STRAIGHT-WEIGHT PERFORMANCE

HIGH PERFORMANCE MINERAL DRAG RACING OIL

Mineral based engine oil designed to enable maximum power while providing ultimate protection under the most severe race conditions.

• Unique friction modifier system enables maximum power output

• “Stay-in-place” chemistry and 2X Zinc anti-wear system provide lasting protection

• High quality base stocks enable effective ring seal

• Advanced, proprietary additive system keeps your engine clean

• Designed to prevent separation caused by fuel dilution

• Available in 50WT, 60WT & 70WT

EDITOR-IN-CHIEF..............................................................

CHRIS BIRO EDITOR@RPMMAG.COM

V.P. MARKETING/CUSTOMER RELATIONS TRISH BIRO TRISH@RPMMAG.COM

E VENT MEDIA ..................................................EVENTS@RPMMAG.COM

E VENT SUBSCRIPTIONS COORDINATOR SHERRIE WEBER SHERRIE@RPMMAG.COM

ART DIRECTOR ............................................................ JIM MCHARG

PHOTOGRAPHIC CONTRIBUTIONS:

MARK GODRAGRACING.ORG, GEORGE PICH, LOUIS FRONKIER, BLAKE FARNAN, JERRY GARRISONI, EDDIE MALONEY, WES TAYLOR, STEVEN TAYLOR AND AMBER HYNES

RPM Magazine is a REGISTERED TRADEMARK of Revolution Publishing & Media Inc. RPM Magazine is a worldwide motorsports publication distributed online.

To subscribe to RPM go to www.rpmmag.com or email Trish Biro at trish@rpmmag.com, or call 519752-3705.

The focus of RPM is to bring a diverse mix of high performance street and race automobiles to life within its pages including race cars, muscle cars, hot rods and street legal machines with an emphasis on the “EXTREME,” including fast doorslammer and outlaw forms of drag racing. Not familiar with these types of cars? They are considered to be the top-shelf of the industry and are on the edge with regard to design, performance, and power!

RPM Magazine does not sell its mailing list or share any of the confidential information regarding its subscribers.

EDITORIAL CONTRIBUTIONS: CHUCK SCOTT, MARK GODRAGRACING.ORG, TIM BIRO, STAN SMITH, GEORGE PICH, JAY MISENER, EDDIE MALONEY, WES TAYLOR, AND SCOTT FORBES

TECHNICAL WRITING CONTRIBUTION: CHUCK SCOTT, SHANE TECKLENBURG, TIM BIRO AND JAY MISENER

S PECIAL EVENTS MANAGER: CHRIS BIRO EVENTS@RPMMAG.COM

S PECIAL EVENTS SALES: TRISH BIRO: 519-752-3705 TRISH@RPMMAG.COM

SUBSCRIPTIONS/ADDRESS CHANGES: CIRCULATION CIRCULATION@RPMMAG.COM

G ENERAL INQUIRIES: 519.752.3705 INFO@RPMMAG.COM

RPM Magazine has been a world leader in motorsports publishing for 24 years and has support locations in Ontario, Canada, Alabama, Texas, and Virginia, along with contributing writers and photojournalists worldwide.

If you have a story that may fit within the focus and scope of RPM Magazine’s coverage, please email our Editor In Chief at editor@rpmmag.com. Submission of an article does not guarantee that it will be published.

Revolution Publishing & Media Inc. (RPM) / RPM Magazine IS NOT responsible for errors or omissions in ANY advertisement or article. Advertisements may be rearranged or altered at the sole discretion of RPM to allow the ad to fit in the space purchased by the advertiser.

WE RESERVE THE RIGHT TO REFUSE ANY ADVERTISING WHICH WE CONSIDER TO CONTAIN MISLEADING, OFFENSIVE OR FALSE INFORMATION. REPRODUCTION OF ANY INFORMATION HEREIN IS STRICTLY PROHIBITED WITHOUT PRIOR WRITTEN CONSENT.

Change can be a difficult pill to swallow...

...for hardcore gearheads that pill came in the form of a new type of car arriving on drag strips around the world; the import.

Ibetter performance. And they were delivering on all counts. Equipment like an advanced handling suspension and 4 wheel disc brakes on their 1979 280ZX, along with sleek styling, definitely made it stand out from the crowd.

As far as straight line racing though, it would be another decade or more before most imports could hold their own, but when they reached that point, the impact was felt throughout the racing scene worldwide. With much lighter weights, but much smaller displacement engines,

many imports were taking advantage of rapidly advancing turbocharger technology and before long the movement was in full swing with their own racing organizations, classes and events. And guys like Paul Bhawan have been there through it all.

Eventually, what was new became mainstream and many of the Import/Sport Compact cars filtered into other organizations, racing alongside their American counterparts.

For Bhawan, his taste for cars came in his home coun-

try, Trinidad. “I started to work on cars with my dad at the age of 12 in Trinidad,” Paul explained. “We would work on Mazdas because my dad worked at a Mazda dealership and then after high school I attended College to become a Mechanic.”

Datsun’s new 1979 280ZX was cutting edge for the time with its sleek look and a bunch of performance goodies, both of which have been taken to whole new level by Paul Bhawan. The company used the phrase, “Datsun, We Are Driven” as their slogan in ’79, something that also fits Paul to a T!

High Power Certified.

There’s no place for middle of the road in high performance. That’s why Trick Flow developed CNC-ported GenX® series cathedral port cylinder heads for GM LS engines. Trick Flow altered the valve angles to 13.5° to decrease valve shrouding, increase airflow, and improve piston-to-valve clearance with stock pistons. Relocating the spark plugs boosts mid-lift airflow and improves combustion efficiency, and extra material at the rocker arm mounting points enhances high-RPM valvetrain stability. Trick Flow’s top-of-the-line CNC Competition Ported runner treatment delivers large amounts of smooth moving airflow for making big power. GenX CNC-ported cylinder heads are offered in 205cc, 215cc, 225cc, 235cc, and 245cc intake port sizes. A 6-bolt mounting pattern is optional on GenX 235 (standard on GenX 245) for extremely high compression, high boost applications.

Your Formula for GM LS Performance!

New heads are just one part of the horsepower formula. To make it complete, you’re going to need some other components.

Track Max® Camshafts

Give your GM LS an even bigger power boost with a Track Max camshaft. Available in several hydraulic roller designs up to 230°/238° duration and .625"/.625" of lift, they are dyno proven to produce significant power increases over the entire RPM range.

Active Fuel Management and Variable Valve Timing Delete Kits

The problem: most performance camshafts don’t work on engines equipped with AFM or VVT. The solution? Ditch them with these delete kits! They include everything to completely remove AFM and VVT the right way, so your engine will make the power you expect with no hiccups.

Cylinder Head Bolt Kits

Keep combustion where it belongs! These high-quality cylinder head bolt kits provide consistent clamping force. The bolts are made from premium quality alloy steel with cold-formed heads and rolled threads. The kit contains all the bolts you need to install a pair of heads.

