In

the early 2000s,

“The Big Three” all had sports cars, but technically they weren’t in the same class.

At the time, the only thing sporty Dodge had worth mentioning was the Viper, but we all know it was more expensive than most could afford. On the other hand, General Motors had just ended their production run of the 4th generation F-bodies and the C5 Cor-

vette lived in a higher price bracket than the Camaro or Trans-Am/Firebird. Then you have Ford, having never stopped producing their “pony car” for the average person. As a result, they had the upper hand from 2003 and up. The Mustang came in all levels, but Ford’s “Special Vehicle Team” took things a step further, making the New Edge 20032004 model years a true wolf in sheep’s clothing. Enter the SVT Mustang Cobra; unlike the other New Edge body style Cobra years (9902), they went all out for 03 and 04.

Factory Ford Torch Red paint looks killer on the Cobra and a few trick Schoneck Composites carbon panels were added for weight reduction. The nose, hood, side skirts, and rear decklid are all carbon wrapped to match the factory paint.

A 390hp Roots style blown 4.6 four-valve Mod motor lurked under the hood completed by independent rear suspension and a six-speed T-56 manual trans, and with individual body styling and paint colors, these models made for a pony breed all on their own.

Mark Rogers has been into cars since he was a kid and obviously gravitated more towards them once he could legally get behind the wheel and drive. He’s had a few brands

other than Ford, but became a Ford man through and through, and like most of us, he doesn’t own anything stock, or at least keep it stock for very long. We all know what happens when we get bit by the bug and while Mark appreciated the Cobra and Modular motor design Ford introduced in 1996; he tinkered with his 1996 Cobra ragtop to get a bit more out of it, going through the motor, putting a blower and full suspension on it and enjoying what it had to offer.

An1100whptwin-turbopieceofhighpower

Mark Rogers Turbocharged 2003 Ford Mustang Cobra

Body and Paint:

Ford Torch Red paint. Schoenick Composites Carbon nose, hood, side skirts, deck lid and dash. Customs by Bigun wing.

Chassis & Suspension/Modifications:

Customs by Bigun has done all the chassis and fabrication on the car. Mag’s Fab Worx upper and lower torque boxes, Menscer front struts, Customs by Bigun spec’d JRI shocks out back.

Engine:

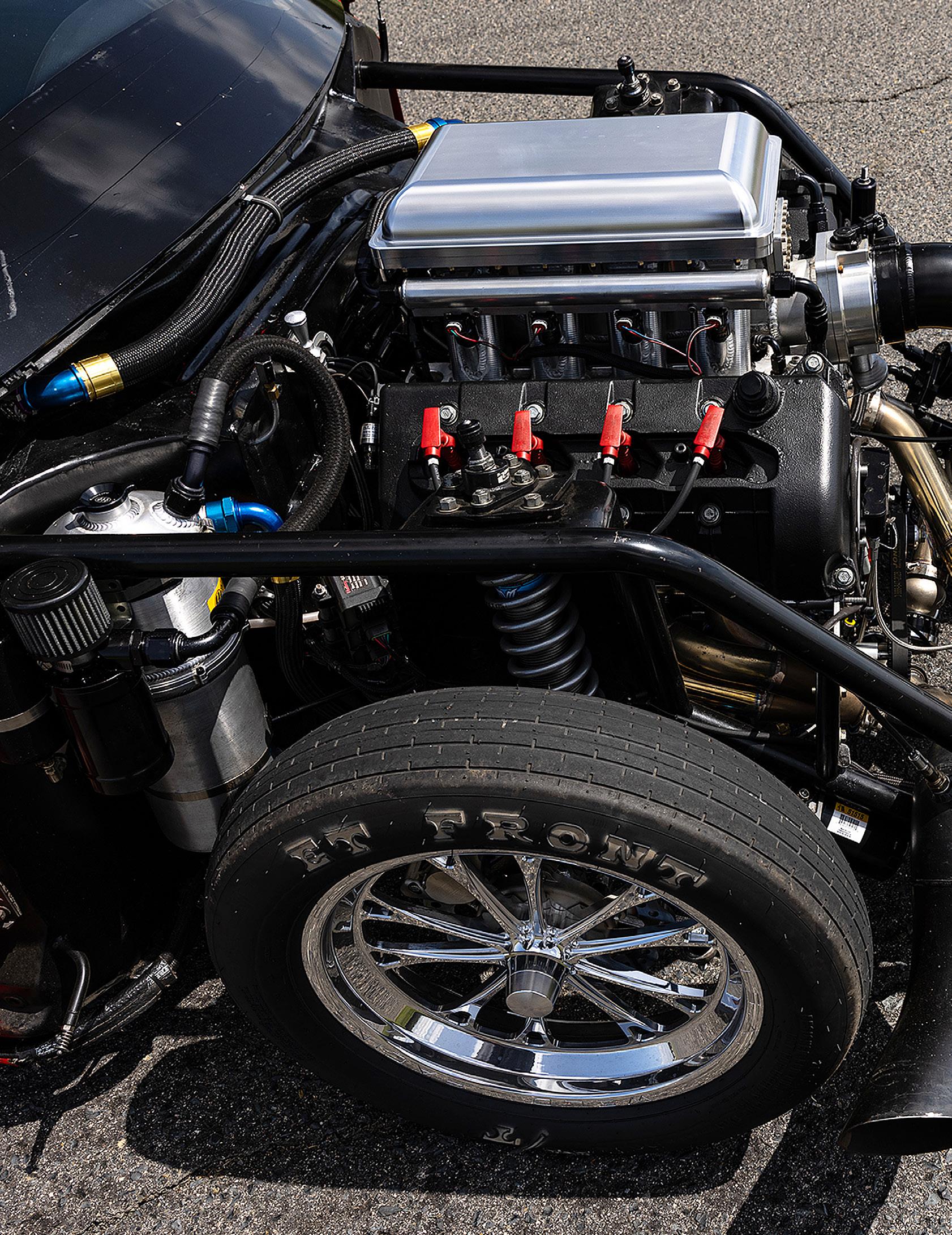

Harrell Engine and Dyno (HED) built 4.6L using a Nemak block with stock stroke and bore. The rotating assembly consists of Ross pistons, Wiseco Boostline rods, an and billet crank modified for a roller thrust bearing.

Cylinder Heads:

Ford GT500 heads ported and dry decked by HED. Stock cam followers and lifters. Stock sized Ferrea intake and exhaust valves with Pac valve springs.

