A FRESH START

An engineer through and through

2 “If you want to know the answer, ask the people who dig the holes” 10 No longer just the wrong sort of snow 12 What now for GBR? 16 Tackling soil moisture defi cit on the West of England line 22 Keeping freight on track

2023 January 2023 INSIDE TRACK

January

Consultant and non-executive director Steve Featherstone has recently been made a Fellow of the Royal Academy of Engineering. He talks about his journey and insights he’s gained through his career

“If you want to know the answer, ask the people who dig the holes”

INSIDE TRACK: PEOPLE 2 January 2023

Digging holes in the road; that’s how engineer Steve Featherstone cut his teeth, and it remains one of the most valuable learning experiences in a long and illustrious career – which, latterly, has seen him make significant contributions to rail.

These contributions include reducing the network’s maintenance backlog from 25 per cent to almost zero during his time as national maintenance director and heading up a ground-breaking high-speed hand back programme as track programme director.

Steve, who now works as a consultant and nonexecutive director, was recently made a Fellow of the Royal Academy of Engineering in recognition of his achievements. Speaking to Rail Director, he discussed the role of the academy, looked back at his time with Network Rail, and shared the insights he’s gained as a consultant to tier two suppliers.

Recognised for his achievements

Steve became an official Fellow of the Royal Academy of Engineering in early November, receiving his certificate from Princess Anne, the charity’s Royal Fellow. For this seasoned engineer, joining its ranks was a career-defining honour.

“I spent a lot of time networking on the day, and I was just blown away by the people I met,” he said. “Some of the engineering fields I didn’t even know existed, but they were fascinating. They were absolute experts at what they do. The academy has this huge pool of resource to tap into. I feel very privileged to be part of that.”

Founded in 1976 with support from HRH Prince Phillip, the academy acts as an advisory body to governments, as well as furthering and celebrating engineering excellence. Up to 60 Fellows are elected each year, alongside a maximum of ten international and five honorary Fellows.

Steve explained that, of its current membership, around two-thirds are academics, while the remaining third are “practical engineers” with a track record of “building things, making things, fixing things”.

“I think it’s a good balance. If we are there as a pool of talented resource for the government, you need that balance of practical and academic,” he added.

To warrant a nomination, individuals must have made significant and ongoing contributions in their fields. Steve attributes his own success, at least in part, to having “worked with some great engineers over the years”.

“I’ve learned from my team, learned from the people at the sharp end,” he explained. “My philosophy is, if you want to know the answer, ask the people who dig the holes. I’ve harvested up all that knowledge from people around me and deployed it as an engineer, both in the gas industry and for the last 15 years, in the rail industry.”

Lessons from a career in gas

Indeed, Steve enjoyed a successful career in energy prior to joining the rail industry and studied natural gas engineering at university.

My philosophy is, if you want to know the answer, ask the people who dig the holes

INSIDE TRACK: PEOPLE 3 January 2023

“My first 20 years were in the gas industry,” he explained. “I started with what was then British Gas; that was at the time when it was a completely integrated company, and looked after everything, from the gas fields offshore, right down to boilers and fires in people’s houses.”

Steve had the opportunity to “see the whole business”, working his way through different departments. It was his time “at the sharp end”, however, that proved particularly formative.

“Probably the experience I draw on most is the six months I spent digging holes in the road and repairing gas escapes,” he said. “Thirty-five years on, it’s probably still the best experience I’ve ever had in terms of understanding the psychology of frontline workers. When you’re digging holes in the road, you really start to understand what motivates them.”

Steve discovered that, whether the workers in question were digging roads or ballast, these motivations didn’t vary.

“In terms of the psychology of the working person and the frontline worker, it’s absolutely the same,” he added. “I would recommend anybody spends time on the tools to really understand that psychology, and what motivates them and makes them tick.

“The importance of work-life balance, the importance of family, the importance of earning enough overtime for your family holiday; all those things you understand when you work amongst them for a while.”

Steve worked his way up in the industry, eventually becoming head of operations for an energy network. When this network was sold as part of the devolution process, he left to work as an independent consultant.

Making rail safer

Just a year later, however, a headhunter approached Steve with a proposition that would alter the course of his career.

“He said, ‘have you ever thought about working in the railway?’ The honest truth was no,” he explained. “From the age of five, I wanted to be an

engineer, but I had never thought about working in rail as I was just completely blind to it as an engineering career.”

The role in question was that of maintenance director for Network Rail, which was working to address safety concerns after a derailment just south of Grayrigg, Cumbria, in 2007. An investigation established that the accident (during which over 80 passengers were injured, one fatally) had been caused by a faulty set of points.

“They wanted to bring in a maintenance director, who wasn’t a railway person, to look after the national infrastructure, I think,” Steve added.

“The root cause of the accident was that the railway wasn’t being inspected and maintained properly, and I think they wanted someone who could come in who knew how to run safety-critical infrastructure and could fix things.”

Steve was offered and accepted the role, inheriting a 25 per cent maintenance backlog.

“Over the next four years, we got that down to virtually zero,” he explained. “Unsurprisingly, I guess it shows that the maintenance engineers know what they’re doing. When we started to maintain and inspect the infrastructure properly and in line with the schedules we were supposed to, there was a 30 per cent reduction in maintenance failures and a 30 per cent reduction in delays for passengers.”

Their success, Steve concluded, is testament to the “blindingly obvious” fact that “if you maintain things properly, they work better.”

Going outside for talent

Asked whether recruiting a gas engineer for a safety-critical role in the rail industry constituted a ‘leap of faith’, he commented: “My belief, which isn’t a confirmed belief, is that there was a desire to go outside. Now in that circumstance, I think it was probably a good thing, and I hopefully added value.”

INSIDE TRACK: PEOPLE 4 January 2023

Probably the experience I draw on most is the six months I spent digging holes in the road and repairing gas escapes

Nevertheless, Steve believes that talent should be sought and fostered internally, adding: “I think Network Rail goes outside for talent too often.

“I came from outside, but the first thing I did was put veteran railway folks around me who could actually advise me really well – offer wisdom and insight about things that had been done before, mistakes that had been made, and why things were the way they were.”

When Steve joined Network Rail, ‘outsiders’ were a relative rarity; five years on, however, he became aware that this had changed.

“We had a leadership conference, and they said, ‘anybody with less than five years’ service, please stand up now’,” he remembered. “Probably twothirds of the people stood up, and this is of the 200 in the leadership group.”

Reflecting on his own approach to recruitment, he added: “I’m actually a huge believer in internal talent. I very rarely appointed from outside; I used to love developing people and appointing from inside.

“I think one of the problems in the industry is that there aren’t enough railway folks left running the railways; there are too many people coming from outside. It took me at least three years to understand the rail network. I’m a career engineer, moving from one safety-critical infrastructure to another safetycritical infrastructure - there are lots of transferrable skills and knowledge - but it still took me three years to work out which way was up. And I had a team of people who would really help while I was on that journey.”

According to Steve, the belief that recruiting externally will yield higher-quality candidates persists in the rail industry. “I completely refute that; I think you’ve got to back your internal talent, your internal talent pipelines and your internal development processes,” he explained. “It should be very exceptional that we go outside of the people we’ve been developing, but I think it seems to be something that is almost endemic in the rail industry – thinking that there’s somebody better outside.”

Steve added that, while internal and external candidates are often equally talented, the former present less of a risk.

“They know the people, the culture, the systems, the processes, and they generally hit the ground running,” he concluded.

Thoughts on devolution

Just as the Network Rail “gene pool” changed dramatically during Steve’s tenure, so too did its organisational structure. Discussing the impact of devolution and regionalisation, he said: “There is no right answer. Probably the best argument for devolution is if you follow the money.

“Increasingly, the funding for transport is getting devolved to regional mayors; the decisions for enhancement projects are increasingly being made at a local level. And if you don’t respond to that and have an organisation that is sympathetic to that, then you might find that the decision-makers decide to spend their money on a new cycle scheme rather than a platform extension.”

INSIDE TRACK: PEOPLE 6 January 2023

They know the people, the culture, the systems, the processes, and they generally hit the ground running

The counter argument, he added, is that devolution has led to Network Rail becoming overlarge.

“You need five performance improvement specialists, five analysts,” he explained. “When I started in 2007, there were 34,000 people in Network Rail, and 18,000 of them worked for me in maintenance.”

He and his team developed ‘2020 vision’, a plan to streamline the maintenance department.

