Rail Safety Week 2024 – Let’s Build Safety Together

How to Get More Tracks for Your Greenbacks & Rail Live 2024 It’s Make-or-Break for US Passenger Rail – Connectivity Is Key for Long-Term Success

Railway-News The latest news & reviews from the industry ISSUE TWO 2024 MAGAZINE Inside:

Together with you, Goldschmidt masters the challenges of modern, railbound mobility – for safe, sustainable and long-lasting railways of premium quality.

Goldschmidt offers a comprehensive range of products and services worldwide for the joining of rails, modern construction of railway track, and inspection and maintenance of your track infrastructure. Using our products and services combined with our intelligent digital solutions, we are pushing for the digital future of track.

The unique global network of experts gives you access to the international range of products and services of Goldschmidt – right where you are, via your local contact person, backed by the power of the entire group.

www.goldschmidt.com

MOBILITY WITH VISION

Letter from the Editor

Dear Readers,

In this issue we have two articles that look at rail in the US. The first one, How to Get More Tracks for Your Greenbacks, presents the key recommendations made by Paul Lewis, Principal at DB E.C.O. North America on how rail infrastructure costs could be reduced in the United States, given that rail projects in the US have a much higher per mile cost than equivalent projects in other countries.

Martin Shaw, Head of On-Train Digitalisation for Icomera, says that following the authorisation of large-scale investment through the Bipartisan Infrastructure Law, rail operators are comprehensively upgrading their vehicles and technologies. He argues that this is a make-or-break moment for US passenger rail in terms of delivering on the digital train.

On the events side of things we are on the other side of the pond. We look at what’s in store for this year’s Rail Live 2024, which will take place in Long Marston this month.

In addition, Elaine Clark, CEO of Rail Forum, raises awareness of the upcoming Rail Safety Week in her contribution, Rail Safety Week 2024Let’s Build Safety Together.

In our sections on track & infrastructure, rolling stock and data & monitoring, you can read the latest news and developments about green loans for infrastructure projects, trackbed maintenance, train seating, wheel profile measurement, FRMCS, revenue management, remote condition monitoring and much more!

If you would like our rail news straight to your inbox, make sure you’re subscribed to us here. If you want to be featured on our site or in our e-magazine, please email Andrew Lush or call +44 7432 725001.

We hope you enjoy this issue. As always, we welcome your feedback and insights, which you can send to editorial@a2bglobalmedia.com.

Josephine Cordero Sapién, editor-in-chief

Josephine Cordero Sapién, editor-in-chief

ANDREW LUSH Director al@a2bglobalmedia.com

JOSEPHINE CORDERO SAPIÉN Editor-in-chief jcs@a2bglobalmedia.com

NICOLA BROWN Head of Sales nb@a2bglobalmedia.com

ZOE GRIFFEY Head of Design zg@a2bglobalmedia.com

TIANA MAY Principal Journalist tm@a2bglobalmedia.com

a2b Global Media Ltd

The Generator Hub, The Gallery Kings Wharf The Quay, Exeter EX2 4AN

Office: +44 (0)1392 580002 Mobile: +44 (0)7432 725001

Email: info@railway-news.com Website: railway-news.com

To subscribe to our newsletter, visit railway-news.com/subscribe

3

Meet the Team! Meet the Team!

Follow us on LinkedIn COVER: Aerial view of Rail Live © JB Media

Issue Two 2024

Features

p.6

How to Get More Tracks for Your Greenbacks

Our journalist Tiana May looks at why rail infrastructure projects in the United States are so much more expensive than elsewhere in the world and presents the key recommendations made by Paul Lewis, Principal at DB E.C.O. North America at the recent High Speed Rail Alliance webinar Global Best Practices for Cutting the Cost of Building High-Speed Rail.

p.10

It’s Make-or-Break for US Passenger Rail –Connectivity Is Key for Long-Term Success

Martin Shaw, Head of On-Train Digitalisation for Icomera, discusses the concept of the digital train and its importance for interoperability and affordability.

p.14 p.81

Directory

A directory of railway suppliers for data & monitoring, track & infrastructure, rolling stock and services. Read about all the latest innovations and product developments in the rail sector.

Track & Infrastructure – p.17

Rolling Stock – p.29

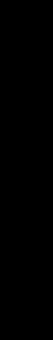

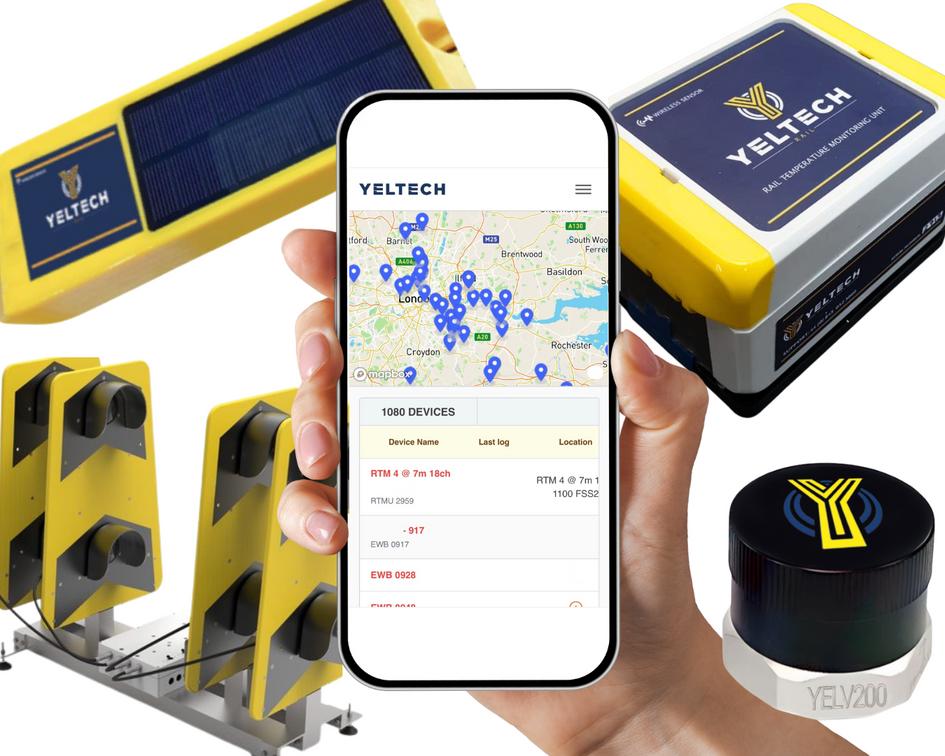

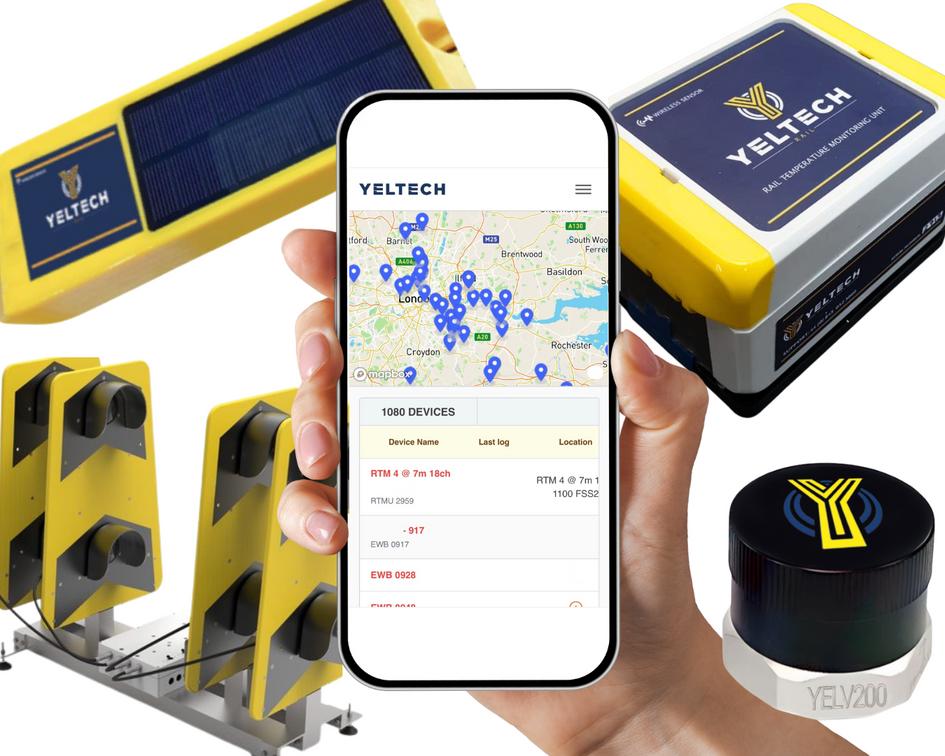

Data & Monitoring – p.55

Events

Rail Live 2024 – p.82

Supplier Spotlight – p.84

Upcoming Events – p.85

Rail Safety Week 2024 – Let’s Build Safety Together – p.86

5

CONTENTS

How to Get More Tracks for Your Greenbacks

By Tiana May, Principal Journalist

The USA is currently experiencing historic investments in intercity passenger rail services thanks to the Bipartisan Infrastructure Law. Among many initiatives, this funding is helping to support the construction of high-speed rail projects, including California HighSpeed Rail and Brightline West.

However, the nation’s High-Speed Rail Alliance argues that a systemic cost problem in the US could risk restricting the impact of such investments. In fact, rail projects in the US currently cost 2 to 4 times more per mile than comparable projects abroad, thus inhibiting the nation’s ability to expand its network.

To address this concern, during a recent webinar, the High-Speed Rail Alliance invited Paul Lewis, Principal at DB E.C.O. North America to discuss global best practices in the industry that could help agencies complete projects at a lower cost and to a more efficient timeline.

As an extreme example, Lewis compared the Hamburg U4 Extension Phase 1 with the NYC 2nd Avenue Subway Extension Phase 1. These projects had comparable scope and similar infrastructure and geology. The U4 extension stretches 2.4 miles under Hamburg, while the 2nd Avenue extension spans 1.7 miles under New York City. However, the former cost 238 million USD per mile to construct, while the latter cost 3.28 billion USD per mile (adjusted for purchasing power parity and inflation). This highlights a delivery cost that was more than 10 times greater in the US compared to Germany.

To explore the reasons behind such a disparity, Lewis identified three key drivers affecting the cost and timeline of a project: project governance, process and standards. With these factors in mind, he offered ten recommendations for delivering cost- and timeeffective projects.

6

Fresno Station © CHSRA

1. Building Simple and Useful Projects

As an achievable commitment, agencies should avoid unnecessary customisations and complexities, including in station designs. Indeed, the most cost-effective approach tends to be for all stations to be functional and interchangeable in design, rather than prioritising unique aesthetics.

Likewise, Lewis stated that the construction of rail infrastructure should avoid tunnelling deeper than required and argued that cut and cover designs should be considered where possible.

2. Break Up Civil Works Contracts and Set Itemised Costs

Currently, the US is one of the only countries in the world that relies on multi-billion dollar mega contracts to deliver major rail projects. Elsewhere, civil rail contracts do not tend to surpass between 100 and 200 million USD. For example, when constructing the Leipzig City Tunnel in Germany, the tunnelling, ramps and stations were broken up into different contracts.

This approach provides greater competition, as more firms can bid on smaller contracts, whereas only a few are qualified for multi-billion dollar endeavours. In addition, this gives the agency more control over the project’s performance as contractors who do not deliver satisfactory work can be replaced. Finally, the project’s schedule can also be better controlled, as

issues can be addressed without disrupting the rest of the project.

3. Manage More Risk on the Public Sector Side

To help lower bids, Lewis argued that public agencies need to assume more risks that are not under the control of contractors. Otherwise, if contractors are expected to assume risks that they do not have control over, they will inevitably price this into their bids.

4. Empower Staff to Engage the Community

Traditional community engagement in the US can be viewed as ineffective or a “tick the box exercise”. Instead of hiring external consultants, Lewis recommended using in-house staff to engage the community during the entire planning, design and construction processes.

Furthermore, he asserted the importance of the agency being empowered to say no, rather than trying to accommodate for every community comment.

5. Proceed with the More Disruptive Timeline

Here, Lewis dismissed the need to minimise disruptions by keeping roads open and limiting working hours. He argued that a more disruptive approach from the start ultimately leads to less disruptions in the long run and helps significantly cut costs.

7

© Brightline

6. Finish the Planning Process before Environmental Review

Environmental reviews are time-consuming worldwide. However, Lewis identified that more efficient projects tend to avoid using this procedure as part of their planning process.

When an environmental review commences before all key planning decisions are made, it becomes an inefficient vehicle for making these decisions. This leads to the creation of environmental impact statements (EIS) with dozens of alternatives, thus elongating the process.

7. Boost Internal Staffing

Typically, the US relies on hiring consulting firms for tasks such as project management and construction management. In contrast, in most other countries, the project owner remains in control of the project using an in-house team. In turn, this leads to more efficient and less costly delivery.

8. Set Agreements with Partners Early

When establishing labour agreements and betterments, it is important to have full transparency with all scope and costs factored in. Lewis suggested that all details and eventualities should be established in advance, rather than allowing conflicts to arise once construction is underway.

9. Address Institutional Governance

Transit agencies are primarily tasked with providing transport, rather than delivering multi-billion dollar projects. It is therefore key to establish whether the agency has the right board structure and staff support to move a project forward before it gets underway.

If this is not the case, the issue should be addressed early through reform or changes to the governance, or by creating a special purpose delivery team, such as that established for the Stuttgart 21 project in Germany.

