CRUSHING CHAMBER APPLICATION GUIDE

SANDVIK CJ JAWS, SANDVIK CS CONES AND SANDVIK CH CONES

SANDVIK CJ JAWS, SANDVIK CS CONES AND SANDVIK CH CONES

The mining and aggregate industries continue to demand even higher levels of safety and productivity. To meet these requirements, we work continuously to develop even safer products, and produce comprehensive manuals enabling safer and more effective use of our products.

Approximately 80-85 percent of crushing equipment accidents leading to Lost Time Injuries (LTIs) occur during maintenance of the equipment. Helping you ensure a safer workplace and healthier workforce is of the utmost importance to us. The well-being of any person coming into contact with our equipment is paramount. Therefore, we strive to identify and assess potential risk factors that could threaten the health of you and your employees. All of the products in this guide are designed to meet safety requirements.

We ask that you start by obeying all instructions given. Safe work procedures should incorporate inspection before the machine operates, and also through regular monitoring based upon local conditions, as well as safety and hazard management systems. Workers should be provided with safety information, instruction and training on transportation, installation, operational care and disposal of the crusher wear parts.

For full list of safety procedures, always refer to the crusher’s Operator and Maintenance manuals.

Sandvik strongly recommends that personal protective equipment is always worn when working in the vicinity of the equipment. Sandvik strongly recommends using a safety harness when working above, inside or under the equipment.

You must wear appropriate personal protective equipment (PPE) at all times. This is what we strongly recommend to help avoid injury:

– Safety helmet

–

Hearing protection

– Safety glasses

– Protective high-visibility clothing

– Respiratory protection

– Safety boots

–

Any site-specific PPE as required

DO

Pay attention to safety when planning all of your work. Before you start, always take your time to go through all operations. Identify any potential risks and take appropriate measures to avoid them. If necessary, seek expert advice on how to help minimize risks. Finally, make sure that you have the right resources to perform all tasks in the safest manner possible.

PERSONNEL

All work on the equipment must be carried out by trained personnel. “Trained” means that the person in question has been given practical instruction by an authorized person on how the various tasks are to be carried out.

Falling stones

Clear the feed arrangement from process material before any maintenance work is carried out inside or below the crusher to prevent stones from falling down.

Always switch off power and lock out the equipment (so that it cannot inadvertently be switched on) before any maintenance work is started. Also ensure that it is not possible for anyone else to switch the power on while maintenance work is being carried out. Avoid staying on the equipment, unless necessary for maintenance work.

Every machine requires access for personnel who carry out inspections and/or maintenance work. Suitable access platforms and guard rails shall be installed. Walkways, stairs and ladders must be designed in accordance with applicable regulations.

Hanging load

Only personnel with adequate lifting training are permitted to perform lifting operations. Check all the lifting equipment for wear and damage. Ensure that the lifted parts cannot be inadvertently moved or lowered. Never work or stand underneath a crane that is lifting material. Keep a safe distance from hanging load.

Some maintenance procedures such as grinding and welding will produce hazardous substances and particles. These can be inhaled or swallowed, or come into contact with the skin or eyes. Wear protective gloves, protective clothing and eye protection. Always use a respirator when welding or torch cutting manganese steel.

Welding on the crusher is only permitted when and as described in the manual. For all other welding operations on the crusher, local service personnel must be consulted. If welding an item to the crusher, the grounding cable must be attached to the item itself. If a crusher component is to be welded, the grounding cable should be attached as close to the welding area as possible.

During crusher maintenance, significant noise is generated (e.g. hammering = metal-to-metal contact, grinding). Suitable hearing protection is recommended.

After setting, epoxy plastic is physiologically harmless. Before setting, however, epoxy resin and hardener can cause skin irritation and allergic-contact eczema.

Crushing rock or ore generates dust. Some dust is hazardous if inhaled. Use of a suitable PPE is always recommended.

Inspect tools before use and at regular intervals. If they are loose, dull, bent, cracked, burred or otherwise unsuitable, DO NOT USE THEM. Replace them.

