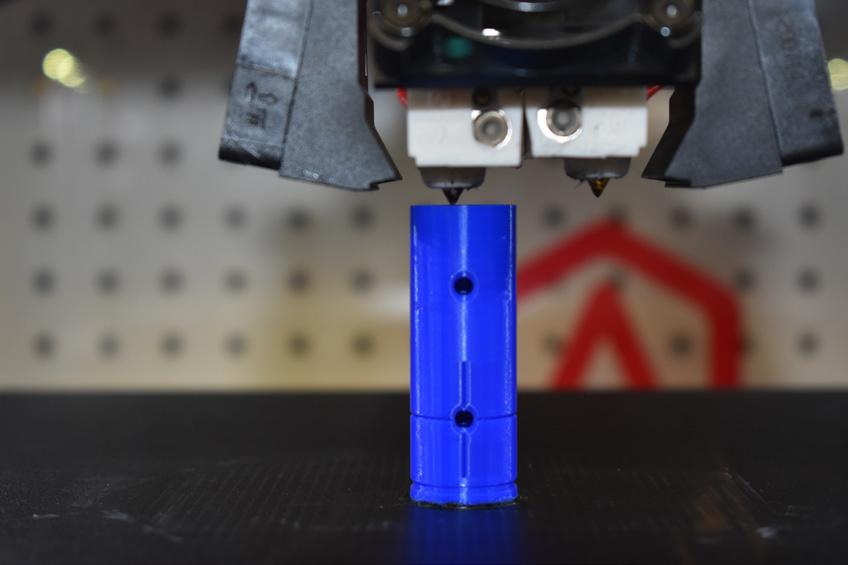

Now is an especially challenging time for machine shops facing capacity shortfalls and labor shortages. To address these struggles, Acieta introduced its simplest to use, most flexible cobot solution ever: the FastLOAD CX1000 collaborative expandable robotic cell.

To prevent shop equipment from sitting idle, the FastLOAD CX1000 is mounted on a mobile platform that one worker can move easily so it can be quickly set up at different machines around the shop. The system is equipped with a FANUC 10KG, 120 V collaborative robotic arm to master material handling tasks. It can be outfitted with up to three modular carts to handle a wide variety of parts or allow more parts in the queue.

“The FastLOAD CX1000 is pre-engineered to meet the most common machine tooling needs so it’s ready for delivery and installation within one week,” said Jake Corning, Product Manager at Acieta. “With the benefits of higher throughput and lower operating costs, users see a return on investment in 6 to 12 months, based on 2 shifts.” An intuitive touch screen interface makes programming very simple. Setup is quick and easy. The FastLOAD CX1000 has a small footprint and doesn’t require safety fencing, so it takes up approximately 80% less floor space than a traditional robotic cell.

Operators work beside the FastLOAD CX1000 to load and unload parts while the robot works continuously on up to two machines, thus doubling throughput. Force sensors stop the robot when pressure is applied, ensuring a safer application for the operator.

“Giving the dull and repetitive tasks to robots allows employers to reallocate skilled workers into more challenging and valuable jobs such as quality control and parts design,” Corning said.

For more information about the FastLOAD CX1000, visit acieta.com/ cx1000 or call 844-4-ACIETA.

About Acieta: A leader in the robotics business for nearly 40 years, Acieta provides a wide range of robotically automated solutions and services for the manufacturing industry. With locations in Waukesha, Wis., and Council Bluffs, Iowa, Acieta has integrated more than 5,000 automation systems for customers across the United States, Mexico

and Canada. As part of its mission to be a true partner to its customer base, Acieta is committed to solving challenges facing all manufacturers, such as lowering costs, increasing productivity and addressing labor shortfalls. Learn more at:www.acieta.com.

Acieta is a leading FANUC Authorized System Integrator and member of the RIA Certified Integrator group.

We Are The Best Bender In The US & We Have Best Website To Prove It!

Our New website is live! www.albinaco.com What does that mean for you?

• Create a Customer login to allow you to: • Edit customer contact information • View Past orders • View Picture Vault Images of your jobs • Order component parts • Read our weekly Blog highlighting recent projects and news worthy stories. • View videos and pictures of the various materials we bend, the bending methods we use, and the types of supplemental fabrication projects we do. • View Professional Images of Award Winning Architectural &

Structural projects, as well as see OEM parts installed on their end use products. • Download our staff’s .vcf file in one click to add Albina contacts to your Address Book. • Utilize the custom Bending Calculators to make your bending calculations a piece of cake. • Download a free copy of the Curved Member Design Guide. • Read intriguing Technical Articles featured in various national steel publications. • Download Brochures.

And so much more! We always like to say we are the Best Bender in the nation, now we have the Best Website to back that up!! Go check it out!

Estimating / Project Managers: Aaron Hughes: ahughes@albinaco.com Joe Daniels: jdaniels@albinaco.com Mark King: mking@albinaco.com Jason Orefice: jason@albinaco.com Production Manager/QAM: KC Lesch: kl@albinaco.com Traffic Manager/Purchasing: Ben Ingersoll: bingersoll@albinaco.com VP of Sales:, Brad Lund: blund@albinaco.com President Brian Smith Albina Co., Inc. Phone: 503-692-6010 Ext. 105

STEEL ALUMINUM STAINLESS COPPER NICKEL YOUR METAL BENDING EXPERTS

CONSISTENT, ACCURATE & REPEATABLE PARTS

TANKS FOOD & BEVERAGE COILS

HEAT EXCHANGERS PIPE SPOOLS

AUTOMOTIVE PARTS AGRICULTURAL PARTS ALTERNATIVE ENERGY

MARINE PARTS LOCOMOTIVE PARTS AVIATION PARTS

AQUATIC PARTS PLAYGROUND EQUIPMENT

HIGH PURITY CLICK HERE FOR COMPANY DIRECTORY!

https:// www.albinaco.com/about/contact (503) 692-6010

BOB KROHA

ROB KROHA

CNC AND MANUAL MACHINERY SINCE 1979 New - Used -Appraisals - Auctions

CONTACT US TODAY: 510-249-1000, PERMACH.COM

Our Showroom At: 3305 Edison Way, Fremont, CA 94538 Is Open Monday - Friday From 8am To 5pm

Announcements Continued

our local communities. financially or growing business, but by expanding our visions outside ourselves and businesses into our communities. Flatline Fabrication Inc. in Portland, Oregon has done just that by creating their DESKSHARE Program.

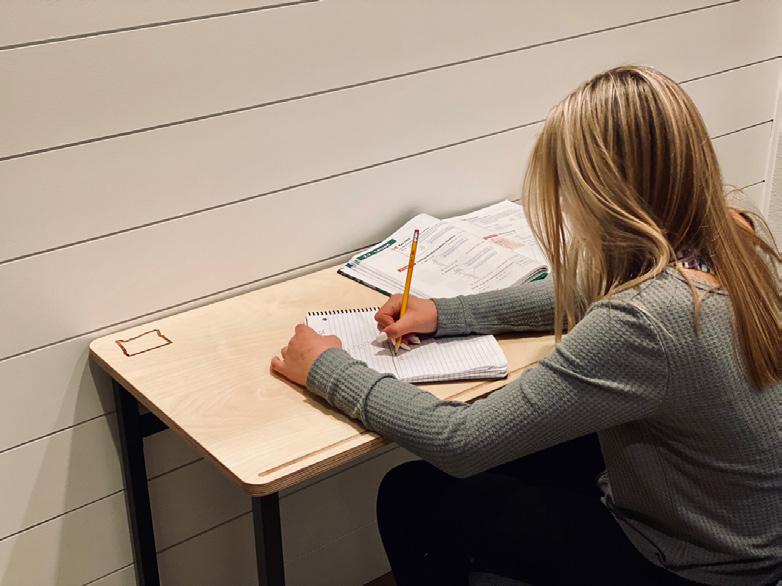

During statewide school shutdowns, parents were thrust into schooling their children from home. They quickly realized their young students worked and learned better when in a dedicated learning environment rather than the haphazardly revamped kitchen or coffee table. With those issues in mind co-owner Steve Fuller and the Flatline management team developed a program to increase the effectiveness of home schooling.

In a collaborative effort, the management and design teams at Flatline created a solution by designing an inexpensive but very personal desk – a young person’s own special learning place where they can have ownership in their learning experience. These desks are intended for donation to low-income households and students with special needs. It is true many school districts have reopened. But there are still many under served young people being schooled from home and the need for their personal creative learning environment still exists.

The DESK-SHARE program has enabled Flatline to not only benefit families in local communities, but also avoid catastrophic layoffs by keeping their valuable employees working on a worthy cause. Flatline Fabrication Inc. is sharing in the manufacturing costs so these desks can be affordably donated to needy students in

Desk Share – A Philanthropic Program

By Stephen M. Hannemann

Last year 2020 was remarkable in many ways. COVID-19 forced many of us in business to think in creative terms to not only survive but how to thrive. By thrive, I don’t necessarily mean The cost of donating a desk is just $220. Flatline is looking for creative ways to expand this program into other states and we are asking people to contact their local school boards and community organizations to help locate sponsors and students who would benefit from this program. To donate a desk, or for more information about this remarkable program call Josh Henry, 503.707.9272 or email josh@flatlinefabrication.com.

Visit Flatline Fabrication Inc., 4322 NW Yeon Ave., Portland, OR 97210. For an appointment to visit call, 503.477.7566 or visit www.flatlinefabrication.com.

Inslee Signs Business Tax Relief Package, Boosts Unemployment Benefits

By Tony Lystra

Gov. Jay Inslee on Monday signed a business relief package that curbs unemployment taxes while expanding unemployment benefits for workers.

SB 5061, which was requested by the governor and approved with strong bipartisan support in both chambers of the state Legislature, relieves employers of individual benefit charges for unemployment claims that occurred during the governor’s “Stay Home, Stay Healthy” lockdown order, which lasted from March 22 to May 30.

The bill also caps certain tax rates through 2025 and will prevent a $1.7 billion increase in unemployment taxes over the next five years. The Legislature curbs more than $920 million in rate increases this year alone, Inslee said.

The legislation also alters the state’s Voluntary Contributions Program, allowing employers to buy down rate increases even further, the governor said.

In a blog post, Inslee called the legislation, the first bill to pass during this year’s legislative session, “a critical piece of the state’s Covid-19 recovery plan.”

The legislation won the approval of the Washington Hospitality Association, which has been a vocal critic of Inslee’s move to close restaurants to indoor dining throughout much of the pandemic.

“The hospitality industry has been hit the hardest by this pandemic, and on behalf of the hundreds of thousands of employees and thousands of businesses that have been impacted, we are grateful this is the first bill this session the Legislature and the governor have taken action on,” said Anthony Anton, the association’s president and CEO. “Historic relief is on the way for workers and businesses, and SB 5061 sets the groundwork for additional relief efforts underway.”

STACKS ON STACKS

Ready for an unstoppable money-making tandem? This is the NHP 5000 with RPS.

On its own, the NHP 5000 is a powerful 40 taper, 500mm pallet horizontal machining center. But when teamed with the stackable multi-level Rotary Pallet System (RPS), it becomes legendary. With a compact floor layout and vertical structure, the RPS keeps you running lights out—without taking up valuable square footage. And if projects change constantly from month to month, JIT scheduling on the RPS cuts setup times like 15,000 r/min cuts aluminum.