8

© CHSRA

Cedar Viaduct © CHSRA

10. Learn from Peer Country Examples

Finally, thanks to the array of successful transit projects worldwide, Lewis advocated for visiting other countries and agencies to learn from their achievements and talk to experienced professionals. This could help agencies expand their knowledge to understand how common problems are overcome and costs are reduced.

By working to adopt these recommendations, it is hoped that the US can overcome its systemic cost problem in delivering large-scale rail projects.

The average cost per mile of transit projects varies significantly across the globe. For high-speed rail, the average cost per mile is 47.4 million USD in France, 53.8 million USD in Spain and 80.7 million USD in Germany. In Taiwan, this figure averages at 133.2 million USD per mile, while in Switzerland, it costs an average of 134.9 million USD per mile.

Higher-cost countries include Italy at 165.9 million USD per mile; Japan at 185.8 million USD per mile; Great Britain at 220.9 million USD per mile; and the Netherlands at 252.1 million USD per mile.

These figures are adjusted for purchase price parity and construction inflation. However, alongside their differing processes and approaches, in some cases, the varied costs also reflect the required complexity of the projects and the percentage of line that has had to be tunnelled or elevated.

Needless to say, in order to successfully deliver a nationwide rail network, the US must aim towards the lower, rather than high end of these figures.

At present, it is estimated that the California HighSpeed Rail project will cost around 200 million USD per mile. However, arguably, by learning from past inefficiencies and adopting global best practices from abroad, future agencies could significantly lower this figure to further optimise investments in rail across the nation.

To read more from our Principal Journalist, Tiana May visit railway-news.com © Brightline 9

It’s Make-or-Break for US Passenger Rail – Connectivity Is Key for Long-Term Success

By Martin Shaw, Head of On-Train Digitalisation for Icomera

The concept of the digital train is not simply an imaginary glimpse into the future; it is the imminent evolution of public transport tailor-made to meet the expectations of a connected world.

With every turn of the wheels, the very notion of travel is being reimagined, shaping up to fit into a digitally dominated era where seamless internet connectivity is as essential as the tracks upon which the trains ride.

Gone are the days when digital transformation within railways was constrained by bits and pieces of technology scattered across compartments. We are venturing into terrains where central connectivity platforms are not the exception but the standard. Guided by the insights of Martin Shaw, an expert, and Head of On-Train Digitalisation for Icomera, we chart today’s ambitious course toward the digital train – an entity that encourages not only modern conveniences but marks a significant leap in transport technology.

Two years ago, the Bipartisan Infrastructure Law authorised the investment of more than one trillion dollars in federal spending on transportation, broadband access, clean water and electrical grid improvements. The transportation industry is now seeing the effects of that funding first-hand: across the country, rail operators are upgrading their infrastructure and purchasing new vehicles that will carry passengers for the next two decades or more. Our country’s passenger rail network has never before seen such a comprehensive upgrade to its vehicles and technologies.

Martin Shaw Head of On-Train Digitalisation for Icomera

Martin Shaw Head of On-Train Digitalisation for Icomera

This is a make-or-break moment for rail travel in the US. While the COVID-19 pandemic led to a sudden drop in ridership for rail operators, the American Public Transportation Association (APTA) reported that overall ridership has recovered to 79 percent of pre-pandemic levels in April 2024. A widespread upgrade of the passenger experience could lead not only to a return of pre-COVID levels, but also a sustained period of growth as customers recognise the advantages of commuting and travelling by train.

This growth will only be possible if rail operators focus on delivering a modern, future-proof, customerfriendly experience. To succeed, these companies need to embrace the ‘digital train – building off a single, centralised connectivity system to integrate everything from passenger Wi-Fi to video surveillance to energy metering to passenger counting.

10

Addressing the Digital Train Need

The digital train is crucial for two main reasons: interoperability and affordability.

Interoperability: A modern train includes a dozen or more onboard systems: GPS, on-train data recorders, real-time passenger information and other dedicated solutions for security and operations. Historically, these many tools have been installed and operated as standalone systems, each with its own source of power and connectivity. Each of these individual systems increased the overall complexity of operating and maintaining the vehicle, while also taking up more physical space in the train itself.

The lack of interoperability of these onboard systems limits the rail operator’s ability to introduce new passenger services. For example, if the passenger counting system operates on the same network as the passenger information system, the rail operator can quickly and seamlessly display which cars are full and which are empty, allowing passengers to move towards the empty cabins for a more comfortable experience. When those two systems are walled off from each other, even this basic service is impossible to implement.

Affordability: Rail operators – and the rail industry in general – can no longer afford to look at these systems in isolation. Instead, every system upgrade or replacement should be looked at in the context of the train as a whole.

There are two paths for rail operators to adopt the digital train strategy successfully. As companies consider how to upgrade their vehicles, they must choose between 1) upgrading their systems all at once with a comprehensive solution or 2) taking a stepby-step approach with each individual improvement. While some European and UK rail operators have achieved success with wholesale overhauls of their vehicles, a step-by-step strategy will be more realistic for most rail operators.

Rethinking Strategy for a Digital Train

The digital train strategy starts and ends with rethinking relationships and mindset.

Rethinking relationships: Working towards a digital train strategy requires rail operators to rethink their relationship to their equipment. Previously, equipment was often sold as ‘fit and forget’ – systems that could be installed and operated with minimal ongoing oversight and maintenance. The next generation of onboard technologies will require more expertise and management.

11

Changing the mindset: Passengers will naturally be critical when systems don’t work as they should – bad Wi-Fi and inaccurate passenger information are common complaints among rail travellers. Rail operators need to take a long-term view of their digital train initiatives and recognise that the shortterm growing pains will allow them to deliver a more comfortable and more innovative passenger experience in the future.

Bringing IT internal: As rail companies upgrade their vehicles, they will need to bring on new personnel to manage the health and reliability of the system. Transportation companies must become technology companies to some extent to remain viable in the long-term; as a result, they’ll need to hire IT experts. While some rail operators may be hesitant to take on the added expense, they will see a trade-off in reducing the maintenance costs associated with isolated, fragmented systems. Instead of having to install, maintain and replace multiple connectivity platforms, they will only need to look after one comprehensive system.

Monitoring cyber security: Rail operators have legal obligations to protect passenger data. They must conduct extensive penetration testing to ensure that systems stay compliant with regulations. But while the overall need for cybersecurity increases as a result of the digital train strategy, it’s important to note that the overall risk does not increase when systems are combined on one connectivity platform. A combined connectivity platform allows for central monitoring to ensure resistance to cyber attacks. Networks can also be segmented, isolating any penetration to a single area, significantly reducing the overall exposure and risk.

Long-Term Implications of a Digital Train Strategy

Decisions made when upgrading transit vehicles will have long-term implications.

As rail operators use federal funding to upgrade their vehicles, the choices they make will have longterm implications both for their passengers and for the organisations themselves. Adopting a single connectivity solution keeps the door open in the

“This is a make-or-break moment for rail travel in the US. While the COVID-19 pandemic led to a sudden drop in ridership for rail operators, the American Public Transportation Association (APTA) reported that overall ridership has recovered to 79 percent of pre-pandemic levels in April 2024.”

Martin Shaw, Head of On-Train Digitalisation for Icomera

future to integrate modern technologies and continue upgrading the passenger experience. Maintaining siloed systems keeps the rail operator frozen in place, unable to keep pace with modernisation.

When passenger rail operators deliver a truly modern customer experience, they can compete with private vehicle travel and steadily increase ridership: instead of being stuck behind the wheel of a car, passengers can stay connected, productive and entertained over the course of their journey.

This customer experience is only achievable with exceptional connectivity – the digital train is an essential strategy for the rail industry’s long-term stability and growth.

The next few years will determine the overall trajectory of rail travel in the United States. Rail operators have an excellent opportunity to increase ridership and demonstrate why passenger travel is an appealing alternative to car travel. We can not afford to miss the opportunity by holding on too long to legacy technologies.

For more information visit www.icomera.com alternatively if you have any questions email martin.shaw@icomera.com.

12

29 55 17 14

Directory

Rolling Stock p.29 Data & Monitoring p.55 Track & Infrastructure p.17 Works Vehicles & Machines p.20 Worksite Protection p.23 Maintenance & Equipment p.26 Train Interiors p.30 Components & Materials p.35 Manufacturing & Maintenance Equipment p.44 Testing & Measuring Equipment p.47 Cleaning & Decontamination p.52 Planning & Management Software p.56 Communications Technology p.58 Computers & Sensors p.62 Revenue Management &Ticketing p.68 Signalling & Train Control p.71 Condition Monitoring p.74 15

Geocomposites: Solving the track stabilisation headache

A one hour overview of the use of geocomposites as a solution to trackbed maintenance problems that includes:

n Why use geosynthetics and geocomposites?

n Cost, time and sustainability benefits

n Installation and best practice

n Product development and testing

n Counts toward PDH and CPD requirements

Contact GEOfabrics for more information or to schedule a session, remotely or in person at info@tracktex.us

www.geofabrics.com tracktex.us/services/professional-development-hour

The experts in rail geosynthetics Free professional development seminars

Track & Infrastructure

KfW IPEX-Bank p.18

Work Vehicles & Machines

Laser Tribology B.V. (LPS) p.20

Worksite Protection

DSRailTech a.s. p.23

Maintenance & Equipment

GEOfabrics p.26

Directory

17

Going Green – How Banks Are Supporting Environmentally Sustainable Projects with Green Loans

Greenloans can help rail organisations get closer to achieving their sustainability goals.

Businesses are prioritising climate neutrality and environmental sustainability more than ever before. Today, stories of the climate crisis make national headlines, and with new record-breaking temperatures reported every month, the world is focused on climate action.

An international goal, known as the Paris Agreement, aims to keep the increase of the average global temperature below 2°C, and also to pursue efforts to keep this rise as close as possible to 1.5°C.

This is no simple task. However, the rail industry has an important role to play in getting us closer to this objective by providing greener transport solutions.

As it currently stands, rail travel is already less polluting than travel by road, but new lower emission and carbon-neutral technologies such as battery electric and hydrogen-powered trains are helping to reduce the sector’s greenhouse gas (GHG) emissions even further.

Opening the Doors to New Financing Opportunities

Across the rail industry we’re seeing a growing number of businesses focus on increased environmental sustainability, which is also opening up new doors to raising finance.

By integrating green finance frameworks into their overall sustainability strategies, businesses are committing to investing in environmentally friendly projects. In order to make this commitment in a credible manner, they often use the widely recognised

Directory Track & Infrastructure

18

© Torkel Dalan / Bane NOR

green loan principles (GLP) of the Loan Market Association (LMA) or green bond principles (GBP) of the International Capital Market Association (ICMA) as the foundation of their frameworks, as complying with these ensures their ability to access green loan opportunities.

This is an example of the banking industry’s commitment to decarbonisation, as green loans were created to finance projects that support the transformation towards a net zero society.

“We’re keen to support our customers doing business in this area,and the green loan principles ensure that projects will truly have a positive environmental impact,” says Sylvia Sedlacek, Director of Mobility and Transport at KfW IPEX-Bank.

As a bank that stands for transformation, KfW IPEXBank finances technologies of the future to support the transition towards a more sustainable society. By implementing ambitious sector guidelines for CO2-intensive sectors, it’s ensuring its financings are compatible with the Paris Agreement goals.

Supporting Green Rail Initiatives in Norway

Scandinavia is a leader in environmental sustainability, particularly in the rail sector. Here we’ve seen the roll out of new night train services powered entirely by green energy from hydro, wind and solar sources, as well as plans for a new Stockholm-Oslo rail connection. These are just two examples of projects in the region designed to promote sustainable public transport options and lower reliance on air travel.

This is why KfW IPEX-Bank was pleased to announce that in late 2023 it signed a green loan with Bane NOR Eiendom valued at approximately NOK 1,140 million (EUR 100 million). This will be used to invest in green projects such as supportive railway infrastructure and service facilities, which can be maintenance depots, trains storage and depot facilities.

The Norwegian state-owned company, which is in charge of the development and management of the country’s supporting rail infrastructure, launched its green finance framework in 2021. This was awarded the Center for International Climate Research (CICERO)

rating Medium Green in 2020. And just recently, in March 2024, it was rated Dark Green by Second Party Opinion Providers S&P Global.

Bane NOR’s overarching goal as a company is to support the Norwegian railway and create attractive transportation hubs. By increasing the efficiency and appeal of rail travel, it aims to encourage people to choose public rail over the use of their own vehicles.

With this financing, KfW IPEX-Bank is supporting a catalyst for environmentally sustainable public transportation.The extension and refurbishment of maintenance workshops will enable maintenance services for the longer passenger trainsets (over 200 metres in length) that will be required to meet the higher demand expected for public rail in the future, as well as increasing the overall efficiency of the maintenance cycle.

Financing Green Rail Projects

KfW IPEX-Bank is experienced in arranging financing for green rail infrastructure projects, as well as the acquisition of rolling stock that uses alternative power sources. This includes innovative and attractive bilateral or large-scale financing structures for among others locomotives, railcars, passenger trains, trams, metros as well as the construction of railway tracks, maintenance depots, station and signalling. By introducing GHG accounting, KfW IPEX-Bank aims to achieve a net zero emissions portfolio by 2050.

Visit our website Follow us on LinkedIn

For further information on how KfW IPEX-Bank can finance your green investments, or for support for developing a green finance framework, please contact:

Sylvia Sedlacek Director of Mobility

and Transport Frankfurt am Main, Germany (Headquarters)

sylvia.sedlacek@kfw.de

Track & Infrastructure 19

Elevating Rail Maintenance: Tackle Autumn Challenges with LaserTrain

The persistent challenge of slippage on the line has far-reaching implications for the industry. As passing trains crush fallen leaves, they become a teflon like substance with an oily residue that diminishes the coefficient of friction (COF) of the railhead and can compromise rail safety. This leads to difficulties accelerating and braking, resulting in hazardous conditions and inevitable delays.