The original 280ZX steel body tub remains and the rear window glass is original, too. A fiberglass front end and doors along with a carbon wing have been added to control weight and credit for the custom blue paint goes to Paul’s brother Richie Bhawan at FH Pro Collision.

Paul used a Nissan TB48 inline six block to create his custom 290-inch mill and paired it with a factory cylinder head fitted with a complete rundown of Ferrea Racing Components parts. A sizeable single turbocharger is plumbed into the left side of the engine with the intercooler front and center feeding the GATO billet intake.

Armed with both family support and knowledge, Bhawan’s interest in cars intensified, but specifically he liked fast cars.

“After moving to Canada I got a Nissan Sentra and souped it up as my daily driver, and after that I was hooked,” he contin-

ued. “Then I found my Datsun with an inline 6 fully modified and I did a lot of street racing back in the day.” Along with the streets, Paul would eventually hit the track racing various other combinations he built, but he had a soft spot for the 280.

It was a mint condition regular street car that he bought in Toronto, Canada back in 1990 for $6,000. Paul jokes about bringing his daughter home from the hospital when she was born in the car and getting pulled over for driving too slow. Back then, he drove the car all year, even through a number of harsh northern winters, but eventually his love of going fast would outweigh practicality and the car was dedicated to fair weather street use and racing.

The

Datsun 280ZX of Paul Bhawan makes a squirrellypassdown the1/8toawin!

Paul Bhawan’s Single Turbo

■ Body And Paint:

Rear body tub is original with rear glass windows. The front end and doors are fiberglass.

Custom blue paint by owner’s brother Richie Bhawan at FH Pro Collision.

■ Chassis Modifications:

Full Chassis NHRA SPEC 25.1 by LE Chassis. Some work by Chassis Stop.

■ Suspension:

Front: Struts.

Rear: LE Chassis custom chromoly Ford 9'' with 4-link.

■ Engine:

TB48 NISSAN. 290 cubic inch. Stock block with custom pistons and rods.

■ Cylinder Heads:

Stock Nissan factory heads with Ferrea valve train.

■ Induction & Fuel Delivery:

Jaz Pro Cell with a Weldon mechanical fuel pump.

■ Power Adder:

Single Precision turbo.

■ Transmission:

M&M 3 speed automatic.

■ Rear End:

Custom LE Chassis Ford 9" with spool and axles.

1979 Nissan/Datsun 280 ZX

■ Tires & Wheels:

M/T rear wheels and ET Drag tires. Weld front wheels and M/T front tires..

■ Interior:

Dash is a C127 Motec, aftermarket removable steering wheel, M&M shifter, Sparco race seat and Racequip 5 point cam-lock harness.

■ ET & MPH:

1/8 mile 4.29 and 179 MPH.

■ Most Unique Feature:

I believe my car is unique because it’s a 1979 Datsun, and it’s like a family member.

■ Most Memorable Experience To Date: Would be winning the Super Street championship in the Canada Heads Up Series for 2022.

■ Build Timeline:

It took way too long lol, and it’s still a work in progress!

■ Thanks To:

I would like to thank everyone who has helped past and present with the Datsun.

Needing more power, Paul swapped out the Nissan engine for a Buick Grand National piece and had some fun for a while, but it too would eventually be replaced. This time, he began the journey of a full build and went back to Nissan power with a turbocharged

RB28 inline six, which made 1300 HP to the wheels.

As you might guess, that 1,300 horsepower ran its course and Paul set his sights on even more, which brings us to the TB48 290-inch inline six Nissan motor now being campaigned in the 280ZX.

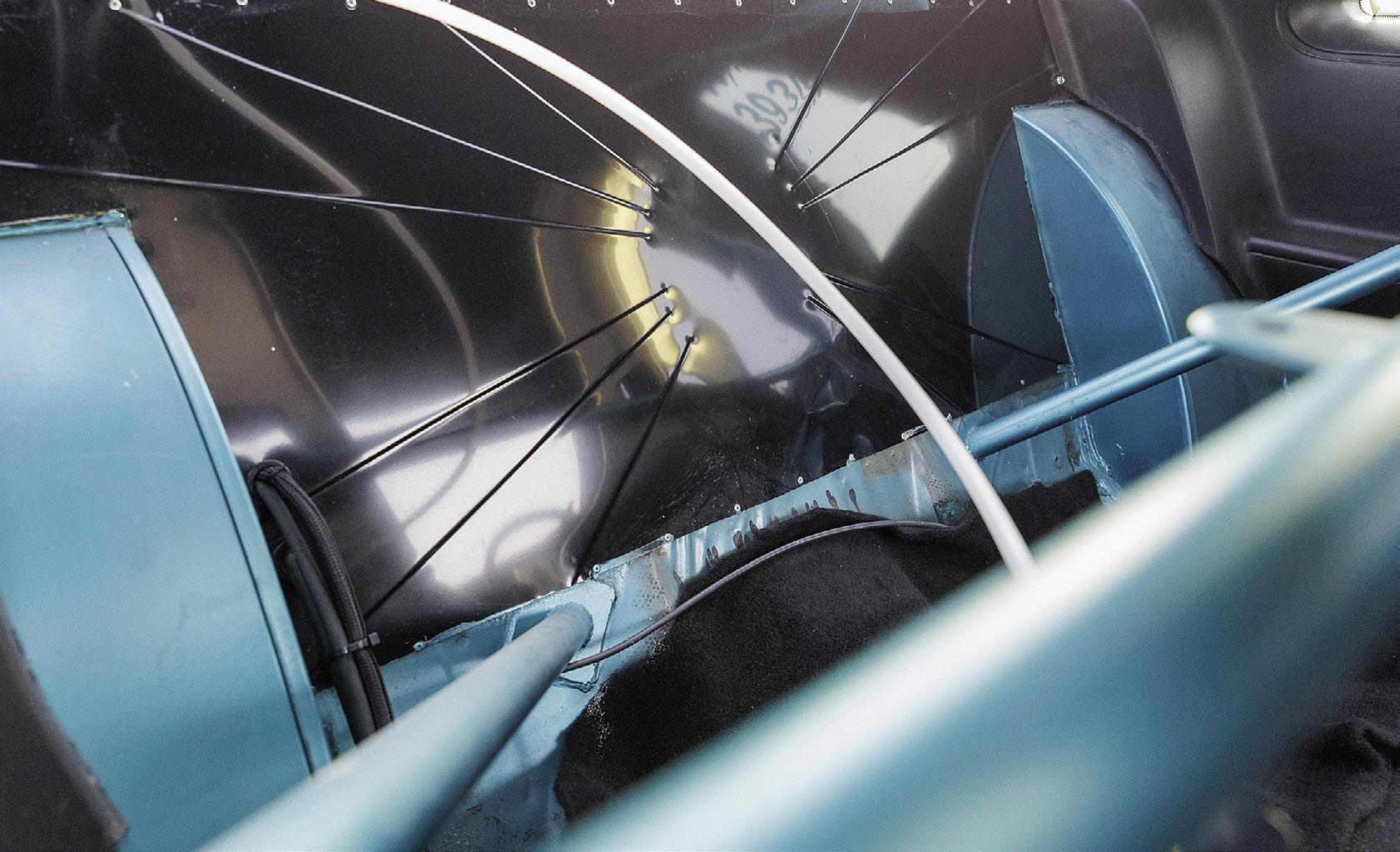

The NHRA 25.1 chromoly chassis and cage is the work of LE Chassis. The cage is finished in silver with Carbon overlays used to protect the finish where necessary. The factory dash pad has received a carbon overlay and holds the C127 Motec display on a carbon panel where factory gauges once sat.

