MANAGING YOUR CARRIER AGREEMENT MAY BE EASIER THAN YOU THOUGHT.

COULD THE RIGHT FACILITY DESIGN HELP YOU BEAT INVENTORY OVERFLOW? PAGE

AVOIDING THE SEVEN DEADLY SINS OF B2C FULFILLMENT. PAGE

SPOTLIGHT: NEED PARCEL INSURANCE?

WHERE IS TRANSPORTATION TECH HEADED?

MAY-JUNE 2023 PARCELindustry.com

16

PAGE

22

26 REGIONAL / FINAL-MILE CARRIER OPTIONS & SERVICE MAP PAGES 18-21

PAGE 8

See pages 7 & 13 RI NJ MAY-JUNE 2023 PARCELindustry.com

Ryan Polakoff

By Josh Taylor

Ryan Polakoff

By Josh Taylor

22 16 24 26 28 /// CONTENTS Volume 30 | Issue 3 06 EDITOR’S NOTE What Lies Ahead for Shippers? By Amanda Armendariz 07 REVERSE LOGISTICS Resales Grow in Popularity By Tony Sciarrotta 08 INDUSTRY INSIGHT Where Is Transportation Tech Going? By Joe Wilkinson 10 PACKAGING What Is Flexible Packaging, and How Can It Influence Your PR? By Alex Selwitz 12 OPERATIONAL EFFICIENCIES Spring Cleaning Your Technology By Susan Rider 13 PARCEL COUNSEL The New Uniform Straight Bill of Lading: Say Goodbye to the Section 7 Box By Brent Wm. Primus, JD 14 SUPPLY CHAIN SUCCESS Dynamic Parcel Market: Assessing the Impact of Recent Industry Developments By

16 KEY STEPS TO ACTIVELY MANAGE YOUR PARCEL OPERATIONS AND AGREEMENTS –SIMULTANEOUSLY By

22 BEAT INVENTORY OVERFLOW WITH FACILITY DESIGN

24 THE CHANGING FACE OF LTL SHIPPING By

26 THE 7 DEADLY SINS OF B2C FULFILLMENT By

SHIPPER SURVEY: LIVE PARCEL FORUM RESULTS UNVEILED – PART

Keegan Leisz

Brian Byrd

By Greg Meyne

Harry Drajpuch 28 INTERACTIVE

TWO

SPONSORED CONTENT

SPOTLIGHT: PARCEL INSURANCE

SPOTLIGHT: PARCEL INSURANCE

USING REGIONAL AND FINAL-MILE CARRIERS? GET OUR NEWSLETTER? SUBSCRIBE FOR FREE 4 PARCELindustry.com MAY-JUNE 2023

07

13

18 ARE YOU

PRESIDENT CHAD GRIEPENTROG

PUBLISHER KEN WADDELL EDITOR

AMANDA ARMENDARIZ [ amanda.c@rbpub.com ]

AUDIENCE DEVELOPMENT MANAGER RACHEL CHAPMAN [ rachel@rbpub.com ]

CREATIVE DIRECTOR KELLI COOKE

ADVERTISING KEN WADDELL (m) 608.235.2212 [ ken.w@rbpub.com ]

JOSH VOGT [ josh@rbpub.com ]

PARCEL (ISSN 1081-4035) is published 7 times a year by MadMen3. All material in this magazine is copyrighted 2023 © by MadMen3. All rights reserved. Nothing may be reproduced in whole or in part without written permission from the publisher. Any correspondence sent to PARCEL, MadMen3 or its staff becomes the property of MadMen3. The articles in this magazine represent the views of the authors and not those of MadMen3 or PARCEL. MadMen3 and/or PARCEL expressly disclaim any liability for the products or services sold or otherwise endorsed by advertisers or authors included in this magazine.

SUBSCRIPTIONS: Free to qualified recipients: $12 per year to all others in the United States. Subscription rate for Canada or Mexico is $35 for one year and for elsewhere outside of the United States is $55. Back-issue rate is $5.

Send subscriptions or change of address to: PARCEL, P.O. Box 259098 Madison WI 53725-9098

Allow six weeks for new subscriptions or address changes.

REPRINTS: For high-quality reprints, please contact our exclusive reprint provider, ReprintPros, 949.702.5390, www.ReprintPros.com.

P.O. Box 259098 Madison WI 53725-9098

p: 608.241.8777

f: 608.241.8666

PARCELindustry.com

MAY-JUNE 2023 PARCELindustry.com 5 SUBSCRIBE FOR FREE!

WHAT LIES AHEAD FOR SHIPPERS?

By Amanda Armendariz

Summer is a busy time for many of us in the small-package sector. Despite it seeming like warmer temperatures have barely arrived (especially for those of us in the Midwest), many shippers are already gearing up for the upcoming peak holiday shopping season, which will be here before we know it. Never is the old adage, “Early is on time, and on time is late” more apt than with respect to peak season preparations. (So this is your push to start solidifying your plans for the latter half of 2023, if you haven’t already!)

This summer will be complicated by the fact that a potential Teamsters strike is on the horizon, which would greatly impact

customers of UPS. As Paul Yaussy noted in a recent article on our website, both leaders (Carol Tomé with UPS and Sean O’Brien with the Teamsters) are new to their organizations, which may increase the pressure both of them feel to deliver a win. The odds that these two entities will reach an agreement that is characterized as a win for both sides are a bit out there, but the industry can certainly hope. After all, the Teamsters comprise about 2/3 of the UPS workforce, so a strike would be no small matter. Shippers would do well to ensure their contingency plans are solidified, whether that entails going with FedEx, the Postal Service, or regional/alternative carriers.

In the meantime, make sure you’re planning to attend the 2023 PARCEL Forum in Nashville, September 11-13. This show is always a great way to connect with other industry professionals and discuss the opportunities and challenges we fact as small-package shippers. I look forward to seeing many of you there (after a hopefully uneventful, strike-free summer).

As always, thanks for reading PARCEL.

EDITOR’S NOTE

RESALES GROW IN POPULARITY

By Tony Sciarrotta

The resale market is growing quickly as consumers become more mindful of sustainable practices. According to a recent report from RLA member ThredUp and research and analytics firm GlobalData, secondhand apparel sales are expected to reach $70 billion by 2027, from sales of $44 billion in 2023.

In 2022, 52% of all consumers shopped secondhand apparel, according to the report, and in particular, two in five items in Gen Z’s closet are secondhand. Gen Z is defined by the U.S. Census Bureau as those born between 1997 and 2013.

Sustainability practices are among the reasons for this growing trend. Retailers are also embracing resales as a means to mitigate the cost of returns and serve as a new revenue stream. Returns management is also being included in more retailers’ Environmental, Social, and Governance (ESG) reports to help measure such impacts as carbon emissions.

ThredUp notes in its report that buying and wearing secondhand clothing instead of new reduces carbon emissions by an average of 25%.

Besides the sustainability benefits of secondhand retail, many retailers are still faced with excess inventory from 2022 supply chain disruptions and are working these inventories down while being more cautious in adding new inventory.

“What we’re seeing now is the opposite of growth problems: ‘How can I effectively manage my inventory because I can’t afford to have excess inventory on shelves?’” said Jonathan Poma, Loop Returns’ co-founder and chief executive officer in a Bloomberg interview.

ThredUp, RealReal, and other similar businesses offer online resale platforms for such retailers as J. Crew, H&M, Hanna Andersson, and 11 Honoré, as well as for individuals and traditional consignment and/or thrift stores.

J. Crew’s initiative “J. Crew Always” includes a resale program powered by ThredUp’s Resale-as-a-Service and a program to sell vintage fashions in stores.

H&M is also partnering with ThredUp’s Resale-as-a-Service. “We need to take responsibility for the impact fashion

has on the climate and the environment. Circular business models can help us reduce and limit this negative impact while continuing to deliver fashion and style for our customers. With the launch of our first resale model in the US market, we’re taking the next big step in that direction,” Abigail Kammerzell, Head of Sustainability, H&M North America, said in a statement.

ThredUp and RealReal act similarly to 3PLs in that they may receive retailers’ returns, disposition the items, pick, pack, and ship orders. They also handle retailer-branded website setups.

FloorFound is a similar online platform but focused on furniture. Besides offering website setups, FloorFound operates five dedicated centers with ½ million square feet of reprocessing space. The processing centers are equipped to consolidate returns, receive returned or trade-in items directly from consumers, and bulk transfers from warehouses or other collection points. Team members carefully inspect and grade every item and repair and

refurbish items as needed.

Using these types of solutions to manage returns can help protect the brand by ensuring items are authentic versus counterfeit. These solutions can also help protect a brand’s reputation by mitigating counterfeits and keeping the returns and the pricing structure in the hands of the retailer.

According to consulting firm BCG, the secondhand market is worth three to five percent of the overall apparel, footwear, and accessories sector and could grow to as much as 40%, depending on macroeconomic conditions.

A note of caution for retailers and brands — their resales may compete against their promotions as consumers look for bargains, particularly in today’s uncertain environment.

Tony Sciarrotta is Executive Director of the Reverse Logistics Association. The RLA offers various tools, white-papers, and monthly webinars that provide best practices in managing reverse logistics.

SPOTLIGHT: PARCEL INSURANCE

Shipsurance has been providing discounted shipping insurance coverage for packages sent via the major shipping carriers worldwide for 20 years. From SMB’s to Fortune 500 businesses, our shipment protection program will greatly reduce your overall shipping spend. Damaged or lost packages? Our shipping claims process is the best in the industry with a streamlined electronic claims management system that will have you paid quickly and efficiently. Our protection program is integrated with most of the leading shipping and marketplace solutions that you are already using. YOU SHIP IT. WE INSURE IT.™

sales@shipsurance.com

866.852.9956

www.shipsurance.com

MAY-JUNE 2023 PARCELindustry.com 7

REVERSE LOGISTICS

WHERE IS TRANSPORTATION TECH GOING?

By Joe Wilkinson

Technology disruptors are going to have a huge impact on the transportation industry in the coming years. But they may not be the disruptors you’re looking for. In 2020, self-driving trucks and drone deliveries were all over the industry press and were thought to be a coming sea change in efficiency and productivity. However, a recent survey by Princeton Consultants showed that only 40% of respondents believed drones would have a moderate/large impact in the next seven years, and an even lower 34% believed self-driving trucks would have a moderate/large impact. So, what changes are going to be the drivers? The Internet of Things (IoT) led the pack, with 74% of respondents saying it would have a moderate/large impact in the coming years. Artificial intelligence/machine learning came in a close second at 67%.

As it relates to transportation, IoT means three things: sensors, sensors, and sensors. Visibility, early warning, and real-time intervention are the name of the game here. Milestone-based tracking has been the default since the early 1990s. In recent years, both national carriers launched consignee-managed delivery management tools and shipper-managed rerouting tools for pharma and other special use cases. For now, these carrier-provided tools come with pretty steep costs.

