The benefits of SPEED

2 Smaller stations are important too 10 Halfway to Leven 18 Railtex 2023 20 Talking about freight 22 Northern City line goes digital 26 SPEED and effi ciency

Swift, Pragmatic and Efficient Enhancement Delivery removes complexity and encourages radical thinking

2023

April

Often overshadowed by larger megaprojects, an increasing number of smaller stations are receiving upgrades as the Department for Transport and Network Rail seek to improve the passenger experience across the nation

Smaller stations are important too

Over the past decade or so, Network Rail has refurbished and rebuilt a number of the largest railway stations in the country. These projects have taken years to complete, cost millions (in some cases billions) and produced some stunning results.

Think of the western concourse at London Kings Cross, London Bridge, Birmingham New Street, Manchester Victoria, Leeds and Reading. Not to mention Edinburgh Waverley, Liverpool Lime Street and Bristol Temple Meads (still underway).

But what of the smaller stations? The ones that commuters, families and tourists use every day?

Network Rail owns over 2,500 stations around the country, most of them managed by one of the train operators. Passengers using these stations need to feel safe and welcome on the network. They need

ticketing, car parking, easy access, waiting areas, refreshments, toilets and good information on when trains are due. They want clean and airy spaces, not dirty and dark places where they don’t feel safe.

Although the results may be less spectacular than the major stations named above, work continues to improve the stock of ‘ordinary’ stations – the ones further down the league table of passenger numbers that rail regulator the Office of Rail and Road publishes every year.

Many of these improvements are funded by the Department for Transport’s Access for All programme. Launched in 2006 to address the issues faced by disabled passengers and passengers facing mobility restraints (such as heavy luggage or pushchairs) when using railway stations in Great Britain, Access for All creates an obstacle-free,

accessible route from the station entrance to the platform. This generally includes providing lifts or ramps, as well as associated works and refurbishment along the route.

By the start of Control Period 6 in April 2019, the programme had already delivered an accessible, step-free route at over 200 stations, as well as smaller scale accessibility improvements at more than 1,500 others. 24 projects were carried over from CP5 and a further 73 were added to the list for CP6.

In February 2020, it was announced that a further 124 stations would receive a total of £20 million funding under the Mid-Tier Programme to deliver accessibility improvements leading to small-scale enhancements such as tactile paving, handrails and Harrington Humps, which increase platform heights and so make boarding trains easier.

INSIDE TRACK: STATIONS 2 April 2023

Announcing the CP6 programme, then-Transport Minister Nusrat Ghani MP said: “Improving access to Great Britain’s railway stations is a key priority for this government and we want all passengers to be able to travel easily and confidently.”

She then explained how the stations had been chosen: “They have been selected following nominations from the rail industry, which engaged with local authorities and other stakeholders. We then assessed them against annual footfall, weighted by the incidence of disability in the area, and also took account of local factors such as nearby hospitals and the availability of third-party funding.

“Due consideration was also given to the preferences of the train operating companies and, finally, a number were chosen to ensure a fair geographical spread across the country.”

However, not all station projects are about improving access. Some features just need to be refurbished to keep them serviceable while others are about improving lighting and station amenities.

Recent activity

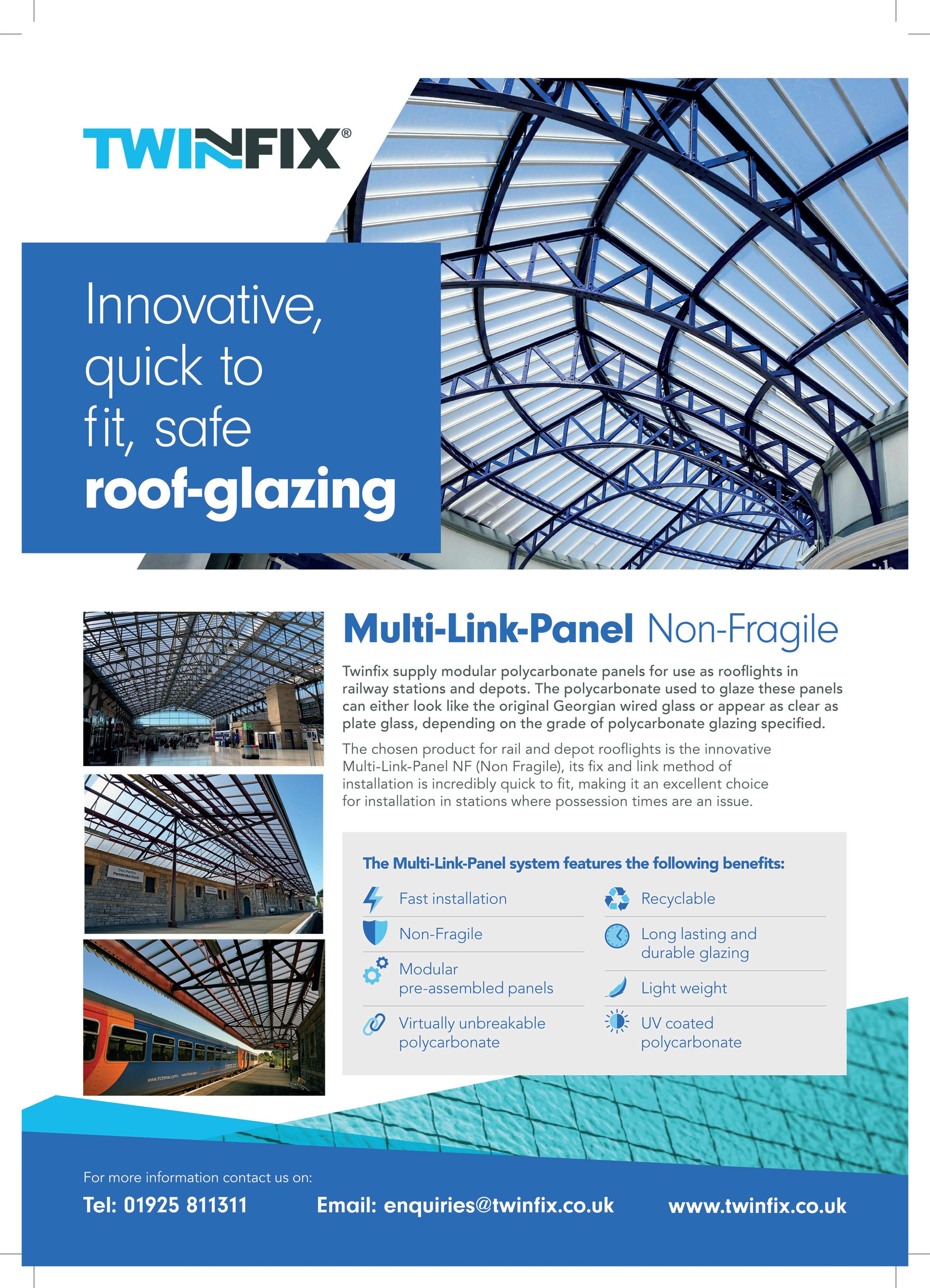

Lancaster station (West Coast main line) is Grade II listed and was built in 1846 by 19th-century architect William Tite. Platform canopies are being rejuvenated as part of a £9.5 million project to restore and upgrade the station building. This will involve replacing all glazing in the platform canopies, repairing and strengthening the structure of the canopy structures and repainting across the station. Work started at the end of March 2023 and will last until spring 2024.

Tilehurst station will receive £4 million of investment for the installation of new lifts and walkways, ensuring all platforms at the Berkshire station are fully accessible for the first time. The station is a seven-minute train journey from Reading and a key station to link a semi-urban location to mainline services. Work to install the new lifts and walkways is due to begin this spring, with the project planned for completion in autumn.

Harrington station’s Victorian footbridge (Cumbrian coast line between Workington and Whitehaven) has been the subject of a four-month restoration project costing £450,000. The six-tonne bridge was moved using a 100-tonne crane and taken off site to be repaired and restored over 18 weeks by specialist firm Taziker. It was returned to its original position on Saturday 4 March.

Improving access to Great Britain’s railway stations is a key priority for this government

