8 minute read

In accounting for compressor

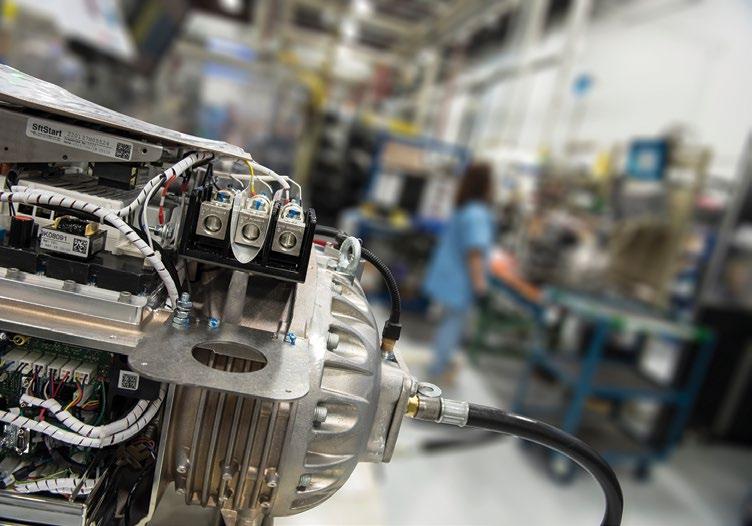

STATE-OF-THE-ART LABORATORY Danfoss

Turbocor’s new customer Application Development Center features three fully automated test facilities capable of accommodating residential and commercial air-conditioning and heat pump equipment, including rooftop units, from 1.2 to 50 tons and air-cooled chillers up to 150 tons. Additionally, the lab will be able to test mildly flammable refrigerants.

Turbocharged Growth

Danfoss continues to generate excitement in Tallahassee

BY STEVE BORNHOFT

In the difficult year that was 2020, business was up 6.1 percent at Danfoss Turbocor, an international manufacturer of oil-free centrifugal compressors for commercial applications whose U.S. headquarters, for 12 years, has been in Tallahassee. Industry-wide, business was off more than 10 percent last year. What, then, is the Danfoss difference?

Demand for its product is high, Danfoss Turbocor president Ricardo Schneider told a January meeting of the Tallahassee-Leon County Office of Economic Vitality stakeholders, in part because of the significant ways in which it departs from conventional compressors.

Danfoss pioneered oil-free, magneticbearing technology for air-cooled and water-cooled chillers. It has more oilfree compressors cooling commercial buildings globally than any other manufacturer. The product is an especially good fit, Schneider pointed out, for hotels, hospitals — and data centers.

Already, 35% of Danfoss’ business volume is related to data centers. The need for more such centers across the world to support autonomous vehicle applications will help ensure that demand for Danfoss compressors remains high. So, too, Schneider said, will commitments by businesses and nations to “green restarts” as they rebound from the COVID-19 pandemic and its impacts.

“A crisis such as the pandemic enables technology to speed up,” said Schneider, who believes that as the world reboots, it will expect buildings to be made smarter and systems more intelligent.

Danfoss’ own Green Restart educational initiative demonstrates how businesses can accelerate the pace of economic recovery and generate sustainable growth.

“The COVID-19 crisis has had a severe impact across the globe, not just from a health perspective, but also from societal and economic perspectives,” Danfoss notes on its website. “Alleviating and recovering from the pandemic must be at the top of anyone’s agenda. We need to boost economies, recreating and creating sustainable jobs and growth.”

Schneider shared with OEV stakeholders a video that detailed advantages of Danfoss’ product versus earlier generations of compressors. n Because Danfoss compressors are oil free, there is no need for complex oil-management systems. n Freedom from oil-degradation issues results in sustained energy efficiency and consistent performance throughout the lifetime of the chiller. n Central to the Danfoss compressor is a single rotating part that levitates and does not make contact with other parts. As a result, wear and tear on components is eliminated, and maintenance schedules are relaxed. Downtime and operating costs are reduced. n Integrated variable speed technology makes for load-bearing efficiency. n The compressors require only low starting current, eliminating costly investment in high-capacity electrical infrastructure. n The compressors are selfmonitoring and generate reports and alerts; they safeguard themselves from failures that might otherwise result from power outages or extreme fluctuations. n They work with established and next-generation refrigerants, ensuring that transitions from old to new are seamless. n And, they result in lower energy bills while providing a comfortable and productive environment for building occupants and users.

Danfoss Turbocor, a maker of oilfree compressors for climate control applications, is undertaking an expansion, depicted in the rendering at right, that will include development of an advanced manufacturing and R & D facility of approximately 90,000 square feet in size.

In January, Danfoss announced plans to enlarge at Innovation Park with a $48 million project that will take place in three phases over the next five years. The company said the expansion will result in 239 highpaying jobs in manufacturing and research; 267 construction; and more than 500 indirect permanent jobs. The undertaking first phase will include the development of an advanced manufacturing and research and development facility of approximately 90,000 square feet in size.