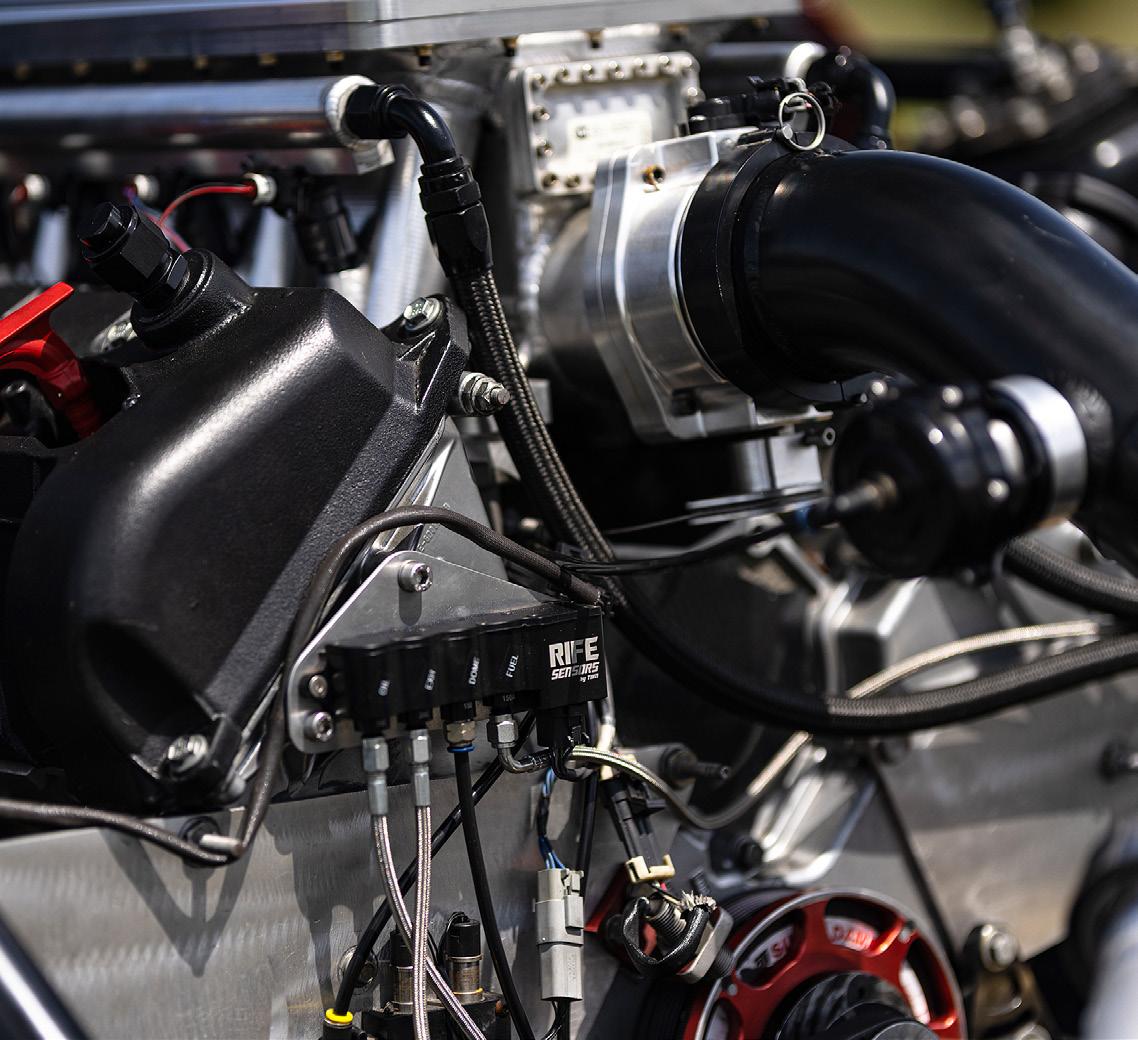

Induction & Fuel Delivery:

Customs by Bigun built intake, headers and turbo kit. Billet Atomizer 325lb/hr injectors.

Electronics:

Holley EFI controls everything with Rife Sensors.

Power Adder:

When in Ultra Street trim it has a 76mm cast wheel from Work Turbochargers.

When in No-time trim it has a billet wheel 88mm from Reed Patridge at Work Turbochargers.

Transmission:

Proformance Racing Transmissions 3spd TH400 with Greg Slack torque converter.

Rear End:

Customs by Bigun built 9” with Tiger Rear Ends supplied parts.

Brakes:

TBM brakes front and rear. Tires & Wheels:

17” spindle mount V-series up front and 15x12.5 Billet Specialties with MacFab Beadlocks and M/T 275 drag radials in the rear.

ET & MPH – Race Only:

Ultra Street Trim: (1/8mi) 4.52@154mph

No-Time: You’ll have to guess but it has been faster than 4.40@170mph!

Thanks To:

Harrell Engine & Dyno: For the engine, dyno and track tunning. Pete Harrell Travels with me to race and tries to make sure I don’t do something stupid. Basically if it wasn’t for him, I wouldn’t be able to race.

Customs by Bigun did the cage, the chassis work, set up the suspension, built the turbo kit and intake, mounted the nose, built the wing and got it ready to wrap. Basically they do anything and everything car-related.

