6 minute read

NEWSROOM

Known forsolving the world’stoughestscientific and technical challenges, RESPEC designed a customized solution for Wyoming’s LaPrele Irrigation District (the District). The project location is the rocky terrain of Wyoming’s Converse County, which is home to many prehistoric fossils.

As one of the only engineering companies that specializes in both irrigation and rock mechanics, RESPEC was hired by the Wyoming Water Development Commission in coordination with the District to assess the entire District, including the LaPrele Dam, a private Ambursen-style dam located below a rugged, weathered canyon wall several hundred feet tall. The 140-foot-high colossal dam, which was completed in 1909, was threatened by obvious loose boulders perched immediately above the dam on the canyon walls—the largest weighed an estimated 410,000 pounds. Other boulders were present higher up on the canyon walls but evaluating them would require rope access. The dam was also found to have cracks that required structural monitoring.

The RESPEC rope team spent 3 days at the dam in September 2019 using rope-access techniques and rappelling skills to map boulders and stratigraphy on the rattlesnake-infested higher canyon walls. After data were analyzed, more than a dozen boulders were determined to be threatening to the dam.

The RESPEC instrumentation team designed a custom data acquisition system (DAS) that used displacement transducers and Geokon RESPEC Engineers Investigate the Site Conditions at the LaPrele Dam During Low Water Conditions.

crackmeters. RESPECfitthe mostthreatening boulder with a string potentiometer that can detect movement as slight as 0.01 inch. The dam wasfitted with five crackmetersthathave a resolution of 0.001 inch and a camera that photographs the water surface behind the dam. The sensors and camera are tied into the solar-powered DAS that uses a cellular gateway to send data to an online dashboard. The dashboard isconfigured with early-warning alarms that will alert District authorities and give them time to warn and clear the area in the event that the rocks or dam begin to move. The solution provides a powerful safety mechanism for the small irrigation district, area hunters and campers, and wildlife and livestock. RESPEC’s creative, cross-disciplined team successfully worked under extreme conditions to create a unique and customized solution.

For detailed information, please contact RESPEC’s Ben Haugen, Remote Geotechnics Program Lead, at Ben.Haugen@respec.com

Established in 1827, South Carolina’s historical Haile Gold Mine was one ofthe first operating gold mines in the US. Today, the mine is owned by OceanaGold, a global gold-mining company. RESPEC began working with the OceanaGold Haile operation to assist the mine in establishing a drill-and-blast engineer role for a future hire. Our work also involved collecting baseline quality assurance/quality control (QA/QC) data to be used in tracking changes and improvements to the drill-and-blast operation. RESPEC’s team targeted drilling accuracies, blast performance, and the design plan versus actual data.

After the successful short-term project was completed, OceanaGold hired RESPEC’s onsite team to implement improvements to the site and track/audit changes in operational performance. RESPEC’s stafffurthered our previous work and assisted with ramping up drill-and-blast production to meet increased production requirements. RESPEC’s team worked closely with the technical services group, mine operations, and blasting contractors. Our Scope of Work included observing and evaluating safety procedures and requirements related to drill-andblast and other programs, as well as formalizing the new engineer position and associated tasks. Our team performed daily drill-and-blast engineering tasks and conducted QA/QC on the drilling and blasting when possible, including on drill quality, loading quality, explosives performance quality, and muck-pile results. We also provided drill-and-blast instrumentation services and interfaced with the explosives service provider. When OceanaGold was ready to hire a full-time, drill-and-blast engineer, RESPEC seamlessly transitioned the role and transferred responsibilities to the new employee.

RESPECSupportedOceanaGoldbyProvidingTransitionalTalenttoDefineaDrill-and-BlastEngineer Position With Associated Responsibilities While Improving Drill-and-Blast Operations.

RESPEC is proud to work with OceanaGold, a

company that shares our own values in caring for

the environment, helping the communities where

we work, and leaving a positive legacy beyond the

mine life cycle.

For detailed information, please contact RESPEC’s Daykin Schnell, Explosives Engineer, at Daykin.Schnell@respec.com

Performing QA/QC Data Collection and Interacting With Drill Operators in the Field Was an Important Part of Helping to Improve and Optimize Drill-andBlast Operations.

For a due-diligence effort, our mining client needed to ensure that blasting vibrations from an underground mine would not affect the homes and buildings of a nearby community once the mine was operational. Concerned with meeting community requirements, safety standards, and environmental regulations, the mining company needed RESPEC’s expertise to better understand the adverse impact of planned blasting operations.

