6 minute read

Feature Articles...........................1,10

and a legacy to be proud of

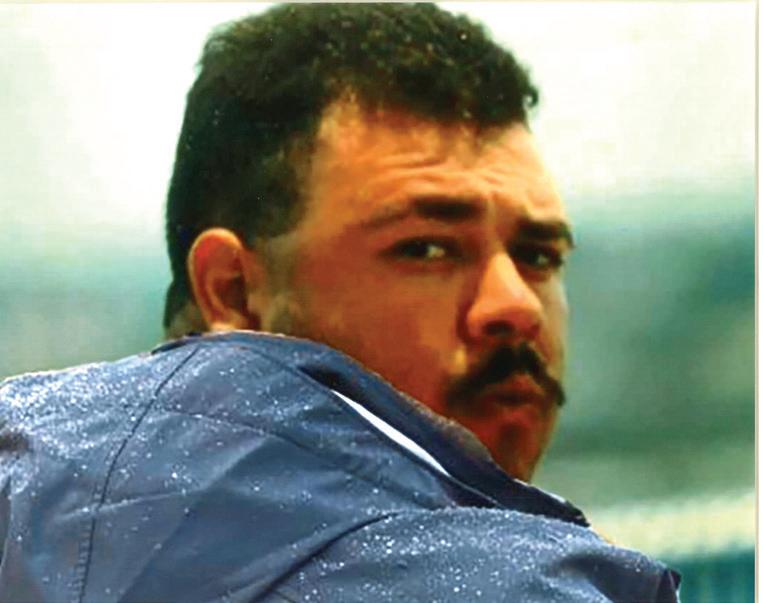

Lin Pryor (pictured on the right side of this page) and Oscar Moreno (pictured below) worked together at Ryerson Steel and Metal West in the late 80’s and through the 90’s. They both cut their teeth in the steel business, and they worked side by side to build a reputation for delivering results for their customers. Lin loves to tell the story about how Oscar was given the toughest sales territory in the market; a territory that no one else wanted. Oscar accepted the challenge and through hard work and dedication, turned it into a territory that generated over a million dollars per month in revenues. Oscar’s philosophy was to service the heck out of every account, not just the big ones. More importantly, he understood the value of relationships and people doing business with people. Big O Metals was founded on this philosophy and still embraces it today.

Lin’s and O s c a r ’s friendship went beyond work; their families were very close, and they spent a lot of time together. You could say that two families essentially became one. Among all the things they had in common, Lin and Oscar shared a love of sports. Oscar was a fitness buff and he worked out on a regular basis. At one time, he held a record for bench pressing 410 pounds. He also loved playing organized sports, but his passion was playing hockey. His competitive nature and muscular build made him a formidable guy on the ice. One night, after finishing a match, he hit the showers where he died tragically of a heart attack due to an undiagnosed heart condition. At 36 years old, Oscar was gone, leaving behind a wife and two young daughters.

In the wake of his death, a common friend of both Lin and Oscar named Kent Grahl stepped in to make sure Oscar’s family was taken care of, even making sure that Oscar’s daughters would receive a college education at no cost to them or their family. Kent and Oscar had been friends since grade school, and it was Oscar who had first introduced Lin to Kent. The importance of this introduction wouldn’t be fully known for many years to come. Oscar and Lin had always talked about starting their own steel service center one day. A few years after Oscar had passed, Lin decided to make their dream a reality by starting his own company. To honor his friend, Lin named the company Big O Metals for Big Oscar. Taking out a home equity loan and with an additional financial investment from Kent Grahl, on January 23, 2006, Big O Metals was born. Needing a logo that matched the name, Lin’s son, Aaron Pryor, took it upon himself to draw one. The company’s original logo depicted an “O” with two muscular arms in honor of the company’s namesake.

In the early years, Lin sold steel, sheared steel, packaged steel, drove a truck to deliver steel; if it had anything to do with steel, Lin did it. As the company gained momentum,

A FRIENDSHIP STRONGER THAN STEEL

Lin hired Christi McCuiston, who was with Metal West at the time, to take over all the planning, forecasting, and purchasing of steel. Christi jokes that in her first months, she was only allowed to buy 40 tons per month. Lin also hired Shawna Noyes, from Reliance Steel, to hit the streets as the company’s first outside salesperson. The early efforts of both Shawna and Christi have had a lasting impact on Big O Metals, and they are both still with the company today.

As the company continued to grow, Lin saw both a need and an opportunity to diversify into value-added fabrication services. Starting with a shear and then a press brake, Big O Metals began to take on more and more fabrication work. Soon it added a dual head plasma machine, then additional press brakes, shears, saws, and a turret. In 2016, BOM took a large leap forward by adding a 4kw laser. Again in 2018, the company stepped up its game by adding a 500ton press brake with sheet followers, Wila precision clamping, auto crowning, and a 6-axis backgauge. In May of this year, the company took another huge leap forward by adding a state-of-the-art 20kw laser with a material automation system. This asset is part of Big O Metal’s ongoing commitment to intentionally design its operations to better serve and support the needs of its customers. Big O Metals added a 72” wide x ¼” Corrective Leveling Line to its operation. This piece of machinery has been a game changer for both the company and its customers. Having the ability to store material in coil form to be cut in house to standard or custom lengths, in a short period of time, is a huge benefit to many of Big O’s customers. It isn’t unheard of for BOM to put up a coil, level it into sheets, and deliver those sheets the same day if a customer is in desperate need of the material.

David Watkins, General Manager of Big O Metals, is one of the primary architects of its current business model. Bringing over 30 years of production and manufacturing experience to the company, he has been able to expand on Lin’s vision of pairing value-added services with BOM’s existing steel service center capabilities.

Under his guidance, Big O Metals has made, and continues to make strategic decisions to be better equipped to serve a diverse, growing, and ever-changing customer base. Dave believes that BOM is uniquely positioned to provide raw materials in conjunction with high mix, high volume fabrication services to OEMs as well as aftermarket and contract manufacturers, often with short lead times, to deliver the value that their customers expect. With the capabilities that BOM has, job shops and precision sheet metal shops can benefit from working with them as well. Having additional resources available to them when and where they need them allows these companies to accept work that may be outside their capacity or capability to complete in-house. By outsourcing with Big O Metals, they can offload commodity type services - like laser cutting, at an economical cost, while retaining forming, machining, and other more intricate operations in house.

David says, “I believe in Alchemy - I’ve seen it work all my life. Not the pseudoscience from the Middle Ages, but a more modern version. Today’s version involves a process of taking something ordinary and turning it into something extraordinary, oftentimes in ways that are almost magical.” At Big O Metals, this idea comes to life daily. Their team members take both durable and service commodities and transform them into something more valuable, and more beneficial to their customers. David adds, “This transformation is driven by our team members - they are the magic.”

Simply put, Big O Metals has the experience, resources, and expertise necessary to become a valuable partner to any organization looking to achieve more with the resources available to them.