16 minute read

Routes to zero-carbon rail

DAVID SHIRRES

In May (issue 184), we reported on the Railway Industry Association (RIA)’s first on-line Unlocking Innovation event. These events have now been running for ten years and aim to inform suppliers about industry challenges and help them respond by encouraging collaboration with research centres such as the UK’s Rail Research and Innovation Network (UKRRIN).

Holding them on-line does not detract from the aim of informing suppliers. Indeed, viewing the event from the comfort of your own home potentially increases attendance, although the lack of exhibition spaces and the opportunity to network reduces opportunities for new collaborations.

In a post-Covid world it will be interesting to see how many, if any, of these events are held online. For now, however, such online events are certainly worthwhile.

RIA’s latest Unlocking Innovation event in October was “Routes to Zero Carbon Rail”, held in partnership with Network Rail, UKRRIN and RSSB. Held in October, 29 presentations were given over four days, each of which had different themes – Driving Electrification on Monday, Decarbonising self-powered rolling stock (Tuesday), Zero Carbon Operations, Maintenance & Renewal (Wednesday) and Generation Decarbonisation to finish up on Thursday.

The bigger picture

Any discussion of decarbonisation invariably turns to how trains should be powered. Whilst this is indeed the main problem, much more needs to be considered if all parts of the industry are to decarbonise. It was therefore good to hear on wider issues and from outside the industry.

Decarbonising telecoms was the subject of Howard Lungley’s presentation on the approach taken by British Telecom, which consumes one per cent of UK’s electricity, has 6,500 buildings and 30,000 vehicles. He stressed that the number of people that need to be involved should not be underestimated. Although this was hard work, he felt that once there was a critical mass of support this becomes self-sustaining. RIA’s Richard Jones introduces the event.

Efficient electricity generation and transmission will be an essential part of a zero-carbon future. In his presentation, Dr Will Drury explained how UK Research and Innovation (UKRI) is supporting the development of clean and resilient PEMD (Power Electronics, Machines and Drives) supply chains. Since 2019, UKRI has invested £80 million to support the growth of companies in this sector.

The construction sector also has a big role to play. It is, for example, responsible for 60 per cent of UK waste. In their presentation, Network Rail’s Janet Dunnett and AECOM’s Philip Charles made the case for a national REM (Resource Exchange Mechanism) to encourage the widespread re-use of materials in construction. They explained what was needed for the exchange of surplus materials within and between companies and how this would deliver a wide range of benefits. Chris Hayes explained what Skanska was doing to reduce its current 350,000 tonnes of CO2 emissions to zero by 2045. This included identifying carbon hotspots in the supply chain and the ranking of construction methodologies by both cost and carbon.

Zero Carbon Rail Routes to

New Track Construction (NTC) train lays track at London Bridge.

Just as diesels need to be eliminated for rail traction, alternative means of powering construction plant is needed. McCulloch Rail’s TRT (Trac Rail Transposer) has been used in track renewal sites for 15 years and will soon be available in a battery-powered version. Andrew Davies of Unipart explained what this involved and how this project had been given funding by Innovate UK. Hopefully, there will soon be many other such conversions.

Rail Traction

Helen McAllister set the scene for the four-day UI event by describing Network Rail’s Traction Decarbonisation Network Strategy (TDNS), which had concluded that traction decarbonisation requires an additional 13,000 single track kilometres (stk) of electrification, with hydrogen and battery trains operating on respectively 1,300 and 800stk of infrastructure. It stressed the need for a long-term plan for a stable and efficient programme and the need to start hydrogen and battery operations as soon as possible to gain experience.

Helen advised how the TDNS interim programme business case report, published in July, provided the rational for this recommendation, in accordance with HM Treasury guidance. This was based on achieving decarbonisation and other environmental benefits, modal shift, passenger and freight end user benefits, operating cost reductions, rail cost savings, other environmental and wider economic benefits.

The interim TDNS report had considered five pathways to various levels of decarbonisation over differing timescales. She advised that those with the best value are those that take longer and go further. The business case, undertaken in accordance with principles agreed with the DfT, gave a range of net present values (NPVs) with a range of electrification costs. Top end costs (GW electrification) gave a negative NPV, with cost effective electrification giving a positive NPV. Helen stressed that this showed that efficient and reliable delivery of electrification schemes was crucial and felt that presentations during the UI event would help set up the industry to do just that.

