19 minute read

Announcements/Releases

Ellison Technologies, Inc. Appointed As The Exclusive U.s. Importer For ONA

About Ellison Technologies

The European builder, ONA, specializing in EDM technology, has named Ellison Technologies, Inc. as their exclusive U.S. importer responsible for sales, support and distribution.

ONA is the pioneer in EDM technology, developing its first die-sinking EDM in 1955. For the past 65 years, ONA has developed their own technology combining the expertise of applications and R&D&i. Today they offer quality EDM solutions, both wire and die-sinking EDM machines, along with customer-specific solutions. “We are confident that our new partnership with Ellison will help U.S. customers to discover our full potential and capacity and will bring a new bright future for us,” said Javier Gonzalez, CEO of ONA.

As the U.S. importer, Ellison Technologies will provide existing and new ONA customers with enhanced local support, including sales and project management, engineering solutions, and national technical response centers for service and parts fulfillment.

“We are pleased to represent ONA EDM products in the U.S,” said Graham Hooper, CEO of Ellison Technologies. “Much like Ellison, their mission is providing solutions that offer productivity and profitability for manufacturers through their advances in EDM technology.”

Ellison Technologies (http://www. ellisontechnologies. com) is one of the largest machine tool integrators in North America. With 16 locations to provide local support across the U.S., the company’s mission is to equip manufacturers to compete and win, both locally and globally. In addition to distributing the latest CNC machine tool technology, Ellison’s team of over 300 industry experts provide its customers with superior engineering solutions, service and parts support, turnkey solutions, robotic automation and machine financing.

About ONA

ONA is a global pioneer in EDM technology. At its corporate headquarters in Europe it brings together the expertise of a workforce skilled in EDM with a strong emphasis on R&D&i to deliver technical solutions tailored to the needs of each customer. Its high standards and the reliability that comes with over 65 years of experience provide a solid foundation for tackling EDM projects all over the world. Projects that focus entirely on meeting the specific needs and assuring the future profitability of each customer. For more information, visit us at: www.onaedm.com

LV Swiss, a Precision CNC Milling and Swiss Screw Machining Company, Adds ISO13485 Medical Certification to Their Portfolio!

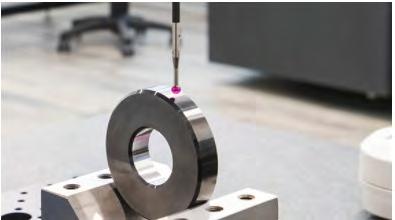

LV Swiss is proud to receive their ISO13485 on May 11, 2021 to round out their portfolio of industry certifications. Per Paul Klein, CEO, “Everyone at LV Swiss worked hard to make it possible for us to achieve ISO13485 Certification. Having gone through an extensive Quality processes earlier regarding certifications, we knew it would be a challenge. We were able to leverage the earlier successes and refinements we made to an already robust Quality Management System. Leveraging our many years of experience supporting AS9100 Rev D and ISO 9001:2015 Certifications shorten the overall preparation time. Also, producing prototype parts for numerous medical companies, especially startups, for the last couple of years we knew what was expected. Our engineering staff consults with the customer during the prototype process to identify various means to improve the machineability of the design thus allowing for potential reductions of cost, and lead time, yet keeping the high quality required. “ LV Swiss, located near the entrance of Zion National Park in Southern Utah, is a contract manufacturer that provides high precision CNC Milling and Swiss Screw Machining to Medical, Aerospace & Defense, Automotive, Industrial and Commercial industries since 2009. We are constantly adding new equipment, for example, this year we purchased a Hexagon Coordinate Measuring Machine (CMM) to assist our QA department with automation and inspection of highly intricate CNC milled parts and other small precision Swiss Screw Machine parts. High Quality and On-Time Delivery are the cornerstone of our business.

We would appreciate the opportunity to assist with your prototype and production requirements.