As the technology improves and end-to-end visibility becomes ubiquitous, costs should come down. Carriers like to inflate prices for value-added services, pointing to

their fees as pass-throughs. But over time, the truth is these charges become margin drivers. However, in this case, third-party providers are probably the solution to the price problem. There are three key elements to this type of solution:

Implementation of low-cost, durable sensors

Integration with a machine learning-capable backbone

Ability to take corrective action at scale

Companies like project44 and Fourkites already offer end-to-end visibility solutions. As visibility becomes more contemporary, machine learning will become more important so that exceptions become predictive rather than reflective, and mitigation can become proactive rather than reactive. The question remains how deeply parcel carriers will allow third parties to integrate into their system for redirects and service changes. Historically, UPS and FedEx have been antagonistic toward third-party service providers — mainly when those providers compete directly with the services they provide. In this case, however, both UPS and FedEx have existing relationships with some of these companies, so there may yet be a path for deeper integrations.

This brings us to machine learning. In my view, this will be the main game changer in

the next three to four years. Machine learning is the necessary unlock to turning real-time visibility into actionable intervention, allowing the real-world experience to dictate what variables lead to late packages, flagging those packages, and instituting corrective action. Moreover, machine learning tells us what we don’t know. Everyone has their key performance indicators that they track on a regular basis, metrics based on hard-won lessons that tell you what has bitten you in the past. But what about those things that haven’t bitten you yet? Machine learning can intake data and, based on patterns indiscernible or apparently irrelevant to a human analyst, learn what is normal for you and flag the exceptions. New packaging resulting in a greater percentage of DIM’d packages? Learn about it in a week instead of a quarter. Fraud on your account? We have seen machine learning pick up on this almost instantly. In fact, there’s practically no limit to what ML might pick up, as it’s not looking at a list of measurable variables. Instead, it’s looking for exceptions to the norm.

RECENT EXAMPLES:

An unexpected appearance of “automatic warranty” charges for a customer that, historically, had no prior charges for this accessorial. After consulting with the

8 PARCELindustry.com MAY-JUNE 2023

INSIGHT

INDUSTRY

carrier, it turned out that during the uprate, the ratings team incorrectly applied this charge. As a result of this finding, the carrier issued the shipper a credit for $138,443.

A customer experienced a per diem charge that was not only its highest historical charge for this accessorial to date, but it was also sent by the carrier with no additional documentation. Meaning, we had no visibility as to how this charge was calculated. After bringing this to the customer’s attention, the entire invoice was short paid and disputed for a total savings of $75,141.

Machine learning flagged disproportionate costs for shipments coming out of a Texas location. It turned out they’d had a team member come from Europe to that delivery center in Texas. In Europe, they use a comma the way we use a decimal point in the US. But the software in Texas wasn’t treating the comma as a decimal point, so instead of a five-pound package it was interpreting the weight as 500 pounds. After consulting with the customer, they advised us that this charge was incorrect. As a result, the charge was disputed, and the customer received a $11,562 credit from the carrier.

A customer received multiple invoices from a carrier for a new and anomalous sender address. After bringing this to the customer’s attention, it was discovered that the carrier had sent incorrect EDI references, and these invoices were sent in error. As a result, the carrier voided these invoices, totaling $649,134.

So, where can shippers find these magical benefits?

I’ve already mentioned a few vendors that are providing real-time visibility. Some audit and visibility providers are offering machine learning integrations and services. And other innovators will spring up as the market further defines the need. It is an exciting time to be in the transportation space. Like the technology we use, we as practitioners must evolve our processes, strategies, and even roles to keep pace with enabling innovations. Peak shipper-side efficiency may be an unreachable goal, but we’re closer than we’ve ever been.

Joe Wilkinson is VP, Professional Services (Transportation Consulting) at Intelligent Audit. He can be reached at joeywilkinson@ intelligentaudit.com.

MAY-JUNE 2023 PARCELindustry.com 9

SUBSCRIBE FOR FREE!

PACKAGING

WHAT IS FLEXIBLE PACKAGING, AND HOW CAN IT INFLUENCE YOUR PR?

By Alex Selwitz

Flexible packaging is a popular choice due to its convenience, space-saving, and sustainability advantages, which can also enhance your brand’s image and reputation. However, it is crucial to select appropriate materials and designs to avoid damaging your company’s credibility.

According to the 2023 Flexible Packaging Market report, the global flexible packaging market is expected to grow at a CAGR of 5.12% from 2023 to 2028, driven by two emerging trends. The first trend is a shift from rigid to flexible packaging, and the second trend is the use of high-barrier plastic materials for vacuum sealing, which extends product shelf life.

So, why is flexible packaging gaining popularity, and how can you ensure that you are using the right packaging for your needs?

The Impact of Flexible Packaging Benefits on PR

Selecting the appropriate e-commerce packaging can be crucial for its success. Your customers may either appreciate it, setting a high bar for future orders — or dislike it, and possibly refrain from making repeat purchases.

When executed effectively, flexible packaging can significantly enhance a brand’s public relations and image in the following ways:

1. Enhanced Brand Image

The first pro of using flexible packaging is an enhanced brand image and reputation. With the help of flexible packaging that’s well-designed and branded, you can communicate your company’s values and highlight what makes your product unique and special.

When customers see a brand’s packaging, they should be able to immediately identify it and associate it with

positive feelings about the brand. This can help build brand loyalty and generate positive word-of-mouth.

2. Increased Customer Satisfaction

Customers love flexible packaging mostly due to its convenience. These flexibles are typically easy to reseal once they’ve been opened, preserving the freshness of the product inside. Plus, they’re lightweight and don’t take up too much space. Naturally, happy customers are more likely to share their positive experiences with others, which can result in increased brand awareness and positive PR.

3. Positive Impact on the Environment

Although most flexible packaging options aren’t recyclable, they still have a lower carbon footprint than rigid packaging, mostly due to their lower weight and size. When a brand adopts environmentally-friendly packaging practices, it demonstrates a commitment to sustainability and earns positive PR for its efforts, as consumers are increasingly concerned about the impact of packaging on the environment.

4. Improved Customer Engagement

With a little bit of creativity, flexible packaging can easily be transformed into intelligent packaging that will engage customers. As a brand, your packaging can become your greatest advocate.

For instance, you can design your flexible packaging with interactive elements such as QR codes or augmented reality experiences that encourage customer engagement. This can create a positive association between the brand and the customer, and lead to increased loyalty and advocacy.

5. Increased Sales and Revenue

Flexible packaging can have a significant impact on a brand’s revenue, which, in turn, can lead to positive PR. The cost-effectiveness of flexible packaging, due to its reduced material usage and lower storage and transportation costs, can improve a company’s profitability. Additionally, the convenience and ease of use provided by flexible packaging can enhance customer satisfaction and engagement, which translates into higher sales.

When customers see a brand’s success, they’re more likely to associate it with positive attributes — such as quality and innovation — and share their positive experiences with others. By designing packaging that is both customer-centric and cost-effective, companies can create a win-win situation that benefits both the brand’s reputation and bottom line.

Why Sustainable and Eco-Friendly Flexible Packaging?

Choosing sustainable packaging made of eco-friendly materials is equally important

10 PARCELindustry.com MAY-JUNE 2023

with flexible packaging as it is with rigid.

In fact, sustainability is one of the biggest packaging industry trends for 2023 as more and more consumers don’t just want it, but expect it, from the brands they choose to buy from.

In a recent McKinsey study, 55% of surveyed US consumers stated that they are extremely or very concerned about the environmental impact of packaging. The same study noted that 60 to 70% of consumers agreed to pay more for sustainable packaging.

This data clearly shows the rise of sustainable packaging, but let’s see its benefits:

Reduced carbon footprint

Easy to reuse, recycle, or dispose of

No harmful substances or toxins

An improved brand image

If you need more reasons to switch to sustainable packaging, especially flexible sustainable packaging, note that in most cases, it translates to cheaper freight, storage, and handling costs, thanks to reduced weight and storage space.

It’s important to acknowledge that the adoption of flexi-

ble packaging is not without its challenges. The rising costs of raw materials such as paper, plastic, and films, as well as the need to keep up with fastpaced technological changes, pose significant obstacles for flexible packaging companies. Additionally, boosting sustainability and finding solutions for end-of-life disposal, while ensuring the protection of the contents — especially for perishable items — is a complex issue.

Despite these challenges, businesses can overcome them by implementing sustainable practices, designing innovative flexibles, and keeping up with industry trends. By doing so, they can achieve a more positive

impact on the environment, build stronger relationships with their customers, and stay competitive in the market.

Although it may present challenges, the benefits of flexible packaging far outweigh the risks. By making the switch today, businesses can secure a brighter future for themselves, their customers, and the planet.

Alex Selwitz is the Director of SEO for Red Stag Fulfillment, an e-commerce fulfillment warehouse that was born out of e-commerce. He has years of experience in e-commerce and digital marketing. Visit https://redstagfulfillment.com/ for more information.

MAY-JUNE 2023 PARCELindustry.com 11

SUBSCRIBE FOR FREE!

OPERATIONALEFFICIENCIES

SPRING CLEANING YOUR TECHNOLOGY

By Susan Rider

Today, having a distribution center that is not driven by technology simply doesn’t make good business sense. If you are in e-commerce, it is a definite business risk. Customers expect their orders to be on time and correct, and it is technology that both drives and satisfies these needs. In today’s world, not having good technology is equivalent to having one of the very first flip phones. It won’t interface to new equipment, and you can’t do anything but make a call. It’s costly, time-consuming, and burdensome. Plus, it eliminates a very valuable market in the labor pool, since young people today prefer to work with the proper tools.

If you have no WMS, TMS, LMS, or dashboards, it is time to either clean your system up and install the newer versions, or select/budget for a new system. If you are still using green screens (yes, there are some very prominent companies still using green screens), it’s time to upgrade to a new state-of-the-art system.

If you have not stayed abreast of current technology or available offerings, it would pay big dividends to hire a consultant to assist you. Think of this person or persons as an adjunct to your team. Technology system companies have changed dramatically over the last five years with new players, cloud offerings, apps, and new technology.

Many companies are still operating on an old version of software that the software company they bought it from no longer supports. A question you may be asking is, “Should I upgrade to the latest version or do a selection?” The answer (which isn’t popular with the software companies) is you should review what is out there because going to the newest version is like a new install anyway, and you will have to pay for the back years of support and updates.

Think about your company and where you have people still printing reports and manually doing calculations instead of simply pushing a button. For instance, if you are a 3PL and you have a team in accounting calculating billing every month, you are antiquated! The installation of a 3PL billing system that will track every movement and every labor second by customer should be installed ASAP.