Use safe lifting practices while working with heavy items. Consider your body position, the awkwardness of the item and its weight. Are two people required for the job or is a lifting device necessary? Are you using the correct Sandvik mantle lifting tool?

SANDVIK

A wide series of safety lifting tools for our CH cone crusher models has been specifically designed for Sandvik mantles. The Sandvik lifting tools are CE marked and are designed to simplify maintenance routines and improve Environment, Health and Safety (EHS) aspects when changing mantles.

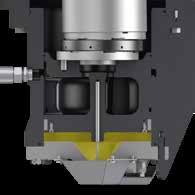

SANDVIK

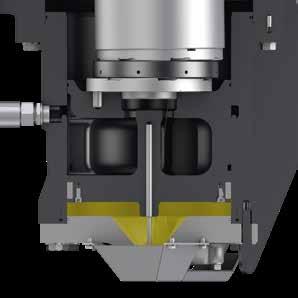

Designed to improve worker safety when removing and installing Sandvik plates in our jaw crushers. The platform is stable and intended to be used by one person including applicable maintenance tools and is easy to access with a ladder.

Every crushing and screening product is preceded by extensive research and development, and backed with application expertise, a worldwide service network, offering on-site service, training and round-the-clock support. We have a tradition of localization and a conviction that there can be no substitute for direct service and direct contact with you. Our service-oriented, global organization is well developed and contains more than 3,500 service technicians located strategically around the world.

Sandvik is a global, high-tech engineering group providing solutions that enhance productivity, profitability and sustainability for the manufacturing, mining and infrastructure industries. We are at the forefront of digitalization and focus on optimizing our customers’ processes. Our world-leading offering includes equipment, tools, services and digital solutions for machining, mining, rock

excavation and rock processing. In 2022 the Group had approximately 40,000 employees and revenues of about 112 billion SEK in about 150 countries within continuing operations.

SANDVIK ROCK PROCESSING SOLUTIONS

Sandvik Rock Processing Solutions is a business area within the Sandvik Group and a leading supplier of equipment, tools, parts, service and solutions for processing rock and minerals in the mining and infrastructure industries. Application areas include crushing and screening, breaking and demolition. In 2022, sales were approximately 9.6 billion SEK with about 2,900 employees.

WHICH INVENTION CAN SOLVE YOUR NEEDS?

Through close customer collaboration, we develop products that are genuinely needed and we have some 8,000 active patents. We also study trends to ascertain what customer needs will be in the future. We are continuously working on unique solutions that help our customers improve their productivity and safety. The spirit of innovation and involvement runs through every product.

At Sandvik Rock Processing Solutions, we believe that sustainable business practices not only help foster a better future: they also translate to better productivity and efficiency.

From operations to logistics, we strive to be a leading sustainability partner for our customers and to help them achieve more sustainable business practices, through the Sandvik way of advancing the world through engineering.

We have established four overarching sustainability goals for 2030 — circularity, climate change, fair play and people: these are our key priorities and core considerations in developing solutions for the rock processing industry.

Sandvik has introduced the first certified Environmental Product Declaration (EPD) in the industry for manganese crusher wear parts produced in our factory in Svedala, Sweden.

As an example of how we innovate and implement initiatives for supporting our sustainability goals as well as those of our customers, our Svedala foundry uses an innovative process of producing manganese wear parts for cone crushers which use more than 90 percent recycled steel as raw material. Avoiding the use of virgin material and internal process improvements have reduced CO₂ emissions by over 16,000 tons per year through international collaboration with customers and other Sandvik business areas

Sandvik has committed to set targets in line with the Science Based Targets initiative (SBTi), consistent with the Paris Climate Agreement of keeping global warming below 1.5° C. We also commit to become a net-zero carbon emissions company by 2050 at the latest.

area

Rock Processing Solutions is a leading supplier of equipment, tools, parts, service, digital solutions and sustainability-driving technologies for processing rock and minerals in the mining and infrastructure industries.