To request a quote or learn more about LV Swiss, please call (435) 635-1482, or website www.LVSwiss.com or email at Quoting@LVSwiss.com

We Bend all Ferrous & Non-Ferrous Metals! YOUR METAL BENDING EXPERTS

AGRICULTURE AQUATIC LOCOMOTIVE AVIATION PIPE SPOOLS FOOD & BEVERAGE AUTOMOTIVE COILS HEAT EXCHANGERS HIGH PURITY TANKS PLAYGROUND MARINE ALTERNATIVE ENERGY SCAN HERE FOR COMPANY DIRECTORY!

www.albinaco.com/about/contact

BOB KROHA

ROB KROHA

CNC AND MANUAL MACHINERY SINCE 1979 New - Used -Appraisals - Auctions

CONTACT US TODAY:

machine tool spindle technology is of the finest quality in the machine tool industry. Accutek, with its high-quality CNC Toolholder technology and CNC Workholding technology will be expanding is product offering to include the highquality toolholder technology of Diebold as well as its high-quality Shrink Machine Technology to further support their Distribution Partners and Metalworking customers through Mexico, Canada, and the United States. Accutek will not only sell the Diebold products but also service and support all application requirements to maintain a strong quality and service position in the markets it serves. With the partnership with Diebold, Accutek will be adding the following products to their already strong product offering: • Goldring Toolholders o CentroGrip® Micro-Precision ER Collet system o UltraGrip® Power Milling Chucks o JetSleeve® 2.0 Shrink Fit Coolant Holders o UltraJet® 3.0 Innovative Coolant-thru Power Chucks 510-249-1000, PERMACH.COM o Diebold ER Shrink - ER collets with Shrink Fit technology o DMS – Diebold Modular ER Tooling System • ThermoGrip® Shrink Fit Machine Technology

Our Showroom At: 3305 Edison Way, Fremont, CA 94538 o MS502-P Mini-Shrink Fit machine o US 1100V – Vertical Shrink Fit Machine Is Open Monday - Friday From 8am To 5pm o US 1100H – Horizontal Shrink Fit Machines Announcements Continued o US 1100VT – Vertical Shrink Fit machines with Integral Solution Cooling Accutek® Inc. and Helmut Diebold® GmbH o Patented Pyrometer Coil Technology for all US 1100 machines & Co. Join Forces • Measuring Technology o Clamping Force Tester Two Leaders In Manufacturing Tool Holder Systems Partner to Bring Latest Technology offerings to the North American Market o HSK Taper and D-BT Taper Measuring Gauges o VEG Presetting and Measuring Systems o 3D Edge Finder Technology Addison, IL: Timothy Fara, Exec. VP of Sales and Marketing at Accutek Inc., a high-quality manufacturer of tool holding and work holding Accutek, a high-quality manufacturer of tool holder and work holding products, has a strong Industrial products proudly announces our new partnership with Helmut Diebold Distributor Partner support system throughout North America servicing GmbH & Co. of Jungingen, Germany. Diebold has been a high-quality all of Mexico, Canada, and United States manufacturing businesses. manufacturer of Tool Holding Technology, Shrink Fit Technology, Measuring Technology, and Spindle Technology for the global markets For more information about Accutek and Diebold, visit since 1952. Their technology advancements in Shrink Fit tooling and www.accutekusa.com , call us at 312-757-6577, machine technology have been at the forefront of the industry. Their or e-mail us at sales@accutekusa.com. Full 360° workpiece

The Royal PowerBlock™ Offers Significant Advantages Over Traditional Vises and Fixtures in Five-Axis Applications:

Full 360° workpiece contact for both secure gripping and even load distribution – incredible rigidity in all directions without the risk of crushing thin-walled parts.

Optimized heights and nose diameters provide superior tool clearance.

Parallel-grip collets ensure full-length part contact, while Royal’s industryleading gripping range (0.062”-0.080”) compensates for workpiece variations.

A perfect solution for holding asymmetrical parts when paired with a Royal custom-profile Quick-Grip™ collet.

Actuated via air or hydraulics – great for automatic load/unload applications.

Ten-second collet changes greatly reduce setup times so your valuable machines spend more time making chips.

Not just for round parts – let your imagination run wild.

CHALLENGE ACCEPTED

The new SVM 4100 goes toe-to-toe with the best value VMCs.

Our customers challenged us to create a lighter, faster, value-based VMC, and it’s here: the SVM 4100 is built and packaged to fit the way you work. Faster feedrates, amped up X/Y/Z accel/decel and boosted spindle accel/decel make this machine special.

