JASON ROSS

XU Fang, Director of the American Softwoods’ China Office Softwood Export Council, has been confirmed as one of the speakers for TimberConstruct, Australia’s largest timber construction conference and exhibition, to be held in Melbourne on August 12 and 13, 2024.

More than one-third of the speakers are international, flying to Melbourne or Zooming from the USA, Canada, China, Finland, and Japan.

“So far this year, we have nine international speakers locked in,” according to Andrew Dunn, TimberConstruct’s conference organiser.

“The bumper turnout is a record for Timber Construct.”

“Ms Fang will join Nick Milestone (from Mercer USA) and Yuichi Shinohara, from Shinohara Shoten Co Ltd (from Japan), to discuss Australasia and the Pacific Visionary Timber Projects,”

Mr Dunn said, adding that as glulam capacity improves, China, the world’s most important forest economy is now a global engine room for softwood—connected to 30% of the world’s trade in forest products through its Belt and Road Initiative.

“China is experiencing a Timber revolution thanks to a rapid rise in the construction of timber buildings,” Mr Dunn said,

“as demand for housing and infrastructure skyrocketed, domestic timber production and imports have surged to meet the need for wood-based.

“That’s why we are thrilled to have Xu Fang join us to discuss how China’s rapid rise as a timber economy,” Mr Dunn said, adding that “large-scale timber plantations and wood processing industries were established to supply the booming timber-building sector, transforming China into a global powerhouse for timber construction.”

As it stands, TimberConstruct has more than 35 presenters locked in for the two-day conference and has a strong focus on

materials and design, prefabrication, and building techniques.

The TimberConstruct Conference and Exhibition is owned and organised by the Timber Development Association (TDA), the industry body representing Australian forestry, timber manufacturing, and timber construction interests.

Incorporated in 1938, the TDA was originally established to promote domestic and imported timber products. Over eight decades, their mission has evolved to advance technological innovation and market growth across the timber sector.

Today, the TDA provides strategic leadership and

research investment to strengthen the industry’s competitiveness and sustainability. They facilitate crucial technical knowledge transfer and collaborative opportunities between manufacturers, engineers, architects, builders, and policymakers.

Previously known as FrameAustralia and Timber Offsite Construction, the annual conference’s initial focus was on timber supply chain topics. It progressively widened its scope to cover the complete construction spectrum—from materials and design to prefabrication and building techniques.

https://timberconstruct.org

Page 5-7: More stories and program

JULY / AUGUST 2024

Issue 3 – Volume 34

Incorporating Australian and New Zealand Timberman. Established 1977.

News 3-8, 14-15

Technology 9 Profile 10

Truss & Frame 11

Fastners 12-13

Training 16

Flooring & Decking 17 Associations 18-19

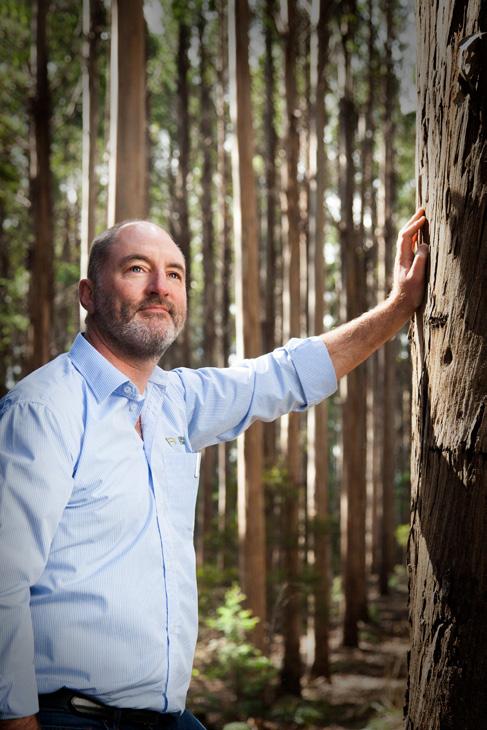

FRONT Cover:

For more than 110 years the name Britton has been synonymous with timber and the North West Tasmanian community. Story Page 10

PUBLISHER and Chief Executive: Hartley Higgins

General Manager: Robyn Haworth

Editor:

Bruce Mitchell

b.mitchell@ryanmediapl.com.au

Adelaide Office (08) 8369 9521

Advertising:

Andrew Everett

a.everett@ryanmediapl.com.au

Adelaide Office (08) 8369 9517

Creative Services: Robyn Haworth

Timber classifieds:

a.everett@ryanmediapl.com.au

Adelaide Office (08) 8369 9517

Subscriptions:

subs@forestsandtimber.com.au

Adelaide Office (08) 8369 9500

Subcription rates

One-year (6 editions) $44.65

Two-years (12 editions) $77.65

Accounts:

ar@winetitles.com.au

Phone: (08) 8369 9500

Postal Address:

630 Regency Road, Broadview South Australia 5083

Phone: (08) 8369 9500

Melbourne Office: Suite 2262, 442 Auburn Rd, Hawthorn VIC 3122

Phone: (03) 9810 3262

Website www.timberbiz.com.au

Printed by Lane Print, Adelaide, SA

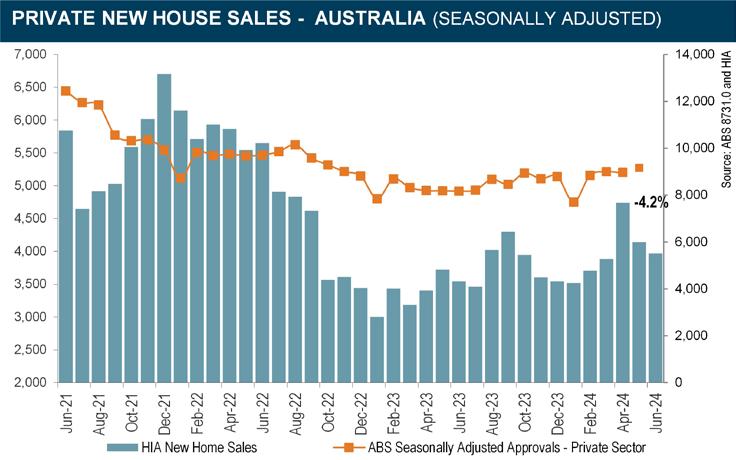

SALES of new homes nationally increased by 15.7 per cent in the June quarter 2024 compared to the March quarter indicating that the number of homes commencing construction is set to increase later this year.

The HIA New Home Sales report is a monthly survey of the largest volume home builders in the five largest states and is a leading indicator of future detached home construction.

HIA Economist Maurice Tapang said that this increase in sales was first observed in Western Australia in the second half of 2023 when sales in that market started to increase.

“This year, sales in Queensland and South Australia have also observed a sustained increase in recent months,” Mr Tapang said.

“Driven by this increase in sales in these three states, new home sales in the June quarter 2024 were 20.4 per cent higher compared to the same period in the previous year.

“With the sales recovery in these markets now sustained, an increase in the number of new detached houses commencing construction will be observed in the second half of this year, albeit from a low base,” he said.

Market confidence was returning as the impact of rate increases dissipated and the shortage of housing stock made new home building increasingly attractive.

“These three markets have seen demand for new homes

increase due to strong employment opportunities and relatively affordable land, driving local population growth,” Mr Tapang said.

“At the same time, new home sales in New South Wales and Victoria remain weak despite similar growth in demand. The adverse impact of rate rises is more significant here due to the higher cost of residential land in Sydney and Melbourne.”

Sales in New South Wales and Victoria had also been constrained by the introduction of additional regulatory costs, through the National Construction Code which had distorted sales data.

“As a result, there is not the significant or sustained increase in sales required to expect an increase in home

building in either of these markets,” Mr Tapang said.

“The higher cost of delivering a new house and land package, due to higher taxes, fees and charges in these markets, is impairing the recovery of detached home building.”

New home sales saw the largest increase in the June quarter 2024 in New South Wales, up by 32.8 per cent compared to the March quarter, followed by South Australia (+29.3 per cent), Queensland (+19.5 per cent), Victoria (+10.3 per cent), and Western Australia (+7.8 per cent).