The NHRA 25.1 chromoly chassis and cage is the work of LE Chassis. The cage is finished in silver with Carbon overlays used to protect the finish where necessary. The factory dash pad has received a carbon overlay and holds the C127 Motec display on a carbon panel where factory gauges once sat.

A custom rotating assembly spins inside a specially prepped stock block and the reworked factory cylinder head was fitted with a complete rundown of Ferrea Racing Components parts. Details are a bit light on exact parts, but we do know that the latest turbocharger

used in the combination is a sizeable Precision unit.

When he first started building the car for big league racing, Paul had a number of setbacks with chassis shops and eventually found LE Chassis to build the NHRA certified 25.1 chromoly skeleton.

The Chassis Stop has handled various quick touch ups as required. LE also built the custom 9-inch rear end and 4-link/coilover setup out back and strut front end.

Of course, this is the same original 280ZX body structure that Paul bought all those years ago and a fiberglass front end and doors have been added to control weight.

Carbon fiber wheel tubs take up the bulk of the rear of the cockpit along with custom fabricated carbon filler panels.

Carbon fiber wheel tubs take up the bulk of the rear of the cockpit along with custom fabricated carbon filler panels.

Summit Racing™

Pro LS Steam Line Kits

Upgrade Factory Steam Tubes

kit

Summit Racing™

Flex Fuel Sensor Bypass and Pigtail Combo Kit for GM LS Avoids Restriction in the Fuel Feed Line

SUM-226305X-KIT $229.97 USD kit

SUM Flex Sensor Combo

EET-9705 $209.99 USD each

EET 19 Flame

DRG2

4L80E 300M

Extended Spline Input Shaft Engineered Durability

TOS-4L80SH $329.99 USD each

TOS 4L80SH 300M Extended

Big Gun X Radial Shocks

Specifically Valved for Drag Radial Competitors as low as $508.99 USD each

AFC Big Gun Radial

Big Switch and Lever

Battery Disconnect Kit

Remote Mount

FLA-FR1003-2 $146.99 USD kit

FLA Remote Push-Pull

Flat Touch Switch Panel Kits

Unique Backlit Design as low as $524.99 USD kit

ARC Flat Touch Kit

Mustang Tubular K-Members

Add Strength to Your Pony as low as $399.99 USD each

AJE Mustang Tubular K Each

TheZXcanbe ahandfulwiththewick turnedupjustahairtoomuch!

Credit for the custom blue paint goes to Paul’s brother Richie Bhawan at FH Pro Collision.

Parts and fabrication work inside the Datsun are, just like the rest of the build, top-shelf. Paul sits in a Sparco padded

race seat and is cinched in by a Racequip 5-point cam-lock harness. The factory dash pad has received a carbon overlay and holds the C127 Motec display on a carbon panel where factory gauges once sat.

ThiscarisDriven.... byDatsun.... and Paul Bwahan!

The 280ZX has seen 1/8 mile hits to the tune of 4.29 with top end speeds of 179 MPH and Paul won the 2022 Super Street Championship with his race series.

The 280ZX has seen 1/8 mile hits to the tune of 4.29 with top end speeds of 179 MPH and Paul won the 2022 Super Street Championship with his race series.

Back in 1979, Datsun used the “We Are Driven” campaign to market their vehicles in North America. It was brilliant, and is definitely worth watching on YouTube

They would host their various models in an advertisement pointing out that model’s specific advantages over their competitors, then, at the end of the ad in bold print the “We Are Driven” slogan would appear and be sung simultaneously. Following the slogan, those various “advantages” would follow. For example, on the 210

Hatchback, the words “to give you the best gas mileage” were sung after “We Are Driven”. For the 280ZX however, there was no additional phrase but rather each commercial emphasized how “awesome” the 280ZX was. Since Paul’s car far exceeds what anyone could have imagined a 280ZX would do on a dragstrip, not only is it “awesome”, but it needs a tagline, and we’d like to add one… “Datsun, We are driven…to kickass on the dragstrip!”

Allyn Armstrong’s ‘71 Opel GT

From the pages of RPM Magazine, December 2017

Personally, I like the road less travelled, to stay off the beaten path, keep away from the monkey see monkey do mentality, boldly go where no one…. well you get the idea. The world we live in today, with everything and anything post ed on the web and social media, has made being “unique” more diffi cult than ever. It’s just plain tough to be original.

Despite my love for all things horsepower, when over 90% of the field at a drag race is the same body style, sooner or later everything starts blending together. I get it, some cars are more popular or lighter, or cheaper to build etc. Heck, most of us at RPM even race or drive the most popular models out there, but that doesn’t take away the excitement we feel when we see something completely unique. And Allyn Armstrong’s Opel definitely fits in to that category.

This very quiet and unassuming man from Kingston, Nova Scotia, along with his brother John own A&J Automotive and Machine and are literally legends for their ingenuity and engine building prowess in the eastern parts of Canada and the States, and well beyond.

A&J build mostly race engines for drag racing, off road and boat racing and boasts a full machine shop with CNC machines for blocks, heads and cam cores. The Armstrong boys, who were both inducted into the Maritime Motorsports Hall of Fame in Novem ber 2009, are no strangers to horse power.

Photos: Tim Lewis

Photos: Tim Lewis

The heart of the little Opel is an all billet 4 cylinder built by Armstrong. The 4.250 bore along with a 2.875 stroke makes the 163CI come to life. A crankshaft from the folks at Byrant help spin rods from M&P which are connected to CP pistons. With such a unique combination that works so well, many racers might be reluctant to give details, but surprisingly, Armstrong being quiet by nature was very open about the combination. The cylinder head is a very trick Slawko Racing Heads GM ROX 4.5 bore space with lots of work done to it. Jesel handles the valve train set up and a billet roller cam helps get things pumping inside the engine. The intake is something that just blows your mind when you see what has gone into fabricating it. The only other place in drag racing where one might see these types of odd crazy and trick parts outside of NHRA Comp Eliminator would be among the ranks of the serious sport compact racers.