If performance per dollar is what you’re after, you won’t find much better. The SVM 4100 is an asset for job shops and production houses that churn out aluminum parts every day. To get to work, contact us today.

WASHINGTON/OREGON Sales: (253) 872-1661 Service: (800) 994-0146 Parts: (888) 207-2787

NORTHERN CALIFORNIA Sales: (866) 814-7238 Service: (800) 994-0146 Parts: (888) 207-2787

SOUTHERN CALIFORNIA Sales: (562) 949-8311 Service: (800) 994-0146 Parts: (888) 207-2787

www.ellisontechnologies.com |

Maximize Five-Axis Performance, Productivity, and Profits with the Royal Power-Block™

Contact Royal Products Today!

NORON PRECISION, A WOMAN-OWNED BUSINESS, CERTIFIES TO ISO 9001: 2015 WITH THE HELP OF CONSULTING GROUP BMSC

Noron Precision Machining is pleased to announce that they successfully certified to ISO 9001: 2015! The company didn’t certify to this renown ISO standard to improve their quality and on-time delivery. In fact, their quality measures were pristine, so much so that for one of their key customers, they have received two consecutive bi-yearly, ‘Supplier of The Year’ Awards in recognition of exemplary service providing 100 percent on-time delivery and quality. That same customer recently told Debbie that if all his parts were with Noron his life would be so much easier!

Established more than 4 decades ago, today Noron Precision Machining, Inc. is a Woman Owned and operated business. Since its inception, the company has supported a diverse array of industries, and today this includes medical, microwave, aircraft, auto, computer peripheral, telecommunications, and biotech. During this past year’s COVID pandemic, Noron Precision was deemed an ‘Essential Business’, and it was tasked with manufacturing components for COVID testing equipment. Owner and CEO Debbie Williams, says, “We have long standing, 30-plus year relationships with several of our customers. We insist on 100 percent ontime delivery, superior quality, and excellent communications. We partner up with our customers and have an obligation to satisfy their demands and grow with them.” Noron Precision is well versed in machining plastics, such as PEEK, ABS, and Delrin, as well as metals including: aluminum, steel, stainless steel, brass, bronze, and copper. Noron offers 5-axis CNC milling and turning, and millturn machines, to make small-to-medium sized components like housings, covers, slides, grippers, levers, mounts, caps, and flow cells. With its machining technology and team expertise, Noron holds very tight tolerances. Debbie and the team recognize the need for continuous improvement, and that has meant upgrading their machine tools over the past several years. Debbie says, “Engineers are leaning toward 5-axis design. Running those parts on a 5-axis is the only way to go because we are able to mill all sides without the need for a second op, thus preventing human error.” she said. “The complexity of parts steered us to buying more 5-axis.” As part of Noron’s pursuit of continuous improvement, Debbie says that the company investigated certifying to ISO 9001 some years ago. “We have been lucky, our current customers, including Tier 1 Aerospace, Medical and Defense customers, have grandfathered us in. Still, we knew it was something that would help our business internally and it would enable us to secure new customers.”

Debbie says, “Years ago, we even hired a consultant, and quickly determined the consultant wasn’t a good fit for us.” Around this time, Debbie had seen Bretta Kelly, owner of BMSC and her colleague, Debbie Hart, on the cover of the A2Z Manufacturing magazine. “I was interested in them to help our company back then, but I thought we couldn’t afford them. They had to be too good (and pricey) – they were on the cover after all.”

Debbie saw BMSC on the cover once again last year, and Noron Precision still hadn’t certified. She said, “It was a sign. I had to contact them.”

Debbie contacted Bretta this past October. “I immediately hired them, and with Covid, all of our meetings were virtual. Bretta and Debbie are just so good at what they do. It was so rewarding to find that their philosophy meshes with the way Noron conducts its business – we do what we say we will do.”

Debbie continues, “Bretta and Debbie were always available, and our meetings were often on weekends and evenings.” Literally in a 6-month period, Noron successfully prepared for and achieved their ISO 9001: 2015 certification. Debbie says, “It will make many of our customers happy, and a somewhat surprising benefit is that it is helping us to streamline operations within our company.”

