Louisville, Kentucky, USA • April 24-26, 2023 Bringing the industry together www.batteriesinternational.com INNOVATIONAWARDSPOWERON BCI Yearbook & Special Pre-2023 Convention Report MAC + Robotics = Innovations Come see our new innovations at booth 113

FREE Subscription Offer FOR FREE SUBSCRIPTION TO OUR DIGITAL MAGAZINE

Louisville, Kentucky, USA • April 24-26, 2023 Bringing the industry together www.batteriesinternational.com INNOVATIONAWARDSPOWERON • Full details of BCI activities over the year • Amplify award for marketing success • WGBI forges on, consolidation and growth

Yearbook

BCI

& Special Pre-2023 Convention Report

USA: sorfin@sorfin-yoshimura.us

FRANCE: paris@sorfin-yoshimura.fr

THAILAND: jiroyoshimura@sorfin-yoshimura.jp

www.sorfinyoshimura.com

JAPAN: tokyo@sorfin-yoshimura.jp

BRAZIL: vendas@sorfin.com.br

CHINA: qingdao@sorfin-yoshimura.cn

MEXICO: dbortoni@sorfin-yoshinura.us

INDIA: sales@sorfin-yoshimura.in SY Innovations: agurevich@sy-innovations.com

Is Proud To Support The Manufacturing of Nearly Half A Billion Batteries Annually

BCI Yearbook & Special Pre-2023 Convention Report

CONTENTS www.batteriesinternational.com Batteries International • BCI 2023 Yearbook • 1 Battery Council International’s Convention and Power Mart Expo, looks yet again to be the hottest meeting of the North American lead (and more) battery community this year. With an exciting agenda covering many issues that urgently need to be discussed. The 600 plus delegates heading to Louisville, Kentucky should find much to talk about.

12 6 30 EDITORIAL: BCI THE FORUM TO SEPARATE HYPE FROM SUBSTANCE 2 There’s a lot to talk about in this fast-changing industry. Louisville is the forum so to do BE THERE OR BE SQUARE: LOUISVILLE! 6 Bourbon, bluegrass music, cigars, what’s not there to like about this latest venue? THE SPEAKERS 8 Three keynotes: Robert Bryce, James Martin, Claudia St John and various industry luminaries BCI — INTERVIEW SUSAN BERNARD 12 A new mentoring program, online training, marketing and sponsorship activities are all part of what promises to be a busy, second full-year of operations for Women in the Global Battery Industry. Director Susan Bernard looks ahead. HAMMOND DOUBLES TREATED SURECURE PRODUCTION 14 THE QUARTER CENTURY CLUB (AND BEYOND!) 16 In honor of the supporters of BCI for 25 years and 50 years and of the battery folk that have led this industry forward over the years. And a sad farewell to John Devitt who enjoyed almost 65 years of BCI membership. THE INNOVATION AWARDS 20 Gopher Resource: Gatting the maximum value out of lead battery slag 22 Daramic: Separator tech charges ahead to new levels of performance 24 STC: A new horizon for lead paste desulfurization 26 Water Gremlin: Gremlin Green shining a light on the environment 28 Ace Green: Electrifying recycling, old batteries to new lead at room temperature 30 THE BCI AMPLIFY AWARDS 34 Shouting the joys of batteries from rooftop to rooftop 34 Communicating excellence: the seven nominations 35 C&D Technologies, Clarios, Club Assist, East Penn, Enovix, Stryten, Trojan 35-36 14

Mike Halls • editor@batteriesinternational.com

It’s time to use BCI as the forum to separate hype from substance

“Ceilings and floors, my boy,” a banker once told me.

It was a phrase that baffled me well over a quarter of a century ago as a trainee journalist writing about financial markets.

My topic: the inexorable rise of the Japanese stockmarket. In just five years the value of corporate Japan had trebled. The Nikkei stock index had soared to 39,000 and showed no sign of flagging.

“What’s ceilings and floors?” I asked.

“Don’t you know anything?” laughed the banker with just the right measure of scorn. “Once the price of the index hits its ceiling, then it’s the floor for its next rise. The only way is up. I expect to see the Nikkei at 40,000 in three months.”

As financial bubbles go Japan’s bubble was spectacular.

At one time the price of the land in the Imperial Palace in the heart of Tokyo was so inflated that, if you could have sold it, you

Publisher

Karen Hampton karen@batteriesinternational.com

+44 7792 852 337

Editor-in-Chief Michael Halls editor@batteriesinternational.com

+44 7977 016 918

Advertising director

Jade Beevor jade@batteriesinternational.com

would have enough money to buy Canada. (And that’s including everything inside Canada too.)

And then came the crash. Floors dropped through ceilings. And then fell through floors again, inexorably downwards.

That same stock index just 12 months later was down at 22,000 —$2 trillion of value had dropped in the value of corporate Japan. And, to make the point more brutally, that same index 33 years afterwards is standing at an average of 25,600 for this April.

So why mention all this in a magazine dedicated to reporting about batteries and the energy storage industry? And in particular ahead of this year’s BCI conference?

What’s true about financial markets is equally true about commercial ones.

This is now a key issue at the heart of the lead battery and energy storage markets. And one that this year’s meetings in Louisville needs to be mulling on in the background.

Editor John Shepherd john@batteriesinternational.com

Contributing editor Julia Berg

Researcher, journalist Frances Jones

Finance administrator Juanita Anderson juanita@batteriesinternational.com

Subscriptions, enquiries subscriptions@batteriesinternational.com admin@batteriesinternational.com

Production/design Antony Parselle aparselledesign@me.com

International advertising representation advertising@batteriesinternational.com

The contents of this publication are protected by copyright. No unauthorized translation or reproduction is permitted. ISSN 1462-6322

© 2023 Mustard Seed Publishing UK company no: 5976361.

Printed in the UK via Method

EDITORIAL 2 • Batteries International • BCI 2023 Yearbook www.batteriesinternational.com

Disclaimer: Although we believe in the accuracy and completeness of the information contained in this magazine, Mustard Seed Publishing makes no warranties or representation about this. Nor should anything contained within it should be construed as constituting an offer to buy or sell securities, or constitute advice in relation to the buying or selling of investments.

Very simply the forces of hype and unreality loom large over the entire energy storage market — and vast swathes of information, misinformation, and disinformation are at play.

A quick glance at the world of start-ups reveals a huge number of extravagant claims about various technologies — many of which have yet even to leave the laboratory bench — which may or may not be true.

It’s in the nature of start ups to boast technologies that are up-and-ready while still not finalized. But frankly they can’t all be true and we all know it.

Then there’s informed opinion.

One sector of the industry reckons that lead batteries are yesterday’s technology (and suppliers are moving away from the chemistry).

Yet other suppliers are predicting that all things will be well and there are huge untapped markets in the developing world about to be tackled.

And yet others see an imminent world energy shortage crisis. Although reputable market analysts predict steady and not explosive growth for lead battery sales, other superoptimists are preaching a gospel where lead batteries will become desperately needed in our decarbonized future.

What this magazine finds so puzzling is why are so many players, big and small alike, so entrenched in their thinking? Where is the balanced view? Where is the mature debate?

Each year our editorial team attends literally dozens of conferences and events. We dutifully try to follow the best presentations, hear the best speakers and keep up to date with an industry that is (perversely) both slow to change yet rocketing away at an unbelievable pace.

But choose the right conference and the right speaker and you may hear that lead acid is yesterday’s news (boo-sucks from the lithium ion community) or that lithium is explosive,

costly and probably bring you out in spots (courtesy of the lead acid gentlemen).

For this magazine we deliberately have to choose a middle path. Because, despite our occasional reservations, our job is to represent what people in this business say and are thinking, not our opinions.

For a profession where its leading lights see themselves as visionaries — and sometimes quite rightly too — there needs to be more coherence in that vision.

There are a host of issues facing this industry now that need to be dealt with in a concerted fashion. And BCI could well provide the forum for these conversations this year.

For example, irrespective of any belief that lithium/lead/nickel/something-brightand-shiny is going to save the planet, a reasonable debate has to be conducted over issues such as recycling batteries.

At the practical level there is a very real risk of an explosion if a lithium battery is smashed in a lead acid battery breaker. The chances of this happening are growing as both types of batteries can look similar. And BCI has made sterling attempts to suggest policies that are practical in this respect.

At the financial level, the commercialities of a huge range of recycling options need to be faced. At present it’s clear that it’s unlikely that anyone is going to be making a profit by selling the elements from a LiFePO4 cell (and other lithium variants also have question marks over them).

Is the world really crying out for more iron, phosphorous or oxygen?

So away from the world of hype will tolling arrangements be the future for most lithium recycling? Sensible discussions are needed over what that means for lead batteries too.

The forum is in place at Louisville this spring.

Let the debates begin.

EDITORIAL www.batteriesinternational.com Batteries International • BCI 2023 Yearbook • 3

Hammond-Engineered to Reduce New GravityGuard

Hammond is a Leading Developer of Lead-Acid Battery Chemistry for Advanced Energy Storage Applications

Red Lead & Oxides

High-Quality Staples of Battery Manufacture, Tailored & Processed

And has Served the Global Battery Industry For 90 Years.