New home sales in the financial year 2023/24 increased by 25.4 per cent in Western Australia, followed by Queensland (+10.6 per

cent) and South Australia (+2.3 per cent). The two other states recorded a decline in 2023/24, with Victoria down by 7.6 per cent and New South Wales down by 7.5 per cent.

Dwelling commencements in the March quarter 2024 increased by 24.9 per cent in Western Australia compared to the same quarter in the previous year, followed by the Australian Capital Territory (+24.7 per cent). The other jurisdictions recorded a declines in commencements, led by the Northern Territory (-41.2 per cent) followed by Tasmania (-37.0 per cent), New South Wales (-29.7 per cent), Victoria (-13.8 per cent), Queensland (-9.5 per cent), and South Australia (-4.8 per cent).

NEW name, new venue, and this year’s Timber Construct Conference and Exhibition will offer an international focus.

Now in its 25th year TimberConstruct, previously known as FrameAustralia and Timber Offsite Construction, has more than 35 presenters locked in for the two-day conference and has a strong focus on materials and design, prefabrication, and building techniques.

It has been recognised as one of the three major

global events focussed on the design and construction of engineered timber and mass wood buildings.

The annual conference’s initial focus was on timber supply chain topics. It progressively widened its scope to cover the complete construction spectrum—from materials and design to prefabrication and building

techniques.

This year more than onethird of the speakers are international, flying to Melbourne or Zooming from the USA, Canada, China, Finland, and Japan.

It comes at a time when Australia is increasingly embracing tall wooden structures, second only to Canada.

The event will be a global ‘hybrid’ format combining ‘in person’ and ‘on-line’ for both speakers and delegates to provide a new and unrivalled experience for all attendees.

Continuing the tradition of previous TOC conferences, the event will offer a diverse range of session topics featuring world-class speakers. Attendees can expect indepth case studies exploring the intricacies of design and construction processes across low-rise, medium, and highrise building projects.

The conference will be held at Rydges Melbourne, August 12-13.

JASON ROSS

THE demand for timber buildings is poised to grow exponentially, far beyond the 25-to-40-fold projected in new studies, but it needs to add the right type of value for developers—whether that’s tangible or intangible, driving carbon savings, lighter and faster assembly and construction, or in attracting A-grade tenants with green design.

That is according to Noel Johnson, a US real estate developer who is now using mass timber construction systems on commercial, residential, and mixed-use projects, ranging from the small to $100m-plus highrises.

Mr Johnson is one of the US’s most prolific mass timber developers, with several projects completed in the residential and commer-

cial sectors. His experience with mass timber has made him one of the industry’s biggest advocates in the US market.

Speaking exclusively to TimberConstruct, Mr Johnson, who is flying from Portland, Oregan, to present in person at TimberConstruct in August, said the building and construction industry (as well as the timber supply chain) needs to change its mindset around the future of development.

“The real estate development world is a world of billions of dollars of capital flow. And that’s part of the mindset that I would bring to our conversation from scaling up this sort of sensibility standpoint because all we’re looking to do is divert a percentage of that flow globally.”

Mr Johnson said that for mass timber to scale and go beyond being a novelty, it needs to meet the requirements of investment and

pension fund money allocators – to appeal to the money markets.

“The core of every fund manager is to acquire differentiated assets – because we all know that will be a better asset,” whether it’s a megadevelopment – which can take years to fully realise or a smaller development with quick turnarounds.

“Mass timber-based developments have the potential to build a 200-unit develop-

ment right here; you can build another and turn around for the next one before the mega-development is even out of the ground.”

“It also has a very distinct look and feel – which is very different,” he said, adding that the intangibles, “like guy or gal that wakes up in the morning and likes the space and therefore doesn’t want to move”, help to drive the net income or numerator, that can help drive future developments.

“So it’s not a game of low costs as much as it is, what are your costs relative to the net income, the numerator because all we’re trying to go towards is the resultant, right, the return on that cost.”

“And that’s a good example of how I would speak on a day-to-day level with my projects to my investors."

https://timberconstruct.org

Automate for speed and efficiency to eliminate labour shortage problems.

The manufacturing world we live in now post COVID-19 has seen international setbacks and problems with delays in importing and increases across the board in prices of goods. Australia has also seen a growing problem with shortages in labour, causing further delays in local manufacturing. This poses great challenges for the economy as a whole, but also for individual businesses. Producing economically while maintaining quality standards is becoming a real challenge for many businesses. One solution to this problem is to expand the automation of individual work processes or entire production lines.

The BeA Group, headquartered in Germany, with APAC headquarter in Sydney and warehouse in Brisbane, Sydney and Melbourne, offers excellent automation solutions. BeA partners with local and world leading automation specialists in timber construction and wood processing, to provide tailored automation solutions across the entire production line in industries such as furniture, production of pallets, house frame and truss, and windows and doors and like manufacturing. With its „Autotec“ division, the BeA Group is one of the world‘s leading manufacturers of equipment for automated production. In this field, BeA cooperates with the world market leaders for wood processing equipment and is a reliable partner with over 100 years of competence and know-how in this field. Autotec equipment is available in a wide variety of versions and for almost any application. Should a very special solution be required, BeA can also offer special solutions with its internal engineering department.

Phone: 1300 232 287 or +61 438 841 708

Email: apac@bea-group.com

www.bea-group.com

The 2024 TimberConstruct conference program features cutting-edge sessions on sustainable practices and innovative timber construction techniques. Unleash your passion for timber construction at this dynamic conference. Join us for an immersive discussion that will provide valuable insights and practical knowledge to professionals in the industry. Discover innovative strategies to overcome barriers and promote the widespread adoption of timber as a sustainable and versatile building material.

Here’s what’s scheduled for TimberConstruct 2024.

9:00AM - 10:30AM: DEVELOPERS TIMBER JOURNEY AND THE LATEST TIMBER ENGINEERING DEVELOPMENTS

Delve into the captivating world of timber building development with renowned speakers offering insights into the remarkable journey that underpins their timber creations. Gain an understanding of the driving factors behind incorporating wood as a primary material. Cap off the session with Fast and Epps, a leading international structural engineering firm specialising in architecturally expressive exposed timber structures.

11:00AM - 12:30PM: ‘ TIMBER TAKES ON HOUSING SHORTFALL’

As the nation embarks on an ambitious quest to provide

housing for all, a panel of experts will convene to explore how timber construction can help drive progress towards this goal. They will delve into the far-reaching potential of wood-based building systems to accelerate housing development across various sectors. The panel will provide a comprehensive overview spanning lightweight off-site timber construction methodologies, offering efficiency and rapid deployment to mass timber structures that can reach remarkable heights. Additionally, the discussion will cover innovative hybrid solutions that combine timber with other modern materials to push the boundaries of design.

1:45PM - 3:00PM: CONQUERING LOW-RISE CHALLENGES AND EXPLORING

THE CUTTING EDGE OF TIMBER CONSTRUCTION ACROSS CULTURES

Delve into the low-rise timber construction world during this comprehensive session. Gain insights into the techniques, materials, and methodologies of building multistory structures using wood-based systems. Explore the advantages, challenges, and emerging trends in this sustainable and versatile approach to construction. Whether you’re an industry professional, developer, or simply interested in innovative building practices, this session promises to provide valuable knowledge and perspectives on the growing prominence of timber in low and mid-rise projects. The Factory of the Future consists of a suite of laboratories, classrooms, and meeting rooms for the TAFE, as well as an innovation hub in the factory building set in the heart of Adelaide’s technology, manufacturing, and industry base.

4:00PM - 5:00PM: EXPLORING THE CUTTING EDGE OF TIMBER CONSTRUCTION ACROSS CULTURES - CONTINUED.

This insightful session delves into the innovative use of timber in construction projects spanning China, Japan, and Europe. Prominent experts from each nation will share their insights and highlight the exciting advancements shaping the timber construction landscape within their respective countries. Discover how these diverse regions are pioneering new frontiers in wood-based architecture and engineering, each pushing the boundaries of timber utilisation in unique and captivating ways. Join us for a cross-cultural exploration of timber’s resurgence as a sustainable and versatile building material at the forefront of modern construction.