Along with the handmade intake are 4 Armstrong-built throttle blades and custom scoop pan. To get the car to fire Armstrong uses MOTEC. And with the addition of MSD and Racepak the car has sensors everywhere. Reading this type of data from many sources is what helps get a car to run most every time down the track, and this car makes it A to B 9 out of 10 runs! The little engine drinks Sunoco SR118 and the sound you hear from the high revving 4 banger comes courtesy a lightweight header built by none other than Allyn Armstrong.

Lamb struts keep the car stable and Lamb brakes help slow the super lightweight Opel to a stop. Rearward, inside the Ford 9” hides Mark Williams axles and a 6.50 ratio gear set! (you can almost hear the sound of screaming RPMs now!). A 4-link suspension and Penske shocks get the GoodYear 10.5 slicks hooked when the clutch is let go and the Liberty 5 speed is allowed to work its magic at the command of Armstrong.

Story by George Pich

Photos By Stephen Taylor

Story by George Pich

Photos By Stephen Taylor

While Paul Johnson’s blown big block 1969 Chevrolet Camaro was built to handle the strip, he insisted it be a dependable, drivable true street machine.

What’s more is that Johnson’s ride can hang out with the best of the best on the car show floor, too. So after years of owning the car, when he was finally able to get serious with the build, he pulled no punches.

Johnson has owned this Camaro since 1989, but he began his love of fast cars on the street behind the wheel of his 1971 Plymouth Cuda 440 6-pack car. He transitioned from street action to include outings at the strip with his next project, a Trans Am with small block Chevy and NOS Cheater nitrous kit.

Just one look at Paul Johnson’s blown big block 1969 Camaro is all it takes to understand it means business. Look a little further and you soon see that the car is built to race specs but also to handle some serious street duty.

Paul bought the ’69 from a friend for just $2,500...

A few years later, marriage, home ownership and work limited his hours working on his own cars, but he found a way to feed his love of fast cars other ways. “I loved going and helping friends like Carlton and Debbie Phillips and partner Al Watters with his IHRA Mountain Motor Pro Stock cars. I was also fortunate toitness the beginning of Pro Mod helping Harry “Buster” Raynor and his son Matt in their Ford T-Bird that started as a nitrous combination and then morphed into a supercharged Ford Boss Hemi,” explained Johnson. He would still get some work in on his ’69 Camaro and get to the track occasionally, but once his two daughters were born he pretty much put everything on hold by 1995. And so the Camaro sat until the girls, born 2 years apart, hit college.

Althoughithasn't beentothetrackyet, thiswickedCamaro issetonKillwhenit getsthere.Recently completed,Paulis lookingforwardto gettingoutthereand seeingwhatit'sgot!

Back in 1989, first gen Camaros were plentiful and Paul bought the ’69 from a friend for just $2,500. He was working at a speed shop in Maryland at the time and having a family wasn’t even on his radar yet, so it was a good platform to work with. It was a very basic cut-up

bracket car with no engine or transmission, and it was in pieces with no paint or glass. The Camaro was set up for a small block Chevrolet and a Powerglide transmission with a Dana 60 rear. Johnson cut it up even more and installed a mild steel backhalf chassis with the stock front end.

He would wrench and race the car through several iterations as he enjoyed a long career from 1984 to 2015 with UPS in Automotive Fleet Maintenance. Once retired though, Paul set his mind to reach new heights with the car, and he certainly

The Camaro has been owned by Johnson since 1989, but he only recently hit this latest build with full force. While the car was a cut-up bracket racer when he got it, it still had the original steel body. A fiberglass front end, hood and rear deck lid were added into the mix. Fitting the pieces of the puzzle together along with enlarging the rear wheel wells to keep an OEM vibe was the job of Bruce Mullens at Paint by Bruce, who also tackled the custom paint work.

accomplished that. Influenced over the past 10 years by helping with a Top Sportsman GTO and few Pro Mods, including one of the first ProCharged cars that ran a 598 cubic inch big block Chevrolet, Johnson hatched a plan.

“I got back on my Camaro and decided that I wanted to make the car less street and more race than ever, but at the same time I wanted to be able to drive my hot rod wherever I wanted on the street,” Johnson added.

The Camaro body is made up of the original steel roof, steel quarter panels, tail section and doors with a fiberglass front end, hood and deck lid. Fitting the pieces of the puzzle together along with enlarging the rear wheel wells to keep an OEM vibe was the job of Bruce Mullens at Paint by Bruce, who also tackled the custom work paint.

With the front end off you get a feel for just how much real estate the engine package takes up, but once it’s all buttoned up you wouldn’t have a clue what lurks within.

■ Body:

Paul Johnson’s Supercharged 1969 Chevrolet Camaro

■ Interior:

Original steel roof, quarter panels, rear section and steel doors with factory glass windshield, door and vent glass. Fiberglass front end, hood and trunk lid. Front end fitment, enlarging rear wheelwells with OEM look and body and paint completed by Bruce Mullens at Paint by Bruce. Paint is black with charcoal/brandywine factory style stripes.

■ Chassis & Suspension:

Chromoly double frame rail chassis done by Chris Cheek. Front strut suspension with 4-link/coilover with anti-roll bar rear suspension.

■ Engine:

632 cubic inch big block Chevy with electronic fuel injection. Shaun’s Custom Alloy intake and valve covers.

■ Power Adder:

ProCharger F-3R-112. Walt Sipp at ProCharger was involved in getting the F-3R-112. CNC machined “EDRC” Eric Donavan Race Cars gear drive with gears/parts and resources by Super Charger Store – Chris Tvedt. Running on pump E85 fuel on the street or Race E85 as needed.

■ Fuel Delivery:

Fuel pump is cable drive Waterman Lil’ Bertha mechanical fuel pump putting out 19.3 gallons per minute mounted near the 15-gallon aluminum fuel cell in rear of the car.

■ Electronics:

Engine management and ignition by Haltech Elite 2500T and tuned on the Haltech Hub Dyno by Victor Contreas of Victory Wiring.

■ Transmission & Converter:

Lenco Drive 3 speed manually shifted by original Hurst Lighting Rod shifters. Neal Chance bolt together torque converter.

■ Rear End:

Sheet metal fabricated 9-inch Ford with aluminum center section and 40 spline gun drilled axles.

Carbon fiber seats. Carbon panels throughout the interior including tubs, trunk and front frame side panels. Custom door panels.

■ Wheels & Tires:

Alumastar front wheels 15x3 with Mickey Thompson front runner tires and 15x15 rears with Hoosier Quick Time Pro 33x22.5-15 tires.

■ Miscellaneous:

All CNC brackets are one-offs for this car including the supercharger brackets, stands and mounts plus the coil mounts, all machined by Eric Donavan “EDRC”.

Jones Racing Products alternator putting out 120 amps at low idle and 160 max.

Howes Radiator custom rad with AN fittings to fit the front end and clear all other components .

All AN fittings, no hose clamps of any kind.

■ Performance:

This is a Street/Strip car. Street miles only to date, however it made over 1800-foot pounds of toque on pump E85 fuel. Plans are to get the car to the track this year and get it and the driver up to speed with possible Drag-nDrives on the east coast. Also to gain some bragging rights with my Pro Street buddies who take their cars to the track.

