1 minute read

Manufacturing for Customization

from BT Bundle 2020

by RuMoer

Manufacturing for customization System for FDM mass customisation based on mono-material, transformable interior components using recycled PET

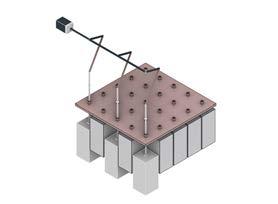

A System for FDM mass customization based on monomaterial, transformable interior components using recycled PET is based on three main ideas; • To give added value to Recycled PET through design. When used as a mono material; it’s possibility to recycle PET without down-cycling its material properties using chemical recycling. • Using 3D printing as technique to use recycled PET as a manufacturing material. The only variants for 3D printing being time and material, COP for any item, customized or not remains the same no matter what the quantity is. • An exemplary design (conceptually driven as ‘living in plastic’ to represent the extent of plastic being consumed) of modular, customizable furniture components of a ‘Tiny house’ The above project is driven by 3D printing of recycled PET of a tiny house. Interior components have been extensively looked into as a way of promoting mass customization. The strongest asset Summary for entire design process/methodology Summary of design methodology in practice of this thesis is a system of mass customizing furniture, made available to anyone in the ‘maker-movement’ with access to a computer and a 3D printer to be able to design and print their own tiny house components. The methodology suggested by this thesis also promotes the designer to become his own manufacturer, reducing the amount of middle men and waste of resources and energy incurred through traditional manufacturing methods. This system hopes to bring together larger communities from around the world to explore their own design process guided by an adaptable methodology, to design more consciously in terms of manufacturing and material selection.

Advertisement

Further reserach possibilities: • Structural testing/optimisation of 3D printed components • Designing of the external shell/ connecitons within modules • Material property testing • Further design testing and validating transformable

connections

Exemplary design

Name Graduation year Tutors