INSIDE TRACK: STATIONS 3 April 2023

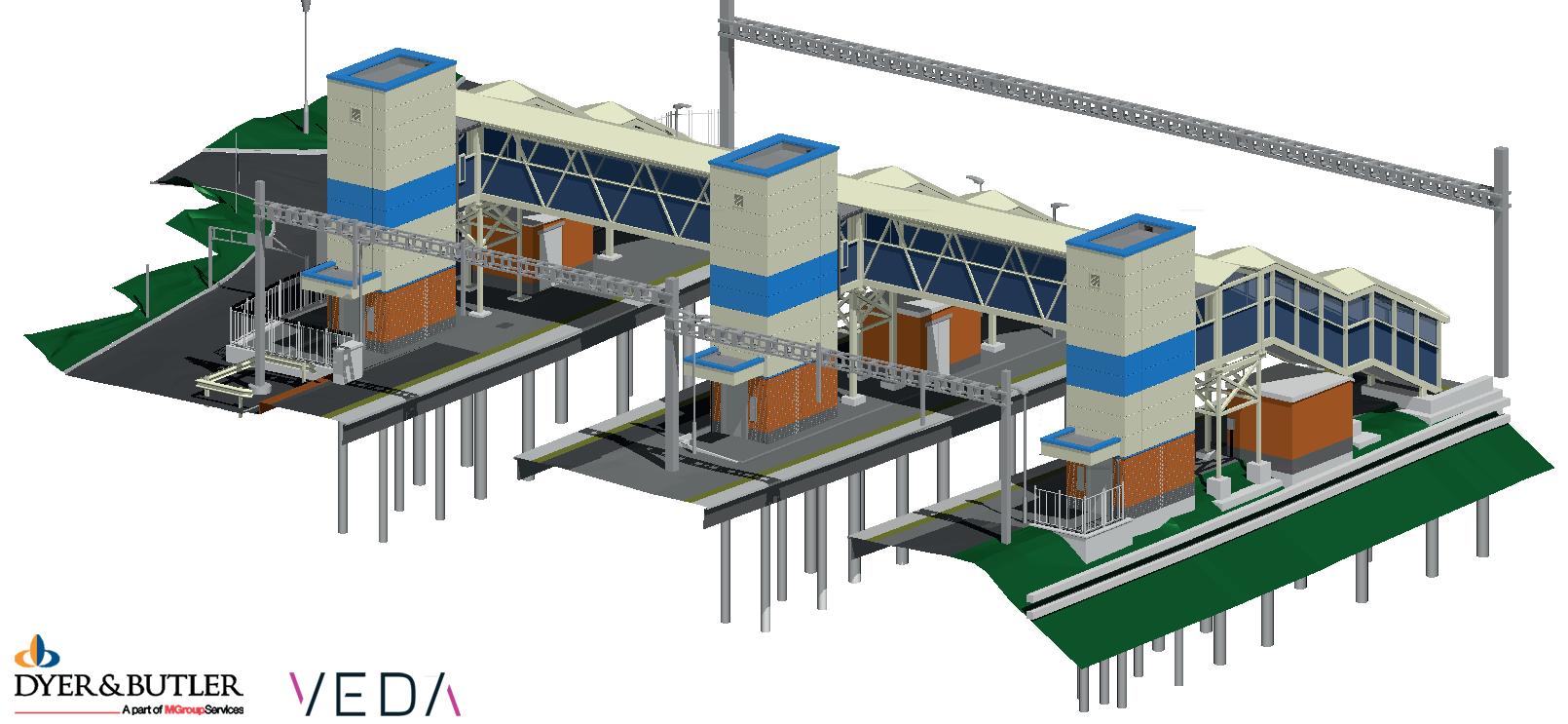

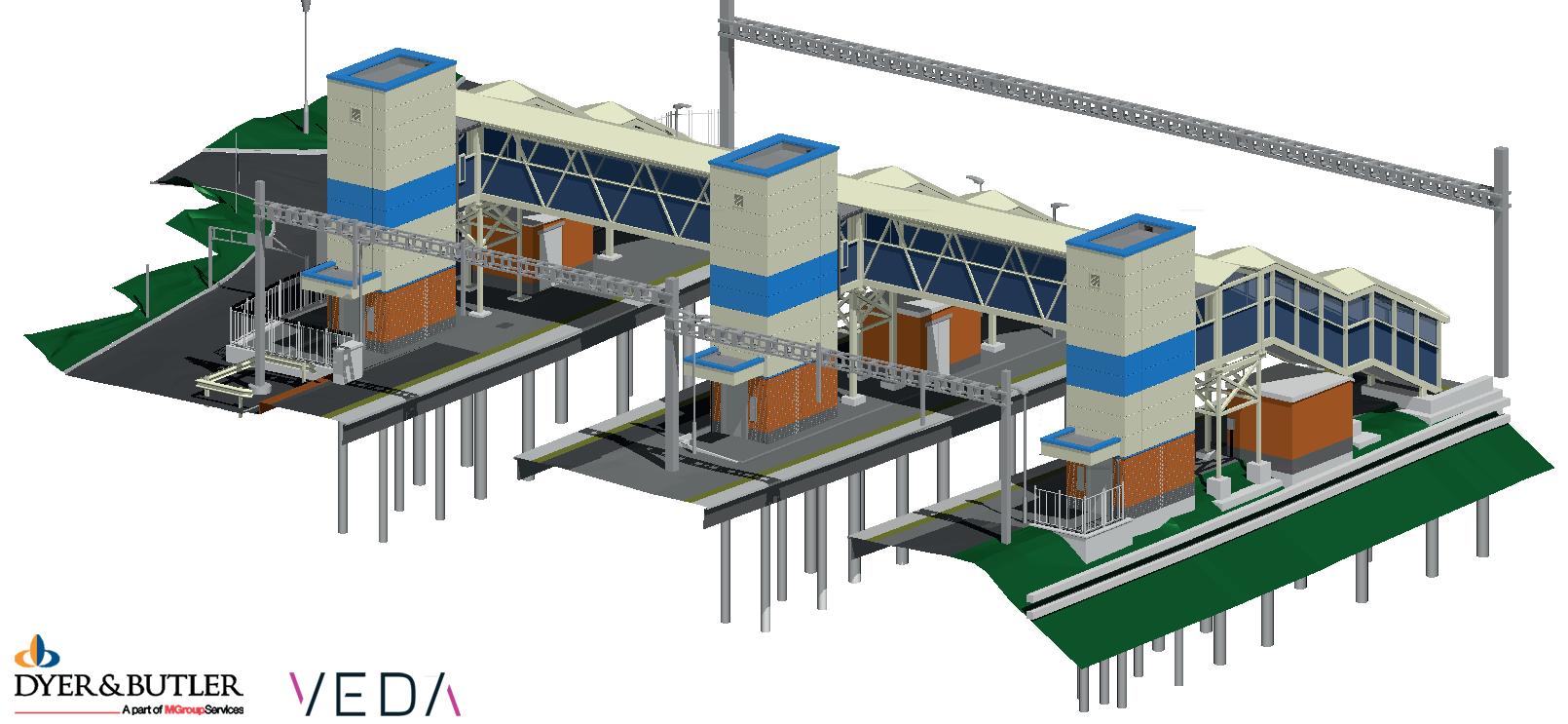

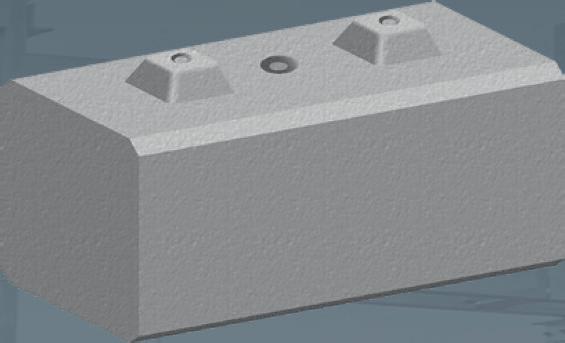

A 3D rendering of Tilhurst’s investment build showing new liftsand walkways

Bexley station in Kent will receive a new footbridge and lifts that will provide passengers with a fully accessible station with step-free access to all of the platforms. Network Rail is working with contractors BAM Nuttall to install two 16-person capacity lifts and Platform 1 will be widened to create space for the lifts and allow passengers to navigate through the station a lot easier. The project, which started in February, is funded through the Access for All scheme and is expected to be completed in late spring 2024.

David Wornham, passenger services director for Southeastern, said: “We’re always trying to do more for our customers, and with this funding from the Department for Transport, Network Rail will be able to significantly improve access around the station as well as measures to make our customers and colleagues safer.”

Oxford station is receiving a major makeover with a new western entrance, a new through platform on the western side of the station to form a second face to the existing Platform 4, including additional waiting facilities, toilets, retail units and construction of a new canopy along the platform length, and new track connections to the line from Platform 5, which will allow trains to leave both Platform 4 and 5 at the same time. Work on the £161 million upgrade will last until the end of 2024.

Both Llanhilleth and Newbridge stations are being upgraded as part of the Ebbw Vale enhancement scheme in South Wales that will enable an additional hourly passenger service from Ebbw Vale to Newport in the future. The £70 million scheme is being funded by Blaenau Gwent County Borough Council via a loan from the Welsh Government.

The work includes building new platforms at both stations and extending the existing platforms so that they can potentially accommodate longer trains in the future. Llanhilleth station will become fully accessible for the first time with the installation of a new footbridge and lifts. Work started in early 2022 and will last until late 2023.

Nick Millington, interim route director at Network Rail Wales & Borders, said: “This multi-million-pound investment will transform services on the line and really benefit the communities it serves.”

St Erth station on the St Ives branch line in West Cornwall is to receive a step-free footbridge with lifts as part of the Access for All programme, turning the Grade II listed station fully accessible for the first time since it was built in 1852. Network Rail’s contractor BAM Nuttall will start construction in late spring with the footbridge expected to be completed and open to passengers the following winter. The project will see the current footbridge, which does not provide stepfree access between the platforms, carefully removed and rebuilt at Cranmore station on the East Somerset Railway – a heritage steam railway.

Earlier this year

Morley station, between Leeds and Huddersfield, reopened on 13 February after nine days while engineers worked around the clock to lay the foundations for new, longer platforms, realign the track and complete drainage work, ready for the new accessible station to be built later this year.

The work forms part of the multi-million-pound Transpennine Route Upgrade that will transform rail travel between Manchester and York.

St Albans City station received a second footbridge to ease congestion at Thameslink’s busiest train station north of London. Almost four million journeys are made to, from or through St Albans City station every year. The multi-million-pound footbridge, which opened on 31 January, will make it easier for passengers to switch platforms, especially during busy times.

Thameslink and Great Northern managing director Tom Moran said: “We’ve transformed St Albans station over the last few years to improve the experience for our passengers. We now have new retail stores, improved toilets, additional cycle facilities with increased security and a wider entrance to help passenger flows through the Ridgmont Road entrance. This second footbridge is yet another substantial improvement that will really help commuters by making it quicker and easier to get from one side of the station to the other – particularly from the central ‘island’ platform.”

Crowborough station in East Sussex has received a £4.7 million new footbridge with lifts as part of the Access for All programme, allowing passengers to easily get from one platform to another. At the same time, new tactile paving was installed on along the edge of both platforms to improve accessibility for people with a visual impairment. Installed by BAM Nuttall, the new footbridge opened on 10 February.

Network Rail will be able to significantly improve access around the station as well as measures to make our customers and colleagues safer