Steve said: “The plan was that it would be reduced from 18,000 to about 12,000 by 2020 and, at the time of maintenance devolution at the end of 2011, we were about halfway there.

“At the same time, other parts of the organisation had some great plans too – to modernise or resignal the old lines, close down the little signal boxes, which are very resource intensive, and move the signalling into the big signalling centres.

“That would reduce the amount of signalling staff we needed quite considerably.”

Had these plans proceeded, Network Rail’s headcount would have fallen to about 24,000 by 2020. When Steve left in 2020, however, the organisation was employing around 44,000 people.

With the exception of odd bits of redoubled line, and odd little enhancements, it’s fundamentally the same railway as it was in 2007

INSIDE TRACK: PEOPLE 7 January 2023 January 2023

Below image: Rob Lacey/Royal Academy of Engineering

“With the exception of odd bits of redoubled line, and odd little enhancements, it’s fundamentally the same railway as it was in 2007,” he commented. “But suddenly, there are 10,000 people more than we needed, and we probably should have been doing it with 10,000 less. So, there’s a delta of about 20,000 people.”

Steve believes that the Network Rail of 2007 was something of a “halfway house”, adding: “You had route directors who ran the routes and route maintenance directors who ran the maintenance organisations, but then you had centralised asset management and centralised performance management.”

High-speed handback programme

The centralised structure made it easier for Steve and his Network Rail team to successfully deliver an industry-first high-speed handback programme, which meant that newly installed infrastructure could be handed back at speeds of up to 125 miles per hour.

Reflecting on the achievement, Steve commented: “I’m hugely proud of it - to actually have challenged my team to take us to a place we’d never been before.

“People will say, ‘we did 125 mph handbacks 40 years ago’, and we did, but we’d never done it on S&C (switches and crossings).

“If you think about all the junctions and crisscrossing, all the potential that you’ve got to derail a train at S&C, your engineering has got to be absolutely spot-on to hand back.”

This programme was included in Steve’s Royal Academy of Engineering citation – as was the fact that his team achieved eight Safety Swords of Honour and a Globe of Honour for Sustainability Excellence.

“What they are looking for when you become a Fellow of the Royal Academy is that you’ve done something which has moved the engineering bar,” he explained.

He attributes the programme’s success to rigorous procedures and a solid understanding of the engineering principles underpinning it.

“The person who signed off the no-go or go certificate was me, and it worked because I understood all the engineering principles, all the mitigations, and all the progressive assurance that we had in place,” he said.

“And that was because my team had worked for three years to understand it all. A huge amount of science and underpinning engineering knowledge was behind that signature.”

A new direction

Steve (who has served as president of both The Institution of Gas Engineers and Managers and The Permanent Way Institution) left Network Rail in 2020. For the last two years, he has worked as a non-executive director and consultant, supporting smaller companies in the rail industry. This transition – from a large, centralised organisation to the private sector – has proved eye-opening.

“The speed of decision-making, the responsiveness, the lack of treacle – it’s so refreshing,” he commented. “I thought there was a lot of treacle when I was in Network Rail. Now that I’m working on the outside with private companies, I can see there’s more than I ever realised.

“It really is bureaucratic and time-consuming; there are committees and panels, and it just takes ages to get a decision. Working with the private sector, you realise that they make a decision –they don’t always get it right, but they make the decision at speed and they move on. It’s hugely refreshing.”

While smaller companies can respond to challenges quickly, Steve has discovered that they also feel the impact of changing market conditions sooner. He fears for small businesses with financed vehicles, plant and equipment, adding that “the rapid increase in interest rates that we’ve seen over the last few months is really hurting the supply chain”.

He explained: “It’s been fine since 2008, financing at a relatively low rate – but suddenly it’s three or four times what it was three or four months ago. I think journalists will be writing about companies that don’t survive the next 12 months, and the causal factor will probably be the sudden increase in the cost of debt.”

This is just one factor in what Steve calls a “perfect storm for the supply chain”.

“Wages have increased, the cost of materials has increased, all the inflationary pressures, then the cost of debt has increased,” he added. “It’s hitting them at various lines on their P&L. And at the same time, because of all the strikes, there’s been an awful lot of work downturn coming from Network Rail.”

Steve explained that this perfect storm is affecting suppliers across the industry.

“There is a downturn in turnover, an upturn in costs, and an upturn in the cost of capital, and it’s really going to hurt things,” he concluded.

Insights into the supply chain

Today, Steve’s diverse client base includes manufacturers, recruitment companies and small contractors. He had expected to work with tier one suppliers after leaving Network Rail, but established that competition between businesses at this level would inevitably lead to a conflict of interest for the consultant supporting them.

“But if you work with tier twos, they tend to be relatively niche,” he explained. “They provide a service or product in a particular area, and they tend not to overlap with each other.”

According to Steve, working with tier two and 3 suppliers has been “the second-best learning experience” of his career.

“What I did at Network Rail, I thought it was pretty sympathetic to supply chains,” he explained. “I’d listen to them, meet with them a lot, and just try to understand their issues and learn from them. But there are things I know now that I wish I’d known then.”

Steve often helps clients to respond to bids in his capacity as an independent consultant, advising them on how to structure their answers and present themselves in the best way.

INSIDE TRACK: PEOPLE 8 January 2023

If you think about all the junctions and criss-crossing, all the potential that you’ve got to derail a train at S&C, your engineering has got to be absolutely spot-on to hand back

“What it’s made me realise is that the bid process is incredibly intensive,” he explained. “It’s very easy to ask the question, which is what I did for years, but it actually takes a huge amount of time to get the data together to construct the answer, and the supporting evidence.”

He added that, while extending deadlines and giving suppliers the opportunity to answer additional questions might seem like a generous move, it often pushes stretched bid teams to the limit.

“Fix the date, fix the time, and stick with it,” he advised. “Because the bid teams will focus on that, and the people who deserve to win will hit that.”

He also touched on the issue of Christmas resourcing, adding: “When you work with the supply chain, you start to realise that probably over 85 per cent of the people we are going to need at Christmas are going to be a contingent resource.

“We’re leaning hard on the supply chain to get the resources and it almost becomes a case of anybody who’s got a qualification and a ticket will get pulled in on Christmas Day and Boxing Day.

“It’s made me realise that the highest profile jobs of the year are on Christmas Day, Boxing Day; the whole world is watching, waiting for us to mess things up, and I’ve had my share of those over the years. But, actually, what I now realise is that at the time I was most under the spotlight, I had the weakest team delivering the work.”

Steve believes that the solution is to “flatten” Christmas Day and Boxing Day to “maybe one and a half times an average weekend”.

This, he suggested, will help to ensure that the industry still gets “good quality resources” at a time when its supply chain is stressed. He added that people could benefit from greater supply chain visibility, saying: “I think getting an understanding of what life is like in the tier twos and threes, which I only had at a certain level, would be good for people.”

Encouraging suppliers to speak openly about the issues they face, however, could present a challenge.

“They’re very open and honest with me now, because I’m part of them, but they did say ‘we would never have told you this when you were in your role at Network Rail’,” he concluded.

Looking ahead

But what next for Steve Featherstone, newly elected Fellow of the Royal Academy of Engineering?

“I’m just really enjoying doing non-exec and advisory stuff,” he explained. “I will only work with companies that I like, I respect, and I think add value.”

He hopes to continue adding value to the businesses he supports and is also keen to support the academy in key areas.

“One is contributing to some of the strategic policy discussions,” he said. “But also, some of the discussions around how we encourage people who are 10, 11, 12 to decide ‘actually, I want to steer my secondary education in a direction that’s heading towards an engineering degree and an engineering career’. I think there’s still a lot of work to do in that space, and I’d like to help.”

INSIDE TRACK: PEOPLE 9 January 2023

Wages have increased, the cost of materials has increased, all the inflationary pressures, then the cost of debt has increased

No longer just the wrong sort of snow

This was only a few months after the country had baked in a heatwave, when the threat of buckled rails and sagging overhead wires forced Network Rail to introduce temporary speed restrictions in some areas while its maintenance teams frantically painted rails white to reflect heat away from critical junctions.

Now the rails were white again as up to six inches of snow fell in the South East.

The heaviest snowfalls might be expected to occur in the highlands of Scotland and across the Pennines, and indeed those areas are well prepared for winter weather. Snowploughs – interestingly, converted steam-locomotive tenders – are strategically located and ready for deployment.

That’s not to say the South East is unprepared. There is a snowplough stabled at Tonbridge in Kent, which can be used in the event of severe drifting. However, the big threat to services in the area is ice, not snow.

