11 minute read

CIRCULAR ECONOMY

cCIRC u LAR ECONOM y

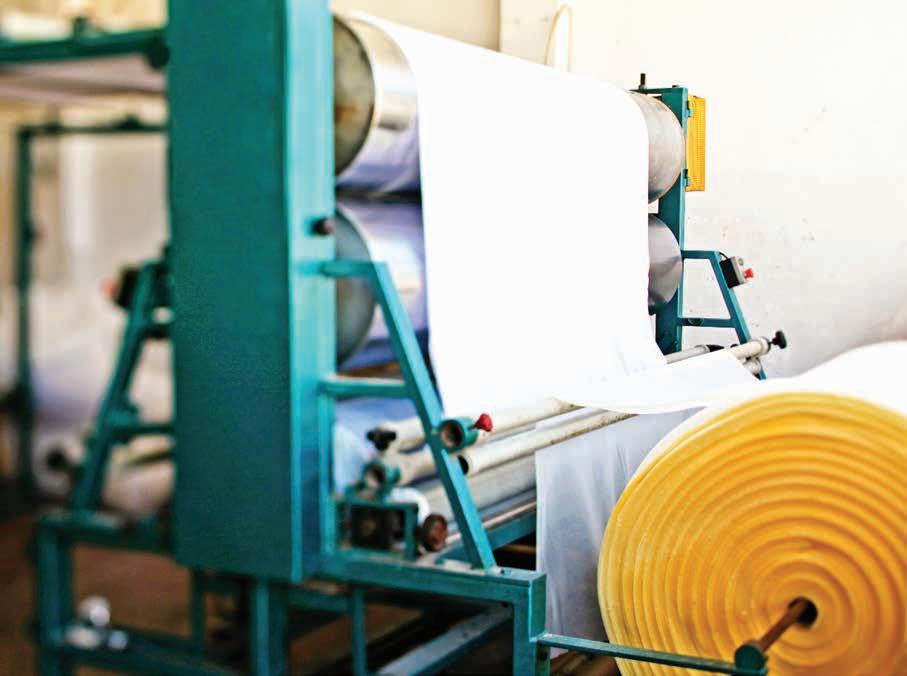

PAPER: an increasingly sustainable industry

The Italian paper industry has long been a leader in the circular economy and, thanks to increasingly selective collection of urban and production waste, has gradually reduced its input of virgin raw materials

Edited by Simone Ciapparelli

In the field of renewability and circularity, paper can certainly play an important role; for the quality and quantity of recycled materials in Italy, in fact, the sector has a particularly strategic value in giving impetus to new good practices in the field of circular economy.

FIGURES RELATING TO A SUSTAINABLE SECTOR

The production of paper and its entire supply chain represent an excellent example of a circular economy based on the use of cultivated renewable resources that would theoretically allow multiple production cycles from a single environmental withdrawal. The manufacture of paper always requires an input of raw material, both cellulose and other materials (minerals, starches), but the secondary material is now the main input. Cellulose fibre is a renewable, biodegradable and compostable material of natural origin, easily returnable for recycling into new paper. On a European scale, fibres are used on average 3.6 times, more than the world average. The fibre, however, undergoes mechanical and chemical degradation, therefore needing to be reintegrated with long fibres. Recent data indicate, for the paper industry, a total consumption of material equal to 10.08 million tons, for the production of 8.9 million tons of product. Of the total consumption, 50.2% is made up of secondary materials, 35.4% of virgin fibres and 14.4% of non-fibrous materials such as starches. It can therefore be estimated, overall, that approximately 89.1% of the materials used are made up of secondary materials (pulp) or renewable materials (cellulosic fibres and starches). The consumption of virgin fibres, in relation to the production of paper, has progressively contracted over the last ten years, reaching its minimum in 2018. Italy imports 94.1% of paper pulp (i.e. cellulose from virgin fibres), mainly from Europe and the Americas; it comes from cultivated forests and, increasingly, from certified forests. In Europe and other areas, forests cultivated for paper timber are increasingly managed in a sustainable manner: 89.8% of the forests owned or managed by the paper industry in Europe are certified according to FSC or PEFC schemes, and 90% of the pulp purchased by the European paper industry is certified.

