8 minute read

Serenity Technologies : Providing turnkey solutions to the Lab Grown Diamond Industry.

An integrated player with a presence from the laboratory to the retail shelves has better chances of becoming successful. To become a globally profitable LGD company it is essential to control the entire supply chain from the lab to the market. It is a known fact that being a grower is most profitable compared to being a reseller especially with the slide in LGD prices. It is relatively easy to invest in equipment but the technical know-how to be successful at growing diamonds of superior quality in large quantities at a consistent pace is much harder to achieve. The technocrat duo Jay & Suneeta Neogi at Serenity are now offering an innovative solution and know-how to enable jewelry manufacturers and retailers to consider becoming independent growers. Dr. Suneeta Neogi, shared many insights during her

Serenity. His passion for problem solving has been the foundation on which Serenity built its strong portfolio of technology and products. He developed the focused ion beam invisible table branding technology which was licensed exclusively to DeBeers and led to Serenity's entry into the Gem industry. His work in invisible marking technology led to an invitation from the White House during President Clinton's time as a speaker at the Diamond identification and Tracking conference.

Serenity is uniquely positioned to help any company seeking to become a Prime Grower by offering the following services:

Guidance to procure the required equipment and create the requisite infrastructure, Process knowledge and recipes to rapidly scale up to production quality without having to expend the time and effort to start from scratch. Today any company can buy an MPCVD machine from the known suppliers, but the challenge is the recipe and process know-how required to ramp up rapidly and produce gem quality roughs within a reasonable time frame. Serenity is focused on development of large crystal growth to enable production of 5-7 carat diamonds.

It is one of the only privately held companies who has developed all the process steps and equipment in-house as shown in the chart below and is now offering an innovative solution that is ideal for companies seeking to become a grower.

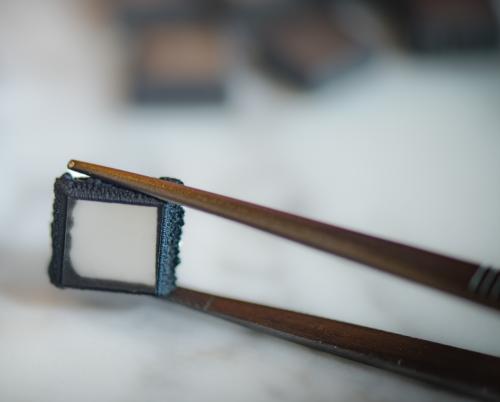

Lab-grown diamond material consists of the single crystal block of a size determined by the seed substrate area and the growth height. The block is typically surrounded by black polycrystalline diamond (PCD) material which can be removed by standard laser sawing (coring process) but if the single crystal block is of a pyramidal shape due to lateral growth and requires complete removal of the polycrystalline diamond then Serenity's proprietary process comes in very handy. This technique “only” removes the polycrystalline diamond without any effect to the single crystal material.

Serenity’s focus on lab grown diamond production has recently led to the development of a new cost-effective solution for the ultra-polishing of both lab grown diamond, as well as mined diamonds. Additionally, as a diamond grower, Serenity recognizes the need for ultra-polishing technology applied to diamond seeds fabricated for growing single crystal diamond blocks.

Most growers use mechanically polished CVD single crystal seeds for their growth process, which typically starts with a laser sliced seed crystal that is polished using a conventional diamond scaife. The quality of the seed surface significantly influences the subsequent growth process due to various factors such as mechanical damage, pitting, cracks, surface stress, point defects, seed angle, thickness etc. A superior polish finish helps reduce stress and damage that result from the mechanical polish process and this can be achieved via Serenity ultra-polishing slurry paste.

The difference between single and poly crystal diamonds:

Single crystal LGD as the name suggests literally refers to diamond grown in a laboratory. Diamond can be polycrystalline, nano crystalline or single crystal. In the context of the gems industry the focus is on single crystal which means the diamond consists of an orderly three-dimensional arrangement of the constituent carbon atoms repeated throughout its entire volume. Diamonds are separated into 5 types - Type Ia, Type Ib, Type IaB, Type IIa, and Type IIbA. A single crystal LGD diamond is of Type IIa which is the purest of forms of diamond (less than 2% of mined diamonds are of this type) and can be cut and fashioned into a gem, its material, composition, and properties being no different than its mined counterpart which has dominated the jewelry industry as the most valuable of all precious stones.

Growing Single Crystal Diamonds:

Single crystal LGDs are grown using two techniquesHPHT (high pressure high temperature) growth process or CVD (chemical vapor deposition) process. In the HPHT technique carbon is diffused through a metal alloy to the seed in a growth apparatus at high temperature and pressure conditions similar to how diamonds were formed in the earth. Large colorless crystals can be grown by this method.

In the CVD technique growth of single crystals is achieved through a homoepitaxial deposition process wherein carbon atoms attach themselves in an orderly arrangement over the starting diamond seed material in a reactor. The conditions for generation of the carbon species is via an energetic plasma that is created by microwave or RF (radio frequency) techniques to dissociate the process gases. The CVD technique has more bandwidth for producing higher quantities of crystals per growth cycle as well as the ability to grow very large size crystals.

CVD has a better future as this is the only method by which ultra-high purity large-area diamond wafers are produced for semiconductor applications which is by far the more significant and larger market for single crystal diamond.