INSIDE TRACK: STATIONS 4 April 2023

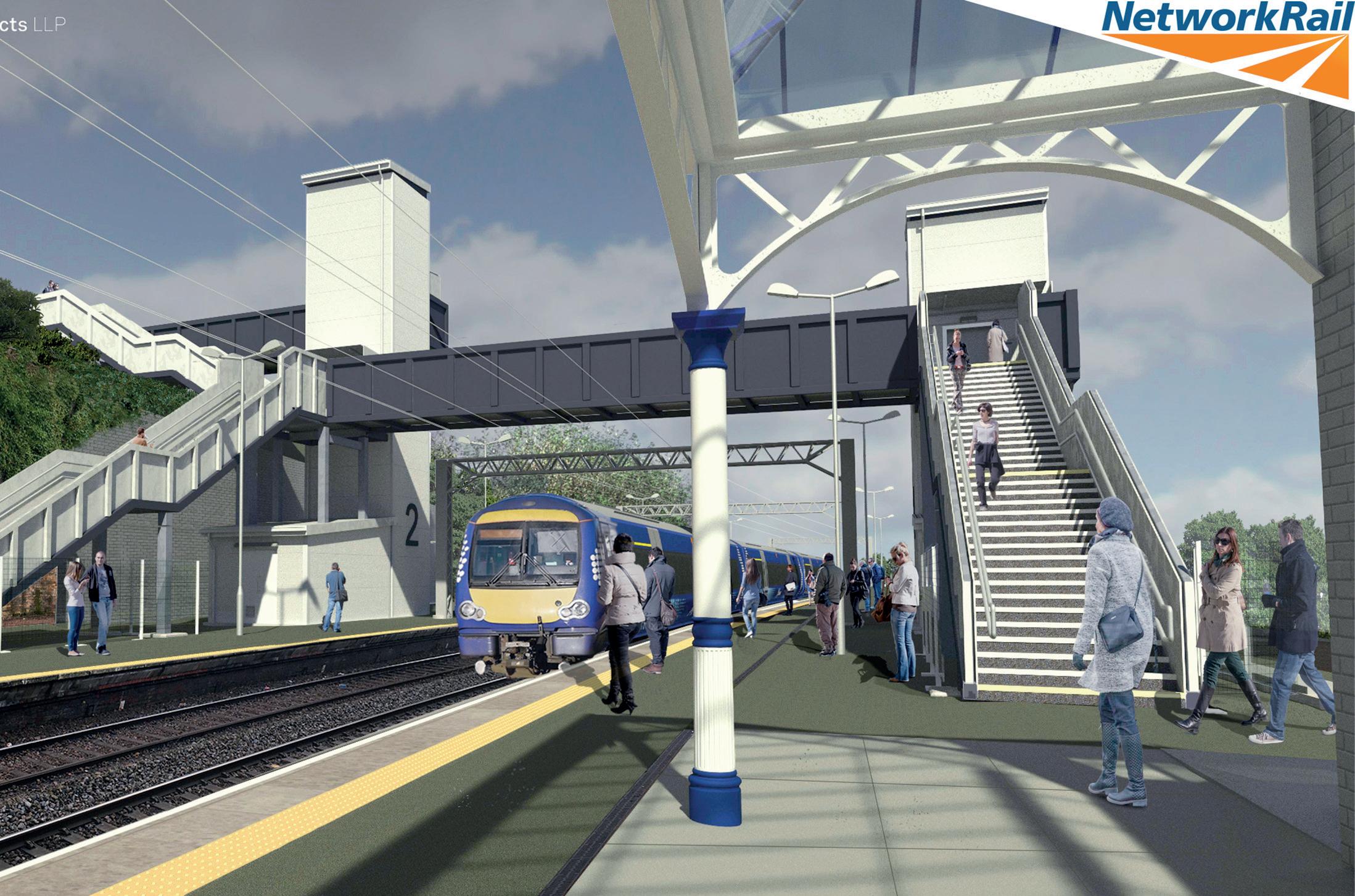

Above Artist’s impression of the footbridge at Bexley Station Below: Crowborough’s new footbridge and lifts

Bridlington station on the Yorkshire Coast line has received a new temporary footbridge, which opened on 6 February, to keep passengers connected while major work takes place to improve access. Network Rail is delivering a £4.6 million Access for All scheme to make it easier for people to move between Platform 4 and Platforms 5 and 6. Lifts will be added to the station for the first time ever, the historic footbridge will be spruced up and strengthened to keep it at the heart of the station for future generations, the station’s roof and canopies will be refurbished and tactile pavings added along the edge of the platforms to help visually impaired passengers travel by train with confidence.

New buildings and stations

Troon station’s Platform 1 building was destroyed by fire in July 2021. The design for the replacement building, which was unveiled in February, uses the existing footprint and same aesthetic as the existing building including traditional timber façade and slate grey roof.

Redundant features such as the chimneys have been removed in this design, though most other features are retained. The project team is working towards completing the construction of the Ayrshire Coast line station building in time for The Open golf in Troon in July 2024.

Is your project EMC compliant? Work with the EMC experts & stay on track. 0330 430 3456 enquiryyork@euro ns.com www.euro ns.co.uk/york EMC Strategy & Control Plans EMC Test Plans EMC Risk Assessments EMC Project Files & Documentation Reviews

INSIDE TRACK: STATIONS 5 April 2023

Above: Artist’s impression of the updated platform at Troon.

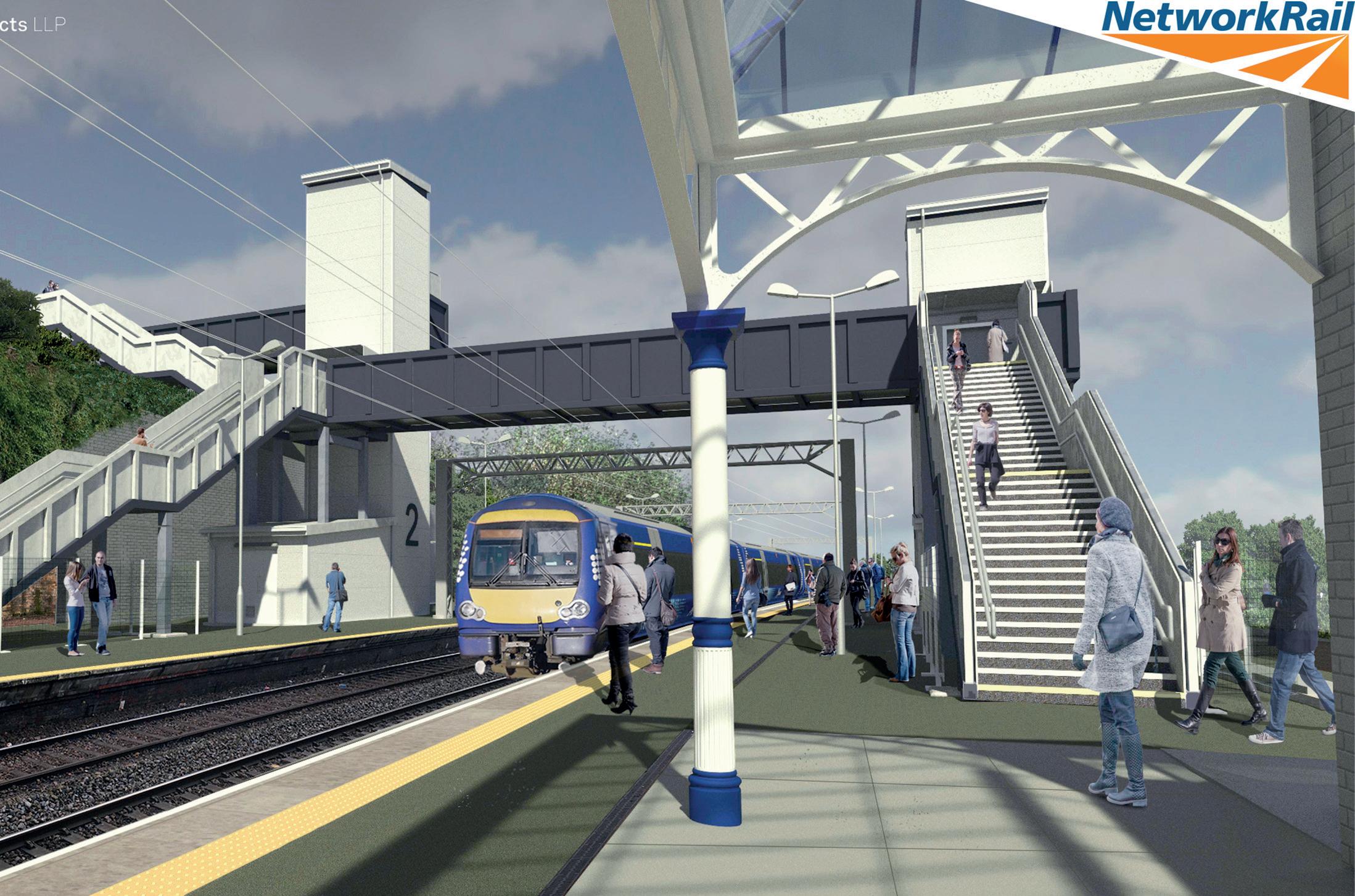

Inverness Airport is a brand new station that opened on 3 February. Constructed over a 15-month period, Scotland’s newest station will improve transport links to the new town of Tornagrain and to the growing Inverness Airport Business Park, acting as a catalyst for further investment and sustainable economic development in the region. The station’s design includes a footbridge that crosses the railway, incorporating stairs and lifts on either side, allowing for step-free access.

Jenny Gilruth, Scottish Minister for Transport, said: “The £42 million package provided by the Scottish Government, including the station and wider rail network infrastructure investment, will build resilience and additional capacity. By making rail a more attractive option, we can encourage more people to choose this sustainable transport option as an alternative to the car.”

Beaulieu Park station in Chelmsford will be the latest station in England when it opens by the end of 2025. Network Rail has awarded a £37.8 million contract to J Murphey & Sons to begin construction and enabling work for the new station on behalf of partners Essex County Council and Chelmsford City Council. This phase of the work includes set up of site welfare, earthworks, civils, modifications to track and signalling systems to facilitate the main construction phase of the new facility.

Main construction for the new station facility will be part of a second contract expected to be awarded in the coming months to complete the

station and open it to train services. As part of a wider regeneration scheme, the new station has been designed to support the wider economic development of the area and its construction will include three platforms with a central loop line and new tracks, to enable stopping services to call at the station while allowing fast trains to pass through unimpeded, and step-free access to all platforms via two lifts.

Looking forward

Port Glasgow station in Inverclyde is set to benefit from a £5 million Access for All project that will see Network Rail, working with principal contractor Story Contracting, install a new footbridge and lifts. Uncovered ramped access to the main station entrance at Princes Street will also be introduced to the station, all designed to make it easier for people with impaired mobility or those travelling with luggage, children or cycles to access the platforms. Preparatory work started in February with the construction of the bridge expected to begin in May. Installation of the bridge and lifts is scheduled to be completed towards the end of the year. Chatham station in Kent has already received its £5.8 million lifts and footbridge, providing stepfree access between the station entrance, ticket office and platforms. They opened in January. Built by BAM Nuttall, construction of the lifts and the footbridge was notable for its use of low-carbon cement-free concrete.

This multimillion-pound investment will transform services on the line and really benefit the communities it serves

INSIDE TRACK: STATIONS 6 April 2023

Visualisation of the grounds at Beaulieu Park station

info@layher.co.uk www.layher.co.uk The past, present and future of system scaffolding SAFE WINNER NASCInnovation oftheYearAward2022 LayherTwixBeam VGS-L 10 07 P Z-8.22.64 and Z-8-22-64.1 FS 554413 Approved Training Provider FAST From footbridges spanning up to 30m LAYHER ALLROUND BRIDGING SYSTEM VERSATILE PROVEN BACKUP to heavy load support girders

The 300-cubic-metre continuous pour was the first use of the product Cemfree on the UK rail network. Production of Cemfree reduces carbon emissions by up to 80 per cent in comparison to traditional cement-based concrete, and its use in Chatham saved approximately 62 tonnes of carbon from entering the atmosphere – the equivalent of 230,000 miles in an average-sized diesel car.

These examples are just some of the stations being worked on at present. A new footbridge is due to be installed at Theale station, between Reading and Newbury in Berkshire, in May. Two lifts are being installed to an existing subway at Warwick station, to be completed by the end of the year.

As CP7 approaches, commencing April 2024, there are sure to be even more Access for All and station schemes. Bidding for CP7 (2024-29) opened on 21 December 2021 and nominations were requested for 15 April 2022. This round of Access for All was launched almost two years earlier than previous rounds and, while discussions were on-going and yet to be finalised regarding government funding, the DfT and Network Rail felt it is prudent to start preparations and receive nominated schemes to enable the rail industry to be in a position to move quickly forward on the selected nominations, should funding be forthcoming.