Developed by LPS, LaserTrain introduces an effective solution for rail maintenance. Its high-intensity lasers clean various contaminants such as leaves, oil, debris and rust from the railhead without compromising track integrity, while its advanced control system enables autonomous operation for optimal results. By enhancing de-acceleration distances and improving rail traction, LaserTrain minimises accidents, prevents slip incidents and ensures safer railway operations for passengers and rail staff alike.

Operational Efficiency and Flexibility

LaserTrain offers faster and more efficient railhead decontamination compared to traditional methods, covering larger areas in less time and eliminating the need for refuelling and complex logistics associated with water-filling stations. This dramatically reduces downtime and minimises disruptions to network operations. Demonstrating exceptional performance with MTA Metro North Railroad, one LaserTrain cleaned

435 miles per day, cleaning over 55% of the network every 24 hours.

Additionally, LaserTrain's remote operations boost efficiency and safety by removing the need for workers to be near the tracks or equipment, alleviating the burden of staff planning during the slip-slide season. A selection of cleaning speeds offers operators the flexibility to adapt to individual cleaning needs. The LaserTrain can be leased or purchased with cleaning speeds of 20mph, 40mph, and 60mph.

Cost-Effectiveness

LaserTrain's higher initial investment is offset by its substantially lower running costs. LaserTrain's ability to achieve comparable cleaning performance to traditional methods like water jet, with far fewer units offers significant reductions in operational expenses over time. Since the majority of LaserTrain costs are upfront fixed expenses, the total cost per distance decreases as more distance is cleaned.

Another benefit is that it helps reduce wheel wear and prevent wheel blocks, thereby prolonging rail wheel longevity and decreasing maintenance expenses. For example, during Metro North's 2022 pilot, LaserTrain delivered savings of $1.6 million, while the Long Island Rail Road in 2020 confirmed its role in reducing wheel truing. This reduction translated to an estimated annual saving of $500,000 in shop labour and material costs. The extended lifespan of the rail due to reduced wear is still to be assessed.

Directory Track & Infrastructure

20

Plug and Play: The Freight Model Advantage

The Freight Model of LaserTrain offers several advantages over bespoke models. Its pre-set design is simpler and more standardised, reducing engineering, build and test time and and providing ensured regulatory compliance. Designed to fit a Y25 bogey or R141 truck without modifications, the 20ft half-height container ensures compatibility with UK, EU and US loading gauges.

The pre-existing design and standardised components streamline production, installation and maintenance processes, resulting in shorter lead times, higher uptimes, reduced costs and easy spare parts management. The Freight Model is constructed and tested in the Amsterdam workshop by LPS staff before installation, minimising any risk of oversights or surprises.

Transportation, Installation and Maintenance

Transporting and installing the Freight Model is effortless, facilitated by a flatbed lorry and a forklift. Installation and de-installation times are significantly reduced, dropping from three weeks to just two days, with no need for scaffolding or LPS staff for completion. Maintenance is equally straightforward, accessible components, ensuring cost savings and shorter lead times.

Operations and Performance

Designed to achieve 200,000 kilometres per year versus 50,000 kilometres per year, the Freight model ensures better longevity and reliability. It requires only one hour of maintenance per week compared to one hour per shift, minimising downtime and operational disruptions. Additionally, it can operate with or without a separate generator, reducing costs and boosting operational flexibility.

In conclusion, LaserTrain's Freight Model delivers superior performance, lower maintenance,

enhanced operational flexibility and cost-effectiveness compared to traditional rail cleaning methods and bespoke options, making it a top choice for rail maintenance. Streamlined installation, maintenance and spare parts management further reduce overall costs and maximise return on investment.

Embrace LaserTrain and drive innovation in your rail cleaning operations today.

Get in Touch

Click here to contact LPS or email info@lasertribology.com to speak to the team

Works Vehicles & Machines

21

M I N I M I S E D I S R U P T I O N S , M A X I M I S E E F F I C I E N C Y . Trust LaserTrain for safer, more efficient operations and keep performance, maintenance and safety on track. laserprecisionsolutions.com

Track & Infrastructure

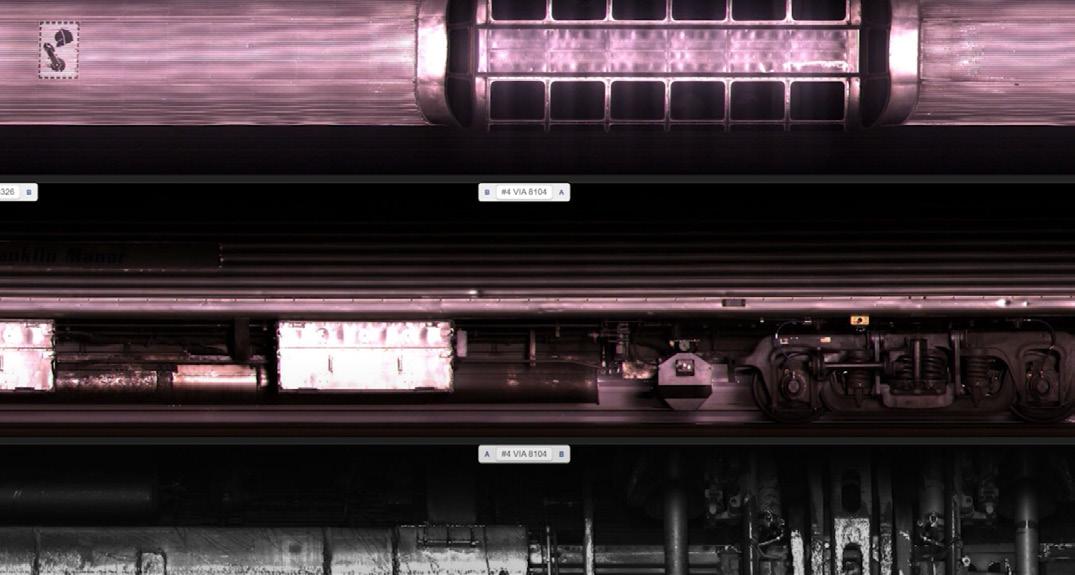

• Innovative railway company located in Czech Republic with operations since 2015

• Specialises in delivering diagnostics and safety systems to the railway industry with a huge scalability potential and innovative factor

• DSRT solutions bring more accurate results compared to existing solutions together with a broader range of metrics and rail coverage with a single system

About DSRailTech

• Our mission is to improve safety in the railways to protect lives and save costs

• DSRailTech is a mid-sized company with highly skilled and experienced professionals specialising in delivering diagnostics and safety systems to the railway industry

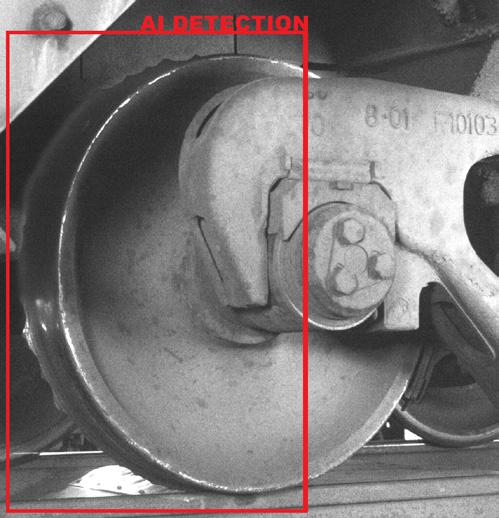

Our Solutions – Railways

• Disruptive deep-tech safety and diagnostics system helping railway operators and infrastructure owners to monitor train movements and detect precursors present or developing in the tracks and on rolling stock, thus increasing railway safety

• Detecting anomalies by analysing the vibrations propagated in the rail over longer distances

• Providing critical information to operators

• Integration with ERTMS and other systems

• DSRT solutions are able to detect accident precursors in advance and in very early stages, monitor their development and severity over time, thus playing a crucial role in preventing accidents from happening

DSRailTech Applications

• Rail occupancy monitoring

• Rolling stock monitoring

• Axle derailment monitoring

• Rail defect monitoring

• Track obstruction monitoring

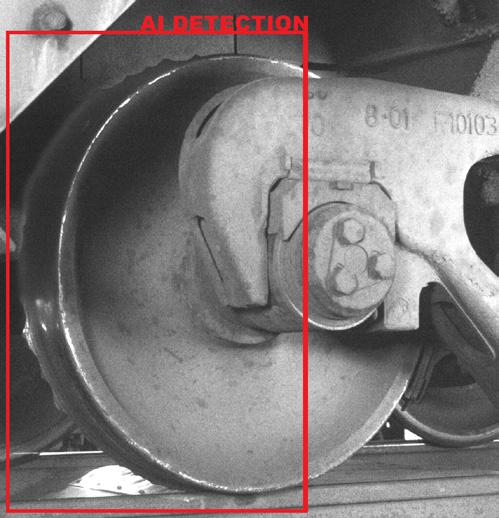

• Flat wheel detection

• Intrusion detection application

• Switch condition monitoring application (dynamic effects)

• Portable warning system

• Rail buckling monitoring

• Hot box detection

• Hot wheel detection

New Applications Launching in 2025

Our R&D department is constantly working on the improvement and innovation of our solutions.

Rolling Stock Weighing

• Rolling stock weighing application measures the load on every wheel of any rolling stock, regardless of speed, informing the operators of any deviations from their set default values

Flood Detection

• Detects the presence of water and generates alarms whenever the water reaches dangerous levels

• Informs when the water retracts (sensors are not submerged anymore)

• Detects whether the water is flowing or still

• Detects solid materials in the water

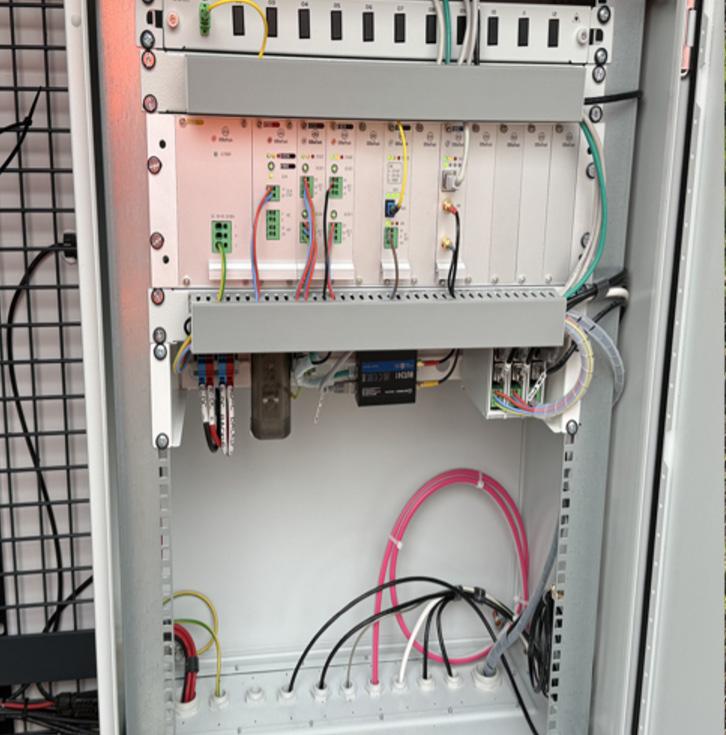

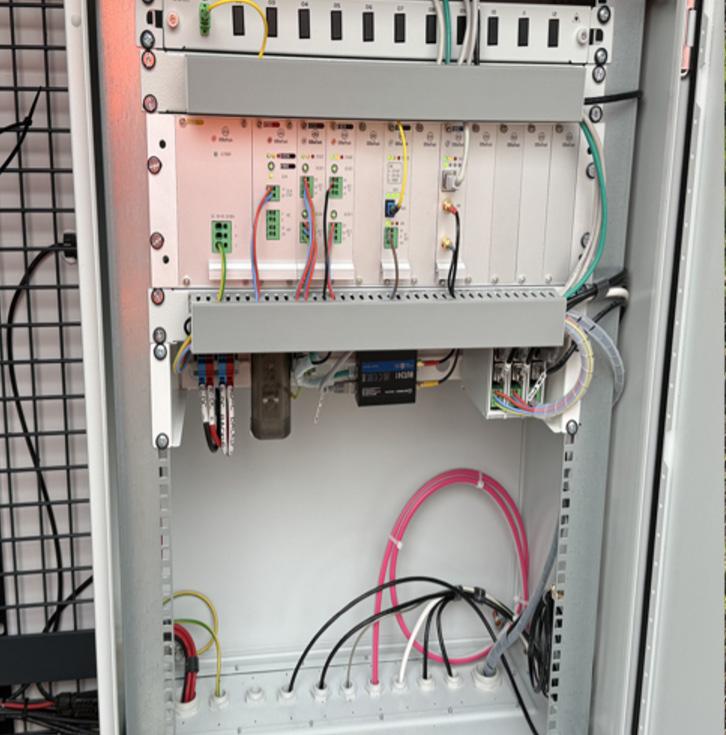

DSRailTech Diagnostic System - DMP Platform

The DMP platform is composed of outdoor components and components which are housed inside an enclosure.

Directory

Worksite Protection 23

The outdoor components are:

• DXMD – sensing element of the platform. It is responsible for detecting vibrations both from afar, and locally on top of the DXMD

• DXIR – IR detector for hot box, hot wheel and hot brakes detection

• DACT – vibration generating element of the platform used for rail defect and rail buckling monitoring

• UNEX – responsible for grounding and protecting signal and power lines against electrical surges

The rest of the components are either inside the DMP Rack, the main processing unit of the platform, or in a cabinet/enclosure together with the DMP Rack.