TUESDAY 13 AUGUST 2024: TIMBER INNOVATION: LEADING THE WAY

9:00AM - 10:30AM: NORTH AMERICA MASS TIMBER SKYLINE, ROOFING REVOLUTION: NAVIGATING MODERN CONSTRUCTION FRONTIERS’

Dive into a whirlwind tour of construction innovation as we explore the cutting-edge new Portland Terminal roof, uncover clever material substitution secrets, and navigate the maze of compliance for off-site manufactured buildings. This action-packed session is a treasure trove of insights, blending architectural marvels with practical know-how, guaranteed

to revolutionise your approach to modern construction challenges. Take advantage of this opportunity to stay ahead of the curve in an industry that’s constantly evolving.

11:00AM - 12:30PM: ‘CONQUERING TIMBER’S ACHILLES’ HEEL: A MOISTURE MASTERY ODYSSEY’

Moisture poses a persistent challenge that can compromise timber buildings’ longevity and structural integrity if not properly addressed. To fully revel in the bounties of wood, confronting this adversary head-on is re-

■ ASH

■ BeA australia

■ Binderholz

■ Cabot’s

■ Cadwork Australasia

■ CLT Toolbox

■ DC Tech (Proctor Group)

■ Hasslacher group/Hess Timber

■ Homag

■ HSBCAD

■ Hundegger Australasia

■ KLH

■ Michael Weinig Australia P/L

■ Rothoblaas

■ Schmid Schrauben

■ Seigware

■ Simpson Strong Ties

■ SMT Research Ltd

■ Spax Pacific

■ Timber Building System

■ Timberlink Australia

■ Wood Solutions

■ Xlam

quired, wielding strategies forged from the depths of expertise.

From the delivery to the intricate ballet of construction and the meticulous choreography of inservice management, each phase demands a tailored approach to subdue moisture’s relentless siege. A panel of experts will discuss their strategies to minimise the effects of moisture.

An experienced contractor will discuss their experience in managing water during the construction of timber buildings.

A world leader in real-time building physics tracking will showcase permanent roof leak detection, which can pinpoint moisture breaches early before significant damage. This proactive safeguard system uses sensor networks installed directly into

roof assemblies. Data on moisture content is continuously gathered, enabling issue identification as it occurs. The technology helps builders maximise roof lifespan, minimise expensive repairs, and rapidly target leak locations to preserve building integrity.

1:30PM - 3:40PM: CONQUERING MID TO HIGHRISE CHALLENGES

Continuing from Day 1, we now look at the mid and highrise sector. We continue to gain insight from design teams behind notable timber projects as they delve into their project objectives, the challenges they encountered, and the strategies they employed to overcome them.

The two projects are: CIT Woden – A new six-storey educational facility in the heart

of Woden, ACT offers smart classrooms and state-of-the-art simulated learning environments. Covering over 22,500 m2 and costing around $250 million, the building offers a contemporary and sustainable campus for up to 6,500 students.

Atlassian Central Update –Pioneering Tall Hybrid-Timber Construction is poised to become a landmark achievement, soaring at an impressive 39 storeys. This ambitious structure presents unique challenges that require innovative solutions across various construction aspects. The seamless integration of mass timber elements with conventional building materials necessitates a collaborative approach, harnessing the collective expertise of architects, engineers, and con-

struction professionals.

4:00PM - 5:00PM: CRACKING TIMBER’S FULL POTENTIAL - CODE UPDATES AND ADVANCED WOOD PRODUCTS

This session examines crucial developments facilitating the rise of taller timber structures. First, an investigation of the code change adopted in Canada and the USA for fire design standards for timber buildings up to 18 storeys. With varying levels of exposed timber corresponding to increased height, this proposal presents a proven approach to meet the growing demand for taller wood constructions while ensuring stringent safety standards. The panel aims to discuss whether the North American experience is suitable for Australia.

Fixed and adjustable heads available.

Pack size up to 1200x1200mm.

Touchscreen operation with pack tallying and self-diagnostics.

Heavy duty construction for hardwood up to 300mm wide.

Ideal for rough sawn, mouldered, or fingerjointed product.

THE proposed multi-purpose $715-million sports stadium at Hobart’s Macquarie Point will feature the largest timber roofed stadium in the world.

The concept designs were completed just eight weeks after Australian firm Cox Architecture, which has been involved in Australia’s last four major oval stadiums including Perth Stadium and the redeveloped Adelaide Oval, was awarded the $37.9m contract as the lead architect in early May.

The fixed, dome-shaped roof is an important part of the design.

“The transparent roof, which is supported by an internal steel and timber frame, provides an opportunity to showcase Tasmanian timber,” Tasmania’s Sport and Events Minister Nic Street said.

“The frame will support a fully

transparent ETFE (ethylene tetrafluoroethylene ) material, which is a plastic based material designed to have a high corrosion resistance and strength over a wide temperature range.

“This will allow light in, support natural turf growth, and avoid the need for large light towers,” he said.

“We’ve worked to design a welcoming, functional and uniquely Tasmanian multipurpose stadium, for this space.

“When completed, the Stadium will be the largest timber roofed stadium in the world.”

Cox Architecture took inspiration from the former railway roundhouse structure, which was part of the old Hobart Rail Yard from 1915 until the 1980s.

According to Tasmanian Forest Products Association Chief Executive Officer, Nick Steel, the stadium’s concept plans are an exciting vision of what Tasmania’s

newest iconic building will look like.

“With the release of Hobart’s new stadium design, including the use of beautiful Tasmanian timber, I look forward to the pride we will all feel when our very own Tasmanian team runs out into the cauldron of our very own stadium. It will be a pivotal moment for the history of our state,” Mr Steel said.

“And now we see our colosseum will showcase the best that or state has to offer – including our beautiful, sustainable and carbon-rich Tasmanian timber.

“This project will showcase Tasmania’s stunning timber to Australia and the rest of the world.”

Mr Steel said the use of timber in our stadium is not just for aesthetics, with modern timber products offer significant advantages over the use of the traditional construction materials such as concrete and steel.

“Aside from its beauty, timber products such as cross laminated veneer and glue-lam offer the strength, durability and fire ratings of more traditional construction materials,” Mr Steel said.

“But unlike concrete and steel, our products are more energy efficient to produce, are carbon-rich and fully renewable, with the Tasmanian forestry industry replanting or regrowing every tree we harvest.

“That means that the trees we replant following harvesting for our stadium will continue to sequester carbon and, when mature, will be available to build future homes for Tasmanian families.”

Mr Steel said the forestry industry is excited to work with the architects, builders and the government in creating this game-changing project but warned the full scope of the stadium’s timber needs are not yet known.

“We are only in the concept stage of the plan. Until actual designs are released, we’re unable to determine how much timber will be needed,” Mr Steel said.

“But the Tasmanian timber industry will be working with all stakeholders to ensure that when timber is required, we’ll be able to supply Tasmanian timber to the project.

“A project of this scale will use a lot of different timbers – whether that be from our managed regrowth forests or our plantation estates.

“Not all timber is suitable for every application. But Tasmania’s timber estate is diverse and will be able to be used across all the applications this project will require.

“This is a unique opportunity to support Tasmania’s timber businesses and the thousands of people we employ across the state,” Mr Steel said.

THE Pentarch Group has grown by becoming a significant stakeholder in prefabricated house component construction business Green Timber Technology (GTT).

GTT was established three years ago as part of a revolution in house construction by fabricating walls, roofs and floors in a specialised factory to be delivered to home sites for assembly.

This new concept in housing construction reduces material waste, time lost through weather events and labour costs when compared to onsite construction.

“Modular and prefab construction is a growing sector which the NSW Government has identified as a solution to ease the shortage of affordable housing by providing a steady supply of cost-effective housing components,” said Pentarch Executive Director Steve Dadd.