Current and future research programmes to support RSSB’s ongoing work on rail decarbonisation were described by Andrew Kluth. RSSB has supported the production of the rail industry task force reports and, as Andrew advised, had been asked to continue to provide guidance to the Rail Minister.

Much of the RSSB research is considering various traction options, although Andrew noted that future electrification was necessary “on certain lines”. He indicated that, although the rail decarbonisation report has shown that hydrogen was not suitable for freight, recent research suggested that it was being considered by a RSSB research project T1160 on freight traction options. Although traction accounts for 85 per cent of railway energy consumption, Andrew stressed the need for decarbonisation initiatives at property, stations, and depots.

He concluded by advising of the need to engage with those outside the rail sector to ensure that rail industry decarbonisation was integrated into the wider transport sector. Efficient electrification

Helen McAllister was right to think that initiatives presented at this UI event would support electrification delivery. Day one of the event had five such presentations. Network Rail’s Richard Stainton gave a wide-ranging explanation of various initiatives. Those intended to reduce the requirement for bridge reconstructions included insulated pantograph horns, ice loading clearances, reviewing OLE gradients, developing a methodology to determine contact wire uplift at bridges and greater use of surge arrestors. Benchmarking piling techniques and OLE structures against European practice could further reduce costs whilst the development of a new supply system using modern protection technology could limit the number of substations required.

Much of this work will be supported by the University of Huddersfield’s research into OLE pantograph interaction. As Professor João Pombo of the university’s Institute of Railway Research (IRR) described, this uses advanced mathematical techniques as well as an advanced test rig that has been recently installed at the university. This new rig complements HAROLD (Huddersfield Adhesion & Rolling Contact Laboratory Dynamics Rig) which is the IRR’s full-scale bogie rolling contact, adhesion and braking rig that was installed in 2016, as described by Professor Paul Allen in a further presentation.

HAROLD.

Surge arrestor.

An industry view on efficient electrification was given by Justin Moss of Siemens. His presentation emphasised that costeffective electrification requires a steady long-term procurement programme in which suppliers are involved at an early stage. He also described how Siemens’ innovative OLE systems were engineered to reduce costs and so, for example, had fewer components and longer span lengths.

Dr Russell Fowler of the National Grid also mentioned the need for long-term planning to ensure that the required connections from the grid are provided for railway electrification, hydrogen electrolysers and battery charging. He also suggested that intermodal hubs sharing the same electricity supply could offer synergies with other surface transport.

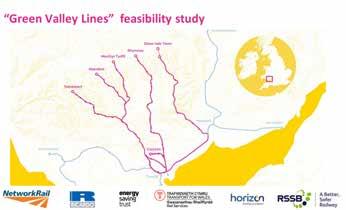

Riding Sunbeams Welsh Valley study.

In contrast, avoiding grid connections was the theme of the presentation by Alex Byford of Riding Sunbeams. This considered how the supply of power directly from lineside solar panels offered greater carbon savings at lower cost than grid electricity. A study of the Welsh Valley lines considered that solar panels within one kilometre, and wind turbines within two kilometres, of the line could directly supply 38 per cent of the traction demand. However, this would not be commercially viable unless Network Rail’s licence conditions allowed it to be exported to the grid and a suitable costeffective three-to-single phase converter could be developed.

The presentation from Loughborough University, mentioned below, also modelled intermittent electrification, which has significant issues of cost and practicability.

Intermittent electrification

Research into Intermittent electrification is one of the recommendations in the rail industry decarbonisation task force report. The concept is to have a number of short or longer gaps in the OLE to avoid electrifying costly sections. It is the only specific initiative mentioned in the Railway Technical Strategy (RTS) for the goal of cheaper electrification and has also been considered in the following RSSB studies: » T777 which considered the risks of associated lowering of the pantograph » T1145 Appendix I, which showed its benefits on three specific routes » COF-IPS 02 Optimal Power Control of bi-modes, as presented to the UI Webinar, which also considered the potential for intermittent electrification.