The DMP Rack can be housed in a SolarXBox provided by DSRailTech where the complete solution is powered solely by solar energy.

Installation

• Installation of DXMD, DXIR and DACT is quick, does not require interruption of traffic on the track and can be done by a single person

Portable Warning System – PWS

• The PWS (portable warning system) enables maintenance work to be carried out without restricting track operation and at the same time without endangering the health of the workers. The PWS is easy to operate without the need for lengthy training, is compact and portable, reliable and most importantly helps prevent serious injuries to people during railway maintenance.

• The PWS is housed in a briefcase which can be easily transferred to a maintenance site. After attaching the sensors under the head of the rail

Installation of external cabinet, DMP Rack located in SolarXBox

Installation of external cabinet, DMP Rack located in SolarXBox

24

Installation of DXMD and DACT

using integrated magnets, the device is ready to detect the approaching train and report this fact to the two-way radio transmitter.

• The system can be connected to two-way radio transmitters from various manufacturers and can operate in PTT (push-to-talk) or VOX mode. The reports are available in several languages, including English, German and Spanish, and contain track identification and the state of the device. The reports are repeated until the danger passes. It is also possible to connect a beacon and a siren to the system wirelessly.

• It is possible to connect eight PWS briefcases together to form one system using cellular network and/or LoRa.

• RALM wireless visual and audio alarms can also be connected to the PWS briefcase. These alarms have a built-in beacon and siren. Up to 16 RALM alarms can be connected to a group of PWS briefcases.

Advantages of Our Solutions

• More reliable broader range of metrics than other systems on the market over further rail distances

• Significant reduction of procurement, installation and maintenance costs

• One system can cover up to 4 tracks using a single DSRT Rack

• Up to 3 applications can run on one system depending on the combination of the applications and the number of covered tracks

• Installation time is within hours, based on the number of covered tracks, and does not require

service interruption on the rail track

• The systems are self-learning which ensures high autonomy and extended categorisation of events

• The systems are modular with self-diagnostic capabilities which decrease the time needed for maintenance and service works to a minimum

• Web-based portal where our clients have a realtime overview about their installations

Unique and Innovative Approach to Acoustic Sensing

• The term ‘acoustics’ is usually associated with sound as perceived by a human; however, acoustics extends to the study of mechanical waves, not necessarily perceived by humans

• DSRailTech solutions are based on this extended expertise in acoustics and other dynamic measurements (such as temperature, displacement and acceleration)

• The sensors (DXMD) are finely tuned, and precisely positioned on the rail to acquire even the smallest vibrations travelling through the rails, as well as huge vibrations induced by a passing train

• By implementing these principles, we achieve that our sensors are the most sensitive, cover the spectral density which is the richest in relevant information and thus significantly increasing the reliability and reducing false positive alarms

• At the same time, by building the evaluation algorithms on deep and machine learning, we provide extended categorisation of events

Our Certifications

• Our company has successfully implemented and is certified in accordance with the internationally recognized ISO 9001, ISO 14001 and ISO 27001 standards

• We are currently preparing for SIL certification and the ISO 45001 (OH&S) certification

Our Ambition

To become one of the leading innovative companies in safety and diagnostics systems in the railway industry adopted across the world.

www.dsrailtech.com

25

PWS portable warning system

Solving Trackbed Maintenance Problems with Geocomposites

There are many problematic ground conditions that exist beneath railway tracks. As a result, track stabilisation, track geometry and trackbed maintenance are major headaches for the rail industry, worldwide.

It’s true that a range of solutions have evolved over the years – but many come with cost, time and environmental implications, which are far from ideal.

The Issue

The passage of trains applies dynamic loads to soil beneath the tracks. This results in intense compression

and decompression cycles, which can lead to fracturing of the foundations – to the point of collapse. Some of the most widely used methods for solving track stabilisation on railroads involve geocomposites. TrackTex, for example, is used in place of sand blankets to prevent mud pumping.

While sand blankets are successful in curing subgrade erosion, achieving the optimum 300mm layer requires a large volume of excavation. This in itself is expensive and incurs further costs for soil disposal. There’s a requirement for extensive materials to complete the work and the disruption to services causes loss of revenue, too. So, while sand blanketing is still used today, it’s an expensive, slow and unsustainable process.

Directory Track & Infrastructure

26

Geosynthetics: A Solution with a Proven Track Record

Geosynthetics have been used for a number of functions in track construction and rehabilitation for almost half a century. When properly specified and installed, they have been proven to significantly enhance the performance of the trackbed, reducing maintenance costs and increasing design lifetime.

Combined in multiple layers, or with the addition of another material, geosynthetics are known as geocomposites. These products provide enhanced benefits, as they reduce required material volumes and speed up installation. With careful design they can provide drainage, protection, reinforcement, filtration and barrier functions while replacing expensive and scarce mineral resources.

GEOfabrics – Experts in Geocomposites for the Rail Industry

GEOfabrics has developed a range of class-leading geosynthetics and composites, specifically geared up to tackling the issues faced by rail operators. These include TrackTex for anti-pumping and RK4 for rail filtration and confinement. Products are performancetested at their state-of-the-art facility which includes a UKAS-accredited laboratory, as well as independently by external bodies.

For example, the TrackTex testing regime included realtime rail loading, simultaneously and cyclically applied to the replicated track construction through three hydraulically powered ram actuators. The rams were programmed to load the installed track dynamically to

simulate anything from an empty passenger train to a fully loaded freight train, or an ultra-high-speed train of the future. Trafficking frequencies were modelled, too. GEOfabrics materials have been used in live rail for many years. So whichever solution a customer opts for, they can feel reassured that it’s been tried and tested by experts.

Free Education Seminars for Businesses

Rail companies across the globe can benefit from GEOfabrics’ expertise in this field through the continuing professional development (CPD) sessions they offer. Delivered by GEOfabrics rail specialists, seminars give businesses greater insight into the use of geocomposites – and how they can solve the challenges they face.

These free-of-charge professional development hours (PDH) are designed to give companies a good understanding of how and where geocomposites provide the most effective performance. Training is usually in person at an organisation’s premises but can also be delivered remotely as a webinar. Sessions can be tailored to meet the training needs of those involved in trackbed maintenance, across all levels of experience. Attendees will gain a good understanding of how to specify and use geocomposites to treat trackbed issues. All workshops are certified by GEOfabrics and count towards professional development hours requirements.

Jim Herbert, Commercial Director at GEOfabrics explains, “Our Technical Sales Team have many examples of clients who use our geosynthetics in their rail schemes reporting reduced costs,faster installation and dramatically extended maintenance cycle times. We offer these training sessions to help clients understand how they can enjoy these benefits on their future projects.”

Contact GEOfabrics for more information or to schedule a session, remotely or in person

Europe, Asia & Africa

Jim Herbert jherbert@geofabrics.com +44 7773 334 742

Frank Pace fpace@geofabrics.com +1 816-305-3160

USA & Canada

Maintenance

Equipment 27

&

Find out how Railway-News is able to help generate as much footfall and interest in your stand as possible with the following: Targeted Marketing Digital Newsletter LinkedIn Campaigns Easy Search InnoTrans 2024 Digital Newsletter Click here to get in touch and find out more Railway-News is going to InnoTrans!