Technical Assistance

Better Paste. Better Plates. Better Battery. Engineered to Customers’ Specific Particle & Batch Size Documentable Savings of Paste Material & Curing Time More Tested & Proven Benefits of Hammond Original & Treated SureCure® Improved Charge Acceptance • Strengthened Positive Plates • Enhanced Curing Consistency Increased Cycle Life • Improved Partial-State-of-Charge Cycling • Reduced Carbon Footprint Hammond Group, Inc. recently announced full-scale operations of its new North American Treated SureCure® manufacturing line, a multi-million dollar investment that doubles production capacity for one of its most effective and in-demand additives. Years of advance planning involving technical experts from across Hammond’s global team

production online at its Indiana facility in early 2023. Hammond uses similar manufacturing practices and raw materials to produce identical products at both its US and Malaysia locations. The facilities are ISO:9001 certified for quality, and the Indiana location is IATF certified to conform with more strict US automotive industry requirements. Read more at HammondGlobal.com/news. North American Investment Doubles Treated SureCure® Production Capacity INDUSTRY NEWS Treated SureCure® Accelerates TTBLS Crystal Growth

brought

Louisville

‘Gateway to the south’

Mint Juleps,

Louisville has many claims to fame — some outlandish, did the cheeseburger and the high five really originate from here? But, as Julia Berg reports, there’s a lot to see and do outside the BCI convention halls.

Louisville — pronounced Loo-ee-vill — is named after King Louis XVI of France and the French word for town (ville), It was so named in 1779 in gratitude to France for its help against the British in the US War of Independence. It was founded by Rogers Clark the Revolutionary War commander.

Among its earliest settlers in the area were second and third generation American-born French, the descendants of Huguenots who had fled France in the late 17th century to avoid religious prosecution.

This French connection persists to this day.

Louisville retains a strong connection with France featuring the fleur-de-lis emblem in the city flag and the thriving, rather French Paristown Pointe district which has boutique shops selling everything from pottery to silk scarves depicting, yes, the fleur-de-lis.

Kentucky’s most famous drink — bourbon whiskey — itself is derived from two historic roots. The first bourbon comes from the ancient French royal family the Bourbons, also as in biscuit and the Irish spelling of whiskey with an ‘e’. In Canada where the Scots were more prevalent the British spelling of whisky predominates.

The state of Kentucky may not be up there in many peoples’ holiday plans yet it has some jaw-dropping and impressive claims to fame.

And Louisville, its largest city is pure Kentucky. It’s the state that created the Mint Julep, bourbon whiskey, the Kentucky Derby and the slogan that its southern fried chicken was “finger lickin’ good”.

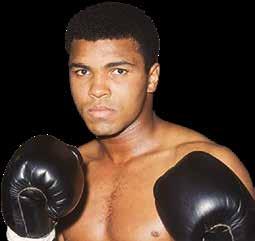

Its famous scions include Abraham Lincoln, Johnny Depp, Muhammed Ali, Rosemary Clooney, George Clooney (Rosemary’s nephew), Jennifer Lawrence and not forgetting ‘Colonel’ Harland Sanders, the mastermind behind KFC.

Louisville has a population of around 1.1 million yet, it feels truly American with that unique frisson of the Deep South but without being overwhelming. “More of a canapé — that’s its French aspect — than a burger,” says one commentator.

Whoever you’re talking to in Kentucky, inevitably the subject of horse breeding (and Bourbon) will come up. There are more than 450 horse farms here.

Experts claim the local water supply is responsible for this. Much of the water is filtered through limestone which, in turn, helps produce strong bones in horses. Or so some reckon.

They also say this pure water supply helps to keep the region’s famous liquid gold, free from impurities. Sensible batteryfolk, however, should just add ice or mint as required to their post-convention electrolytes.

Hang on a week after BCI is over and you could enjoy the world famous Kentucky Derby. It’s located at the Churchill Downs racetrack close to the university and a couple of miles from the old centre of town.

There’s serious money on the races and just as serious dress codes. So as you wander the grounds sipping on your Mint Julep and flapping your prize hat or cap, remember the race organizers say:

Hit the road Jack …

Imagine a tutored tasting of seven varieties of Bourbon whiskey while being watched over by a million dollar thoroughbred horse. This is just one of the many tours in the city and formally called the “Bourbon distillery and Horse Farm Tour”. It lasts a whole day with lunch included and if you’re staying on after the conference, it’s worth a thought.

6 • Batteries International • BCI 2023 Yearbook

BCI 2023 • Louisville, Kentucky

hats and horses

• Dos: Jackets and blazers optional. Vests, shirts with collars, sweaters, dresses, pantsuits, dress jeans, dress shorts and slacks are appropriate.

• Don’ts: Cargo shorts, t-shirts, crop or midriff tops, athletic wear, swim wear, frayed or torn denim or shorts, and don’t forget tennis shoes, trainers are considered inappropriate attire.

Electrolyte preparation: Julep juice

Ingredients: 1 teaspoon powdered sugar, 2 oz. Bourbon whiskey, 2 teaspoons water, 4 Mint leaves

Preparation: In a highball glass muddle the mint, sugar and water. Fill the glass with cracked ice, add Bourbon and stir well until the glass is well frosted. Garnish with a mint sprig.

Light version: Sugar, mint, water, ice may be replaced with extra measure of bourbon. Recommended for dieters.

The official starting point of the Kentucky Bourbon Trail starts in Louisville and crosses four regions and 18 so-called “distillery adventures”.

For batterymen and women keen to preserve the integrity of their livers, consider the “light” version called The Urban Bourbon Trail listing watering holes in Louisville with standout whiskey menus, many in a walkable stretch of historic buildings just blocks away from the convention hotel.

Floats like a butterfly …stings like a bee

Muhammad Ali, né Cassius

Marcellus Clay, reckoned to have been the greatest boxer of all time, was born in Louisville in January 1942. The Muhammad Ali Center — a museum about five blocks from the convention hotel — tells the story of the local boxer who became world champion and fervent supporter of civil rights. A conscientious objector during the Vietnam War, he was banned from professional boxing during his prime fighting years. Look out for the chance to shadow box with the champ courtesy of technology. Deeply moving.

Belle of Louisville

No, not a lady wearing a huge crinoline dress yet she is indeed a beauty. The last remaining, authentic Mississippi river style steamboat for trips along the River Ohio. About three blocks from the hotel.

Butchertown

The name won’t appeal to some, yet this is Louisville’s old meatpacking district, now buzzing with cool restaurants, beer garden and an artsy-bohemian market. Visit Cooper & King’s distillery (they make brandy, gin, absinthe) or sip something cool on the rooftop bar with possibly the best views of the city skyline. About 10 minute taxi ride from the hotel.

Keep Louisville Weird — the Highlands district

Not a nature experience but the city neighbourhood for funky eateries and offbeat shops. When you spot the “Keep Louisville Weird” stickers, you’ll know you’ve arrived, There’s more: coffee shops, vintage markets, comic-laden bookstores, trinket shops galore (some in extremely poor taste). Well worth dropping by. About 15 minute taxi ride from the hotel.

Retail therapy — opportunities galore

It’s impossible for any international delegate to overlook America’s shopping opportunities, and a list might well have been produced from home. Louisville is no exception with plenty on offer from the quirky city shopping districts selling vintage and luxury trinkets galore, many rather specially hand crafted to the big malls both in the city or a short drive. The Outlet Shoppes of the Bluegrass offers savings of up to 75% on international brands including Adidas, Nike, BOSS and more, located at Exit 29 on the I-64.

…

Things to see — don’t miss

BCI 2023 • Louisville, Kentucky

Check these out, to find out more: www.gotolouisville.com and www.kentuckytourism.com

Three keynotes set to make a splash

Meet the three keynote speakers for this year’s BCI convention. There is quite the mixed bag this year — Texan Robert Bryce, an energy industry veteran, author and known as a green energy myth-debunker, James Martin, associate director: consulting at S&P Global, who will be sharing his automotive battery expertise, and HR guru Claudia St John, founder of the national Affinity HR Group.

Will the transition to clean energy ever happen? Apparently not, according to Robert Bryce. taking a decidely contrarian outlook.

Robert Bryce is a Texas-based author and journalist focusing on energy, power, innovation, and politics. He has written over a thousand articles and six books, spanning over three decades.

Robert argues that renewable energy is not ready to meet real-word energy needs at a scale that can save the climate. Instead, he advocates for natural gas to nuclear power as the fuels of the future. There is likely to be more of his critical assessment of clean energy during his presentation ‘a sober look at the energy transition’.

Robert is the host of the Power Hungry Podcast, where he talks with a range of people from leading energy company CEOs to regular citizens. He is also the executive producer of the feature-length documentary, Juice: How Electricity Explains the World.