If you still have a call center doing returns, you are a dinosaur. Sorry to be harsh, but those 30-plus people in customer service can be replaced by a web portal. Companies should follow the direction of the key players when it comes to IT departments. The folks in this department should be walking the distribution network looking at ways technology can help operations run the business better. If you are an executive or senior manager and your company is IT-driven versus operations-driven, it is time for a change. Technology departments should have the attitude and desire to be the customer service center for the company. Operations is their customer, plain and simple. Some questions to ask a prospective vendor:

How are you using the new AI technology today?

What are your plans for the future?

Who in your vertical industry is using the system?

What functionality have you built specifically for my industry?

What is the up time?

How hard is it to upgrade (ask to see proof, and perhaps talk to a company that has upgraded)?

Besides having the functionality I need, what are the tools your software provides to make my facility more efficient and effective?

If my turnover is high, what are your training tools? (They should have online training support. If they hand you a manual, the software company is antiquated! It’s practically

a guarantee that three months after the go-live, the manual has disappeared and no one knows how to use all the great features of the system).

Address all your problems. If the software can’t meet these needs, find software that can!

If you are looking at an international company, verify they have support offices here in the US. If you have major issues, you cannot wait for the time zone to change. Think about the 100 or more people sitting idle. Every minute of downtime is costing you thousands of dollars. A little hint: some companies may say something like, “We have four offices across the US.” Dig deeper! You may find out that those four offices are full of salespeople, not support people. It is human nature to want to believe everything you are told, but when purchasing software technology, it is better to question and validate everything.

This article is a little blunter than I normally write because the bitter reality is, companies are throwing millions of dollars away yearly by either not installing technology, selecting the wrong software vendor, trusting the wrong people, letting IT drive their organization instead of supporting it, or not following the old adage, “You don’t know what you don’t know!”

Susan Rider, President of Rider & Associates, Supply Chain Consultant, and Executive Life Coach can be reached at susanrider@msn.com.

12 PARCELindustry.com MAY-JUNE 2023

THE NEW UNIFORM STRAIGHT BILL OF LADING: SAY GOODBYE TO THE SECTION 7 BOX

By Brent Wm. Primus, JD

In December 2022, the National Motor Freight Traffic Association (NMFTA) published a thoroughly revised Uniform Straight Bill of Lading as part of the National Motor Freight Classification (NMFC). Although many parcel shipments move pursuant to the terms of an air bill, other parcel shipments are transported by motor carriers pursuant to the NMFC Bill of Lading.

One of the most significant revisions to the new Uniform Bill of Lading relates to Section 7 of the Bill of Lading Terms. Previously, Section 7(a) stated:

The consignor or consignee shall be liable for the freight and other lawful charges accruing on the shipment, as billed or corrected, except that collect shipments may move without recourse to the consignor when the consignor so stipulates by signature or endorsement in the space provided on the face of the bill of lading.

This was known as a non-recourse provision. It provided a method for a consignor to avoid liability for freight charges on a collect shipment by entering a signature or endorsement in what was known as the Section 7 box (see Figure 1) on the Bill of Lading. If the carrier accepted the shipment for pickup, then the carrier would not be able to go back against the consignor for the freight charges in the event the consignee did not pay.

The Section 7 box no longer appears on the Bill of Lading. Section 7(a) of the new Terms reads as follows:

The consignor, consignee, or shipper shall be liable for the freight and other lawful charges accruing on

the shipment, as billed or corrected as specified in 49 U.S.C. §13710, and carrier may require prepayment of the charges prior to delivery and refuse to give up possession at the destination until payment is made, as specified in 49 U.S.C. § 13707(a).

In other words, when it is a “collect” shipment the consignor will always be liable to the carrier for its freight charges if the consignee fails to pay the carrier, unless there is an individually negotiated contract stating otherwise. Accordingly, parcel shippers need to be aware of this. If

it is their customary practice to ship “collect” and have previously been endorsing the Section 7 box, they should now include, or try to include, such a provision in an individually negotiated contract with the carrier.

All for now!

Brent Wm. Primus, J.D., is the CEO of Primus Law Office, P.A. and the Senior Editor of transportlawtexts, inc. Previous columns, including those of William J. Augello, may be found on PARCELindustry.com. Your questions are welcome at brent@ primuslawoffice.com.

SPOTLIGHT: PARCEL INSURANCE

Parcel Insurance Plan has been insuring packages since 1966. All policies are underwritten by Allianz Global Corporate & Specialty (A+ Excellent by A.M. Best). Shipping insurance protects your company by providing coverage for lost or damaged packages, which can disrupt business operations and lead to unsatisfied customers. Shipping insurance can’t prevent lost packages but can shield you from costly replacement expenses and save you at least 50% over similar coverage from your shipping carriers. To qualify, your company must ship packages over $100 in value daily or spend at least $1000 annually on declared value. Request a quote at www.pipinsure.com/parcelmedia/.

office@pipinsure.com 800.325.7390

www.pipinsure.com/parcelmedia

MAY-JUNE 2023 PARCELindustry.com 13

PARCEL COUNSEL

Figure 1 SUBSCRIBE FOR FREE!

DYNAMIC PARCEL MARKET: ASSESSING THE IMPACT OF RECENT INDUSTRY DEVELOPMENTS

By Keegan Leisz

In 2023, shippers are acutely aware of the annual rate increases by the prominent carriers. Additionally, the escalating labor negotiations between UPS and the Teamsters have also caught their attention. However, in February and March, there were two industry developments that received less publicity but deserve some focus as they could have significant implications for the broader parcel market. These announcements are likely to intensify the competition in the already dynamic parcel arena.

has been truly able to compete with services like UPS Ground or FedEx Home Delivery. The disconnect has always been USPS First Class is typically competitive in price and transit standards but has only been available for packages under one pound. USPS Priority Mail has been competitive with transit standards and is available for packages above one pound, but generally comes in at a higher price point after factoring in UPS and FedEx discounts.

Announced in February, USPS has developed a service offering called Ground Advantage, which may prove competitive against other Ground services in the market. Per the release, this new service will replace the First-Class package service, is available for packages up to 70 pounds, will have two-tofive-day service standards, and includes $100 of insurance.

Many of the announced details of the Ground Advantage service seem to mirror

ground offerings from other carriers. As of the writing of this article, USPS has not released the published rates for the new service, but the expectation is that they will be lower than Priority Mail and could compete with the ground rates some shippers have with other carriers.

2. OnTrac Looking for Additional Volume, Moody’s Downgrades Debt Rating

LaserShip made waves in October 2021 when it was announced that it would acquire OnTrac for $1.3 billion — later rebranding under the OnTrac name. The timing of this announcement seemed ideal. National carriers were dictating pricing due to the limited capacity, and shippers were looking for any option to mitigate the cost increases being forced on them. Since that announcement, however, parcel volumes have softened, and national carriers are looking to gain back volume that left their networks. While OnTrac does not have publicly available financials, we can look at the financial reports of the national carriers to see where parcel volumes have trended in Figure 1.

OnTrac’s expanded capacity from the acquisition, along with the declining parcel volume, likely played a role in a report from Moody’s Investor Service. In early March, Moody’s downgraded OnTrac’s debt rating, citing “very high financial leverage, weak liquidity and moderate scale in

14 PARCELindustry.com MAY-JUNE 2023

SUPPLY CHAIN

SUCCESS

1. USPS Announces New Ground Advantage Service

To date, USPS has not marketed a product offering that

the competitive e-commerce residential delivery market.”

The volume of shipments has changed post-pandemic and carriers have seen capacity decline. The era of stimulus money is behind us and now carriers are looking to right-size their businesses.

What do these two announcements mean for shippers?

On the USPS side, it’s been long overdue for USPS to have a service that can directly compete with UPS Ground and FedEx Home Delivery. While the pricing and execution of Ground Advantage remain to be seen, initial signs point towards it being a potentially viable alternative that shippers could take advantage of in future parcel bids.

With OnTrac, a downgraded debt rating is a bit of a mixed bag for shippers. On one hand, it signals that there could be more risk with OnTrac than previously thought. On the other hand, it could potentially mean that OnTrac will be looking to gain more market share to fill its expanded capacity from the 2021 acquisition.

OnTrac’s March rebrand and subsequent marketing strategy seem to point to an initial push to gain the additional volume that it needs. Shippers can leverage this by evaluating opportunities that would give OnTrac some much-needed volume in exchange for aggressive pricing.

It’s crucial to have the right carrier negotiation professionals to assist you, especially with the continuous evolution of the broader shipping industry at a rapid pace. Although the attention has been mainly focused on UPS and FedEx in 2022-2023, it’s worth noting that updates

from USPS, OnTrac, and other carriers are continually transforming the competitive landscape, challenging the status quo. Therefore, shippers must be equipped with an acute awareness of all the changes in the parcel market, as well as the right negotiation skills to create a carrier mix that allows their businesses to deliver efficiently and profitably in the foreseeable future.

SUBSCRIBE FOR FREE!

Keegan Leisz is Project Manager, Transportation Consulting, Körber Supply Chain.

KEY STEPS TO ACTIVELY MANAGE YOUR PARCEL OPERATIONS AND AGREEMENTS –SIMULTANEOUSLY

By Brian Byrd

By Brian Byrd

Actively managing your carrier agreement isn’t something that requires countless hours every week. In fact, there are just a few easy steps you can take to reduce your costs and optimize your small parcel contract. Unfortunately, many shippers don’t take advantage of these steps because they don’t fully understand what they’re signing.

One common concern of shippers is the belief that they can’t lower their costs because their small parcel contract hasn’t expired. This belief is false. In fact, the arrangement between the shipper and the carrier isn’t truly a contract.

This misconception feeds into a second one: that carrier agreements are static. Yet, for many logistics managers, once the negotiations are over, the documents are filed away, never to be looked at again.

For shippers, this can be a costly belief, as rates are constantly changing. Every year, major small parcel carriers implement rate increases and introduce new charges and fees. If you sign a parcel agreement lasting three years and don’t actively manage it, you could be paying hundreds of

thousands of dollars more for rate increases and new fees that didn’t exist when you signed the deal.

So while it not take much time, actively managing your carrier agreement is still a necessity.

Start by Managing What’s in Your Parcel Agreement

Even if you are not satisfied with your current parcel contract, there are still ways to save before you renegotiate.

First, audit your invoices. While you’re required to meet the minimums for service guarantees, many shippers overpay by up to 10% because they continue to utilize their carrier once they’ve met the service guarantees, even if they aren’t getting the best deal.

If you audit your invoices, not only will you catch these extra charges, but you can also address them with your carrier to ensure they don’t perpetuate.