Mr Dadd will become Chair of the GTT board as part of the investment and said Pentarch’s existing infrastructure and manufacturing capability is aligned with GTT’s vision for the future.

“With our understanding of major capital projects and factory efficiency in softwood construction, Pentarch is positioned to take GTT to the forefront of the prefabrication market,” he said.

“We already have in place supply capability with our Oberon softwood facility close to the GTT location in Orange, NSW, and a network of stakeholders in the housing construction industry.

“It’s an exciting time in housing construction technology which meets an immediate challenge with our housing shortage crisis and Pentarch is proud to be a part of the solution.”

Prefabricated timber kits can be constructed with all the components, such as windows, insulation, electrical wiring and plumbing conduits, installed and flatpacked to be transported to new home sites.

Specialised machinery is incorporated to maximise the use of the plantation softwood and other materials which combine to create attractive and durable housing components.

TIMBER Unlimited has partnered with Australia’s CLT Toolbox to offer parts of this advanced software for free to New Zealand industry.

“With the release of the new Timber Structures Standard (NZSAS 1720.1:2022), it’s essential that we provide the industry with the resources to implement these new standards effectively,” Technical Manager at Timber Unlimited Bjørn Stankowitz said.

CLT CEO Adam Jones said CLT’s goal was to empower engineers with the tools they needed to design sustainable, resilient timber structures.

“Our software does just that, making advanced timber design accessible to all,” Mr Jones said This collaboration brings advanced, world-class design software to engineers across the country at no cost, streamlining complex design processes and promoting sustainable building prac-

tices.

CLT Toolbox, a leader in timber engineering software, has developed solutions that address the technical challenges of timber design, focusing on reducing embodied carbon in construction.

The technical challenges of timber design are addressed by providing streamlined automated design routines and comprehensive educational support which CLT Toolbox has developed.

Unlike other tools, CLT Toolbox offers transparent calculation methods that are not a ‘black box,’ enabling

engineers to understand and trust the design processes to build confidence when specifying timber.

This collaboration equips New Zealand engineers with advanced design methods, empowering them to create higher-performing and lower-risk timber structures with greater confidence.

The CLT Toolbox software aligns with the newly released NZS AS 1720.1:2022 Timber Structures Standard. This standard introduces new design methodologies and requirements for structural elements and connections,

including brittle failure modes, based on the latest research and international knowledge.

The software includes educational features that guide users through these advancements, reducing the learning curve and promoting widespread adoption.

The Timber Design Society is particularly excited about the potential of this validated software package to empower smaller engineering firms in New Zealand.

“New design methods can be a barrier to adopting a new material or construction

typology, and this software will help engineers become confident timber designers. We look forward to seeing an increasing number of timber buildings in New Zealand and an increase in the quality of those designs”, Timber Design Society president Lisa Oliver said.

Interim Portfolio Leader of Trees to High Value Wood Products at Scion, Elizabeth Dunningham, said that it was satisfying to see this collaboration between Timber Unlimited, Timber Design Society and CLT Toolbox progress with Scion’s support as the contract holder for Timber Unlimited for the past two years.

“This collaborative effort delivers an easier pathway for increasing timber in New Zealand buildings, improving sustainability credentials,” she said.

The partnership between TU and CLT Toolbox addresses the resistance faced by many designers due to the complexities of the new standard.

FOR more than 110 years the name Britton has been synonymous with timber and the North West Tasmanian community.

The Britton brothers who arrived in the cold, wet blackwood swamps of Northern Tasmanian in 1907 could not have imagined that a century later their family would be leaders and innovators in the Australian forest industry. They couldn’t have comprehended that the business would be so vertically integrated to eliminate waste that the offcuts from the Britton Timber mill would be used as boiler fuel for the local McCains potato factory, the local pool and vast flower farms of the north west would use their sawdust to heat their greenhouses.

Today Britton Timbers distributes timber all over the world through their distribution centres in Tasmania, Melbourne, Sydney and Brisbane. Britton Timbers supply timber for applications including flooring, furniture, cabinetry, joinery, boating, decking including sports floors and cladding. Britton’s also have specialty products including Touchwood, a timber tongue and groove panelling product, which overlays Tasmanian Oak veneer onto a substrate.

Shawn Britton, Managing Director of Britton Timbers spoke on the Original Thinkers Podcast about his pioneering family, the beginning of sawmilling in Tasmania, Britton Timbers today and shared his thoughts on some of the biggest questions about the Tasmanian timber industry.

“They carted equipment

“Sustainability is very important. Our business relies on a natural product that grows in forests and without those forests being managed on a sustainable basis, we wouldn’t have a business. We wouldn’t be here now if the forest hadn’t been managed responsibly over generations to continue supply of Tasmanian Blackwood and Tasmanian Oak.”

When asked about the challenges in today’s Tasmanian forest industry, Shawn said misinformation is a constant battle.

coupes. And here’s the Forest Practices Plan for those logging coupes to show that full chain of traceability.”

Shawn says that often builders, joiners and architects like to come and see where their timber comes from, and they are welcome to see the Britton plantations and the sawmill and understand the process.

out into the middle of a forest with no roads, no tracks. It would have been wet, cold, very tough conditions and they forged an existence out of the Blackwood Swamp. They built their own tramways and a sawmill and started supplying timber particularly to the mainland.

Melbourne, Sydney and Adelaide were going through big growth stages in that era and had an insatiable demand for timber, not much has

changed 115 years later.”

Today the mill processes about 30 – 35,000 cubic meters of sawlogs annually. Britton’s also employs 100 people, some who have been with them for 40 years, as well as a whole host of contractors.

Shawn Britton is the fourth generation to be running this highly successful business which he says is a testament to the sustainability of the resource in Tasmania.

Shawn explained on the podcast the importance of chain of custody. Each piece of timber can be traced from coupe to end product:

“It’s possible for us to say to a customer, that pack of timber that you’re using on this hotel project, was cut in our sawmill on the 10th of July last year and it came from this bunch of logs that came from this particular coupe or these three logging

ARBORTECH Industries Ltd, an Australian innovator and manufacturer of cuttingedge power tools and accessories worldwide, has reached a strategic licensing and supply agreement with worldwide industry leader Stanley Black & Decker.

The agreement allows Arbortech to transition into cordless equipment supported by Stanley Black &

Decker’s world-class DeWalt battery system for professional users.

Arbortech’s “Powered by DeWalt” products are expected to be unveiled mid-year, beginning with the BA200X, an evolution of Arbortech’s renowned Allsaw technology which over many years has revolutionised the masonry cutting industry.

Subsequent product releases will include a range of woodworking and

trade tools, marking a new era of versatility and performance.

Headquartered in Perth, Arbortech has solidified its position in global markets, with offices spanning North America, Canada, and Germany.

“This agreement with Stanley Black & Decker signifies a momentous leap forward in our journey,” Arbortech

chairman Kevin Inkster said.

“Not only does it underscore our

“They like to understand. They like to come to Tasmania, have a look at our processes to see how we create the timber and timber products for them. They can then also understand the supply chain and understand the sustainability of what we have and how it all works. And then they pass that on to their customers as well. It’s a pretty good news story.”

To hear more from this conversation with Shawn Britton, listen to the episode from the Original Thinkers Podcast at https:// tasmaniantimber.com.au/ podcast/shawn-britton/

dedication to innovation, but it also heralds a period of unprecedented growth and recognition for our brand.

“In alignment with the Federal Government’s ‘Future Made in Australia’ policy, we are poised to contribute to the diversification and growth of the Australian manufacturing sector. This agreement presents boundless opportunities for global expansion and innovation.”

KAT WELSH

WHETHER you believe in climate change or not, one thing is very clear – governments globally are moving to circular economies, including Australia, which means that construction materials that fit that impending demand, are renewables.

As society becomes more aware of environmental responsibility, people want their home and urban community to be sustainable, green, and conscious. Promoting Carbon Warrior, and what it means within the built environment, will only lead to people making more ethical choices, and if the industry collaborates with the benefits of timber, we all win.