■ Thanks To:

I have to thank Jerry Bickel, Tim McAmis, Andy McCoy and Rick Jones for different chassis and carbon parts used on this build. A special thank you to Danny Bogle for all his help working on the car and getting it completed. While this car was going back together we lost a close friend and car cruising buddy who helped on this car and was an all-round great person, Bryan Bogle, Danny’s brother. So, not a day or car cruise goes by when we don’t think about all the great times.

A bullet-proof fabricated sheet metal 9-inch Ford rear end with aluminum center section and 40 spline gun drilled axles is suspended from a 4-link/coilover with anti-roll bar. Up front, a custom coilover strut design is used

•

•

•

•

The chromoly double framerail skeleton was built by Chris Cheek. A strut front suspension and 4-link/ coilover with anti-roll bar rear setup were added and a fabricated sheet metal 9-inch Ford with aluminum center section and 40 spline gun drilled axles distributes

By the way, on that pump-fuel, the combination churned out over 1,800 pounds of torque!

Loving both the race and street scene, Johnson wanted to shake things up in the transmission department a bit and chose a Lencodrive 3 speed auto with Neal Chance bolt-together converter that is manually shifted by original Hurst Lighting Rod shifters.

Custom interior door panels were created to work with the exterior paint scheme and the steel doors and original door jambs are still equipped with factory latching hardware. Electronics are meticulously laid out inside the Camaro.

That trick transmission is the centerpiece of an interior filled with carbon fiber goodies too numerous to mention (check out the pics). The chromoly cage, certified to run 7.49 quarter miles and quicker, snakes its way through the cockpit and a Racepack dash tells Johnson everything he needs to know about what’s happening up front. Custom door panels were created to work with the exterior paint scheme.

It was long tedious process but Paul couldn’t be happier with the outcome. “I am not getting any younger and I need time to enjoy the car. The Camaro is everything I dreamed of and I couldn’t have accomplished this without my family and friends!”

A few shots taken during the build show the intricacies of fitting the big block and supercharger with associated equipment within the confines of the chassis and front end. Mockup, disassemble and repeat was a common theme, but Johnson and his team hit it out of the park!

I am not getting any younger and I need time to enjoy the car on the street

paul johnson

“If it wasn’t for my family and friends helping me on this quest, I could not have brought my vision to life. I would not be cruising the streets with people asking if it’s really street legal and if I actually drive it.” And drive it Paul does. Last year he logged 200 miles for one outing alone and drove it to a number of other events and shows every chance he could. “I am not getting any younger and I need time to enjoy the car on the street,” he added. But just because the Camaro logs a bunch of street miles doesn’t make it a pushover on the strip, and Johnson intends to prove that in 2024. “Plans are to get the car to the track this year and get it and the driver up to speed with possible Drag-n-Drives on the east coast. Also to gain some bragging rights with my Pro Street buddies who take their cars to the track.”

Story by Jack DuBois

Photos By Stephen Taylor

Story by Jack DuBois

Photos By Stephen Taylor

Five years ago Mike

"Fiveohh" Mack doled out 3,500 bucks for a 1992 Mustang LX he found on Marketplace in Indiana.

It was a perfect driver with complete black factory interior, but it wouldn’t be long before he decided to cut it up and turn it into a race car. No stranger to straight-line action, Mike has been involved in drag racing since he was 15 years old. Along the way he positioned himself to gain as

much knowledge as possible through working with experienced pros and learning from them every chance he could. Most notably, he was able to work on a Top Fuel Funny car team with Tim Wilkerson out of Springfield, Illinois. “I was the bottom end specialist on the car,” Mike explained.

Schoneck Composites doors, an earlier “4-eye” front clip and hood were added to the ’92. Ford Bright Calypso Green Metallic, arguably one of the hottest colors when it first appeared on the Mustang back in 1991, was sprayed to perfection by DP Kustoms, and although Mike’s son calls it “blue”, the Mustang never fails to attract attention.

“I learned a lot in that position and from a number of other people. I've also become friends with Bobby Ducote and have been on several episodes of Street Outlaws with him over the years.”

Mike’s nickname “Fiveohh” is well earned since he’s had close to 40 Mustangs, and as for the car’s name “Regulator”, well that just sort of came along naturally.

What’s Old Is New if you haven’t read it yet!

Over the coming months we will be hosting some of our past issues of RPM Magazine in this section. If you haven’t read them yet, they are new to you! If you have, maybe there’s a favourite car/story you want to read again….here they are!

Since Mike is a guy who always names his cars, when he first started the build of this LX for small tire no-prep action, he and his buddies wanted to “regulate” the competition. And since Mike liked the Warren G song “Regulator” the

name stuck. “The build took what seemed like forever and many times I wanted to quit, but it is finally finished,” Mike said. And while a lot of things had changed in small tire no-prep racing during that 5 year period, the Regulator name stayed.

Originally, incentive to build the car came from some pretty intense local competition. Every place where there is drag racing or street racing, there are rivalries, and Mike’s arch rival was his motivation to get the Mustang completed. “I had a local kid who was a fellow racer,” he explained. “It was definitely a Ford vs Chevy thing but went deeper than that. He would get me so mad. He talked down my whole program and my ability of building cars. I guess the bottom line was that we both always wanted to be fastest in our county, so I set out to prove him wrong at any ex-

Some of the extra time taken to build the car was due to waiting on parts or chassis work to be completed, and, since Mike is a single parent who has been growing his own business, some of the delay was the result of finances. But in the end

the car was completed and was everything Mike expected.

To start with, Mike wanted to lighten up the already svelte Fox Body and to do so he added Schoneck Composites doors, an earlier “4-eye” front clip and hood.

Swapping out the 1992 front end with the earlier 4-eye recessed headlights has become popular among enthusiasts.

Ford Bright Calypso Green

Metallic, arguably one of the hottest colors when it first appeared on the Mustang back in 1991, was sprayed to perfection by DP Kustoms, and although Mike’s son calls it “blue”, the Mustang never fails to attract attention.

With the intention of running small tire stuff, the car was backhalved and mini tubbed while keeping the

factory floor pan, firewall and front strut towers in place. Chassis work was completed by Mild To Wild FAB and Overdunn Services. Full bolt-on front and rear aftermarket suspension parts were used with Santhuff front struts and AFCO Big Gun rear coilovers. An 8.50 certified chromoly cage was also fabricated in place during the process.

Mike "Fiveohh” Mack’s "Regulator" 1992

Nitrous Small Block

Ford Mustang LX - Small Tire No Prep

■ Body & Paint:

‘92 factory shell with Schoneck doors, front clip and hood. Paint was handled by DP Kustoms and the color is Ford Bright Calypso Green.

■ Chassis & suspension /modifications:

Factory firewall and floorpan car. Full bolt on front and rear aftermarket suspension, 8.50 cert chromoly cage, mini tubbed, stock front strut towers.