QUARRYING

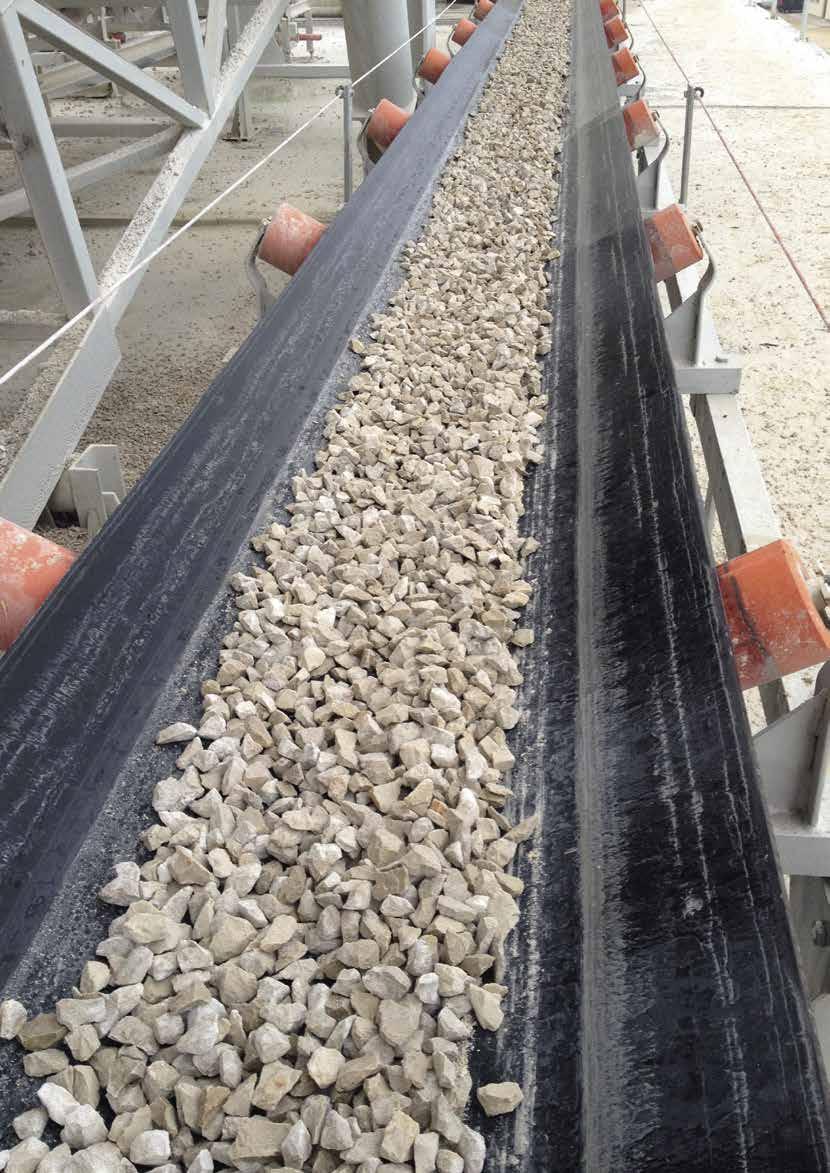

Aggregates are produced for a few different purposes, mainly as crushed rock, concrete, and asphalt. Demands on size, shape, and strength are placed on the produced material, depending on the application. The size of premium product in a crushing and screening plant normally ranges from 2-63 mm. Quarrying is different than mining in that the material produced from the crushing and screening plant requires no further size reduction.

MINING

THREE-STAGE CRUSHING & SCREENING

Conventional crushing and screening circuits provide crushed products for further processing, such as grinding or heap leaching, for either milling or other beneficiation. Traditionally, rod milling and ball milling are the next step after staged crushing, but are no longer used in plant practices due to their higher operational cost and lower energy efficiency. The technology is only used in older existing installations and would not be chosen for a new greenfield project. More efficient crushers, such as staged crushing and ball milling, are now available and commonly used. The feed size to ball mill normally ranges from 6-12 mm; however, in some practices, coarser particles up to 18 mm are fed to the ball mills.

