If there is one rail project on which everyone has an opinion, it’s HS2. Depending on who you talk to, it’s either the greatest infrastructure project currently under construction in the UK or a white elephant that is costing taxpayers billions and should be scrapped immediately.

The entire country seems to be polarised, with seemingly nobody sitting on the fence. It’s either great news or scandalous!

Except, perhaps, for the government. Originally planned to join London with Birmingham, Manchester and Leeds, with stops along the way, the eastern leg has now been cut short and will terminate partway between Nottingham and Derby. Onward travel will still be possible on HS2 trains travelling at reduced speed on the conventional rail network, as they will north of Manchester, but the dedicated highspeed railway will no longer reach Yorkshire.

Still, the core programme was confirmed in the latest financial statement, and construction is well underway.

The cost of HS2

Not wishing to dwell on the question of cost, which has been aired elsewhere in great detail and using numbers that seem to change almost daily, Phase 1, from London to Birmingham, is currently budgeted at £44.6 billion at 2019 prices, including contingency. Phase 2a to Crewe adds another £5-7 billion and Phase 2b to Manchester an extra £13-19 billion. Taking the eastern leg to East Midlands Parkway and upgrading the Midland and East Coast main lines is an additional £12.8 billion, making the final bill somewhere in the region of £86.3 billion at 2019 prices.

Four main reasons have been given for the increase in costs over the original estimate for the whole programme of £37.5 billion in 2009 prices.

To start with, the original figures were purely to build the railway. Trains would be leased from banks, so didn’t figure in the capital costs. That plan changed, and £7.5 billion was added to the bill to buy the trains.

An extra £1 billion was added after the Chiltern tunnel was lengthened in response to a request from parliament, along with a few other changes.

As construction companies developed detailed designs and were finally able to conduct detailed geological surveys once the Hybrid Bill was passed and they had authority to do so, they discovered that ground conditions were poorer than had been expected and so more piling and other reinforcement would be needed – add another £5 billion.

And, as has happened on other major projects (GWR electrification, Crossrail etc), optimism bias was a factor as costs were estimated before a detailed design had been completed.

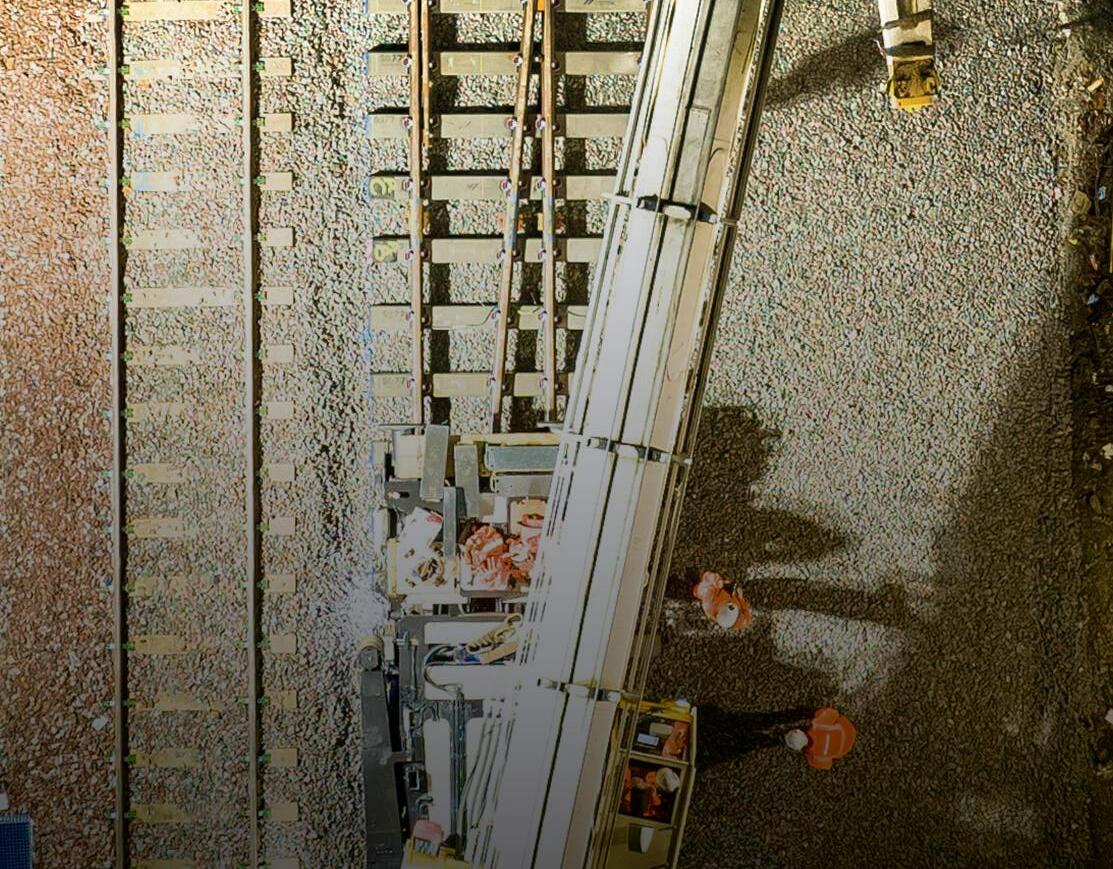

Almost one quarter of the HS2 route to Birmingham will be in tunnels, and construction has already started