The list of ‘winners’ is not likely to be released until later – the CP6 list was released four days after CP6 actually started. But there seems little doubt that the programme will continue, with yet more station platforms sprouting lift shafts and new footbridges as the railway strives to provide stepfree Access for All.

How they rank

By making rail a more attractive option, we can encourage more people to choose this sustainable transport option as an alternative to the car

Entries and exits Apr 21 to Mar 22 Ranking out of 2,568 stations listed Lancaster 232 St Erth 793 Tillehurst 1,029 Harrington 2,085 Bexley 486 Oxford 51 Llanhilleth 1,826 Newbridge 1,610 Morley 929 St Albans City 75 Crowborough 1,236 Bridlington 727 Troon 962 Inverness Airport New Beaulieu Park New Port Glasgow 998 Chatham 220 Theale 1,108 Warwick 766

INSIDE TRACK: STATIONS 8 April 2023

Artist’s impression of the Port Glasgow station work

Getting him through his working day. Safely. www.steponsafety.co.uk 01206 396 446 GRP Access Solutions.

Halfway to Leven

First opened in 1854, the Levenmouth rail link connected the town of Leven in Fife, Scotland, with the junction at Thornton on the Edinburgh and Northern Railway main line.

Intended to serve the local clothing mills and distillery, the line was steadily extended eastwards, first to Kilconquhar in 1857, then on to Anstruther in 1863 and then St Andrews in 1887.

The line grew busier as it acquired traffic from fisheries, farming and, latterly, coal. A good passenger business also developed.

But road transport undermined the rail freight business and the line fell into decline. The line from Leven to St Andrews closed to passenger traffic in 1965 and then closed completely in 1966.

The remaining line from Thornton to Leven struggled on, but passenger services ceased in 1969. Bulk freight continued until 1999, and the short stretch between Thornton North junction

and Earlseat opencast mine reopened in 2012 and operated around two trains a week until 2015, after which the line was again closed and mothballed, leaving Levenmouth, with a population of 37,500, as the largest urban area in Scotland without a rail link.

However, local support for the line’s reopening grew, and the Levenmouth Rail Campaign (LMRC) was formed in 2014. The Levenmouth Sustainable Transport Study was set up by Transport Scotland and Fife Council during 2018.

This proposed a rail link between Thornton, which is on the Fife Circle, and Leven with a stop at Cameron Bridge, combined with improved bus services as well as cycling and walking facilities, as the best option.

The Study suggested that, by 2037, there will be 750,000 passengers annually, boarding or alighting trains in the area. Reinstatement of the rail link will cut the current three-hour return journey to Edinburgh by public transport by up to 50 minutes,

with the journey time from Leven to Edinburgh by train being approximately 70-75 minutes.

There would also be an opportunity for freight to use the reopened line, particularly the distillery located next to the station site at Cameron Bridge. This would get lorries off local roads and help towards the government’s decarbonisation agenda.

The appraisal concluded that these measures would enhance employment opportunities as well as access to education, health and leisure services. As a result, the project progressed to the detailed design phase, with initial estimates of construction and preparation costs of around £70 million.

Announcing this move, Scottish Cabinet Secretary for Transport, Infrastructure and Connectivity Michael Matheson also committed an additional £5 million to a Levenmouth Blueprint fund, to be made available to partners to maximise the benefits of the Scottish Government investment in the area.

The Scottish Government’s £116 million Levenmouth Rail Link project to reconnect Leven to the railway network has passed the halfway point with three miles of track already laid

INSIDE TRACK: LEVENMOUTH 10 April 2023

PROTECTING INFRASTRUCTURE SINCE 1956 WWW.MACCAFERRI.COM/UK INFO@UK.MACCAFERRI.COM SLOPE STABILISATION SOIL REINFORCEMENT RETAINING WALLS PROTECTING INFRASTRUCTURE SINCE 1956 WWW.MACCAFERRI.COM/UK INFO@UK.MACCAFERRI.COM SLOPE STABILISATION SOIL REINFORCEMENT RETAINING WALLS PROTECTING INFRASTRUCTURE SINCE 1956 WWW.MACCAFERRI.COM/UK INFO@UK.MACCAFERRI.COM SLOPE STABILISATION SOIL REINFORCEMENT RETAINING WALLS

“I am extremely pleased that the case has been made for the Levenmouth rail link,” he said, “and I look forward to seeing this project being taken forward to the next stages of design.

“The detailed appraisal work that has been carried out suggests that improved transport links, which give Leven a direct rail link to the capital, will lead to an enhanced local economy, bringing better access to employment and education and the potential for new investment. Easier and more sustainable travel options will make it easier for people to reach hospitals, schools and visit other areas of the country as well as giving better access to Levenmouth.”

Making a start

In September 2020, work started on the project to reconnect Leven to the national rail network as Network Rail began to clear vegetation on the Levenmouth line. Although it closed to passengers in 1969, and freight traffic to Methil power station ended in 2001 when the plant closed, the line still existed, but was heavily overgrown. Ahead of work starting, Network Rail undertook environmental and ecological surveys to develop appropriate methods of working to safeguard species, roosts and habitats of value.

The first phase of the work, which lasted until early 2021, also included surveying, drilling boreholes, sampling ballast and extracting core samples to assess the condition of the ground under the railway.

On 15 June 2021, Scottish Government Transport Minister Graeme Dey confirmed that the the line would be double tracked and electrified. He also confirmed the exact locations of the new stations to be built at Leven and Cameron Bridge stations.

Network Rail was commissioned to design and construct the line and, while the line was to be be electrified with overhead wires, services would initially be operated by battery electric units in order to reduce the number of diesels operating on the network as early as possible.

Although dependant on Fife Council planning processes, the line was planned to be open in 2024.

Removing the disused track and excavating the old ballast began in July 2021 and was completed by October, clearing the way for construction of the new lines would begin early in 2022. The redundant equipment was itemised and offered to a range of Heritage railways, as it was Network Rail’s intention that all of the assets removed would be recycled and re-used within a railway environment, with some of it being repurposed for use on the construction of the new line.

Laying track

The first new rails were laid in March 2022. Extensive preparatory activity around Thornton Junction to the west of the route, where 16,000 new sleepers had been stored since mid-2021, led to an early opportunity to put down the first new sections of rail.

Existing track sections within the first mile of the rail corridor were utilised to deliver the new ballast, sleepers and rails to where they would be needed in the section. Specialist plant positioned the concrete sleepers in batches of seven covering 72 metres per hour and creating the early chance to put down the first of the new rails. Seven pairs of continuously welded rail sections in 240-metre lengths were positioned on the sleepers before being clipped into place to form the first mile of the new Levenmouth branch line.

Culvert

Improved transport links, which give Leven a direct rail link to the capital, will lead to an enhanced local economy

To Perth/Dundee

Dunfermline LevenmouthRailLink Markinch Cameron Bridge Leven A92 Edinburgh Stirling Glasgow Dundee To Edinburgh January 2023 INSIDE TRACK: LEVENMOUTH 12 April 2023

Kirkcaldy

Thornton Distillery

To

Rail asset life extension with geopolymer technology

Geobear is a modern ground engineering company delivering asset life extension to railways in minimal possessions. We use advanced modelling to design solutions using geopolymer injection technology.

Our solutions are award winning, fast, safe and emit 75% less carbon than alternative methods.

www.geobear.co.uk

• Slab track levelling

• Embankment stabilisation

• Level crossing stabilisation

• Formation improvement

• Transition zones

• Subgrade improvement

• Track lifting

• Sinkholes

• Void filling

WE KEEP YOUR WORLD RUNNING

Joe Mulvenna, project manager for the Levenmouth Rail Link project, said: “Even at this early point in the work, laying the first rails feels like a symbolic event that will be warmly welcomed by all of the people who have worked hard to make this project a reality.

“Utilising much of the existing track bed and extensive preparatory work has enabled the project to get quickly out of the blocks and we can already see the project taking shape but obviously there is still a long way to go.

“With the first rails down along the first mile, the focus will turn to other aspects of the programme –particularly work on some the structures – but it is great that the project has got off to such a great start.”

Delivery model

The project is being delivered through an ‘integrator model’, which brings together a range of contractors with the skills, disciplines and capabilities to deliver the project on behalf of Scotland’s Railway efficiently and economically, saving the Scottish taxpayer around £3 million.

The Levenmouth Rail Link Team includes Network Rail, Atkins, AmcoGiffen, Babcock, BAM Nuttall, Siemens, SPL Powerlines UK, Story Contracting, QTS Group, and Fife Council. Focused on providing reduced risk increased social mobility, talent growth, health and economic recovery, while recycling 100 per cent of track materials and engaging over 250 young people from local schools, the success of the integrator model has also led to the creation of a £10.6 million fund for local projects, with the cost shared between Transport for Scotland and Fife council.

As well as the old, existing track and ballast, which was lifted and replaced, structures on the former line also had to be inspected and repaired or replaced. Five underbridges along the route had to be gritblasted to remove the old paint from the bridge and take it back to the base metal.

Corroded sections of the bridges were replaced and repairs carried out where needed. New timber bridge decks were installed to strengthen and support the new double-tracked railway that would be running over them.

The bridges were then repainted using a special paint system that will ensure they are water-proofed and coated to protect them for 25 years. To create the right conditions to carry out this work, engineers built a fully encapsulated access scaffold – one that surrounds the bridge on all sides, including underneath, and is fully covered and sealed.

The encapsulation protects the work from the impact of weather but, more importantly, is a crucial environmental protection – stopping the old toxic lead paint from leaking out into the environment.

Sean Clemie, senior project manager for the structures work on the route, explained: “In the same way as the old track bed is being dug out and replaced to bring it up to modern standards, the same principle applies with the underbridges on the route.

“Taking them back to their base metal lets us see clearly what we need to do to repair and replace any damaged or corroded steel sections, as well as strengthening the timber bridge decks.

“Once we have carried out the structural repairs, we can then apply the specialist paint system that lasts for 25 years and ensures the bridges are coated and protected against the impact of weather and corrosion – something which is particularly important in a coastal location.”

Safe foundations

Work to build the second mile of new track on the Levenmouth Rail Link got underway in August 2022. This is the first section of the reinstated railway which will be double-tracked, so, as well as needing significant work to install drainage and troughing for cable routes, the railway solum had to be reprofiled to ensure it was wide enough to accommodate both running lines. Ballast, which has been stock-piled in Thornton yard, was then delivered to site ahead of new sleepers being positioned and rails being placed.

In September, the old station platforms at Cameron Bridge were demolished. 210 metres in length and made up from masonry and fill materials totalling approximately 5,000 tonnes, their removal was needed to clear the way for the double track railway that was under construction.

The demolished platform material was retained onsite and fittingly, will be used as infill for the new Cameron bridge station platforms which are being built 200 metres to the east.