None of these research reports consider the requirement to provide individual OLE segments with a 25kV supply, which would require a feeder cable to be laid along the line. At a recent RTS webinar, Network Rail’s Richard Stainton indicated that the cost of such a cable could actually be more than the OLE itself.

Until recently, it was necessary for bi-mode trains to operate in diesel mode under Steventon bridge, on the Great Western main line in Oxfordshire. This required the pantograph to be lowered quite some distance before the bridge at a location where the driver was not overloaded with other information. After the bridge, the pantograph could only be raised at speed where there was only a simple wire run. As a result, the pantograph had to be lowered for six miles.

This aspect considered by research study T777 proposes an automatic lowering and raising system (ALRS) for the pantograph. It estimated the cost to be, at 2020 prices: £3 million development, £40,000 per train and £30,000 per gap.

Fortunately, a simple engineering solution was devised by Atkins such that the train could continue through the bridge under electric power, with only a speed restriction of 110mph to make it work (issue 182, March 2020), so intermittent electrification was not required.

As far as Rail Engineer is aware, no other railway in the world has electrified routes with intermittent gaps.

Transitional solutions

Transitional technologies, that reduce the carbon impact of existing diesel traction before it can be eventually eliminated, are an important aspect of rail decarbonisation. One such technology is G-volution, which is a dual fuel diesel/LNG system which offers CO2 reductions of about 35 per cent. G-volution’s Chris Smith explained how a trial of the system on a Grand Central Class 180 DMU is projected to give 20 per cent fuel savings with a three to five-year payback.

Whilst hybrid cars are now commonplace, this technology has yet to be applied on Britain’s passenger railways. Brian Reynolds of Angel Trains explained that this is to change soon as his company is modifying a Class 165 for use on Chiltern Railways that is scheduled to enter service next year. This involves the removal of old batteries, engine and transmission and their replacement with an underfloor 300kW traction motor, traction battery packs and twin 120kW generator sets with an intelligent IGBT (insulated-gate bipolar transistor) power system. This is expected to offer a 25 per cent reduction in CO2 emissions, as it will enable the unit to operate like a hybrid car with one exception: GPS geofencing will ensure that the unit operates in battery-only mode in stations and other sensitive areas, such a low-emission zones.

125mph Grand Central Class 180 DMU.

Mike Edwards of MotiveZero was also promoting hybridisation of an existing diesel train, in this case a diesel shunter. His company produces kits that enable Class 08 locomotives to have their engine/generator set and control system replaced with a traction battery, a ‘range extender’ with a small clean engine and a modern control system. He advised that the modified shunter offers 95 per cent CO2 savings with a 30 per cent reduction in fuel and maintenance costs. Such savings are to be expected, as shunters spend most of their time idling.

Three presentations showed the possible energy savings by changing their duty cycle. Dr Tim Harrison explained how Loughborough University had modelled class 802 bi-mode trains operating between London and Plymouth to consider possible fuel savings. This model showed potential CO2 emissions savings of 3.3 per cent from controller optimisation and 19 per cent from selective engine shut down.

Enerail’s Peter Ainsworth described how the company’s traction system optimisation, which is intended for the light rail market, had achieved traction savings of up to 20 per cent. It does so by offering a cost-effective driver advisory system and a performance tool that enables drivers to improve their skills by assessing their own performance. Savings from such advisory systems are also shown in our accompanying feature on Russian Railways decarbonisation.

125 mph Grand Central Class 180 DMU.

Dr David Golightly described how Newcastle University had developed DECIDe (Digital Environment for Collaborative Intelligent De-carbonisation). This provides a collaborative simulation environment that facilitates the use of different rail decarbonisation and power optimisation simulations which he illustrated with examples of driving techniques and the provision of hydrogen for a specific service.

Hydrogen trains

Not surprisingly, the webinar included presentations from Mike Muldoon on Alstom’s ‘Breeze’ concept and Stuart Hillmansen of the University of Birmingham on the development of HydroFLEX. These are both described in our accompanying feature on hydrogen trains.