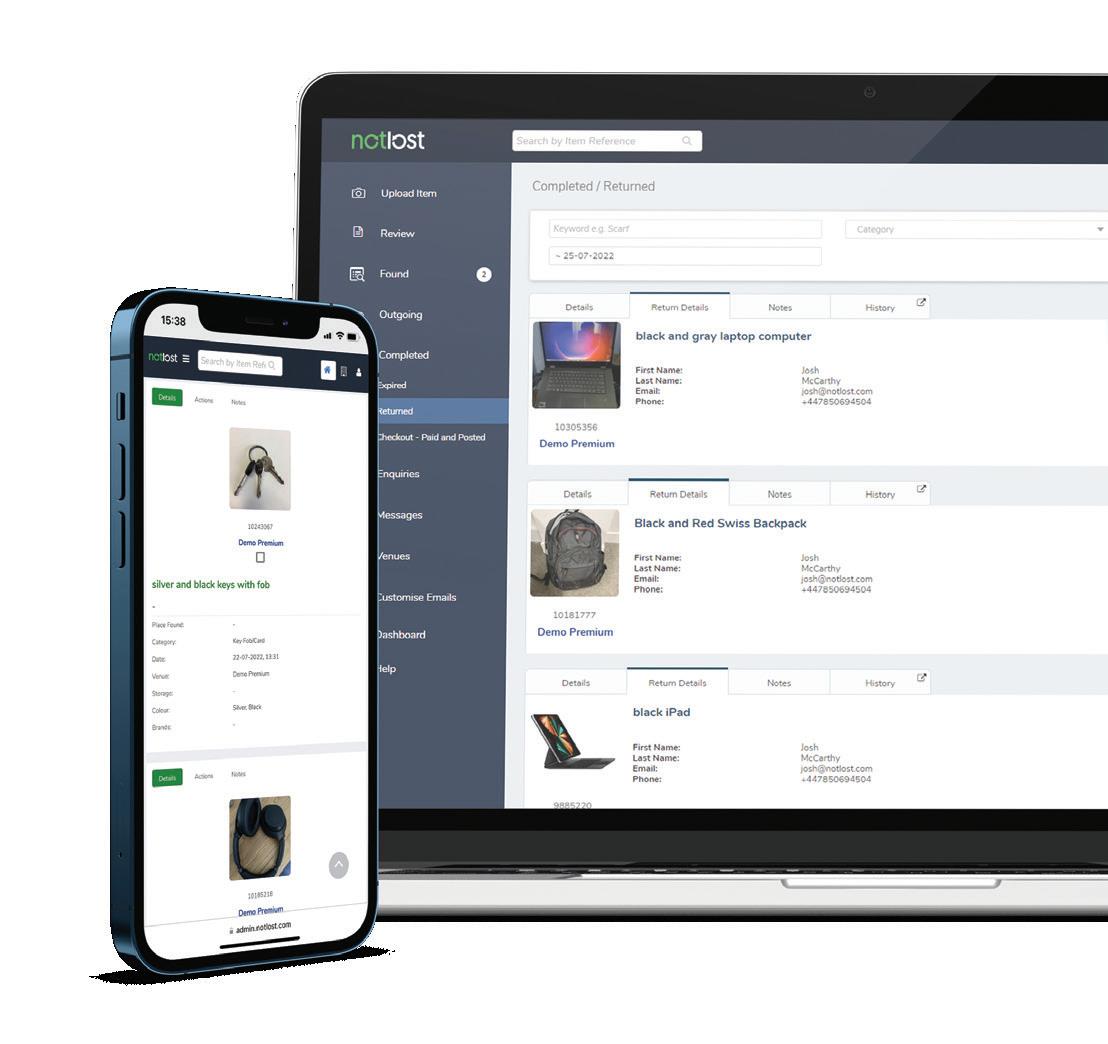

MWe have been providing a valued lost property service for travellers in London since 1933 and we are excited to upgrade our lost property system so that our staff can deliver a better experience to those customers who unfortunately lose their belongings on our network. We look forward to working with NotLost in delivering a system that modernises our approach to lost property, ensuring more customers get back their valued possessions.

TfL Performance Manager

TfL Performance Manager

As the design firms up, costs tend to rise. On top of all that, inflation added another 25 per cent to the original 2009 estimate to bring it up to 2019 prices –or 47 per cent to be right up to date.

The line from London Euston to Birmingham Curzon Street stations will be 140 miles (225km) of twin-track, high-speed railway designed solely for passenger train operation at speeds of up to 225mph (360km/h) on a formation that has passive provision for that to be increased to 260mph (415km/h) at a later date.

32 miles (51km) of the route will be in twin-bore tunnels. Most of these will be bored but some will be ‘green tunnels’ constructed using a cut-and-cover process. A cutting is excavated, a concrete floor is laid and a concrete ‘tunnel’, either made up of a large number of individual precast segments or of slabs cast in situ, is constructed on top of that. Once complete, the soil excavated from the cutting is backfilled, trees and shrubs planted and the tunnel disappears from sight.

Between the tunnels, the line will run over 500 bridges and bridging structures, through 70 cuttings and on 110 embankments. However, it is the tunnels, which make up almost one quarter of the entire route,

that are the long lead-time items, meaning that construction is already underway.

Leaving London Euston station, HS2 trains will travel through the 4.5-mile-long (7.2km) Euston tunnel to Old Oak Common station. Two large tunnel-boring machines (TBMs) will be launched from the Old Oak Common site towards Euston, creating the twin bores as they go.

TBMs are large tunnelling factories, consisting of a disc-shaped cutter head that bores its way through the ground, pushing the spoil behind it. A screw conveyor removes that spoil, whereupon it is fed back through the already-bored tunnel to the surface either as solid material on a conveyor belt or, having been mixed with water, as slurry pumped back through pipes.

Concrete tunnel-lining segments, each measuring around two metres by four metres and weighing up to 8.5 tonnes, are fed along the tunnel in the other direction, and these are installed in a ring behind the cutter head to support the bored tunnel and to form the finished lining. All of this happens while the TBM, which can weigh up to 2,000 tonnes, moves slowly forward, lengthening the tunnels by about 15 metres a day.

Previous page: HS2 Chiltern tunnel cross-passage formwork Image: HS2

Between the tunnels, the line will run over 500 bridges and bridging structures, through 70 cuttings and on 110 embankments

The cutters bore a hole up to 10.2 metres in diameter for the high-speed Chiltern tunnel, around 9.8 metres where speeds are lower such as the approach to London. Once the lining is installed, the finished tunnels will have a bore of around nine metres. This may sound huge, but the bottom of the round bore will be filled to flatten it off so the slab track can be installed, and the top of the bore will taken up with the overhead electrification system. Still, there will be room for a European-gauge high-speed train, although the fact that trains will have to run off the end of the HS2 line onto the classic network will mean that only smaller, British-gauge trains have been ordered.

For the Euston and Northolt tunnels, the concrete tunnel-lining segments, each weighing seven tonnes, will be manufactured by Pacadar UK at its factory on the Isle of Grain, Kent, and transported to site by rail. The two TBMs will be launched for their journey towards Euston during 2024.

The Euston tunnel will have two ventilation shafts, one at Adelaide Road in Camden and the other between Canterbury Road and Canterbury Terrace in South Kilburn.

These will regulate air quality and temperature in the tunnel and allow smoke to be extracted in the event of a fire. Headhouses will be built on top of the shafts, and these will contain fire control systems and ventilation systems for the railway tunnels below.

Trains for Birmingham and the North will emerge from Euston tunnel into the lower level of Old Oak Common station, so they will still be underground. From there, they go straight into the 8.4-mile (13.5km) Northolt tunnel. This is being dug in two stages. Two TBMs will drive 3.4 miles (5.5km) northwards from Victoria Road, just north of the Old Oak Common box, commencing later this year. This is effectively Northolt Tunnel East.

To complete the tunnel, two further TBMs have already departed from West Ruislip boring the fivemile (8km) twin-bore Northolt Tunnel West back to Green Park Way.

TBM Sushila, named after Sushila Hirani, head of department and lead for STEM at Greenford High School, whose name was put forward by local school children, launched from West Ruislip on 6 October 2022.

Three weeks later, on 21 October, TBM Caroline followed. Named after 18th-century astronomer Caroline Herschel, the huge machine will now dig for 22 months, non-stop except for Christmas Day, towards Green Park Way in Greenford. Five ventilation shafts, along with their accompanying headhouses, will be built along the Northolt Tunnel route. One will be at Green Park Way in Ealing, another at Mandeville Road.

The Victoria Road crossover box, located just to the west of Old Oak Common station, will be 130 metres in length and 24 metres deep complete with 1.5-metre-thick walls constructed by a diaphragm piling method, with top and intermediate levels of reinforced concrete props. The base slab of the crossover box will be supported by 77 piles which are being installed 20 metres into the ground below the slab level.

The box will contain the crossover that will allow HS2 trains to switch between tracks on the approach to and descent from Old Oak Common station. It will also be the site of the Victoria Road Ancillary Shaft, which will provide ventilation and emergency access to the rail line during operation. The short section between Victoria Road and the Old Oak Common station box will be excavated using a sprayed-concrete lining technique.

As Birmingham-bound trains emerge from Northall tunnel, they were planned to run into a deep cutting. However, a late design change has changed this into Copthall green tunnel, 0.7 miles (1.1km) long, which will allow for improved landscaping and environmental protection.

The cutter head had to be transported by road through country roads back to the start point

Emerging from Copthall tunnel, trains will then pass over the Colne Valley viaduct. Stretching for more than two miles across a series of lakes and waterways between Hillingdon and the M25, it will be the longest railway bridge in the UK.

From the wide-open spaces of the Colne valley, trains will then enter the longest tunnel on the HS2 route – the twin-bore 10-miles-long (16km) Chiltern tunnel.

Two TBMs, Florence and Cecilia, were launched in the summer of 2021 from a site next to the M25 in Buckinghamshire. A crew of 17 operatives keep the machines running, working in shifts and supported by over 100 people on at the main compound, managing the logistics and maintaining the smooth progress of the tunnelling operation.

Each of the separate northbound and southbound tunnels will require 56,000 fibre-reinforced concrete wall segments – which are all being made in a new factory located close to the launch site.

Approximately 2.7 million cubic metres of material will be excavated during the construction of the tunnels and used for landscaping around the south portal site. Once construction is complete, this will help create around 90 hectares of wildlife-rich chalk grassland habitats.

In August 2022, work commenced on 38 cross passages linking the northbound and southbound tunnels. Each passage is between 15 and 20 metres in length and is being constructed using a remote-controlled excavator with the ground being supported by a sprayed-concrete lining.

Once this is complete, a waterproof membrane is installed followed by a secondary concrete lining constructed by placing concrete behind formwork installed in the cross passage. Safety doors can then be installed at either end. Similar crosspassageways will be built on all the major HS2 tunnels.