Work to install the first of the piles that will act as foundations for masts that will carry the overhead electrification wires commenced on 24 October and lasted for three weeks. Further piling along the Levenmouth rail corridor has been programmed so that it works in tandem with other activities on the project, such as work on bridges and track laying.

While the work is being delivered as part of the reinstatement of the branch, electrification of the line to Leven is part of the wider electrification of the railway in Fife as part of the Scottish Government’s plan to decarbonise passenger services on the network by 2035.

INSIDE TRACK: LEVENMOUTH 14 April 2023

Reinstatement of the rail link will cut the current three-hour return journey to Edinburgh by public transport by up to 50 minutes

For more information phone 01952 588 885 or browse www.eliteprecast.co.uk or email sales@eliteprecast.co.uk Everywhere on rail networks Elite products are seen in use British made Suppliers to 2012 London Olympics, 2014 Glasgow Commonwealth Games and approved suppliers to Tideway, Crossrail and HS2 (fully compliant transport) Get on track with Elite interlocking blocks and barriers KM 642263 BS EN 1917 & BS 5911KM 658166 Workforce protection barriers avoiding all line closures with adjacent line open Rockfall prevention with our multi-purpose Jersey barriers Hoarding stabilisation utilising Elite Duo interlocking blocks Large ballast bays with walls constructed from our Legato interlocking blocks Large scale embankment retention using the versatile Legato blocks Workforce safety refuges built from Elite Duo blocks

Sean said: “The first piles going into the ground in the Thornton area is big for the project but also an important milestone for the wider aspirations to decarbonise the railway across Fife.

“With the first mile of the Leven branch already operational railway, we can use this to move the track-based piling rig to each location to sink the foundations and then insert the masts that will ultimately carry the overhead wires that will power the railway.”

Protecting the river

The Levenmouth Rail Link runs alongside the River Leven. After investigation, a number of sites were identified as being in need of reinforcement. The riverbanks at these locations were stabilised and voids were infilled before ‘rock armour’ was positioned to protect the area. This involved positioning large boulders in the river to change its course and to prevent running water from scouring away the newly strengthened embankments.

Joe commented: “It’s important that we work with the river and not against it to ensure that the railway is protected from the impact of more frequent and more intense spells of wet weather and the flooding it could cause.

“Strengthening and reinforcing embankments and defending them with the addition of rock armour is one element of our plan to do this but we are working with partners to enable the addition of more natural measures to protect the embankments and to allow the river to work more naturally.

“And while we carry out the work, utilising innovative measures like bubble curtains is just one way we are reducing the risk to the river from the adjacent construction activities.”

Bubble curtains are created by gasses being let out on the riverbed and when they rise they act as a barrier to stop the formation of waves and block the spread of contaminants, including silt and plastics.

New stations

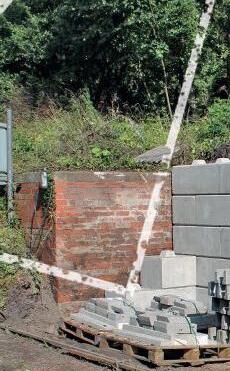

Construction of the two new stations got underway early in 2023. Cameron Bridge will have two 196-metre platforms with a connecting footbridge and lifts and work began with the construction of the foundations for the platforms, using more than 100 precast units and approximately 200 cubic metres of concrete.

Leven station will boast 205-metre island platforms and a pebble styled pavilion area as the entrance to the new station. Here too, work commenced with the foundations and it is anticipated that work to create the new station will take approximately 14 months.

Both stations will be opened as part of the overall Levenmouth Rail Link in spring 2024.

As of 16 March, the first three miles of rail are now in place from Thornton Junction, extending more than halfway to Leven. Since the start of work on the line, the track bed has been dug out with 30,000 tonnes of spoil removed. The ground has been waterproofed and approximately 37,000 tonnes of new stone ballast laid. Engineers have installed more than 18,000 sleepers and one hundred 215-metre-long sections of rail, in total 22km, to complete the new section of track.

Patrick Harvie MSP, Minister for Zero Carbon Buildings, Active Travel and Tenants’ Rights, said: “It is really encouraging to see the halfway point for track laying being reached as work continues to reconnect Leven to the mainline rail network.

“With work now underway on both stations and activity all along the rail corridor, I really get the sense that momentum is building around the project as well as the feeling of excitement in the community in anticipation of the benefits the new line will bring.”

INSIDE TRACK: LEVENMOUTH 16 April 2023

It’s important that we work with the river and not against it

Full steam ahead with powerful partnerships, a strong line-up of new exhibitors and an exciting programme

Railtex 2023

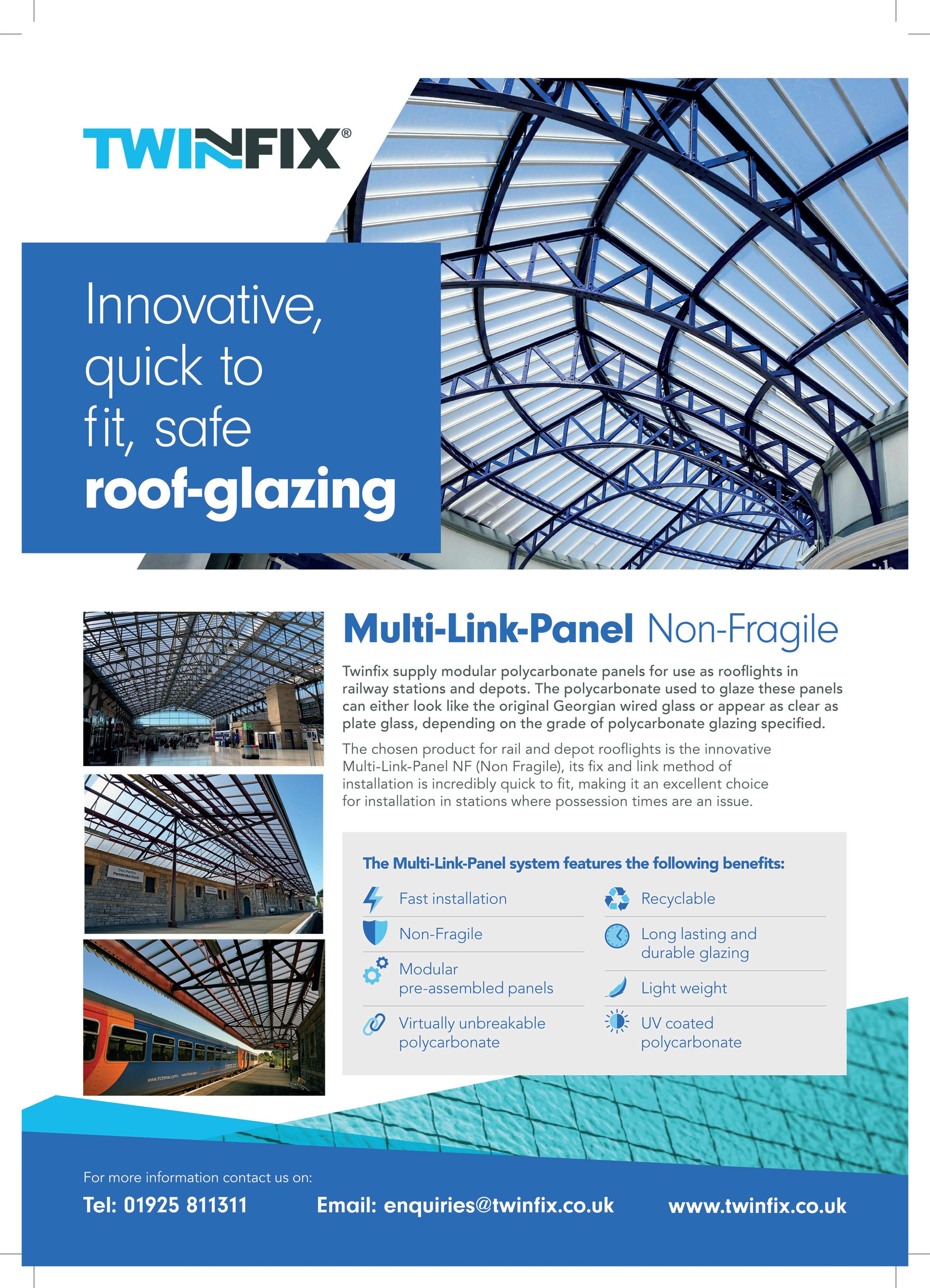

From 9 - 11 May 2023, the rail industry will gather for Railtex 2023 at the NEC in Birmingham. The show provides a unique opportunity to meet with national and international players and thought leaders, all looking to enhance the passenger experience, freight logistics and the overall efficiency of railway operations.

Participants can expect live demonstrations of new machines and systems, technical in-person discussions and a rich supporting programme packed with keynote speakers from leading industry names. Railtex will once again reinforce its role as the central marketplace for the industry to come together and discuss both challenges and opportunities in the light of current developments within the rail industry.

Keeping the current rail market in mind, it is particularly important to focus on crucial topics such as decarbonisation and investments to create a more sustainable rail industry, the digitalisation of rail transport, as well as the passenger experience. It is essential to not only address and mirror these topics, but to also come together to find common solutions and shape a successful future for the rail industry. This is precisely what Railtex facilitates. “Railtex 2023 is the place to be with all key players gathered in one place. We are glad to have the great support from our main show partner RIA – the Railway Industry Association, as well as our show partners, Rail Forum, Railway Benefit Fund, the CPD Certification Services, our media partners, and many more.” states Olaf Freier, the Transport Portfolio Director.

Network Rail and GBRTT

As the leading one-stop-shop event for the entire railway industry in the UK, Railtex reflects the dynamic developments in the sector and the vision of the rail network of the future via an exciting supporting programme. “We are delighted that the Railway Industry Association will be the main show partner at Railtex 2023, providing an extensive programme across the event. Our programme this year is bigger than ever and includes a Future Focus Conference, to provide an environment where strategic discussions on the future of UK rail can take place, an Innovation Village, where key clients, stakeholders and suppliers will showcase what they are doing on innovation, the RIA Networking Zone and Meet the Buyer programme to support companies looking to get new products and services onto the network, and a Young Rail Professional Conference, bringing a new generation in rail to the show.” says Darren Caplan, Chief Executive of the Railway Industry Association.

The programme will include keynotes, Q&A sessions and panel discussions held by a remarkable line-up of speakers, including leading figures from politics and industry and many other valuable actors from the rail industry, with the participation of Network Rail and The Great British Railways Transition Team. All sessions are free to attend and CPD certified. More details will be published in the run-up to the show. The Innovation Village will be part of the ‘Unlocking Innovation’ programme, organised by RIA and supported by Network Rail’s R&D Portfolio. Furthermore, the show features the popular On-Track Display area, sponsored by long-standing partner British Steel. It demonstrates tools and equipment in an authentic rail setting.

Products and services at the show

So far, fifty new companies are amongst the exhibitors that have already confirmed their participation at Railtex 2023, all serving the future development of the UK railway industry with their products and services.