Santhuff front struts and AFCO Big Gun rear coilovers.

■ Engine:

The engine is a Bennett SBF 444 inch. Dart block with Trick Flow 255 high port heads.

■ Rotating Assembly:

Callies Crank, GRP aluminum rods, Diamond pistons.

■ Induction:

Edelbrock intake with a single direct port nitrous system.

■ Power Adder:

Fastlane Nitrous Systems .

■ Electronics:

Full MSD Grid system, crank trigger, Speedwire overhead panel, Induction Solutions Nitrous controller, Holley 686 dash for engine monitoring.

■ Transmission & Converter:

Sonnax 1.69 gearset, Reid case Powerglide SBF bell. Ultimate Converters 5500 converter.

■ Rear Differential:

All Moser Fab 9 inch 40 spline gun drilled axles, 4.30 Pro gear, Moser 3rd member.

■ Brakes:

4 piston brakes all four corners.

■ Tires & Wheels:

Mickey Thompson 26 inch front runners, 3055 28x10.5 non-W slicks. Billet Specialties 15x3.5 front wheels and Street Light 15x12 single beadlock rears.

■ Interior:

Holley 6.86 dash, Grant wheel, Precision Performance Products shifter, Kirky seats, DJ safety belts, Stroud parachute and the only sound system is open headers!

■ Best ET & MPH:

This is a N/T car, but I can say that it has been low 5's and has much more to go!

■ Most Unique Feature(S):

The fact that it is actually still a Ford powered car which is most unique these days, and I would also say a lot of people love the color of the car and its looks.

■ Special Reason For Build:

Yes there are definitely a couple good reasons. I had a local kid who was a fellow racer (Ford vs Chevy thing) who got me so mad, he talked down my whole program and my ability of building cars. We both always wanted to be fastest in our county! So I set out to prove him wrong at any expense.

I also became good friends with racer Bobby Ducote and always had hopes of racing on the show with him. I have been on several episodes but unfortunately never with my own car.

■ Most Memorable Experience:

I have done more testing than anything with this car to date. But I have entered the car in 3 events and in those events I have finished runner-up in one and won another. Plus I have set many personal bests at the track with it.

■ Thanks To:

Chassis Work done by Mild To Wild FAB and Overdunn Services. Paint and body was done by DP Kustoms -Dalton Payne, The Keen and Farr family for wiring and tuning help and big support from family and friends to finish the car. Also big thanks to Bobby and all the wonderful people I’ve met through him that have had a part in build.

A single Fastlane Nitrous Systems direct port setup was plumbed into the intake. Backing the sprayed small block is a Reid-cased Powerglide with Sonnax 1.69 gearset and SBF bellhousing with a 5,500 converter.

built in mounting bracket

Tri-lobe scavenge sections feature individual timing gears to ensure proper clearance at high rpm

Spur Gear pressure sections based off Moroso’s highly successful Billet Wet Sump Pump Design

A Moser 9-inch complete with 40 spline gun drilled axles, 4.30 Pro gear and Moser 3rd member hangs out back.

With blue blood running through his veins, there was just no way that Mike would bastardize his Mustang with another brand’s engine, so he went with a tried and true small block Ford combination. Under the hood sits what Mike calls an “older” Bennett small block 444-inch Ford.

When Mike bought the car 5 years ago it had a mint black interior, but when he decided to cut it up for track-only duty he axed most of it. Everything but the factory dash is gone which now holds a single Holley EFI display. An 8.50 cert cage was fabricated and a pair of aluminum race buckets were installed in place of the factory fabric seats, with a nitrous bottle taking up the passenger seat.

The trunk area now houses the fuel cell and battery and the cage work and tubs were painted to match the body.

In

A Callies crank, GRP aluminum rods and Diamond pistons spin inside a Dart block topped with legendary Trick Flow 255 highport cylinder heads and an Edelbrock intake with Quick Fuel nitrous-spec carburetor. That being said, a single Fastlane Nitrous Systems direct port setup was plumbed into the intake. Two things we

don’t know about the small block are cam specs and size of the hit Mike uses, but in the no-time no prep game it’s best to either keep those details to yourself, or send them out as fake news. To back the sprayed small block, a Reid-cased Powerglide with Sonnax 1.69 gearset and SBF bellhousing was paired with a 5,500 converter.

Originally, Mike planned to hit the track hard most weekends, but once again, being a single dad and business owner has to take precedent. These days he gets to test quite a bit and

do 3 or 4 events per year, and while he still won’t divulge any specific info on the capabilities of the car, he did say that it has been low 5s with much more to work with!

These days, Mike spends a lot of his time in passing the torch to his son Tucker who has been racing a Junior Dragster for the past 7 years, and at the age of 15, Tucker is ready to kick things up a notch or two.

“I am now at a point of life where I am showing my son what I know,” Mike added. “He was recently a Track Champion in his Junior Dragster at Coles Co Dragway and we are starting to build him his own drag car. I’ve enjoyed my time with him and am excited to help build him a new car over the next year. I give him a hard time because he wants a late 1980s RX7, but of course it will be Ford power!” But just because Mike is building a car with his son, don’t count him out of local no-prep action with the Stang. Rest assured, the Regulator still has some hometown feelings to hurt.