PEBBLE CRUSHING IN SEMI-AUTOGENOUS (SAG) AND AUTOGENOUS (AG) MILLING CIRCUITS

Autogenous Grinding (AG) is the process of milling primary crushed ore, approximately minus 300 mm in size, stone against stone in a big AG mill. The AG process only works with ores that have suitable mechanical properties. Bigger stones must be able to break smaller stones; therefore, special size distribution of the feed is needed. In plant practices, ores that are too soft (low competent) or too hard (high competent) are not suitable for the AG process. Semi-Autogenous Grinding (SAG) was introduced to accommodate those ores by adding grinding media (big steel balls, normally 125 mm in diameter) to the AG mill, converting it to a SAG mill.

Often the SAG and AG processes face difficulties in maintaining the intended production rate and energy consumption. Some of the stronger stones, mainly medium-sized stones and pebbles ranging in size from 20-70 mm, build up, affecting the performance of a SAG or AG mill. To improve the SAG/AG milling performance and reach requirements for downstream fine grinding processes, a pebble crusher is added to the circuit to crush down the 20-70 mm pebbles. A grate in the SAG controls the upper size; the pebble screen controls the smaller.

Crushed material can be sent back to the SAG or directly to the ball mill. If sent to the ball mill, the pebble crusher needs to work in closed circuit with a screen to achieve the necessary small feed size.

Heap leaching is a chemical or biological metal extraction method. The size of material sent to the heaps depends on the ore and targeted recovery rate. Lower grade ore might not economically merit more than primary crushing — or, in some cases, may merit no crushing at all. Usually, material is crushed to -6 mm, -25 mm or even -50 mm. Therefore, the crushing circuits can be quite different from case to case. Sometimes, the ore creates a lot of fines when crushed down. In these situations, there can be problems with the liquid penetration in the heaps. To reduce the amount of fines, agglomeration is added to the process.

Lump ore is used in the blast furnace process to achieve a good gas flow. To get a maximum amount of the desired lump ore fraction, crushers are set for a low reduction ratio. Usually, three crushing stages are used to produce highgrade iron ores. First, the fines (normally -8 mm) are screened away. Then a fraction of lump ore between 8 mm and 30 mm or 5 mm and 16 mm is produced.

(CNS image of a guy holding a stone in his hands)

THE SERVICES AND PARTS YOU NEED – WHEN YOU NEED THEM

Our four proactive service agreements cover the entire lifecycle of your crushing and screening plant. Through our highly-trained expert engineers, our service agreements are designed to provide you with safer operations, low operating costs and long service life, unlocking the full potential of your crushing plant 365 days a year.

CONDITION INSPECTIONS

Comprehensive inspections from a certified Sandvik service engineer covering the most critical points. You get continuous status reports on your equipment health, improving reliability and saving costs by avoiding expensive failures.

EXTENDED WARRANTY

Get the extra protection you need for your equipment. Built on the Condition Inspection offer, this program goes beyond maintenance recommendations; it gives you 85% coverage on the list price of major components*. Designed to keep your equipment running smoothly for longer, a Sandvik Extended Warranty program gives you peace of mind.

ADVISORY SERVICES

Minimize networking capital and ensure you have the right inventory with regular parts planning. Built on Condition Inspection, our Advisory Services program combines regular inspections with comprehensive parts and maintenance planning, giving you up to 15% more machine availability.

PRODUCTIVITY SERVICES

Extract the most out of your equipment and enjoy an up to 10% increase in productivity. Our most comprehensive service package gives you increased uptime, profit and complete peace of mind in a risk-controlled operation. Ensure consistent, high-volume performance and get more of the product you want with the optimization of all crushing equipment parameters.

FOUR REASONS WHY

• Experts offer dedicated knowledge and experience in OEM equipment and the applications surrounding it

• Proven and globally established optimization procedures use thousands of applications as a benchmark to find you the most efficient solutions

• Customized training sessions and frequent on-site support foster the transfer of knowledge to staff and develop skills

• Clear guidance leads you toward higher reliability, availability and productivity, ensuring lower operating costs

PRODUCTIVITY SOLUTIONS YOU CAN COUNT ON Sandvik offers a wide range of standard, premium and customized crushing chamber solutions that are created based on your needs, and deliver consistently high availability and reliability. These solutions offer significant productivity gains and safety improvements in your crushing operations, and improve your bottom line.