The 3-tier, 21-pallet RPS is the perfect partner for the massive metal removal of the NHP 5000. So buckle up, because you’re about to produce day in and night out.

WASHINGTON/OREGON Sales: (253) 872-1661 Service: (253) 246-0130 Parts: (888) 207-2787

NORTHERN CALIFORNIA Sales: (866) 814-7238 Service: (800) 994-0146 Parts: (888) 207-2787

SOUTHERN CALIFORNIA Sales: (562) 949-8311 Service: (866) 576-1125 Parts: (888) 207-2787

www.ellisontechnologies.com |

The Washington State Labor Council and the Association of Washington Businesses also voiced their support.

The bill was sponsored by Sen. Karen Keiser, a Democrat who represents Burien, Normandy Park, SeaTac, Kent and Des Moines. She noted, also in the governor’s blog post, that before the bill employers were facing having to pay increases of 300% to 500%. The legislation raises the minimum unemployment benefit payment to $270 per week from $201 for low-wage workers. It also allows those who quit working during a public health emergency because of personal health risks for themselves or their household members to receive unemployment benefits.

Rep. Mike Sells, D-Everett, who sponsored the companion bill in the House and is chair of the Labor and Workplace Standards Committee, Continued P age 11

noted that the legislation “does not solve everything.”

Here’s What’s Next For

Amazon’s Jeff Bezos

WE BRING YOU MAGIC!

Full Fabrication Utilizing ALL Materials! From Design, To Laser Cutting, Forming, Welding, To Finishing And Full Assembly

Bezos said he’ll turn his attention to his other initiatives, including Blue Origin, his space travel enterprise, The Washington Post, which he bought nearly eight years ago, and various environmental and social equity projects.

• Blue Origin: Blue Origin is Bezos’ Kentbased space enterprise, which aims to make spaceflight cheaper and safer. Like its competitor, Elon Musk’s SpaceX, Blue Origin builds reusable launch vehicles. Launched in 2000, company’s vision includes establishing a permanent moon base and the establishment of floating space colonies.

The company also aims, according to its website, to harness space’s “unlimited resources and energy.” Bezos has called the company his “most important work.”

•TheWashington Post: Bezos purchased the paper, which famously broke the Watergate story during the Nixon administration and, during the same era, published the Pentagon Papers, for $250 million in 2013. Bezos shifted the paper’s strategy from regional coverage to direct competition with The New York Times, which covers national and international news.

Post Executive Editor Marty Baron, who is stepping down this month, told the New Yorker last week that Bezos “actually believes in the mission of journalism; that he thinks it’s really important for a democracy; that he believes in democracy quite firmly; and that he thinks it’s important to have an institution like the Washington Post and to make sure that it has a bright future, has a sustainable business model, and can do its work properly.”

• The Bezos Earth Fund: Bezos has called climate change “the biggest threat to our planet.” He launched the organization last year to fund nonprofits preserving the natural world. In November, the $10 billion fund announced its first 16 grant recipients, including The Nature Conservancy, Natural Resources Defense Council, World Resources Institute, the World Wildlife Fund and the Environmental Defense Fund.

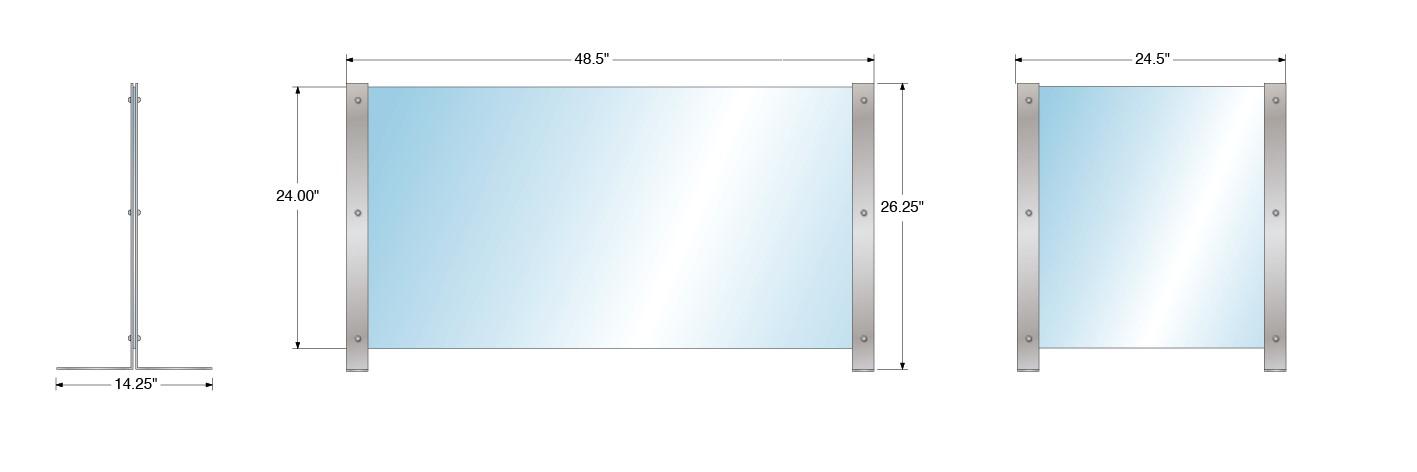

COVID 19 SNEEZE GUARDS, QUICK, SAFE, HIGH QUALITY

CALL TODAY TO PLACE YOUR ORDER: 503-477-7566

existing non-profits that help families experiencing homelessness. The organization draws its inspiration from Mary’s Place, an organization fighting homelessness, for which Amazon opened a 63,000-square-foot shelter on its South Lake Union campus last year. The Day One Fund also builds what it calls Day 1 Academies, which are full-scholarship, Montessori-inspired preschools located in underserved communities. The first academy opened in Des Moines, Washington, in October. It offers year-round programming, five days a week, and serves children between the ages of 3 and 5.By Tony Lystra

Arcimoto Preps For Expansion With $10.25M Eugene Property Deal

•The Bezos Day One Fund:The organization provides grants to nonprofits helping homeless families and is launching a network of preschools in low-income communities. The $2 billion fund provides grants to

Your partner for innovative manufacturing

REVO®—the 5-axis revolution

In nite positioning and synchronized 5-axis motion provide measurement access at unprecedented speed and accuracy. Our newest solution—the RFP fringe probe—expands our family of multisensors further. It adds non-contact structured light inspection to our revolutionary 5-axis measuring system that already includes tactile scanning, touch-trigger, surface nish and vision probe solutions.

www.renishaw.com/revo

Renishaw Inc West Dundee, IL

© 2020 Renishaw plc. All rights reserved. usa@renishaw.com

CMM Revo Half Page Final.indd 1 deal to purchase a manufacturing site five times the size of its current plant in Eugene, the electric vehicle maker announced. The heart of the property, a couple of blocks east of Arcimoto’s headquarters and factory, is a 155,630-square-foot industrial building occupied now by Pacific Metal Fab.

Arcimoto will need to outfit the building for its purposes, but CEO Mark Frohnmayer said that as a manufacturing facility “it has really good bones for the type of operation we are.”

The purchase from RLH Holdings is scheduled to close at the end of March. The contract allows Pacific Metal Fab to rent back the building for up to six months before it moves into a new facility of its own.

Frohnmayer said Arcimoto’s goal is to be doing “meaningful production” at the 311 Chambers St. location by the end of the year.

“We’re really stoked,” Frohnmayer said. “This facility is in a great spot, the timing is incredibly good as far as when it’s available and when we’ll need it. It gives us the space we’ll need to ramp up.”

Arcimoto has been inching production back up after a pandemic interruption and supplychain issues, with a goal of building four vehicles per day on a four-day workweek by the end of March. But it’s also working on design and production refinements in the hope of scaling to an annual output rate of 50,000 vehicles — driving down costs and prices in the process — by the end of 2022.

A fast-rising stock in 2020 put Arcimoto in position for moves like this; the company raised more than $53 million after expenses and commissions in a series of direct offerings at ever-higher share prices, despite the stock dilution. By Pete Danko – Portland Business Journal

4/6/2020 2:04:17 PM

Why The Covid-19 Economic Recession Is Accelerating Workforce Automation

A recession accelerating automation might seem counterintuitive. With high unemployment, labor is more available and less expensive. However, past recessions have taught us that automation is not a steady, linear process.

Instead, automation happens in spurts. Employers seek to offset declines in revenue but replacing less-skilled workers with a combination of technology and higherskilled workers. The shift increases labor productivity

UNIQUE DESIGN. PRODUCTION DELIVERED.

FT-150 FIBER

SMALL TO MEDIUM DIAMETER TUBES

U-AXIS

PROPRIETARY U-AXIS

Stellar cutting speeds and superior part accuracy are achieved through the unique and proprietary U-Axis.

B-AXIS

2.5D CUTTING HEAD

B-Axis enables bevel cutting provides improved welding, multi-tube assembly, fit and finish. EXTRUSION-TAPPING

The process of direct tapping can be combined with extrusion to offer proper thread depth. PROCESS ENHANCEMENT

Spatter guard, part sorting and weld seam detection options offer upgraded tube production.

www.faheyinc.com | 503.620.9031

going into the next economic cycle. [1]

The classic example of automation is the use of robots in auto manufacturing. Increasingly, automation is impacting jobs far from the production line. In office and clerical jobs, automation has changed the way workers collect and process data. In communications, automation is changing the way business advertise and stay in touch with customers. Lawyers, fast food workers, longhaul truckers, and customer service are just a few of the jobs that are already being reshaped by automation.

The EMSI Automation Index measures the potential for automation of common tasks within a given profession. On this scale 100 is average. An occupation with a score of 120 or more has a high risk of automation and anything above 130 has a very high risk of automation.

In the Portland-Vancouver-Hillsboro metropolitan statistical area (MSA), there are 28 occupations (55,500 jobs) at very high risk of automation. All of these occupations require no formal education or high school diploma. Nineteen of these occupations have workforces that are 90% male or more. The impact of automation varies across industries. Some industries, like community and social services have a low ranking on the automation index. Jobs in these industries will remain relatively safe from changes brought by automation. Other industries, like production, transportation and material moving, and office and administrative support have higher rankings on the Automation Index. Workers in these industries will be more vulnerable to job loss.

This doesn’t mean that 55,500 people will lose their jobs. Rather, that is the number of people who are currently working in professions that are at high risk of automation. Over time, the way work is organized and performed in these occupations will change at an accelerated rate. This will lead to occupations shrinking through attrition and reduced hiring.

In the Portland MSA, 28 occupations have a score of 130 or more on the Automation Index. This means they are at very high risk of automation. Currently, just under 55,500 people are employed in these occupations. The vast majority of these jobs, 94%, require no formal education. However, 11 percent of them pay a median wage that is above the regional median. And some of the lower paying jobs in this category are steppingstones to the higher paying jobs.