Keeping third rails clear

South of the Thames, most passenger services are powered by electricity provided by a third rail alongside the running rails. This poses a different challenge. While the wheels on the train itself need to break through any snow covering the rails and find grip from the steel underneath, the collector shoe that draws power from the third rail needs to slide along it and make a good electrical connection. Network Rail takes several steps to ensure this process is not interrupted.

Its rail treatment trains, which are used to blastclean the rails in leaf-fall season, removing the slippery residue from crushed leaves, are repurposed and sent out on the network to spray the running rails and third rail with de-icer.

There are six of these multi-purpose vehicles (MPVs) based at Tonbridge to cover Kent and a further five at Horsham in Sussex. Surrey has still more, based at Effingham Junction and Totton. In cold weather, they run circuits, laying de-icing compound and keeping the network open.

Snow team

The Tonbridge depot also houses a dedicated fleet of snow and ice treatment trains, which have brushes to scrape away the ice and nozzles to lay anti-ice fluid. These trains are available for use right across the south of England if the weather gets severe enough.

So, Network Rail has plenty of kit that it can use to keep ice at bay. It also has other tricks up its sleeve, such as heated third rails in stations and at junctions to ensure there is good electrical contact when trains are pulling away from a stop.

Sophisticated technology on the trains can help too. Southeastern’s Class 375 trains have an ‘ice mode’ that helps them to keep going through icy conditions by stopping their traction current converters from shutting off when the current becomes intermittent.

Thameslink’s Class 700 trains are also very resilient in ice and snow, have excellent traction control and are fitted with sanders.

The British weather struck again in mid-December when an unseasonable snowstorm hit the south of England, disrupting rail travel

A couple of times a year, it is timing that causes the problems

INSIDE TRACK: SNOW 10 January 2023

Medway Valley line at Allington Image: Network Rail

It’s not all about the third rail, though that is a particularly southern problem. Points freeze in cold weather – the snow and ice get in the mechanism and then they seize up and won’t change direction or, even worse, get stuck partway through a cycle, rendering that set of points completely out of action. Point heaters are the traditional solution to this problem –heating elements keep the point mechanism above freezing point and so free to move.

Then there are icicles – the ones that hang from tunnel roofs and vent shafts where water runs down into the cold air of the tunnel. They may look pretty, but they can end up nearly a metre long and weigh several kilos. When a train knocks them off, they damage roof-mounted equipment and can even punch their way into the passenger compartment below, so they are best removed by track workers before they can cause too much damage.

The railway is well prepared for winter. But, as the saying goes, nothing is ever perfect. However well thought out the plan, Mother Nature always has a spanner she can throw in the works.

A question of timing

A couple of times a year, it is timing that causes the problems. The de-icing trains are deployed to cover the network in the early hours of the morning, clearing away any ice ready for the first train at around 05:30. But then temperatures suddenly plummet, freezing rain covers the cold rails in a layer of ice at around 4:00, and trains cannot run as planned.

In these circumstances, the de-icing trains are redeployed and the first train on every route is cancelled but still runs. These ‘ghost’ trains help clear any remaining snow and ice without the risk of having a train full of passengers stranded if things go wrong.

That’s not what happened on Sunday 11 December though. Instead, it was an inaccurate weather forecast that caught the railway planners out.

One to five centimetres of snow had been forecast – that’s under two inches. Network Rail’s normal preparations can cope with that, so, other than making sure the de-icing routes were planned and the equipment was working, nothing abnormal was arranged.

Suddenly, at 11:00 on Sunday, the forecast changed to between eight and 10 centimetres of snow in the east of the region (mostly Kent), just about four inches, and that figure continued to increase as the day went on. The railway was going to be in trouble.

By the time the evening came around, the Hastings route had closed with heavy snow on the live rail making it impassable, and trains were beginning to stack up in London instead of running down to the carriage sheds at St Leonard’s West Marina, where they are stabled overnight.

It took all of Monday to get everything back up and running, with staff and stock in the wrong places and anti-ice and empty stock trains running across the network to get the ice off the live rail.

It was a difficult day for passengers and shows the importance of accurate weather forecasting. And although snow was indeed forecasted, the amount of it wasn’t. Not only the railways were affected. Gatwick Airport closed, cancelling around 150 flights, and the M25 was shut. The importance of accurate forecasting is self-evident. But it’s not a new concept.

In February 2021, the final report of the Weather Advisory Task Force (WATF) was released, prepared by Prof Dame Julia Slingo FRS, Paul Davies FRMetS (Met Office) and Prof Hayley Fowler of Newcastle University.

Planning ahead

The report had been commissioned in the aftermath of the accident at Carmont, near Stonehaven, where a ScotRail train derailed due to a landslip, killing three people. The WATF was asked to review Network Rail’s capability to understand and manage adverse weather, particularly with regard to earthwork failures, with the aim of equipping Network Rail with the knowledge base and competencies, so that it becomes better prepared and more resilient in the future.

Although primarily looking at rainfall, the task force’s recommendations make important reading. These include:

“Advances in forecasting across minutes, hours to weeks are not being exploited by Network Rail. These would open up some major opportunities to deliver better early warnings to aid logistic planning, as well as new real-time, dynamic, location-specific forecasts and warnings that will improve operational safety and performance.”

and

“Network Rail urgently needs to transform the delivery of its weather services, by considering the development of a new hazard and impactbased digital platform which integrates all the relevant information to provide accessible, flexible and seamless services, driven by dynamic user specifications.”

It was never going to be a quick fix, but it seems like there is still work to do…

The importance of accurate forecasting is self-evident

INSIDE TRACK: SNOW 11 January 2023

Snowy Sussex Image: Network Rail

A number of rail industry eyebrows were raised, and questions asked, when the latest issue of a respected railway magazine announced “GBR dead” on its front cover!

What now for GBR?

The full headline on the front of Rail Magazine’s 13 December 2022 issue read: “GBR dead but reform lives on!”, followed by the quote: “We cannot carry on as we are” – NR’s Hendy.

Inside the magazine, a 700-word article reported a conversation between BBC transport correspondent and Rail contributor Paul Clifton and Network Rail chairman Sir Peter Hendy (now Lord Hendy of Richmond Hill CBE). In it, Hendy said he had stopped using the Great British Railways name, but work on the project would continue, particularly in the areas of ticketing rationalisation and developing the next generation of passenger train operating contracts.

So, just what is the status of the plan for Great British Railways, the implementation of the recommendations of the Williams Review and the adoption of the Williams-Shapps Plan for Rail?

It’s not surprising that the future is a little uncertain. Having three transport ministerial

teams in the space of a few months has led to plans looking shaky. Now that stability has returned, at least to the government, those plans are starting to look a little firmer, though the disruption to the rail network caused by industrial disputes isn’t helping, distracting attention from long-term planning.

Government view

On Wednesday 7 December, the latest Secretary of State for Transport, Mark Harper MP, appeared in front of the Transport Select Committee, flanked by his permanent secretaries Bernadette Kelly and Gareth Davies.

Responding to a question from Chris Loder MP, himself a former railway employee and RMT member, Harper said that fully implementing the Plan for Rail is “very much my plan, which is to get the railways to have a guiding mind behind them to have a more integrated position between how the different parts of the industry work”.

Andrew

Haines speaking in Sheffield Image: GBR TT

Buying a ticket can be mind-numbingly complex and fares don’t always feel fair

INSIDE TRACK: GBR UPDATE 12 January 2023

Andrew Haines

ASSET INSPECTIONS Earthworks Structures Drainage ACCESS SOLUTIONS Rope Access Underwater Drones Confined Space T: 01543 411994 E: info@geoaccess.co.uk www.geoaccess.co.uk WE COLLABORATE WE INNOVATE WE SOLVE

“I’ve started that work, I’ve spoken to Mr Williams and I’ve spoken to a number of colleagues who’ve got views on this matter,” he continued. “I’m taking some time to just reflect on it and to make sure when we move forward that I’m entirely happy with what we’re doing. I know there are a range of views in parliament, and I think it’s important that I take some time to listen and bear those in mind before I make any final decisions.”

One can hardly blame the Secretary of State for wanting to be clear on the issues in his own mind before he makes a decision, but, with legislation already overdue (it should have commenced around October 2022), any further delay would be unfortunate.

Much of the programme doesn’t need legislation, of course. Ticketing reform is one such area, as is driving forward closer cooperation between train operators and the infrastructure manager.