Pinelock Systems, a Western Australian frame and truss fabricator, have embraced the Carbon Warrior identity, and are spreading the message to make sure timber is utilised to the maximum. Kenny McGonnell and Kristin Small, have taken on Carbon Warrior merch for their team at Pinelock, and make the most of the positive interactions that stem from the t-shirts or hoodies that they wear.

“I think some industries have forgotten what timber can actually achieve and do… offering what it can actually do and how much better and efficient it is in the building industry, and doing bigger commercial builds with it, a lot of people go ‘you’ve got to go with steel’ with bigger builds, but you don’t have to. We can design in timber,” said Kenny.

Kenny and Kristin are located in an interesting demographic in Australia. Albany, Denmark, Esperance, Witchcliffe and Margaret River have a substantial alternative scene –people dedicated to environment and making green lifestyle choices. As a business, it means that Kenny and Kristin are promoting Carbon Warrior because it’s important, not because it’s necessarily essential for trade.

Kenny talked about the lack of knowledge/education for people, to understand the capabilities of timber and renewables in regional WA. They usually seek guidance from other businesses on the eastern side of Australia.

“You need to work with someone who’s keen in that area, to go ‘yes this will work’. Timber was huge back in the day, for hundreds of years. I don’t know how all of a sudden it can’t comply when it does. It should,” said Kenny.

Any plans that Pinelock design list the carbon footprint on the paperwork. It’s a subtle way of suggesting to clients, to think about the impact of the build. If others aren’t including that on their designs (i.e. steel framers) why not? It’s a great way to promote, but not to force. It gives enough of an indication to start consciously determining their choices.

Kristin talked about other frame and truss fabricators in Perth and Albany, also pushing the benefits of timber and its capabilities. Even though the businesses are competitors, they collaborate where they can, and in the messaging around timber – there is more than enough work for everyone. The housing needs won’t be disappearing anytime fast.

For them both personally, and Pinelock, their vision is to show how great timber is. To support change, it’s great to evidence the data – actions, not just words. “We have to push timber more to show what we can do with it,’ said Kenny, “I’ve always been leading by example, have it for someone to say ‘here, look, this is the better solution. Look it’s there.’”

Incorporating Carbon Warrior as an

LOCALLY grown and manufactured timber will provide the building blocks for South Australia’s new technical colleges at Tonsley in Adelaide and in Mount Gambier.

NeXTimber’s state of the art manufacturing facility at Tarpeena will be supplying the Cross

Laminated Timber for these projects with every cubic meter for finished softwood storing 718kg of CO2-e, the only building product that is carbon positive.

The technical college at Mount Gambier, which is due to begin construction in early 2025, will be co-located in the research and education

identity, is helping to market the industry. It’s a part of the picture when it comes to timber, not something to be silent about. Why leave the environmental benefits off the marketing campaign when trying to sell sustainable wood? “It’s not just FTMA pushing it, it’s actually the fabricators

as well,” said Kristin, talking about the response they’ve had from taking on Carbon Warrior, wearing hoodies, and promoting the messaging.

“It’s working for all of us,” said Kenny, “every frame and truss manufacturer should be going ‘oh yes, this is a part of it, helping our businesses’.”

precinct alongside the existing TAFE and the new Forestry Centre of Excellence.

The State Government has committed $208 million to five technical colleges, which will see three opened in metropolitan Adelaide, one in Port Augusta and one in Mount Gambier, by 2026.

A European company has been chosen above a leading Victorian manufacturer, Australian Sustainable Hardwoods, to supply a major timber structure for Melbourne’s new underground Anzac metro station, prompting anger from the State Opposition and the CFMEU manufacturing union.

The Victorian State Opposition claims that the action has destroyed the Andrews Government’s commitment of 88 per cent local content for the project, and that ASH, based at Heyfield in Gippsland, was unfairly treated in the tender process.

2018

More than 50 buildings in Australia have been built from engineered timber in the past five years, with Australia now having the third highest number of tall buildings in the world made from wood.

Mass timber – CLT, GLT (Glulam), LVL and NLT (Nail Laminated Timber) – has come a long way since the Forte building in Melbourne’s Docklands was first discussed nine years go and completed in 2012, said the chief executive of the Timber Development Association, Andrew Dunn, when he addressed the Frame Australia conference in Melbourne, which was attended by more than 200 delegates.

2013

In collaboration with FWPA, the Australian Timber Importers Federation (ATIF) will be holding the timber industry’s must attend event for 2013 on 11 October in Sydney at the Novotel Rockford Darling Harbour Hotel.

The Obstacles and opportunities seminar will cover key aspects of the timber industry supply chain, together with wider aspects of the timber industry’s business environment, wood-based product marketing and matters related to company-level business success.

The seminar speaking line-up will include leading international and Australian timber supply chain experts, policy-makers, marketing specialists, technology providers and regulatory authorities.

GABRIEL MARTINS GRADUATE ENGINEER MULTINAIL

AGIRDER truss is one that is designed to be stronger than a standard truss in order to support other trusses and beams in a roof.

When utilising a girder truss to support standard trusses perpendicular to it, the connection between the two must accomplish three things:

• Support the Load.

• Ensure Girder bottom chord cannot be separated from standard trusses.

• Prevent rotational forces from being applied to the standard truss.

Prior to the availability of a wide variety of anti-twist and high-load girder bracket products, it was common practice in the construction industry to apply a standard connection detail between girders and standard trusses specified in AS4440 (see figure 1).

In conjunction with the girder bracket, this detail involves the installation of a tension strap nailed to the underside of the girder and supported truss. Whilst the bracket provides the appropriate fixing and transfer of reaction forces, the tensioned strap aims at preventing rotational forces in the standard truss.

With the progressive development of girder bracket products, the use of this method has become decreasingly common. The need for anti-twist bracing straps has diminished with the increased popularity of products advertised by manufacturers as providing rotational restraint to the supported truss. The preference for these products over the traditional method can be attributed to their simpler and quicker installation and their ability to accomplish all three requirements of girder-to-standard truss connections.

Recently, issues have been arising on site where the bottom chord of girder trusses, especially those supporting trusses with long spans, have become twisted. So why is this problem occurring even with the availability of so many rotation-resisting truss boots?

To provide a more economical design, detailers will often refrain from specifying these “all in one” products such as anti-twist or high-load truss boots and will instead opt to use products such as joist hangers or regular girder brackets for girder to standard truss connections. Even though these connectors may correctly transfer the

reaction forces, they may not provide appropriate rotational restraint.

It seems as if one of the reasons these rotation issues in trusses on site are occurring is that some builders and detailers are unaware of the need for rotational restraint in girder brackets or are not familiar with which products provide anti-rotation properties.

Which bracket provides anti-rotation properties?

When using a particular product for girder-to-truss connection, it is important to know whether it provides restraint against twisting. If not, the appropriate anti-rotation measures must be taken.

Section 5.3 of AS4440 speci-

fies 4 types of truss-to-girder truss connections.

1. FRAMING BRACKET (JOIST HANGER)

It is specified in AS4440 that joist hangers may be used to support trusses with a small span such as half trusses, jack trusses or creeper trusses. No rotation restraint detail is specified for this case since small span trusses will not inflict a significant rotational force on the girder.

2. STANDARD TRUSS BOOT

Standard truss boots are designed to support standard and truncated standard trusses. For this type of connection, anti-twist bracing is required. Depending on the

product, standard truss boots may have anti-rotation measures built into them. These come in the form of anti-rotation flanges, which extend along and fix to the bottom chord of the supported truss, and anti-rotation tabs, which protrude behind the bracket under the bottom chord of the girder (see Figure 2 for example). If a standard truss boot does not have these features, anti-twist bracing elements will have to be applied manually such as the tension strap detail displayed in figure 1.

3.

These are designed to support standard and truncated standard trusses as well as small girders. As its name suggests, these products provide anti-twist bracing with no additional bracing required.

4. HIGH-LOAD TRUSS BOOT

This is usually, a welded bracket designed for heavy loading from large standard, truncated standard, girder, and truncated girder trusses. These products also provide

anti-twist bracing with no further bracing required.