Each running tunnel has an emergency walkway that allows passengers to evacuate trains safely and walk through the cross passages into the other tunnel where they can be rescued by a passenger train. Access for emergency services is from either the portal or one of the five ventilation/emergency access shafts.

After leaving the Chiltern tunnel, trains will pass through open countryside and three more green tunnels, Wendover (0.9 miles, 1.4km), Greatworth (1.6 miles, 2.6km) and Chipping Warden (1.5 miles, 2.4km). This latter is already under construction, using 5,000 concrete tunnel segments that are being made at the Sateba Stanton factory in Derbyshire before being assembled on site.

The completed tunnel will then be covered by earth, with trees, shrubs and hedgerows planted to fit in with the surrounding countryside.

A quality scare caused construction to be halted for a short while as manufacturing techniques, transportation and on-site assembly were all reviewed, with changes being made to all three before work recommenced.

The twin-bore tunnel at Long Itchington Wood, close to Royal Leamington Spa, is unusual in that both bores are being dug by the same TBM.

At only one mile long (1.6km), the first bore has already been completed and the TBM pulled back ready to begin the second bore.

However, the cutter head itself, which is, of course larger than the bore of the lined tunnel behind it, couldn’t be pulled back, so it had to be removed from the TBM, along with is shield and other components, and then transported by road through country roads back to the start point.

Long Itchington is preceded by a very short (100 metre) green tunnel before trains enter the bored tunnel proper.

The green tunnel at Burton Green, only 400 metres long, follows before trains arrive at Interchange station, close to the M42 and Birmingham Airport.

Here, trains can either continue north onto Phase 2a of the HS2 project to Crewe, join the West Coast main line at Handsacre near Lichfield, or take the phase 1 route to Birmingham Curzon Street.

This takes the line through the twin-bore Bromford tunnel (3.5 miles, 5.6km). It will be constructed in the same way as all of the other bored tunnels with a porous-portal design to ensure that the waves produced by the ‘piston effect’ of the train moving at speed, which can otherwise result in noise as the

train exits the tunnel, are kept at a level which does not adversely affect the surrounding area.

A porous portal is generally achieved by providing perforated structures, usually of concrete, at the tunnel entrances. The exact design of the portals for the Bromford tunnel have yet to be finalised.

After Bromford, trains will have an almost-straight elevated run in to Curzon Street station, the site of both the oldest (opened on 24 June 1838) and newest stations in Birmingham city centre.

That, however, isn’t quite the end of the story of HS2’s tunnels. There is one other tunnel, which isn’t on the map and through which no trains will pass.

The Atlas Road logistics tunnel will be built by contractor Skanska Costain Strabag joint venture (SCSJV) between its Atlas Road logistics area and the Old Oak Common site.

Built using a former Crossrail TBM, with a smaller bore than the HS2 running tunnels, the logistics tunnel will be used to transport the tunnel segments from the Atlas Road site to the works to build the Euston Tunnels.

The logistics tunnel will also contain a conveyor system to remove excavated materials from works to build the Euston Tunnels to the Willesden Euroterminal site where they will be removed by rail.

So that really does complete the story of HS2 phase 1’s tunnels. Five twin-bored tunnels, six cut-and-cover green tunnels and one logistics tunnel. And people ask why HS2 costs so much?

Network Rail’s annual programme of work over Christmas and New Year went ahead despite industrial action

Christmas wouldn’t be Christmas without at least one news story about how a family couldn’t meet up over the festive period due to “disruption on the railways” and “significant closures due to engineering works”.

The truth of the matter is that Network Rail actually has very restricted access to the railway during the normal year. Last trains run on any particular route up until around midnight, and first trains start around five in the morning. In those five hours, many freight trains run and empty passenger trains are moved from wherever they finished their last service to wherever they start their next one, or to or from a maintenance depot.

Before Network Rail or contract maintenance teams can get on track, they have to wait for clearance from signallers and for confirmation that the power has been turned off in electrified areas. They also have to finish early to hand the track back before trains are due to run, so they are lucky to get four hours on track – often less.

Hence why the Christmas period, when the network is largely closed on Christmas Day and Boxing Day, gives a valuable opportunity for maintainers to get

a significant time on track. 52-hour possessions are the norm – 48 hours for the 25th and 26th and four hours on the morning of the 27th – and sometimes 76 hours can be achieved by closing the line for an extra day. Then 28 hours can be added over New Year’s Day, and suddenly it is worth paying everyone to be working over Christmas due to the sheer volume of work that can be delivered.

Over Christmas 2022 and New Year 2023, there were a few added complications. Rail union RMT called a strike between 6pm on Christmas Eve until 6am on 27 December. This meant that trains would stop running earlier on Christmas Eve and start again later on 27 December.

It also meant that RMT members who work for Network Rail and its contractors wouldn’t be available for work either – which caused a number of planned maintenance and enhancement activities to be replanned.

As a result, approximately 90 per cent of the original £119.7 million work bank was delivered successfully within 1,589 possessions nationwide.

Of these, 30 projects delivering infrastructure upgrades were identified as RED through the Delivering Work Within Possessions (DWWP) standard, which meant that they were highlighted as carrying a greater risk of possession overrun and/or a more significant impact in the event of an overrun. A number of major projects progressed satisfactorily, including:

The resignalling and recontrol of the former Birmingham New Street Power Signal Box into West Midlands Signalling Centre; S&C (switches and crossings) and plain-line renewals at York North junction, within the York station area;

The successful commissioning of the Victoria Phase 3 resignalling scheme, transferring control to Three Bridges Rail Operating Centre (ROC);

The renewal of 16 S&C units at Lewisham between 24 December and 3 January;

Renewal of bridge LEC1/9E at Camden, where the West Coast main line crosses the Regents Canal north of Euston;

Renewal of five S&C units at Stoke Gifford West junction in the Bristol area.

Not everything went completely as planned. Of the planned 1,589 network-wide possessions that took place between 24 December and 3 January, 12 service-impacting overruns occurred, five of which were linked to delivery of a major ‘RED-ranked’ scheme. Just three overruns accounted for 90 per cent of the total delay minutes:

3,631 minutes at Paddington on the morning of 27 December as a result of issues encountered with moving tampers out of a possession following completion of a maintenance tamp;

1,985 minutes at Camden during 29 and 30 of December following agreed possession extensions associated with delivering the replacement of bridge LEC1/9E;

1,043 minutes at Gatwick following issues encountered with a set of points and a number of signals, which were rectified later in the day posthandback.

Given that the total number of possession overrun delay minutes incurred was 7,357 minutes across 12 incidents and the total number of booked possessions across the wider network was 1,985, this represents a successful possession hand back rate of 99.2 per cent, which is comparable with performance during previous Christmas and New Year periods.

We are ready to face whatever the future may bring as we encourage more people back to using the railway Denise Wetton

In total over the period, and across all 1,589 possessions, only two accidents were reported, one of which was classified as a minor injury with no lost time, and one was classed as being RIDDOR reportable.

The RIDDOR reportable accident took place in the early hours of Christmas Day near Maidenhead, when an operative changing an RRV (road-rail vehicle) attachment moved out of the way of the machine and fell into the four-foot, resulting in a dislocated arm. They were taken by ambulance to hospital nearby.

The second accident took place within the Birmingham New Street Resignalling site, where a worker received a minor low-voltage electric shock (24V) during project activities. No treatment was required.

In addition, there were six reported general incidents, and five reported operational close calls. No environmental incidents were reported.

Four of Network Rail’s regions undertook most of the work, with Eastern doing much of it.

Although now largely open, work continues on the Crossrail project. In Anglia, the team has been delivering a new autotransformer +/-25kV traction power system that, once in operational service, will double the existing capacity of the electrification scheme between Bow and Gidea Park ready for the May 2023 Crossrail/Elizabeth line timetable change.

During the Christmas possession, the Crossrail Anglia project completed works between Pudding Mill Lane and Shenfield that included overhead line equipment (OLE), traction-power upgrades, line of route and station works.