Sandvik works closely with you to find the best solution for your needs – in terms of performance and safety, as well as application and material feed properties. Using our application expertise, we work with you to find your perfect fit.

We offer standard crushing chambers – which are a combination of mantles and concaves – and jaw plates based on our M1 alloy. Over the years, we have engineered newer alloy mixes like M7, M8 and M9 with a higher resistance to abrasive rock, but a lower resistance to shock and impact.

We have also added new, patented design patterns that are unique to Sandvik. The Flexifeed mantle increases uptime with up to 20% longer lifetime, while our High Reduction concave has been proven to offer up to 10% more final product, when they are compared to a correctly configured standard chamber. We have also developed Oversize Breakers for our CH range of crushers that increase the allowable top size in finer chambers.

No matter the Sandvik crusher model you have, we have quality OEM parts that are designed to fit your machine perfectly. Tested to the extremes, they will give you more working time and greater efficiency than non-original parts.

Sandvik has the application expertise to increase the product quality in your crushing and screening operations, as well as optimize your profits and productivity 365 days a year.

TOTAL COST OF OWNERSHIP

When Total Cost of Ownership (TCO) is taken into account, our Sandvik wear parts can generate significant savings and increase your profits. The longer lifetime of our Sandvik wear liners means that fewer sets need to be purchased, machine uptime is higher, and fewer liner changes are needed during maintenance. And when Sandlock lifting tools are in place, you can save up to one hour per liner change.

The crushing chamber is the geometric profile between two wear liners. One liner is static while the other is moving. In a cone crusher, the moving part is the mantle – which sits on the main shaft – and the fixed liner is the concave inside the top shell. In a jaw crusher, both liners are called jaw plates with one fixed plate and one moving plate.

Wear is the removal of particles from the surface and is an inevitable occurrence in crushing chambers. The crushing force and the rock characteristics will wear down all liners over time, but we have engineered ours to offer a longer lifetime and a higher wear resistance.

Abrasion is the main cause of liner wear. Friction is created between moving particles or rocks that causes mechanical scratching, grinding and gouging. The Abrasion Index (AI) measures the abrasive characteristics for different types of rock, and we can personally assess the abrasiveness of different feed materials at our Rock Processing Test and Research Center in Svedala, Sweden.

Based on our testing methodology, the following chart indicates the abrasiveness of different rock types and the wear on manganese steel liners in jaw and cone crushers.

< 0.1 Very low wear Limestone, Dolomite

0.1-0.2 Low wear Hard Limestone

0.2-0.4 Intermediate wear Basalt, Diabase, Gabbro

0.4-0.6 Normal-medium wear Granite, Gneiss

0.6-0.8 High wear Porphyry, Quartzite

> 0.8 Extremely high wear Sandstone, Iron Ore

PREMIUM CHAMBER DESIGNS

Sandvik offers an innovative range of premium chamber solutions that are created based on your needs, and deliver consistently high availability and reliability. These innovative and patented solutions offer significant productivity gains and safety improvements in your crushing operations, and improve your bottom line.

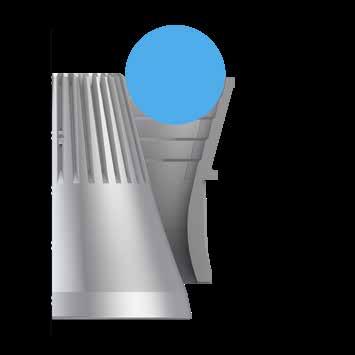

FLEXIFEED MANTLE

Our Flexifeed (FF) mantle – or moving liner – is engineered for your secondary crushing applications, and offers up to a 20% longer lifetime compared to a correctly configured standard chamber. Created for crusher models CH420 to CH890i, it has a varying feed opening that is ideal if the crusher feed is not calibrated.

You can use it with the following concaves: EC, C and MC.