The impact of Covid-19 related closures is apparent in the current labor market data. The industries with the highest scores on the automation index, including food preparation and serving, construction, and production, have all experienced year over year job loss, representing 8 to 28 percent

Biden Set For ‘Buy American’ Push To Boost Domestic Manufacturing

US president Joe Biden is set to tighten “buy American” provisions as part of a push to boost domestic manufacturing, in a move that risks straining relations with key US allies.

Mr Biden is on Monday expected to order an increase in domestic content requirements for federal procurement contracts, following a campaign pledge to boost the US manufacturing industry as he aimed to outflank Donald Trump in key swing states.

However, America’s top trading partners and strategic allies, including Canada and a number of European countries, have long complained that buy American measures are a protectionist attempt to shut out their multinationals from the US economy.

Biden administration officials laid out the changes to US federal procurement rules in a call with reporters, saying it marked an effort to rebuild “the backbone of America”. manufacturing and our industrial strength, and a big piece of that is centred around the idea that when we use taxpayer money to rebuild America we buy American,” said a Biden administration official. “We support American jobs, union jobs.”

Mr Biden is expected to order an increase in domestic content requirements for federal contracts, a $600bn industry, as well as crack down on waivers that are routinely allowed for the use of foreign suppliers.

Administration officials said Mr Biden would also reiterate his support for the Jones Act, which requires goods shipped within the US to be transported on American vessels. They say this could help “invest in building offshore renewable energy and put Americans to work doing it”. US allies in Europe have long pressed Washington to repeal the Jones Act to allow greater competition in the shipping sector.

Mr Biden’s arrival in the White House has been broadly welcomed by America’s western allies and some of his early actions have been cheered. These include the decisions to rejoin the Paris climate accords, halt US withdrawal from the World Health Organization and scrap the entry ban on citizens of several Muslim-majority countries.

One exception was his decision to revoke the permit for the Keystone XL pipeline connecting the US with Canada, which triggered unhappiness north of the US border, particularly in the energy-

producing western provinces.

Mr Biden’s early move on procurement is also likely to be criticised in the capitals of several US allies, including Canada, because it will cement concerns that the new administration is not interested in returning to an agenda of liberalisation in trade and investment, after four years of Mr Trump’s trade wars.

Mr Biden and members of his team have frequently said that securing trillions of dollars of new federal investments in the US economy are the priority before new trade deals are considered. In conversations at the weekend with Boris Johnson, the UK prime minister, and Emmanuel Macron, the French president, Mr Biden emphasised his desire for cooperation on issues such as climate change, but there was no mention of trade, according to the White House accounts of the calls.

One Biden administration official said the US administration was “very committed to working with partners and allies to modernise international trade rules to make sure we can use our taxpayer dollars to secure investment in our own countries”.

He also said tighter procurement could help build the resilience of US supply chains, given the weaknesses that emerged during the pandemic, so “we are never put in a position where we are reliant on countries who don’t share our interests to deliver critical materials”. James Politi – Financial Times

Metalformers Starting To Feel A Little Optimistic About The Economy

Metalformers are starting to feel some optimism about the economy, according to the most recent Business Conditions Report from the Precision Metalforming Association.

The Independence-based association’s January report found that 39% of respondents expect economic activity to improve in the next three months, an increase from the 34% who thought that in December.

“Metalforming manufacturers continue to make the products essential to keep the engine of our economy running during the COVID-19 pandemic,” association president David Klotz said. “While members expressed optimism that business conditions would improve, great challenges remain, including the current record high prices for steel and supply-chain problems that are causing low steel inventories as supply tightens.”

Few companies had workers on short-time or layoff — just 12% — and 56% reported actively expanding their workforce. More respondents — 43% this month compared with 39% in December — reported that average lead times were longer than they were three months ago, though most (54%) said they were the same. By: Rachel Abbey McCafferty

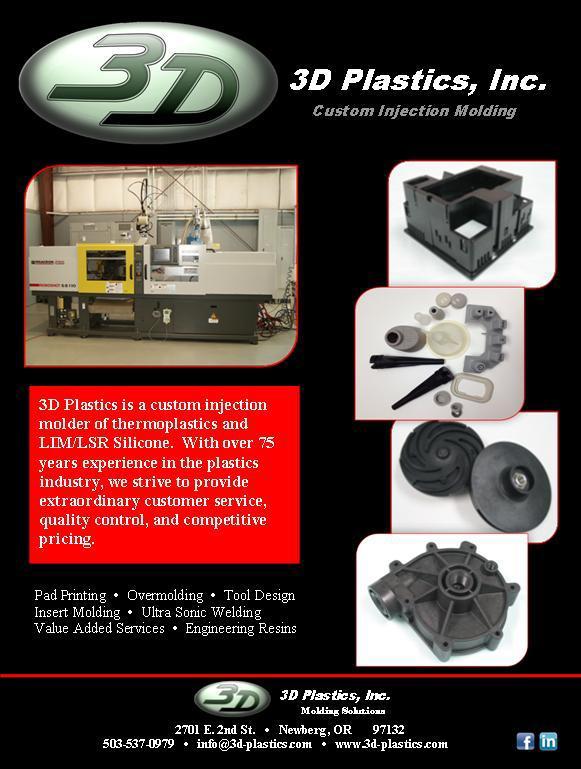

Precision aluminum and zincdie casting, machining and finishing.

Quality, Reliabilityand Service

We are a fullservice job shop, providing asmuch or aslittle projectinvolvement as required – from tooland die design to finishing and assembly.

tvtdiecast.com ▼ 800 280 2278

ISO 9001:2008 Certified

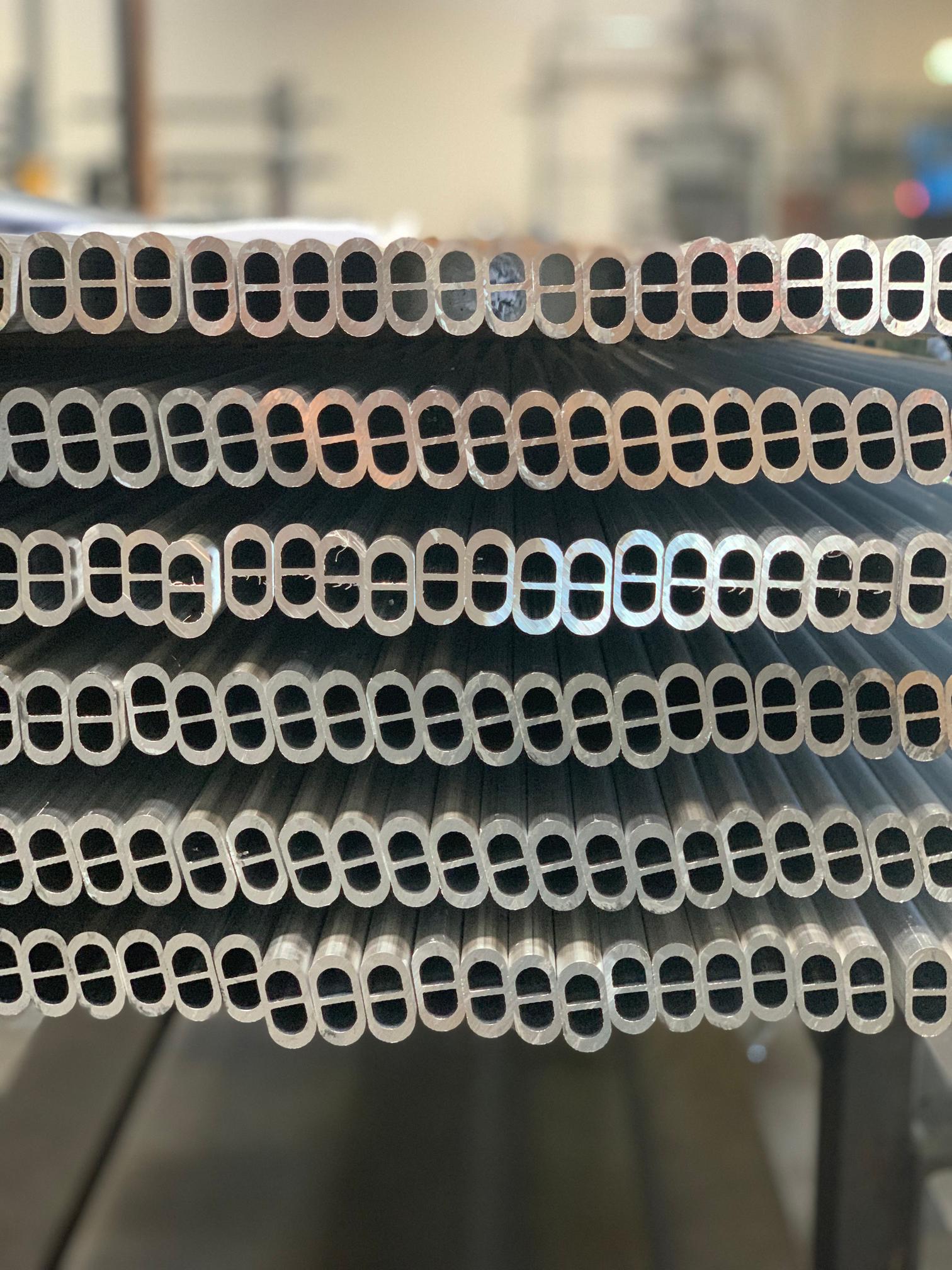

Precision Micro Aluminum Extrusions

AS 9100 & ISO 9001 CERTIFIED

Well-designed extrusions can cut machining costs by 60%.

We can help! Contact us for a quote today. Family-owned and operated since 1983.

Thin, difficult hollow & multi-void hollow shapes Tolerances +/.001 5" maximum circle size 25 lb minimum order qty Shapes as light as .015 lb/ft CNC machining & fabrication Hard alloys- 2024 & 7075 Soft alloys- 6061 & 6063 Engineering & design assistance

4730 Eucalyptus Ave. Chino, CA 91710

909-947-3455 www.superiormetalshapes.net svargas@smshapes.net A subsidiary of aerospace defense contractor Kratos Defense & Security Solutions Inc. has won an additional $3.6 million logistics support and engineering services contract to service jet-powered drone aircraft it builds in Sacramento.

Earlier this month, Kratos (Nasdaq: KTOS) won a $38.7 million order to build aerial target drones for the U.S. Navy. The company manufactures and designs the target drones in Sacramento County and several locations at McClellan Park. Kratos, which also has a design center in Roseville, employs more than 450 people locally, making it the sixth-largest manufacturer in the region.

With this latest contract, Kratos’ Sacramento operations have won more than $90 million in orders this year. Last year, Kratos took more than $100 million in a series of drone orders, and it won more than $117 million in a series of orders for tactical drones in 2018.

Kratos is based in San Diego. It has manufacturing operations in Oklahoma, as well as Sacramento.

The jet-powered target drones the Navy buys from Kratos are 17 feet long with a 7-foot wingspan. They can fly at just under the speed of sound at altitudes from 7 feet over sea level to 40,000 feet. The Navy uses them to train and test sailors to shoot down enemy aircraft, missiles and cruise missiles.