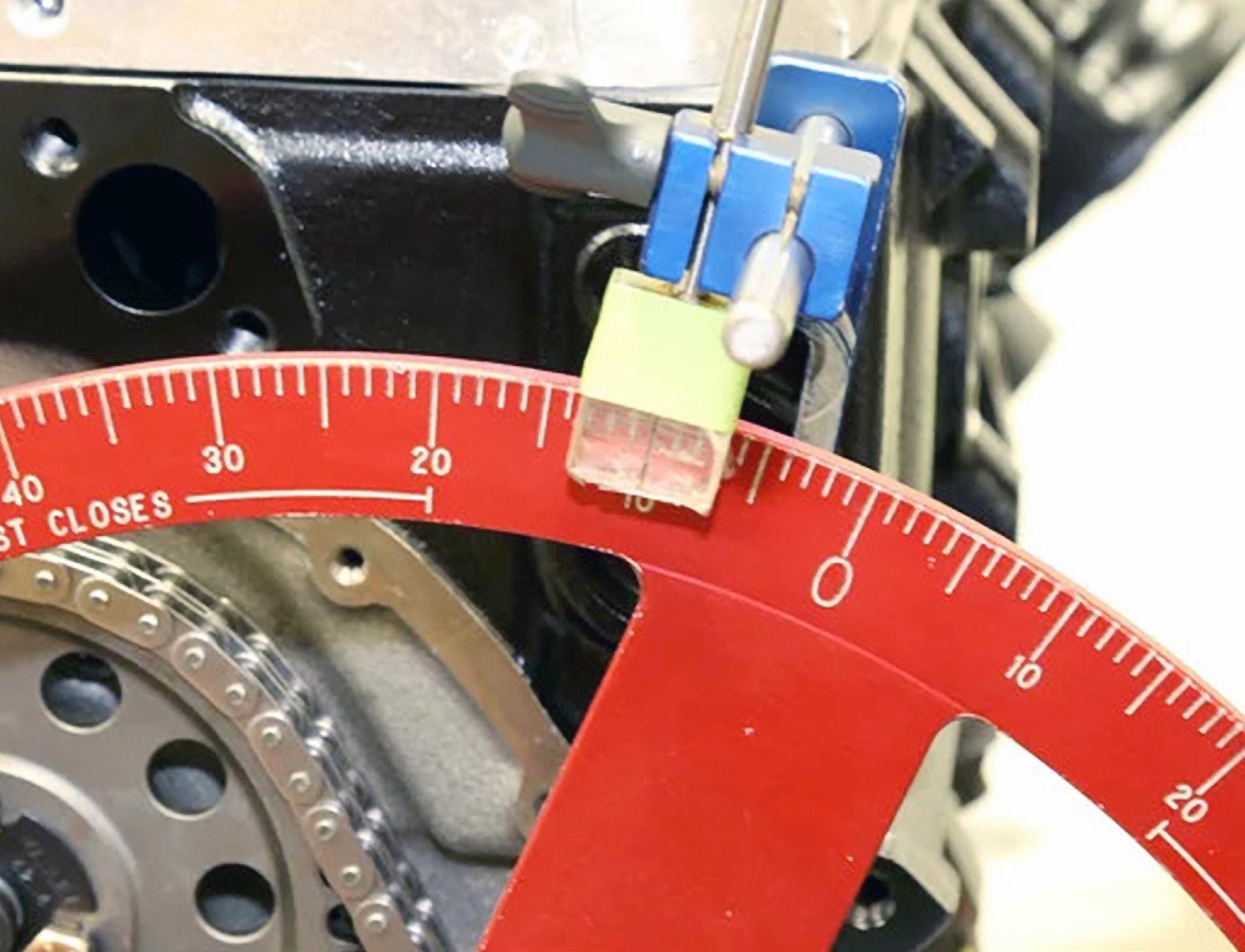

CheckingPiston-ToValveClearance

ThisStepCouldPreventCatastrophicDamageToYourEngine

Checking piston-to-valve clearance is an essential part of any engine build.

In this tech installment, we show you how to do it.

Aggressive camshafts and high compression ratios are necessary for maximum power in an engine, but they also create a very risky relationship between the valves and pistons. Basically, the two components can get too close to each other, and at high RPM any contact will result in some type of damage.

The relationship between pistons and valves is one of high volatility. Too

much clearance and you're giving up performance from low valve lift; too little and absolute carnage ensues. Checking piston-to-valve clearance is a mandatory practice to ensure the relationship is perfect.

The trend towards boost has relaxed some of the anxiety among engine builders as the static compression ratios have decreased when compared to high-strung naturally aspirated or nitrous oxide engines. However, it’s still critical that the piston-to-valve clearance be checked during engine assembly—especially if there have been any changes to the engine that could affect this critical clearance. Examples include resurfacing the deck of the cylinder block or cylinder head, going to a thinner head gasket, increasing the

ratio of the rocker arms or installing a high-lift camshaft.

Opinions may vary between piston and valve manufacturers, but a popular consensus is a minimum clearance of .080-inch for the intake and .100inch for the exhaust. The exhaust valve expands more due to heat from combustion and therefore needs additional clearance. If the engine is equipped with aluminum connecting rods, it’s usually a good idea to add .030-inch to the minimum clearance because aluminum expands more than steel. When the rod expands, the piston is shoved closer to the cylinder head.

There are two popular methods for checking clearance: the clay method and the dial-indicator method. This tutorial will focus on the latter as it is

generally considered the more accurate of the two methods.

Required tools include a dial indicator and base, low-tension valve springs, and a large timing wheel.

Following is a quick example of measuring piston-to-valve clearance as demonstrated by John Himley of CNC Motorsports in Brookings,

South Dakota.

With low-tension checking springs installed in the Number 1 cylinder, the cylinder head is snugged down to the block with the gasket in place.

The gasket doesn’t have to be compressed, but you’ll need to know the compressed thickness (usually listed on the packaging) and measure the

uncompressed thickness to determine the correction factor after measuring valve travel. Install the lifters, pushrods, and rocker arms for the Number 1 cylinder and adjust to zero lash with the crankshaft at TDC on the compression stroke. This ensures that both lifters are on the base circle of the cam lobe.

With low-tension checking springs installed in the Number 1 cylinder, the cylinder head is snugged down to the block with the gasket in place. The gasket doesn’t have to be compressed, but you’ll need to know the compressed thickness (usually listed on the packaging) and measure the uncompressed thickness to determine the correction factor after measuring valve travel.

The relationship between pistons and valves is one of high volatility. Too much clearance and you're giving up performance from low valve lift; too little and absolute carnage ensues. Checking piston-to-valve clearance is a mandatory practice to ensure the relationship is just right.

Rotate the crankshaft to 10 degrees before TDC on the exhaust stroke.

Position the dial indicator on the top of the exhaust-valve retainer and zero the dial indicator. Next depress the exhaust valve.

Note the distance traveled. Now subtract the difference in the gasket thicknesses and you should have an accurate measurement of the piston-to-valve clearance. For this example on a turbocharged SBC, the exhaust clearance was .220-inch.

Rotate the engine to 10 degrees after top dead center on the intake stroke.

Repeat the procedure with the intake valve and compute the clearance. For this valve, the clearance measured .219-inch.

Rotate the crankshaft to 10 degrees before TDC on the exhaust stroke. Position the dial indicator on the top of the exhaust-valve retainer and zero the dial indicator. Next, depress the exhaust valve.

Note the distance traveled. Now subtract the difference in the gasket thicknesses and you should have an accurate measurement of the piston-to-valve clearance. For this example on a turbocharged SBC, the exhaust clearance was .220-inch.

Rotate the engine to 10 degrees after top dead center on the intake stroke and repeat the process. For this valve, the clearance measured .219-inch.

It’s really that basic and results can be double checked in no time at all. So do yourself a favor, no matter what your static compression may be, always make this simple process an essential step in any build or when changes have been made that will affect piston-to-valve clearance.

Source:

Story by: George Pich Photos by: Stephen Taylor

Story by: George Pich Photos by: Stephen Taylor

Twenty four years ago, the Wagner family had a top of the line Super Gas class legal 1957 Chevy built from scratch, and a week later it was gone!

When a race car is stolen, it’s not like a regular daily driver as most racers do not have insurance coverage on their cars. Coverage for a race car is available, usually for all off-track activities, but most car owners either just don’t think about it, or they play the odds as they know their race car will always be within an eyeshot of them…but that, as you are about to find out, can be a serious miscalculation. The fact is that 90%

Back up to the 1960s and you would find Scott Wagner’s dad at the dragstrip racing whatever was in the garage at the time, eventually running a 1969 Corvette in the Super Gas class. Scott’s dad raced until the 1980s and eventually Scott himself would pick up a 1969 Camaro street car that would double as a weekend warrior at the drags, and by the time he got to college he was behind the wheel of their family Corvette.