HPHT diamonds have various impurities involving transitions metal atoms (such as nickel, cobalt or iron) which affect the electronic properties of the material making them less suitable for semiconductor applications. Also, the presence of metal contamination in HPHT crystal leads to mis-identification using standard thermal tests used in the gem industry. HPHT diamonds test as moissanite in a standard thermal tester and require diamond certification from a gem lab to identify them correctly as lab grown diamond. CVD diamonds have no such detection problems with thermal diamond testers.

915 MHz and 2.45 GHz MPCVD platforms: CVD technique requires the generation of an energetic plasma using microwave or RF sources. Microwave Plasma is the more common technology used for CVD technique. Microwave plasmas can be generated using 915 MHz frequency or 2.45 GHz frequency magnetron sources. 2.45 GHz microwave plasma systems are the most common reactor platforms that are manufactured worldwide. These reactors can generate plasma sizes large enough to grow single crystal in an area not larger than 60 mm. Most of the LGD producers worldwide rely on 2.45 GHz MPCVD reactors running on 6 kW microwave generators. The development of microwave cavities for large area diamond CVD requires plasma reactors that generate a large flat plasma in close contact with the substrate holder where the growth takes place. The main criteria determining reactor performance is the shape and position of the plasma.

915 MHz frequency plasma reactors have the advantage that it is possible to generate large flat plasma on substrates that are more typically 150 mm in diameter and even unto 300 mm in diameter based on the size of the power sources typically from 30 kW and up to 70 kW. The capacity of a 915 MHz reactor is thus much larger than a 2.45 GHz reactor.

While 915 MHz plasma reactors offer greater cost-efficiency in production they are not as commonly used as the 2.45 GHz plasma reactors due to technical challenges relating to process chemistry, substrate holder design, heat dissipation, flexibility in growth rate and related HPHT processing of grown crystals. The current drive towards production efficiency in MPCVD makes 915 MHz reactors more attractive for growers who have the technical know-how to develop processes (recipe design and infrastructure) specifically for these systems.

The 915MHz reactors are the future as the throughputs are much higher but requires expertise during growth and post processing and Serenity is very uniquely positioned to assist. 915 MHz reactors are also perfect for high throughput seed production.

The 2.45GHz reactors are smaller and easy to handle but the throughputs are not very high, and many multiples of reactors are required for high volume production. Serenity has made advances in the 2.45GHz platform and are working on cluster systems that have 5-10 small 2.45GHz chambers running on a single processing central controller for better process control and consistency. The 2.45 GHz Cluster setup is ideal for companies seeking to grow production quality large crystal using seeds from 10 mm - 20 mm size to produce finished goods in the 5 - 12 carats range in high color.

Currently many companies in India are opting to procure cheap home-grown copies of small reactors. Such reactors offer a low investment opportunity but do not offer consistent quality, reliability, and reproducibility for high volume production.

As compared to natural diamonds, do LGDs tend to chip and crack? Which is better in this respectHPHT or CVD?

Lab grown diamonds match their mined counterparts in hardness, strength and durability. In fact some lab grown diamonds of the highest purity have properties of hardness, thermal conductivity and electron mobility that are superior to most naturally formed diamonds. Lower clarity diamonds whether mined or lab grown increase the risk that a diamond will crack or chip when exposed to direct, brash impact, due to internal flaws or fractures present in the stone.

For lab grown diamonds the type of seed and growth process can produce crystals that are internally stressed which can lead to challenges during gem cutting of the diamond crystal causing fracturing. CVD crystals generally have more internal stress as compared to HPHT crystal. This can be mitigated by stress reduction techniques after CVD diamond growth is completed.

The importance of seeds in growing diamonds: Starting seed quality is important for the growing of diamonds. Seeds can be of HPHT or CVD origin. Serenity’s focus is on growing large crystals for which CVD seeds are the best starting material.

In fact the main challenge a new grower faces is the lead time in getting delivery of the reactors from these manufacturers based upon the delivery of the key hardware components such as the microwave generator, and magnetrons.

With the shift to India as the key growing center of the world the problem of procuring reactors has evolved into a more complex situation due to numerous companies who have cropped up in India that are manufacturing copies of the typically used reactor platforms developed elsewhere in the world. Today any diamond company can decide to become a grower and shop for the cheapest home-grown reactor setup and demand that it come with a recipe to perform growth. This could lead to failure in the long run. In achieving success as a grower requires attention to not only the reactor setup but also a whole host of other factors such as : the infrastructure, gas delivery systems, cooling systems, reliable hydrogen generation, seed quality, growth recipes, process monitoring and process adjustments during growth runs, post processing of LGD crystals, HPHT/LPHT treatment conditions for whitening of rough . Serenity, with its strong background in materials science and semiconductor process technology has accumulated a wealth of knowledge and IP in diverse fields with application to gem technologies in particular LGDs. There is no need for a new aspiring grower to reinvent the wheel and spend the years required in developing recipes and methods. Serenity is the one-stop technical partner and solution provider for any new diamond grower and can help them get established and reach production scale in a short timeframe thus achieving quick ROI. Procuring a reactor is just a small fraction of what it takes to become a successful grower.

The quality of polish on the starting seed material, and the orientation of the growth surface to the (100) crystallographic plane and presence of point defects at the surface greatly influence the quality of growth achieved. Serenity’s core business does not include supplying diamond seeds to other growers as typically the seed business is more like a one-time business for a grower as most growers focus on developing in-house processes for developing their seed bank to satisfy their production needs.

What are the challenges faced by diamond growers in procuring reactors and developing the perfect growing recipe? How can Serenity help them ?

There are a few established manufacturers of CVD reactors in the world, and it is easy enough to procure reactors from any of these companies.