The long-term outlook for low voltage automotive batteries, James Martin brings a wealth of experience

James Martin joined S&P Global (formerly IHS Markit) in June 2018. He leads the automotive consulting services team for the US, based near Detroit.

James’s expertise includes propulsion system design, and forecasting the expected efficacy of new technologies. He looks at how these technologies might appear in the development of hybrid and electric vehicles for key automotive companies.

Commenting on lagging EV adoption in the central US, he said that the availability of EV products in a form that customers are willing to purchase, is a factor of equal importance to charging infrastructure.

He brings a wealth of experience to his talk; he worked for General Motors as director for global product planning from 2004 to 2007, and as senior manager for global product planning from 2011 to 2017.

Re-imagining the world of work — strategies for adjusting to a new normal? About time too, says Claudia St John

People power. It’s much talked about but less acted on. This will be the underlying theme of the presentation given by Claudia St John, the founder and president of Affinity HR Group, a national human resources and management consulting firm.

Since founding the group in August 2010, it has become the endorsed HR partner for more than 17 national trade associations and their member companies.

As a consultant and speaker, Claudia has given hundreds of presentations and workshops on topics such as how to recruit like a pro, common management mistakes and how to address inter-generational workplace challenges.

Claudia is the author of Transforming Teams — Tips for Improving Collaboration and Building Trust.

BCI CONVENTION — THE SPEAKERS 8 • Batteries International • BCI 2023 Yearbook www.batteriesinternational.com

And not forgetting these discussions…

BCI CONVENTION THE SPEAKERS

Over the three days of the conference, BCI have brought together a constellation of expert presentations on a host of mainstream and erudite topics.

And not forgetting these speakers …

How

enable automation

Mining for lead in a post

Mining for lead in a post-mining age for lead supply

Solutions to battery fires in our waste and recycling streams

How American electric power meets the needs of new and existing customers

Barite nucleation and growth from a fundamental perspective

Barite nucleation and growth from a fundamental perspective

Power

Mining for lead in a post-mining age for lead supply

Christopher

Time for lead to re-energize its resilience: the changing North American landscape for battery metal lead and its global green role

Neil

Time for lead to re-energize its resilience: the changing North American landscape for battery metal lead and its global green role

Time for lead to re-energize its resilience: the changing North American landscape for battery metal lead and its global green role

Design of superior expander molecules for advanced lead batteries

superior

Design of superior expander molecules for advanced lead batteries

Opportunities for storing energy, one

Vivek

and

oxide: preliminary modelling and simulation to understand competing kinetics in reverberatory furnaces Vivek

Silicon and lead oxide: preliminary modelling and simulation to understand competing kinetics in reverberatory furnaces

BCI CONVENTION — THE SPEAKERS 10 • Batteries International • BCI 2023 Yearbook www.batteriesinternational.com

Andy Fisher How industrial batteries enable automation

Nick Starita North America industrial lead battery trends and forecast

Ryan Fogelman Solutions to battery fires in our waste and recycling streams

George Brilmyer Opportunities for storing energy, one electron at a time

Isaac Rhoades How American electric power meets the needs of new and existing customers

Michael Starke Power electronics integration with batteries

Patrick Balducci Storage innovations 2030

Galbraith

Hawkes

Andrew Stack Barite nucleation and growth from a fundamental perspective

Cora Lind-Kovacs Design of

expander molecules for advanced lead batteries

Nick Starita North America industrial lead battery trends and forecast

George Brilmyer Opportunities for storing energy, one electron at a time

Isaac Rhoades How American electric power

Over the three days of the conference, BCI has brought together a constellation of expert presentations on a host of mainstream as well as eclectic topics.

Andy Fisher

industrial batteries

Ryan Fogelman

Isaac Rhoades

Christopher Galbraith

Andrew Stack

Michael Starke

electronics’ integration with batteries

Neil Hawkes

Cora Lind-Kovacs

Michael Starke Power electronics integration with batteries

Patrick Balducci Storage innovations 2030 Patrick Balducci

Storage innovations 2030

Nick Starita

North America industrial lead battery trends and forecast

George Brilmyer

electron at a time

Rao Silicon

lead

Rao

OVER A DECADE OF TECHNOLOGIES AND PROCESSES SPECIFICALLY DESIGNED FOR TPPL PRODUCTION: CONTINUOUS GRID CASTING PRECISION PASTING SORTING - STACKING OFF LOADING - PALLETIZING Discover the benefits and market advantage your company can experience from our TPPL processes by calling +1.810.987.7600 or emailing sales@wirtzusa.com. www.wirtzusa.com THIN PLATE PURE LEAD your one source solution INNOVATIVE | RELIABLE | PERFORMANCE The Wirtz Group of Companies

WGBI gearing up to expand world of industry opportunities for women

Following the successful launch of WGBI’s pilot mentoring program last year, this new initiative to boost career skills and personal development for women in the industry is moving ahead at pace in 2023.

Bernard, who took over as director following last year’s retirement of Pam O’Brien, said program applications and consulting those interested started taking place this spring and the next steps will be to finalize the mentor/ mentee partnerships for participating members.

“It’s all part of us supporting our members,” said Bernard, who is also BCI’s director of regulatory and technical affairs.

The 2022 three-month pilot program included a survey of WGBI’s membership to find out what would be most beneficial to them.

“We had really positive feedback from that and started to hear about who wanted to become a mentor, those interested in being mentees, their respective strengths and also what they expected to get out of the program,” Bernard said.

The information gleaned from the pilot has been analyzed by WGBI’s member education subcommittee, which is pairing up those taking part in the program.

“It’s then up to those involved to decide on the duration of the mentor program — probably six or 12 months — whatever best suits their individual circumstances.

The first round of mentoring began at the end of March and the second round is to take place in September.

“Depending on the work and commitments members have, we thought the staggered approach worked best and made it easier for some people to participate throughout different times of the year.”

The aim of the program is to empower women in the industry and make sure they have the resources they need for their professional and personal development.

“Some of the feedback we received was how great it was for members to

have support readily available and to also use the program as a sounding board to bounce ideas off industry peers and help them grow in their careers.”

Members from all sectors of the battery industry are taking part and last year WGBI tried to match people in terms of their jobs, such as engineers to engineers and marketers to marketers.

This year, members have been asked if they would like to be matched with a colleague in a different role.

WGBI has also consulted widely through the BCI to find out what mentoring and skills programming are made available by companies and to see whether there is anything WGBI can do to support corporate activities.

Meanwhile, Bernard said WGBI is stepping up efforts to expand the reach of the organization beyond North America and into Europe and the wider EMEA region.

Additional funding is key to promoting the organization. WGBI will also take part in key upcoming events on the global battery calendar including Pb2023 in Greece in June and 20ABC in Cambodia in September.

The organization has been supported financially through its first year of operations by BCI, which will continue to be a founding sponsor, but Bernard said WGBI has already begun to expand its funding base, including by signing up ‘sustaining sponsors’.

“We have opened up opportunities for companies and battery associations

to become sustaining sponsors as WGBI looks to become more independent.

“We’ve brought in a good amount of money this year already and by the time of the BCI Convention we expect to have announced new sustaining sponsors in the WGBI newsletter and on the WGBI and BCI websites.”

Programming includes training courses on a variety of topics, webinars and intimate and confidential group conversations about topics directly affecting women in the industry, several of which were held in the past year.

Another professional training webinar will take place soon. Meanwhile, WGBI expects to unveil its distinct brand identity and marketing materials ahead of the organization’s members’ meeting and networking reception at the BCI Convention.

That is set to be followed in June with the launch of a dedicated WGBI website. “We’ve achieved so much in our first year thanks to the hard work of our steering committee, member volunteers and supporters across the industry and we’re excited that the next stage of WGBI’s development is already in full swing,” Bernard said.

President: Julie McClure, MAC Engineering & Equipment

Vice president and treasurer: Virginia Archibald, Surrette Battery Secretary and chairwoman of the membership recruitment subcommittee: Teresa GrocelaRocha, Hollingsworth & Vose

Chairwoman, member education subcommittee: Angelika

Mayman, Hollingsworth & Vose. Chairwoman

STEM subcommittee: Negin Salami, Clarios

Chairwoman, marketing subcommittee: Rebecca Conway, Clarios

BCI — INTERVIEW SUSAN BERNARD 12 • Batteries International • BCI 2023 Yearbook www.batteriesinternational.com

A new mentoring program, online training, marketing and sponsorship activities are all part of what promises to be a busy, second full-year of operations for Women in the Global Battery Industry. Director Susan Bernard looks ahead.

WGBI STEERING COMMITTEE

Bernard: advancing empowerment

FLY HIGH Above the Rest Automation • Oxide Production • Material Handling • Service Sorfin Yoshimura LTD 100 Crossways Park West, Suite #215 Woodbury, NY 11797 Tel: + 1.516.802.4600 Email: sorfin@sorfin.com Eagle Oxide Services Inc. 5605 W 74th Street Indianapolis, IN 46278 Tel: 317.290.8485 Email: sales@eagleoxide.com www.eagleoxide.com Accurate Products Hvidsvaermervej 135 DK-2610 Roedovre Denmark Tel: +45.4453.4546 Email: accurate@accurate.dk FLY HIGH Above the Rest.