“We’ve already brought the transition team together,” the Transport Secretary stated. “We’ve got Network Rail and DfT teams working more closely together to look at business planning between track and train, which is one of the things that we need to do.”

What will need legislation is the formal change to the franchising authority, and this could now go before parliament during the second half of 2023.

Without committing himself to detail – in fact, without committing himself to anything at all –the Secretary of State does seem to believe that establishing a ‘guiding mind’ for the railways is still on the agenda.

Transition to GBR?

On the following day, Network Rail chief executive Andrew Haines, who also heads up the GBR Transition Team, addressed the question in a speech to business leaders at Arup’s offices in Sheffield.

“Rail has a big future,” he told his audience. “In the years ahead, it can do much more to serve our country than it does today. But our customers’ demands are changing fast, so the way we work will have to change, too.”

He continued: “Where rail is succeeding, it is often despite the way the industry is set up, not because of it.

“We can all see this as passengers. Buying a ticket can be mind-numbingly complex and fares don’t always feel fair.

“We are using resources badly so that busy routes can be overcrowded, and some operators have really struggled to run the promised service.

“And industrial relations are at a low point so that services into Christmas are now almost certain to be massively and needlessly disrupted.

“What links all of these is that they are not simply the result of investment decisions, but also the consequence of a lack of joined-up thinking and coordinated intervention, which, to fix, requires reform of rail’s disjointed structure.”

Andrew then moved on to talk about the Integrated Rail Plan for the North and the Midlands (IRP), described by the government at the time as “the largest single rail investment ever made by a UK Government”. Even so, the IRP is just one part of what he feels is needed to create the better railway that everybody wants.

The problem, in Andrew’s view, is not that the individual elements of the railway aren’t working or

are badly run. “Generally, each part of the railway acts rationally in isolation, motivated by the targets against which it is measured,” he said.

“But when the different pieces and targets are put together, the structures and incentives mean that all the momentum tends to pull in different directions, with today’s customers and tomorrow’s potential customers feeling the effects.

“This dysfunctionality means that, until we have a more coherent industry structure, the promises of investment in things like the IRP won’t bring all the benefits that customers need – whether that’s passengers or businesses using rail freight.”

Guiding mind

Keith Williams began work on his review of the railways in 2018. In his report, he wrote: “The railways lack a guiding focus on customers, coherent leadership and strategic direction. They are too fragmented, too complicated, and too expensive to run. Innovation is difficult. Incentives are often perverse. Some working practices have not changed in decades. There must be single-minded efforts to get passengers back.”

That was written before the COVID pandemic. Today, it is even more important to get passengers back onto trains and encourage office workers to commute again rather than work from home.

“But delivering the benefits people, businesses and communities want – whether it’s more frequent trains, improved connectivity or faster journey times – will need rail to work in a different way. A way that it is not set up to work today,” Andrew Haines stated.

“All parts of the rail system will need to work together, with a guiding mind capable of making the changes and trade-offs to realise and optimise the benefits of what is an enormous investment.”

The crux of Andrew’s argument is that the failure to make this structural reform is a big part of why rail underperforms. It lies behind high industry costs, the current difficulties with workforce reform and the painful pace of new infrastructure.

“Ultimately, it lies behind our broken promises too,” he added. “The problem, every time, is not that we haven’t spent enough money, carried out enough consultations, or published enough plans for the future.

My plan… is to get the railways to have a guiding mind behind them

Mark Harper MP

Mark Harper at Transport Committee Image: parliamentlive.tv

INSIDE TRACK: GBR UPDATE 14 January 2023

Image: DfT

“It’s because we aren’t set up as an industry to use the infrastructure we create, or the trains we buy, efficiently and reliably, or to work in collaboration with other organisations locally.”

There is fundamentally little difference between the railway today and the one that was privatised in the mid-1990s, at least in terms of the way it is governed and organised.

True, it is now a little more devolved, and COVID killed off the franchise system that was already dying beforehand, but the basic structure is unchanged.

Over the same period of time, the non-railway world has discovered smartphones, digital ticketing and climate change.

Railway governance is completely devolved to Wales and Scotland, and the ways they organise their railways are starting to look quite different from arrangements in England.

Twelve million more people now live in urban areas, and so need to be able to commute to work, shops and nightlife.

But, Andrew argues, rail hasn’t adapted to these changes because it is not set up to do so and is structurally incapable of doing so effectively.

The answer isn’t just to throw money at the problem, which has been the government’s solution in the past.

Andrew argues that investment without reform will produce incremental, guaranteed-to-disappoint improvement at best, while investment in track and trains alone, without changing how rail works, won’t reduce costs so that the railway is less of a burden on the taxpayer.

It also won’t drive the commercial hunger to make services better and sell more tickets or make moving goods by rail materially more attractive for businesses.

It also won’t make rail more responsive as travel patterns and the needs of businesses and communities change, as they have since COVID, or take rail to the forefront of the opportunities created by digital systems and connected data.

Looking forward

Andrew believes that only by creating a single leadership and decision-making body for the railway – “what has been called Great British Railways by the Boris Johnson administration, although I am not fussy about what title it gets” – can the industry join up decisions to maximise efficiency and speed up improvements.

“Currently, the Great British Railways Transition Team is producing the first version of a long-term strategy, which will be core to a new guiding mind,” Andrew announced.

“It will give clarity across the rail industry and to passengers and customers, about how the railway can best respond to long-term objectives which are rightly the preserve of politicians and policy makers –like levelling up and decarbonisation – and inform the trade-offs between them.

“Short, medium and long-term decision-making about rail, but also about other things like local land-use planning, will be guided by those objectives and led by evidence and data.

“This will mean better decisions, not only by rail but by local partners so that the railway better supports their priorities for housing, jobs and green economic growth.

“Priorities that will be brought to the fore of rail’s thinking by local agreements, put in place, as part of a reformed system, so that local political leaders have a greater say over their services.”

Williams also recommended a new approach to contracts with the private sector to run trains, a conclusion he reached even before COVID broke the old business model which sustained them. What’s needed, he said, is a range of contracts that reflect the needs of the market a train operator serves.

“Contracts to run trains should reflect the things we need from our railway, which were changing before the pandemic, and even more so now. They will include a greater focus on core service delivery such as punctuality and customer service – where the scope to influence demand is less, like on commuter trains.

“They will offer greater incentives to operators to grow revenue – and more control of the levers to do so – where there is real scope to grow passenger numbers rather than fight over revenue allocation, but not in a way that encourages over-betting on the economy, and franchises collapsing.

“Contracts that facilitate delivery of major changes rather than act as a serious constraint on their efficient deployment for fear of triggering an expensive contractual dispute or claim.

“In addition, there is a hunger for growing rail services integrated into wider transport networks in city regions.

“To support this, a new guiding mind for rail must have a decentralised approach of working through regional businesses, a long-term strategy and partnerships with regional authorities.”

So, it seems that Great British Railways – the future guiding mind of the railways – is far from dead. Except maybe the name…

The railways lack a guiding focus on customers, coherent leadership and strategic direction

Keith Williams

Keith Williams and Grant Shapps

INSIDE TRACK: GBR UPDATE 15 January 2023

Image: Grant Shapps on Twitter

In the wake of summer heatwaves, Network Rail has been working to restore uneven track between Salisbury and Exeter St Davids

Tackling soil moisture deficit on the West of England line

Network Rail recently announced that it had been able to lift line speed restrictions and restore South Western Railway’s regular timetable between Salisbury and Exeter St Davids, after record-breaking summer weather caused the clay-based track bed to shrink, leaving rails bumpy and uneven.

Known as soil moisture deficit, the issue led to speed restrictions of 40 and even 30mph being introduced at locations near Tisbury, Gillingham and Axminster. Network Rail stated that, since then, work to restore the track levels has progressed well, with engineers’ efforts aided by regular rain and cooler temperatures.

But what lessons have been learned – and, with heat waves set to become a more regular occurrence in the UK, can soil moisture deficit be prevented?

Speaking to Rail Director, Network Rail track maintenance engineer John Hope suggested that, on his stretch of the railway, the problem can be managed, but not easily prevented.

Due to the region’s geology, clay forms the core

of many embankments on the West of England line. When this clay dries out in hot weather, it shrinks, leading to the track becoming uneven. While this is not a new phenomenon, global warming means that it is becoming more frequent.