RESPEC was hired to perform a feasibility analysis and meet the challenge of predicting vibrations without any preexisting data. Our work included evaluating blast vibration amplitudes that could potentially be generated at surface structures above the proposed mine. RESPEC ultimately established a regression equation for surface vibrations that result from underground blasting to be tested and compared to additional blast vibration data from similar operations across the industry.

Literature reviews of published blasting documentation provided little information, data, or models on surface blast vibrations produced by underground mines. At the client’s request, RESPEC collected blast vibration data from underground operations and developed an underground-to-surface blast vibration regression equation.

Our team worked with three underground metal-mining operations to collect surface blast vibration data produced by heading blasts and stope blasts: Dragon Mining’s Jokisivu Mine, Nyrstar’s Middle Tennessee Mines, and Lundin’s Eagle Mine. The data included blast vibration

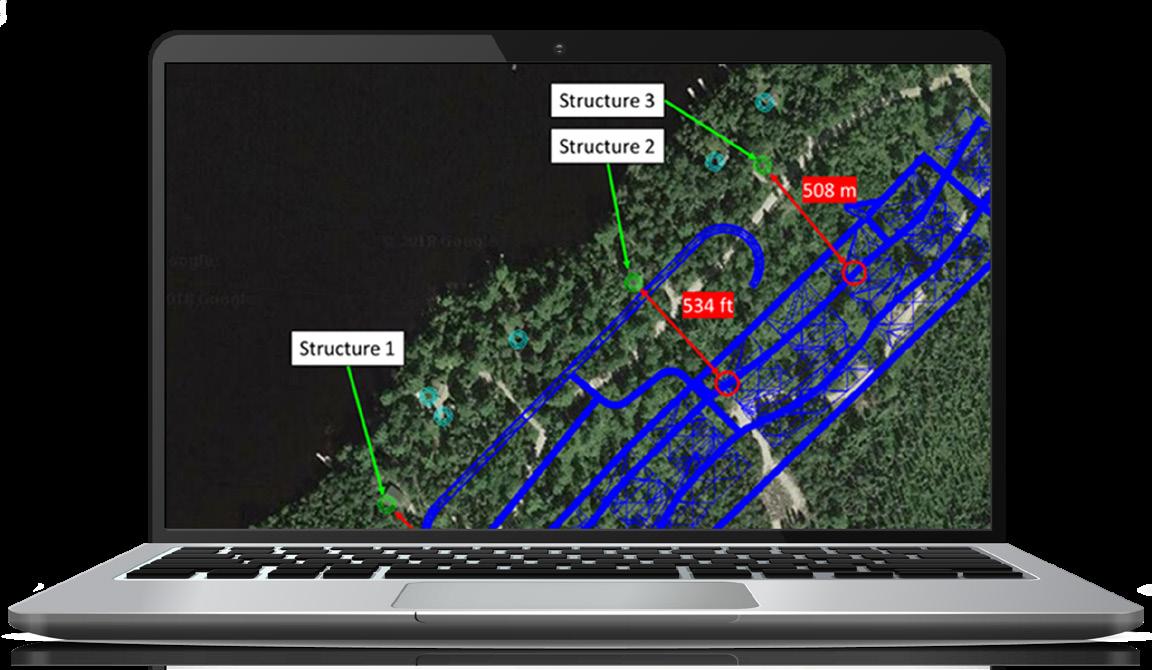

Plan View of the Closest Structures to the Stopes.

amplitude values, seismograph records, blast design geometry, charge weights, and detonator delay and sequence designs. The collected information was used to produce a regression equation and summary dataset that could be used by our client’s proposed underground mining operation to evaluate blast vibration amplitudes that would be generated on the surface above the proposed mine.

RESPEC’s team successfully identified problem areas before the mine’s start-up. We also devised new ways for the client to control and reduce the dangers ofblasting, such as flyrock, air blasts, ground vibrations, and dust, to ensure mine safety and meet environmental regulations. The project is proceeding under RESPEC’s guidance for further testing to predict more specific vibrations at the site. The project is gaining community support and our team is confident in finding the right plan for blasting the area in a way that reduces vibrations on local housing.

For detailed information, please contact RESPEC’s Daykin Schnell, Explosives Engineer, at Daykin.Schnell@respec.com