Major Investment Doubles Hammond’s Production of

Treated

SureCure®

Additive Increases Formation Efficiency, Reducing Manufacturing Costs; Increases Battery Life

Hammond, IN (April 2023) — Hammond Group, Inc. recently announced full-scale operations of its new North American Treated SureCure® manufacturing line, a multimillion dollar investment that doubles production capacity for one of its most effective additives.

“Our new state-of-the-art Treated SureCure® line represents a substantial investment for Hammond,” said Terry Murphy, Hammond’s President and CEO. “It doubles our production capacity and tightens manufacturing controls. Demand for Treated SureCure® has grown quickly since its introduction, as many of our larger North American customers have adopted it. Treated SureCure® allows for 4BS to form at lower temperatures, which means battery manufacturers can save money on energy input, lower their carbon footprint, optimize equipment investment, and produce a more reliable product. The uniform crystals formed in the cured positive material using Treated SureCure® provides benefits to production in terms of shorter formation times and greater formation efficiency over steam cured plates.”

What is Treated SureCure®?

Treated SureCure® is a micro-milled seed crystal that facilitates, controls, and improves the growth of tetrabasic lead sulfate, often called 4BS, which strengthens the positive active material allowing for extended cycle life and cost savings due to the ability to reduce the density of lead in customer paste formulations.

“Treated SureCure® is to the battery what steel reinforcement is to concrete,” explains Tom Wojcinski, Hammond’s Senior Research and Development Chemist. “It provides an extra layer of durability to your material and even allows you to use less since what you have is stronger.

“It had been known in the battery industry that 4BS crystal structures gave increased material durability and cycle life, but often the problem was in controlling the size and consistency of the 4BS structure,” said Wojcinski.

“Most manufacturers used very high temperature to induce 4BS growth, which was not easily controlled. The process for synthesizing pure 4BS crystals from the reactions of B-PbO and acid were also known. Thanks to the innovative thinking from Hammond researchers like Dr. David Boden, the idea to use pure synthesized 4BS crystals of a controlled particle size as nucleation sites for the rapid growth of small uniform 4BS in the battery was developed. The process was tested, and beneficial results confirmed with the help of Hammond’s industry partners.”

Treated SureCure® is a major advance over Hammond’s SureCure 100. The Treated SureCure® additive undergoes an additional finishing step which, when used during the curing process, helps to modify the crystal size and structure of the final 4BS in a different way from the original process. This additional modification helps to improve formation efficiency and charge acceptance of batteries.

“Since the improvements in formation efficiency are all linked to controlling the final crystal size of 4BS in the cured material, it is important to note that increasing or decreasing the loading can affect this final crystal size,” said Wojcinski.

“More seed sites through higher loading means smaller final crystal sizes, and lower loading equates to fewer seed sites and a larger final crystal size. If the crystals are too big, you lose the benefits in formation efficiency, and if your 4BS is too small, you will not improve your cycling performance.”

With the improvements in crystal size control offered by the finishing treatment for Treated SureCure® and Hammond’s experience in optimizing the loading rates of the additive to achieve the best balance of efficiency versus durability, the recommended loading is at 1% of the weight of the leady oxide used in a customer’s formula to gain the benefits.

According to Wojcinski, “Customers

HAMMOND 14 • Batteries International • BCI 2023 Yearbook www.batteriesinternational.com

Capable of producing 5 million pounds of additive per year, Hammond Group’s new Treated SureCure® manufacturing line in Hammond, Indiana doubles the capacity of its existing operations in Kuala Lumpur, Malaysia.

SEM images at 5000x comparing the crystal structures of cured positive material showing the differences between Tribasic curing, Tetrabasic curing without seeds and Tetrabasic curing with Treated SureCure™.

using Treated SureCure® have noted increased charging efficiency, allowing the batteries to perform better with less overcharge. All these improvements translate to better battery performance in cycling, in some cases up to 70% improvement in cycle life over 3BS and older SureCure additives.”

Indiana Location Key for New Production Line

Hammond has been making tetrabasic lead-sulfate, known as SureCure 100, for over 15 years. The company has a production line capable of making just over 4.1 million pounds, or 1900 metric tons, per year at their Malaysian facility in Kuala Lumpur. The demand for the product had risen to such a degree that Hammond installed the new production line to serve North America and Europe from Hammond, Indiana. This new line has a capacity of nearly 5 million pounds per year.

“As plant manager, I was tasked with working across the various departments, outside contractors, and equipment manufacturers to ensure project completion in order to meet the growth in demand for Treated SureCure®,” said Dean Botts, HLP Plant Manager. “The Hammond, Indiana location was specifically chosen for our new Treated SureCure® line as we produce the feedstock material here and we’re centrally located to minimize freight costs to our customers. It’s near our R&D lab, which developed the Treated SureCure® process, and near our Corporate Quality team, which will monitor the process under our IATF quality umbrella.”

Hammond’s new manufacturing line consists of a stainless steel reactor for making the feedstock material, stainless steel reactors for making the tetrabasic lead sulfate, several processing tanks, a technically advanced mill, dryer, and an automated packaging line. “The key to consistent results is controlling the process,” Botts said. “During the reaction process, we monitor the crystal structure and halt the reaction to obtain pure tetrabasic lead sulfate. The tetrabasic is then milled to the exact particle size required by our customers.”

Hammond uses similar manufacturing practices and raw materials to produce identical products at both its Indiana and Kuala Lumpur locations. The facilities in Asia, America, and the UK location are ISO:9001 certified for quality. The US location is IATF certified to conform with more strict requirements needed for automotive industry customers. Hammond provides full traceability on all their products including Treated SureCure®.

Treated SureCure® Creates Energy Savings, Reduces Inconsistencies During Curing

Treated SureCure® allows for 4BS to form at lower temperatures, which means battery manufacturers can save money on energy input and equipment investment and gain a more reliable product. The smaller crystals formed in the cured positive material using Treated SureCure® provides benefits to production in terms of shorter formation times and greater formation efficiency over steam cured plates. Additionally, the more durable active material will enhance battery performance by extending cycle life compared to traditional tribasic cured material. The increased durability of the active material means manufacturers may save money by using less material to achieve the same performance.

Ng Ming Yeow, General Manager at Hammond ALSB-Malaysia, has decades of industry experience in the Asian market. He notes, “By improving the cohesion/adhesion of the active material/ grid and the durability of the positives, some of our customers have been able to reduce costs by lowering their paste densities to use less lead, up to 5%.

“That can be a large cost savings with no loss of battery performance using the additive. Not to mention that our new Treated SureCure® also helps form batteries quicker and more efficiently than traditional 4BS curing methods and even our older line of standard SureCure®. Customers who have adopted Treated SureCure® have seen increased post formation voltages and higher initial capacities as well as greater PbO2 content and higher surface area in their formed positive plates using our additive.”

Treated SureCure® is taking the guesswork out of crystal growth. It eliminates the activation energy needed for 4BS formation and allows for a consistent final product in terms of conversion to 4BS.

“Steam curing does produce 4BS crystal structure in the active material,” said Wojcinski. “However, it is a very uncontrolled process and can lead to large, irregular crystal sizes which in turn will increase formation times later in production. Also, steam curing requires a lot of energy to maintain the high temperatures needed to grow the 4BS. So you put in a great deal of resources, in terms of energy and equipment, and end up with an inconsistent product.”

Incorporating Treated SureCure®, battery manufacturers can eliminate much of the guesswork in producing consistent positive plates, saving time, energy, and money. With its new North American production line, Hammond is well equipped to meet the growing demand for Treated SureCure®.

The building blocks of improved battery performance are contained in the modified tetrabasic lead sulfate seed crystals, Hammond Group’s latest generation of positive paste additives, Treated SureCure™. Research and testing conducted in Hammond’s industryrecognized E=(LAB)2 was instrumental in the development of the additive.

Years of advance planning involving technical experts from across Hammond’s global team brought the new multi-million dollar Treated SureCure® manufacturing line into operation. Production on the North American line began in early 2023.

HAMMOND www.batteriesinternational.com Batteries International • BCI 2023 Yearbook • 15

Working with Dean Botts (right), HLP Plant Manager in Indiana, Ng Ming Yeow, General Manager of Hammond Group’s Malaysia production facility, shared his expertise on Treated SureCure® manufacturing during a visit to observe operation of the new production line in the United States.

Hammond’s high-speed finishing mill optimizes production capacity, ensures consistency, and allows for customization of particle size to meet exacting customer demands.

The quarter century club — battery heroes reunited

What is it with the US obsession with crack-of-dawn meetings? And breakfasts too. Was a whole nation raised on farms in the mid-West? This year, BCI, has consulted the meteorologists for Louisville, Kentucky and set the time for 7am, “6.53am is sunrise so we’ll all have been up for at least half an hour from first light, caught up on our emails by then but we’re adding another 10 minutes for the East Coast softies and the Europeans to get up,” says one of the organizers.