Reed at Work Turbochargers for the only turbos I’ve ever used since going racing.

MacFab Performance Beadlocks for the best beadlock on the planet!

Motion Raceworks/TBM brakes/Rife Sensors for their continued support and just making parts that we need right here in the United States of America.

Greg Slack for going above and beyond on the torque converter.

It’s cool to see a car of this caliber and capability use stock parts inside as it keeps the street vibe alive in the street car drag racing. theme The meticulously Bigun-fabricated 25.2 cage snakes its way through the interior and a composite dash was added along with a slew of race oriented parts, but factory door panels, console and trim were kept in place. A cooler tank rides shotgun and the rear area is tubbed with carbon fiber and finished to a show quality.

Ford did an outstanding job in picking the red paint for its Cobras; they call it “Torch Red.” Mark’s Mustang uses the factory paint on the original body panels and a few trick Schoneck Composites carbon panels were added for weight reduction. The nose, hood, side skirts, and rear decklid are all car-

A Bigun custom suspension was used front and back and they also fabbed up the 9-inch rear using parts from Tiger Rear Ends.

bon wrapped in red to match the factory paint. Eric also hand-built the aluminum wing.

The car rides on 15-inch spindle-mounted V Series wheels with Mickey Thompson skinnies on the front, while out back a set of 12.5 inch wide Billet Specialties and Mickey

Thompson 275 Radial Pros mate together using MacFab Beadlocks from Tommy Kirk. Jason Smith of TBM Brakes hooked Mark up with a set of their drag brakes featuring wave rotors on all four corners that ensure the Cobra will stop after a mid-4-second hit in the 1/8th.

While the stock Teskid block from the Ford factory takes a beating, Pete Harrell of Harrell Engine and Dyno advised on an upgrade. Pete started with a Nemak block and chose to stay with the factory 281ci. The rotating assembly consists of Ross Racing pistons, Wiseco Boostline rods, and a Molnar billet crank. In addition, Pete modified the crank to accept a roller thrust bearing. Ported GT500 heads top the little 281, and although the valves stay factory-sized, replacements from Ferrea were chosen and

are mated with PAC Racing springs. Camshaft wise, they found that the stock 4.6 Cobra cams worked very well. Finally, Eric worked his magic to complete the short block with a custom intake manifold. The healthy Mod motor drinks M1 race fuel through Billet Atomizer 325lb/hr injectors and an Aeromotive fuel pump. Bigun also had his way with the entire turbo kit down to the headers. Mark runs not one but two turbo configurations, one to fit the Ultra Street class rules and the other for no-time racing. For

Ultra Street, a 76mm cast wheel unit was chosen and an 88mm billet wheel monster is used for no-time action.

The entire system is controlled by a Holley Performance Dominator ECU and a long list of Rife sensors.

Most opt for the two-speed Powerglide or Turbo-glide transmission, but in Mark’s case, they went with a three-speed TH400 from Proformance Racing Transmissions and a spec’d Greg Slack converter from the man himself. Bigun got after it again on the rear end, building a complete 9-inch using a Tiger Rear Ends center section and 35 spline axles.

The cockpit has all of the racing essentials, a Schoneck Composites dash, Holley Performance digital display for checking vitals, a Kirkey racing seat, and a fire extinguisher in the event of a worst case scenario. In place of a passenger seat is the Bigun-built coolant reservoir, an organized display of wiring, and a co2 tank.

Buttons for staging are on the Sparco steering wheel and within reach is a lever for the fire suppression system and the slick M&M Transmission shifter. Placed over the custom carbon tubs is the company that has the most time and effort into the car, Customs By Bigun. Mark and the team have competed in multiple big events across the east coast, but the most significant achievement was setting the Ultra Street record back in 2019, going a blistering 4.52 at 154mph!

As for the cars actual capability in no-time race trim, well Mark says that you’ll have to guess, but he can guarantee that the car has been faster than 4.40 at 170mph…now that’s one mean Red Cobra!