Kratos has received orders this year for at least 83 of the drones to be delivered to the Navy by the end of 2023. Kratos also makes target and tactical drones for the Air Force and other governments. By Mark Anderson – Staff Writer, Sacramento Business Journal

The Innovation That Will Ensure U.S. Security In Space

During the Cold War, it was not the U.S.’ superior weapons or soldiers that ultimately led to the Soviet Union’s capitulation. Historians record that the relative economic might of the U.S. ultimately brought the Cold War to a peaceful and conclusive end. Three decades later, the U.S. again finds itself at the dawn of what many have dubbed the “Second Space Race,” for which the U.S. ought to remain mindful of this lesson, lest it be used against us.

The West is once again threatened by a hegemonic national security rival. This time, America’s archnemesis is characterized by planning for a long contest that will feature fast-forward economics, global diplomacy, military muscle and information manipulation: China, it appears, is preparing to use its economic power to win. While maintaining its deep belief in Marx’s communist vision, the Chinese one-party government has fashioned a national economy that learned from the Soviet Union’s mistakes. Through friendly engagement with Western economies, China strengthens its own economy and weakens the West’s, nudging the world toward the worldview Continued Page 18

of the Chinese Communist Party.

What then, are the best avenues for the U.S. to win this new near-peer space competition? They are the same ones that delivered victory in the last century: free markets, real economic growth and the productivity that often follows. This time, however, we must keep in mind that our rival is a keen student that has learned from our earlier successes—and Soviet failures.

The American response must not repeat the Cold War strategy of outspending our rival in government programs. Instead, the U.S. long game must put the commercial industry first: deliberately buy goods and services from our commercial domestic market, only providing government solutions when the commercial market cannot meet requirements. Unlike other military services, there are no real “weapons” in space. Much of what the government is developing for civil and national security space needs also exists as products or services in the commercial market. By encouraging the commercial industry to grow and not competing against it, the U.S. will The U.S. economy has generated growth and prosperity unmatched in human history, with billions of dollars being invested every year into profitable commercial space companies. To outpace China militarily and economically, the new administration must double down on space privatization projects like NASA’s Commercial Crew and Commercial Resupply Programs started under the Obama administration. The Trump administration correctly reprioritized the importance of space for national security, but it directed too much government spending to legacy space projects and fell short in encouraging the next generation of commercial space companies.

An American “commercial first” policy for space technologies can solve government needs at the federal and state levels, which account for about half of commercial space company revenue. By prioritizing the highly competitive commercial sector, the government will bolster U.S. competitiveness without illegally subsidizing it. More important, it would reinforce the American values of free markets and open competition.

As the new administration settles in, national security political insiders are already hedging their bets on who and what will be the winners and losers of the new political cycle. This is especially true for the space sector, not only because it was an area of significant emphasis during the last administration but also because there continues to be significant private investment and anticipated growth in the area.

The unrelenting march of the knowledge economy and remarkable utility of the commercial space industry is limited only to our imaginations. The new U.S. Space Force and other civil space agencies will be better positioned if they leverage the burgeoning industry and do not overshadow it with government alternatives. If, however, the government decides to compete against the private sector with its top-down directed design methods and protocols, our commercial industry will be lost to China, much like the drone market was just a decade ago.

Economic dominance in the space industry, not space weapons, will ultimately decide which side defines the 21st-century space domain and the national security implications that come with it. America must strategically rethink policies that will take advantage of, rather than compete against, its blossoming commercial space industry. Getting space policy right— commercial industry first and using government solutions only when necessary—will lead to explosive growth. Getting policy wrong? Well, just ask the Soviets.

Palo Alto Spac Gigcapital 3 To Take Colorado Electric Fleet Vehicle Company Public

A Colorado electric vehicle company plans to list on the New York Stock Exchange and raise about $273 million by going public through a reverse merger with a Palo Alto “blank check” company.

Loveland-based Lightning eMotors Inc. will merge with GigCapital3 Inc., a special purpose acquisition company, in a deal that values the combined companies at about $651 million. They plans to trade with the ticker symbol of ZEV, with Lightning eMotors’ existing investors owning about 66% of the newly listed company.

The deal includes commitments from BP Technology Ventures, the startup investment arm of London-based energy giant BP plc., and other unidentified institutional investors to back the business, the company said.

Lightning eMotors installs electronic drivetrains and power systems in commercial delivery trucks, cargo vans, buses and other large fleet vehicles, turning them into zero-emission electric vehicles.

“Today marks an important step forward in Lightning eMotors’ mission to lead the commercial medium-duty zeroemission vehicle market,” said Tim Reeser, Lightning eMotors founder and CEO, in a statement that estimated there’s a $67 billion worldwide market opportunity for electric fleet vehicles. “We see tremendous demand from fleets to transition their commercial vehicles from internal combustion engines to zero-emission solutions at an attractive total cost of ownership, even without state and federal grants.”

Lightning eMotors will continue to be led by Reeser, who has founded and managed multiple technology and cleantech businesses, the company said. Bill Kelley, a 35-year veteran of automotive industry engineering and manufacturing, will remain chief technology officer and chief operations officer of Lightning eMotors. Teresa Covington, a veteran of public and private manufacturing and technology companies, will become chief financial officer of Lightning eMotors, the company said. The business can modify 1,000 vehicles a year at its Loveland facility now and is expanding that to 3,000 next year. It plans to be able to transform more than 20,000 vehicles annually by 2025.

The company is on track to reach $1 billion in annual revenue from existing vehicle conversion contracts, and projects reaching $2 billion in annual revenue by 2025.

Lightning eMotors has partnerships with Ford, Winnebago, ABC coach and other specialty vehicle manufacturers for the fleet vehicles it can cove

The company has an order backlog of more than 1,500 vehicles for delivery in the next two years, recently picking up an order from Denver-based truck rental company Fluid Truck to convert dozens of vehicles. By Greg Avery – Senior Reporter, Denver Business Journal

Intuitively, every small manufacturing company recognizes the need to invest in continuous improvement.

While all owners know that this is an absolute must for their business longevity, actually committing the time and money to doing this is much more of a challenge. And then add a pandemic, with all the economic uncertainties that accompany that, and I would wager to guess that a very, very small percentage of small businesses made significant investments in their businesses this past year.

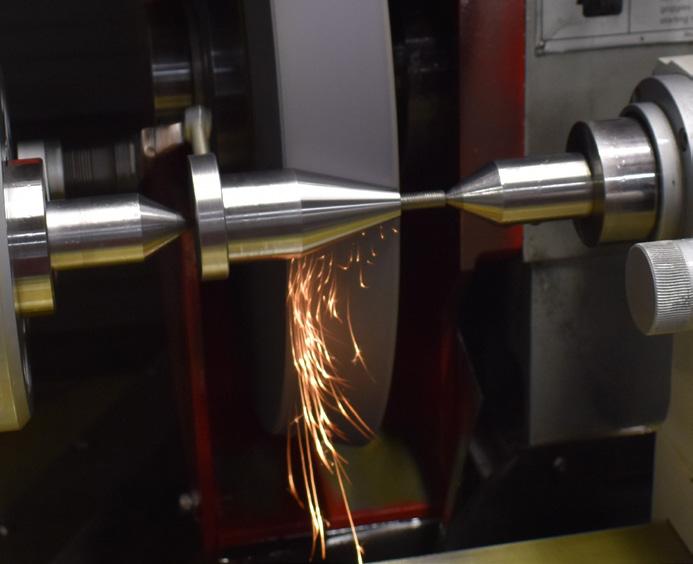

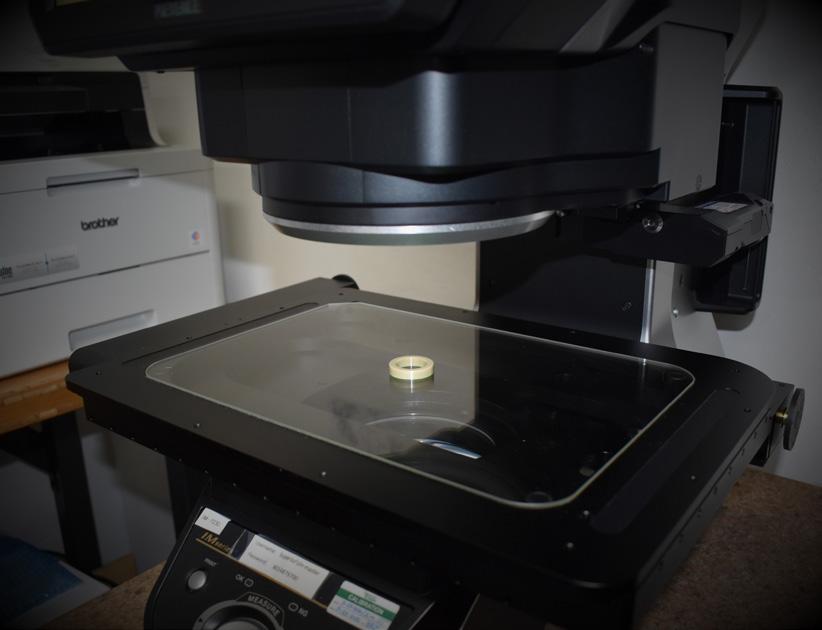

Superior Grinding & Swiss Machining did just that. The Woman-Owned company, located in a designated HUB (Historically Underutilized Business) Zone, celebrated its 3rd decade in business last year. The company specializes in production runs of pins, shafts, and small aerospace and medical parts. And during this past year, a year that can only be described as horrific, Superior Grinding & Swiss Machining made some major upgrades to their Quality Department, including the acquisition of a Hexagon CMM (Coordinate Measuring Machine) as well as a Keyence Measurement System. They additionally certified to AS9100 Revision D, and their audit resulted in an astounding and unheard of ‘0’ findings!

Wendie Flitton isn’t a machinist, or a grinding expert. She did have experience working as an office manager in a machine shop as a very young lady, though, and her financial acumen was exceptional for such a young person. Wendie’s employer closed its doors, but in Wendie’s role as office manager, she was privy to the company’s finances, and she recognized that the unprofitable company had one area of its business that was profitable, their grind shop. And so when the business closed down, Wendie made the decision to open her own grinding company, which she named Superior Grinding & Sales. One employee from the closed business joined Wendie in the start-up, Bryant Bennett. 30+ years later, Bryant still works for and is an incredible asset to the company!

I mentioned that Wendie isn’t a machinist, but Wendie’s husband Jeff Flitton was introduced to the trade while in high school. When Superior Grinding first opened for business, Jeff supported the Flitton family with a steady income, employed as a fire fighter. When the business could afford it, ~ 20 years ago, Jeff left his employ to join the family business, where today both he and Wendie co-manage the business with their team.

Wendie, a member of Goldman Sachs’ Small Business Association, has an uncanny ability to pivot in business to ensure its ongoing success. The company launched as a service business, sharpening blades for the printing industry. It enjoyed success in this industry in the early years, but Wendie recognized that the printing industry’s need for grinding would decline. Before this occurred, Wendie and her team had the foresight and confidence to launch the manufacturing side of the business, where the company offered grinding to machine shops. Jeff says, “With our grinding capabilities, we began supporting customers in Aerospace, Defense and Medical. We offered every type of grinding to our customers, including CNC ID/OD, ID, OD, Angled, Surface, Blanchard & Centerless Grinding. We additionally offered honing and lapping for our customers’ very tight tolerance requirements, and we have a mill and lathe to support specific machining requirements.”