Secondly, pay attention to the delivery method. Companies often pay for premium services they don’t need. Sometimes Ground services can get a package to its destination just as quickly as Air. Or customers might be as satisfied with an evening delivery as they are with a morning delivery, which is more cost-effective for the shipper. Create a reliable process for determining which method of delivery is optimal to save on costs.

Thirdly, don’t default to a single carrier for every shipment. While your preferred carrier will give you the better deal most of the time, a different carrier could offer an advantage in at least one area. If you only rely on a single carrier, your budget likely suffers. UPS, FedEx, and the USPS all offer distinct advantages depending on the service. Before you send a package, compare costs to choose the optimal carrier.

These three steps will help you reduce your shipping spend under your current small parcel contract, but sometimes, reducing costs still doesn’t get your prices low enough.

Now Turn Your Attention to Your Carrier Agreements

Even if you’re vigilant about every step, there’s a chance your parcel costs are still not optimized. There are several reasons why this might be the case.

The first is that your strategy might need to change. For example, if your company promises its customers free two-day delivery, examine whether it’s a vital part of the business. If you have customers that are satisfied with slightly longer delivery times, use two-day delivery as an upcharge rather than the default.

Another factor could simply be a change in market conditions, which happens quickly in the logistics industry. When it does, rates that once looked good are now hurting your business.

Shippers often believe that when market conditions change in the carriers’ favor, there’s nothing they can do because of their parcel agreement, but this isn’t the case.

Most small parcel contracts can be renegotiated at any time. If your rates are hurting your business, you should always renegotiate.

Prepare for Renegotiation — Here Are Six Ways

Of course, actively managing your carrier agreement isn’t only beneficial for the one you already have; doing so can also help you save more money in future negotiations.

16 PARCELindustry.com MAY-JUNE 2023

1. Know Your Shipping Profile

You won’t be able to optimize costs if you don’t know your own shipping profile. Examine your data trends and determine how often you ship packages with certain dimensions and weights, volumes, and service modes, and also look at where your packages are being delivered to.

2. Know Your Parcel Agreement

It is vital to know what is in your current carrier agreement. Which services are you paying for, and which surcharges can you avoid? Identifying which parts are working for you and which are not can help you craft a small parcel contract that better suits your needs.

3. What Is the Shipping Environment?

Are you hitting the service-level minimums? Do you have exposure in the areas where carriers are increasing rates the most? These are just two questions you need to answer before you renegotiate. Understanding the shipping environment will help you make adjustments that optimize your small parcel costs.

4. What Are the Carrier’s Pain Points?

Just because the carrier makes a few extra bucks for every package where there are dimensional adjustments or for incorrect commercial or residential information, that doesn’t mean the carrier enjoys the work. Sometimes, imposing these extra fees is more of a hassle than a benefit. Savvy shippers can identify what these areas are and how to leverage them.

5. Look at the Competitors

With FedEx and UPS reaching capacity (and one being on the verge of a potential strike), it could be an optimal time for a change. You might even be able to leverage one carrier to get a better deal with your incumbent, or you may find that a different carrier suits your needs best. Either way, exploring the options on the table can help you take advantage of opportunities to lower costs.

6. Negotiate Confidently and Collaboratively

Actively managing your carrier agreement doesn’t mean coming to the negotiating table with hostility. You want to be confident and firm about your needs, but without aggravating your carrier. After all, you’ll be relying on them for the next few years.

Don’t Let Misconceptions Hurt Your Budget

Monitoring your parcel operations can seem like a time-consuming obligation if you’re just getting started. Add contract negotiations into the mix, and it can look like you’re creating a headache for yourself.

The truth, however, is that not only are these two tasks easy to manage, but you can work on them simultaneously without burning through hours and hours every week. Following these key steps will not only save you money now, but will help you save money on your small parcel shipping in the years to come.

Brian Byrd is EVP, Operations, at TransImpact. In this role, he assigns responsibilities, develops functional roles, and oversees operations to help ensure that the company remains an industry leader in developing innovative technological solutions that help its clients to grow their companies.

MAY-JUNE 2023 PARCELindustry.com 17

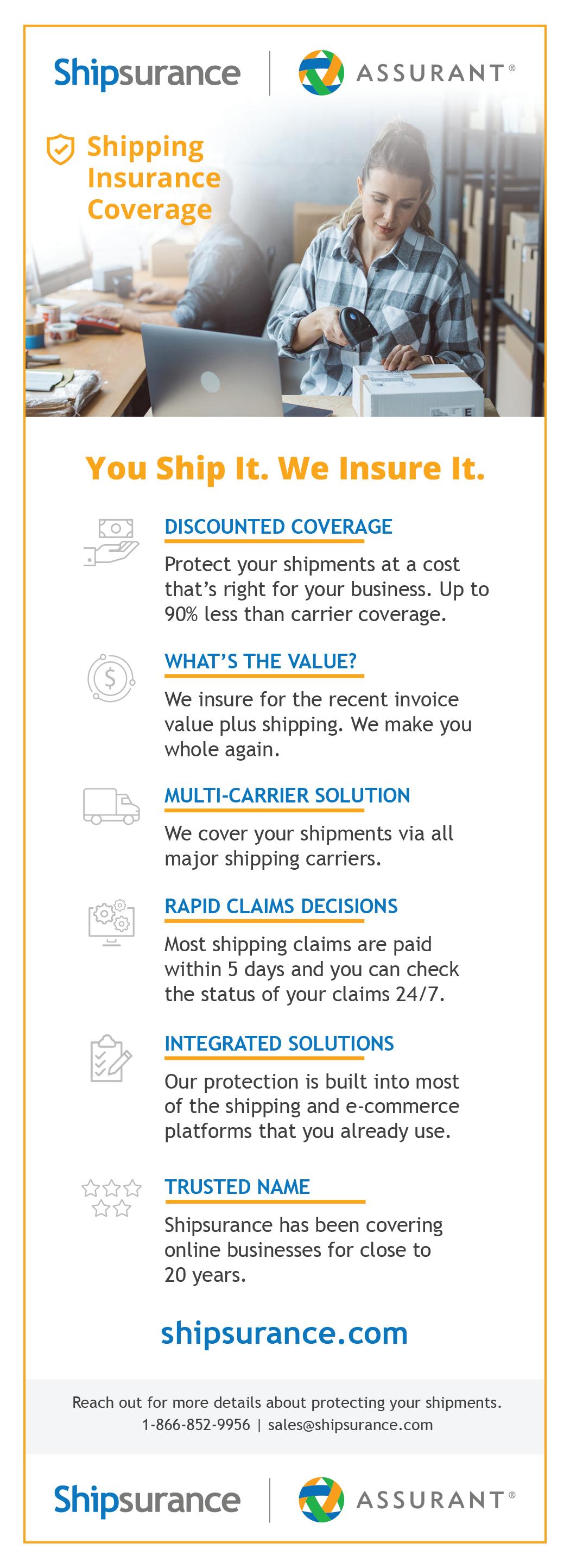

ARE YOU USING REGIONAL AND FINAL-MILE CARRIERS?

Regional and final-mile carriers are a very effective and efficient means of getting parcel shipments from city to city, state to state, and coast to coast. One or more of these featured carriers may have just the answer you have been looking for in your quest for a more efficient and reliable delivery method for your products. Please review their information and check out the service map on the following pages.

GLS provides parcel and freight delivery services in California, Nevada, Arizona, New Mexico, Oregon, Washington, Idaho, and Utah. The business needs of our customers are constantly shifting and changing to adapt to ever-changing work environments. To help with this, we offer convenient delivery options for your Ground and Freight shipments, as well as Priority delivery at significantly less cost when compared to the national carriers.

gls-us.com | marketing@gls-us.com

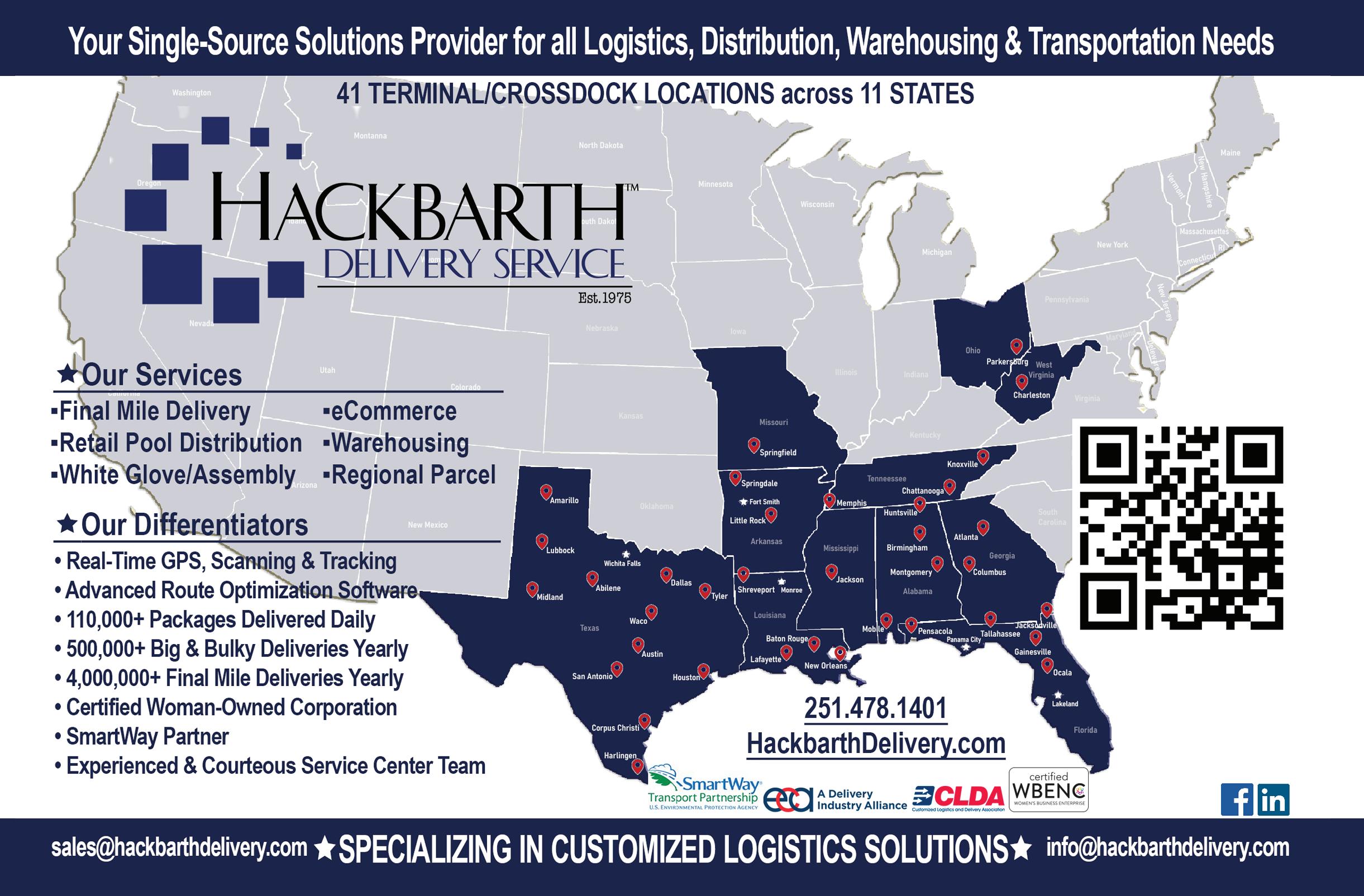

Specializing in Customized Logistics Solutions, *Hackbarth Delivery Service, Inc. is your single-source solution and regional connection for large and small parcel distribution and e-commerce shipments. Established 1975 in Mobile, AL with $500 and one van, Hackbarth currently delivers 100K+ packages/day, completing 4MM+ final mile deliveries/year from our now 41 terminal/cross dock locations across 11 states of the Southeast, Midwest, and Mid-Atlantic US regions. Hackbarth exemplifies first-rate customer service and customized competitive solutions for all transportation, logistics, distribution, and warehousing needs. We provide realtime scanning/delivery updates, live tracking and tailored reports, employing technology to drive efficiency, optimization, and complete visibility. Certified Woman-Owned Corporation & SmartWay partner.