John Hope, Network Rail’s track maintenance engineer for the region, explained. “I’ve been the engineer here now for 21 years, so I’ve seen this quite a lot, though not to the extent we’ve had in 2022,” he said. “I remember back in 2002, which was an extremely hot year, we had massive problems.

“This year (2022), we went into the summer season well prepared in generic terms…and the geometry on the west of England was absolutely fantastic.”

Network Rails’ New Measurement Train (NMT) travels over this stretch of railway every four weeks, assessing and recording its condition – which, in June 2022, was good. However, John suggested that even Network Rail’s risk-based maintenance programme did little to help his team monitor the track as temperatures soared.

We knew that the track was drying out because we were starting to get sporadic ‘rough rides’ in various locations

Class 159 unit at Salisbury

INSIDE TRACK: WESSEX 16 January 2023

Image: South Western Railway

For more details, call our specialised team to discuss your particular project on: 01233 639039 sales@sunraydoors.co.uk www.sunraydoors.co.uk SECURITY DOORS FOR THE RAIL INDUSTRY ● SPECIALIST RAIL SOLUTIONS - Overground, Underground/TFL, DLR ● REFERENCE PROJECTS - Crossrail, DLR, TFL, EuroTunnel ● BESPOKE SOLUTIONS - Tailored designs to meet project criteria. ● INSTALLATION & MAINTENANCE - Qualified, Compliant & Trained Operatives ● TECHNICAL SUPPORT - Consultative advice with complete back up concept to installation.

“When you have risk-based maintenance, it eliminates any basic visual inspections taking place,” he explained. “The only visual inspections on the West of England line are of S&C (switches and crossings), so all the large swathes of CWR (continuous welded rail) don’t have any manual inspections.

“Not only that, they don’t have any supervisory management inspections either. So, the only inspection that takes place is the engineer’s one, and that’s every two years.”

Following June’s “fantastic” NMT results, technical failures meant that John and his team were without recording details for several periods.

“At this time, we knew that the track was drying out because we were starting to get sporadic ‘rough rides’ in various locations,” John remembered. “And then we did get a New Measurement Train run – that was in August – and it confirmed our worst fears. The track went off, hugely.”

The rough ride reports preceding these results had been provided, not just by drivers, but guards too.

“Obviously they’re walking in the train. As they hit rough sections, they get to feel it more than the driver, who is sitting down. So, most of the reports were actually coming through from the guards,” John explained.

Speed restrictions

“Loaded with the data, we were left with no option but to mitigate the risk of anything happening by imposing four rather long speed restrictions,” he added.

The normal speed limit on 90 per cent of this route is 85 miles per hour. In August 2022, however, a speed limit of 30 miles per hour was introduced between Tisbury and Gillingham. On three additional stretches – between Templecombe and Gillingham, Yeovil and Crewkerne, and Axminster and Honiton – speed restrictions of 40 miles per hour were imposed.

Indeed, data shows that the hot, dry weather had a dramatic impact on the quality of the track, which went from ‘good’ or ‘satisfactory’ to ‘poor’ and even ‘very poor’ in some areas. John and his team use a range of measurements to monitor conditions, recording both track and geometry faults.

In addition to imposing speed restrictions, they also introduced weekly cab rides, which enabled them to keep a close eye on the route.

“We didn’t have any data to go off, so the section manager would cab ride it every Monday, and I would cab ride it every Friday,” John explained. “Knowing the line like we know it, it just involved standing in the cab.

“We have both been on the section for many, many years, we know where the problematic areas are, we know how it should feel, so there were no instruments; we were just getting a feel for it, and whether it was deteriorating.

“This normally for me is a six-monthly inspection, but I was doing it every week. So, we were getting a good flavour of how it was, how it had developed, and of course, how it was improving.”

A tamper is used to restore track that has been destabilised by SMD (also known as desiccation). This heavy-duty machine raises the track and pushes ballast underneath it, creating a stable and solid foundation.

INSIDE TRACK: WESSEX 18 January 2023

After being caught short in 2002, John and his team have put cyclic possessions in place to cover the locations affected by SMD from September to December. They cannot tamp in August, as the rails are likely to be too hot.

“When we put in for our allocation of tampers, we make sure that those tampers are hitting the cyclic possessions we’ve got booked,” John explained. “That doesn’t necessarily mean to say we’re going to get them, because it depends on the renewals programme works, delivery programmes and so on.”

Big yellow machines

John and his team generally lease around four of these ‘big yellow machines’ from Colas Rail and Balfour Beatty on an annual basis, using them to re-tamp ballast and gradually straighten the track. Rainfall also helps to rehydrate the dry, crumbling clay, with any excess water squeezed out as trains pass over it.

For the West of England line team, restoring the track after 2022’s heatwave was a considerable undertaking.

“To get the speed restrictions off, these sites had to have two tamps because we needed such big lifts,” John explained. “The first tamp was just to get it back to some sort of normality, and the second tamp was when we were hoping to start looking at taking speed restrictions off.

“It’s still not there yet, but the speed restrictions are off and the track is safe.”

John explained that this restoration work is a

temporary solution, adding that the track will dry out “in exactly the same way” if the UK experiences more hot, dry weather this summer. There are, at present, no easy preventative measures he and his team can take.

“We’ve got all this technology now; there must be trains with huge water bowsers that can go through a site at night and just drop water onto it in a controlled manner,” he suggested.

Vegetation management could also help to alleviate the problem, but this presents its own challenges.

“Obviously if there are large oaks in the vicinity, for example, then they are very thirsty trees, so removing them would definitely help,” he commented. “But the trouble is, we go to these sites and think ‘there’s a huge tree’. And it looks like our land, but, lo and behold, it’s not; it’s just over the fence at the start of the farmer’s field, in which case we can’t touch it anyway. But the vegetation management is very poor, and that would help matters.”

John was already preparing for it to settle again in 2023 when he spoke to Rail Director.

“We’ve just got the access in for this quarter next year, and I’ve just loaded it all up in preparation,” he explained. “It’s quite disheartening, actually; you’ll eventually get it back, and then it goes off again, and you think ‘right, I’ve got to start this again’.”

John added that there is “still work to be done”, not just in terms of preparing for summer; he and his team were also planning to carry out another tamp between 10 and 18 December 2022.