This year the quarter century club — those BCI members who have supported the council for 25 years and not forgetting the few that have even clocked up a half century — will listen to a short presentation by a guest speaker before the roll of honor is read outloud.

“The quarter century club is a fine tradition to uphold,” one BCI veteran told Batteries International. “It’s more about friendship than anything else. We get together and have a good time!”

ROLL OF HONOR

A. J. BROGAN

A. M. HARDMAN

ACHIM LULSDORF

AKIO WATANABE

AL SCHMIDT

AL VINCZE

ALAN KOHLER

ALBERT BRICE

ALFRED C. LAZAGA

ALFRED J. PAUTLER

ANDY BUSH

ANDY WADDELL

ANNIE ZHENG

ANTONIO MUNOZ

ARDELLE E. MILLER, SR.

ARNIE O. NILSSON

ARNIE Y. SAKAI

ARNOLD FISCHER

ARTHUR G. KOCH

ATTILA CARUSO

AYKAUN OKUMA

B. A. HILL

BARRY WALKER

BERNARD J. ELZER, JR.

BERNIE BEALS

BERT BRIDGEWATER

BILL BARNES

BILL BESSIRE

BILL LINCOLN

BILL ROORK

BO McCANN

BOB CULLEN

BOB LINDSAY

BOB PEPPERS

BOB SLAUTTERBACK

BORIS MONAHOV

BRAD DWAN

BRIAN GUNNIN

BRIAN LEWIS

BRUCE A. COLE

BUD DeSART

BURCHARD VON CAMPE

BYRON ROTHPLETZ, JR.

CARMEL M. CLEMENTSON

CARRI MOFFATT

CHAD ROGERS

CHARLES A. BURKHART, II

CHARLES K. McMANUS

CHARLES-LOUIS ACKERMANN

CHERYL MINOR, PH.D.

CHI-HWA LU

CHRIS PRUITT

CHUCK FOWLER

CHUCK GIESIGE

CLEVE BENNETT

CLIFF J. CROWE

D’ARCY O’NEILL

DAN DUFFIELD

DANIEL A. MELVILLE

DANIEL D. BREIDEGAM

DANIEL P. ASKIN

DARRELL HIMMESOETE

DARYLL RARDON

DAVID A. WINTERBOTTOM

DAVID BEIDLER

DAVID LONGNEY

DAVID LUND

DAVID M. SHAFFER

DAVID MCMULLEN

DAVID MORRALL

DAVID RITTENHOUSE

DAVID WEINBERG

DAVID WILLIAMSON

DENIS S. HOWARTH

DENNIS ULRICH

DON BARNARD

DON HODGES

DON HULL

DON J. DEL DOTTO

DON PRIEBE

DON WENSINGER, II

DON WILSON

DONALD A. MASSELLE

DONALD A. WOJTON

DONALD L. OKESON

DONALD L. PIERSON

DONALD RABON

DONALD WALLACE

DONNA SNYDER

DOUG BORNAS

DOUG BRADLEY

DOUGLAS BROWN

DOUGLAS F. HUTTON

DOUGLAS GORDON RIST

DOUGLAS J. BOUQUARD

DOUGLAS R. TUPLING

ED FINK

ED FREY

ED PUCKETT

EDDIE BRICE

EDUARDO BURGIO

EDWARD M. KSENIAK

EDWARD M. MARWELL

ELLEN MAXEY

EMMETT R. JAMIESON

MAURICE JAUREGUI

ENRIQUE CARREON

ERIC HOLTAN

EUGENE P. FINGER

EVAN R. WESCOE

FARID AHMED

FELIX TESHINSKY

FOLCO GIBELLINI

FRANCISCO TRINIDAD

FRANCOIS GONNARD

FRANCOIS STEFFENS

FRANK DUMAS

FREDERICK TESHINSKY

FROSTY TUNNELL

G. A. CLERICI

GARY G. BRYAN

GARY SANTASPIRIT

GARY TAYLOR

GEORGE BRILMYER

GEORGE NADER-LATUFF

GEORGE SMITH

GEORGE STRATIS

GEORGE W. AYRTON

GERALD (JERRY)

DUERKSEN

GERALD Z. DUBINSKI, SR.

GERARD CHAI

GIUSEPPE BAUDO

GORDON BECKLEY

GREG HUMPHREY

GREGG BENNETT

GUIDO LEVATI

HAL HAWK

HARRY D. McVEY

HARUKA MIURA

HARVEY S. GERSHENSON

HEINZ-ALBERT KIEHNE

HELMUTH FAUST

HENRY BRICE

HERB ELLIS

HUBERT ABNER

ISRAEL COHEN

J. QUINN SELSOR

J. ROY BRAY

J. WORTH WILLIAMS

J.D. SURRETTE

JAHAR SENGUPTA

JAMES B. ROSKI

JAMES C. DeBRAY

JAMES H. BARRETT

JAMES H. THRASH

JAMES I. SIKORA

JAMES KANDA

JAMES RUBRIGHT

JAMES S. HARDIGG

JAMES TUNNELL

JAMES W. DOUGLAS

JAMES W. LORIO

JASPER HARDIN

JAY K. PARMAR

JAY NORTHEY

JEANITH L. MILLER

JEFF JORDAN

JEROME F. COLE

JERRY DARLING

JERRY HOFFMAN

JERRY SHASSERRE

JERRY V. CROW

JIM BOUCHARD

JIM FAIST

JIM JOHNSON

JIM KLANG

JIM PEDERSEN

JIM SNOOK

JIM TOEWS

JIMMY STEWART

JOAO A. MESTRE

SALVADOR

JOE ESSING

JOE JARVIS

JOE McKINLEY

JOHN A. BITLER

JOHN BRODHACKER

JOHN CONNELL

JOHN E. MANDERS

JOHN L. DEVITT

JOHN LUTES

JOHN MURPHY

JOHN NEES

JOHN P. BADGER

JOHN R. SHAW

JOHN SEMENIUK

JOHN STANPHILL

JOHN T.C. KAN

JOHN WIRTZ

JOSE M. PUIG

JOSEPH A. BLACK

JOSEPH F. DONAHUE

JOSEPH F. SZABO

JOSEPH J. JERGL

JOSEPH MAJESKY

JOSEPH RIVERA

JOSEPH T. GUSHUE

JULIE MCCLURE

JUNIOR ROCKHOLD

K. D. MERZ

K. FRED WEHMEYER

K. M. AZHMAGANBETOV

K. MURATA

KARL E. HANSLIK

KATHRYN R. BULLOCK

KATHY PERZEE

KATHY PETERSON

KAZUO OKADA

KEITH HARNICK

KELLY McCANN

KEN MARSHALL

KENNETH A. SUTTON

KENNETH E. ZALECKI

KENNETH SCHADLER

KENT HUDSON

KEVIN CAMPBELL

KEVIN SMITH

KEVIN WHEAR

KIYOTAKA IKAWA

KLAUS H. KRAFT

KYO FUCHIDA

LARRY MIKSIEWICZ

LARRY SCHEINBAUM

LARS KALLSTROM

LAURIE SZPARA

LAWRENCE B. WINDISCH

LEE SWAIN

LOUIS J. MAGDITS

LOUIS NAGY

MALCOM DEWAR

MANUEL SANTOS

MARK ALLAN KNOWLTON

MARK KELLEY

MARK STEVENSON

MARK WELS

MARK WINSLOW

BCI BATTERY VETERANS 16 • Batteries International • BCI 2023 Yearbook www.batteriesinternational.com

ACCURATE DATA

ABERTAX® AT-114B

Wireless Battery Analyzer

All the advantages of a scientific data logger with the durability of our acid-proof sensors and housing: Analyze your batteries in any environment!

Measurement and recording of full pack and half pack voltage, current, battery and ambient temperature, and electrolyte level (optional).

Fast logging at up to 10 samples per second. Data storage up to 32GB (> 24 years @ 1 sample per second)

Embedded web interface to configure, start, stop and downloaded data.

RELIABI LITY QUALITY

+356 23678100 info@abertax.com Abertax Technologies www.abertax.com @Abertax

Visit www.mac-eng.com to see how we can bring the MAC Advantage to you! ➤ Robotic Load/Unload ➤ Robotic Cell Insertion ➤ Finishing Automation ➤ Reduced Labor ➤ Reduced Lead Exposure ROBOTIC automation trustworthy value customized quality engineering solutions reliable MAC ENGINEERING & EQUIPMENT COMPANY, INC.

One of the most talked about features of recent BCI meetings has been the Sally Breidegam Miksiewicz Innovation Award. This was set up in 2016, as a tribute to East Penn’s CEO following her untimely death in June 2014.

The award celebrates innovation in equipment, processes, services and products that advance the lead battery industry.

The range of innovations set up as candidates for the award has been startling.

Some have been as simple as a better design shape for a marine battery; others have embraced the latest technological advances in our understanding of the lead battery.