www.HACKBARTHDELIVERY.COM | info@hackbarthdelivery.com | sales@hackbarthdelivery.com | 251.478.1401

OnTrac is the carrier of choice for last-mile e-commerce deliveries that helps retailers and shippers build a competitive advantage through faster delivery times, lower costs, coast-to-coast coverage, and reliable on-time performance. The OnTrac delivery network reaches approximately 80% of the U.S. population in 31 states and Washington, D.C. and enhances retailers’ ability to meet growing demand in the consumer e-commerce delivery market. With more than 65 years of experience, OnTrac has evolved into a critical part of the e-commerce infrastructure and is trusted by leading retailers and shippers that desire reduced transit times and increased flexibility within their supply chains.

ontrac.com | sales@lasership.com

18 PARCELindustry.com MAY-JUNE 2022

SPONSORED CONTENT

SEE LARGER MAP ON NEXT PAGE

Optima Overnight’s expedited ground delivery network offers unmatched service throughout New England. With over 40 years’ experience meeting the delivery needs of our customers, Optima continues to grow as the first choice in final-mile delivery for e-commerce, retail, meal kits, medical, and more! Our customized solutions can get you to your customers faster, with more consistent service and more cost-effectively than the competition. To learn more, please visit our website below or give us a call. We deliver, on-time, every time!

For 25 years, Pace has been your go-to final-mile provider for the Southeast. Our 18 facilities effectively serve customers in endeavors including e-commerce, retail, automotive, healthcare, business and industrial supply, and hospitality. Our services for these customers feature final-mile, pool distribution, scheduled courier routes, and linehaul. Pace’s transportation solutions range from small vehicles, cargo vans, straight trucks, to tractor trailers. Pace is excited to fulfill our mission with you of Solving Logistics Together!

Sonic Transportation & Logistics was founded in 1976 providing final-mile, statewide, next-day delivery in Florida. Sonic provides the tools to enable your company to track your shipments in real time. Sonic provides VPOD & VPOA for all shipments. Whether you’re shipping payroll, e-commerce, retail, or any small package to Florida, Sonic Transportation and Logistics is your trusted source to get the job done. For more information, please contact us at gcampbell@sonictl.com / 800-627-6642 ext. 203.

Spee-Dee Delivery Service, Inc. is proud to be celebrating 45 years of providing reliable and cost effective service in the Midwest. Our company has grown to include 35 locations, serving over 12,000 daily customers throughout 9 states. We continue to add to our menu of service offerings including Spee-Dee On-Call, Spee-Dee LTL, and most recently Spee-Dee Logistics, which provides warehousing and fulfillment services. With our simplistic approach to pricing, Spee-Dee Delivery makes it easy for shippers to identify and understand cost savings.

United Delivery Service (“UDS”) is a premier last-mile next-day regional courier. For more than 50 years, many of the world’s most trusted brands have partnered with UDS to enhance the delivery experience of their customers in the Midwest. UDS offers proprietary software that allows us the flexibility to develop solutions to meet the specific needs of our customers. Our technology stack offers real-time tracking including SMS notifications, Visual Proof of Delivery, and a suite of online tools for complete visibility of your shipment every step of the way. UDS . . . The First Name in Last-mile Delivery

MAY-JUNE 2021 PARCELindustry.com 19

www.pace-usa.com | sales@pace-usa.com | 866.410.7222

www.uniteddeliveryservice.com | Sales@uniteddeliveryservice.com | 630.930.5201

www.shipoptima.com | sales@shipoptima.com | 781.328.0081

www.speedeedelivery.com | sales@speedeedelivery.com | 800.862.5578

www.sonictl.com | gcampbell@sonictl.com | 800.627.6642 ext. 203.

2023

F E AT U R E D R E G I O N A L & F I N A L - M I L E

FEATURED REGIONAL FINAL-MILE CARRIER SERVICE MAP

C A R R I E R S E R V I C E M A P

WASHINGTON DC

GLS

AR, CA, CO, ID, NM, NV, OR, UT, and WA

Hackbarth

AL, AR, FL, GA, LA, MS, MO, OH, TN, TX, and WV

OnTrac

AR, AZ, CA, CO, CT, DE, FL, GA, ID, IN, KY, MA, MD, MI, MS, NC, NH, NJ, NV, NY, OH, OR, PA, RI, SC, TN, TX, UT, VA, WA, WV, and Washington DC

Optima Overnight CT, MA, NH, and RI

Pace

AL, AR, GA, KY, LA, MS, NC, TN, (Dallas and east TX)

Sonic FL

Spee-Dee Delivery Service IA, IL, MN, ND, SD, WI and select ZIP Codes in MI, MO, and NE

United Delivery Service IL, IN, and WI

BY GREG MEYNE

BY GREG MEYNE

BEAT INVENTORY OVERFLOW WITH FACILITY DESIGN

Over the last quarter, warehouse and distribution center leaders have grappled with higher than usual inventory levels, which are often more than their facilities are equipped to handle. In this situation, it is common to put money and labor into standing up additional facilities to manage the overflow. But what if this wasn’t the only option? In the current market, where every dollar and every employee is immensely valuable, what if you could create space for your overflow leveraging only the facilities you already have? This is where optimal facility design comes in.

The Importance of Facility Design

Designing your facility to maximize space is of the utmost importance. For facilities that are not optimally designed, the top 20% of the building is left unused; that’s almost a quarter of your total warehouse space being wasted. Tactics such as vertical cube storage, narrower aisles, and implementation of the right automation and technology are all great not only for using the 20% of unused space, but also for creating 10 to 15% of additional storage that didn’t previously exist.

Three Keys to Increasing Inventory Space

The three tactics that will make the most use of the facility space you already have, as well as create more facility space,

are using the full vertical cube, narrowing aisles, and increasing storage density.

Vertical Storage

One of the main mistakes facility leaders make is not leveraging the full vertical of the cubic space available in the warehouse. The top 20% of the building is valuable space that is too often left completely empty due to inadequate facility design. There are a couple of ways to reconfigure your warehouse to accommodate storage in the upper quarter.

1.Add different types of racks and automation. There are systems and equipment specifically designed for vertical storage. Anything from an individual unit to a full pallet can utilize the full vertical cube. Adding these into your facility will make all the difference.

2.Leverage automation and robotics systems. Robotic shelving systems are a good avenue for leveraging the vertical space in your facility, and level picking systems will transform the way warehouse associates can pick items while leveraging the full vertical cube.

Narrowing Aisles

While it is important to leave space in the facility for employees and picking systems to navigate, narrowing aisles can add an additional 10 to 15% of space in your facility.

22 PARCELindustry.com MAY-JUNE 2023

SUBSCRIBE FOR FREE!

Different types of lift trucks and other technology can create more storage per square foot, allowing you to use less aisle space. With the right facility design, storage media, and lift equipment, aisles can be as small as 6’-6” in a Very Narrow Aisle solution. This is down from 10’-0” or more, which is the standard aisle size in standard solutions.

Storage Density

While narrowing aisles is a great tool for increasing inventory space and storage density within the facility, some systems can even eliminate unnecessary aisles. There are tools for any system your facility may need.

Pallet racking options such as double deep, push back, and drive-in are great for improving storage density.

Deep lane mole systems are great for manufacturing environments connecting to storage systems and pallet handling systems.

Robotic systems are beneficial for carton or tote storage and retrieval using the full vertical of the building. They can assist with restacking to ensure that all units are stacked to create as dense a storage location as possible.

Leveraging these systems to increase the storage density in your facility can shrink your utilized space down by 30 to 40%.

Getting Started

When beginning your facility design project, it is important to start by researching the right technology and automation for your facility’s unique needs. A common mistake among operations leaders is applying storage equipment based on material handling or lift equipment that is already in the facility. While this may seem efficient and cost-effective, it will ultimately land you with the same technology that was already not working for your inventory needs and a lot of new and expensive equipment that does not solve your inventory challenges.

Instead, begin by figuring out exactly what technology and automation your facility needs in order to function at its peak and work backward from there to determine what pieces are appropriate based on the technology. Take care not to rush this process. You will want to research all of the options available to you and choose the ones that best suit your facility’s unique needs.

Greg Meyne is senior director of automation at enVista. Meyne has nearly 30 years of industry experience, including nearly 10 years of facility design experience at enVista, where he helps warehouse and distribution leaders optimize their facilities and designs material handling systems for clients. Meyne’s expertise includes facility design, material handling equipment design, automation, manufacturing, supply chain management, operations, and more. He graduated from the Rose-Hulman Institute of Technology with a degree in Mechanical Engineering.

MAY-JUNE 2023 PARCELindustry.com 23

www.sonictl.com 800-627-6642 Ext. 203 gcampbell@sonictl.com Servicing the Sunshine State Since 1977 Next Day State Wide Delivery Residential Delivery Experts State Wide Distribution Electronic Signature Capture Professionally uniformed couriers One of the largest independent courier companies in FL. Over 500 active customers In excess of 3 million packages delivered annually Visual Proof of Attempt Visual Proof of Delivery VPOD Florida’s

Delivery Experts VPOA Our dedicated team of logistics experts with over 30 years of experience, know where to look for incentives and optimization

the carriers don’t want you to see. Parcel optimization and savings experts Auditing of all freight modes Reporting and analytics tools Payment processing solutions General ledger coding solutions White label solutions for consultants www.Go-ACT.com 248-630-1326 | Connect@Go-ACT.com Our goal is to reduce your shipping costs, it’s all we do. Are your shipping costs too high? We’ll get you back on track.