Rolling Stock

Train Interiors

Kiel Americas p.30

Artex p.32

Components & Materials

FreiLacke p.35

HellermannTyton p.38

FinnProfiles p.40

Roxtec International AB p.42

Manufacturing & Maintenance Equipment

Columbus McKinnon p.44

Testing & Measuring Equipment

Evident/Olympus p.47

HEXAGON p.50

Cleaning & Decontamination

Roediger Vacuum GmbH p.52

Directory

29

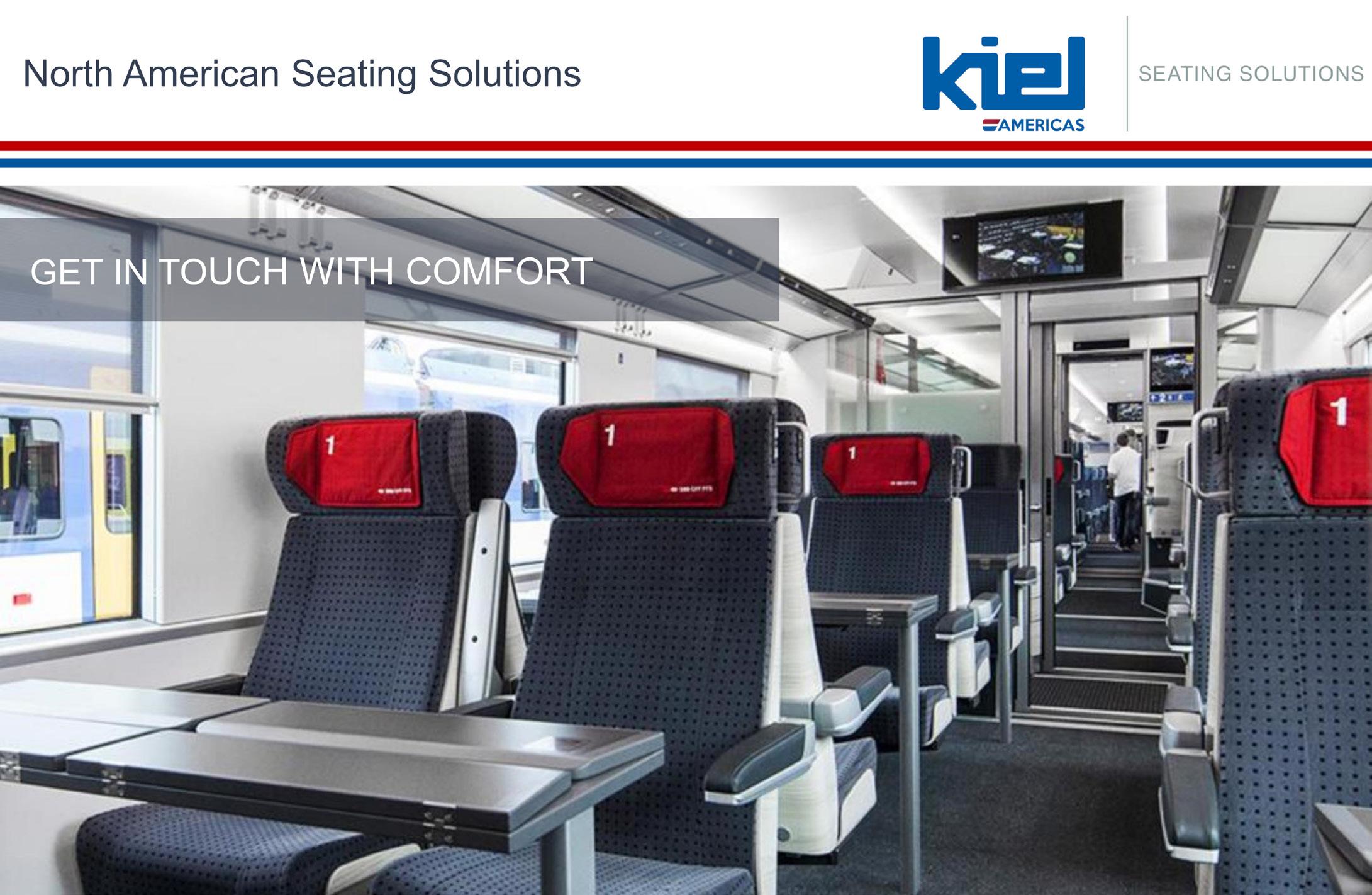

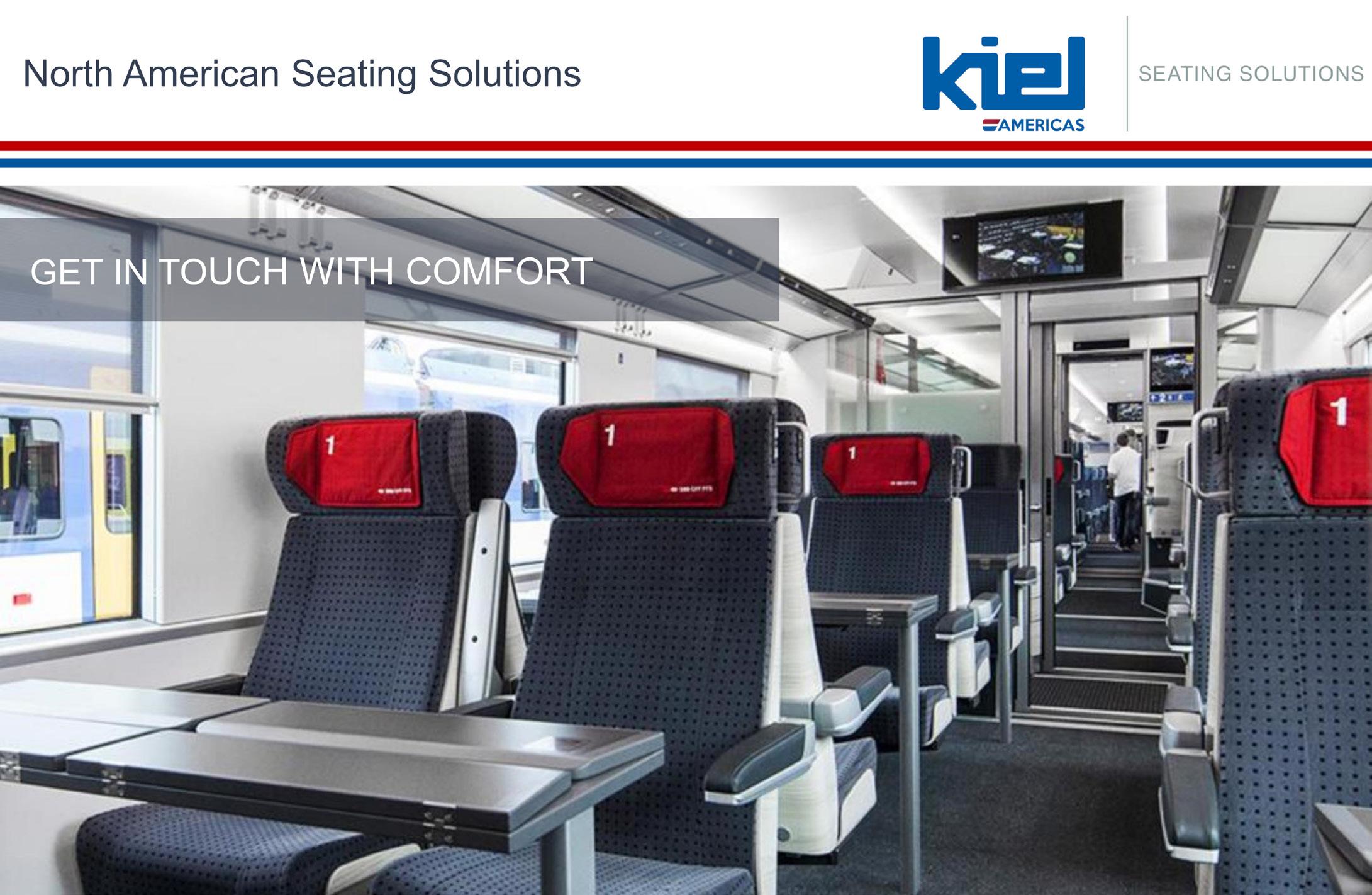

Kiel Americas

Seating Solutions for Mass Transit

Kiel Americas, as a part of the Kiel Group, has been providing seating solutions for the North American mass transportation industry since 2009.

Kiel Americas employs approximately 150 employees and has full R&D and manufacturing capabilities at its facility located in Bellwood, Illinois. However, we are also part of a global network, with additional production facilities and technical resources in Germany, Poland, Turkey and Macedonia.

Kiel Americas offers a wide range of passenger rail seating systems for local, regional and intercity transport. In the best Kiel tradition, all our seats combine quality, individuality, cost-effectiveness and safety with innovative ideas and attractive, lightweight designs. With a commitment to ergonomic design, durability and space optimisation, we’re not just seating passengers; we're elevating their experience.

With safety always at the forefront of our designs, Kiel engineers have experience working and conducting crash testing in many different countries. Because they

Directory Rolling Stock

30

incorporate standards from a variety of safety boards around the world, Kiel passenger seats have achieved high quality standards.

Kiel Americas utilises modular, recyclable construction systems, aiming to conserve resources and provide as many environmentally friendly options as possible. Most importantly, a Kiel seat can be renovated after 10 years of use by simply replacing the fabric and foam.

When it comes to designing and producing the optimal seat for a given application, Kiel Americas stands behind the slogan ‘It’s up to you’. At the end of the day, it is a question of what a specific country or a specific customer wants. For instance, this can mean a steel structure with steel components, or a composite material base. It is not only the travellers who have specific requirements for seating: Kiel’s customers – the manufacturers of passenger intercity rail cars, commuter rail vehicles and light rail vehicles – expect seats that are increasingly economical, robust and lightweight. Furthermore, Kiel’s customers expect seating that covers all eventualities, from basic to luxury features, depending on the intended purpose. Simply put, it’s up to you.®

To find out more about Kiel Americas visit www.kiel-seating.com, email rkomm@kielamericas.com or call +1 (0) 708 547 – 7000 Train Interiors

Artex Group - Specialist in Seats and Interior Components

Artex designs, redesigns, refurbishes and upgrades seats and other interior components for trains, aeroplanes, trucks and public spaces. With a presence in Sweden, Latvia and now also in Denmark and Finland, Artex employs approximately 500 people.

Artex Expands through Acquisition in Denmark and Initiates Its Own Foam Production in Finland

Artex, a leader in large-scale textile projects for public spaces, public transportation and the automotive industry, is enhancing its offerings in the transportation

sector with the acquisition of the Danish company JP Train, formerly part of JP Group.

JP Train specialises in the disassembly, renovation and assembly of train interiors, and their logistical expertise will now be integrated into the entire Artex group as Artex Denmark.

In the transportation sector, Artex has successfully provided services such as the refurbishment of train seats, involving the reuse of load-bearing structures in steel, aluminium, or plastic, resulting in significant energy savings compared to replacing them with new seats.

The acquisition of JP Train aims to broaden Artex’s expertise and strengthen its market presence in

Directory Rolling

Stock

32

Refurbished seats for the Stockholm metro

Denmark. JP Train is well-known for its expertise in the disassembly and assembly of interiors in public transportation. This competence will now be an integral part of the Artex group, providing a more comprehensive customer offering.

Artex operates in various business areas, primarily focusing on textile projects for public spaces, public transportation, and the automotive industry.

Björn Samenius, Chief Marketing Officer, explains that this decision is based on Artex’s ambition to be a comprehensive supplier throughout Scandinavia.

Artex Group Strengthening Customer Benefits

The establishment in Finland, with a management and production team that has over 20 years of experience in our field of textiles and foam, means that we are now creating a platform for expansion both geographically and into new business areas. This benefits customers within the Artex group as we can now control and oversee the foam manufacturing process in our projects.

“Refurbishment at Artex implies that the supporting structures in steel, aluminium or plastic are re-used,providing great energy savings.The seats are reupholstered to the latest standards with great freedom of choice regarding customisation,”

Björn Samenius, Artex Group CMO

“We can respond more quickly to our customers’needs and improve delivery reliability,” Björn says.

Refurbishment of train seats is a sustainable choice compared to discarding old seats and buying new ones – Artex is repurposing the waste material from the old seats, such as foam and fabrics, for other products, e.g. sound absorbers and room dividers. Recirculating the material reduces the need for virgin materials and, therefore, the amount of CO2 emissions created in producing new materials.

Environmental and Financial Benefits

Artex offers mid-term refurbishment of train seats, typically taking place after 15 years of service. A new

Train Interiors 33

New material made out of old train seats

seat generates about 205kg of CO2e compared to a refurbished seat that generates about 31kg of CO2e. The savings are multiplied by the number of seats on each train, usually around 10,000 but sometimes up to 100,000. In addition, the climate is half the price compared to buying new seats.

“Refurbishment at Artex implies that the supporting structures in steel,aluminium or plastic are reused,providing great energy savings.The seats are reupholstered to the latest standards with great freedom of choice regarding customisation,” says Björn Samenius, CMO.

Recirculation Creates Value from Waste

To further reduce CO2e, Artex enables the reuse of old foam and fabric for new purposes in other industries. There is approx. 5kg of waste foam and fabric from each refurbished train seat. Artex refurbishes more than 15,000 seats, adding up to more than 75 tonnes of waste material annually.

“Through the help of external experts,we have been able to develop a method to recirculate waste material such that 75 tonnes of waste has been turned into valuable products by others,” says Björn.

The waste material is tested for chemicals, processed into grains and, in some cases, pressed into blocks in preparation for other industries that further refine the recycled material for their products.

“This process reduces the footprint of a refurbished train seat to around 10kg of CO2e,to be set against the 205kg of CO2e of a new seat.The savings in a train with 20,000 seats will be about 4,000 tonnes of CO2e, which corresponds to about 1,000 petrol cars that are driven for a year,” Björn concludes.

Meet Artex at InnoTrans, Berlin, 24–27 September 2024

You’ll find Artex in Hall 5.1/Stand 150. Set up an appointment in advance through info@artex.se or visit artex.se

34

Foaming machine and ABB robot in Artex Finland

System coating solutions for rail vehicles

Certified solutions of the highest quality.

FreiLacke has stood for innovative paints and coatings since 1926. The family-owned company has already entered its third generation and develops customised solutions for clients from the wheel and vehicle manufacturing industries, as well as those in the fields of mechanical and apparatus engineering, job coating, functional furniture, rail vehicles, wind power, storage technology, construction and sanitation, directly through its 600 employees at its Döggingen base in the Black Forest.

As a modern family-run company now in its third generation, the safeguarding of the head office is just as important as our worldwide sales and our international subsidiaries and partners.

The product range of Europe’s leading system coating provider covers the entire spectrum from industrial coatings, powder coatings and electrodeposition coatings to composite solutions.

International sales are handled by a global network of subsidiaries and partners around the world.

Environmental protection has always been a key priority for FreiLacke. Therefore, the company makes every effort to develop environmentally friendly products, reduce emissions, packaging materials and waste and use resources sparingly.

Applied solutions. www.freilacke.com Our solutions at a glance (video). Our solutions at a glance (brochure).

Applied solutions. www.freilacke.com

Composites

Powder Coatings

Liquid Coatings

E-Coats

HellermannTyton

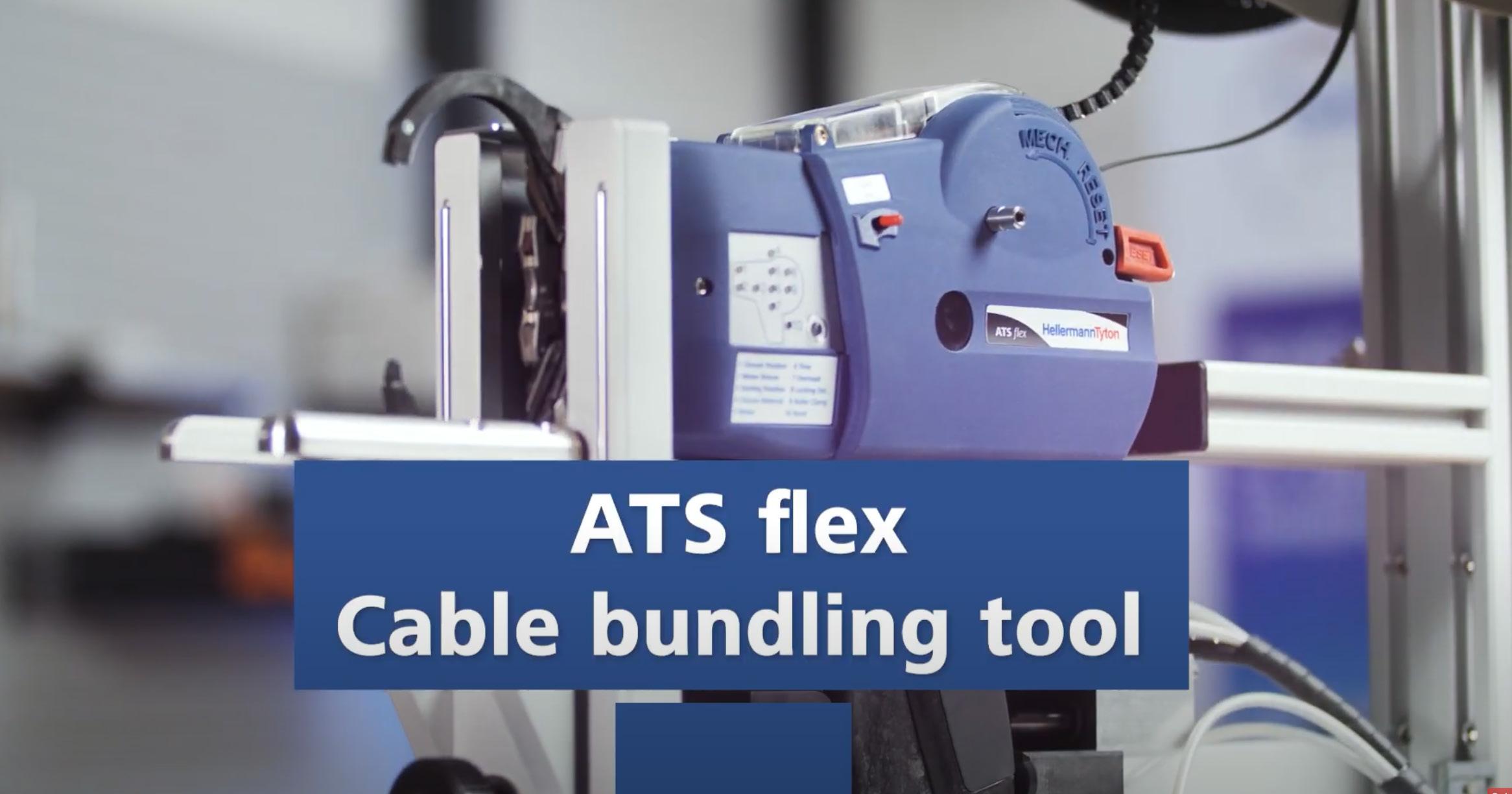

How to Bundle Rail Vehicle Cables in Record Time and without Wasting Material

The millions of cable ties used every year in the manufacture of rail vehicles is a testament to their indispensable role.

But when you consider that it takes more than 10 seconds to apply a cable tie by hand, this is a significant amount of time for what is essentially a straightforward process. This begs the question: Is there a more efficient method for large-scale industrial use? Read on to discover a remarkably fast solution that can revolutionise this aspect of rail vehicle wire harness production.