“We are pleased to bring additional engineering and manufacturing investment to Tallahassee, and we are excited to continue building on our successes here,” Schneider said at the time of the announcement.

At present, Danfoss employs 28,000 people worldwide; sells its products in more than 100 countries including its chief markets, the U.S., Germany and China; and operates 28 factories.

At the invitation of Cristina Paredes, the executive director of the TallahasseeLeon County OEV, Schneider listed reasons for the continuing and growing commitment by Danfoss to Tallahassee.

He ticked off several ... n Danfoss has assembled a highly skilled team with a record of success in Tallahassee. “We have been meeting and exceeding goals in Tallahassee for 12 years,”

Schneider said. n Research and development infrastructure is well-established and strong. n Research and development and production have been co-located in Tallahassee. n The presence of a “magnetic ecosystem” and the largest magnetic lab in the world is “one of the main reasons we are here,” Schneider said. “We use a lot of magnetic material and employ magnetic science. It makes logical sense for us to be near the kind of expertise that

FSU has in that area.” n FAMU-FSU College of Engineering supplies Danfoss with a talent pool to draw upon. n Tallahassee and Leon County have been generous with local incentives. For example, the

Blueprint Intergovernmental

Agency has committed $2.3 million in sales tax revenue to

Danfoss’ expansion project.

“We appreciate your leadership, especially your involvement in continuing to push us and challenge us in growing a magnetic cluster,” Paredes told Schneider. “It is very exciting to see a company that located here, less than 15 years ago continue to grow and expand here and shine a spotlight on Tallahassee.”

“We are very glad to be anchored in this community,” Schneider said. “We are proud to be here, and we are going to continue to generate jobs and generate excitement.” ●

SPERRY & ASSOCIATES

Building facilities and relationships that strengthen Tallahassee

anfoss is a well-known com-

Dpany name in Tallahassee, but most might not know what the international firm does. At its location in Innovation Park, the Denmark-based multinational company designs and manufactures oil-free, magnetic bearing compressors for heating and air conditioning. That’s why Danfoss was initially drawn to Tallahassee and its close proximity to their research partner — the National High Magnetic Field Laboratory. Even though the pull of the world’s most powerful magnets compelled Danfoss’ move to Tallahassee, it is the relationships they’ve built since that keeps them here.

As one of the biggest economic development success stories in the Capital City this century, Danfoss’ Turbocor manufacturing facility is a quiet operation with an impact worth shouting about. With over 200 employees in Tallahassee, the company has become a significant provider of careers for highly skilled workers. Soon there will be even more Danfoss jobs coming to the area as the company recently announced a massive expansion project that will double the company’s Tallahassee presence.

“We are pleased to bring additional engineering and manufacturing investment to Tallahassee through this expansion project,” said Ricardo Schneider, president of Danfoss Turbocor Compressors. “The Tallahassee community affords us tremendous opportunity to collaborate with world-class researchers in aerodynamics, power electronics and magnetic technologies.”

After growing their footprint for nearly two decades, Danfoss’ manufacturing and research campus has become an integral part of the Tallahassee innovation economy. All of which has been designed and built by the locally owned construction firm Sperry & Associates.

“Sperry has helped Danfoss achieve its construction goals on a variety of projects over the years because a local design team ensures a quick turnaround on questions and changes,” said Chris Neal, senior manager, facilities with Danfoss. “The design-build process used during our projects has helped us achieve the results we wanted — and on budget.”

Sperry & Associates is a leading commercial and industrial construction company in Tallahassee that specializes in both award-winning design and building practices. They are known across the Southeast for their expertise in pre-engineered metal buildings, which the Danfoss campus was built with.

“A company like Danfoss, with such specialized requirements, needed the level of involvement that our designbuild process could provide,” said Jay Bostwick, Vice President of Sales at Sperry & Associates. “We have the capacity to sit down with them and learn everything about their company, which has resulted in both

functional and beautiful buildings, years of trusted partnership and the promise of future builds.”

Landing the opportunity to construct the Danfoss project was a landmark deal for Sperry & Associates. In 2006, when Danfoss first came to Tallahassee, the buildout needs were extensive and the timeline was demanding. With all those realities in play, Sperry’s design-build approach became attractive to Danfoss because of streamlined processes and tighter budget controls — not to mention Sperry’s excellent reputation from both clients and fellow construction firms.

Since the company’s founding in 1973, Sperry & Associates has garnered consistent recognition for exceptional design, attention to detail, personalized service and superior project management throughout the Southeast. With over 70 percent of projects stemming from existing or previous clients, Sperry & Associates earn their reputation from building strong relationships. The partnership between Sperry & Associates and Danfoss merges local building expertise with international engineering excellence. This combination of innovative technology and exemplary construction has helped bring a spark to the Tallahassee economy in ways that are far-reaching across the globe.