Next Day

opportunities

Parcel shipping is used for small amounts of goods or products, usually under 150 pounds. Parcels are more manageable for shipping companies to work with, as they usually can be lifted by one worker without assistance. Less-than-truckload (LTL) is most often used for shipments over 150 pounds but no more than 10,000. Multiple items, boxes, or shipping units are secured to pallets for LTL transit. While the carrier may accept loose freight, it is best to use a pallet, as it dramatically reduces the chance of damage or loss in the LTL environment. When comparing LTL vs. parcel, larger bulkier materials may be a better fit to move via LTL.

How Do You Know Which Transport Mode Is Best to Use?

Shippers must first consider shipment size and weight when determining whether to ship via LTL or parcel. LTL is typically used for larger, heavier shipments that are too big for parcel carriers to handle. For small and lightweight packages, parcel shipping may be more cost-effective.

If speed is a priority, parcel shipping is a better choice. LTL shipments usually take longer than parcels, as LTL shipments can involve multiple stops along the delivery route. If the shipment is fragile or contains high-value items like furniture or artwork, parcel shipping may provide better handling and protection. LTL shipments are usually consolidated with all types and sizes of freight, which may lead to potential damage of items as packages can shift during transport.

THE CHANGING FACE OF LTL SHIPPING

BY RYAN POLAKOFF

BY RYAN POLAKOFF

Regarding costs, LTL shipping is more cost-effective for larger shipments, while parcel shipping may be more cost-effective for smaller items. Rates should be compared from different carriers to determine which option is best.

Plus, some areas of the country or city may be better served by LTL carriers than parcel. Consider destination locations, such as a rural or urban area, and available carrier options when deciding which carrier to book.

When shippers use parcel shipping, they must schedule pickups and deliveries, typically during office hours. What does a shipper do if they need something shipped after hours? Many parcel carriers offer drop-off locations shippers can utilize. But as LTL shipments contain larger and heavier products, it’s imperative shippers schedule the pickup and delivery during regular business hours so that the carrier can use the shippers’ loading dock.

Still, LTL is a great mode to choose when all the packages are smaller but in the same location. LTL shipping allows shippers to transport more items together in one place while also saving money.

Working with a 3PL specializing in helping shippers reduce and mitigate freight costs, while improving customer service, can ease the decision process. These third-party logistics companies understand their customers’ needs, issues, and service contracts and can make the best decision for them. 3PLs have contracts with various carriers, including parcel, LTL, TL, and regional carriers, and can best decide how to meet the shippers’ needs.

24 PARCELindustry.com MAY-JUNE 2023

SUBSCRIBE FOR FREE!

LTL Shipping Is Undergoing Changes

LTL shipping is undergoing several changes that are transforming the industry, such as using advanced technology to streamline operations and improve customer service. This includes transportation management systems (TMS), real-time shipment tracking, and automated invoicing and payment systems. A TMS can provide rate quotes for LTL, parcel, or TL; create bills of lading; dispatch shipping instructions to carriers electronically; track shipments in real-time; help file damage or loss claims; provide freight bill audit and pay services; and generate reports for continuous improvement. Many TMS systems can electronically connect to carriers so that carriers can book their loads and manage freight without a person involved. The near future will continue to see the adoption and implementation of predictive analytics, rating structure changes, and freight optimization strategies.

The rise of e-commerce has led to an increase in small- and medium-sized shipments, which are ideal for LTL carriers. As e-commerce grows, LTL carriers will likely see more business from online retailers and consumers. However, many e-commerce retailers will continue to use parcel carriers to ship items depending on the size and weight of the products.

Many LTL carriers are reducing their environmental impact by investing in fuel-efficient vehicles to reduce emissions and optimizing routes to reduce mileage and fuel usage. Some LTL carriers use technologies that automatically shut down the engine during idling to reduce emissions.

Like many transportation industry segments, LTL carriers face capacity constraints due to a shortage of drivers and other operational challenges. This is leading to higher prices and longer lead times for LTL shipments. If a shipment needs a faster delivery time, it might be best to choose parcel.

The LTL industry is currently undergoing consolidation as carriers seek to gain scale and improve their competitive position by acquiring other carriers. This is leading to fewer but larger carriers in the market, which could affect pricing and service levels.

Partnerships Are Key

Many LTL carriers are forming strategic partnerships with other carriers or 3PLs to expand their capabilities and service offerings. The expertise of the 3PL allows the carrier to offer more comprehensive solutions to customers than just working alone. 3PLs have expertise in managing logistics and supply chain operations, as well as risk and compliance, reducing carriers’ exposure to regulatory and legal risks. 3PLs can manage customs and trade compliance, insurance coverage, and liability issues, and also provide greater flexibility and scalability.

Whether a shipper transports shipments via parcel or LTL carriers, the expertise of a 3PL provider can be used to help the shipper decide which type of carrier to use, resulting in lower costs and the best service for the customer.

MAY-JUNE 2023 PARCELindustry.com 25

Ryan Polakoff is President, Nexterus. Visit www.nexterus.com for more information.

THE 7 DEADLY SINS OF B2C FULFILLMENT

By Harry Drajpuch

By Harry Drajpuch

Successful online sales increasingly depend on an agile, efficient back-end fulfillment operation — to drive profitability and to keep customers happy and coming back. Here’s how you address some common challenges.

1. Bad Forecasting

Your company’s fulfillment operations need accurate sales forecasts to match labor with demand. Poor forecasts beget bad labor plans that beget inflated operating costs — or worse, staffing levels inadequate to get orders out on time.

Here’s what we see:

Marketing doesn’t inform fulfillment of upcoming promotions

Procurement doesn’t let fulfillment know when inbound products are on the way or stuck at the port

Operations and logistics fail to leverage historical insights that can help predict upcoming volumes

The data is there. It’s just not being communicated to the people making staffing decisions in the warehouse.

How do you fix the problem? With data, whether this is historical data like monthly sales averages, data from marketing and merchandising departments on upcoming promotions, or data from your 3PL on historical volume spikes or lulls.

It’s crucial to educate marketing and other upstream

functions about why accurate forecasts are so important to downstream operational efficiency.

2. A Single Warehouse Strategy

Using a single warehouse to provide national fulfillment is nowhere near sustainable for your business — unless you have a unique or special product that customers are willing to wait for. What are the downsides of a single-DC strategy?

If you’re shipping cross-country, the costly, high-zone parcel moves are killing you. A multi-DC network puts products closer to customers and reduces parcel costs.

With a single DC, you’re taking too long to deliver, which is bad for repeat business.

If a pandemic or natural disaster stops shipments for a week, can your business withstand that interruption?

While a single DC strategy makes sense for start-up brands, it’s a harder strategy to rationalize if you’re a high-volume B2C brand — especially since, in our analysis, there’s at least a 10% net savings when you add a fulfillment center in another region. How do you fix the problem? Do a distribution network analysis to determine the optimal number of warehouses you should have and where they should be.

3. Poor Retention of Warehouse Associates

Until machines completely replace people, the biggest productivity and profit killer in the B2C warehouse is an inability to hold on to warehouse workers.

Most acknowledge that labor is the toughest order fulfillment challenge right now. But the response tends to be more around recruitment than retention. If your workers leave as fast as they arrive, what have you accomplished — other than creating a highly efficient revolving door?

We estimate that each warehouse associate who leaves costs companies $8,500. And that’s just for HR-related departure and replacement costs. It doesn’t measure the productivity loss.

How do you fix the problem? Simple employee-care practices like the following are good investments:

Keep up with market wages.

Listen to those who are leaving to understand why.

Show appreciation.

Invest in developing your middle-level managers. Until robots are widely embraced (just a matter of time), curbing worker turnover is the most effective and inexpensive way to increase productivity and boost company profits.

4. No Performance Standards for Fulfillment Associates

How do you handle the picker with 50% of the throughput of most others? Many companies don’t have productivity standards for warehouse workers and don’t measure their productivity. Without such standards, unproductive associates fly under the radar and your throughput falls at least 10–15% of where it could be.

How do you fix the problem? Develop productivity standards — the time it takes an average worker to perform a particular task correctly. You can set standards for almost any activity, but

26 PARCELindustry.com MAY-JUNE 2023

some of the most common in the fulfillment warehouse are:

# of pallets that can be put away per hour

# of lines that can be picked per hour

# of lines that can be packed per hour

Time required to build a specific kit

Once established, start monitoring that standard and applying it across your operation.

5. Failure to Automate as Order Volumes Increase

Brands are understandably cautious about any capital expenditure to automate fulfillment operations. But there’s a cost to waiting, such as high labor-to-sales ratio; poor accuracy from reliance on manual, paper-based processes; and staffing challenges, particularly during peak shipping periods.

How do you fix the problem? Companies can take a slow, modular approach to technology investments so that expenses are in line with the business’s size and growth rate.

While your business is gaining traction, a predominantly manual approach supported by a Warehouse Management System (WMS) is, frankly, the right approach. But as your business matures and requires high-volume, high-velocity picking and shipping, investments in automation — automated/smart conveyors, robots, and more advanced picking technology like voice picking and pick to light — are essential.

6. Failure to Optimize Packaging

To reduce parcel shipping costs, don’t make the mistake of only looking downstream to the carriers. It’s very hard to influence those rates. Instead, look upstream. There you’ll find huge opportunities to cut costs through simple changes to your packaging.

For example, why can’t brands get something as simple as box size right? We’ve all experienced it. That tiny thing we ordered online arrives in a box big enough for two throw pillows.

Streamlining your packaging size and form can spare your brand from looking like an inefficient, non-green-conscious bumbler, while saving you a cool two to 10% in parcel shipping costs.

How do you fix the problem? Rightsize your packages. Could you go smaller using your current box selection? Maybe you need to expand your sizes to provide a more exact fit. Every ounce you lose helps.

Another weight loss strategy is to switch from a box to a poly bag or jiffy bubble mailer for smaller, lightweight shipments. It can effectively eliminate a few ounces, while still protecting products

7. Set-It-and-Forget-It Slotting Strategy

Slotting is the process of organizing inventory in a warehouse to minimize space requirements and reduce travel time. Efficient slotting lets fewer workers pick more orders, more efficiently.

The issue isn’t that warehouse operators don’t do slotting, but that they don’t do it often enough. Typically, slotting happens at the onset of a project. But over time, the volume changes or the SKU mix changes and no adjustments are made. Labor costs creep up, but very gradually, and no one

attributes the increase to poor organization of inventory.