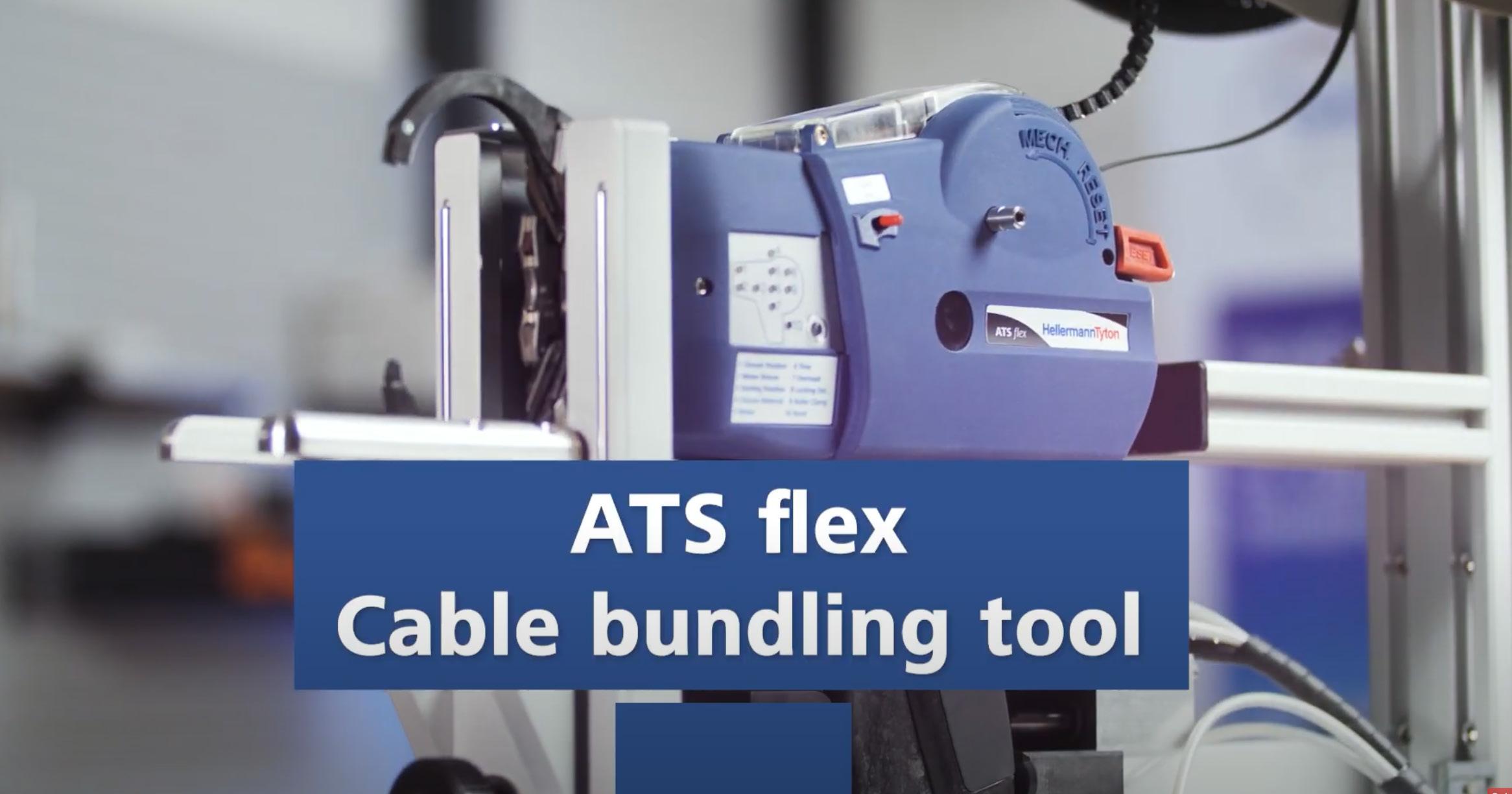

HellermannTyton’s ATS Flex bundling system is a real game-changer in mass processing of cable ties in wire harness production. Not only does it repeatedly complete a bundling cycle in a mere second, it also ensures consistent tying force and eliminates the risk of sharp edges that could potentially injure workers or damage wire insulation during assembly.

Looping, Threading, Tensioning and Cutting at the Touch of a Button

The ATS flex distinguishes itself through its operational simplicity – looping, threading, tensioning and cutting are all executed at the touch of a button. Unlike a conventional cable tie, the ATS strap and locking head are fed separately from two different dispenser reels. This innovative approach allows the tool to automatically feed the strap through the locking head and cut it precisely, ensuring no material wastage.

A key feature of the tool system is its mechanical diameter detection, which is critical to maintaining a

Overhead suspension kit

secure fastener in the vibration-intensive environment of rail vehicles. The correct jaw size and speed are automatically determined during the set-up phase. The system is supplied with jaws in three different sizes: 30mm, 50mm and 80mm. These help to optimise the cycle times for different bundle diameters. A 100mm jaw is available separately for larger bundles.

The strap and locking heads are made from PA6V0, which is certified to the EN 45545-2 European railway standard for fire safety. The outside serration of the tie strap is particularly suitable for minimising the risk of damage in applications involving sensitive cable insulation.

Directory Rolling

Stock

The ATS Flex with three different jaw sizes

38

Reducing the Cost of Material Waste

A major benefit of the ATS Flex system is its ability to drastically reduce material waste, in line with the wider environmental objectives of the rail industry. While trains are inherently environmentally friendly once in service, manufacturers still face challenges in minimising the use of resources during production. The ATS Flex addresses this by precisely optimising the length of the tie strap for each bundle, effectively eliminating the need for post-application material removal and the associated waste management processes.

This not only translates to significant savings in material costs, but also in the time and resources spent on waste collection, storage and recycling. By way of illustration, using the ATS Flex system can save approximately 100kg of strap waste compared to the use of 150,000 conventional cable ties, highlighting both the environmental and economic advantages for rail vehicle manufacturers.

Benefiting from Speed and Versatility

The versatility and speed of the ATS Flex make it an exemplary solution for high-volume industrial bundling applications. Its adaptability allows it to be seamlessly integrated into fully automated production lines, mounted on a workbench or used with an overhead

suspension device for manual handling, to suit a wide range of assembly environments. For organisations that use over 200,000 cable ties per year, the return on investment is rapid, with subsequent applications at a fraction of the cost.

In summary, the HellermannTyton’s ATS Flex bundling system offers unrivalled efficiency, safety and environmental benefits for rail vehicle manufacturers. Its ability to speed up cable bundling processes while minimising material waste is a compelling reason for rail vehicle manufacturers to consider this technology.

Click here to find out more about HellermannTyton’s portfolio of cable management solutions for the railway industry, or to request an on-site demonstration of the ATS Flex bundling system.

HellermannTyton manufactures cable management products for fastening, fixing, routing, connecting, insulating, protecting and identifying cables

www.hellermanntyton.com

Components & Materials 39

Directory

Rolling Stock

FinnProfiles

“The Quality Is Good, and Deliveries Are on Time!”

Mika Korhonen, Polarteknik’s Business Development

Polarteknik, based in Finland, manufactures reliable, sustainable, highquality interior door systems for the world’s leading train manufacturers.

As you can imagine, seals play a significant role in their door solutions!

Polarteknik and FinnProfiles have collaborated since the early 2000s. Around the same time, Mika Korhonen began working at Polarteknik, where he currently serves as the company’s Business Developer.

We met Mika at Polarteknik’s headquarters in Huittinen and asked a few questions about collaboration.

FinnProfiles: First, could you tell us a little about Polarteknik’s products?

Mika Korhonen, Polarteknik: Well, we produce approximately 4000–5000 train door systems annually,

primarily delivered to Central Europe. The systems can be single or double-leaf doors or telescopic, curved and hinged doors. Additionally, we manufacture gangway cassettes, toilet and cabin doors, each with their own specific requirements.

“Seals contribute to passenger comfort and are associated with many safety aspects.”

FP: How significant a role do seals play in your products?

MK: Each of our door systems contains several metres of seals, so in that sense, seals are a significant part of the structure of our products. Additionally, they contribute to passenger comfort and are associated with many safety aspects, in case of fire and smoke, for instance, that we must consider.

40

Mika Korhonen Business Development at Polarteknik

“The collaboration works extremely well!”

FP: How has the collaboration with FinnProfiles gone so far? What do you particularly appreciate about it?

MK: The collaboration works extremely well! The quality is good, and deliveries are on time. At the same time, we can rely on the fact that our seals are manufactured according to all required standards. In fact, FinnProfiles was one of the first companies to meet our needs when Europe transitioned from national material standards to unified standards.”

Click here to read more about Polarteknik’s products and services.

Learn more about FinnProfiles’ sealing solutions for the Rolling Stock industry.

Polarteknik’s employee installing a window seal frame

FinnProfiles supplies several different sealing materials and profiles to Polarteknik.All of them comply with the EN 45545-2 standard

Polarteknik uses several kilometres of sealing material every year

Polarteknik’s employee installing a window seal frame

FinnProfiles supplies several different sealing materials and profiles to Polarteknik.All of them comply with the EN 45545-2 standard