He adds, “Over time, we recognized that particularly with our customers’ medical parts, we needed a better way to manage the lengths and diameters of the parts we were grinding. In 2014, we invested in our first Swiss CNC machine, a Tsugami.”

Wendie adds, “With our Swiss CNC machining capabilities, we were now able to reduce the steps for our customers’ outsourcing needs. We were able to buy the material, grind it, machine it, send it out for heat treat, and then finish it with OD or Centerless grinding. Additionally, the Swiss CNC machining enabled us to cut up to 1.250 diameter materials, and we were able to reduce the costs on many parts that needed to be machined and ground.”

Swiss CNC machining has been such a value add for their customers that today the company owns 4 high precision Swiss CNC machines. Jeff says, “With our grinding and Swiss CNC capabilities, we can offer high production, as most Swiss CNC shops do, but with our grinding capabilities, we can support our customers’ much higher tolerance parts. We can take a job in and measure to +/-.0005 tolerance.”

Part of continuous improvement, and a key requirement for entrée, Wendie says, was certification. In 2010, as they ramped up their customers in the Aerospace, Medical and Defense industries, they took the critical step of certifying to ISO 9001. Wendie says, “We’ve continued to certify to ISO 9001, Then in 2018 we added AS9100 Revision D to our list of certifications.”

When asked what factors the Flittons partners view as most critical to their success, both Jeff and Wendie agree that their employees top the list. Jeff says, “The majority of our team (~ 2 dozen) has been with us for more than 7 years. We are blessed to have the first employee Wendie started the business with, and our daughter Kellie Addington and her husband Sam offer business continuity as the next generation for Superior Grinding & Swiss Machining.” Wendie adds,” Our long time employees are efficiently skilled, pay attention to detail and take pride in our high quality work. They set us apart from the competition by specializing in the ability to hold exceptionally tight tolerances.”

Wendie and Jeff recognize the role their employees play in their success, and as such they provide 100% medical benefits to their employees, a 401-match retirement plan, paid vacation days as well as a competitive salary.

Wendie and the team at Superior Grinding & Swiss Machining recognize that careful selection and retention of their customers is key to their ongoing success. Today, with the expertise of long term employee Rhonda Butrick, the company is officially an ‘ Approved Government Supplier’, and they have annual contracts with a number of their customers. Jeff says thankfully they didn’t experience significant cancellations or push outs on contracts during the Pandemic. “Our ongoing contracts and our loyal customers helped our company during what could have been a real hit to our business; in fact with our new acquisitions plus our certification to AS9100 Revision D, Superior Grinding had a record year in 2020.”

Wendie says, “At Superior Grinding, we recognize that we are more valuable to our customers when we offer a niche that others in the industry aren’t offering. We clearly understand how critical it is to keep up with technology, and as such, we make technology investments regularly. Our latest investment in our Quality Department with our Hexagon CMM and our Keyence measurement system has resulted in immediate quality improvements. With the Keyence, each of our operators can do their own measurements; they can easily print these out to evaluate. This frees up our Quality Control Brian Jaensch to become a true Quality Manager, and in fact our new equipment eliminated our need to hire an additional person for our quality department.” Jeff adds, “With our Hexagon and Keyence, we are now measuring to .00025 (anything closer than that would requirement a laboratory environment), and when we can essentially do measurements in 3 seconds, we now have the ability to increase the sample size of our parts measured. We have fewer corrective actions, we’ve reduced waste and we are nearly eliminating ‘escape defects’.” Superior Grinding’s roots hail from sharpening blades, and true to their loyalty to customers, the company still offers these services. Wendie and Jeff’s daughter Kellie Addington, says, “We sell and service all types of industrial specialty blades- metal shear blades, granulator blades, Guillotine (fassco f-3000), book binding, & sheeter blades. We also sharpen recycling and metal cutting blades, punches and dies, circular blades, slitters and perforator blades, planer and jointer blades, and many other types of cutters. We are additionally carbide blade grinding certified, and we distribute band saw blades for the Amada and Wikus brands.”

Wendie says, “We are committed to constant improvement and exceptional quality output to our customers.” Jeff adds, “We recognize that we are far more valuable to our customers when we do what we say we will do.”

To learn more about how Superior Grinding & Swiss Machining can support your precision machining needs with exceptional quality, contact them at: (801) 4879700 or visit their website: www.superiorgrinding.com

Kellie adds, “Want a job where you don’t have to work out in the elements? If you’re mechanically inclined, have any machine shop experience, surface grinding a plus or CNC Fanuc controls, dependable, willing to learn and work hard. Come join our team! Drop off your resume and take a tour of our shop.

The Boeing Co. has reported more monthly deliveries than rival Airbus for the first time since its 737 Max was grounded in 2019.

Boeing on Tuesday said it delivered 26 commercial jets in January, driven by a total of 21 Max deliveries, to best Airbus’ perviously reported January total of 21 overall deliveries.

On the sales front, Boeing’s order book took another hit — though one much smaller than it experienced in previous months.

The company reported a loss of 13 net orders in January. Boeing ended 2020 with a loss of nearly 1,200 net orders due to cancellations and accounting protocols.

Airbus reported zero new orders and no cancellations in January.

Boeing’s four gross orders in the first month of the year were for the final 747 freighter jets, previously announced as having been sold to Atlas Air.

As expected, Boeing recorded no deliveries of its 787 Dreamliner for a third consecutive month as the company works through quality control issues and inspections on that wide-body jet.

The company’s other deliveries in January consisted of one older model v777 freighter to China Airlines; two 777 passenger jets to Novus Aviation Capital; and one 767 freighter to FedEx.

Deliveries of the Max on the heels of its 20-month grounding will be closely watched over the next two years, especially as the pandemic has significantly lessened planned output on twin-aisle jets like the Dreamliner.

Boeing leadership has said deliveries of the Max — grounded in the U.S. from March 2019 to November 2020 following two deadly crashes — will be weighted toward the jets it built but couldn’t give to customers while the jet was idled.

The company delivered 27 Maxes in December. Boeing intends to try and deliver around half of the roughly 450 completed Maxes it has in inventory this year. Future production rates will be dictated by how quickly it burns through that inventory. Lockheed Martin Space has a new contract worth $4.9 billion to build three advanced missile-launch detection satellites for the U.S. military.

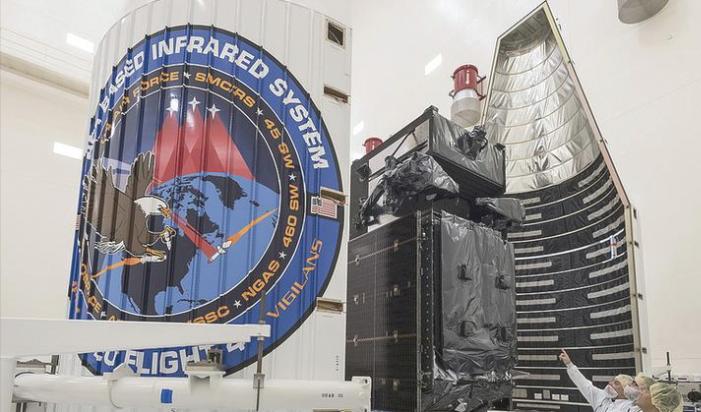

The U.S Air Force contract modification, announced Monday, covers ground control systems and launch vehicle adaptations in addition to the trio of geosynchronous missile-detection satellites the space company has worked on since October 2018 for the Air Force.

The new contract, with a maximum value worth $2 billion more than the original, calls for three orbiters to be built and launched by 2028.

The satellite construction is based at the Sunnyvale, California, campus of Lockheed Martin Space, a 21,000-employee division of Bethesda, Maryland-based defense giant Lockheed Martin Corp..

The company partnered with Boulder, Colorado-based Ball Aerospace and Falls Church, Virginia-based Northrop Grumman to develop instruments for the satellites, known as the Next Generation Overhead Persistent Infrared geosynchronous satellites. The companies passed a design review for the instruments on the satellites last summer.

Northrop Grumman is the prime contractor building two polar-orbiting OPIR satellites that will be paired with the three geosynchronous ones Lockheed Martin Space is developing.

The U.S. military is preparing for a future in which Russia, China or other nations have fleets of non-nuclear missiles that cruise faster than the speed of sound and give little advanced warning.

In contracting the Next Gen OPIR satellites, the Air Force also sought to buy satellites that are more resilient against space-based weapons in orbit than previous generations of satellites have been.

It built the Space-based Infrared System, or SBIRS, satellites for the Air Force, four of which have been launched into orbit in the last decade and are flown from Buckley Air Force Base in Aurora, Colorado.Two final SBIRs satellites are expected to launch soon, one this year and one in 2022.

The original contract for the Next Generation OPIR geosynchronous satellites replaced the expected final two satellites of the SBIRs fleet. The Air Force “urgently” sought missile-detection orbiters that would be harder to attack in orbit.

Lockheed Martin Space at the time was deemed the sole contractor capable of having the first such satellites ready for launch by 2025. The contract obligates $99 million to Lockheed Martin Space in the current federal fiscal year. By Greg Avery – Denver Business Journal

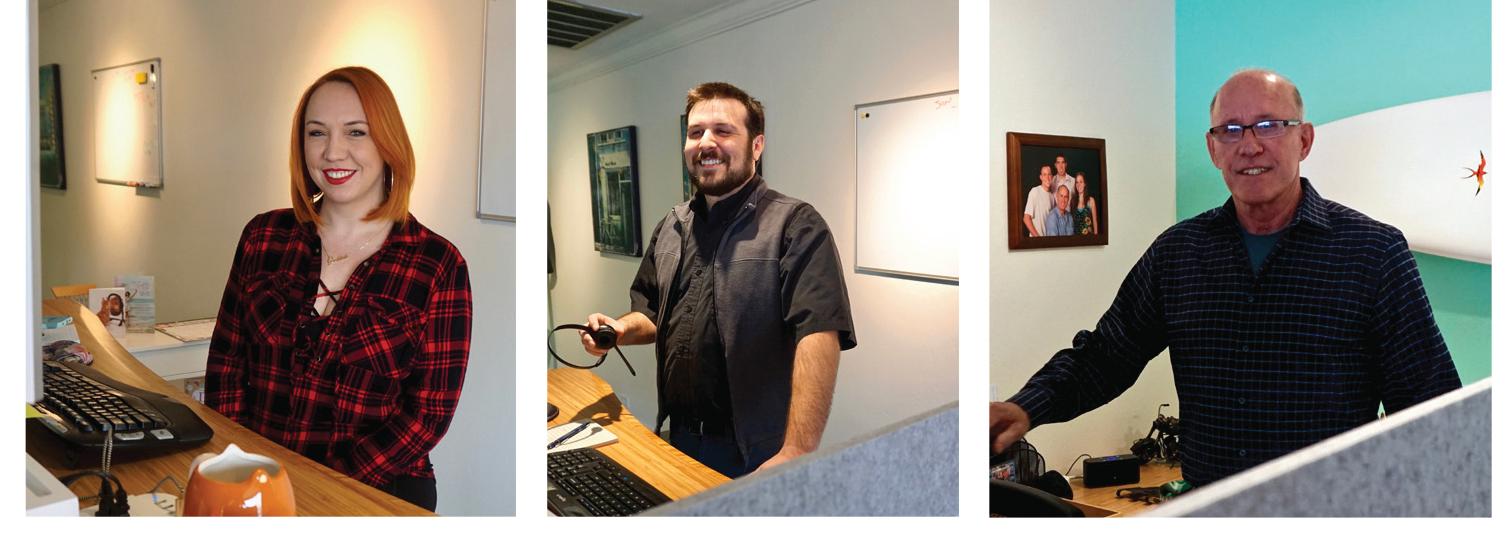

Machinery Resources International (MRI) Brings Mike Mills On To Manage Its Arizona Office

Machinery Resources International, is proud to announce its expansion with the opening of their Scottsdale, Arizona office. Mike Mills is heading up the new locations for MRI. Alan Gottlieb, owner of MRI, says, “I have known Mike since 2003, when he first started selling and buying used machinery. Though we were essentially competitors during these nearly 2 decades, Mike and I respected eachother for our integrity and sound business principles.” Mike adds, “ Alan first taught me how to buy and sell equipment, and though we weren’t working together during those early years, we found ways to send referrals to one another when we saw a better fit. It is such a pleasure to work with Alan, who was truly a mentor to me.”