With Scott becoming handy behind the wheel of race car, the family commissioned Tim McAmis to create a purpose-built Super Gas 1957

What’s not to love about the iconic Shoebox Chevy?

Body and paint was completed by Scott and the killer air brush work was done by local legend John (Tiny) McTaggert of Tiny Signs

The car was topshelf and got the attention it deserved, along with a bit too much attention from the wrong person...

Wagner got the call that the car was ready and the family was excited to get it out on the track, so the very next week they ventured to Kansas City Raceway. Their intention was to just test, but since there was a big money bracket race they entered to get more shakedown passes on the ’57. As it turns out, Scott ended up winning the race, which set in motion an unimaginable chain of events. He explains; “After

the race myself and everyone who was with me hopped in the truck and stopped at a pizza place in a town not far from the dragstrip. We parked right out front with the truck and trailer, went inside to have a pizza and when we came back out, no truck and trailer. There was broken glass on the ground, and we quickly realized what happened.

Of course we called the police and all that good stuff and

In 2021 Scott had Gary Stinnett build a new 632-inch big block Chevy engine for a return to Super Gas competition.

the next day we put out a bunch of flyers offering a $5000 reward.”

The Wagners got a tip call to tell them the truck was located back in that same town behind an old motel. They were able to get the restored 1978 crew cab Chevy back, undamaged, but the trailer and car were still nowhere to be found.

A few more days passed and another tip came in, this time on the car. Scott called the police and hopped in the car with some buddies to go check it out. By the time they arrived, the police and helicopters were there. “It was a gnarly area,” Wagner continued. “There was this really small house that looked like it would hold about 5 people. By the time the cops rolled up there was a big wooded area behind the house and it looked like 100 people came out of that house and they all ran into the woods.

So of course the police were chasing those people and went

Scott Wagner’s 1957 Chevy 150 Series NHRA Super Gas Drag Car

■ Body & Paint:

Body and paint by owner. Air brush work by John (Tiny) McTaggert of Tiny Signs.

■ Chassis & Suspension /Modifications:

Tim McAmis Race Cars (TMRC) tube chassis, carbon fiber wheel tubs.

■ Engine:

632ci. Dart 4.600 aluminum block, Callies crankshaft, Carrillo connecting rods, Wiseco pistons, 55mm. Comp Cams camshaft, Jesel Belt Drive and Jesel .937 lifters. Brodix SR20 cylinder heads with Titanium valves and Jesel shaft rockers. Edelbrock intake manifold with Stinnett Dominator carburetor and throttle stop. Engine Misc: MSD distributor, Moroso spark plug wires, Moroso aluminum oil pan, ARP bolts, ATI balancer, Moroso vacuum pump.

■ Electronics:

K&R delay box and throttle stop timer, MSD Power Grid ignition, Biondo trans brake button.

■ Transmission & Converter:

Coan Powerglide 1.76 ratio Reid case/ Coan 9" torque converter.

■ Rear Differential:

9" custom TMRC housing, Mark Williams 40 spline gun drilled axles, 4.10 ratio gears.

■ Brakes:

Mark Williams.

■ Tires & Wheels:

Mickey Thompson 33.5/16.5/16 rear slicks, American Racing Torque Thrust wheels.

■ Interior:

Autometer gauges, Grant steering wheel, Hurst Quarter Stick shifter, carbon fiber seat and tubs from TMRC, Pro 1 belts, Simpson fire suit and helmet.

■ Best ET & MPH:

9.90 @ 173mph in Super Gas trim.

■ Most Unique Feature(s):

The 7/8 scale body is a crowd pleaser combined with the timeless flames and our signature Orange color.

■ Special Reason For Build:

I wanted to build a new car in the late 1990s and while I was at a race in Phoenix Arizona I saw in person the '57 Chevy of Jay Don Blake and knew that was the body I wanted to go with.

■ Most Memorable Experience:

Winning the 2002 Sears Craftsman Nationals in St. Louis, Mo. as well as being picked Best Appearing Car.

■ Thanks To:

Tim McAmis Race Cars, Gary Stinnett, Jerry Taliaferro @ JTRC, Tim Dacus at Edgars Transmission, Gary Nicholson, John Freeman @ Midwestern Mechanical. A huge thank you to my father-in-law Paul Bowman for all his help as well as being my crew chief for all these years. Big thanks to my Dad Willie Wagner for getting me started in drag racing many years ago and for all of his support. My wife Kim for making this a family affair.

into the house to secure the scene. I was called in to identify the car sitting out behind this old crack house. It’s a Pro Stock style car and those are not easy to unload from a trailer, it takes some care, so I was pretty nervous. Anyway, I got behind this house and the car is sitting there with the front end off and the hood scoop off and a sawzall laying right next to the car, so they were getting ready to start cutting it up…piecing it out. We caught it just in time!” Scott was able to bring another truck and trailer to take the car home and noticed something a bit odd about the overall condition of it. Despite the seedy nature of the crooks, they had obviously taken care in unloading the car as there was hardly even a scratch on it.

Although the trailer was never recovered, getting the car back was the main objective and the truck was a bonus, and Scott promptly paid the tipster the $5K reward.

The thief, as they came to find out, was a sketchy racer that

ianhillracing.com

followed them to the pizza joint from the track, and a few years later Scott heard a rumor that he had been shot and killed in a carjacking. As they say, what goes around comes around.

The car proved to be a winner and after the recovery and repairs, Scott went on to win several races and a National Event with it in 2002. It was also featured on the

cover of National Dragster for both winning the event as well as being selected Best Appearing car.

As years passed, Wagner, a former college baseball player, opted for travelling the country with his son Wyatt playing competitive ball and racing Junior Dragsters over running the ’57.

By 2016, Scott decided to commit some time to the

Shoebox Chevy, running it in Top Sportsman with a 706 big block, but quickly realized that wasn’t the place for them. It sat again as his focus was now on building a 1968 Camaro for his son to run in Super Stock when he turned 16.

Scott took the first year testing the new Camaro and, as promised, handed the keys to Wyatt when he turned 16. “He took those keys and drove the car in his first year at 16 years old to a Division 5 Super Stock Championship and was selected Rookie of the Year and the Jegs All-Star for Division 5. Needless to say, I never got those keys back,” Wagner added with a smile.

In 2021, Scott decided to get the ’57 back out before he got too old to drive it and had Gary Stinnett build a new 632inch engine for a return to Super Gas. Two years later, with covid delaying the build considerably, they debuted the car. The Chevy performed well and with some tuning Scott hopes to be competitive in Super Gas this season.

As we’ve said many times, every car has a story, but we doubt that many are as surreal as Scott Wagner’s lost and found Super Gas 1957 Chevy. It’s the stuff movies are made of.