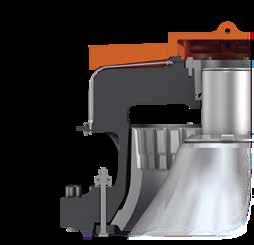

OVERSIZE BREAKER MANTLE

Our Oversize Breaker (OB) mantle is engineered for tertiary crushing applications. Created for crusher models CH865i, CH870i and CH895i, it has a varying feed opening that is ideal if the crusher feed is not calibrated. It also increases the allowable top size in finer chambers and helps to prevent bridging from oversized rock.

It is based on our EF-mantle profile design and you can use it with the following concaves: F, EFX, EF, EEF.

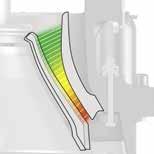

HIGH REDUCTION CONCAVE

Our High Reduction concave – or fixed liner – has a unique shelf design that increases the crushing chamber pressure in crusher models CH430, CH660, CH865i, CH870i and CH895i. This patented design feature has proven to offer up to 10% more final product in tertiary applications compared to conventional designs, and offers up to 19% less recirculating load.

Our A, B and HC mantles can be used with the High Reduction concave.

FLEXIFEED

OVERSIZE BREAKER

HIGH REDUCTION

Manufacturing manganese steel is like baking bread. Even if you have the right ingredients, the bread doesn’t turn out well if you don’t fully understand and control the baking process.

We offer a range of standard and premium alloys to choose from that meet your specific needs – whether it is increased impact and shock resistance or higher resistance to abrasive rocks. These alloys form the base for our wear liners, and all are made from manganese steel – a mixture of manganese, carbon and chromium.

KEY

ALLOY MIXES – FROM MANUFACTURING TO WORK HARDENING

Each ingredient brings a different characteristic to our wear liners. Manganese, for example, dissolves carbon to prevent carbide formation, while carbon and chromium increase hardness. Chromium has a further benefit of preventing so-called “metal growth”. The ratio of manganese to carbon, as well as the amount of chromium, is directly related to wear resistance during crushing, and the entire casting process needs to be well optimized to produce high-quality liners.

We bring our deep manufacturing process knowledge to create the highest quality wear liners. The casting process begins with careful raw material selection for melting in order to reduce impurities. Temperatures are carefully controlled during the melting and pouring phase to get a fine-grain structure for the castings. We then pour the melted metal into carefully designed sand molds for it to solidify and create a solid casting. The castings are then heat treated to dissolve carbides precipitated during solidification and quenched to keep the austenitic microstructure at room temperature, then machined to ensure a perfect fit in your crusher.

We use austenitic manganese steel, and the major advantage of this wear material is the work hardening for crushing applications. The high impact in the crushing chamber causes the formation of a surface layer that is two to three times harder than the physical composition of the alloy mix in the wear part. It results in a very tough and durable material that offers superior wear resistance in the surface zone compared to other materials. Through this work-hardening process, the hardness of manganese steel can increase from 210-240 HB to 340-470 HB.

Casting process – pouring, solidification and heat treatment including quenching

The work-hardening process created by impact offers greater surface hardness and thus increased wear resistance.

LOW

Hardness

Standard

Sandvik offers a range of standard cone crusher liners (mantles and concaves), as well as jaw plates, that are based on our M1, M7, M8 and M9 alloy mixes. The M1 alloy mix has a high resistance to impact and shock, and does not crack easily. Our M7, M8 and M9 alloy mixes offer higher resistance to abrasive rock compared to the M1, but have a lower resistance to shock and impact.

Our standard alloys are tough and long lasting, made with Sandvik’s extensive knowledge in the alloy process. You experience all of this in the final quality of our liners.

Sandvik routinely partners with our customers to find new solutions that will improve your crushing operations. We have combined this knowledge with our application expertise and in-depth knowledge of materials technology to design an optimized crushing chamber.

The customized EEF/EF chamber for our Sandvik CH870i and the CX concave for our Sandvik CH660 are recent customer partnership examples. We’ve also developed our EC Top Grip concave, our High Reduction concave, and our S-mantle based on customer collaborations.

Within Sandvik’s own foundry, we have full control of the manufacturing process. This ensures consistent quality, predictable service life, a perfect fit and high availability.