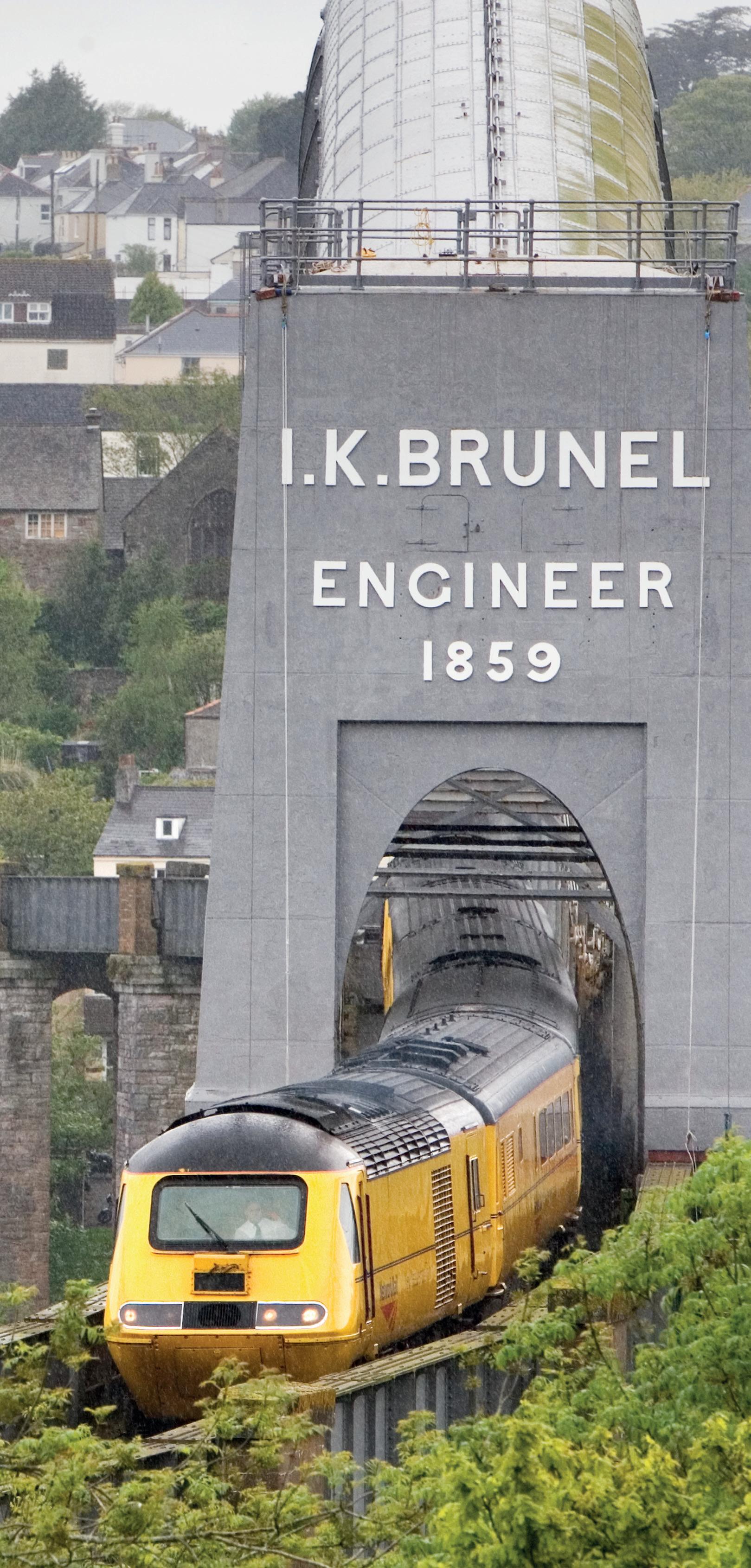

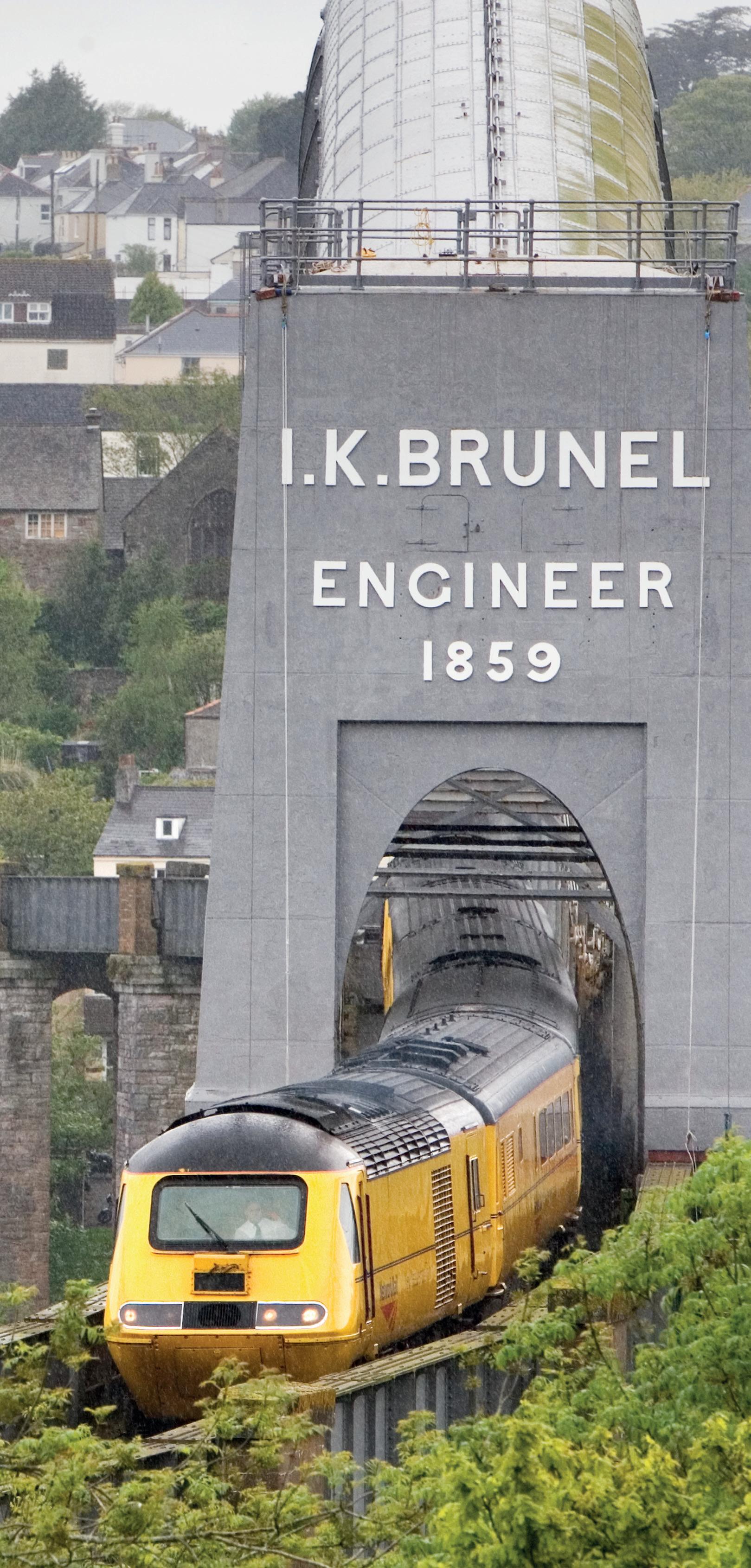

Opposite: The New Measurement

Train checks track quality around the network. It is seen here crossing the Royal Albert Bridge at Plymouth. Image: Network Rail