Mike brings a wealth of industry experience to MRI’s customers. In the ~4 decades since he came into the industry, Mike founded CNC-Trade in Machinery, and worked in positions from Sales Manager to President of nationwide precision machinery resale entities. Mike has also worked as a machinist for a decade early in his career and has sold tooling as well as new machinery.

Joining Mike’s MRI Scottsdale team is Sarah Mills, who while new to the machine tool industry, has experience in sales, where she even worked for a period in Mexico. Sarah says, “I really enjoy learning about the people who I buy and sell from. I also love learning about machine tool equipment.” Drew Kirkendall is the newest member to the Scottsdale MRI team. Drew came to work for MRI’s California headquarters as a laborer, doing odd jobs for the company. With a strong work ethic and a quick learner, Drew was promoted first to supervisor and then to project manager. When an opportunity for sales came up in the Scottsdale office, Drew interviewed with Mike, and today he is happy to be located permanently in Arizona.

Founded in Los Angeles in 1995, Machinery Resources International has emerged as one of the premier names in the worldwide industrial machinery resale marketplace. The company’s headquarters are located in Los Angeles, CA with warehouses located around the country. With over 100 combined years in the business, customers can count on their experienced and seasoned professionals to find them the best deal for their machinery.

As proud members of the MDNA, AMEA, and NAAA, MRI supplies high quality, pre-owned machinery. In addition to buying and selling previously owned machine tools, the company has AMEA certified and ASA candidate appraisers on staff. In addition, they conduct auctions and liquidations worldwide. To learn more about how MRI can help you with your machinery resell needs, contact them at: 877-568-2121 or visit machineryresources.com

The Right Waterjet Abrasive

Choosing the right abrasive for a waterjet cutting application can significantly improve the performance and profitability of your waterjet operation. BARTON has published an in-depth look at the many factors that impact the cutting efficiency of a waterjet abrasive.

Download a FREE copy: barton.com/WaterjetAbrasiveGuide

BARTON INTERNATIONAL USA/Canada 800-741-7756 • 518-798-5462 • barton.com • info@barton.com

BARTON is a trademark of BARTON Mines Corporation.

OIL MIST AND SMOKE IN YOUR SHOP?

Low-Cost, Highly Efficient Mist and Smoke Collectors Designed Specifically for the Metalworking Industry

www.mistcollectors.com 1-800-645-4174

By Annlee Ellingson

AeroVironment Inc. has increased the size of unmanned aircraft systems (UAVs) in its arsenal with the acquisition of Arcturus UAV Inc.

The total purchase price was $405 million, including $355 million in cash and $50 million in AeroVironment stock.

The move expands Simi Valley-based AeroVironment’s business into adjacent segments and broadens its capabilities and customer footprint.

Specifically, the privately held Arcturus UAV, founded in 2004 and based on Petaluma, California, designs and manufactures Group 2 and Group 3 unmanned aerial systems (UAS) and provides related services, including contractor-owned, contractor-operated services. The company is the leading supplier to the United States Special Operations Command, supporting its $1.4 billion Mid-Endurance Unmanned Aircraft Systems III and IV programs, and has been selected for funded development and demonstrations supporting the U.S. Army’s Future Tactical Unmanned Aircraft System program. Arcturus UAV’s topline growth exceeded 20% for each of its last two fiscal years.

“Group 2 and 3 UAS and services, collectively, potentially represent more than one billion dollars in annual contract value, according to an independent forecast,” said AeroVironment President and CEO Wahid Nawabi in a statement. The acquisition gives AeroVironment “a complete set of Group 1 through 3 UAS, tactical missile systems, high-altitude pseudo-satellites and unmanned ground vehicle solutions,” he added.

“With the support of AeroVironment, we will have greater scale, expanded resources, cutting-edge technology and superior capabilities to meet the growing global demand for our products and solutions,” added Arcturus UAV President and CEO D’Milo Hallerberg.

Arcturus UAV brings with it about 270 employees, and after the acquisition, key members of its executive management team will remain in leadership positions, the companies said. The transaction is expected to close during fourth quarter of AeroVironment’s fiscal year 2021, subject to customary closing conditions and regulatory approvals, at which point Arcturus UAV will operate as a wholly owned subsidiary of AeroVironment.

Jefferies LLC served as exclusive financial advisor, and K&L Gates served as legal advisor to AeroVironment on the deal. Evercore served as exclusive financial advisor, and Hogan Lovells served as legal advisor to Arcturus UAV.

THE NEW MITSUBISHI EDM...

BURNING CIRCLES AROUND THE COMPETITION.

- CYLINDRICAL DRIVE TECHNOLOGY - 19” TOUCHSCREEN CONTROL - FIBER OPTIC SERVO CONTROL - INDUSTRY LEADING AUTO-THREADING

NEW M800 CONTROL

REMOTE MONITORING

TRADE-IN PROGRAM

Electric Plane Maker Eviation Hiring For New Assembly Facility In Snohomish County

Eviation, the developer and maker of the futuristic-looking Alice electric regional airplane, has leased several hangars and is now hiring staff for facilities located in Arlington, north of Seattle, the Business Journal has learned.

The project will be unveiled during the first quarter of 2021.

Israel-based Eviation has agreed to lease three hangars in two buildings on the flight line at Arlington Municipal Airport for aircraft assembly, flight testing and eventual Alice deliveries to its customers once its airplane is certified by the Federal Aviation Administration, according to two confidential sources familiar with the project. The people spoke on condition they weren’t identified because they aren’t authorized to discuss the matters publicly.

Eviation’s expansion, though not publicly announced, has already included aerospace recruitment notices on its career web page for nearly a dozen jobs, stating they’re for a new “assembly facility” in Arlington.

In a telephone interview from Israel, Eviation CEO Omer Bar-Yohay confirmed some details about the Arlington project, saying it represents an investment “well north of $10 million.”

Eviation CEO, Omer Bar-Yohay revealed his company’s all-electric Alice airplane at the 2019 Paris Air Show, which was attended by thousands of airline officials and aerospace suppliers from around the world.

“Once ready, the site will be a pillar in our testing, certification and delivery plans,” Bar-Yohay told the Business Journal. “It will also be a significant part of our manufacturing. In the longer term, we are also moving other significant parts of the company to the Seattle area as well.”

Bar-Yohay declined to elaborate, saying those plans — along with renderings of the company’s new Arlington facilities — will be shared publicly sometime in February. The plans include transfers of key personnel to Arlington from Israel. By Andrew McIntosh – Staff Writer, Puget Sound Business Journal

Swift Tool Co. Inc. PVD COATING CENTER

OUR STATE-OF-THE-ART NANOCOMPOSITE COATING CENTER

OFFERS THE HIGHEST QUALITY PVD COATINGS WITH: • LOW PRICES • FASTEST DELIVERY IN THE INDUSTRY • UNMATCHED CONSISTANCY & PERFORMANCE

Most tools in our industry are coated together with all other types of tools, using the same process and coating formula. We have specific preparation processes, coating processes, and coating formula for each individual tool type and size • ENDMILLS • TAPS • INSERTS • DRILLS • MEDICAL PARTS • PUNCHES • DIES • GUN COMPONENTS • GEARS • HOBS • VALVES • BLADES

Our AlTiN coatings work 20-30% better than other AlTiN’s, and our high performance coatings like MDC, often double tool life or more over industry standard coating like AlTiN.

MDC

MOLECULARLY DENSE COATING

RUN 15-30% HIGHER SFPM THAN AlTiN MDC COATING

30% HIGHER HEAT RESISTANCE THAN ALTIN, WHILE PROVIDING MORE WEAR RESISTANCE AND LUBRICITY. ALLOWS FOR 20+ PERCENT FASTER SPEEDS AND FEEDS, WHILE INCREASING TOOL LIFE 30-200%.

Are you ready to implement or upgrade your Quality Management System to the new ISO 9001:2015 or AS9100D / ISO 9001:2015 Standard, AS9110C or AS9120B? Special Packages available, take advantage of 20 plus years’ experience implementing and auditing quality management systems for commercial and aerospace companies! Bretta Kelly, President and Owner of BMSC, LLC www.businessmsc.com has proven, copy written templates for ISO 9001:2015, AS9100D / ISO 9001:2015, AS9110C / ISO 9001:2015 and AS9120B / ISO 9001:2015 Standards with more than 30 companies upgraded and certified with zero to one finding results to date in their upgrade audits! Packages Available:

Complete Electronic QMS System/Templates and 4 hours consulting – Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s - $3,500

Complete Electronic QMS System/Templates and online webinar of how to complete –Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s - $2,500

Do you need Quality Management System Software? Bretta Kelly is also President of CIS WWSG, LLC and is now offering the $3,500 Templates for FREE with purchase of CIS Software! www.cissoftware.com. CIS Software costs $5,000 upfront (one time) and $385/month license and server fees for UNLIMITED users, request a demo today! Testimonial from BMSC Clients featured in the A2Z Manufacturing Magazine who have taken advantage of the BMSC Templates for successful upgrades:

Bretta, I wanted to email you and let you know that because of the help of yourself and Debbie we completed our audit to the new revision with no findings! :) We very much appreciate all of the help that you both did for us and will recommend your company to anyone looking to get certified. Your system really makes it easy for companies like ours to stay organized and compliant to the guidelines. Kristie McKee, Gibbs Precision Machine

A2Z MANUFACTURING WEST COAST • 26 • FEB- MAR 21

Within a decade, cruise missile options for the B-52 will include new versions of the conventional AGM-158 as well as the all-new nuclear Long-Range Standoff missiles and possibly future Hypersonic Attack Cruise Missiles.