One of the other reasons for bottom chord twisting issues on site is errors in the installation of truss boots. Even though the correct product may be used, if the correct installation procedure is not followed, these issues can still occur. One common installation error of truss boots is failing to fix the required number of screws at the flange on the supported truss, reducing the anti-rotation potential of the product. Another common error is letting the supported trusses sit in the brackets for too long before fixing, causing the girder bottom chord to twist under the own self weight of the supported trusses. An example of an on-site girder rotation issue can be seen in figure 3.

It is important to note that connection details vary by product and to achieve the anti-rotation properties advertised for a specific product, it must be installed

and connected to the girder and supported truss in accordance with the manufacturer’s specifications.

With the abundance of truss boot products available in the market which account for all relevant forces, it is easy to forget the need for anti-rotation bracing on girder-to-standard truss con-

nections. When designing such connections, it is important to remember that end reactions are not the only force to be considered. Detailers should be familiar with the product they are specifying and whether they provide anti-rotation restraints. If not, the correct bracing detail should be specified (such as that in figure 1) and used in conjunction with the

Multinail Advance is an exciting addition to the Multinail Brand. Our core focus is to introduce Multinail’s extensive range of products and services to new markets while innovating and developing solutions tailored to both existing and emerging sectors.

Our primary focus includes multi-residential projects, mid-rise buildings, and mass timber construction.

Multinail Advance is committed to enhancing the competitive edge of our fabricators by expanding timber construction into new markets and contributing to the growth of the Australian timber industry.

Short Wall Bracing using a pair of Stronghold tie-down brackets can provide various options depending on the bracing requirements, ranging from non-cyclonic to cyclonic regions.

Simple and effective site-built portal for achieving loading bearing and/or wall bracing requirements in residential construction with superior capability for withstanding lateral loads.

bracket. If you are unsure of whether a product you are specifying has anti-twist measures built into it, don’t hesitate to contact your supplier and ask. It is important to establish this during the design stage to avoid expensive issues on site. More information on girder bracket connections can be found in AS4440-2004 section 5.3 and Appendix G.

ATRIO of key Australian forestry industry bodies are undertaking collaborative research that will support new market opportunities for Engineered Wood Products (EWPs) using lower-quality Eucalyptus globulus (blue gum) and Pinus radiata (radiata pine) logs.

This important value-add project, funded by the Department of Agriculture, Fisheries and Forestry (DAFF), is being led by the Green Triangle Forest Industries Hub (GTFIH), with support from Forest & Wood Products Australia (FWPA) and the Australian Forest Products Association (AFPA).

The origins of the initiative can be traced back to November 2021 when demand for this low-value resource from major importer China ceased. With little-to-no existing domestic demand for timber products manufactured using these logs, timber began accumulating in Australian plantations. New markets are needed to prevent this resource going unused.

In response, the three collaborating bodies developed a grant application to the DAFF-led Agriculture, Trade

and Market Access Cooperation (ATMAC). ATMAC agreed to provide funding for an extensive program of research, which has progressed positively during the past two and a half years.

A specially assembled team is studying relevant end-use market specifications, conducting in-depth market research, and undertaking manufacturing and development trials of EWPs with potential appeal to new export and domestic markets. The ultimate objective is to create additional market opportunities and fresh income streams for industry.

“FWPA sees this project as a highly significant initiative and we are committed to offering ongoing support to the Hub as the research is conducted,” FWPA CEO Andrew Leighton said.

“This work is a wonderful example of three organisations with a shared commitment to creating a sustainable future for Australian forestry coming together to create new opportunities to help secure our industry’s ongoing success.”

The technical aspects of the research are being conducted at the Queensland

Department of Agriculture and Fisheries (QDAF) Salisbury Research Facility in Brisbane, under the direction of Principal Scientist Dr Benoit Gilbert.

The market research elements are being led by Tim Woods of IndustryEdge, a consultancy that provides data analysis, intelligence and advice to the forestry industry.

“The market scopes and assessments conducted by IndustryEdge provided the research team with crucial information relating to the total scale of EWPs in the Australian economy by volume and value, segmented by sector and utilisation,” Woods said.

“This analysis helped the team to identify laminated veneer lumber (LVL) and glue laminated timber (GLT) as the preferred options for technical and market assessment.”

A total of 120 blue gum and 60 radiata pine logs were harvested from the Green Triangle and processed at the QDAF Salisbury Research Facility.

“Two-thirds of these logs were rotary peeled for use in LVL manufacturing, and the remaining third were sawn into boards to produce GLT,” Gilbert said.

“Promisingly, recovery rates calculated throughout each of these processes were found to be consistent with rates found elsewhere in the industry.”

During its LVL research, the team measured key characteristics of the peeled veneers, including Modulus of Elasticity (MOE), the measurement industry uses to quantify the ability of timber to resist elastic deformation when stress is applied. Encouragingly, high MOE measurements were observed in veneers recovered from blue gum, offering a potentially attractive attribute for buyers in markets where strength is the key requirement of LVL.

After applying the industry grading system to predict the visual quality of EWPs manufactured from veneers, the researchers found veneers recovered from both log types to be D Grade – the lowest grade on the scale. This knowledge has allowed the team to focus on manufacturing LVL products intended for use in markets where aesthetic appeal is not a vital consideration for the end user, such as internal structural applications.

Alongside the results of

the technical work, the team used the findings of an export and domestic market study focused on LVL to identify five specific types they believe have the greatest potential for successful commercialisation. These products have already been manufactured and the next steps will involve testing to assess the products mechanical properties.

The team’s work on GLT has involved dressing and grading selected blue gum and radiata pine boards to assess their visual suitability for use in the manufacture of GLT products. They have now been tested for MOE, modulus of rupture (MOR) or ‘bend strength, as well as shear modulus (or modulus of rigidity) and density. This data is currently being collated to help determine the specific GLT prototypes for manufacture.

A GLT market assessment study is set to be conducted, with the findings used alongside the results of mechanical testing to determine the most appropriate GLT products to be manufactured. The suitability of these products for commercial use will be demonstrated through destructive testing at a commercial facility.

FOREST and Wood Products Australia is set to spearhead an initiative highlighting the advantages of timber framing in construction, promising a significant boost to its promotion efforts.

First established in the Australian Forest Products Association’s Softwood Manufacturing Chamber and funded by the Timber Framing Collective, the ‘Timber Framing: The Ultimate Renewable’ campaign will continue its success with a WoodSolutions rebrand and be managed by FWPA.

To oversee the effort, FWPA has appointed former board member and Timber Framing Collective founding member, Christine Briggs, as Campaign Manager.

Ms Briggs brings a wealth of sales and marketing experience along with a breadth of industry knowledge, ensuring the campaign’s ongoing success.

FWPA’s Head of Build Environment and WoodSolutions Program, Kevin Peachey, said this campaign plays an important role in supporting the forest and wood products industry.

“Timber framing is a cost-effective, long-lasting and sustainable option for framing in construction, and we believe it should remain a part of the DNA of Australian homes,” said Mr Peachey.

“The timber framing industry employs over 45,000 people across the supply chain, providing significant job opportunities. By

highlighting these advantages and promoting timber framing as the preferred material among builders, we can support our members and expand the market share of timber framing in Australia.

“Under Christine’s guidance, FWPA can enhance its creative and strategic efforts to communicate this story to builders, developers, and the broader construction industry.”

Ms Briggs expressed her enthusiasm for the campaign and the benefits it would have for suppliers, builders and consumers alike.

“From bolstering jobs and the supply chain to delivering costeffective, renewable materials and creating high-quality, durable homes, timber framing is a success story from beginning to end,” Ms. Briggs said.

“I am eager to spotlight this valuable product and highlight its essential role in Australian homes.”

In addition to existing campaign funding provided by the Timber Framing Collective funding partners, FWPA has committed further investment to ensure the ongoing success of the campaign.

FWPA Head of Marketing and Communications, Sarah Downey, said FWPA is uniquely placed to use its well-established reach and influence to champion this message.