Some of the nominations have been breakthroughs in the laboratory but struggled to be commercialized. And yet others — think of advances in EFBs — have been quickly embraced as a new standard in an emerging marketplace that continues to grow exponentially.

But be they large or small, these innovations matter.

For the last decade a tonne of investment has been flung at developing better lithium batteries while lead research has been side-lined.

The revamp of the ALABC and its replacement by the Consortium for Battery Innovation is putting the lead battery back in the spotlight.

Clear advances are on their way and credit must go to CBI for pulling it all together.

That said credit must also go to a generation of lead researchers that have remained in the background — think RSR, Hammond, East Penn, Daramic and many others — that continue to shape the lead battery industry.

This year there were five firms that applied for BCI’s innovation award: These were: Ace Green, Gopher Resource, Daramic, STC and Water Gremlin.

“Innovation is the thing that gives you the opportunity. It’s the promise of our future.”

Sally Breidegam Miksiewicz

www.batteriesinternational.com Batteries International • BCI 2023 Yearbook • 20

A B C ’ L E S S B -BE(TM) P R E G S (TM) T . B -BE S D M E S N T F G . D D B B , B W (C), B -B S D E , S E R . www.advancedbatteryconcepts.com info@advancedbatteryconcepts.com 1-855-230-3390 A B C ’ L E S S B -BE(TM) P R E G S (TM) T . B -BE S D M E S N T F G . D D B B , B W (C), B -B S D E , S E R . www.advancedbatteryconcepts.com info@advancedbatteryconcepts.com 1-855-230-3390 A B C ’ L E S S B -BE(TM) P R E G S (TM) T . B -BE S D M E S N T F G . D D B B , B W (C), B -B S D E , S E R . www.advancedbatteryconcepts.com info@advancedbatteryconcepts.com 1-855-230-3390

Getting the maximum value out of lead battery slag

Disposing of the slag from lead battery recycling has always been problematic — the end residue from smelting is toxic with a high lead content and traces, among other things, of antimony, arsenic, bismuth and cadmium. This slag, perforce, has to go into landfill.

Attempts to reuse it in, for example, paving blocks is just kicking the can further down the road. Finally, the paving will crack up and the poisons will leach out. Now perhaps a permanent solution is in sight.

Gopher Resource has developed a Slag Cleaning and Recovery of Useful Metals (SCRUM) process that is says can reduce its solid waste footprint by 99%.

The patent-pending approach, takes end slags that are typically landfilled as waste and economically recovers the tin and lead for reuse in the lead battery supply chain.

Each year the lead battery industry globally disposes of end slags that have approximately 100,000 tonnes of lead, and 30,000 tonnes of tin. This tin loss is equivalent to three quarters of US domestic tin consumption

This SCRUM process slag is a value-add product that avoids landfill for reuse in building construction and roadway aggregate industry sectors.

The SCRUM process uses furnace fuming technology to separate the tin and lead into a concentrated fume form with very high selectivity and efficiency, leaving behind a “cleaned” bulk iron sodium-silicate “SCRUM Slag”.

Previous fuming efforts have not been feasible due to poor selectivity and high partitioning of bulk slag components, in particular sodium, into the fume. “Our process leaves greater than 70% of the sodium in the slag, and recovers 99.9% of both tin

into lead, and LME tin. The ability to recover these metals from lead battery recycling slag in a safe, economically feasible way is an industry first”

and lead in the fume,” says Gopher Resource.

“This tin and lead concentrated fume can be combined with other byproducts for refining into lead, and LME tin. The ability to recover these metals from lead battery recycling slag in a safe, economically feasible way is an industry first.

“Waste minimization is a key goal of ours in developing this process. To reach that goal our SCRUM Slag has trace ppm levels of RCRA elements enabling its use in a variety of value added applications.”

This cleaned slag is applicable for use in commercialized products such as cements and roadway aggregates. SCRUM Slag valorization improves process economics, minimizes our environmental footprint, and is an embodiment of the circular economy.

How it developed

Gopher Resource has supported SCRUM process development efforts for over five years with hundreds of person hours and over $1 million spent in external and internal funding.

Internal R&D resources were committed in 2016 when desk studies began to develop a process to recover metals from the blast slag

BCI INNOVATION AWARDS: GOPHER RESOURCE 22 • Batteries International • BCI 2023 Yearbook www.batteriesinternational.com

Slag. It’s been a persistent problem from the moment lead was first smelted or batteries recycled. There’s always an irrecoverable residue that is toxic, useless and needs disposal. But better extraction methods are on the horizon.

Typical leaded battery end slag chemistry ranges Toxicity characteristic leaching procedure (TCLP) of leaded battery recycling end slag and SCRUM slag Ag As Ba Cd Cr Hg Pb Se Description ppm ppm ppm ppm ppm ppm ppm ppm LBFS 0.01 0.03 81.8 0.05 <0.01 <0.01 66.85 0.54 SCRUM Slag <0.1 <0.1 29.6 <0.1 <0.1 <0.1 <0.1 <0.1 TCLP limits 5.0 5.0 100.0 1.0 1.0 0.2 5.0 1.0 Fe Na Pb S Sb Si Sn Measurement Units XRF Analysis 20 - 30 8 - 13 1 - 4 3 - 7 0.2 - 0.5 8 - 15 1 - 3 Wt%

“This tin and lead concentrated fume can be combined with other by-products for refining

and render a “cleaned” slag available for value-addded applications.

As part of these investments, from 2017-2019 various process technologies were evaluated and tested at the lab scale, including hydrometallurgical and mineral processing technologies. These technologies were found not viable, and pyrometallurgical process routes were then tested.

Gopher said it initially investigated pyrometallurgical lab scale work on “extreme” methane reduction which was promising but ultimately unsuccessful, and the research results were published at the Pb/Zn (LeadZinc) 2020 conference.

Pyrometallurgical fuming

Pyrometallurgical fuming was then evaluated, which has been demonstrated in zinc and other industries but not successfully in the lead battery recycling industry. There was some reluctance to strongly pursuing pyrometallurgical fuming processing routes as every single expert Gopher conferred with discouraged this as being practical.

Conventional wisdom argues selective fuming in high sodium slags doesn’t work as there isn’t sufficient selectivity in the separation. “We persisted and after repeated lab scale tests and advanced thermodynamic calculations, we generated some initial results that were promising enough to proceed to the next stage,” says the firm.

Gopher Resource continued to support this work through piloting efforts through 2020-2022 where various components of the SCRUM process were tested at larger scales. The firm worked with multiple partners to test various process parameters and equipment configurations, and eventually discovered a set of process conditions that separated 99.9% of the tin and lead to the fume, keeping >72% of the sodium in the slag.

To date, SCRUM has been successfully piloted at scales of 100lb through repeated tests by multiple independent parties, with 1000s of lbs of material having been processed.

“These pilots used equipment and process parameters that are realistic, scalable, and economic. In parallel to the SCRUM process development work,” says the firm.

“The SCRUM process successfully

demonstrated pilot results on metal fuming, impurities management, and metal conversion and refining.

“SCRUM slag has also been demonstrated to be sufficiently clean for a variety of applications. Process information collected in our pilot tests provide engineering information for equipment sizing,

labour, utilities, consumables, etc., to generate CAPEX and OPEX estimates.”

The firm says that product streams with required specifications have been demonstrated to provide realistic cashflow forecasts for lead bullion, >99.9% tin, and SCRUM Slag.

“Cashflows are resistant to low tin prices and NPV (net present value) analysis has shown favourable results. We’re evaluating next steps and appropriate strategies to bring SCRUM to market,” says the firm.

The future

Gopher Resource continues to have multiple external projects funded looking at value add applications for its slag past 2025. These include road aggregates, cement paving stones, and advanced manufacturing applications such as 3D printing.

Development of this technology has been a global undertaking with test work conducted at Gopher Resource facilities and partner facilities in six countries across North America, Europe, Australia and Africa.

This cleaned slag is applicable for use in commercialized products such as cements and roadway aggregates. SCRUM Slag valorization improves process economics, minimizes our environmental footprint, and is an embodiment of the circular economy

WHAT’S LEFT OF THE SCRUM SLAG

The SCRUM Slag byproduct is also applicable for use in building materials such as concretes and dense or porous monoliths. Slag is granulated using air or water and made into a slurry mortar via a binder/activator [such as Metakaolin (MK; Al-Si), limestone (LS; CaCO³), Alkali salts (mainly Na) (Na2CO3 (Nc), Na2SO4 (N$), NaOH (NH), Na-silicate (NS)],

Controlling the TBRC slag to retain the high concentrations of sodium, provides benefits of a natural binder/ activator in the slurry. This reduces the amount of additives needed to meet specifications for use. This mortar has multiple uses in

structural applications or design applications and uses 5x less cement than typical mortars resulting in approximately 80% less CO2 production. The strength of the mortar projections matches that of current commercial produced mortars.

These mortar products allow for efficient construction customization and complexity in building systems, while reducing CO2 footprint. Leaching results from column tests have shown non-hazardous solids. The mortar can be 3D printed or cast into different types of monolithic construction materials (dense or porous).