Both the Railtex Exhibitor List tool and the Online Show Preview with detailed information on the many exhibitors and products are regularly updated and available at www.railtex.co.uk. The Exhibitor List tool helps users to effectively prepare for their visit by finding the companies and products most relevant to them. The Online Show Preview provides an overview of the wide variety of innovations, technologies and systems on display at the event.

Visitor information

The visitor registration is now open, and free tickets can be ordered online ahead of the show. During the exhibition, tickets can be purchased on-site or via the online ticket shop. For smooth entry, visitors are advised to print out their e-ticket or download their mobile ticket prior to the show. Show opening hours are from 9:00 AM to 17:00 PM on Tuesday, 9th May 2023, and Wednesday, 10th May 2023, and from 10:00 AM to 16:00 PM on Thursday, 11th May 2023.

More information at: www.railtex.co.uk

INSIDE TRACK:RAILTEX 18 April 2023

ASSET INSPECTIONS Earthworks Structures Drainage ACCESS SOLUTIONS Rope Access Underwater Drones Confined Space T: 01543 411994 E: info@geoaccess.co.uk www.geoaccess.co.uk WE COLLABORATE WE INNOVATE WE SOLVE

Talking about freight

As the UK aims to cut carbon emissions in all sectors, moving freight and lorries off the nation’s roads and onto rail is becoming increasingly important.

At the same time, making sure that rail freight uses electric traction, rather than diesel, is also becoming a ‘hot topic’ at industry conferences and events.

Railway infrastructure manager Network Rail is talking about ‘customers’ rather than ‘passengers’ because freight is an important customer of the railway, with its own needs and demands.

The UK Government has committed to removing all diesel-only trains from the network by 2040, although it did not include diesel-hybrid trains in this target. The Scottish Government set a more ambitious target for itself and targeted no diesel-only trains by 2035.

On 23 March 2021, the Transport Select Committee published a paper entitled “Trains fit for the future?” which explained the government’s thinking: “In June 2019, the UK Government set legally binding targets to reduce net emissions of greenhouse gases by 100 per cent relative to 1990 levels by 2050 – commonly referred to as the ‘net zero’ target.

“In response to this, all sectors of the UK economy are beginning to outline the infrastructure work and investment required to achieve this target. Some areas of the economy, such as aviation and agriculture, will be very difficult to decarbonise. Therefore, other sectors, such as rail, will be required to reach virtually zero or zero greenhouse gas emissions if the national net zero emissions target is to be achieved. For rail to support the UK in

achieving its net zero legislative target, diesel operation would need to reduce and potentially cease.”

The obvious course of action is to electrify the entire network by 2040, or as soon as possible after that date and in any case by 2050. That will be in immense undertaking. To simplify matters, particularly regarding lightly used branch lines, bridges and tunnels that will be difficult or costly to upgrade, diversionary routes and the ‘last mile’ run into depots and sidings, passenger train owners and operators are considering alternatives such as hydrogen power and on-board batteries.

However, rail freight doesn’t have that luxury. Freightliner claimed that its aggregate train that it ran from Merehead in Somerset to Acton in London on 17 July 2019 was “the heaviest ‘jumbo’ train currently running in the UK” at 4,624 tonnes.

Rail freight is back on the agenda as two major reports highlight the steps that need to be taken to strengthen the rail freight industry and help the UK to meet its decarbonisation commitments over the next 20 years

INSIDE TRACK: RAIL FREIGHT 20 April 2023

Noise

Biodiversity

Clean air

Zero waste

Social value

People-centred rail

Supply chain resilience

Net Zero Carbon

Sustainable rail Climate change

Rail is undeniably sustainable. But with the right data, we could direct our resources to achieve even more.

RSSB is leading industry efforts to quantify how sustainable GB Rail is, and could be. That includes calculating the network’s carbon footprint. Developing our Rail Carbon Tool, which helps you do the same for your projects. Valuing dozens of social and community activities. And measuring air quality around the network for the first time.

This is only the beginning.

For more on how sustainable rail adds up, visit www.rssb.co.uk/measuring-sustainability

We’re with you every step of the way

The possibility of hauling that weight of train using hydrogen or battery-power seems remote. Overhead electrification is currently the only way to go.

Freight volumes

In the year April 2021 to March 2022, the industry moved 16.87 billion net tonne kilometres of freight, according to rail regulator the Office of Rail and Road. In terms of distance, that works out as 6.4 per cent of all train kilometres recorded.

Alternative fuels are one option, and they can improve sustainability and reduce greenhouse gas (GHG) emissions. Freightliner pulled one of its 4,000tonne ‘jumbo’ trains using a Class 70 locomotive fuelled by HVO (hydro-treated vegetable oil) on a 106-mile run between Merehead and Acton. The result was a reduction of GHG CO₂ emissions of 1,810kgs compared to standard EN590 diesel, as well as an improvement in almost all areas of air quality emissions. The journey also equated to the removal of 90 HGV journeys from the UK’s roads.

Electric spine

The obvious and only answer is electrification, and the government realised this a decade ago. Announced by the Department for Transport in its High Level Output Statement (HLOS) for 2012, covering Control Period 5 (2014-2019), the Electric Spine was a proposal to electrify the line from Southampton to Sheffield.

The Secretary of State wishes the industry to develop and deliver within CP5 the major rail electrification and capability enhancement referred to as the ‘Electric Spine’, in order to increase regional and national connectivity and support economic development by creating a high-capability 25kV electrified passenger and freight route from the South Coast via Oxford and the Midlands to South Yorkshire.

The routes to be electrified as part of the Electric Spine are:

Southampton Port – Basingstoke (conversion from 750V DC);

Basingstoke – Reading;

Oxford – leamington – Coventry;

Coventry – Nuneaton;

Oxford – Bletchley – Bedford (East West Rail core route);

Bedford – Nottingham and Derby, and Derby –Sheffield (Midland Main Line);

Kettering – Corby.

The work should include gauge clearance for large containers and appropriate electrified links to adjacent electrified routes, depots and freight facilities. Electrification of the line from Reading to Oxford would be part of the already-approved GWR electrification programme. Oxford to Bedford would be East West Rail and Bedford to the north part of the Midland main line electrification.

Much of this never happened. Southampton to Basingstoke is still at 750V DC, Basingstoke to Reading was cancelled, East West Rail is no longer to be electrified, though the design includes passive

Rail HLOS electrification by 2019

provision for it, and Midland main line electrification only reached Kettering and Corby, although masts are now going up to Market Harborough.

The development of electric freight has faced other challenges too. The abortive Electric Spine programme didn’t make any attempt to electrify access to Felixstowe and, in 2021, Freightliner mothballed its entire electric fleet, saying that rising electricity costs had made them more expensive to operate than diesel.

However, electrification remains the only way that rail freight will hit its 2035/2040/2050 decarbonisation targets.

Cleaner alternative

In 2023, there is a renewed emphasis on rail freight, and electric traction in particular. Rail Partners issued a report in March – Freight Expectations: How rail freight can support Britain’s economy and environment.

Map from 2012 HLOS showing plans for the Electric Spine, to be delivered by 2019

The obvious and only answer is electrification, and the government realised this a decade ago

Legend Electrification already announced New electric spine in HLOS New electrification in HLOS rail Network Selected stations © Crown Copyright.AllrightsreservedDepartmentfor Transport1000392412012 gisu1112j082 York

Selby

Nottingham

Blackpool Leeds

Liverpool Manchester Sheffield Rugeley TrentValley Derby

London Cardiff

Heathrow

Walsall Birmingham Nuneaton Coventry Corby Swansea Oxford

Newbury Reading

Southampton

INSIDE TRACK: RAIL FREIGHT 22 April 2023

It states: “To harness rail freight’s potential, Rail Partners is calling on government to set an ambitious target to treble the amount of freight moved by rail by 2050. New analysis in this report demonstrates that this will create a minimum of nearly £5.2 billion in economic benefits annually, and remove over 20 million HGV journeys from the road network each year.”

Of course, to remove those HGVs from the roads, rail will need to offer a cleaner alternative. The report continues: “Given rail’s strong existing environmental credentials, rail freight can play a key role in accelerating the transition to net zero between now and 2050 if a clear pathway to decarbonise the railway is put in place. This should include early commitment to infill electrification schemes that will have a large and immediate benefit for decarbonising key rail freight flows.”

The report also makes a strong case for delivering infill electrification schemes. It looks at two lines in particular, the branch that connects DP World London Gateway to the Tilbury Loop of the London, Tilbury and Southend line, and the branch that connects Felixstowe to Ipswich.

Electrification of the London Gateway Branch would, the report estimates, enable over a third of traffic from the port to convert to electric traction –saving around 10,000 tonnes of CO₂ across freight routes every year.

Similarly, the electrification of the Felixstowe branch line to Ipswich, while significantly longer than

Gauge enhancements

Transpennine Route Upgrade

High Speed 2

Including an alternative to the Golborne Link

the route from London Gateway, is also identified as a priority within the freight industry due to the high volumes of freight moved by rail from the UK’s busiest port. The scheme would also benefit passengers. Analysis informed by RSSB project T1186, which maps rail’s air quality impacts, estimates the electrification of this route would reduce carbon emissions by almost 29,000 tonnes per year and lower air quality pollutants by nearly 200 tonnes per year.

vvww Swansea • Bristol • Kent 01792 301818 www.kaymacmarine.co.uk

Tamworth Scour Protection Scheme

Redbridge Scour Protection Scheme, River Tweed, Galashiels, Scotland

Kaymac Marine & Civil Engineering is the leading provider of marine civil and subsea diving engineering services supporting major rail asset maintenance schemes across the UK Rail specialist contractors since 1989

Engineering Innovation Above and Below the Waterline

Felixstowe to Nuneaton Upgrade

Angerstein Wharf Chord

Syston to Trent Gauge enhancements

Wembley to Channel Tunnel Gauge enhancements Gauge enhancements

INSIDE TRACK: RAIL FREIGHT 23 April 2023

Map from Rail Partners report showing additional upgrades needed to the freight network

mature, proven use for over Europe and, 10% of British locomotives.

main lines thirds of the core already electrified, electrification to be Transport map to Trunk haulage by distribution multimodal solution, fully – shown trains being distances. total less million train equivalent miles off estimated to than the cost ‘no regrets’ UK logistics which can the UK

In addition to infill electrification, the Rail Partners report identifies a series of enhancement projects that would go a significant way in delivering a trebled freight market by 2050. Some schemes, such as HS2 and the Transpennine Route Upgrade, have already received commitment from government – though, in relation to the former, an alternative to the Golborne Link connecting the high-speed network and West Coast main line will be needed to maximise the benefits of HS2 for freight.