“FWPA’s WoodSolutions program is a recognised brand across industry, with established connections and

THE latest data from the United States Department of Agriculture shows stellar growth in the export of American red oak lumber to Australia in the first quarter of 2024.

Compared with the same period in 2023 there has been a value increase of 1687% to over USD 4million in this species alone, a volume increase of 1531% to nearly 4,000cubic metres.

The ever-popular American white oak also experienced growth of 52% in value and 64%

in volume in this period, but this is the first time that its share has been overtaken by its close relative.

“We have been promoting the benefits of American red oak in Australia for the last few years,” Roderick Wiles from the American Hardwood Export Council said.

“It shares many of the characteristics of American white oak and is readily available and a cost-effective choice, so I am not surprised that it’s taken hold in the Australian market.

We always encour-

authority in the building design and construction sector,” said Ms Downey.

“By bringing the timber framing campaign under the WoodSolutions

umbrella, we can expand its reach and increase funding opportunities.”

FWPA began management of the campaign from 1 July 2024.

age specifiers to look to use what the forest provides; too much focus on the best grades of a few popular hardwood species increases pressure on one part of the resource and encourages waste,” he said.

“There are over 22 commercial species in the US forest and red oak is the most abundant, accounting for 18% of the hardwood growing stock. Some of Australia’s importers have recognised and seized the opportunity to encourage buyers to consider red oak.”

DAVID MCELVENNY

‘ THE only thing worse than training your employees and having them leave, is not training them and having them stay’. That’s what Henry Ford said in 1914.

It’s a great statement, but like many truisms, much easier said than done. For example, what if you couldn’t find any courses on offer that were suitable for your company’s needs? Or what if you went to the effort and expense of enrolling your workers in a qualification and at the end of it they still didn’t have the hard-edged skills you were looking for?

In this series of articles for Australasian Timber, I’m going to look at some of the dilemmas faced by businesses when they’re contemplating how best to train their workers. My own background is as a timber industry worker (from the mid 1970s to 80s), then timber yard manager (1980s to 90s), and then a trainer and finally owner of a registered training organisation (RTO).

But in these articles, I won’t simply be looking at the issues from the tunnelvisioned perspective of an RTO professional. I’ll be taking a more traditional approach and will include other methods of structured training that have been used for a very long time by employers, tradespeople and skilled operators as they passed their skills and knowledge on to the people working under their direction.

• Internal training programs can be tailored to meet the

direct needs of your own company’s employees and be as focussed as you want them to be.

How much of the training can my organisation manage within its own resources?

This is a question that in my view employers don’t ask often enough. It’s true that some job roles require formal accreditations that can only be delivered by an RTO – particularly in trade skills and high-risk activities. These sorts of jobs require formal recognition of competence because they involve higher levels of responsibility and legal liability. In some cases, they also require licensing or registration with an administrative body.

There are also various qualifications that provide workers with a good grounding in the skills needed to take a big picture view of their job, and develop a better un-

derstanding of how to solve problems in non-standard ways. Again, these sorts of external courses will always be needed, because most companies are not equipped to handle the training internally.

However, there are many procedural skills where the best-placed people to provide face-to-face instruction and monitor the learner’s progress are fellow employees within the company. These trainers could include section supervisors and key operators, and the learning materials they use could be based on the company’s own standard operating procedures and other procedural documents.

In my experience, there is a misconception among

many businesses that accredited training is somehow superior to non-accredited training simply because the development and delivery of competencies are regulated by government agencies under the national vocational education and training (VET) system.

What’s less well understood is that national units of competency, by their very nature, are designed for the industry at large and the benchmarks of performance are set at the lukewarm average level of competence that a normal worker would be expected to hold in the majority of workplaces.

By contrast, internal training programs can be tailored to meet the direct needs of your own company’s employ-

ees and be as focussed as you want them to be. The subject matter can be site-specific, task-specific and even machine-specific. And the required standards for performance can be set at any level you wish – low, moderate, high, expert – depending on the importance of that task to your business.

When an internal training system is managed well, with structured goals and rigorous assessment processes, the outcomes can help the business in several ways. The most obvious benefits are improvements in the skill levels and background knowledge of the workers, which have a flow-on effect through to the company’s productivity, quality control and general workplace morale. A welldocumented system also helps the company to demonstrate that it is satisfying its ‘duty of care’ responsibilities to employees, which is very valuable when negotiating insurance covers or dealing with workers compensation claims.

Nonetheless, in-house training has its own share of potential problems and pitfalls. In Part 2 of this series, I’ll talk more about some of these problems and look at various way of dealing with them.

David McElvenny is the CEO of Building Learning (www.buildinglearning.com. au) and Workspace Training (www.workspacetraining. com.au).

THE Director of the Centre for Timber Durability and Design Life Professor Tripti Singh has been recognised by The Society of Wood Science and Technology (SWST) for her contribution to wood science and her renowned research excellence.

The Centre is a FWPA-supported initiative that aims to be a global leader in timber durability and design life research, by creating coordinated exploration into timber durability and encouraging and educating a new generation of research scientists to continue this work across the country.

Professor Singh joined the Centre as Director in August 2023.

FWPA CEO, Andrew Leighton said the award was further recognition of the Centre’s important work and Professor Singh’s leadership.

“Since its inception, the Centre has made important progress to ensure Australia has access to the world’s leading research, building strong links between industry, academia and customers,” said Mr Leighton. “Professor Singh’s reputation for research and collaboration makes her the ideal leader for this innovative work.

WITH all the types of timber available, it can be hard to decide which one is right.

A local and overseas timber, Merbau grows in northern Queensland and continues up into Asia. Its heartwood is orange-yellow-brown when freshly harvested, but develops into a deeper red-brown as it ages. In contrast, the sapwood is pale yellow, white or buff coloured.

Most Merbau has a wavy and interlocked grain – one of the reasons why it’s so popular. When sealed with a clear coating, or lightly stained with a semi-transparent finish, Merbau has a distinct and attractive appearance. Those who don’t care about the grain will be happy to know that it holds paint well too.

While coarse in texture, Merbau retains a moderate lustre. There are also mineral deposits in most Merbau, which provides another dis-

tinguishing feature.

Merbau is the timber of choice for decking throughout Australia. It’s perfect for the wear and tear of foot traffic that comes with decking and for supporting the weight of people and furniture.

Merbau is known for its durability. It has a Class 1 durability rating when used above ground and a Class 3 rating when used in-ground. This means that – when used as deck planks, boards or rails – it can last for over 40 years (with an average life expectancy of 25 years).

The natural oils in Merbau help prevent cracking, splitting and shrinkage – while also allowing it to endure harsh temperatures and climates, salt water and other

extreme conditions. It has natural resistance to both termites and fungal rotting, and it is suitable to use in areas susceptible to bushfires.

Even though Merbau is durable and strong, it still responds well to hand tools – a characteristic that some other hardwoods don’t share. It cuts cleanly and glues and nails together well, making it easy to use in a variety of projects. However, you’ll still want to pre-bore all holes for fasteners.

Thanks to its inherent strength, Merbau isn’t only for residential decking and flooring. It’s also used in shipbuilding, construction and engineering. While its natural appearance is gorgeous, you can finish it with paint, polish or stain and achieve outstanding results that match your desired aesthetic.

While Merbau has several great qualities, many people love it simply because of its stunning good looks. Aside

from its rich red-brown hue unique grain, small golden or yellow flecks often permeate Merbau, which easily differentiates it from similar species and gives it an exotic edge.

Like all timber, Merbau’s maintenance requirements will depend on the conditions it is exposed to. However, its inherent qualities mean that it requires comparatively little maintenance. A simple clean with soapy water and a stiff-bristled brush, along with a coat of high-quality oil, every 12 months is often enough.

Because it’s often harvested from forests, it’s crucial to know where your Merbau is coming from. At Narangba Timbers, we go to great lengths to ensure that all our timber is from ecologically sustainable and ethical suppliers. Always make sure that your Merbau was obtained from genuine, well-managed and eco-friendly sources.