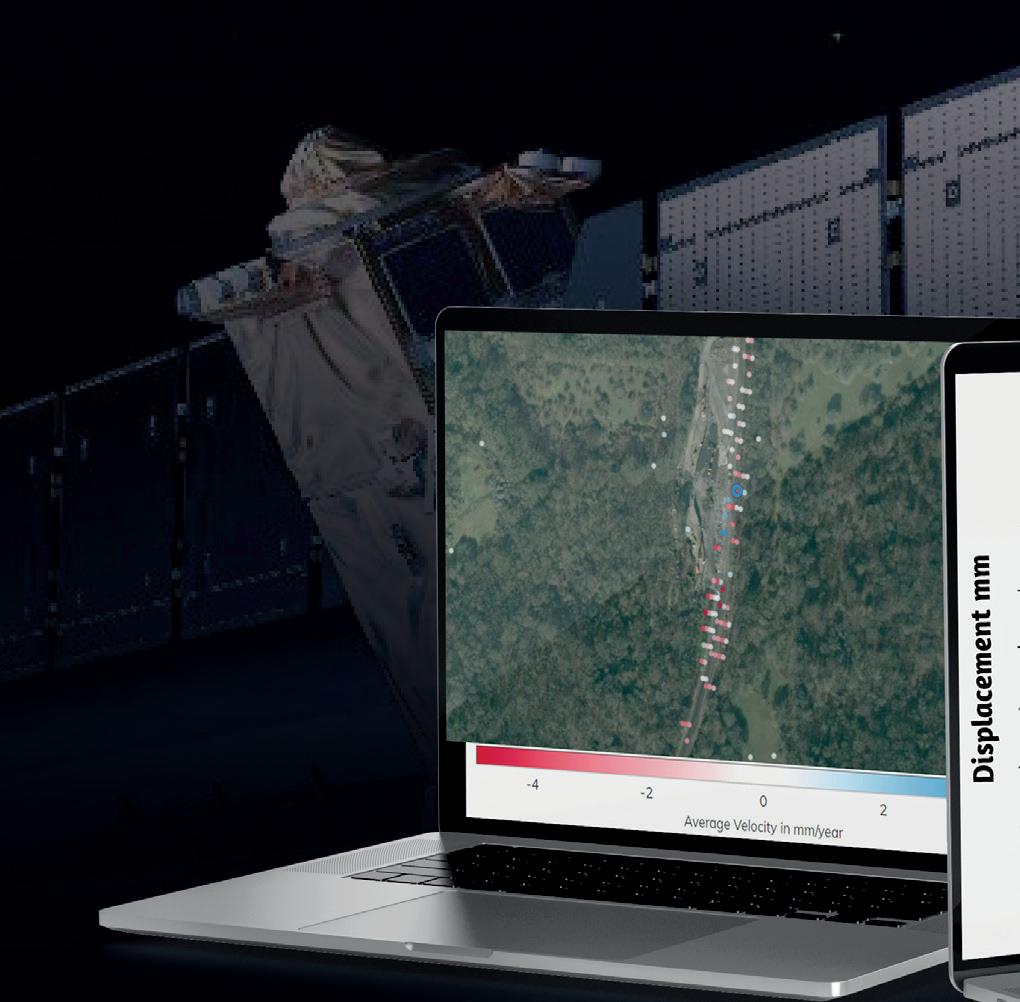

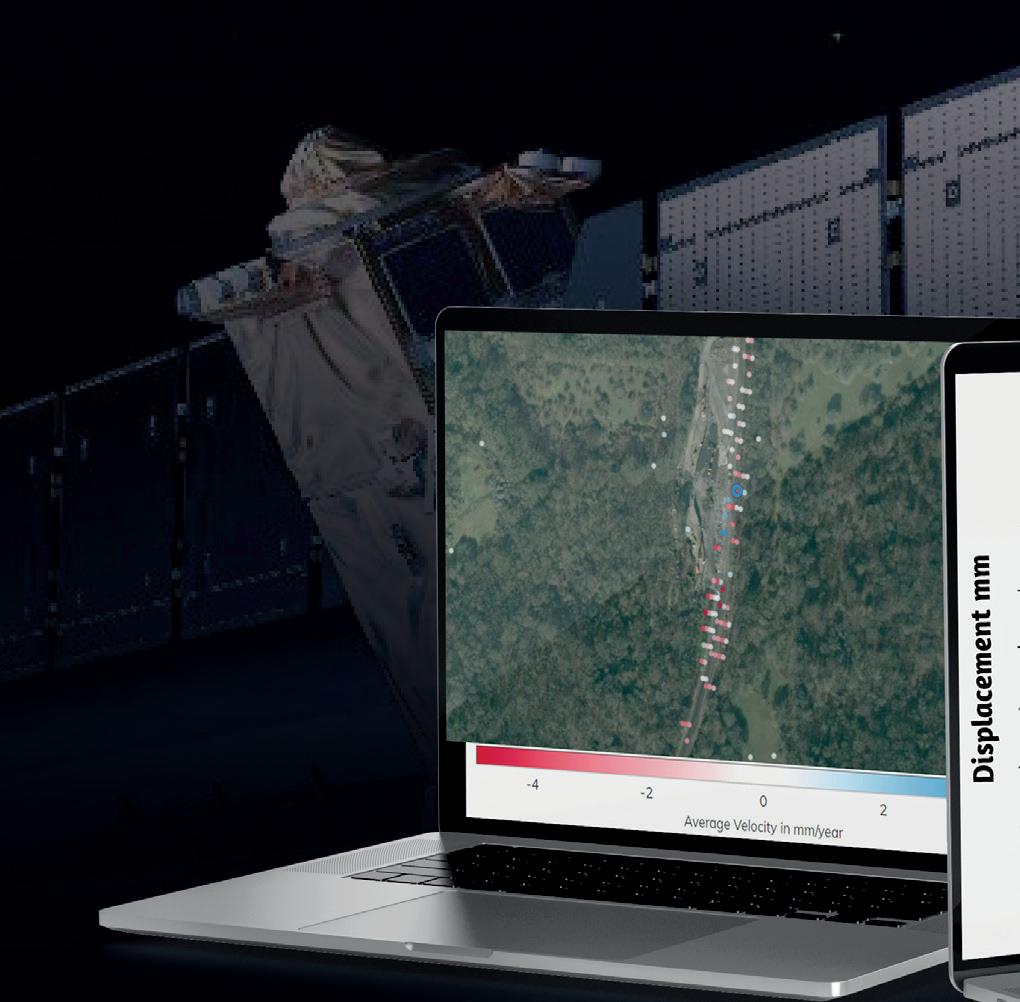

Restoring the track after 2022’s heatwave was a considerable undertaking Identify and monitor ground and structure movements InSAR remote sensing - millimetre precision, updated every 6 days • InSAR www.satsense.com INSIDE TRACK: WESSEX 19 January 2023

John’s stretch of the railway is not hugely busy, and much of the route is single tracked. This means that the speed restrictions, while disruptive, have not inconvenienced many thousands of passengers.

“It’s a category 3 track, which takes about nine million gross tonnes on average, so it’s not heavily trafficked,” he explained.

But this means that money is less likely to be invested in addressing the issue of SMD. Nevertheless, track renewals are taking place in this area on the West of England line, so John and his team did not tamp sections of the track that were due to be replaced anyway.

They also tend to avoid tamping switches and crossings (S&C), focussing instead on the plain line. John added that their efforts had been hampered by access issues, commenting: “Every time we take a Rules of the Route possession, access is getting chipped away – 10 minutes here,

10 minutes there - so we’re lucky now if we can get three-quarters of a mile of tamp.”

Ultimately, he is prepared to tackle the issue again and explained that neighbouring regions also struggle with SMD.

“I know Western have problems as well because obviously, we’re on the boundary with them,” he added. “When we do the cab rides on a weekly basis, we have to cover their section from Exeter to our boundary, and they suffer with it.”

The Cambridge line and a section of the railway between Basingstoke and Reading are also affected due to their geology.

Without innovation and investment in vegetation management, John and his team can only continue to manage the effects of SMD.

“You do all this work to get the track in a good position – we will be talking about 105 miles a year –and then for it to just go off – it’s quite demoralising,” he concluded.

Opposite: The New Measurement Train uses Plain Line Pattern Recognition to determine track quality

Below: Tamping restores track condition. Network Rail employs several tamping machines, such as this one working at Taunton Images: Network Rail

SALISBURY SOUTHAMPTON BOURNEMOUTH TAUNTON WEYMOUTH NEWTON ABBOT POOLE Tiverton Parkway Bridgewater Axminster Crewkerne Exmouth Dawlish Torquay Starcross Exton Honiton Feniton WhimpleCentralStJamesPark Newton St Cyres Dawlish Warren St Thomas Maiden Newton Castle Cary Brunton Dorchester West Dean Grateley Romsey Upwey Thornford WoolDorechesterSouth Yetminster Chetnole Yeovil Pen Mill Yeovil Junction Wareham Christchurch Pinhoe Torre Lymington Pier Warminster ParkstoneBranksome BeaulieuRoadNewMiltonBrockenhurst Tisbury SherborneTemplecombeGillingham Hamworthy EXETER Affected Track Branksome SALISBURY SOUTHAMPTON BOURNEMOUTH TAUNTON NEWTON ABBOT PLYMOUTH PORTSMOUTH READING SWANSEA FISHGUARD SWINDON HEREFORD CHICHESTER PENZANCE NEWPORT

INSIDE TRACK: WESSEX 20 January 2023

When the clay dries out in hot weather, it shrinks, leading to the track becoming uneven

Have recent incidents and accidents taken the shine off rail freight’s image?

Keeping freight on track

Britain has the safest railway in Europe –that’s a fact of which the whole industry can be proud.

The Office of Rail and Road (ORR), the UK’s rail regulator, published its assessment of achievement of safety targets for 2020 on 19 May 2022. It uses Common Safety Indicators (CSI) data to assess the level of safety risk over the preceding five calendar years – in this case, 2016 to 2020 – associated with six risk categories:

Passengers

Employees

Level crossing users

Others

Trespassers

Whole society (collective risk to all categories of persons above)

It also compares the number of fatalities and weighted serious injuries (FWSI) in Great Britain against other European countries for each of the six risk categories.

In terms of whole society, the UK is the best in Europe – ranked first out of 28 European countries. In the other categories, Great Britain was ranked behind some of the smaller railways but performed favourably in comparison to countries with similarly large rail networks.

GB was third in employee safety risk, fourth in trespasser safety risk, third in level crossing safety risk and eighth in passenger safety risk, beaten by Ireland, Lithuania, Luxembourg, Sweden, Switzerland, Finland and the Netherlands – all of which have smaller rail networks.

In terms of major incidents, the accident at Carmont, near Stonehaven in Scotland, which occurred on 12 August 2020 and in which three people died, was the first fatal accident since Grayrigg on 23 February 2007.

So, the passenger railway is a pretty safe one, though one should always strive to do better.

However, there has been a worrying spate of freight train derailments recently. Freight accounts for only 6.4 per cent of all train kilometres recorded, yet there have been several major incidents which closed the railway to both passenger and freight traffic.

On 26 August 2020, a train consisting of 25 laden tank wagons derailed near Llangennech, Carmarthenshire, resulting in a significant spillage of fuel and a major fire. Subsequent examination of the site found that ten wagons (positioned third to twelfth in the train) had derailed, and that around 446,000 litres of fuel had escaped.