In an ongoing project, the Mark 1 OLE system that was originally commissioned across Anglia between 1959 and 1962 is being replaced to improve performance. The project will replace 143 wire runs and 99 structures between Fenchurch Street to Upminster and Barking to Pitsea. This will improve train performance by improving the reliability of the OLE system, remove obsolete overhead line equipment from the infrastructure and reduce maintenance cost and time, providing a more reliable network for passengers and freight.

Over the festive period, the team renewed four complete wire runs and replaced the contact and catenary wires on an additional four, including replacing the wires over four crossovers.

The bridge that spans Three Colts Lane in Bethnal Green, East London, carries four lines, the Up and Down Fast and the Up and Down Suburban. The bridge supporting the Suburban lines was life expired and was replaced during a 10-day blockade.

The work included the removal of the permanent way, demolition of the bridge, partial demolition of the masonry abutments to accommodate the new precast cill beams, construction of the new bridge in-situ, waterproofing and p-way reinstatement and adjustment to the OLE.

Despite adverse weather and high winds, which put critical lifts at risk, there was enough contingency/ float available in the programme for the project to be completed on time.

South Rail Systems Alliance (SRSA) renewed 887 yards (811 metres) of plain line on the Down North London line on Hampstead Heath to reduce the amount of disruptive possessions for maintenance and faulting activities that will be required in the future. During the work, plans were revised due to encountering excess water during the dig, but this had no negative impact on the line’s hand back into service.

Two pairs of points were renewed by SRSA at Gospel Oak during a six-day blockade of the Up and Down Main lines and Platform 3. Although unknown cables were discovered during the dig, these didn’t delay the overall timetable and right-time hand back was still achieved.

Sonic Rail Services, on behalf of Works Delivery Anglia (Track), planned to undertake 16 S&C refurbishments involving the ironwork and timbers of a number of double-slip switch diamonds at Liverpool Street station. All of the planned scope was completed although, due to issues with the cutting and drilling of the existing infrastructure abutting the new installation, the team was forced to renew an additional three point ends as well as an additional nine closure rails and three long timbers. Combined with problems setting up the points due to additional faults on the equipment, the job overran by 48 minutes and was handed back with one set of points clipped out of use. All faults were rectified on 6 January and the overrun didn’t delay any trains due to the late start because of industrial action.

At York, life-expired junction trackwork was renewed. Consisting of two crossovers, four turnouts and one fixed diamond, this layout allows access

from the North to Platforms 4, 5 and 8 to 11 as well as access to the Scarborough branch from Platforms 4 and 5. Despite a couple of snags with the track-lifting programme after a strop broke and one item had to be manually lifted back into place, and the need to bring in an additional train to supply extra ballast, the possession was handed back at line speed, albeit 58 minutes late.

The East Coast Digital Programme is preparing signalling on the East Coast main line for the introduction of an ETCS Overlay, the start of digital signalling on Britain’s main line railway, and the impending life expiry of Welwyn Garden City and Langley Junction interlockings, track circuits and surrounding lineside infrastructure. The programme includes the re-signalling of Welwyn Garden City, Langley Junction and the Hitchin South and Hitchin North interlockings, which control the section of the East Coast main line from north of Hatfield station to south of Biggleswade station. It will also involve minor works on the Hertford Loop and the Shepreth Branch.

LNER managing director David Horne said: “The East Coast Digital Programme is taking our railway into a digital age. It will transform journeys for passengers by making them even smoother, more punctual and more sustainable.”

As part of this programme, over the end of year holiday, the team installed 73 new axle counters and their associated cabling, 22 new balises and 15,200 metres of fibre-optic cable. However, the refusal of an isolation request due to errors in submitted paperwork had an impact on the overall programme, and the team now needs to understand how much work needs to be recovered in later blockades.

I’m so pleased that we were able to push ahead with this work despite the strike action and do the right thing for passengers Paul Rutter

Two bridges on the Darlington to Saltburn (DSN) line in Middlesbrough were renewed over the holiday. Both the single-span underbridges over Denmark Street and Boundary Road (8.6 metres and 10.7 metres respectively) have two decks with twin tracks on each. The decks carrying the Down and Up Main lines on each bridge were replaced using selfpropelled modular transporters (SPMT) to carry the old decks away and bring in the ready-built new ones.

As well as replacing the track over the two bridges, it was also realigned between them. The timetable had to be rescheduled due to the industrial action, with both the possession being taken early and the new track tamped early. The Boundary Road bridge needed three passes of the tamper rather than two, but the line was handed back on time at line speed.

The Ferrybridge to Goole re-signalling project is renewing the existing Goole, Monkhill, Prince of Wales and Cutsyke Junction Route Relay Interlockings (RRIs) with a new Smartlock computer-based interlocking (CBI) located at York ROC (onto Brough workstation) and Ferrybridge signal box (extension of the NX panel). Over Christmas, the Westlock central interlocking processor (CIP) covering Hensall and Sudforth Lane was relocked into a Smartlock central interlocking (CIXL) and the existing panel multiplexer (PMUX) was replaced by a Delphin 1024-based system.

Three elements of work on the Transpennine Route Upgrade (TRU) were carried out over Christmas. Between Church Fenton and Colton junction, a new culvert was installed along with 88 10-metre-long sheet piles, OLE was adjusted and 32 new signal-post telephones were commissioned.

A new scissors crossover was installed at Holbeck in Leeds along with track and signalling to create a new turn back facility, and plain-line track was replaced on the Up Huddersfield line towards Dewsbury at the site of the new Morley station, along with four under-track crossings and improvements to track drainage.

Paul Rutter, Network Rail’s East Coast route director, said: “I’m so pleased that we were able to push ahead with this work despite the strike action and do the right thing for passengers. Better equipment and new weather-ready tracks will all help to offer more reliable journeys through York.”

TRU managing director Neil Holm added: “The multi-million-pound Transpennine Route Upgrade will completely revolutionise rail travel between regional hubs such as Manchester, Huddersfield, Leeds and York and it is great to see all this work delivered successfully over the festive period.”

The Birmingham New Street Area Resignalling scheme reached its climax over Christmas 2022 after many stages including the previous two Christmas blocks and a programme of platform closures that saw the renewal of life-expired signalling systems and trackside equipment and finally the transfer of control from Birmingham New Street Power Signal Box (PSB) to the West Midlands Signalling Centre (WMSC) at Saltley.

Over Christmas 2022, around 400 people worked around the clock during an 80-hour possession to transfer the central panel control from the Birmingham PSB to WMSC – New Street PSB was the last area in the country relying on Westpac Mk1 relays.

Final changes were made to signalling, redundant items of equipment were recovered and the new connections tested and checked. Several signaller observations were made, these were checked against the design and a data upgrade took place on 6 January to account for them.

Denise Wetton, Network Rail’s Central route director, was pleased with how the work had gone. “While some may be sad to see the Power Signal Box operate for the final time, the transfer of signalling control to our state-of-the-art signalling centre in Saltley marks a new dawn for the West Midlands’ railway network,” she said.

“Now the 17-year-long project to digitalise the signalling system is complete, we are ready to face whatever the future may bring as we encourage more people back to using the railway as a safe and green way to travel and provide reliable journeys for our passengers and freight customers.”

The replacement of a bridge over Regents Canal in London proved more problematic. Bridge LEC1/9E in Network Rail parlance (Bridge 17 to the Canal & River Trust) was to be replaced with a new bridge complete with a driver’s walkway. This would allow more trains to use the bridge every hour on this busy section of the London Euston to Crewe (hence LEC) line and make it safer for drivers and other railway staff to walk the line.

Originally scheduled for a 142-hour possession from 25 to 29 December, this was always going to be a challenging project with the track needing to be removed and replaced along with the OLE and the finished p-way needing interfacing with the existing signalling system.

However, the abutment preparation and demolition of the old bridge took longer than anticipated. Two important pieces of plant were incorrectly orientated and other machines had reliability issues. As a result, the bridge was handed back 46 hours late (2,760 minutes), although close collaboration between the project team, the West Coast South operations teams and affected train operators meant that delays incurred from the overrun were limited to 1,985 minutes.

At Euxton junction, the planned renewal of 717 yards (655 metres) of trackside drainage to improve track quality on this buy section of the West Coast main line was reduced to 479 yards (437 metres) due to an unstable outfall.