How do you fix the problem? Assign the right resources to determine the best slotting strategy for your current orders and revisit this strategy monthly (ongoing adjustments to the existing strategy), quarterly (more substantial changes), and annually (major changes involving rezoning, additional racking, or different racking solutions).

To reduce pick time, consider the following:

Put promoted/high-volume SKUs in forward-pick areas

Create adjacent locations for products that often sell together

Place fast-movers in locations that allow picking without bending or reaching

Separate similar products/SKUs that could be mis-picked

Balance picking activity across aisles to reduce productivity-killing congestion

It comes down to making sure that all the inventory is where you want it — for efficient receiving, picking, and shipping.

GET FULFILLMENT RIGHT

The new battleground for competitive advantage in online selling is no longer product or price. It’s customer experience. As a result, brands need to get order fulfillment right.

MAY-JUNE 2023 PARCELindustry.com 27

Harry Drajpuch is CEO, Amware Fulfillment. Visit www.amwarefulfillment. com or email Harry.drajpuch@amwarelogistics.com for more information.

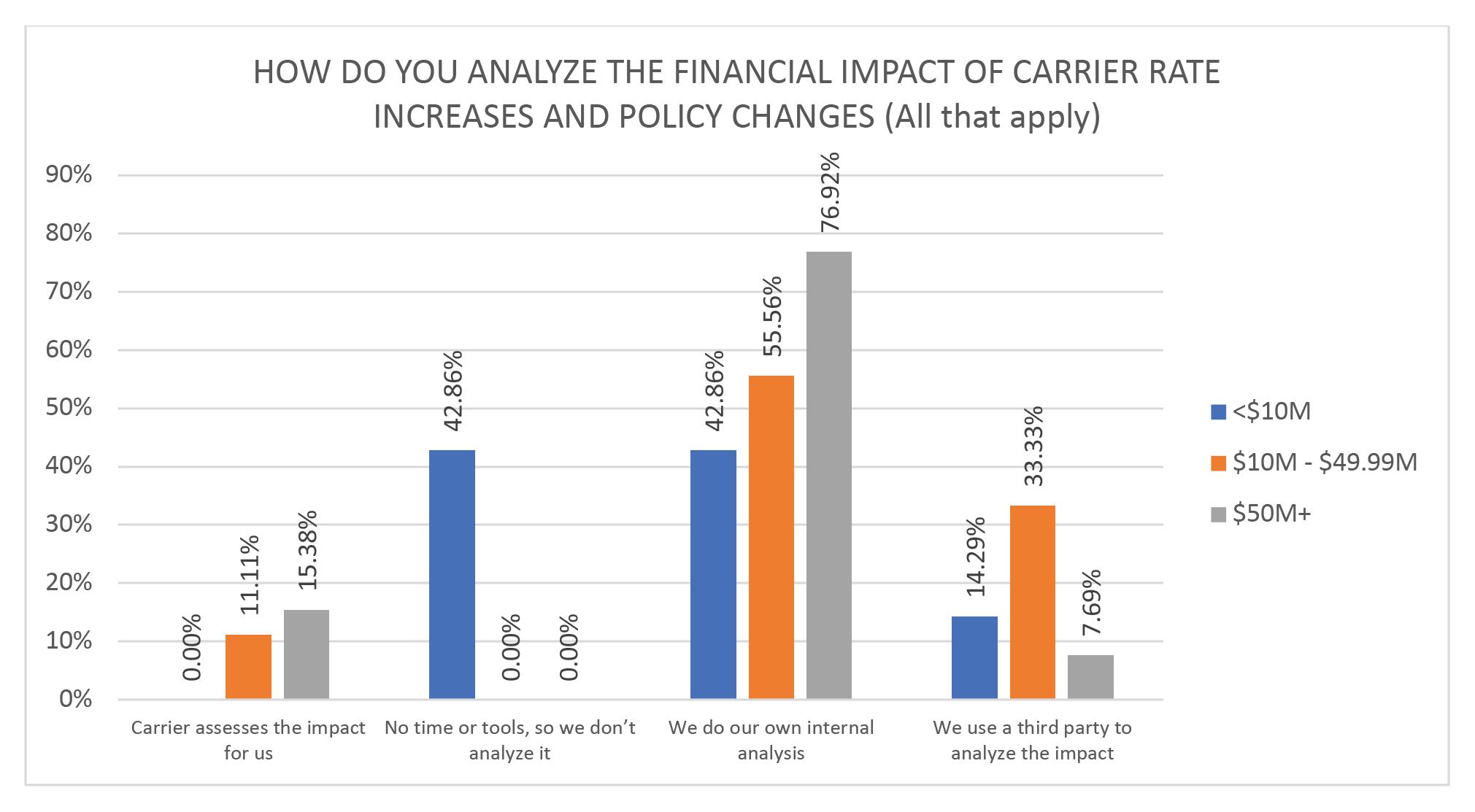

INTERACTIVE SHIPPER SURVEY – LIVE PARCEL FORUM RESULTS UNVEILED: PART TWO

By Josh Taylor

Dozens of shippers (commanding approximately $3.5 billion in aggregate annual shipping spend) participated in Shipware’s live parcel pricing and benchmarking survey at the 2022 PARCEL Forum in Chicago. Participating shippers responded anonymously to survey questions based on ranges. Technology-enabled and totally blinded to avoid

confidentiality concerns, the survey was designed to help shippers better understand how their pricing compares to other shippers. Moreover, all survey responses were cross-tabulated by industry, company revenues, primary carrier, and annual parcel volume/spend for more meaningful correlations. Part One covered demographics, negotiating histories, and best practices (PARCELindustry.com/LiveBenchmarking

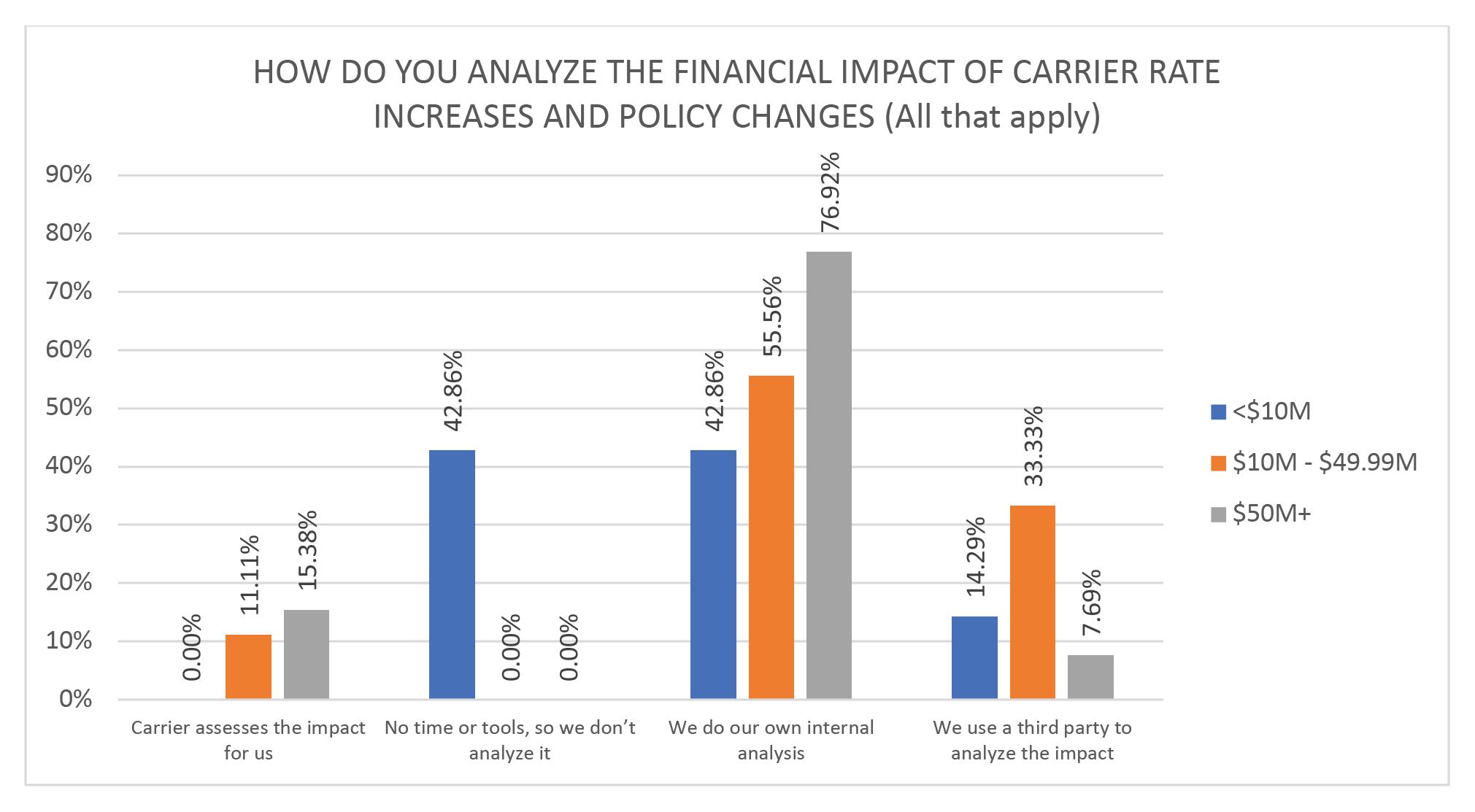

ANALYZING FINANCIAL IMPACTS

PartOne). Part Two delves into actual discounts and incentives, as well as the shipper’s relationship with their carrier rep.

While no shipper would ever knowingly leave money on the table, some shippers have clearly done a better job than others when it comes to negotiating the most favorable rates and terms. Find out if you’re one of them by reading the results below!

Analyzing the financial impact of carrier rate increases, policy changes, and contractual modifications is vital to negotiating the best possible discounts, but some shippers lack the necessary expertise and ability, or report just not having the time to do it. In fact, 11.11% of medium shippers ($10M-$49.99M in annual parcel spend) and 15.38% of large shippers ($50M+) rely on their carrier rep to tell them the value, and 42.86% of smaller shippers (less than $10M) don’t analyze it at all. Carrier pricing processes are intentionally opaque, even for your carrier rep, which can cause an imbalance of power in the negotiation. Take back some of that power by quantifying any changes using your own independent analysis.