BCI INNOVATION AWARDS: GOPHER RESOURCE www.batteriesinternational.com Batteries International • BCI 2023 Yearbook • 23

Initial testing processing phase distribution Fume 26.4% Slag 44.6% Metal 21.7% Matte 8.2% Proportion of phases (wt%)

Daramic has featured in the innovation awards since their inception in 2016, receiving an Honorable Mention for its HD Plus separator in 2022. This year, the company presents its latest innovation — the HiCharge advanced separator.

Separator tech charges ahead to new levels of performance

Faster rechargeability and lower maintenance continues to be the holy grail for batteries and now Daramic is pushing the envelope further still with its latest separator technology — HiCharge.

HICHARGE INDUSTRIAL SEPARATOR FEATURES

Key characteristics of Hi-Charge separators are their serrated rib pattern, designed with a 3.5mm pitch to enhance circulation, improve backup time and aid rechargeability.

An antimony suppression formulation reduces top-up frequency, lowers float current and reduces plate corrosion.

HiCharge’s closer rib pitch allows for uniform compression and reduces sulfation.

HiCharge separators deliver strong results when tested in deep cycle applications

In motive power (flooded flat plate battery) the separators provide:

• Greater than 2x battery cycle life improvement in repeated testing

• 2.5x longer life in discharge motion testing

• 2.75x longer life in a stationary discharge test.

Solar battery application (flooded tubular battery):

• Enhanced battery life with capacity improvement of 6% during cycling

• Positive plate corrosion improvement through Sb suppression and water loss reduction of 25%

• Decreased active material shedding and deposition on separator surface.

Flooded deep cycle batteries tend to operate in a partial-stateof-charge, causing plate sulfation, continued decline in backup time and premature battery failure.

However, Daramic says its innovation solves these issues, delivering faster rechargeability, lower maintenance and longer life.

Examples of deployment in practice include a forklift battery that lasts 100% longer than current batteries on the market — with the ability to charge up enough over a lunch break to last through the remainder of the day with more than 10% improved backup time, sustained over the unit’s cycle life.

HiCharge can also boost the efficiency of a solar battery’s energy capture during peak sunlight periods, with 10% improved charged acceptance and reduced maintenance from a water loss reduction of 20-25%, Daramic says.

And with the increasing take-up of residential UPS systems in mind, Daramic says using HiCharge could see a home UPS unit continue to

provide power over 15% longer during an outage than competing products.

Daramic’s award entry aims to step up to meet evolving market needs for deep cycle applications, which have been identified by the Consortium for Battery Innovation as a priority area of research for lead acid batteries.

For more than 90 years Daramic has been a market leader in developing new and innovative technology for the lead acid battery market and is the global leader in supplying high performance polyethylene battery separators to the Pb battery industry.

The 2023 award entry takes Daramic’s technology development to a new level, following its presentation of HD Plus at last year’s convention in Naples.

HiCharge can change what is possible across many deep cycle applications.

Testing of HiCharge in many deep cycle applications was completed in 2022 and the product is just now being offered to most markets.

BCI INNOVATION AWARDS — DARAMIC 24 • Batteries International • BCI 2023 Yearbook www.batteriesinternational.com

6 © 2023 Daramic, LLC. ALL RIGHTS RESERVED HiCharge separator battery life is more than double the control separator battery in repeated testing 70% 80% 90% 100% 110% Cycle 10 14 28 42 56 70 84 98 112 126 140 154 168 % of Nominal Capacity PPSoC Customer Week PSoC Cycling - Discharge Motion - Motive Power Cells 75 77 79 81 83 85 87 89 91 0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050 1100 1150 1200 % CAPACITY AT MANUAL DISCHARGE CYCLE (50 CYCLES = 7 CUSTOMER WEEKS) PSOC Life Cycle Capacity Comparison – Stationary test Control HiCharge LVC Failure Criteria Program terminates and cell is removed after manual discharge capacity test when any cell reaches voltage limit of 0.00V Battery type: Flooded flat plate Battery Validation Data Motive Power Application Test 2.5 times longer life 2.75 times longer life

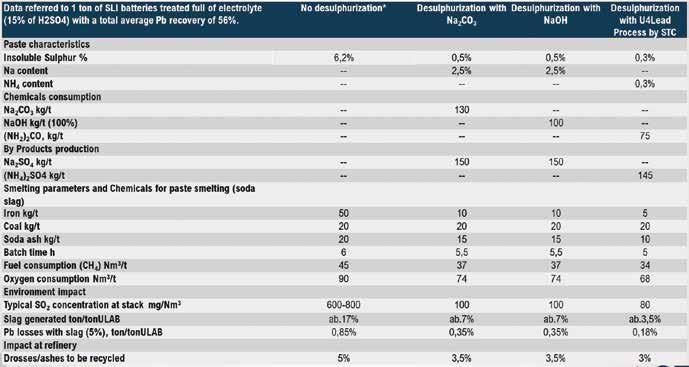

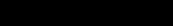

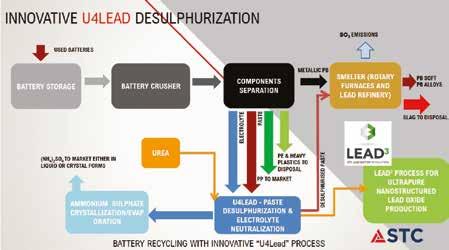

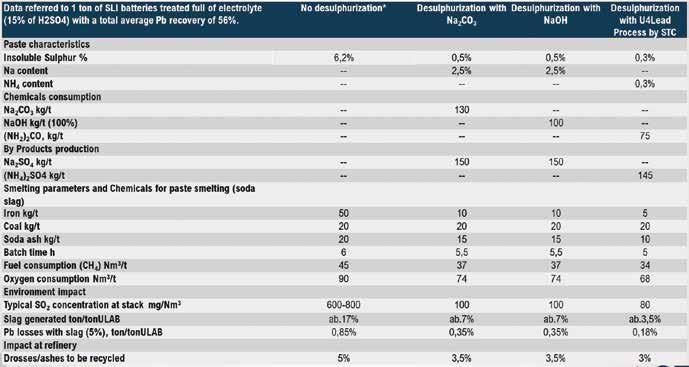

A new horizon for lead paste desulfurization

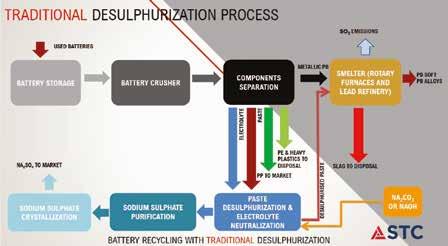

Desulfurization is a key step in the recycling of lead batteries. In the first step (Figure 1) of recycling the casing and the electrolyte is separated off before the pure lead and lead paste are processed.

Traditional desulfurization of the paste typically uses sodium hydroxide or sodium carbonate. The reactions are:

PbSO4 + Na2CO3 ⇒ PbCO3 + Na2SO4

PbSO4 + 2NaOH ⇒ Pb(OH)2 + Na2SO4

H2SO4 +Na2CO3 ⇒ Na2SO4 + H2O+ CO2

H2SO4 + NaOH ⇒ Na2SO4 + H2O

The chemistry of the traditional sodium carbonate-based desulfurization is a simple and straightforward reaction.

Among the main advantages, it is possible to highlight the easy availability of the reagent, the well known and studied mechanisms of reaction the process is based on, the possibility to use the obtained by-product (sodium sulfate) as an intermediate in the chemical industry and the stability of the reagent and its product.

In summary this hydrometallurgical approach resulted in savings of a variety of production expenditure:

• Reduction of slags generated

(-65%)

• Iron consumption reduced by 90%

• Less fuel required (-15%)

• Less oxygen required (-15%) when using oxy-fuel burners

• Higher productivity

• Faster cycle

• Less lead lost with slags

• Revenue from sodium sulfate covers some of the additional costs (chemicals and energy).

Also, the environmental impact was also lessened:

• Drastic reduction of generated hazardous waste to be transported and disposed of in special landfill sites

• Reduction of SO2 emissions -90%

• Less fuel consumption (oil or natural gas etc.)

• No liquid effluents as the process is zero liquid discharge when crystallization is adopted: the condensate is reused inside the plant

• No need for an external electrolyte neutralization system as the sulfuric acid can be converted into sodium sulfate by the same equipment used for

paste desulfurization.

The desulfurization of lead paste has become so essential in the ULAB recycling activities: this chemical reaction via sodium carbonate or sodium hydroxide leads to the reduction of the environmental impact (less SO2 emissions and slags production) and to an increase in productivity of the subsequent lead paste smelting operations.

It has however limitations related to the relatively poor market for sodium sulfate (a by-product of the process), also important here is the high level of equipment corrosion which is part of the process and to the high costs of the chemicals used.