The spilled fuel caused major damage to the environment in an area which is both a site of special scientific interest (SSSI) and a special area of conservation (SAC), including cockle beds, natural tidal mud flats and wetlands.

Derailment

An investigation by the Rail Accident Investigation Branch (RAIB) concluded that the derailment occurred because one set of wheels on the third wagon in the train stopped rotating during the journey. The wheelset had become locked, probably because of a defect in the braking system on the third wagon, arising from deficiencies in the design and maintenance of components.

The sliding of the locked wheel along the railhead caused damage to the profile of the wheel treads.

This meant that the wheels were unable to safely negotiate Morlais Junction, near Llangennech, damaging the pointwork and causing the third wagon to become derailed. The following wagons derailed on the damaged track. Some of the derailed tank wagons were ruptured in the accident, and the spilling fuel ignited.

Locked wheels

In simple terms, the front axle of the third wagon stopped rotating. The rubbing of the locked wheels on the steel rails wore flats into the tyres of both wheels, resulting in a ‘false flange’. The wheel now effectively had two flanges – one on the inside – the normal flange every rail wheel has – and another ‘false’ one on the outside, outboard of the flat.

When the train reached the trailing crossover at Morlais Junction, the false flange on the right-hand leading wheel rode along the inner face of the stock rail and caused the rail to rotate outwards towards the six-foot. The right-hand wheel then travelled along the web of the rail until it reached a fishplate, at which point the left-hand wheel climbed over the lefthand rail.

INSIDE TRACK: FREIGHT SAFETY 22 January 2023

The wagon then ran with its leading wheelset derailed to the left for around 175 metres until it met the facing turnout, where it was guided to the left along the Central Wales line.

Marks on the track showed that the derailed wheelset travelled approximately eight metres along the Central Wales line until the third wagon began to tip over, and the coupling between the second and third wagons broke.

This caused the train brakes to apply, resulting in the train driver becoming aware of the derailment. Damage to the track caused by the derailed third wagon caused the derailment of the following wagons.

The Heart of Wales line, which runs from Shrewsbury to Swansea, was closed for six months. Ground teams from Network Rail, Natural Resources Wales, Adler and Allan and partner agencies put in a total of 37,500 hours of work to protect the local environment, remove the wagons from the site and repair a large stretch of damaged railway.

30,000 tonnes of contaminated soil were excavated from 150 metres of railway, at a depth of two metres and width of 20 metres, and replaced with new, clean material from quarries in Carmarthenshire and Pembrokeshire, with the fuel-soaked soil taken to a licensed waste management facility in Merthyr.

Finally, Network Rail fitted around 530 metres of brand-new track before reinstalling the signalling, damaged in the fire.

Sheffield

On Wednesday 11 November 2020, 16 wagons of a freight train that was conveying cement powder from Hope, Derbyshire, to Dewsbury, West Yorkshire, derailed at the north end of Sheffield station. A number of wagons were damaged and there was significant damage to the track, resulting in a partial closure of the station. No one was injured.

The RAIB reported that the train was coasting through the station at a constant speed of around 12mph (19km/h) when the leading right-hand wheel of the twelfth wagon dropped into the space between the two running rails because the rails were too far apart – a problem known as gauge widening.

The track gauge had widened because a number of track screws, which secured the rails and baseplates to the wooden bearers, had broken, allowing the rails to spread apart under the loads from passing trains.

The track screws had failed several weeks, or perhaps months, before the derailment, but the failures had not been identified by Network Rail’s maintenance inspection activities.

The accident partially closed Sheffield station for five days while investigations took place, the damaged wagons were recovered and track and signalling equipment repaired.

London Gateway

On 24 December 2021, a freight service from Hams Hall (near Birmingham) to London Gateway derailed on the down Thames Haven line while on the approach to London Gateway port, near to Stanford-le-Hope in Essex. The freight train involved was formed of a Class 66 locomotive and 33 wagons, all of which were of the ‘container flat’ type.

The initial derailment occurred on Network Railmanaged infrastructure, when the leading bogie of the twelfth wagon derailed on plain line at about 13mph (20km/h).

Raise your profile in rail through the industry’s largest media business LIMITEDTIMEOFFER Phil@RailBusinessDaily.com FIND OUT MORE TODAY

If we are going to improve wagon productivity, we are going to have to put money into it

Above: Freight train derailment in Sheffield Image: Network Rail

INSIDE TRACK: FREIGHT SAFETY 23 January 2023

Opposite: Llangennech Image: RAIB

The train continued travelling for around 500 metres after this initial derailment, before it reached a set of facing points within the port boundary and a further four wagons derailed.

The wagon involved in the initial derailment was the middle wagon of an Ecofret2 set. This consisted of three wagons semi-permanently connected to each other by steel draw bars. The wagon involved in the initial derailment was the only one in the train not loaded with a container.

There were no injuries caused by the derailment, but extensive damage was caused to track and signalling equipment inside the port boundary. The rail connection to the port remained closed until temporary repairs allowed it to reopen on 4 January 2022. Investigation into the cause of the accident continues.

Carlisle

On 19 October 2022, a Clitheroe to Carlisle Yard freight service derailed at Petteril Bridge Junction, near Carlisle. The freight train involved was formed of a Class 66 locomotive and 14 loaded cement wagons. Five of these wagons derailed. One of the derailed wagons subsequently entered the river Petteril.

No injuries were caused by the accident, which led to substantial damage to railway infrastructure and some of the vehicles involved. The passenger lines from Newcastle to Carlisle were blocked as a result of the accident until 7 December due to extensive damage to a Victorian-built railway bridge, railway lines and signalling equipment. More than 25,000 hours of work was needed to restore the railway.

According to the RAIB, currently available evidence indicates that the derailment was almost certainly a result of a wheelset with false flanges encountering a set of switches that are part of the junction.

Of the above accidents, two were down to damaged wagon wheels with false flanges, one down to poor track maintenance and the cause of the fourth, as yet, is undetermined. In its report on the accident at Llangennech, RAIB said the industry had to do better in the safe maintenance of freight wagons, and added it was time freight wagon maintenance practices were subject to careful examination.

Above: Workers extracting cement from derailed wagon in river Petteril Image: RAIB

Below: Repairs and recovery of derailed freight train in Sheffield Image: Network Rail

A recommendation was made to the organisations who carry out surveillance and certification of entities in charge of maintenance of rail freight vehicles to review their processes.

Two recommendations were made to improve the management of wagon maintenance on the railways in Great Britain, and to review the technology and systems used to alert traincrew, signallers and railway control offices to wagon defects that may lead to derailment.

Regulatory oversight

The final recommendation was for a review of the arrangements for regulatory oversight of entities in charge of maintenance and certification bodies that are not based in the UK.

John Smith, chief executive officer of GB Railfreight, touched on the subject of wagon maintenance when he spoke to the Rail Freight Group in October. Most wagons are leased from specialist companies, and when a wagon is inspected and found to be unfit to run on the network, the problem is that it has probably been running around “in a fairly poor condition” for some time.

“This is going to require investment - if we are going to improve wagon productivity, we are going to have to put money into it. We’re going to have to change the way we work. We need a supply chain that’s going to adapt, and we need wagon owners that are willing to start going digital.”

In short, the rail freight industry in general, and the wagon leasing and maintenance sector in particular, is going to have to up its game to improve both reliability and productivity.

24 January 2023

INSIDE TRACK: FREIGHT SAFETY

■ Quickly measure the track and rail corridor to Band 1A accuracy

■ Significantly reduce the risks associated with trackside working

■ Avoid disruption to rail services by removing access possessions

To find out more visit fugro.com/raildata

Get in front of the decision makers of the rail industry BE FEATURED IN FUTURE ISSUES Email: Chris@RBDPublications.com A platform for success CLAIRE MANN EXCLUSIVELY FOR RAIL INDUSTRY LEADERS Robin Coombes Walking in the footsteps of one of the railway giants Mike Roe Driving Northern’s environmental sustainability Martin Beable New software reducing delays due to train faults Simon Higgens Joining rail from the front line Meeting post-pandemic demands 26 MARY GRANT EXCLUSIVELY FOR RAIL INDUSTRY LEADERS Martijn Gilbert Keeping up the momentum of the customer experience Hugh O’Neill Decarbonisation of rail freight traction – what needs to be done to accelerate change Darren Caplan Let’s get rid of the vacuum of ‘uncertainty’ in rail Maria Grazia Zedda Working for change in the railways December 2022 Delivering industry-leading innovations 28