6 minute read

The Digital Railway

Smarter working improves safety and productivity for Network Rail

Working smarter, not harder and ensuring track inspection workers get it right first time is the remit of a new digitisation project for Network Rail and the Central Railway Systems Alliance (CRSA), that is delivering efficiencies of up to 70 per cent and track safety improvements thanks to the adoption of digital work instruction platform WorkfloPlus from Intoware

Last year Network Rail and the CRSA approached digital workflow specialists Intoware as data on its track renewals was not being fully captured and utilised efficiently across the business. They aimed to digitise critical data and processes of Network Rail’s frontline teams to help deliver quality data, improvements in track safety and reduce costs.

A digital ‘connected worker’ solution was required to help mitigate a series of ongoing challenges for Network Rail’s track renewal operations that included: time lags in receiving documentation and data; sometimes incomplete asset intelligence and a reliance on paper-based processes.

It was agreed that an Accelerated Innovation R&D project technology trial, to be delivered from June 2021 would bring together existing innovative solutions to help standardise data collection and reporting for safety critical renewals from legacy paper-based processes into one, easyto-use and adaptable solution to be trialled at Network Rail’s Aston Depot.

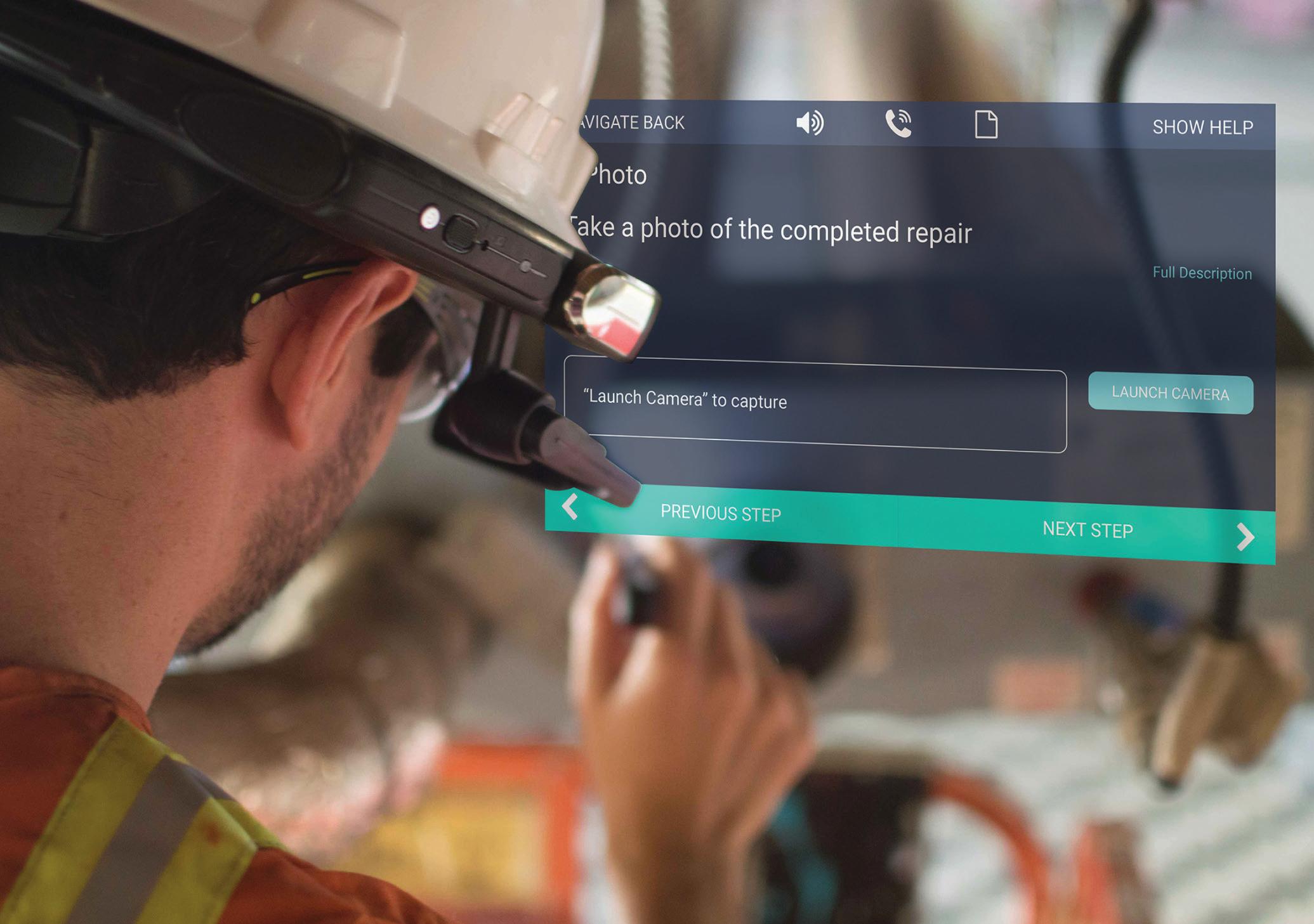

The solution Digital work instruction platform WorkfloPlus was chosen as it easily integrates with RealWear HMT-1 (head mounted tablet) assisted reality headsets, tablets or smart phones for collaborative working. Intoware helped Network Rail to create a solution that would allow its workers to easily create, edit and adapt digital workflows using an easy-touse interface.