Sandvik offers a series of safety lifting tools for our CH models of cone crushers. These tools are CE-marked, and specifically designed for Sandvik mantles. Instead of having to weld on attachment points when replacing parts or undertaking maintenance work, you use these self-locking jaws. They are easy to attach and release, and strong enough to handle the weight of your mantle. The result is faster, safer and easier maintenance.

CH830i (CH540) BG00332725

CH430 BG00332725 CH840i (CH550) BG00227706

CH440 BG00227706 CH860i/CH865i (CH860, CH865) BG00328140

CH660 BG00328140 CH870i (CH870) BG01533237 CH890i/CH895i (CH880, CH890, CH895) BG01533238

In addition, Sandvik offers a service platform (BG01476760) to improve worker safety when removing and installing Sandvik jaw plates in crusher models CJ411, CJ412, (CJ612), CJ613, CJ615, and CJ815. The platform is stable and intended to be used by one person including applicable maintenance tools and is easy to access with a ladder. The platform is only valid for removing and installing the crushing chambers (i.e., wear parts) manufactured by Sandvik.

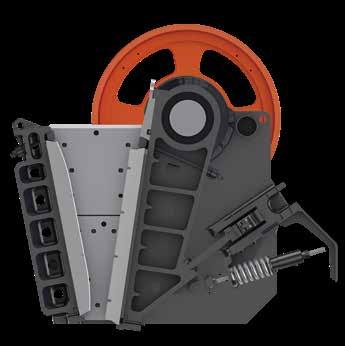

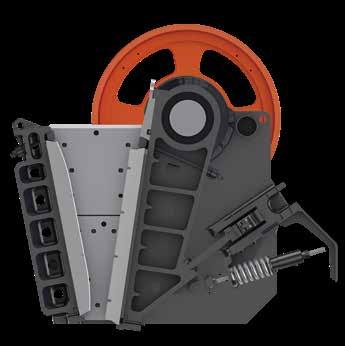

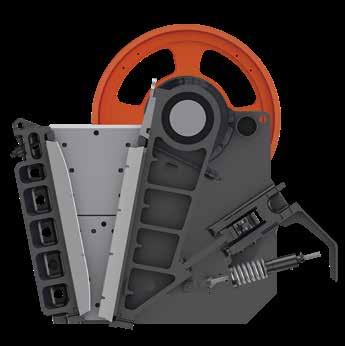

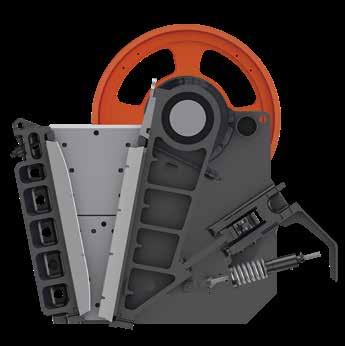

Sandvik’s top-of-the-line CJ-type jaw crushers are specifically built for your primary applications where resizing is the key objective. They allow the material to be processed within your crushing plant. To ensure optimum performance, the jaw crusher needs to have a good feed level and a homogeneous feed.

The size distribution of the raw material is called the particle size distribution, or PSD for short. It is commonly referred to as the gradation. The PSD of the feed can be expressed as F90 (90% passing square hole size) or F100 (100% passing square hole size), for example. The feed opening determines the maximum feed size for your crushing chamber.

In a jaw crusher, the feed opening is equal to the feed gap – or the distance from the fixed to the moving jaw plate. The recommended maximum size of the material is approximately 90% of the feed opening and you do not want to bridge the feed opening with slappy or large rocks.

The closed side setting (CSS) is the last crushing zone and this setting defines your reduction ratio, with a significant effect on the product curve (P80) – your resulting product. The CSS is the minimum discharge opening with moving jaw plates, and the minimum is decided primarily by the power draw (kW), which varies depending on the application.

The open side setting (OSS) is the largest distance between the two jaw plates at the bottom of the crusher, and the maximum discharge opening. The space created here allows the product to fall through the crusher to the next crushing stage. The OSS is also the opening of the crusher at rest.