Opposite: Installing new track crossing at Holbeck, Leeds

The replacement of 322 yards (294 metres) of plain track at Harlesden looked likely to run into problems due to the industrial action closing the planned haulage route. However, the job was replanned and the full length of rail and sleepers, installed on top of 300mm of fresh ballast, geotextiles and 100mm of sand, was completed on time.

Also at Harlesden, a project to renew 860 yards (786 metres) of six-foot drainage and inspect using CCTV and repair cess drainage was successfully completed, despite a delay to the start of the blockade due to industrial action. Bridge LEC1/174 carries all four lines of the WCML over the Grand Union Canal at Wolverton, just north of Milton Keynes. The track was removed and a waterproof membrane laid to prevent water from leaking through the structure and causing corrosion to steelwork in the adjoining girders and abutment. The track was re-laid and tamped and handed back on time with a published temporary speed restriction (TSR) of 50mph.

Further north on the WCML, the discovery of ‘pitching stone’ (200-400mm size stones sometimes used for embankment stabilisation) at the site of a track renewal near Lancaster prevented a full-depth dig and meant that the line was handed back with a TSR of 60mph rather than the planned 90mph.

The fast line at Hanslope in Buckinghamshire is part of the crucial four-line section of the WCML that runs freight and passengers in and out of central London. Track quality throughout the site is poor with high rates of deterioration. However, plans to renew 390 yards (356 metres) of track were downscoped to ballast replacement due to industrial action preventing the delivery of new rail.

Joint failure

OLE modifications in preparation for a new HS2 overbridge were carried out at Carol Green near Meriden in the West Midlands under a 53-hour planned possession. During the work, a historic spliced joint failed, which bought down catenary wire throughout the section. As a result, the OLE teams had to survey the area and not only replace the splice but also 450 metres of contact and catenary wires, neutral section torsion tubes, a cable terminal connection and a feed support insulator. Despite this, the works were handed back two hours ahead of schedule.

Constructed around 1916, the Cathedral substation in Willesden, North London, was one of 10 substations built for the electrification of the London & North Western Railway. It was a large, two-storey lineside brick building with a duo-pitch slated roof and an additional mezzanine floor in part of the upper storey. Alongside the main building was a raised room on steel columns.

Internally, various items of historic railway-related equipment remained within the building and there was a travelling gantry crane installed above a test track on the first floor. The building was subject to a controlled demolition design sequence which took account of the fact that the Cathedral was in close proximity to existing 750V DC and 25kV substations, both of which were operational and live during the demolition.

A bat licence was in place before the demolition commenced to mitigate any problems with roosting bats, and the historic equipment, including the old stock test train, was removed for possible future display in a heritage museum.

The building was then demolished to remove any requirement for ongoing maintenance of the building and completely eliminate any potential future disruption to the operational railway.

While the DC lines at Watford were already closed over Christmas, use was made of the six-day blockade to undertake significant refurbishment works at Carpenders Park, Headstone Lane, Kenton, North Wembley and South Kenton stations. This included platform surfacing work including new backing kerbs, spot coper replacements, the installation of new dagger boards and canopy steelwork repairs. Additional waterproofing to canopies was also included, but some of this could not be completed due to low temperatures and incessant heavy rain during the period.

Since November 2019, the Victoria resignalling project has been renewing life-expired assets in an area that was last resignalled in 1980. The Clapham and Balham interlocking areas have been resignalled, the Victoria Eastern, Victoria Central Throat and West London lines relocked and all control moved from the Victoria Area Signalling Centre to the Three Bridges ROC.

Around 200 people worked on each shift between 24 December and 3 January, completing 91 LOC and relay room changeovers. The Eastern Area interlocking was recontrolled to Three Bridges along with Victoria Central. A large amount of redundant equipment was recovered, including two gantries, five cantilevers, 20 signal posts and 34 signals.

Gatwick station has been undergoing a major reconstruction to improve operational flexibility and capacity. On 27 December, Platform 5 and Platform 6 were signed back into operational use with the final installation, testing and commissionong of the new track layout. GTR proving trains ran on 27 – 30 December and the first timetabled passenger services on Platform 5 and 6 scheduled from 14 January 2023.

The multimillion-pound Transpennine Route Upgrade will completely revolutionise rail travel between regional hubs such as Manchester, Huddersfield, Leeds and York Neil Holm

Full end-to-end capabilities, as a trackside POS and Principal Contractor; From ground investigation, design, and temporary works through to all types of ground engineering and geotechnical solutions

A track record of 450+ completed Network Rail projects; Including over 200 stations, major electrification schemes, re-signalling projects, track bed stabilisation, slope retention, sheet piling and ground investigation

Track Bed Stabilisation is a system unique to Van Elle and is used to stabilise the track bed without the need for removing the track or ballast

Van Elle has the in-house ability to design and manufacture off-site, for both steel and precast concrete in our in-house factories and workshops

Off-site manufacturing and other modern methods of construction (MMC) has the potential to transform the delivery of construction activity

ScrewFast Foundations, the UK’s leading helical piling and steel modular company, is now part of the Van Elle Group, offering additional design and construction solutions for the rail network.

STRATA Geotechnics, part of the Van Elle group, has the expertise and specialist equipment to perform on and off-track ground investigation (GI) projects for the rail network.

Lewisham Junction is located on the four-track DC electrified section of track immediately west of Lewisham station. The junction layout, with 16 units of S&C including double scissors and fixed diamonds, was replaced to provide smoother, more reliable journeys for passengers and reduce the need for future maintenance at this critical junction.

As part of the Victoria resignalling project, a new ladder across the four-line DC-electrified tracks north of Clapham Junction station was installed in May 2022. Over Christmas/New Year, the original ladder, immediately north of the station, was removed and replaced with plain-line track.

In total, 830 yards (750 metres) of track was renewed with new sleepers, rail and top stone. Pointheating on the new S&C layout was commissioned. Alongside the renewal, critical signal gantries and four-foot equipment was recovered. The site was tamped and handed back at line speed on time.

As part of the ‘Safer Faster Isolations’ programme, whereby electrical isolation of a section of line can be achieved remotely without workers having to access the track, installation, final setup, electrical and function testing of Ladbroke Grove and Paddington area switches was carried out over the holiday period. In total, final setup, electrical and function tests were carried out on 14 switches at Ladbroke Grove, five switches at Paddington station were rectified and five more electrified and motorised at Royal Oak and Portabello junction.

Work on the same programme took place at Reading, with work taking place on 15 new switches and remedial works to 15 more that were displaying a fault.

Also at Reading, over 2km of HV feeder cable was installed in troughing alongside the railway. Once fully commissioned in October 2023, this will allow an independent feed to minimise disruption to the network if maintenance works are required.

The like-for-like replacement of five life-expired sets of points at Stoke Gifford West will reduce maintenance and improve reliability on the Great Western main line, with the 1970s wooden-bearer units exchanged for concrete-bearer units with in-bearer clamp-lock MKII points operating equipment.

Work to improve gauging on Bristol Parkway Platform 3 also took place, with Secretary of State Mark Harper MP and Network Rail chief executive Andrew Haines visiting the site to see meet the team.

The bridge at Leonards Mill, on a freight-only line just north of Frome in Somerset, was repaired and upgraded to remove a long-standing TSR. The track was lifted, steelwork repairs made, and the track replaced. Upgrading the bridge to RA10 (Route Availability for up to 25.4 tonne axle loadings) will future-proof the route for any future increase in freight capacity.

A total of 19km of 650V signalling power cable was renewed around Taunton as part of the Western Cable Renewal programme, which will see 90km of cable replaced across Western Region. All of the cable was laid in troughs with the lids replaced and secured in this one possession, which represents 20 per cent of the entire programme.

A new footbridge is to be constructed to the north of the Dawlish station buildings that will include lifts for step-free access and stairs onto each station. Lift machinery will be located beneath these stairs. In this challenging location right on the sea wall, piling for the foundations of this bridge involved lifting plant into place followed by the installation of three piles on the landward side and five piles on the seaward side. Somewhat further west from Dawlish, a new open-sided ‘tunnel’ is being constructed to protect the railway from rock falls. This shelter will extend 119 yards (109 metres) from the existing Parsons tunnel portal.