Debbie says, “I just can’t say enough about how great BMSC was for our business —particularly their gift for simplifying the whole process. I recommend them to anyone and everyone I meet in the industry.”

Bretta says, “Debbie was a dream client to work with; she wanted to be sure that we were able to understand every part of her business and how important customer satisfaction was to her. Debbie did not want us to just write something that would get her certified!” We decided to write Debbie’s system to be compliant with AS9100D / ISO 9001:2015, because she already met the additional requirements for the aerospace standard including additional traceability and comprehensive inspection processes. The impeccable performance to objectives and metrics made it easy to implement the aerospace standard. Are you ready to implement ISO 9001or AS9100? Call (602) 445-9400 or visit BusinessMSC.com to learn more.

To learn more about how Noron Precision Machining, a Woman-Owned, ISO 9001: 2015 Certified company, can help your business, contact them at: (408) 739-6486 or visit NoronPrecision.com

By Stephen Hannemann

WE BRING YOU MAGIC!

Full Fabrication Utilizing ALL Materials! From Design, To Laser Cutting, Forming, Welding, To Finishing And Full Assembly

Flatline Fabrication Inc. in Portland, OR is developing the perfect portable fireplace. We have all wished to gather around a cozy fire at an impromptu gathering at one time or another whether on our patios, in our backyard, or while traveling.

Unlike many cumbersome stationary offerings on the market, Flatline’s answer is a collapsible, durable all steel creation that disassembles into a 4” high flat pack with its own leather case for easy garage or RV storage. Assembled, this handsome unit is 29.5” long by 13.75 “ wide, by 10” high. The Flatline Fireplace produces a cinder-less fire, and is much safer in wooded areas and a lot less work than constantly scavenging wood

and tending a fire.

Prototypes have been completed and Flatline is gearing up for production soon with planned deliveries scheduled for midsummer. The unit can be purchased with or

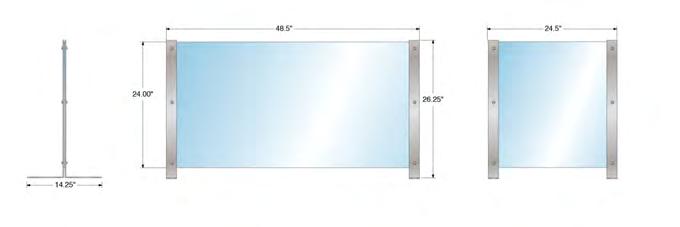

COVID 19 SNEEZE GUARDS, QUICK, SAFE, HIGH QUALITY CALL TODAY TO PLACE YOUR ORDER: 503-477-7566

without a propane tank. A smaller propane bottle adapter can be used for the hardy back packer.

Flatline is accepting pre-production orders. Call Flatline Fabrication Inc. at 503.477.7566 to reserve your fireplace now and be the envy of the neighborhood as the good weather sets in. When in full production the Flatline Fireplace will also be available online through the ThunderStruck Race Co website at thunderstruckraceco.com, but for now call 503.477.7566.

Also check out contact Flatline Fabrication Inc. for all your metal, wood, and plastic fabrication needs: www.flatlinefabrication.com, phone 503.477.7566 4322 NW Yeon Ave., Portland, OR 97210.

Your partner for innovative manufacturing

REVO®—the 5-axis revolution

In nite positioning and synchronized 5-axis motion provide measurement access at unprecedented speed and accuracy. Our newest solution—the RFP fringe probe—expands our family of multisensors further. It adds non-contact structured light inspection to our revolutionary 5-axis measuring system that already includes tactile scanning, touch-trigger, surface nish and vision probe solutions.

www.renishaw.com/revo

Renishaw Inc West Dundee, IL

© 2020 Renishaw plc. All rights reserved. usa@renishaw.com

CMM Revo Half Page Final.indd 1 The Cost of Poor Manufacturing Quality and 5 Ways You Can Improve It

Ken Feitz

We have all heard the quality team referred to as the “brakes” or “bottleneck” of manufacturing but at the end of the day, what truly sets you apart from your competitors? Is it innovation? Operations? Speed? Hopefully, you have those things, but none of them really matter if your product isn’t perfect. Manufacturing quality is the key to differentiation and a competitive advantage.