Elsewhere, gauge enhancements will be needed between Didcot and Cardiff, Syston and Trent junction, Eaglescliffe and Northallerton, and from Wembley to the Channel Tunnel. The Felixstowe to Nuneaton route should be upgraded and a new chord constructed at Angerstein Wharf in Greenwich.

Infill electrification

Returning to the question of electrification, the Chartered Institute of Logistics and Transport (CILT) recently released its research that estimates only 800 miles of additional electrification is needed in the UK to enable 95 per cent of rail freight to be electrically hauled. Just 40 miles of electrification per year would deliver this in 20 years, well ahead of the 2050 deadline and, CILT estimates, at a cost of £100 million per annum.

Following the Infill schemes, progressive implementation of the electrification strategy is proposed, with a rolling programme to ensure efficient delivery at lowest possible cost. Around 80% of the lines to be electrified are in – or form key routes to – the Midlands, the North, Wales or Scotland. Accordingly, the strategy makes a major contribution to levelling-up, regional equality and connectivity. It would also increase productivity in transport.

The CILT electrification strategy benefits passengers as well as freight customers. Almost all the routes involved carry passenger trains and the strategy would enable life-expired diesel trains to be replaced by modern electric units.

On the accompanying map, CILT highlights in red just 60 miles of infill electrification as a priority, which it estimates can be done in two years at a cost of around £50 million per year. Electrifying these short sections would, CILT suggests, allow around two million train miles a year to be decarbonised, the equivalent of taking around 80 million diesel HGV miles off Britain’s roads each year.

CILT is working with colleagues in engineering institutes to identify lower cost methods of electrifying freight routes and it is already clear that this will cost considerably less than electrification of high-speed intercity routes. Freight train speeds are much lower, meaning that a simpler form of wiring can be used, and there are credible grounds for expecting the cost of freight electrification to be less than half the cost of higher speed passenger routes

An electrification programme of c.40 route miles per annum for 20 years would see the CILT electrification strategy delivered at an estimated cost of c.£100m p.a. This is a modest outlay in the context of the UK transport budget and would produce substantial decarbonisation benefits.

The CILT strategy would result in the core Freight network being electrified by the mid-2040s, with virtually zero carbon emissions from c.95% of rail freight operations, and encourage modal shift of long-distance trunk haulage from road to rail.

Following the infill schemes, progressive implementation of the electrification strategy is proposed, with a rolling programme to ensure efficient delivery at lowest possible cost. Around 80 per cent of the lines to be electrified are in – or form key routes to – the Midlands, the North, Wales or Scotland. In this way, this strategy would make a major contribution to levelling up, regional equality and connectivity.

Together, the two reports give a good idea how rail freight can progress over the next 20 years and help government meet its commitments while, at the same time, easing congestion on Britain’s roads. DB Cargo chief executive Andrea Rossi expressed his support for the plans, although some of his frustration with the inertia shown in some quarters was evident in his comments.

“We’ve spent the last two years lobbying politicians and civil servants of the significant economic and environmental benefits of rail freight over road

haulage,” he said. “Freight belongs on rail. We know it. Our existing customers know it. The public knows it. We now need the UK Government to work with us to enable more of it to switch from road to rail.

“Setting a clear and ambitious target for rail freight growth, as already exists in Scotland, will give confidence in the sector, stimulate investment and unlock rail freight’s true potential.”

Electrification infill (red) and additions (orange) proposed in the CILT report

STIRLING EDINBURGH GLASGOW CARLISLE DARLINGTON YORK LEEDS DONCASTER MANCHESTER PRESTON BLACKPOOL LIVERPOOL CREWE STOKE-ON-TRENT STAFFORD WOLVERHAMPTON BIRMINGHAM COVENTRY MILTON KEYNES CARDIFF CENTRAL NEWPORT BRISTOL PARKWAY SWINDON BASINGSTOKE SOUTHAMPTON CENTRAL BOURNEMOUTH WEYMOUTH PORTSMOUTH BRIGHTON EASTBOURNE ASHFORD DOVER CAMBRIDGE LEICESTER PETERBOROUGH NORWICH IPSWICH COLCHESTER HARWICH READING MIDDLESBROUGH NEWCASTLE SHEFFIELD OXFORD Dorchester West Wareham Poole Brockenhurst Lymington Ryde Sandown Shanklin Havant Fareham Bognor Regis Worthing Chichester Barnham Lewes Newhaven Seaford Haywards Heath Three Bridges Gatwick Airport Redhill East Grinstead Oxted East Croydon Hastings Tunbridge Wells Paddock Wood Tunbridge Sevenoaks Orpington Bromley South Swanley Maidstone Petersfield Haslemere Alton Guildford Epsom Farnborough Horsham Crawley Eastleigh Winchester Andover Romsey Salisbury Warminster Castle Cary Frome Westbury Newbury Chippenham Didcot Severn Tunnel Junction Bridgend Port Talbot Parkway Cheltenham Spa Worcestershire Parkway Bromsgrove Bletchley Watford Junction West Hampstead St Albans Luton Bedford Wellingborough Northampton Rugby Nuneaton Kettering Market Harborough Corby Oakham Stamford Mowbray Hinckley Potters Welwyn Stevenage Hitchin Sandy Huntingdon March Ely Royston Stansted Airport Bishops Stortford Broxbourne Hertford Soham Bury St Edmunds Stowmarket Diss Westerfield Felixstowe Manningtree Walton-on-the-Naze Clacton-on-Sea Marks Tey Witham Southminister Chelmsford Shenfield Romford Statford Abbey Wood Dartford Gravesend Strood Sheerness-on-Sea Chatham Faversham Herne Bay Margate Ramsgate Deal Canterbury Folkestone Downham Market Kings Lynn DERBY Loughborough East Midlands Parkway Alfreton Chesterfield Grantham Spalding Lincoln Sleaford Newark North Gate Retford Barnetby Haborough Thirsk Northallerton Eaglescliffe Durham Tamworth Lichfield Rugeley Kidsgrove Congleton Macclesfield Sandbach Wilmslow Runcorn WestKirby Birkenhead Bidston Earlestown Bootle Formby Southport Kirkham Wesham Chorley Bolton Salford Cresent Shipley Keighley Skipton Ilkley Guiseley Morpeth Alnmouth Chathill Berwick-upon-Tweed Dunbar North Berwick Haymarket Kirknewton Lancaster Oxenholme Lake District Penrith North Lakes Lockerbie Carstairs Lanark Hamilton Larbert Falkirk High Linlithgow Bathgate Drumgelloch Airdrie Cumbernauld Lenzie Dumbarton Central Helensburgh Central Balloch Braintree Nottingham Shoeburyness Tilbury Town London Gateway Hadfield Glossop Buxton Bradford Port Glasgow Gourock Wemyss Bay Largs Ardrossan Troon Kilwinning Prestwick Ayr Girvan Stranraer Kirkby Neilston Dunblane Wickford Rayleigh Southend Airport Southend Victoria Upminster Grimsby Immingham Wakefield Ormskirk New Brighton Newmarket Thetford Attleborough Wymondham Hoveton & Wroxham North Walsham Cromer Sheringham Great Yarmouth Reedham Lowestoft Beccles Saxmundham Hull Scarborough Hellifield Carnforth Sunderland Dundee Perth Aberdeen Inverness Mallaig Chester Holyhead Aberystwyth Shrewsbury Fishguard Swansea Hereford Bristal Temple Meads Bath Spa Taunton Exeter Plymouth Penzance Paignton Okehampton Barnstaple Newquay St Ives Falmouth Barrow-in-Furness Workington Whitehaven Cleethorpes Skegness Boston Banbury Leamington Spa Pwllheli Gloucester HS1 Electrified routes ( in delivery) Key early infill sections Strategic freight routes for electrification Unelectrified routes Not all stations/rail lines shown KyleofLochalsh Thurso Grain Mendips Seaforth Docks Worcester

3 CILTUK.ORG.UK

produces over a UK carbon emissions freight over longer presents a particular

INSIDE TRACK: RAIL FREIGHT 24 April 2023

Experts in delivering on and off-track ground engineering solutions to the rail sector

Full end-to-end capabilities, as a trackside POS and Principal Contractor; From ground investigation, design, and temporary works through to all types of ground engineering and geotechnical solutions

A track record of 450+ completed Network Rail projects; Including over 200 stations, major electrification schemes, re-signalling projects, track bed stabilisation, slope retention, sheet piling and ground investigation

Track Bed Stabilisation is a system unique to Van Elle and is used to stabilise the track bed without the need for removing the track or ballast

Van Elle has the in-house ability to design and manufacture off-site, for both steel and precast concrete in our in-house factories and workshops

Off-site manufacturing and other modern methods of construction (MMC) has the potential to transform the delivery of construction activity

ScrewFast Foundations, the UK’s leading helical piling and steel modular company, is now part of the Van Elle Group, offering additional design and construction solutions for the rail network.

STRATA Geotechnics, part of the Van Elle group, has the expertise and specialist equipment to perform on and off-track ground investigation (GI) projects for the rail network

Challenged by former Prime Minister Boris Johnson to deliver public investment projects faster and for less money, the rail industry came up with SPEED – Swift, Pragmatic and Efficient Enhancement Delivery. It does what it says on the tin

SPEED and efficiency

Many people have criticised the construction industry’s project delivery record, particularly on multi-millionpound mega projects.

Rail hasn’t been exempt from these criticisms. Network Rail in particular has been said to be overly bureaucratic, too inflexible, risk averse, unwilling to take a chance on innovation and slow to react to changing requirements.

The Department for Transport (DfT) has similarly been accused of dragging its feet on making decisions, micro-managing projects, coming up with requirements that are hugely over-specified and then moving the goalposts once a project has started.

Both claims are no doubt true in part, although there are often extenuating circumstances. However, the results in those cases when the complaints are justified are often project overruns, soaring costs and critical articles in the popular press. Something had to be done. In June 2020, as part of the government’s COVID-19 recovery plan, the Prime Minister announced a new taskforce to deliver public investment projects faster and for less money across all sectors.

In response, and representing the rail engineering sector, Network Rail and the DfT sat down to work out how the management of projects could be improved so as to improve the delivery of rail investment. Not only should projects be delivered on time, to budget

and safely, they should even be delivered UNDER budget and EARLY if possible.

Six infrastructure projects of differing scale and stages of development were identified and the project teams were asked to consider past and current constraints, and what would be needed to unblock them.

All six programmes developed proposals to reduce timescales and cost, and then defended their proposals through peer reviews and challenge panels. The programmes’ ‘wish lists’ were grouped into eleven cross-cutting themes, such as removing complexity from planning processes, that would lower costs and speed up the delivery of infrastructure schemes.

INSIDE TRACK:PROJECT SPEED 26 April 2023

These new and innovative ways of working were rolled out across all rail upgrades as Rail Project SPEED (Swift, Pragmatic and Efficient Enhancement Delivery), with the intention of:

Ensuring passengers experience better journeys more quickly;

Giving greater value to taxpayers;

Transforming the pace and way in which the railways are improved.