28 PARCELindustry.com MAY-JUNE 2023

INTERACTIVE SURVEY

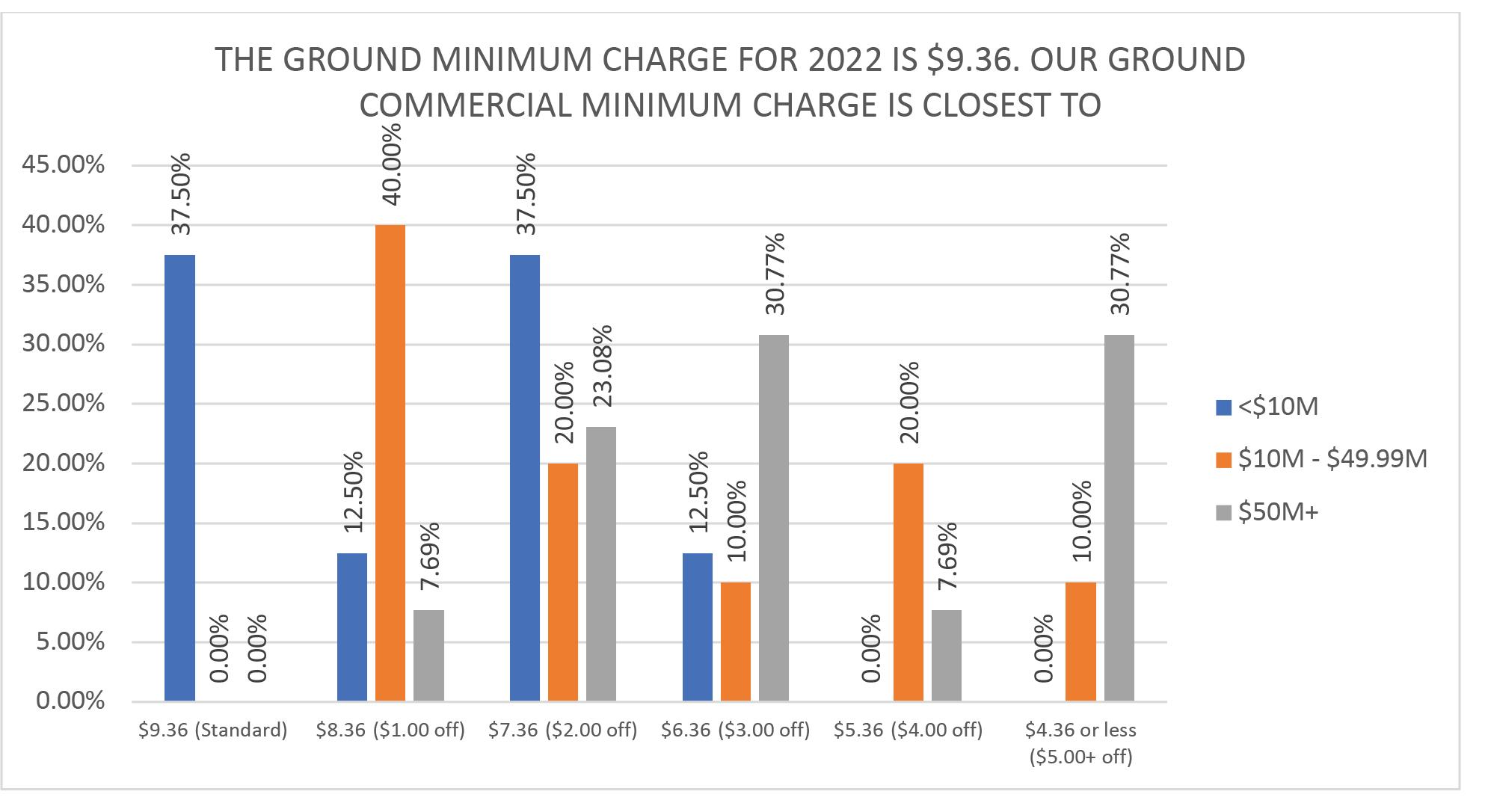

MINIMUM CHARGE ADJUSTMENTS

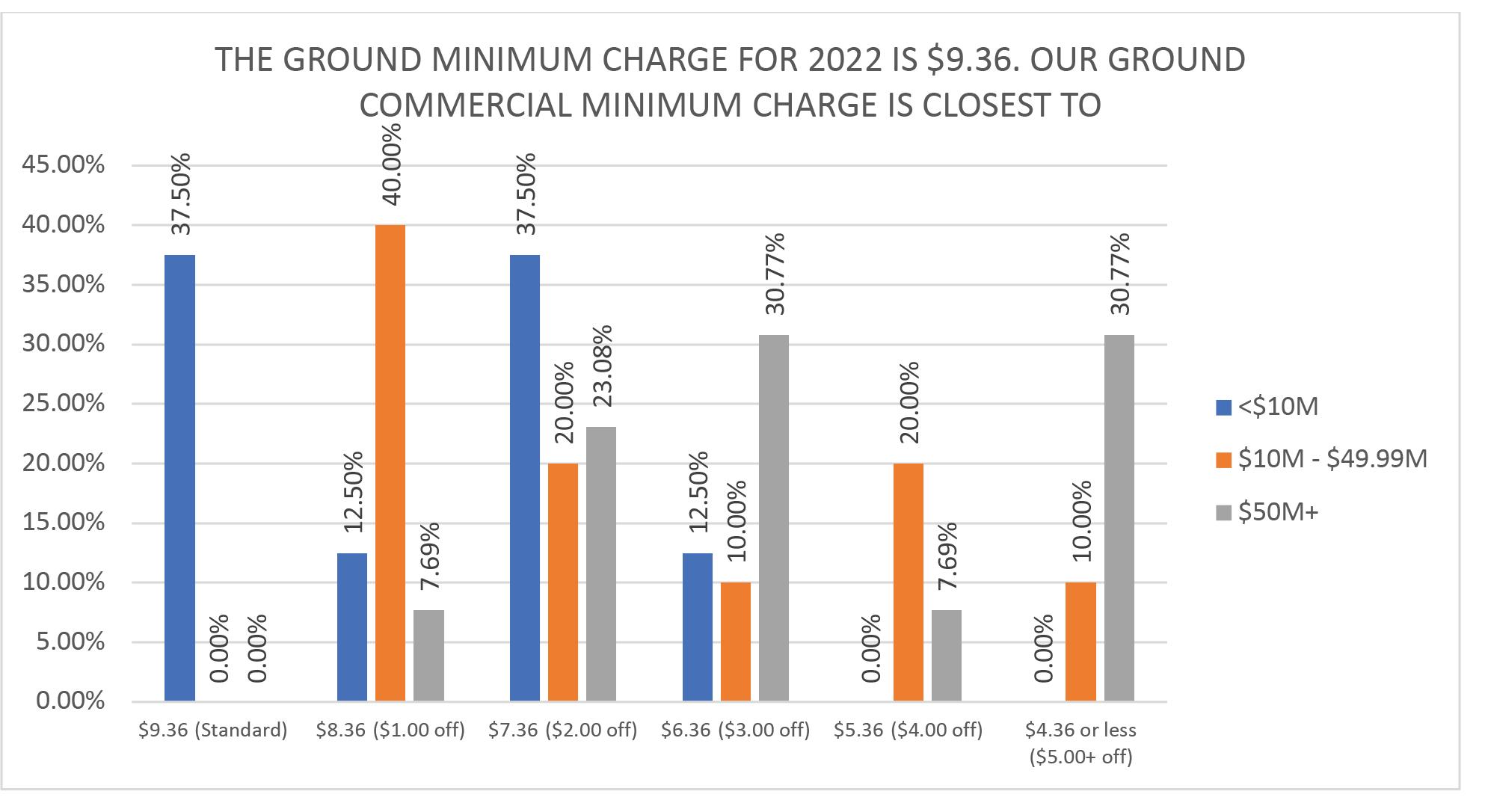

Most carrier contracts include minimum charges, the lowest amount a carrier will accept for a given type of package. For both FedEx Ground and UPS Ground, the most common minimum is the current published rate for a Zone 2, one-pound package. When this survey was administered in 2022, the minimum charge was $9.36. In 2023, shippers pay at least $10.10 for every Ground package (not including surcharges), unless they negotiate a minimum charge reduction. For packages weighing 10 pounds or less, the net rate a shipper pays is often dictated more by the minimum charge adjustment than the discount.

Commercial Ground Services

For commercial Ground services, the smaller shippers in the survey (<$10M) ranged from no minimum charge adjustment to $3.00 off, while larger shippers reported adjustments of up to $5.00 off or more.

Residential Ground Services

The mix changes somewhat for residential Ground shipments, especially for the largest and smallest shippers in the survey, with residential Ground minimum reductions trending larger than for similar commercial Ground shipments.

MAY-JUNE 2023 PARCELindustry.com 29

SUBSCRIBE FOR FREE!

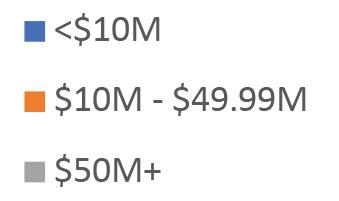

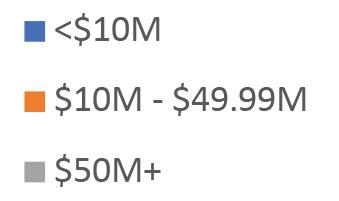

BASE RATE INCENTIVES (aka, service-level incentives)

The base rate is the service-level charge before any accessorial charges or surcharges are applied. Due to low utilization and to save space, three-day products, FedEx Ground Economy (SmartPost), and UPS SurePost are excluded from this article despite being included in the survey.

1-Day and 2-Day Services (FedEx Overnight, UPS Next Day Air, FedEx 2Day, UPS 2nd Day Air)

While the largest shippers had the highest discounts and the smallest shippers had the lowest, there is a noticeable trend toward the middle, regardless of shipper size. Questions about applicable minimums are planned for the 2023 survey.

Josh Taylor is the Senior Director of Professional Services at Shipware, LLC, a parcel consultancy that helps high-volume shippers reduce shipping costs by as much as 30%. He previously spent 17 years at UPS in Revenue Management Strategy, Pricing, and Sales. He uses his broad industry knowledge and specific expertise in parcel pricing and services to help clients optimize their supply chain. He is a frequent speaker at industry conferences and webinars, and his opinions and articles are regularly published in industry-specific and mainstream outlets.

To see even more results, please visit PARCELindustry.com/LiveBenchmarkingPartTwo

30 PARCELindustry.com MAY-JUNE 2023

WHO’S HOT SEE THE CURRENT HOT COMPANIES BIG ANNOUNCEMENT IN AUGUST Find out who the industry’s 2023-2024 HOT Solution Companies are!

AUSTIN HOUSTON SAN ANTONIO DALLAS

Ryan Polakoff

By Josh Taylor

Ryan Polakoff

By Josh Taylor

By Brian Byrd

By Brian Byrd

BY GREG MEYNE

BY GREG MEYNE

BY RYAN POLAKOFF

BY RYAN POLAKOFF

By Harry Drajpuch

By Harry Drajpuch