WATER INPUT, EMISSIONS AND CONSUMPTION

Internal water recycling is high and only 10% of process consumption is made up of withdrawals. Water con-

3.1 Acqua: impiego d’acqua, riciclo dell’acqua ed emissioni in acqua L’acqua è un elemento fondamentale del processo produttivo cartario. Il riciclo interno dell’acqua è elevato e soltanto il 10% dei consumi di processo è costituito da prelievi. sumption in the sector has greatly reduced over the years. To produce a I consumi idrici – diversificati a seconda del prodotto finito e tra processi di produzione della pasta e processi di fabbriton of paper, 26 cubic metres of water cazione cartaria – si sono drasticamente are used today, compared to the 100 ridotti nel corso degli anni. Se, infatti, alla needed up to forty years ago. Due to fine degli anni settanta erano necessari the effect of discharge regulations, mediamente 100 metri cubi d’acqua per Italian water consumption remains on average higher than in other Europrodurre una tonnellata di carta, attualmente ne vengono utilizzati 26 (dato medio del campione Assocarta). pean countries and could be halved. Il dato, sostanzialmente stabile negli ultimi The pollutants present in paper mill anni, evidenzia il raggiungimento di un wastewater are essentially of biologilimite tecnologico sotto il quale sembrecal or natural origin, such as cellulose, rebbe difficile spingersi senza incorrere starch and inert mineral fillers. in un incremento delle concentrazioni. I consumi idrici italiani, per un effetto para-

dossale della normativa sugli scarichi, restano quindi mediamente superiori a quelli di altri paesi europei e potrebbero essere almeno dimezzati. Gli inquinanti presenti nelle acque reflue di cartiera sono essenzialmente di origine biologica o naturale (cellulose, amidi, cariche minerali inerti come il carbonato di calcio). Rispetto ai principali parametri di caratterizzazione delle acque reflue, i valori medi di emissione di COD e di solidi sospesi (alcune sostanze più critiche sono ormai state eliminate dai processi) mostrano nel tempo un continuo ridimensionamento, attestandosi sempre ben al di sotto dei limiti di legge. La stabilizzazione registrata negli ultimi anni è anche il segno di un sostanziale limite, oggi difficilmente superabile con le tecnologie di trattamento disponibili.

Trend of the specific use of water (m³/T)

11 - ANDAMENTO DELL’IMPIEGO SPECIFICO DI ACQUA (M3/T INDICIZZATO AL 1995 =100) 120 100 80 60 40 20 0 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 Source: Assocarta data processing

cCIRC u LAR ECONOM y

Air emissions into the atmosphere come, above all, from energy production and are emissions of CO2, nitrogen oxides, SO2 (sulfur dioxide) and fine dust. The conversion of industrial power to natural gas has effectively eliminated sulfur dioxide emissions and greatly reduced particulate emissions. The emissions of nitrogen oxides and CO2, on the other hand, are proportional and determined by the extent of energy consumption. Paper processes require significant quantities of energy, both heat and electricity: energy consumption in the paper sector has been progressively made more efficient, with a reduction in total consumption - fuel and electricity - and specific consumption. Energy requirements in the production process vary according to the raw material, the technology used and the finished product. The production of pulp from wood requires an energy equivalent of approximately 4300 kWh/t, while, when using recycled paper, it requires only 1300 kWh/t. This difference is due to the fact that the fibre is basically already available from the recycling process. In the Assocarta sample, which does not include companies in the printing sector, a reduction in energy consumption of approximately 30% has been recorded over the last 20 years. Currently, the sector produces about 76% of the electricity it needs, using almost exclusively natural gas as the source.

WASTE PRODUCTION AND MANAGEMENT

The specific production of waste per ton of product has remained constant over the years, with a slight increase since 2013; we are talking about 1.5 million tons of waste, corresponding to approximately 165 kg per tonne of

03 RINNOVABILE E RICICLABILE A PARTIRE DALLE NOSTRE MATERIE PRIME

Trend in specific energy consumptions of the paper sector in relation to production

17 - ANDAMENTO DEI CONSUMI ENERGETICI SPECIFICI DEL SETTORE CARTARIO IL RELAZIONE ALLA PRODUZIONE (GJ/T INDICIZZATO AL 1995 =100) 120

100

80

60

40

20

0

1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019

WHAT IS ASSOCARTA

Assocarta is the trade association that aggregates, represents and protects the companies that produce paper, cardboard and pulp in Italy. The Association, which is a member of Confindustria and acts as an institutional interface with the main national political and administrative institutions, defines and orients its institutional activity according to the different needs of the Italian paper industry in order to represent its legitimate interests and promote its development and competitiveness. Through the European Confederation for the Paper Industry (CEPI), Assocarta represents the interests of the sector and raises the profile of the industry with EU and international institutions.