After successfully fielding only one new cruise missile during the past 30 years, the U.S. Defense Department hopes to multiply that result over the next decade.

role as well. Two new candidates for a future hypersonic cruise missile are currently in testing, while a third has entered the design phase. A subsonic replacement for a nuclear version of the Boeing AGM-86 air-launched cruise missile is in development. Another replacement for the Navy’s RGM/UGM-109 Tomahawk is on the drawing board and may be adapted for a nuclear

Scramjet-powered cruise missiles gain traction

INF Treaty demise restarts production of ground-launched cruise missiles Meanwhile, new versions of the Lockheed Martin AGM-158 Joint Airto-Surface Standoff Missile (JASSM) and the Tomahawk missiles are set to enter production. Finally, a new class of air vehicle that blurs the line between a cruise missile and an unmanned aircraft system is gaining traction.

The Biden administration, however, might intervene. Two nuclear cruise missile projects—the Air Force’s Raytheon Long-Range Standoff (LRSO) and the Navy’s sea-launched cruise missile (SLCM-N)—could become targets of a pending review by President Joe Biden’s appointees of the $1.2 trillion nuclear modernization program. And the extent to which Biden’s national security team supports conventional hypersonic cruise missiles is not yet apparent.

But U.S. military support has never been higher for a powered alternative to ballistic missiles with the capability to maneuver during a flight without sacrificing speed.

In the category of hypersonic weapons, scramjet-powered cruise missiles are seen as a more affordable and versatile option than the larger and more expensive hypersonic glide vehicles, such as the air-launched Lockheed AGM-183A.

As recently as December 2018, senior defense officials viewed scramjet propulsion as less mature than rocket-boosted hypersonic gliders. But scramjet technology has evolved rapidly in wind tunnel testing.

In 2020, Aerojet Rocketdyne demonstrated that an 18-ft.-long scramjet engine could generate 13,000-lb. thrust in a wind tunnel. Northrop Grumman Innovation Systems achieved the same result with another scramjet design in 2019. Both engines are now set to enter flight testing in 2021 under DARPA’s Hypersonic Air-Breathing Weapon Concept program; Aerojet has partnered with Lockheed, and Northrop has teamed up with Raytheon. A follow-on operational prototyping program, known as the Hypersonic Attack Cruise Missile, is set to begin, and air-launched and sea-launched versions are possible.

A third option could enter the competition this year. In November, the Pentagon awarded Boeing a contract to complete a preliminary design and component-level testing of the Mach 5-plus HyFly 2, a concept for a dual-combustion, ramjet-powered cruise missile optimized for the Navy’s carrier decks.

All three conventional hypersonic cruise missiles are expected to enter service years before the Air Force fields the nuclear LRSO, but the program is making progress. The Air Force selected Raytheon over Lockheed to continue development of the LRSO, which will be armed with an upgraded W80-4 warhead.

The LRSO entered development under the Obama administration, but the SLCM-N joined the future arsenal following the Trump administration’s Nuclear Posture Review. A Navy analysis recommended developing the SLCM-N as a nuclear variant for the Next-Generation Land Attack Weapon (NGLAW), which is intended to replace the ship- and surfacelaunched Tomahawk.

As a bridge to the fielding of the NGLAW, the Tomahawk itself reentered production in 2020 to support the improved Block V variant. The Maritime Strike Tomahawk, which integrates a new seeker, is scheduled to enter service in 2023.

Ground-launched cruise missiles (GLCM) also are making a comeback since the demise of the Intermediate-Range Nuclear Forces Treaty in August 2019. That 31-yearold pact compelled the Air Force to retire an arsenal of deployed BGM-109G Gryphon missiles. But conventional GLCMs will reenter the arsenal. Last November, the Army selected the BGM-109 Tomahawk to form half of a new Mid-Range Capability with a groundlaunched version of the Raytheon SM-6 in 2023.

Lockheed’s AGM-158 JASSM provided the Air Force a stealthy option to strike targets at ranges of up to 500 nm. Although the AGM-158 fell far short of the AGM-86C conventional air-launched cruise missile, the Air Force allowed the latter to be retired from service with no direct replacement in November 2019. That gap will be addressed partially by the fielding in 2024 of the AGM-158D, a new version of the JASSM with a range of up to 1,000 nm and the same radar cross section.

METALS Aluminum Steel Stainless Brass Copper Ornamental

SHAPES SERVICES Sheet/Plate Production Shim/Bar Cutting Tube/Pipe Precision Channel Sawing Angle Beam Shearing

Perf./Expand. 818-729-3333, www.IMSmetals.com So-Cal’s Source For All Your

Metal Needs Next Day Delivery - No Minimum - Open Saturdays

STOP BY TODAY!

Los Angeles | Orange County | San Diego | Inland Empire

Contracts

Raytheon Technologies Corp., Pratt and Whitney, Pratt and Whitney Engines, East Hartford, Connecticut, is awarded a $49,195,531 fixedprice-incentive-firm-target modification (P00025) to a previously awarded contract (N0001918C1021). This contract provides for one conventional take-off and landing and two short take-off/vertical landing F135 engines to support F-35 Lightning II Block Four developmental testing program for the Air Force, Navy, Marine Corps, and non-U.S. Department of Defense (DOD) participants. Work will be performed in East Hartford, Connecticut (33%); Kent, Washington (15%); El Cajon, California (15%); Whitehall, Michigan (8%); West Palm Beach, Florida (6%); Dover, New Jersey (5%); East Lake, Ohio (3%); Rockford, Illinois (3%); Houston, Texas (3%); Portland, Oregon (3%); North Berwick, Maine (3%); and Milford, New Hampshire (3%), and is expected to be completed in January 2023. Fiscal 2020 research, development, test and evaluation (Air Force) funds in the amount of $3,690,000; fiscal 2020 research, development, test and evaluation (Navy) funds in the amount of $2,500,000; and non-U.S. DOD participant funds in the amount of $1,083,021 will be obligated at the time of award, $6,190,000 of which will expire at the end of the current fiscal year. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity. (Awarded Feb. 5, 2021)

Bell Boeing Joint Project Office, Amarillo, Texas, is awarded a $17,852,939 modification (P00012) to a firm-fixed-priced order (N0001919F0305) against a previously issued basic ordering agreement (N0001917G0002). This modification exercises an option to procure 60 MV-22 and 10 CV-22 proprotor hub spring and drive link retrofit kits; and six CV-22 modification spares kits, in support of the Marine Corps MV-22 aircraft and Air Force CV-22 aircraft. Work will be performed in Fort Worth, Texas, and is expected to be completed in February 2023. Fiscal 2021 aircraft procurement (Navy) funds in the amount of $14,675,618; and fiscal 2021 aircraft procurement (Air Force) funds in the amount of $3,177,321, will be obligated at time of award, none of which will expire at the end of the current fiscal year. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity. (Awarded Feb. 5, 2021)

BAE Systems Platforms & Services, Minneapolis, Minnesota, is awarded a $17,576,524 fixed-price incentive (firm target) contract for Virginia-class submarine propulsors (delivery order N00024-21-F-2100 under basic ordering agreement N00024-20-G-4107). Work will be performed in Louisville, Kentucky (90%); and Minneapolis, Minnesota (10%), and is expected to be completed by October 2024. Fiscal 2020 advanced procurement shipbuilding and conversion (Navy) funding in the amount of $17,576,524 will be obligated at time of award and will not expire at the end of the fiscal year. This contract was not competitively procured in accordance with 10 U.S. Code 2304(c)(1) (only one responsible source and no other supplies or services will satisfy agency requirements). The Naval Sea Systems Command, Washington, D.C., is the contracting activity. (Awarded Feb. 5, 2021)

American Petroleum Tankers LLC, Blue Bay, Pennsylvania (N3220517C3502), is awarded a $16,479,750 option (P00021) for the fixed-price portion of a previously awarded firm-fixed-price contract with reimbursable elements to exercise a one-year option in support of the Department of Defense Logistics Agency Energy aboard the M/V Evergreen State. This contract includes a one-year-firm period of the performance, three one-year options periods, and one 11-month option period, which if exercised would bring the cumulative value of this contract to $81,048,250. Work will be performed in Norfolk, Virginia, and is expected to be completed, if all options are exercised, by Jan. 8, 2023. Working capital funds (Navy) in the amount of $10,565,100 are obligated for fiscal 2021, and will not expire at the end of the fiscal year. Funds in the amount of $5,914,650 for the remainder of Option Three are to be provided for fiscal 2022 and are subject to availability of funds in accordance with Federal Acquisition Regulation 52.232-18, availability of funds. This procurement was released under full and open competition, with an unlimited number of companies solicited via the Beta.SAM.Gov website with three offers received. The Navy’s Military Sealift Command, Norfolk, Virginia, is the contracting activity. (Awarded Feb. 5, 2021)

Bell Boeing Joint Project Office, Amarillo, Texas, is awarded a $12,273,267 cost-plus-fixed-fee, firm-fixed-price order (N0001921F0090) against a previously issued basic ordering agreement (N0001917G0002). This order provides non-recurring engineering services for the conversion area harness aircraft modification. Additionally, this order procures 72 conversion area harness base retrofit kits, 63 conversion area harness supplemental retrofit kits, and interim spares in support of the Marine Corps MV-22 aircraft, the Air Force CV-22 aircraft, the Navy CMV22 aircraft, and the government of Japan V-22 aircraft. Work will be performed in Simpsonville, South Carolina (80%); Fort Worth, Texas

(10%); Long Beach, California (7%); Austin, Texas (1%); Dallas, Texas (1%); and various locations within the continental U.S. (1%), and is expected to be completed in January 2026. Fiscal 2021 aircraft procurement (Navy) funds in the amount of $8,626,985; fiscal 2021 aircraft procurement (Air Force) funds in the amount of $1,787,911; fiscal 2020 aircraft procurement (Navy) funds in the amount $480,888; and Foreign Military Sales funds in the amount of $1,377,483 will be obligated at time of award, none of which will expire at the end of the current fiscal year. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity. (Awarded Feb. 5, 2021)

General Dynamics Ordnance and Tactical Systems, Garland, Texas, was awarded an $111,853,284 firm-fixed-price contract for MK80 series general purpose tritonal bomb components. Bids were solicited via the internet with one received. Work will be performed in Garland, Texas, with an estimated completion date of Dec. 30, 2022. Fiscal 2019 and 2020 aircraft procurement (Army) funds in the amount of $111,853,284 were obligated at the time of the award. U.S. Army Contracting Command, Rock Island Arsenal, Illinois, is the contracting activity (W52P1J-21-F-0104).

Armtec Countermeasures Co., Coachella, California, was awarded a $24,953,504 firm-fixed-price contract for Flare Aircraft Countermeasure M206 and Flare Aircraft Countermeasure MJU7A/B. Bids were solicited via the internet with three received. Work will be performed in Camden, Arkansas, with an estimated completion date of Dec. 31, 2026. Fiscal 2019 and 2020 aircraft procurement appropriations funds in the amount of $24,953,504 were obligated at the time of the award. U.S. Army Contracting Command, Rock Island Arsenal, Illinois, is the contracting activity (W52P1J-21-F-0101).