These projects will make our railway more efficient and reliable

Andrew Haines

Work continued to construct the new portal from precast columns and U-beams, with advantage being taken of the Christmas closedown to work with a gantry crane for a sustained period to enable efficient working on future ROTR (Rules of the Route) Saturday nights.

In South Wales, work continued on phase 2 of the Port Talbot West re-signalling programme, which will see the condition-led renewal of signalling, power and communications equipment between Swansea and Carmarthen, including five level-crossing renewals, extensive track rationalisation and some new S&C. The team made efficient use of blockade access over Christmas and took the opportunity afforded by the strike action to work between Christmas and New Year. Preparatory testing of non-commissioned assets took place to facilitate commissioning in early March.

Despite the replanning needed due to industrial action, the Christmas and New Year programme went well. Speaking on 28 December, Network Rail chief executive Andrew Haines said: “Christmas for Network Rail means a period of heavy investment in our railway. Since Christmas Eve, more than 300 upgrade projects have been underway across Britain – renewing tracks, signals, delivering station enhancements, working to facilitate third party investment in the railway and much more!

“These projects will make our railway more efficient and reliable. It was great to get out on Boxing Day and yesterday to meet some teams delivering these works.

“I also enjoyed welcoming the Secretary of State for Transport Mark Harper MP to Bristol Parkway. More than £4 million is being spent here to replace old tracks from the 1970s, massively modernising and improving the reliability of services to the west of England and Wales.

“Months of hard work and planning has enabled these works, and, despite strike action, it has been great to see the majority of these works get underway.”

While the reasons behind climate change are a matter for debate, with many people attributing it to man’s pollution of the environment while others think that’s all a myth, one thing is certain – the weather is getting wilder. Colder winters, hotter summers and periods of drought are followed by more abundant rainfall.

All of which has an effect on the structure of the railway.

Last month’s issue looked at the effects of snow and ice on third-rail electrified lines and at how prolonged high temperatures can dry out clay-based embankments and make railway lines uneven.

This month, there have been several examples of how rain affects the earthworks upon which the railway is based.

A large landslip in Hampshire left one of the tracks of the main line from London to Basingstoke hanging in mid-air, one other track damaged, and caused huge disruption for customers. The slip, on an embankment to the northeast of Hook station, left only two tracks of the four-track railway passable by trains, with both tracks designed to be used by London-bound trains only.

The embankment, made of a mixture of London Clay and other local soils, was saturated after days of heavy rain and a very wet winter. The slip happened when the soil gave way along a 44-metre

section of 10-metre-high embankment, sliding out from underneath the tracks, in what is known as a ‘rotational failure’.

On Tuesday 17 January, a 10-metre stretch of a seven-metre-high embankment slipped away from the railway around half a mile north of Lingfield station, between East Grinstead and Hurst Green in Surrey. In addition, cracks spread six metres on either side of the slip site, leading to fears it could get worse if action wasn’t taken immediately.

The embankment was built in 1884 of Wealden Clay, a material that absorbs water rather than draining, which makes it vulnerable to prolonged very wet weather and freezing conditions.

The railway reopened on 24 January after having been closed for seven days.

The West Coast main line was closed near Carstairs, between Carlisle and Glasgow, on 30 December to repair flood damage. Engineers had to remove landslip material affecting a 40-metre-long section of the line before they could begin to reinforce the area with over 200 tonnes of new stone. The line reopened a week later on 6 January.

Those are just three examples. Another was on the Gloucester to Newport line, where it runs alongside the Severn estuary.

the Severn estuary in an area that has often caused problems for engineers in the past

We’re quite rehearsed at this now, and we’ve taken about 48 hours off the time

In this area, for a stretch of railway around two to six miles upstream of Lydney station, the railway runs directly alongside the river. It is benched into the natural slope of the ground down to the river from the fields above. So, on one side of the railway is a steep slope, steeper than would occur naturally after the railway was cut into it, and on the other is the retaining wall down to the estuary.

During periods of heavy rain, water runs off the fields and down the slope, saturating the earth bank, which is naturally unstable and has slipped on several occasions. Some portions are already covered in steel mesh to retain the soil and there is a five-year programme of work – the £25 million Severn Estuary Resilience Programme – to stabilise the slope along its entire four-mile length.

The first intensive phase of the programme was completed during a temporary closure of the line between Lydney and Gloucester for seven weeks from 18 July to 3 September 2022. More than 15,000 tonnes of material was removed from the face of a threemile stretch of slope. Teams on ropes then installed a mesh and bolt system to stabilise the slope faces and prevent landslips. In total, 27,000 square metres of mesh is secured by 1,000 soil nails, drilled to a depth of up to 10 metres. A second phase of work is scheduled for 2023 with a third phase in 2024/25.

Due to its instability, Network Rail has also installed a monitoring system on the slope. These are a series of wireless tilt sensors, supplied by Findlay Irvine, that provide early warning of earthworks failures which could cause potential derailments. Any change in

orientation of the sensor, caused by movement of the ground below, is immediately notified to the control centre. A single sensor activation could be caused by wind, or an animal knocking it, but if several sensors in one section go off at the same timer it is likely that the whole bank has moved.

In this case seven sensors out of a row of 40 tripped at once, so the line was immediately closed to rail traffic and an engineering team despatched to site to find out what had happened. In this area, Network Rail has a contract with GeoAccess, so they were despatched to the scene.

Findlay Irvine wireless tilt sensors monitor the slope for any sign of movement.“GeoAccess are geotechnical engineers who go out and assess and tell us ‘Do we have a problem?’

And, if so, what’s the scale of the problem?” explained Chris Howchin, Network Rail’s senior network delivery manager. “In this instance, they came back and said: ‘Yes, you’ve got a problem, and we’re not comfortable with you reopening the line, because of the amount of material that’s left to come down, and it does need to

have the works undertaken immediately’.”

The investigators had discovered that the lower half of the slope had slid down into the cess, an estimated 100 tonnes of material.

While the line itself wasn’t blocked, the upper half of the slope had remained in place and was now undercut. There was a severe danger that it too would fall and then could well block the line, hence the

recommendation that the railway remained closed. Annoyingly, the new slip was just to the side of a meshed area that had been installed during the 2022 works.

With the railway shut, decisions on what to do, and how to do it, had to be taken quickly.

Culvert LYDNEY Norchard Station Purton Newerne Sharpness Docks Cross Hands“We’ve got the geotechnical asset management team within Network Rail, who provide the scope of how much we want to do and to what extent,” explained Chris.

“Because they’re the budget holders, they’re the ones that have got the plan and own the monitoring equipment. They’re the ones that sign off what they are happy for us to do. But they get their guidance from our own internal design engineers – the network route design delivery team.

“They go up on the ropes as well and look at what the current state of play is. Once they’ve done their bit, they write the scope and the remit and decide how much further each side we need to go, to prevent it happening again. They then put all the drawings together and that’s what gets signed off by the asset manager. We get given that remit to go off and do what we have to do.”

In this particular case, the slip happened late on Wednesday 4 January.

By Thursday afternoon the plan was in place, everything was confirmed during a 30-minute conference call, and the contractors were geared up to start work on Friday.

Having taken part in that conference call, AmcoGiffen, as delivery partner, mobilised its team and also its own specialist subcontractors, including the rope access team from Bespoke Rope Access, based in South Wales, and road-rail vehicles (RRVs) from Total Rail Solutions.

Although the railway runs directly along the bottom of the slope, the cess gave enough room to gather the spoil and take it away.

The rope access teams then dragged down the rest of the affected material to the space at the toe of the slope and that too was removed by the RRV.

The ballast in the cess, that aids drainage, was contaminated by all the dirt brought down on top of it so that was replaced with clean material which was then flattened so that a couple of rows of ‘Legato’ interlocking concrete blocks could be placed there to form a retaining wall.

Finally, the three-axis-tilt monitoring system was replaced.

While the line was closed to clear the landslip, engineers from AmcoGiffen addressed problems that were discovered by the driver of a roadrail vehicle on its way to the work site. A culvert half a mile away had collapsed due to the heavy rain, washing away four tonnes of track ballast underneath the Up Main six-foot rail. Further inspection also revealed a severe crack in the culvert’s headwall.

