5 minute read

Business Profile

Innovative ground anchoring foundation systems for level crossings and trackside

Established in 1995 and based in the UK, Anchor Systems are a global leader in the supply of earth anchoring products and solutions. They provide a vast range of anchoring systems for all sectors, including rail, highways, civil engineering, construction, utilities, marine, horticulture, agriculture, geotextiles and domestic.

With considerable expertise in rail infrastructure, Anchor Systems (International) Ltd offer a comprehensive technical support service including advice, design specification, site testing services, full installation training and approved specialist installers if required. They have designed several new and innovative systems for use on Level Crossings and trackside, which can be found throughout Network Rail and London Underground lines. Anchor Systems have an ever-growing number of anchoring solutions developed using the Anchor Screw foundation system, all approved by Network Rail and London Underground. Their products have been commissioned for projects including the erection of Westbourne Park segregation barrier, Hither Green Signalling Renewal, West Hampstead Life Extension programme, Phase 3 of the Victoria Resignalling Programme and the South Harrow Cable Route Management System as part of the TfL Piccadilly Line Upgrade Programme (PLU).

The Anchor Screw foundation system has a patented domed head and interface plates which can be easily incorporated into any design, providing huge cost savings on your project. This system eradicates the need for traditional installation methods, such as concrete, is rapidly deployable and installed with portable handheld equipment only. This system is preferable over concrete and other methods in the rail sector due to time and cost savings, as well as offering an average carbon reduction of 70 per cent.

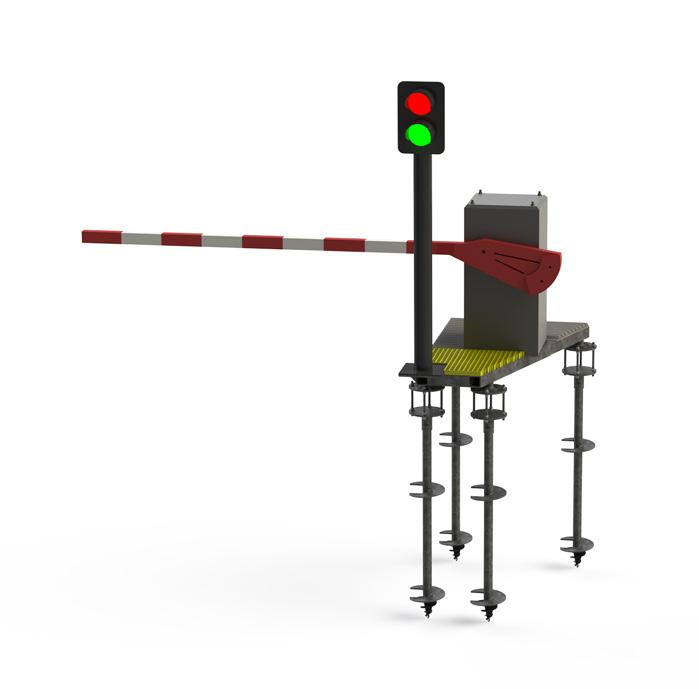

Amongst Anchor Systems’ list of products are the Anchor Screw level crossing signage solution, level crossing grillage and foundation for automatic barriers and Road Traffic Light (RTL) and Box on Post (BOP).

The level crossing signage solution has been designed using modified Anchor Screw foundations, for the rapid installation of a level crossing sign or asset. Anchor Screw Piles at a length of 1.68 meters are used with adaptor plates which connect directly to the signposts. The Interface plate allows for 7° lateral adjustment in any direction, giving a total tolerance of 14° and ensuring that the sign is always level. Being fully removable, the system can be repositioned easily and reused if required. Network Rail specify that two rounded posts are required to account for wind loads and prevent any rotation or movement of the sign, therefore two Anchor Screws are necessary. The Anchor Screw foundation system is a one-of-a kind design and has UK and European Patents. It eradicates the need for hand excavation, muck away and most importantly, there is no concrete required. The systems installation techniques and its generic NR design means that ground investigations are not necessary in advance of the installation, which is a huge expense saved to the network. The system is manufactured entirely within the UK from 100 per cent recycled or scrap steel.

The level crossing grillage with Anchor Screw foundation features Anchor Screw piles with interface plates. The interface plates attach directly to a steel grillage base, making this a quick and efficient installation method with minimal disruption to the surrounding area. The design was created for use as part of the Southern Level Crossing Renewal project, commissioned by Network Rail to reduce the risk to the public in urban and heavily trafficked areas. A helical screw pile foundation design with steel grillage was required to support a lifting barrier machine and RTL above a buried High Voltage (HV) route and various other obstructions, in West Sussex. The renewal comprises the removal of the existing Automatic Half Barrier (AHB) level crossing which is considered a substantial risk, and replacement with a new Manually Controlled Barrier (MCB) CCTV Level Crossing type. This includes the installation of one lighting column, one CCTV camera and four new barriers, housed on the grillage with Anchor Screw foundation.

The BOP and Anchor Screw foundation design, incorporates the same principle as the level crossing signage solution, but is for a single asset only. The BOP, or Signal Post Telephone (SPT) in this instance, will house telephones located near signal points. These are used for the train driver to directly communicate with the signaller or for other railway staff to contact the signal box directly. The system has been designed to easily penetrate poor ground conditions, and as the NR standards specify average ground conditions, no local ground investigations are required. A single Anchor Screw with domed head and interface plate are supplied pre-assembled with the fixings in place, as the hole in the top of the interface plate allows for both to be installed as one. Once installed into the ground, a signal post is easily attached for the telephone to be connected to. The design includes rubber grommets around the entry holes to protect the flexiduct as it is fed through the side of the interface plate and up through the top face into the pole.

As with all Anchor Screw products, the benefits of the handheld installation far

Anchor Systems (International) Ltd are fast becoming the preferred supplier for anchoring systems within the rail sector

outweigh other methods, eliminating the need for OLE isolation, on track plant or RRVs and no concrete or wet trades are used. This installation method is portable, lightweight and produces no hand-arm vibration syndrome (HAVS) during use. Installation is quick, with the average time to install a 1.5 metre Anchor Screw, in medium density ground conditions, being only three to four minutes. The torque head has a zero dB reading and the power pack has a reading of 88dB at two metres, making this the ideal solution for night shift work and use in noise sensitive areas. Full GPR scanning can be carried out to identify potential services prior to installation.

Environmental benefits of the Anchor Screw include: • All materials being recyclable, easily removable, and reusable. • Made in the UK from one hundred per cent recycled steel. • Anchor Screw has a 100 year design life • No wet trades used, curing times or excavation. • No requirement for RRVs. • Materials can all be transported by hand and with track trollies. • Portable and lightweight installation equipment. • Zero HAVS (Hand Arm Vibration

Syndrome). • Installation head offers low noise pollution output offering lower disturbance to residents. • On average the Anchor Screw foundation offers a carbon reduction of over 70 per cent.

For more information on the Anchor Screw systems and other available products, get in touch via the contact information below.

Tel: 01342 719 362 Email: info@anchorsystems.co.uk Visit: www.anchorsystems.co.uk

Seeyouat StandF11