Northrop Grumman Systems Corp., Linthicum, Maryland, is awarded a $236,941,008 modification for the firm-fixed-price portion of previously awarded contract M67854-19-C-0043. The total cumulative face value of the contract is $686,355,923. This modification provides for the exercise of three option contract line items to procure eight Ground/Air Task Oriented Radar Gallium Nitride full rate production systems with associated travel and one lot of the initial provisioning package (spares) in support of Program Executive Officer Land Systems, Quantico, Virginia. Work will be performed in Linthicum, Maryland, and is expected to be complete by Feb. 28, 2024. Fiscal 2021 procurement (Marine Corps) funds in the amount of $236,941,008 will be obligated at the time of award and will not expire at the end of the current fiscal year. The contract modification was not competitively procured. The base contract was not competitively procured pursuant to Federal Acquisition Regulation 6.302-1 and 10 U.S. Code § 2304(c) (1). The Marine Corps Systems Command, Quantico, Virginia, is the contracting activity (M67854-19-C-0043).

BAE Systems Land & Armaments L.P., Sterling Heights, Michigan, is awarded an $183,840,645 fixed-price incentive (firm target) modification to previously awarded contract M67854-16-0006 for Amphibious Combat Vehicles (ACVs). The total cumulative face value of the contract is $3,304,536,113. This modification provides for the exercise of options for the procurement of 36 full rate production ACVs and associated production and fielding and support costs. Work will be performed in York, Pennsylvania (60%); Aiken, South Carolina (15%); San Jose, California (15%); Sterling Heights, Michigan (5%); and Stafford, Virginia (5%). Work is expected to be completed in April 2023. Fiscal 2021 procurement (Marine Corps) funds in the amount of $183,840,645 will be obligated at the time of award, none of which will expire at the end of the current fiscal year. Marine Corps Systems Command, Quantico, Virginia, is the contracting activity (M67854-16-C-0006).

ARMY

Raytheon Co., Tucson, Arizona, was awarded a $53,861,439 modification (P00009) to contract W15QKN-19-C-0017 for Excalibur Ib projectiles. Work will be performed in Healdsburg, California; Karlskoga, Sweden; East Camden, Arizona; Cedar Rapids, Iowa; Southway, United Kingdom; Cincinnati, Ohio; Glenrothes, Scotland; Salt Lake City, Utah; Joplin, Missouri; Gilbert, Arizona; Lansdale, Pennsylvania; Santa Clara, California; Woodridge, Illinois; Trenton, Texas; Valencia, California; Cookstown, New Jersey; Tucson, Arizona; Phoenix, Arizona; Anniston, Alabama; Chino, California; Inglewood, California; McAlester, Oklahoma; and Farmington, New Mexico, with an estimated completion date of April 29, 2024. Fiscal 2019 and 2021 other procurement (Army) funds in the amount of $53,861,439 were obligated at the time of the award. U.S. Army Contracting Command, Newark, New Jersey, is the contracting activity.

The Manufacturer’s Secret Weapon

New Beginnings

By Stephen M. Hannemann

Getting settled into a new year, given the turmoil of 2020, may be somewhat unnerving. We can choose to dwell on the negatives and brood or learn from our experiences and get stronger. I choose the latter. Positivity is a great attribute.

My daughter’s son-inlaw is in the restaurant business. Recently I asked her how he was holding up amid his industry’s seemingly endless and everchanging stream of mandates. She told me he was doing quite well actually. My daughter went on to explain how he would respond by gathering his people together to roll out the new action plan. It did not matter whether it was rearranging the dining room, covering and refurnishing the patio, or setting up for takeout, he would revamp to accommodate new guidelines. Please do not think I do not understand the financial impact of these moves, though they are far superior to the alternative of closing. But they did remain open and compliant and his staff is still in place and meals are being prepared and sold!

What does this have to do with manufacturing, you may ask yourself. It is the attitude! A positive attitude is crucial in times of crisis, in any environment. It not only alleviates stress but imparts confidence within any organization, and that is a winning combination when transition needs to move smoothly but quickly.

Organizations that survived and even grew, are the ones where management and employees pulled together, assessed, made a game plan and stuck to it, modifying when necessary, but never losing focus. Please do not misunderstand; all was not sweetness and light. In many businesses, hard decisions were necessary. In some instances, it seemed like starting over. But the fact remains if you are still in business, you made the right moves.

As an aside for those of us in manufacturing, I highly recommend a field trip to a commercial kitchen. You will see the epitome of lean manufacturing on a grand scale. The larder, prep counters, cook tops, ovens, hot tables, every implement, tool and ingredient are positioned precisely where they are needed. All is laid out for the economy of motion with food moving in one direction. Continuous improvement in any environment should never end. Efficient flow is conducive to fewer rejects and higher revenues.

As we enter the new year, take inventory and review the positive moves you made. Look for additional ways to improve, but most of all, have an attitude of gratitude as we embrace another new year in rapidly changing times.

Photos courtesy of Flatline Fabrication Inc. in Portland, OR. SMH Inc. is proud to spotlight Flatline Fabrication, their lean manufacturing practices, their creativity in 2020, and especially their Desk Share program rolled out in October. Be sure to check out the Flatline press release, Desk Share – a Philanthropic Program on page 8 and 9 of this issue. Read about the inspired plan to benefit low income families who home school their children.

State Logo on DESK SHARE desk

Museum Quality Fixtures Commercial fixtures

For more information regarding Flatline Fabrication Inc., and all the well vetted suppliers represented by SMH Inc., visit www.smhincllc.com; email stephen@smhincllc.com or phone 425.501.7342

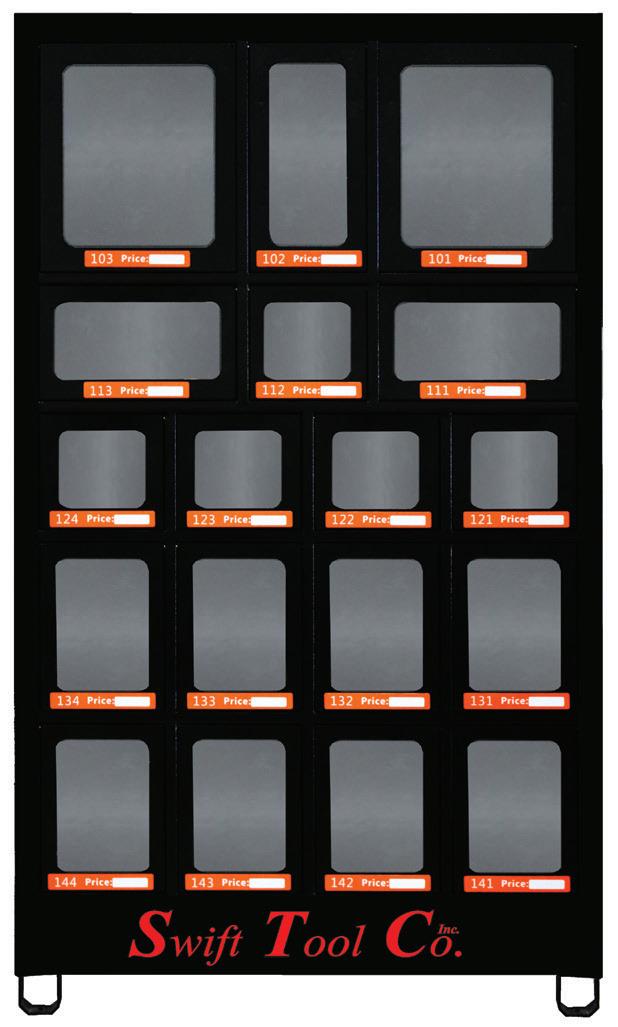

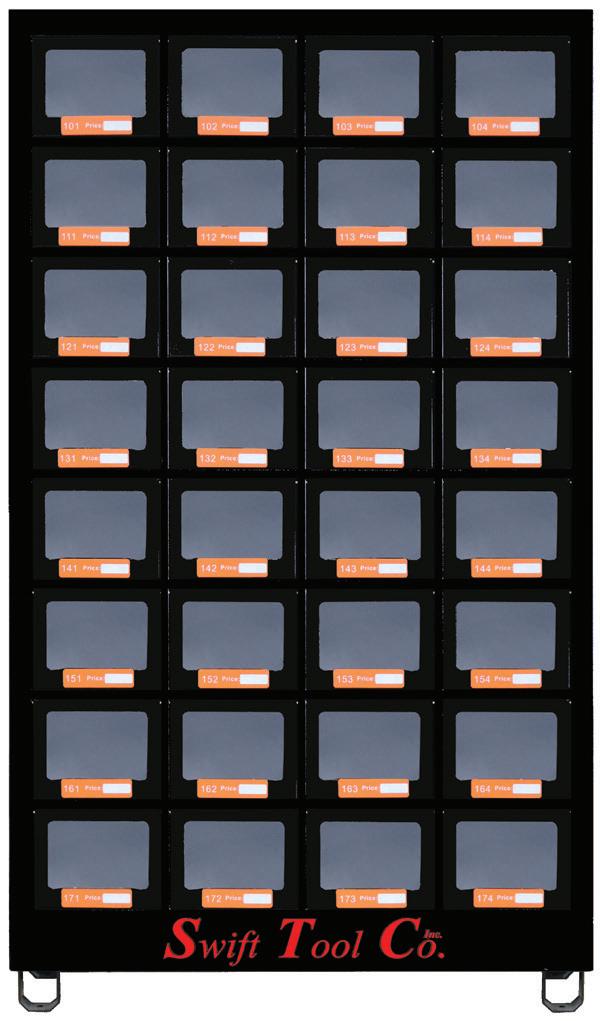

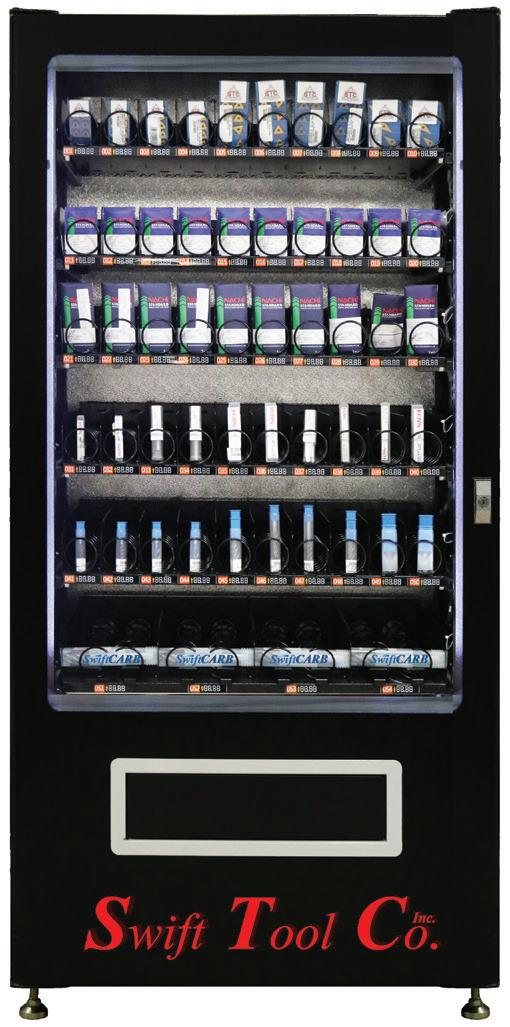

INDUSTRIAL TOOL VENDING & MANAGEMENT

INVENTORY MANAGEMENT solution custom designed for your company!