In conjunction with delivery subcontractor Protech Rail, engineers undertook temporary repairs to the culvert, its headwall and the track infrastructure and formulated a monitoring regime that would allow the line to be reopened at line speed until such time that a permanent repair solution could be developed and delivered.

Similar to the system employed to monitor the slope at the site of the landslip, AmcoGiffen and Protech Rail installed a series of sensors that measure track level and twist in real time and will automatically send an alarm to all relevant parties in the event of track movement above an allowable threshold. This will allow engineers to intervene in the event of any future track bed movement in the area of the culvert failure.

Despite the added complication of the unexpected culvert repair, Chris Howchin believed he could have had the line reopened sooner.

“We’ve had five of these in the past three years at this location, along this four-mile section, hence the significant investment along this line,” he explained.

“So, we’re quite rehearsed at this now, and we’ve taken about 48 hours off the time in reopening the line compared to the first one we did, when it was closed for five or six days.

“We could have had it open sooner this time. I think we could have had it open on the Saturday – with the assessments on the Thursday, the hard work on the Friday, ready for first service on the Saturday –but unfortunately there was industrial action on the Saturday.”

Which just goes to show that, however well planned any works are, there are always outside influences that can trip the team up.

Atkins global cyber security discipline lead Matt Simpson argues that to deliver truly holistic security, rail organisations need to integrate their IT and OT cyber approaches and develop their internal resource

It’s all about people (and elephants)

yber security in the rail industry has come a long way since the Centre for the Protection of National Infrastructure first started looking at the issue in around 2006. Back then, the focus was – quite rightly – on the cyber security of operational technology (OT) assets, the engineering elements that keep the trains running, rather than on the important, but less safety-critical, information technology (IT) systems.

As cyber programmes become larger and more complex, however, their core focus on people – and specifically on addressing the risks posed not only by external hackers, but also by an uninformed workforce – has seen them increasingly classified as transformation programmes. These programmes’ requirement for extensive funding and a diverse skillset has resulted in them being taken out of the engineering domain and put into the IT domain under, for example, chief information officers (CIOs), chief data officers (CDOs) or chief technology officers (CTOs).

But CIOs, CDOs and the CTOs often come from an enterprise IT background and, while they understand corporate systems and business impact, they don’t necessarily understand the engineering systems in the same way the engineers who work with them every day do.

Effectively, both the IT ‘top down’ approach protecting the business systems, and the OT ‘bottom up’ approach protecting the engineering systems are valuable, but, for truly holistic cyber protection in rail, these approaches need to meet in the middle.

Cyber security is a team game: everybody has a part to play, everybody is part of the team, and everybody needs to understand their role and the protection they are accountable for. But, while investment into the technology and processes for cyber in the rail sector has grown since 2006, the elephant in the room is that those two distinct approaches of top-down and bottom-up have become disjointed. They need to be bought back together so that cyber risks can be fully managed.

This doesn’t mean that the engineering and IT experts have to form part of the same team on the organisation chart, but they have to know how each of their teams and systems interact, to show the company’s true risk picture. There also needs to be appropriate funding for both IT and OT cyber, with reporting from engineering into enterprise risk management so the board gets a complete picture of the organisation’s threats and defences.

At Atkins, we’re seeing both sides of the coin. With our management consultancy hat on, we’re helping the top-down transformation programmes ensure their organisations are secure and resilient, using the NIS regulations (the Security of Network & Information Systems Regulations 2018) at a corporate enterprise level and helping corporate leaders to have the right people, governance, risk management, policies and standards in place.

And then, using our engineering expertise at the bottom-up end, we’re using the NIST frameworks (US National Institute of Standards and Technology), and TS50701 as the new rail standard equivalent of

IEC 62443, to bridge the gap between engineering language and enterprise language and bringing the two together. And what we’re seeing is that, at all levels, those working on cyber protection are aiming towards a common goal: that the railway keeps running, ensuring passengers can enjoy reliable journeys and employees work on the rail network safely.

Because, when we consider cyber in rail, our key focus must be on the threats and attacks that will impact the railway. A major cyber attack on the network’s infrastructure could very soon stop an entire route; and losing all traction power or communications would have a huge knock-on impact on operations. The engineers know the critical assets that cause the most downtime and will have the most operational impact, and these should already be included in rail organisations’ incidentresponse and business-continuity planning.

From a cyber protection point of view, we then need to look at how cyber vulnerabilities could cause these critical systems to fail – reverse engineering from worst case scenario incidents. This helps identify where spending should be prioritised to ensure resilience. It’s about aligning the funding, which often filters from the top down, with the actual impact on the railway – another reason why the top-down and bottom-up approaches must be brought together.

By understanding each other’s cyber challenges, IT and OT can work together to ensure board level decision-makers are aware of the investment needed to address the risks their systems face.

Bringing teams together will help rail manage its cyber risk, but there is one key challenge to overcome: the lack of available resource to form those teams. There are not enough railway cyber security experts within the UK, Europe or beyond. Fortune magazine reports that there’s a 3.4 million head count shortfall globally for cyber security experts across all domains – and rail OT roles are even more specialist, because you need to understand the railway as well as the cyber security and people, process and technology controls and mitigations.

Cyber security is a team game: everybody has a part to play

We created our award-winning Cyber Security Academy to upskill our resource – taking engineers or IT/digital people and putting them in that middle ground of railway cyber and OT cyber risk management, coupling their knowledge and experience with training and mentorship to generate exactly the type of person we need. We’ve trained well over 200 people, with an order book of at least 100 people waiting to attend.

There is no reason why rail organisations or suppliers couldn’t build a similar model, to solve their biggest issue – quality people with the right expertise. There are some organisations – Transport for London and Network Rail, for example – who have created OT cyber security apprenticeships and learning pathways, and while these are great local initiatives they’re just a drop in the ocean. We need the specialist railway further education colleges that are training students not just in the engineering skills to maintain and grow the railways, but in the cyber skills to protect them too. This will help the realignment of expertise at all levels of the cyber security requirements and life cycle of an organisation.

For all rail organisations, investing in your cyber expertise is going to be a worthwhile investment and can save you money – whether ensuring you comply with NIS regulations and avoid potential fines of up to £17 million per incident, or updating fast-evolving policies and processes so you can avoid hiring expensive contract resource. With the potential cost of not managing your cyber risk so much bigger than the cost of managing it, why would you not do it?

The cheapest way you can ‘fix’ cyber is through people – and as many of them as possible. The only way you can eat an elephant, the joke goes, is a little piece at a time: if you can see this elephantine problem coming down the tracks towards you, and it’s getting closer and closer, the more people you’ve got who understand cyber security, the quicker and more digestible it is to eat the cyber elephant.

“Atkins is supporting railway clients as trusted cyber security partners in the UK and globally. We are valued for defining pragmatic whole railway risk reduction strategies in alignment with regulations such as NIS, supporting implementation planning, business case development to secure long-term funding, ensuring effective technology architecture is implemented across IT and OT through effective procurement and integration. We support Network Rail from OT and IT cyber assurance through to delivering key IT systems. We are committed to helping manage cyber security risk across industry, including at the forefront of ETCS deployment on the East Coast Digital Programme. If you’d like to know more about our approach, join us at Cyber Senate Rail in London on 21-22 March.”

Mark Fielding-Smith, national services director, Atkins

We’ve come a long way in the last 17 years but, as a whole, has the rail sector measurably reduced its cyber risk?

I think we haven’t reduced the risk as much as we could have done – the understanding of the essential need to protect OT cyber wasn’t well enough understood – and there’s still a lot of work to be done to fill that gap. But we’re learning the lessons from the past, and we will continue to do so as cyber programmes transform in the future.

Cyber isn’t just something you buy, or a skill to plug a hole, it’s evolutionary and ongoing. So, you need to make sure that you have joined-up teams, working together to protect both your business and engineering systems, and that you develop and retain the skills inside your company to become more resilient and secure – training IT specialists and engineers who understand the railway, understand the legislation and understand how they can protect your organisation from a cyber incident.