Points about hydrogen supply in this feature were also amplified in the presentation by David Horsfall of Tyseley Energy Park and Stephen Kent of the University of Birmingham. This made it clear that supplying a fleet of hydrogen trains by road was unrealistic. Whilst an HGV diesel tanker can deliver diesel to refuel 20 threecar units, an HGV hydrogen tanker can only fuel two such trains. A typical fleet of ten trains would require around three tonnes of hydrogen per day, which could be produced by an electrolyser that would require a 10MW electrical supply.

Unlike red diesel, there are currently no tax incentives for the production of hydrogen to power rail and road vehicles by fuel cells. Hence, if hydrogen is to be affordable, the electricity that produces it needs to be generated locally to avoid grid fees and taxes. David Horsfall explained how the Tyseley Energy Park has a 10MW waste-wood biomass plant and two 25MW energy-fromwaste plants, together with a 3MW electrolyser plant which will supply the fleet of 20 hydrogen buses that will start service in Birmingham in 2021. If a fleet of hydrogen trains was based at Tyseley, they could be supplied with a new 25MW electrolyser directly supplied with energy produced from waste.

Matt Candy’s Steamology team designed the 380hp steam turbine that powered the world’s fastest steam car, which achieved 148mph at Edwards Air Force base in 2009. Since then they have used this experience to develop an efficient turbine fuelled by mixing hydrogen and oxygen. As a method of producing energy from hydrogen, Matt advised that this has three advantages over fuel cells: the turbine is more energy dense; it has a longer life and is less expensive. However, unlike a fuel-cell-powered vehicle, which combine hydrogen with oxygen taken from the air, the Steamology turbine requires the on-board storage of compressed oxygen.

There is no doubt that the Steamology turbine is an impressive piece of kit. Matt advised that it “challenges the assertion that hydrogen freight could not be done”. However, his presentation did not consider the fundamental problem that hydrogen takes up more than seven times the space of diesel fuel. Indeed, the Steamology turbine requires the storage of both hydrogen and oxygen.

Matt advised this is not a problem, as the turbine takes up much less space than fuel cells. Yet, on the iLint, the space required by the fuel cells is a quarter of the total fuel cell/hydrogen storage space, so the space saved by the use of a turbine would only be a small percentage of this and probably taken up by the additional oxygen tanks required. This presentation, therefore, offered no reason to contradict the TDNS report’s conclusion that hydrogen traction is not practical for rail freight.

Similarly, an energy-dense steam generator offers little advantage for freight traction. The diesel tank of a Class 66 freight locomotive holds 6,400 litres of diesel. Storage of the same amount of energy would require 50 cubic metres of hydrogen at a pressure of 350bar. In practice, even more space would be required, as this pressure requires small diameter tanks which cannot be efficiently packaged.

Storing this large amount of hydrogen would require at least one tender vehicle to power a locomotive with the power of a Class 66 (2.3 MW). There can be little doubt that, to attract freight from road to rail, the rail freight business would prefer a 4MW electric locomotive with three times the efficiency of a hydrogen locomotive.

Decarbonisation innovation

As ever, the RIA Unlocking Innovation event highlighted some impressive initiatives, good practice in other industries, and showed the availability of funding to develop worthwhile innovations. If Britain’s railways are to achieve net-zero carbon emissions, innovations that deliver efficient electrification, fuel savings, lower carbon transitional arrangements and improve the capabilities of battery and hydrogen trains will have an essential part to play.

However, innovations cannot change the laws of physics that make electric trains more powerful and efficient than selfpowered traction. This is even more true in a net-zero world, when diesel will have been replaced by much less energy-dense batteries and hydrogen.

Yet there remain calls for innovative alternatives to electrification from some influential politicians, which resulted in a recent newspaper headline of “Rush to electrify rail risks new diesel fiasco.” The chairman of the House of Commons Transport Select Committee also recently stated that electricity is dirty and we have hydrogen just around the corner.

Whilst it is important to keep an open mind about nonconventional solutions, such as Steamology’s hydrogen-powered freight trains and intermittent electrification, it is also essential that fundamental constraints are assessed and addressed before they are presented as real possibilities and taxpayer’s money is invested in them. Otherwise, such proposals can only undermine political acceptance of the industry’s vision for rail decarbonisation.