BIG River Industries Ltd has acquired Specialised Laminators (SLQ), a renowned panel products company based in Brisbane. This strategic move enhances Big River’s panel product offerings and strengthens its presence in the industry.

SLQ, established in 1977, has earned an outstanding reputation for producing high-quality decorative and functional panel products. Known for their innovative solutions and commitment to excellence, SLQ’s products are highly regarded in the construction and architectural sectors. The acquisition will allow customers to access an expanded

range of premium panel solutions through Big River’s Timberwood Panels division nationally, combining the strengths of both companies to deliver superior products and services.

“Bringing SLQ into the Big River family is a significant milestone in our mission to offer top-quality panel products to our customers,” said John Lorente, CEO of Big River Group. “This acquisition allows us to expand our specialised Panels Division, providing customers with a broader selection of innovative and high-performance panel solutions. The synergies between SLQ and Big River create exciting opportunities for growth and

product development.”

John Closter, one of SLQ’s founders, and Wayne Austin, General Manager, will continue to lead the business under the Big River umbrella, ensuring continuity and leveraging their expertise to drive future success.

“Joining Big River Group is an exciting new chapter for SLQ. We are confident that our combined expertise and resources promise enhanced product availability, improved supply chain efficiencies, and innovative panel solutions tailored to meet diverse construction needs,” said Closter.

“We are thrilled to become part of Big River, a company that shares our commitment to quality and customer

As one of the most attractive and durable hardwoods, Merbau is often the best choice for any kind of home renovation. Aside from being a timber decking favourite, Merbau is also a best-seller for:

• Pergolas

• Fencing

• Garden edging

• Flooring

• Rails and balustrades

• Screening

• Support posts

• External stairs

The team at Narangba Timbers have decades of knowledge about both Merbau timber and decking. If you have any questions, start with Narangba Timbers’ Decking FAQ and Calculator. Need more advice? Contact Narangba Timbers on 1300 477 024.

https://narangbatimbers. com.au/blog/

satisfaction. Our customers can look forward to an expanded product range and enhanced service capabilities,” Austin adds.

Big River has been operating for over 120 years, manufacturing and distributing timber and steel formwork products, timber flooring, building products, structural plywood and related timber products. It also distributes a broad range of other building products, including MaxiWall and MaxiFloor, primarily to the commercial, residential and infrastructure construction market segments.

For more information, visit www.bigrivergroup.com.au.

WE were delighted to host a delegation tour aimed at showcasing the critical role our sector plays in the future of Victoria’s housing.

The participants included key leaders and policy-makers who are pivotal in shaping our housing policies. Representatives from various government levels joined us, alongside industry experts and our valued Principal Partners.

The tour coordinated and instigated by Dr Alastair Woodard from Wood Products Victoria and FTMA took four top Victorian bureaucrats on a tour of our wonderful industry.

Joining us was Jeroen Weimar, Deputy Secretary, Housing Statement Implementation, and Dept of Premier & Cabinet, Anthony Sherry, Executive Director of Program Engagement & Delivery (Department of Jobs, Skills, Industry & Regions (DJSIR), Lauren Heidecker, Senior Policy Officer (DJSIR) and Adrian Yeung, Senior Policy Officer (DJSIR).

We were fortunate to also have Nick Hewson of Arboralis/WPV and Kat Welsh join us on the tour.

The tour started at the Holmesglen TAFE Mid-Rise model sponsored by WoodSolutions. It was a great opportunity to demonstrate

KERSTEN

GENTLE Executive Officer FTMA

what our sector can do in the midrise market and was a real eye opener for the delegates.

Given we only had half a day, we then took to them to three facilities in the nearby vicinity including AAA Advanced Trusses, Peuker & Alexander and finished with Timber Building Solutions.

In Victoria, as we will highlight in next week’s Frame & Truss Sector Outlook (FATSO), 91.1% of every house is framed in timber and 83.8% of all townhouses are also framed in timber.

This demonstrated to the delegates the importance of our sector on the future of Victorians housing, and that we should have a seat at the table ensuring our sector is represented. Whilst perhaps 10% or less is stick built, the rest is quality engineered prefabricated products from the 96 frame and truss manufacturers in Victoria.

This also gave us an opportunity to highlight the amazing support of our nail

plate engineers, as finding the right engineers in the construction industry can be difficult, but our valued Principal Partners have qualified building and structural engineers who support fabricators with complex work.

FTMA is keen to demonstrate to all levels of Government the importance of our sector when they are talking about Modern Methods of Construction. We must take an elemental approach, ensuring the government does not implement policies that undermines the future of our 287 fabricators in Australia.

The key points we continue to raise include

1. We must support Aussie jobs as nearly 1 in every 10 jobs is in the construction industry, and we don’t want to go too far down the modularisation pathway, which results in housing being shipped into Australia in shipping containers. We are already seeing this happening with Chinese Steel, and as a country we must protect our jobs and industries.

2. We continue to highlight the capabilities of our sector, and I must say everyone on the tour was so impressed with the operations, and they could definitely see the many benefits of offsite prefabrication in the frame and truss sector.

3. We also must make sure that all future housing uses renewables. As the figures about demonstrate, timber is already being used, and we must continue to push for this if we are to lower emissions in the built environment.

We also provided delegates with a breakdown of the 96 plants, which were put into State Electorates and of the 88 electorates in Victoria, 33 have at least one fabricator.

I’d like to thank Dr Alastair Woodard and Nick Hewson of Wood Products Victoria, Liz Jansz and David Hulett and their team from Holmesglen TAFE, Tim Newman of TBS Solutions, Peter Alexander & Luke Blackwell of Peuker & Alexander and Andrew Clements and Ryan Goodes of AAA Advanced Trusses for taking the time to showcase our industry.

FTMA is recognised as the trusted representative body and unified voice for all timber frame and truss manufacturers in Australia, whilst strengthening the connection with the broad supply chain.

FTMA thanks our dedicated partners and encourages you to support those who support your industry

IN a move that mirrors other governments around the country, the NSW Government has introduced the offence of industrial manslaughter, allows for a maximum penalty of 25 years jail for an individual and $20 million in fines for a body corporate.

The industrial manslaughter laws will allow for a business or individual to be held responsible for the death of a person due to gross negligence in the workplace. NSW is the last mainland state without an industrial manslaughter offence and with the election of the NSW Labor government in March 2023, and pressure from the trade union movement, this was expected.

The state government maintains it has consulted work health and safety experts, business groups, unions, legal stakeholders and the

families of people who have been killed at work and has incorporated that feedback into the creation of the new offence and penalties.

The current maximum penalty for the highest form of offence under the WHS Act – Category 1, is five years’ imprisonment for an individual or a $3.8 million fine for a body corporate. A unit will be established in the NSW Office of the Director of Public

Prosecutions that will be responsible for the prosecution of industrial manslaughter offences against individuals and, where appropriate, related bodies corporate.

Minister for Work Health and Safety, Sophie Cotsis, is quoted as saying any workplace death is a tragedy, and in cases where a person with a work health and safety duty has been careless or irresponsible, they must be held accountable. “Every worker deserves to go home to their loved ones at the end of the day. No government should ever want to have to use these laws. The offence of industrial manslaughter will apply to the worst of the worst cases where gross negligence has caused the death of a person in a workplace.” Cotsis said.

The NSW government claims that strengthening the existing laws with a new

COX Architecture’s Melbourne studio was dubbed the “Box Office” on account of its design, which involved cutting a large void in the upper floor and creating a series of tiered platforms down to the lower level.

The resultant open box created an internal connection between floors, increasing the opportunity for staff to come together. Cox Architecture describe the box as being “at once a theatrette for office presentations and a connection between the two studio levels”.

An important factor in the design was the use of blackbutt veneer, specified throughout. Quarter-cut was selected because the grain pattern appears as a series of straight lines. “While still having the natural variance that is found in all timber products, quarter cut veneers have a linear appearance which is ideal for fine joinery” a Cox spokesperson stated.

The designers considered that blackbutt complemented the original character of the warehouse-style space. Blackbutt veneer was specified for engineered flooring as well as wall panelling, reception desk and drawer fronts.