With Intoware’s support, Network Rail started to digitise a series of legacy paperbased renewal activities. This meant working with the Aston depot teams on the ground to fully understand their current activities, assess issues and challenges and then design, digitise and standardise the workflows to meet existing requirements and make time, safety and sustainability benefits.

Network Rail’s processes are currently focussed on regularly occurring and timeconsuming operations. These processes represent a suite of track assessments and

Hannah Bailey, Business Development Director

authorisation activities that are undertaken daily in the lead up to renewals activities to assess the site and ensure the team are prepared for the works to be carried and enable authorisation to progress.

These paper-based processes are now standardised to enable a consistent approach across its teams based on best practice. WorkfloPlus has also been integrated with the ‘Track Locator’ app, which means that all data that is collected is automatically tagged with GPS locations, meaning that the location of additional works or hazards can be accessed in real time, providing more robust and accurate information for the business.

This technology trial has demonstrated in a short time, that frontline workforce is able to do things quicker, better and smarter to deliver a 70 per cent time saving, thanks to greater accuracy, efficiency and visibility of a ‘connection solution’ for critical track renewal processes.

Intoware’s business development director, Hannah Bailey, comments: “We’re really pleased to be partnering with Network Rail, the challenge for this project was to reduce print costs and avoid lengthy delays incurred by paper processes for rail track renewals. But most importantly, improvements in data quality were critical, as incomplete intelligence would necessitate further inspections to recapture missing information to ensure track safety and compliance.

‘WorkfloPlus improves the quality of data captured as it auto generates data reports in ‘real-time’ from inspections that are instantly shared with colleagues and supervisors to deliver significant performance improvements. While ‘handsfree working’ also means better situational awareness so it’s easier for the workforce to pick up on any potential hazards.’

As a result of this technology trial, Network Rail and the CRSA have facilitated a best practice consistent approach for teams to follow across track renewals. WorkfloPlus provides a central repository of data that is automatically updated and can be accessed live by a wide range of stakeholders, each with their own relevant dashboard. This additional intelligence, including the identification of trends, risks and opportunities, ensures that Central Rail Systems Alliance is focussed on continuous improvement.

The benefits of WorkfloPlus combined with HMT-I’s and other devices are wide ranging: • Reduced time to conduct data collection and reporting • Improved quality and consistency of data, first time • Improved access to data and reporting, gaining faster insights improve decision making • Improved collation and storage of data • Improved worker safety by freeing up workers hands • Reduced paper, printing and photocopying

Reduced time to conduct data collection and reporting The connected worker solution allows Network Rail to utilise existing hardware to do things better, faster. Staff are also very clear on what they need to collect, which means they can do this quicker.

Improved quality and consistency of data, first time Currently data is captured differently by each worker. This means there are varying quality levels of data provided and often missing, or inaccurate data which requires reassessment and reworks.

Standardised and consistent workflows will mean that workers know what data needs to be collected, they will be guided through a process so that know what they need to check, what they need to take photographic evidence of and when issues need to be reported. WorkfloPlus ensures the same standard for all workers. This will mean that the data will be right first time and will significantly reduce the need to undertake re-assessments or extend assessment time due to missing, incomplete or unclear information. Improved access to data and reporting, gaining faster insights improve decision making Currently it takes several days to collect, collate and report on the data. The solution provides a live cloud based central storage for all assessments. This means that teams will be able to access assessments and refer back to images or written notes provided, all GPS stamped.

This solution exports into report structures that replicate existing processes and can be amended easily to align with refinements or improvements made. Trends can be identified and there is an audit trail of data

Improved collation and storage of data Currently data is written on paper and then written into Excel or Word documents, which are then circulated by email.

A digitised solution will mean that the information that workers are collecting is secure in the cloud and can be accessible at a later date for finalisation and submission. Rather than the need to make written notes and then transcribe them two or three days later, the information can be inputted and submitted immediately or as soon as the worker is ready. Track locator provides GPS stamp and there is an audit trail of data.

Improved worker safety by freeing up workers hands Rather than taking pens and swathes of blank paper for note taking or print outs and photocopies of designs, form templates or the need for reference materials, the solution will enable the worker to take out either their mobile phone, their iPad or a HMT1 device and they can collect everything they need.

Reduced paper, printing and photocopying It is estimated that for every process completed between ten to 20 sheets of paper are needed for note taking and up to ten photocopies. The new process will remove this requirement.

Chloe Denham, Programme Manager Innovation, The Central Railway Systems Alliance: ‘By working collaboratively with digital specialists Intoware we have successfully trialled WorkfloPlus, its digital work instruction platform together with RealWear’s voice-controlled headsets to successfully capture track renewal data, paving the way for the future of frontline teams.

Our previous paper-based systems were replaced with a single collaborative hands-free solution that allows data to be consistently captured and shared with colleagues to satisfy regulatory compliance. Its application has been proven to deliver efficiencies of up to 70 per cent, reducing costs and improving worker safety on site.

By digitising critical track renewal processes in this way as part of an NWR R&D trial, it will help to further advance innovation as the results are now being shared and adopted by the wider business.’