Polarteknik uses several kilometres of sealing material every year

Components & Materials 41

Supplied sealings also include strips to prevent draft and smoke in case of fire

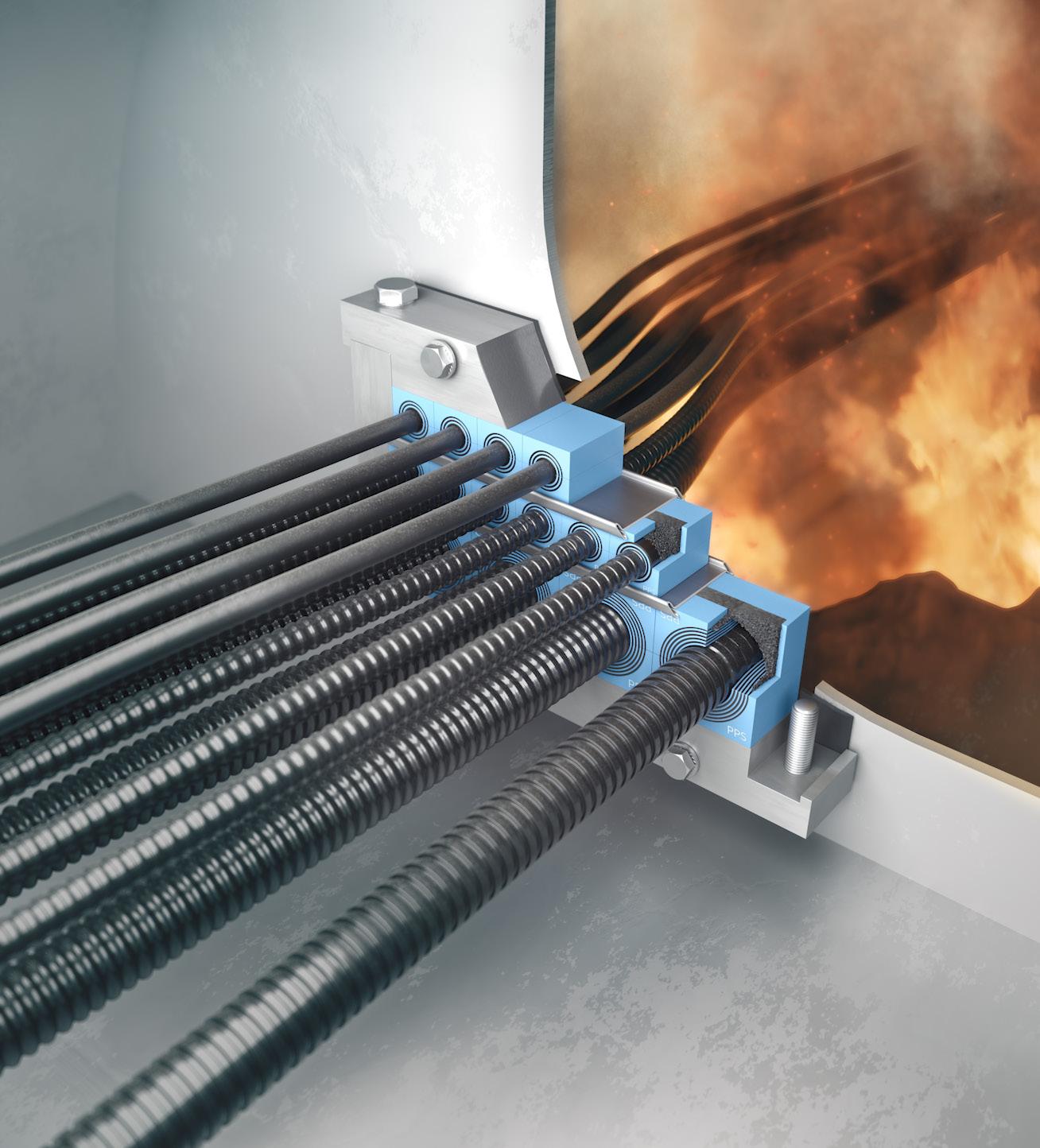

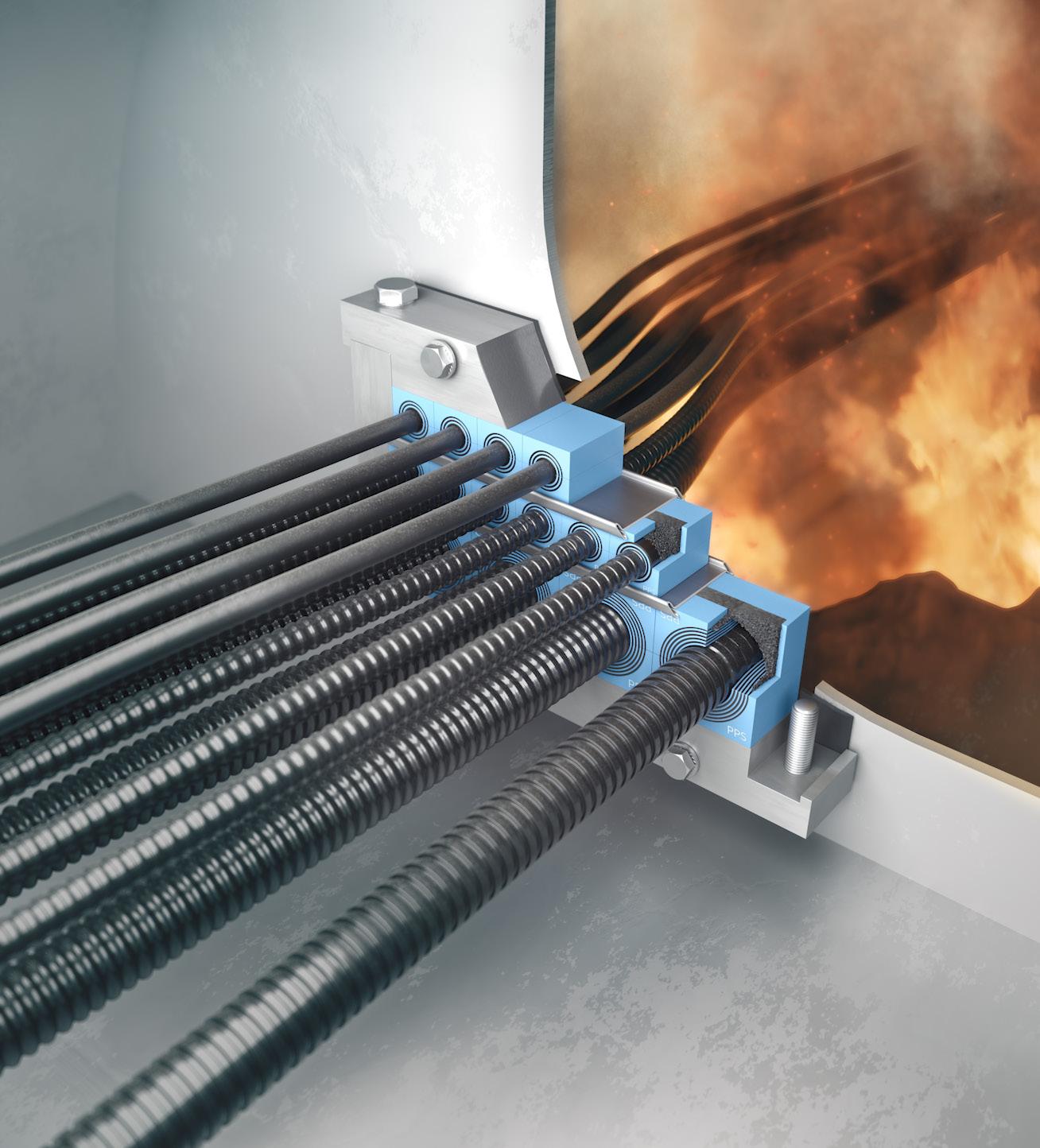

Flexible Seals for Cables, Pipes and Conduits

Lightweight Yet Robust Protection for the Rolling Stock Industry

Designing locomotives, high-speed trains, metros and other rail vehicles is a constant search for the optimised combination of strength, safety and low weight.

To ensure operational reliability and safe transportation of people and goods, and to avoid the risk of damage or downtime, engineers look for the very best components and every detail that can make a difference – such as Roxtec cable and pipe seals. Roxtec has an impressive history of solving problems in the rolling stock industry. Roxtec sealing experts know what it takes to seal off around cables and pipes in fire rated barriers throughout the vehicle structure. They have developed penetration seals that fulfil the highest fire resistance requirements and cover the highest hazard levels. Roxtec has thereby become an important partner for many rolling stock manufacturers around the world, providing innovative seals that ensure certified protection against multiple hazards and offering sealing knowhow, design services and software that enable fit-for-purpose solutions. The Roxtec sealing system is recognised by and familiar to most operators, engineers and installers who focus on speed, safety and sustainability. This has made it convenient to standardise with Roxtec penetration seals to enable success on the global market and to secure easy maintenance and reliable operation wherever the rail vehicle will be rolling.

Developed to Protect Life and Assets

Roxtec provides standard and tailor-made solutions to cover all sealing requirements to help manufacturers ensure passenger safety while maintaining operational

performance throughout the vehicle lifecycle. Roxtec has extensive research and development resources, including a technical centre and a material development lab, and is working together with manufacturer teams to continuously develop efficient seals. The company has advanced fire and test labs where internal and third-party witnessed tests are performed to support the product development process and verify the performance of the Roxtec products. The Roxtec system protects against fire, smoke, dust, water and vibration. The seals are tested in accordance with the major standards, such as EN 45545, NFPA 130, EN 60529 and UL/NEMA.

Tailor-Made Sealing Solutions

Roxtec sealing experts often create and design seals and transits according to specific needs. The team of designers, engineers and test technicians is always ready to take on a sealing challenge, even if it requires the creation of a completely new solution. The certified

Directory Rolling

Stock

42

Roxtec cable and pipe seals are designed for easy installation

and well-proven Roxtec system is often the base for new tailor-made seals, as Roxtec can supply it in other dimensions, with special frames, other rubber materials or bespoke sealing modules. Customisation of seals according to manufacturer needs is part of the service concept which includes everything from design support to fast deliveries.

Smart Engineering Tool

Roxtec Transit Designer™ is the rolling stock design engineer’s shortcut to safety and efficiency. This free, web-based engineering tool simplifies product selection as well as the entire design process that surrounds cable and pipe transits. Users simply enter input, such as cable schedule, sealing requirements and mounting preferences, and the software automatically provides full documentation. There are currently more than 50,000 users in more than 100 countries, and it is free to sign up for the tool on roxtec.com.

Multidiameter™ by Roxtec

Roxtec modular-based mechanical seals are lightweight, compact and openable – and they ensure a perfect fit, regardless of the dimension of the cable or pipe. This is thanks to Roxtec Multidiameter™, an innovation for flexibility based on sealing modules with removable rubber layers. It makes the system adaptable to cables, hydraulic pipes and plastic conduits of different sizes. With only a few parts, manufacturers get a strong reliable barrier against multiple threats. The multicable transits are quick and safe to install from one side of the structure and allow for sealing of several cables, pipes and conduits in the same opening. This allows for high cable density, which in turn allows designers to save space by reducing the size and weight of enclosures and junction boxes. One cut-out is, in fact, enough for routing and sealing of dozens of pre-terminated cables. Another advantage is the builtin spare capacity for additional cables and pipes which simplifies retrofits and upgrades. The seals are available with frames in different shapes and materials, for welding or bolting, and for a variety of applications.

Seals for Any Rail Vehicle Application

Manufacturers all over the world rely on Roxtec because there are so many applications where they can benefit from the sealing system. The transits are available for sealing floors, partition walls and roof

tops. It is used for converters, inverters, motors, brake systems, hydraulic pipes, junction boxes, pantographs, antennas, roof boxes, HVAC systems, air conditioning, switchboard panels and equipment. One example is cable management, cable retention and vibration damping. The area-efficient sealing system is gentle to the cable sheath, but also extremely resistant to pressure and excellent for keeping cables in place to avoid damage. It helps manufacturers extend cable lifetime and ensure long-term functionality.

World Leader in Modular-Based Seals

Roxtec is a global company with a strong local presence that understands the international activities of the leading rolling stock players. Roxtec supports customers and partners in design, production and modernisation across continents and geographies, and is present all over the world to ensure everything from quick support to smooth logistics and just in time deliveries from local stocks. This partner strategy has made Roxtec the world leader within flexible cable and pipe transits for the rolling stock industry.

For more information visit www.roxtec.com.

Roxtec sealing solutions provide fire protection for cable,pipe and conduit penetrations Components & Materials 43

Columbus McKinnon

Integrated CMCO Solution Expertise for Railways Worldwide

Since Pfaff Verkehrstechnik was fully merged into Columbus McKinnon (CMCO) in mid-2023, integration within the Group and the mutual support of the Group’s various brands has been further strengthened.

When it comes to project execution, it is not only the Pfaff-silberblau brand that is involved – STAHL CraneSystems and YALE also play their part in the success of the projects. Co-operation within the Group results in new outstanding railway technology solutions, which are realised worldwide together with local partners and subcontractors.

The portfolio of the former Pfaff Verkehrstechnik continues to be expanded under the umbrella of CMCO.

Sister brands YALE and STAHL CraneSystems also make a strong contribution towards implementing specialised railway technology solutions. These include transport components, but also the complete planning, installation and maintenance of turnkey lifting systems for a wide range of railway projects worldwide.

Diverse Projects in Europe

A huge number of major projects have been realised or are underway worldwide. In India alone, large projects are currently in progress at eight different locations, including Delhi, Pune, Bangalore and Mumbai. CMCO is highly active in Europe too – for example for the German Eiffage Group, which requires a Wi-Fi controlled system (10 lifting units for 30 tonnes each) for lifting maintenance vehicles and track-laying machines over a length of up to 110m.

Directory Rolling

Stock

44

Underfloor lifting system for heavy trains with up to seven carriages and a length of 120m

In recent years, for Swiss Federal Railways, existing rail platforms in Basel have been upgraded with roof working platforms, crane rails and service lifts. Skanska AB, a Swedish multinational construction company, also uses CMCO technology – for example to equip a depot in Sävenäs, Gothenburg, including 25-tonne lifting jacks on a rail-guided lifting system with automated laser tracker positioning.

‘Make in India’ Projects

CMCO recently delivered an underfloor lifting system to an Indian customer, HYT Engineering Company. It was manufactured under the ‘Make in India’ initiative, i.e. more than 50% of the production was carried out in India. For the first time, the factory acceptance test of an underfloor lifting system including load tests was carried out on site in India, and was approved in Ahmedabad at the first attempt without any defects. To meet the requirements of the initiative and factory acceptance, Pfaff Verkehrstechnik co-operates with local manufacturing partners, such as STAHL India, part of Columbus McKinnon, and Techno Industries, a leading Indian manufacturer of cranes, lifts and escalators.

Major Projects in Israel

Desiro HC (High Capacity) electric trains made by Siemens Mobility are maintained at the railway depot in Ashkelon, Israel. CMCO has provided solutions to fully equip the depot’s workshop. In addition to track systems, these include an axle changing system,

multiple lifting tables, mobile lifting jacks, hydraulic support jacks, turntables and roof working platforms (‘flying carpets’) for maintenance work on the train roofs. Twenty-four mobile lifting jacks each with a load capacity of 20t are used to lift up whole trains for maintenance and servicing work. The entire lifting jack system is controlled by frequency converters. Synchronisation of the individual lifting jacks makes it possible to lift a train with a precision of ± 4mm.

For maintenance and repair work on the train roofs, all three maintenance tracks were equipped with ‘flying carpets’ by CMCO subsidiary STAHL CraneSystems. These cradles are suspended from crane runways on the workshop ceiling. They can be moved over an extensive range of 175m along the entire length of the workshop and thus along the entire length of the train. Each ‘flying carpet’ has two hydraulically lowerable gondolas that can be operated either as a pair or individually.

Railway Technology in Peru

CMCO has supplied workshop equipment system components for the new Santa Anita depot for the Lima metro in Peru. The entire equipment was installed together with Berlin-based company SIM IMPEX, and includes an underfloor lifting system as well as bogie lifting stands, axle lifting systems (underfloor), mobile lifting jacks, manual turntables, lifting and turning equipment for bogie frames, auxiliary bogies and transport devices in large quantities.

Manufacturing & Maintenance Equipment 45

Underfloor bogie lifting stands in Peru

Major Siemens Order in Egypt

Two years ago, Siemens announced it had received the largest order in the company’s history, from Egypt. The order includes 41 eight-car Velaro high-speed trains, 94 four-car Desiro High Capacity regional trains, and 41 Vectron freight locomotives. Siemens Mobility will provide the latest technology platforms to optimise train operations, the rail infrastructure and subsystems throughout the network.

The Green Line is serviced at the October Gardens depot (west Cairo) to ensure maximum availability. Here too, CMCO has supplied numerous system parts, components and other equipment for the maintenance of the rail vehicles, including underfloor lifting systems for the Velaro and Desiro trains. In addition, lifting and turning equipment for bogies, wheelset changing systems, lifting stands, working platforms and overhead cranes from STAHL CraneSystems have been installed.

All-Round Expertise: Hydraulic Solutions from YALE

In the German rail transport network, Deutsche Bahn uses lifting solutions from YALE, including small hydraulic pumps, to maintain the bogies on DB Regio trains. A PYB cordless battery-powered pump together with the YALE YLS-20/45 low-profile cylinder slightly lifts the train by a little over 2mm so that the wheels can be turned and checked for damage – this is an official railway maintenance procedure that used to be done by hand.

Deutsche Bahn has now opted for the mobile solution with the PYB cordless battery-powered pump, which can develop an operating pressure of up to 700 bar. Applications include the operation of small to mediumsized cylinders, such as the YLS single-acting low-profile cylinder with a lifting capacity of 10 to 100 tonnes and a spring return. Such cylinders are ideal wherever space is limited. They are mainly used for lifting, positioning and clamping.

Normally, the bogie is lifted from at least four points – with this solution, it is sufficient to lift it on one side (i.e. slightly tilted) because the wheel only has to be rotated once to check for damage and cracks, for

example. However, the CMCO solution also allows the entire bogie to be lifted, by simply replacing the 2-way distributor with a 4-way distributor.