Manufacturing quality is about conformance to specifications – the design, the manufacturing process and the regulations. It doesn’t matter where the part is manufactured – in-house or with an external supplier. As customer expectations have gone up, manufacturing quality has become a necessary requirement. The bottom line is that manufacturing quality is a critical component of success. And poor manufacturing quality will be a downfall.

High QA provides manufacturing quality management software (QMS) solutions that enable companies to efficiently create, manage and monitor all manufacturing quality requirements across produced parts The cost of poor manufacturing quality is high. Product failures, scrap and recalls will have a lasting negative effect on a manufacturer. Avoiding customer dissatisfaction, damaged reputations and low shareholder confidence from the beginning will aid in success. Products must meet design specifications, comply with industry regulations and meet customer expectations, the first time and every time to be competitive in global markets.

There are several things you can do to improve your manufacturing quality process. Here are 5 basic elements you should implement:

1 - Eliminate Interpretation Errors

The quality process is rife with paper drawings and spreadsheets often with handwritten notes, coffee stains and smudges. Creating digital versions stored in a centralized database ensures that everyone is working from the same up-to-date data and all numbers and notes are clearly readable.

2 - Understanding Quality Beyond Pass/Fail

Quality is not just at the end of the manufacturing process. By leveraging data throughout the manufacturing and quality process, potential issues can be identified and prevented before the final product is completed. Analyzing the data also provides knowledge of how processes are actually performing allowing for changes and adjustments.

4/6/2020 2:04:17 PM

3 - Automate Labor Intensive Processes

Often similar templates and forms are needed for the quality process for each individual part. Creating a standard library helps eliminate wasted time re-creating each form or report. Many quality software management systems consolidate operations, templates, reporting and digital data to reduce the labor needed to complete tasks.

4 - Reduce Bottlenecks

Monitoring and in-process data is vital to keeping an operation functioning. Is a certain process taking longer than was planned? Is a process identifying more issues than it should? Notification and correction of potential issues help ensure the manufacturing process will run smoothly.

5 - Develop Better Quality Documentation

Standard and custom reports, including FAI, PPAP, SPC, NCR, should be easily accessible for all stakeholders who need that information. A company standard and a centralized database will help maintain consistency, accountability, traceability and repeatability.

Quality parts are demanded by consumers. But maintaining manufacturing quality is a constant challenge for manufacturers. Investing in sound processes and technology that will put manufacturers ahead of their competitors in the long run is a must. Don’t get left behind watching your competitors implement better processes and technology

High QA™ provides integrated manufacturing quality management software (QMS) solutions for manufacturing companies of every size to streamline and cost-effectively manage quality processes and efficiently work in partnership with their entire supply chain.

The innovative software solutions provide all the procedures, workflows, structures and resources needed to monitor, manage, communicate and document your manufacturing and quality processes.

With High QA manufacturing quality management software solutions, your products are delivered within tolerance, comply with all applicable standards, and are made in less time with less mistakes.

High QA supports the following key industries and compliance standards; Aerospace (AS9100/EN9100, AS9102), Automotive (QS-9000/ISO/ TS16949, APQP, AIAG guidance), Medical (21CFR, ISO 13485), Defense, Heavy Machinery, Oil and Energy and others with multiple best practice standards.

Fahey Machinery Company, Inc.

Specializing in New and Used Metal Cutting and Fabricating Machinery since 1962. Servicing Oregon, Washington, Idaho and Northern California

Did you know? Fahey Machinery Company, Inc. has a Machinery Service Technician based in Boise, Idaho. Getting on site is a vital first step in any service industry and we believe having Jordan in the Boise area will increase our ability to provide efficient timely service for our customer base east of the Cascades.

Jordan has been a valued machinery service team member since 2018. After the customary training period with our Service Manager, it was evident he would soon become a valued asset to both company and customer. His background as a production press brake operator and programmer coupled with a broad range of mechanical and technical skills have enabled him to quickly diagnose and resolve issues with a wide variety of metal fabrication machinery. His ability to train, share insights and tips with machine operators is a welcomed bonus as well.

Our service team is an integral part of Fahey Machinery Company’s daily operation, and each member is ready to meet your service and maintenance needs.