In February 2021, the then Rail Minister Chris HeatonHarris spoke at a conference organised by the Railway Industry Association, introducing the new concept to delegates. He said: “The whole country has relied on the transport industry over the past year to keep the country moving, supplies delivered and key workers to their jobs saving lives (during the COVID-19 pandemic). We are now depending on transport to kickstart our economic recovery.

“Rail Project SPEED, forged alongside Network Rail, is a call to arms to cut unnecessary red tape, be bold and purposeful, and empower the railway to be radical in its thinking to halve the time and reduce the cost of delivering infrastructure projects.

“By maximising the benefits of every pound that we’re channelling into rail, we will make the case for continued investment. Our intention is to create a more resilient, resourceful and robust railway, equipped for the challenges ahead and delivering better for its passengers, as we build back better from COVID-19.”

Andrew Haines, Network Rail’s chief executive, speaking at the same conference, added: “There has never been a more important time to make the case for rail. The pandemic has spurred us to make real progress in removing barriers that have long hindered industry transformation.

“But, of course, there is still much more to do, and we will do that faster and more effectively when we work together across the industry.”

Industry reaction

Shortly after the conference, the three largest rail industry membership organisations, the Rail Industry Association, Rail Alliance (now the RBD Community) and Rail Forum joined in welcoming the initiative and asking for progress in five key areas that they felt would help make Rail Project SPEED a success:

1. A partnership approach between DfT, Network Rail and the supply chain that embeds early supplier involvement and collaboration, and which recognises all parties have a key role to play in reducing time/ costs on projects (for example, ensuring timely planning and funding decisions and delegation);

2. A cross industry approach to identify and action practical solutions, such as improved access to track and improved planning processes;

3. A clear investment roadmap, providing visibility and certainty of rail schemes, so suppliers can take key decisions on investment and skills;

4. A new, transparent, approach to risk and benefitssharing, which drives innovation and cost reduction; and

5. Recognition that the whole industry workforce is key to success with commitment by all parties, including those involved in education and training, to bring about changes to reduce time/cost on projects.

The themes

As mentioned, SPEED (the ‘Project’ qualifier was dropped as the programme was more than just a project) has 11 cross-cutting themes.

Planning and consents: The long timeframes associated with planning and consents form the critical path for many rail enhancement schemes, with long lead times associated with decision making.

Assurance: Planning proportionate assurance, removing duplication and low value activity, reducing cost, schedule and risk through early identification of issues will enable speedier client decisions through increased confidence and collaboration.

Governance: Streamlining the Rail Network Enhancements Pipeline (RNEP) process to introduce greater flexibility that makes governance proportionate to risk and reduces decision points for projects, removing duplication.

GRIP/PACE: As the rigid stages set out by GRIP, the tool used to manage project delivery in Network Rail, can often lead to unnecessary delays, it was replaced in January 2021 by PACE, a new tool that allows project managers the flexibility to adapt their approach, make decisions that best meet the needs of their project, overlay stages and define a single viable option quicker while maintaining rigour.

By maximising the benefits of every pound that we’re channelling into rail, we will make the case for continued investment

INSIDE TRACK:PROJECT SPEED 27 April 2023

Engineers repairing the Royal Border Bridge using a rope access system

Timetabling: Timetabling and operating principles are not considered early enough in many programmes and the lack of alignment into timetabling and resourcing processes prevents an effective industry plan and a working end state timetable. A new industry-level framework, developed throughout the programme lifecycle, will provide options for realising benefits in the timetable and changes to scope assessed against infrastructure capability.

One-team culture: Fostering a one team culture between DfT and Network Rail and other partners around project delivery will result in an integrated team that is empowered to make collaborative decisions and work towards the same objective.

Railway Interoperability Regulation (RIR): Achieving an authorisation to enable a passenger service that requires additional assurance via third party verification and the ORR can add time and cost to projects. An alternative assurance process will apply RIR in a more strategic way.

Standards challenge: Unquestioning compliance with standards can result in over engineering and reduces the opportunities to realise efficiencies. An improved process for challenging standards will save time and cost.

Procurement strategy: Inadequate procurement time, rushed governance, a lengthy tender process and existing frameworks that often have selfimposed restrictions on use and complex call-off arrangements all drive up cost and time.

Access and possession: Access is a critical driver of programme schedule and cost. It is critical to work with industry parties in order to optimise the access strategy and make the most efficient use of the access available.

Capability and culture: The cultural change required to deliver the SPEED vision will require a change in the approach to project delivery improvements – being bold and challenging the status quo is encouraged to generate new thinking.

Proof of the pudding

SPEED has grand ambitions. However, two projects stand out as proving that, when the rule book is torn up and the ‘traditional’ project planning and delivery process is stood on its head, the results can be outstanding. In the spring of 2020, as ideas for SPEED were being formulated, the country was suddenly gripped by the COVID-19 epidemic. No one was catching trains. An enterprising team on the West Coast main line pulled out of their wish list a project they had wanted to do for years but could never get track access to do – the remodelling of Kilsby tunnel, near Daventry in Northamptonshire, to sort out severe drainage and track quality issues.

A 15-day blockade of the tunnel, during which time 1.3km of track was replaced, 2,458 new concrete sleepers laid, 7,700 tonnes of railway foundation stone (ballast) laid, 745 metres of new drainage created and a total of 23,870 hours worked on the project, was planned in just nine days!

Although the work needed was already known, in those nine days all trains due to run through the tunnel had to be rerouted via Northampton, plant and contingent labour booked, contractors called in and briefed, supplies ordered and, in many cases, manufactured specially, and a myriad other plans finalised.

It was a remarkable feat, made even more unusual in that 250 other jobs were also planned and completed on the closed section of railway between Rugby and Milton Keynes in the same tight timescale. The Kilsby experience must have given the SPEED planners confidence in just what could be achieved.

The first scheme to incorporate the principles of SPEED after they had been announced was the restoration of passenger services to the Dartmoor line between Exeter and Okehampton in Devon. Benefitting from the application of SPEED approaches, the line was transformed from a mothballed, former freight railway with occasional Summer Sunday services to a full seven-days-per-week passenger operation in a mere nine months since the government confirmed its investment of over £40 million under the Restoring Your Railway programme.

In those nine months, the project team designed, planned and delivered a huge programme of work, including laying 11 miles of new track and installing 24,000 concrete sleepers and 29,000 tonnes of ballast in a record-breaking 20-day period.

Repairs were also made to 21 structures along the route including four bridges. Other infrastructure work included level crossing improvements and the installation of railway communications equipment, along with vegetation clearance, earth and drainage works and fencing.

The project was delivered £10 million under budget.

The project was delivered £10 million under budget

INSIDE TRACK:PROJECT SPEED 28 April 2023

Kilsby Tunnel Image: G. Bickerdike

1 Geotextiles Ballast Re-inforcing Track Drainage Geotextile: Aquatex® Trenchliner® Geocomposites Re-inforcing composites Buried Cable Ducting THIEEL® Undertrack Chamber (UTX) Carpark and Station Lightening Concrete and GRP Troughing Off-Track Drainage: Ditchlinner® 6ft Drainage Catch-pits CESS Drainage Catch-pits Track Drainage Pipes 1 2 3 4 5 6 7 8 9 10 11 12 13 2 3 4 5 6 7 8 9 10 11 13 12 AQUA FABRICATIONS LTD Belmont House, Garnett Place, Skelmersdale, Lancashire WN8 9UB Telephone 01695 51933 Email sales@aquafab.co.uk AQUA FABRICATIONS LTD INC. AQUA S+TS & AQUA GEOCOMPOSITES www.aquafab.co.uk

More recently, £5 million was saved on repairing the Royal Border Bridge in Northumberland, which sits across the River Tweed and transports freight, goods and passengers between England and Scotland along the East Coast main line.

By using abseilers (engineers on ropes) to repair the 28 arch, Grade I listed masonry viaduct, Network Rail and its contractors were able to make effective repairs including replacement brickwork and maintenance and replacement metal straps.

It had been 30 years since such repairs were carried out on this structure due to the difficulty in gaining access and complex arrangement with effective scaffolding and traffic disruption.

Traditional measures would have taken £9 million and six months to carry out this work. However, by adopting better ways of working and embracing SPEED principles – replacing scaffolding with abseilers – engineers were able to access the bridge and carry out much needed repairs swiftly.

In the West Country, passenger demand travelling to and from the popular destination of St Ives in Cornwall has been increasing dramatically –especially since people have reduced international travel.

To cater for this growing demand, Network Rail extended the platforms at St Erths and Lelant to accommodate five-car trains.

This allowed the train operator to increase capacity by 25 per cent to and from St Ives, with up to 10,000 seats now available during peak summer days, supporting businesses and tourism in and around the local area.

The programme took just nine days in March 2022 to complete. Network Rail, working with contractor BAM Nuttall and Great Western Railway, invested £1.14 million to extend the existing platforms by 13 metres at Leland and six metres at St Erths, so the increase in capacity would be available for the summer season.

Derek Thomas MP for St Ives, West Cornwall and the Isles of Scilly, said: “Improving capacity on the branch line to St Ives is a core part of our work to reduce the pressure on traffic in the town centre so this is a great step in the right direction. In St Ives, we are ambitious to achieve a low-carbon transport network and have appreciated the way that Network Rail and GWR have engaged with us as we work towards this shared goal.”

These projects are a few of the many examples where Network Rail is working with its supply partners to reinvent its approach to delivering projects, bringing safe and timely benefits to rail customers at an affordable price to government.

Regional teams have worked hard to embed these principles and are now extending the application from enhancements to renewals, with training development and support being provided. The opportunities for savings in both time and cost therefore continue to grow as SPEED becomes embedded into the project management process.

The initial SPEED projects have conservatively identified savings of £3.4 billion in costs and 261 months in schedule across the network, showing what the industry can achieve when working together.

SPEED principles are now applied to all capital investment projects, whether they are enhancements, renewals or better value footbridges. SPEED is now the industry’s approach to delivering better value projects for the benefit the railway.

SPEED projects 2023/24 include:

Eastern Region York Area Capacity

Leeds Area Capacity

Midland main line electrification 3

Transpennine Upgrade

Northumberland Line (NWR Element)

Cambridge South

ECML Power Supply Upgrade 2

North West & Central Redevelopment of Euston Conventional Station (RECS)

Manchester Reliability Transformation Programme

Crewe

Wigan-Bolton

Southern Waterside

Wales & Western Reading Feeder

Oxford Phase 2

MetroWest (Phase 1) Portishead

Ashley Down New Station

Newtown (Wales AfA)

The line was transformed from a mothballed, former freight railway to a full seven-days-perweek passenger operation in a mere nine months

INSIDE TRACK:PROJECT SPEED 30 April 2023

Track laying near Okehampton