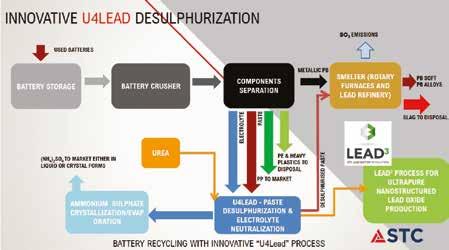

Thanks to the R&D team and support from Renato Guerriero, president of STC at that time, the company discovered that it was possible to implement an even more efficient desulfurization process that was able to overcome these limitations while ensuring at the same time all the advantages of the most recent desulfurization process.

The U4Lead process by STC uses an amino compound — urea, as chemical for the desulfurization of paste and electrolyte neutralization process.

The simplified reaction can be summarized as:

CO(NH2)2 + PbSO4+H2O

⇒ PbCO3 + (NH4)2SO4

CO(NH2)2 + H2SO4 + H2O

⇒ (NH4)2SO4+CO2

The U4Lead patent was published in November 2019 but the installation of this technology on an industrial scale was started in 2020 as a subproject of a larger project for a new complete battery recycling plant entirely supplied by STC to our Nigeria plant.

The U4Lead process by STC, protected by national and

BCI INNOVATION AWARDS: STC 26 • Batteries International • BCI 2023 Yearbook www.batteriesinternational.com

The ability for lead to be endlessly recycled — and profitably so — gives it a strong advantage over lithium batteries. But any improvement on the mechanisms to do so and related cost considerations has to be welcomed.

Figure 1: the traditional desulfurization process

international patents, is based on the use of urea as chemical for the desulfurization of paste and electrolyte neutralization. Compared to traditional processes, the U4Lead solution offers the following advantages (Figure 2):

• PbSO4 conversion >97% = low residual sulfur (< 0.3%)

• No side reactions ⇒ no sodium/ lead double salts formation

• Further reduction of iron addition

⇒ less slag production, natural gas/oxygen consumption, etc.

• Ammonium sulfate valuable as a fertilizer

• No Na2S

Convenience of the desulfurizing agent: urea is a very cheap amino compound, easy to find, to treat, it is chemically stable as not subject to sublimation and odour-free.

The reaction by-product is ammonium sulfate, which is a precious compound with a very low affinity with lead, nickel, arsenic and other heavy metals and it is therefore easily recovered, crystallized to produce pure crystals and sold as fertilizer.

No special material is required for the evaporation or crystallization operations of the by-product solution, due to the absence of chlorides from reactants and there is finally no need to employ dangerous chemicals such as sodium sulfide for heavy metals

abatement from the by-product solution.

• Reduction of the energy consumption and costs of the subsequent smelting activities due to a lower duration of the batch time and therefore of the fuel and oxygen consumption

• Consequent reduction of environmental impact due to the abatement of SO2 and CO2 emissions, slags generated and Pb losses with slags

• As a result, all the analyzed data are improved when U4Lead is adopted, from chemical consumptions to energy reduction and environmental performances.

BCI INNOVATION AWARDS: STC www.batteriesinternational.com Batteries International • BCI 2023 Yearbook • 27

Comparison summary

ULAB recycling plant in Nigeria

Urea conversion system

Figure 2: The U4Lead process

Gremlin Green shining a light on the environment

For several decades, Water Gremlin has been manufacturing battery terminals for a wide range of applications such as automobiles, motorboats, military, recreational vehicles, and many more. Battery terminals are an essential component of lead acid batteries, and lead acid batteries play a critical, often assumed role in our everyday lives.

The coating on a terminal is critical in preventing leakage and corrosion between the terminal and the plastic cover of the battery. The adhesion of the plastic to the lead allows the battery to last longer, perform more efficiently, and function safely.

The traditional coating on a terminal is a solid polymer which requires a significant amount of solvent to reduce the viscosity of the polymer so that it can be easily and smoothly applied to the terminals.

Water Gremlin’s long term goal is to significantly reduce the use of organic solvents in its manufacturing process.

Initially, Water Gremlin has been able to reduce solvent usage by 25% moving to a water-based process. However, the water-based process proved to be unsuccessful in all applications thus requiring the continued use of organic solvents. Water Gremlin then looked for an alternative that would allow further reduction of the use of organic solvents with the goal to eventually eliminate the usage of solvents in their facility.

After three years of research and development, Water Gremlin has been able to successfully develop and patent a proprietary ultraviolet light curable coating that is completely solvent-free.

This new process is far more ecofriendly for the environment as compared to the previous formula. It eliminates the need for solvents and is proving to be more durable and reliable.

As a trial, Water Gremlin converted one of its coating machines to the

new ultraviolet light cured coating process. To date approximately 10% of their coating capacity has been converted to a UV curable coating, known as Gremlin Green.

By doing so, it has impressively been able to reduce solvent usage by nearly 20%. Water Gremlin intends

to continue to implement UV cure technology to eventually end all usage of organic solvents for coating in their facility. Water Gremlin’s commitment is to reduce solvent usage by more than 50% by the end of 2023 and by more than 80% in 2024 and beyond.

Water Gremlin intends to continue to implement UV cure technology to eventually end all usage of organic solvents for coating in its facility

WATER GREMLIN — PROFILE

Founded in 1949 on farmland in White Bear Lake, Minnesota, Water Gremlin has been a well-known supplier of innovative products to the recreational fishing market. These initial products included fishing lures and lead sinkers.

However, its manufacturing scope broadened in the 1970s to include industry leading terminals for leadacid batteries.

The company has over 160,000 square feet of combined manufacturing and warehousing space in Minnesota. It is the superior supplier of battery terminals to battery manufacturers in both North and

South American and has expanded to other markets throughout the world during its 75 year history.

The Water Gremlin Company has been at the forefront of technology and is a market leader in lead battery terminals.

Manufacturers rely on Water Gremlin to deliver consistent, highquality solutions through custom engineering, design, and precise automation. Water Gremlin is a single-source solution — from conception to finished product. Its applied coating technology provides a strong and reliable barrier to inhibit acid leakage.

BCI INNOVATION AWARDS: WATER GREMLIN 28 • Batteries International • BCI 2023 Yearbook www.batteriesinternational.com

Water Gremlin has pioneered a unique process to reduce the environmental impact of organic solvents as a coating material by using UV light.

Tried and tested Improved inside

Our genuine system - your first choice

• Highest quality

• Constant improvement

• Excellent performance

• Reliable service

Over 40 years of developing and perfecting battery filling products allow us to provide you with the most reliable system focusing on innovation and usability – a valuable contribution to an extended battery lifetime.

batterie füllungs systeme GmbH info@bfsgmbh.de Mitterweg 9/11 | 85232 Bergkirchen | Germany bfsgmbh.de | +49 8131 36400

bfs

Electrifying the recycling process: old batteries to new lead at room temperature

COMPLIMENTARY TECHNOLOGIES

ACE Green says it is piloting several important new initiatives.

• Production of 99.99% pure e-lead

The firm says it can now directly obtain 99.99% high-purity e-lead from battery paste. This new process is also at room temperature, requires no external heating and can use the same commercial-scale electrolysis machines.

• In-process regeneration of desulfurization agent

ACE has developed a modified process to regenerate the desulfurizing agent, helping to further reduce costs. This improvement does not require any changes or modifications to the electrolysis process.

• Electric kettles for melting e-lead

By utilising a new electrically heated kettle, the firm say it is moving towards 100% electrification of the lead recycling process.

• Baghouse dust treatment

The firm has a room temperature technique to treat and recover lead from baghouse dust.

• Smelting furnace slag treatment

Fascinatingly, the firms says it has created a technology to treat and extract metals from slag generated during conventional smelting. Besides the recovery of lead and iron, there is also a reduction of more than 65% in the net solid waste for disposal in landfill.

US corporation ACE Green Recycling

Inc has developed a proprietary new technology that produces no waste products that require smelting and furnaces. The process, the firm says, operates at room temperature with no carbon or heavy metal emissions. It replaces the conventional smelting furnace with an oxygen-producing pH-basic electrochemical process. This modular process is also readily scalable to suit any production capacity needs.

“Our zero-emissions technology is a game-changer for the heavily regulated secondary lead industry,” says Farid Ahmed, business development manager for ACE Green. “Automated material handling enables plant operation

with minimal operator intervention, further reducing exposure to health and safety risks. Higher lead recovery and lower waste generation contribute to our process having more favourable economics than traditional smelting. The two streams of lead components from the battery breaker — battery paste and battery metallics — are treated separately.

Paste

Battery paste is treated with proprietary chemicals in the presence of sodium hydroxide, removing sulphur and preparing it for the next stage. This is then fed to the room temperature electrolysis process, producing ‘spongy’

BCI INNOVATION AWARDS: ACE GREEN RECYCLING 30 • Batteries International • BCI 2023 Yearbook www.batteriesinternational.com

Hydrometallurgical processing of scrap lead batteries has long been a dream in the recycling industry. It offers a less energy-intensive route to recycling with all the additional savings that entails.

ACE’s cofounders Nishchay Chadha (L) and Dr Vipin Tyagi (R)

your solution for increased production and productivity from labor shortages