Conclusion

Operators of modern transport systems depend on reliable maintenance and inspection. Equipment from CMCO enables maintenance work to be organised and carried out efficiently with the shortest possible downtimes. As well as supplying transport components, the company also offers complete project planning, installation and maintenance of turnkey lifting systems for all kinds of rolling stock worldwide. The comprehensive portfolio is complemented by various types of roof working platforms, cranes and a wide range of workshop equipment.

A CMCO premiere took place in April 2024: numerous key customers from across Europe met in Augsburg, Germany, for the two-day CMCO Customer Exchange & Show 2024, with a theme of ‘Inspiration, Growth, Partnership’. Here they gained direct insights into the Group’s integrated solution offering.

Click here to find out more about Columbus McKinnon and Pfaff Verkehrstechnik.

46

Cordless battery-powered pump moves a low-profile cylinder at 700 bar

Railway Wheelset Inspections Made Easy PASAWIS

Phased Array Semi-Automated Wheelset Inspection System

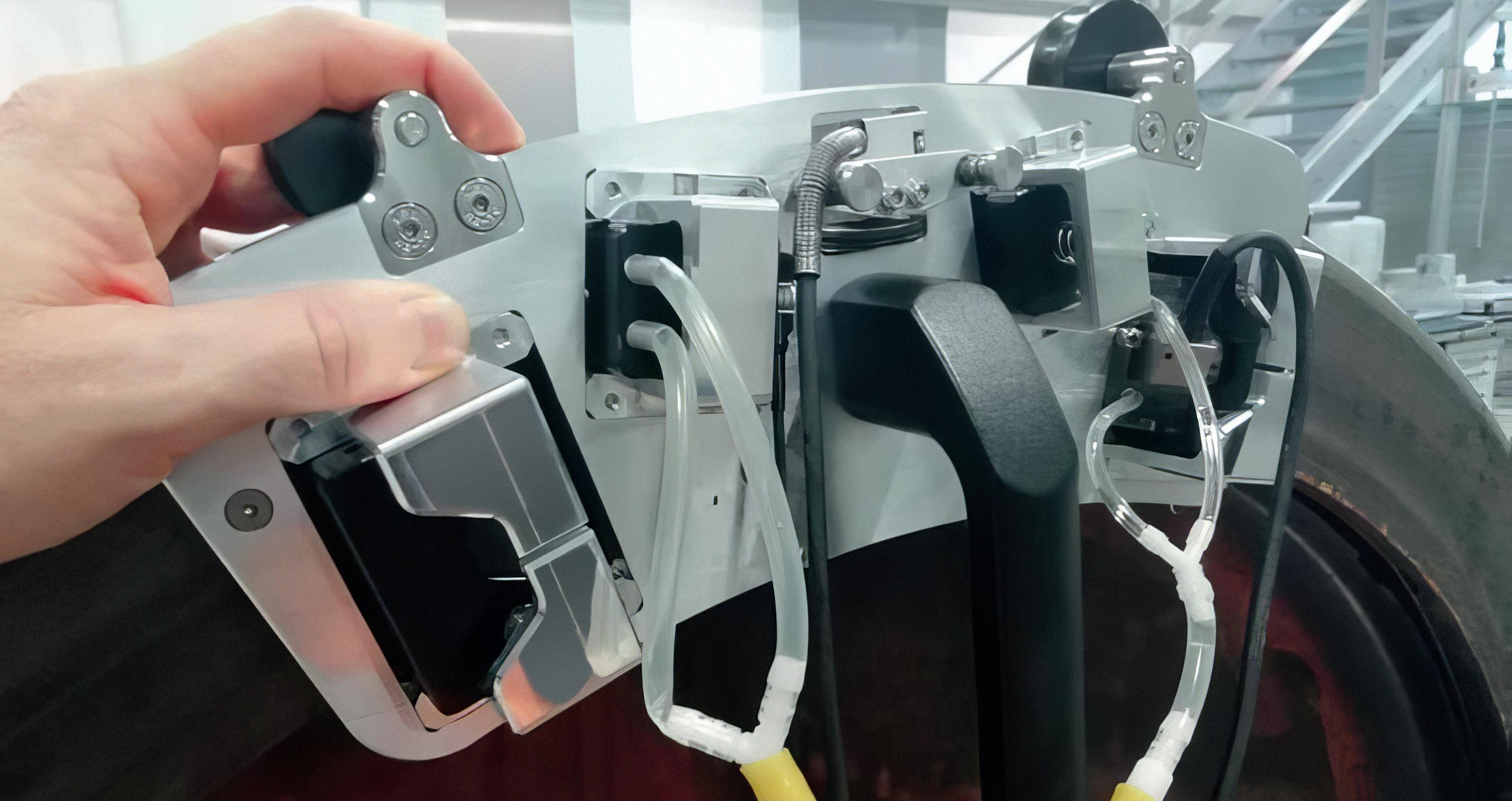

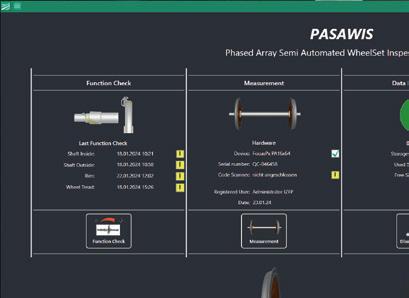

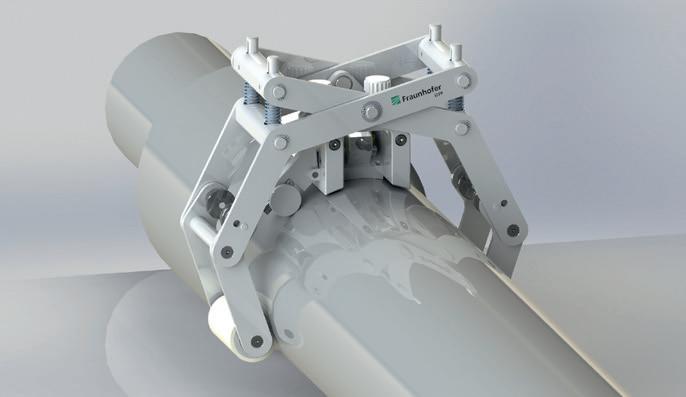

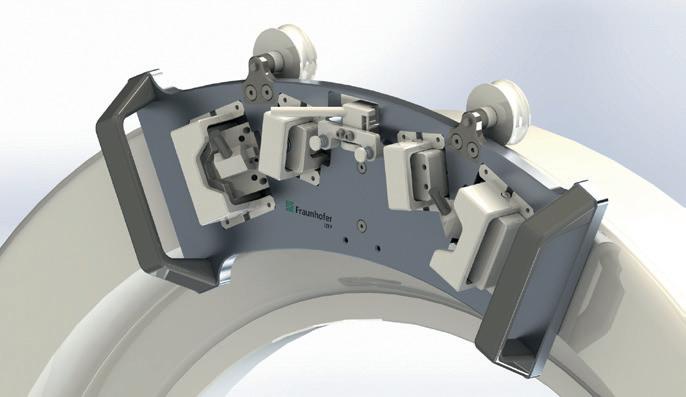

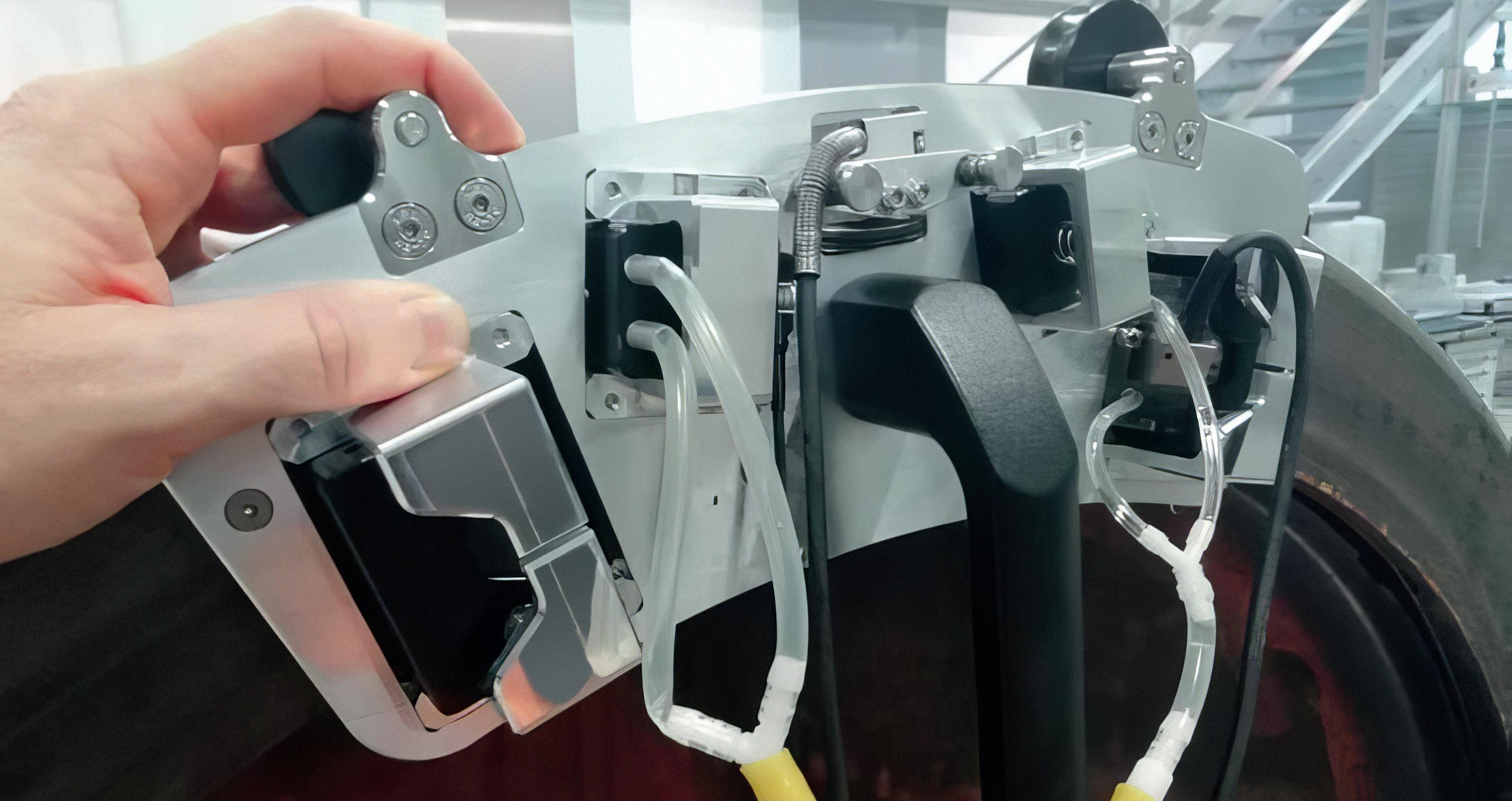

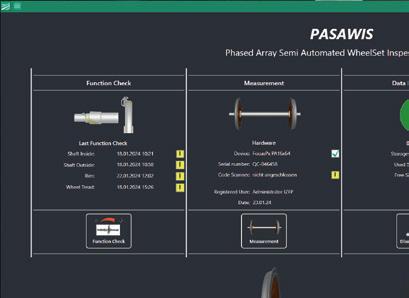

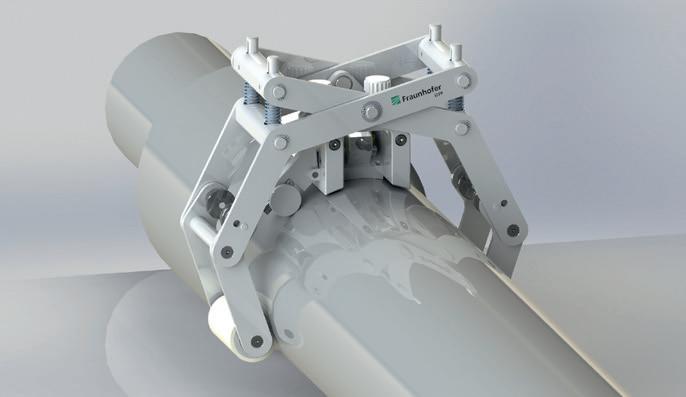

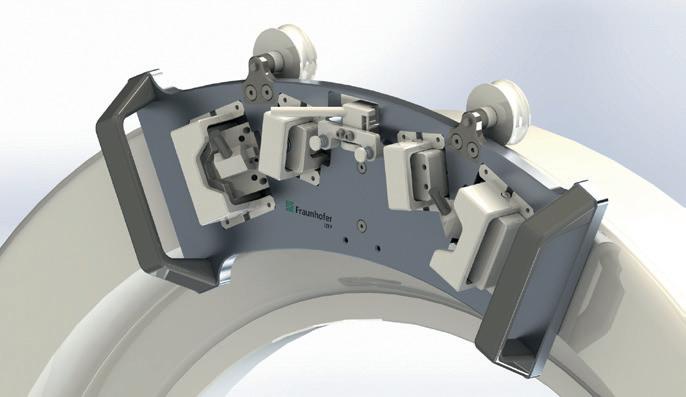

Get outstanding coverage of wheelset components for faster, more efficient inspections with the Evident PASAWIS system. Developed in collaboration with Fraunhofer IZFP and RailMaint, this powerful testing platform combines the latest ultrasonic and phased array scanning technology with dedicated software—meeting the VPI-EMG09 regulation for NDT maintenance. With a complete step-by-step workflow, the software guides you through the inspection procedure from functional check to results and report creation.

www.EvidentScientific.com

Caffamacherreihe 8–10, 20355 Hamburg, Germany