By integrating your IT and OT cyber approaches and developing your internal resource you can ensure your rail cyber programme doesn’t become the white elephant in the organisation.

Meet Matt Simpson and the Atkins team at the 9th annual Rail Cybersecurity Summit UK Europe taking place on 21 and 22 March in London to find out more about the topics discussed in this article.

Rail Director editor Danny Longhorn has visited the site of the Global Centre of Rail Excellence in South Wales to meet the team leading the creation of the UK’s fi rst purpose-built railway research, testing and innovation complex

It is only really when you are at the Global Centre of Rail Excellence (GCRE) that you can truly appreciate its size. Nestled on the edge of the Brecon Beacons National Park on a ridge between the Swansea and Dulais valleys, it covers a space of 700 hectares; the size of Gibraltar, or Gatwick Airport.

On the day Rail Director visits, it is looking particularly magical, with a layer of snow enhancing its rugged beauty. For the last 200 years, the site has been extensively mined, initially deep mining and the last 40 years a succession of open cast pits.

Fast forward to the present and the former Nant Helen opencast mining site and Onllwyn Washery in Neath Port Talbot and Powys is being transformed, putting Wales and the UK at the very heart of 21st-century sustainable transport innovation.

“Every time I go out there it blows me away with the scale of the site, the setting and the opportunity of what we can do here,” said Simon Jones, GCRE’s chief executive officer (CEO), speaking at the site’s Onllwyn Washery.

“There is an infectious buzz from everyone who visits the site. This is a facility that the industry is so

keen to have, and I am super privileged to be involved in something which is so positively received, so many people want it to happen and knowing the huge impact it will have on the rail industry.”

When it opens in 2025, the facility will provide worldclass research, testing and certification of rolling stock, infrastructure and innovative new technologies that will fill a strategic gap not just in UK rail, but across Europe.

The project was established by the Welsh Government as a Special Purpose Vehicle (SPV) in 2021, with Simon involved from its early days through his role as director of transport for Welsh Government.

“I’ve been lucky enough to be involved in this project from the start and helped to initiate it, so it was a real thrill for me when I was asked to become the CEO here to run it because it’s not very often in life you get to pitch an idea and see it all the way through to reality,” said Simon. “That is the engineer in me, I want to see things getting built, I’m really enjoying this, it is like a dream job for me.”

At the heart of the GCRE will be two test loops, both electrified at 25kVAC. The outer is a 6.9km high-speed rolling stock test track with a speed of 177km/h (potential for 201km/h under review), while the inner is a 4km infrastructure loop designed for speeds of 65km/h. GCRE will run trains to load the infrastructure loop with 20MGT (60,000) axle passes per year.

“The larger loop will be used for testing vehicles and the smaller loop for testing infrastructure,” said Simon. “The vehicle testing loop will be rented for organisations to test their trains. It could be rented out for eight hours with you being able to do everything from continuous mileage, testing new systems and carrying out certifications on vehicles.

“The infrastructure loop will be used to apply a known load; we will put down five million tonnes of load every 10 weeks on that track. We will run a fleet of our trains around that track on a semi-continuous basis for 10 weeks.

“During that period of time, we will commit to 480,000 axle passes and 12,000 vehicle passes. This feature of our site is not available anywhere else in Europe.”

Simon explained that the target audience for the infrastructure loop will be organisations who want to prove their infrastructure product can withstand those kinds of load conditions. The product in question might be anything from a track clip and sleeper, through to a telecoms system, or something on the electrification system.

For this loop, GCRE Ltd has bought its own fleet of trains – three-five car Class 360s (Siemens Desiros) which were Heathrow Connect trains, and will available to clients as “mule” trains for experimentation too.

“As it stands people have to negotiate with organisations like Network Rail to put their new components into a live rail setting,” he said.

“Both loops will be electrified with 25kv overhead lines and there will be switches between the loops so customers could rent out both if they wished to run them as an inverted figure of eight.

“We will have different signalling systems on the two routes. The inner route will have Network Rail classic signalling system and both loops will have European Train Control System (ETCS) level two. We could have a world where we are replicating the transitions between ETCS and classic signalling.

“The whole site can be used for telecommunications testing, for things like drainage proving and testing; a variety of different activities.”

There are three core areas to the GCRE. As well as the loops for testing, there are plans for a business park and sidings and depot area. One of the first buildings on site will be a headquarters, which will also include hot desks/offices that clients can use, research and development facilities that the UK Rail Research and Innovation Network (UKRINN) university consortium will use, a visitor centre, and a 100-bed hotel.

“This will be the centrepiece of the site and one that our architects are calling base camp,” said Simon. “Our ambition is to create a place that businesses want to be near.

I’ve been lucky enough to be involved in this project from the start and helped to initiate it

Simon Jones, chief executive officer, GCRE

“Our model for that is places like Horiba Mira and Silverstone in the automotive world, where if you go to these places now, you will see the names of all the tier one automotive companies you’ve ever heard of. They have a presence on those sites because they want to be able to use their facilities. That is what we want to create here and that is what the business park is all about.

“The sidings and depot are the engineering areas which will offer the facilities for people to store trains for prolonged periods if they wish. There will be a depot there with a large commissioning shed, train wash and fuelling points and all that kind of stuff, allowing organisations to carry out light maintenance, carry out tweaks during the commissioning process and overhauls.”

GCRE will be the UK’s first net zero railway and only purpose-built rail test facility with features unique in Europe, regenerating a former carbonintensive industrial site and creating a laboratory for decarbonising the UK’s railway.

“The site is criss-crossed by National Grid overhead lines so we will tap into that, but our intention is to run this as net zero in operation,” Simon said. “This will include putting solar panels on top of a hill and also negotiating with one of the local wind farms to bring a private wire in, so we get renewables either generated on-site or locally.

“We are going to tap into the energy network so the days the wind isn’t blowing or the sun shining, we can keep operating.

“There will also be the potential to commercially develop renewable energy opportunities at the site.”

The project has so far received £70 million from the Welsh and UK governments, which is funding the first phase of the project. This includes groundworks, site preparation, outline design and the development of rolling stock storage facilities.

In January, this year, GCRE Ltd formally launched the procurement process for investors from across the world to take a majority controlling equity stake in its business to support and fund the next development phases of the facility in South Wales. Applicants need to prequalify by the end of February, with selected bidders invited to tender in April, with a contract hoped to be signed by October this year.

“To develop the railway with its two loops of track, sidings and depot area, commissioning shed and base camp building and connecting it to the electricity grid is a £400 million project, so we need to raise £330 million from the market,” said Simon.

“The reason we’re running it as an open procurement is down to the fact we’ve got £70 million of public funding, so it protects us from any potential conflict of interest and ensures everyone has an opportunity to state a case for getting involved.”

The GCRE is due to be fully operational in 2025, although from June this year, services of sidings will be available to the marketplace. Within the next few weeks, GCRE Ltd will be going to the market for contractors to build the railway.

From March this year, earthworks will get underway, a tall order with 3.5 million m3 of material needing to be moved. Backfill from the former Nant Helen opencast coal mine will be used to build the earthworks needed for the testing loops, including one embankment which is 1.5km long and at one point 35 metres high.

Simon said: “We are selling a business, not a project. Someone who buys into this is buying GCRE Ltd and all its assets. There has been a lot of interest so far and we have a business plan, a set of financial forecasts and a financial model that I think is very attractive so I’m confident that we will get the investors.

“GCRE Ltd has an ambitious vision to create a genuinely world-class facility that can transform innovation across European rail, with multiple benefits for the sector, for the taxpayer and for our economy.

“For the industry, we can speed up innovation and bring products to market faster; for governments, we can reduce the cost of rail by helping deliver major projects to time and to budget; and for future generations, we can help accelerate our path to net zero and support the creation of good quality jobs in an area that needs it.

“We believe that the customers needing and wanting to use a facility like ours – not just here, but across Europe – are significant and that in turn makes GCRE Ltd a strong commercial proposition and a unique investment opportunity.”

To develop the railway with its two loops of track, sidings and depot area, commissioning shed and base camp building and connecting it to the electricity grid is a £400 million project