3 minute read

Bridges and Tunnels

Bringing rail industry maintenance and construction into clear focus

New build and refurbishment projects across the rail industry are now enjoying benefits from one of the latest design developments from system scaffolding manufacturer, Layher Ltd

The company’s Scaffold Information Modelling (SIM®) tool comprises a range of planning features that not only help to make the creation of the optimal scaffold structure safer and more efficient, but which also interface directly with Building Information Management (BIM) methodology. The increasing inroads now seen into the building and construction industry are also clearly reflected across projects in the rail sector.

‘SIM helps with planning operations which, in turn, can maximise installation efficiency, reduce risk and enhance cost savings’ says Sean Pike, Layher’s UK Managing Director.

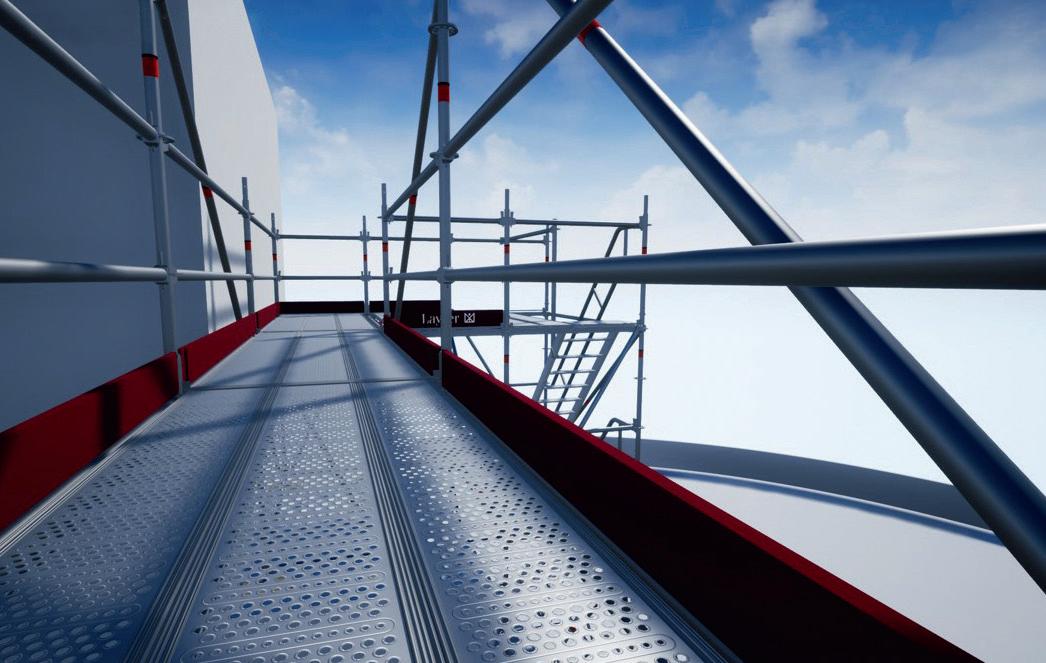

‘The system builds on the Layher LayPLAN and LayCAD software and enables users to create 3D visualisations either on screen or via a VR headset which take them into the digital world. Once

there, scaffolds can be rotated, ‘flown-through’ and readily adapted before key information outputs such as material needs, weights and logistical details are produced.’

Apart from a valuable planning and operational tool, Layher SIM also offers enhanced presentation opportunities, construction sequence simulation, communication with mobile devices via mixed reality and storage in the cloud. Importantly, the visualisation modelling allows virtual tours to be experienced and any clash detection issues to be resolved at an early stage.

‘Realistic rendering can also be added while ease of operation is

LAYHER ALLROUND BRIDGING SYSTEM

From footbridges spanning up to 30m to heavy load support girders

SAFE

enhanced by extensive component libraries, He points out that the full and detailed a search and filter function and the visualisation that can be utilised before capability to hold pre-fabricated assemblies equipment is even despatched to site can and template drawings on file to aid rapid bring important scheduling and operational design’ continues Sean Pike. advantages. In the rail industry this can Significantly, Layher’s SIM software translate into reduced possession times – the helps to optimise the use of a range importance of which needs little emphasis. of components and systems from the Recognised recently as a runner-up company that have been shown to offer key in the Innovation of the Year Awards gains in the rail sector. given by the National Access and ‘Our bridging systems, which can achieve Scaffolding Confederation, SIM reflects spans of up to 30 metres with either in-situ Layher’s commitment to innovation or ground level construction and interface with a number of optional fittings such as and design. ‘While the system brings greater opportunities to building and FAST our Protect panels, are an excellent example’ maintenance operations across all our adds Sean Pike. markets’ concludes Sean Pike, ‘it also ‘In the rail sector the benefits of their reflects our belief in working closely with use has been proven repeatedly – typically our customers in all sectors to optimise where workforce or public access is required safety, efficiency and performance. The rail between platforms during refurbishment industry is a major field in which this is programmes.’ He also draws attention to clearly and repeatedly demonstrated.’

Layher’s choice of public access stair systems and DDR-compliant handrails in this context Tel: 01462 475100VERSATILE PROVEN BACKUP – both of which are often used in connection Email: info@layher.co.uk with the company’s bridging systems. Visit: www.layher.co.uk ‘Installations such as these, just as with our choice of Allround® scaffolding systems, all bring installation versatility and ease of handling, transportation and storage to the The past, present and future of user and, in all cases, equipment selection and installation is enhanced by our SIM Layher UK system scaffolding capability’ explains Sean Pike. info@layher.co.uk | www.layher.co.uk