Source: Assocarta data processing

paper produced. More than a third of the waste consists of paper streams that are sent for recycling. Excluding the flow of recovered waste, production waste from the paper industry is composed of sludge and residues from water purification, residues from the recycling process and de-inking sludge, various types of waste such as iron, plastic and wood, stemming from the packaging system. The most critical waste stream is the estimated 250,000 tons of pulp and de-inking sludge produced by the recycling paper industry. Despite improvements in processing techniques, there has been an increase in the generation of these residues due to the introduction of new processes like de-inking, the increased treatment capacity of water treatment plants, and, above all, the increased use of waste, especially from separate waste collection, which has a higher content of impurities and non-reusable fibre.

CIRCULAR ECONOMY POLICIES

The European paper industry has set itself the goal of reducing CO2 emissions by 80% by 2050 compared to 1990, through the decarbonisation of production thanks to the combination of interventions based on recycling, energy efficiency, use of renewable fuels and electrification. For Italy, substantial investments have been made in recent decades by equipping the system with natural gas-based cogenerators; more drastic decarbonisation is not an easy goal to achieve, but technologies are largely available and new technologies are being developed. The paper industry cannot do without the contribution of primary fibres (wood and pulp), a cultivated and therefore renewable and potentially fully sustainable product. It is necessary to strengthen and generalise the use of only fibres from sustainable management, whether European or non-European, in the knowledge that there are still areas of the world where forest production is not sustainable. A major development opportunity for the paper industry is the transition towards a reduction of disposable and hard-to-recycle products and packaging. Paper products, also combined for example with bio-plastics, represent the answer to the demand for truly recyclable and biodegradable packaging. Of all packaging products, paper products are the only ones with the potential to be almost completely recyclable, so they deserve to be promoted by public policies, through programmes to phase out inappropriate materials and packaging or equivalent measures that allow the necessary time for production conversion and economic optimisation of processes. As regards paper production waste, in the context of Italian production, the anaerobic co-digestion of paper sludge with other more nitrogen-rich streams, such as municipal sludge, manure and herbaceous productions, is particularly interesting and applicable; these technologies can enhance the energy content of sludge with the production of biogas that can be upgraded to biomethane. ■

Source: Assocarta, “Rapporto Ambientale dell’Industria Cartaria Italiana”

The last five years have been instrumental in the growth of Paredes. The transformation began in 2017 with a new management, ably led by Francois Thuilleur, who launched an ambitious plan with the aim of, in his own words, transforming “an old company that is becoming modern”. Paredes is currently celebrating its 80 years of service to the professional hygiene market, of its development from a family business into the company it has become today with over €220 million turnover, 650 collaborators, 2 production sites and 16 commercial and logistic sites spread between France and Italy. Their history contains important milestones such as the invention of the first single-use, paper roll for hygienic purposes and the first auto cut dispenser for hand towels or the establishment of Paredes Italia in 1988. 2022 marks the end of the overarching project #Dèfi22 that encompassed all aspects of the business – a new visual identity, renewed product lines including its dispenser line Paredis Style and Paredis Style Elite and many other important investments. Examples of this are the inauguration of HUB Paredes – a central logistics port that accounts for 20% of the 100 000 m² of the Groups warehouse space – and Université Paredes, their training centre. The modernisation of their commercial activities include the development of the myparedes application, a 100% digital hygiene solution and last year’s launch of their e-shop that, paired with experts divided by client sector to consult on the most appropriate solutions for their clientele, is garnering considerable success. With the attention these Covid-tainted years have brought upon professional hygiene services comes a spotlight on social and environmental issues for which Paredes has always been an active spokesperson since its launch of its philosophy Eco Attitude® in 1995. These solid foundations have been built upon with the adhesion to the UN Global Compact in 2017, a Gold EcoVadis Sustainability Rating since 2019, Social Accountability certification and Carbon Footprint certification for its products, to name but a few of its CSR initiatives. This development has launched Paredes to the position of modern front-runner on the European hygiene market. In fact, its development over the next few years will reach further afield; whilst Paredes Italia has launched its own growth project #Forza25, the Group is currently opening up the Swiss, German and Benelux markets. Paredes has come a long way since its early days and they have navigated these recent tumultuous times with success. Their client-centric approach is greatly appreciated and looks set to confirm its growth trajectory in the years to come. ■

www.paredes.it

Soluzioni d’igiene e di protezione professionale