The reduction ratio is the particle size reduction you get from your crusher. It is defined as the ratio between the feed size and the size of the outgoing product, usually measured at the 80% passing point. The feed to the crusher (F80) is divided by product size (P80) giving you the reduction ratio.

Jaw crushers are normally capable of a reduction ratio of 1:2 or 1:3 in primary applications where resizing is the key objective. This ratio is affected by the feed material’s bulk density, crushability, size distribution and moisture content – among other factors – and will affect the crushing chamber performance.

The nip angle is the angle between the fixed and moving jaw plates. Our Sandvik CJ crushers have an optimum nip angle in the 16-23 degree range. When the OSS is reached, the nip angle is almost at its smallest. The inward motion of the moving jaw plate changes the nip angle, making it larger.

At small CSS settings, the nip angle increases. A shim plate should be used to improve the crushing chamber’s nip angle, preventing the feed material from moving upward and decreasing your crusher’s performance. The shim plate – which is installed behind the fixed jaw plate – should also be used with slippery rock feeds (a mix of sand and clay, for example). Using a shim plate will decrease the intake opening slightly.

Our Sandvik jaw crushers are of the single-toggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiency. Jaw crushers are excellent in primary stages where the capacity need is below 800 t/h.

The feed material is crushed between two rigid surfaces – one fixed and the other moving. The motion of the moving surface is independent of the load on the jaw crusher, and the crushing action is achieved by the movement of the jaw, which together with the frame and the cheek plates, form the crushing chamber.

The power from the motor is transferred through V-belts to one of the flywheels mounted on the eccentric shaft. The rotation of the eccentric shaft and the movement of the toggle plate cause an elliptical motion of the jaw. When the distance between the jaw and the frame decreases, the incoming process material will be subjected to a compressive stress and thereby be crushed. When the jaw moves away from the frame, the process material can flow down through the chamber.

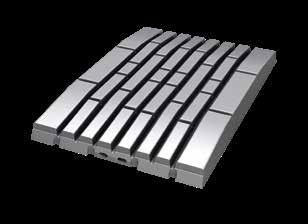

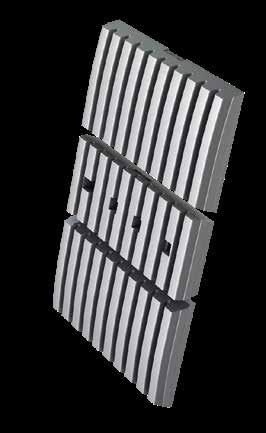

There are four desired characteristics to remember when it comes to jaw plate patterns. The “grip effect” means that sharp profiles grip the rocks to improve crushing and reduce wear; the “wear surface” means there is a sharp profile that is worn down quickly; “fines passage” means that there are grooves that help pass fines; and “prevent packing” means that there are grooves and ridges to prevent compaction.

Sandvik offers six teeth patterns and up to three alloy selections (M1, M8, M9) to suit the different types of quarrying and mining applications. Our patterns include

Wide Teeth (WT), Corrugated (C), Coarse Corrugated (CC), Sharp Teeth (ST), Heavy Duty (HD) and HD Ultra-Thick (UT).

M1 is the standard alloy, offering high resistance to shock and impact. It also work hardens well with hard rock. Our M8 and M9 alloys offer high resistance to abrasive rock, but have lower resistance to shock and impact.

The optimal jaw plate selection can be determined based on the rock/ore type characteristics (WI, AI) and the feed characteristics (friction, gradation).

High

ROCK/ORE TYPE CHARACTERISTICS; INTEGRITY AND ABRASIVENESS (WI, AI)

Low

SHARP TEETH

Wet, round rock with clay or high fines content

Good wear resistance. For feed with a lot of fines. Can be used on both fixed and moving sides.

For flaky feed material with a lot of fines. Good gripping ability. Very good top-size control. Highly recommended if the AI is not too high.

Suitable for less abrasive material. Good for small CSS settings. Good top-size control.

CORRUGATED

HEAVY DUTY FEED CHARACTERISTICS; FRICTION AND GRADATION

Dry, angular rock, low fines content

The application area determines the most suitable jaw plates - and ultimately the right crushing chamber. We offer seven pattern designs and up to three different alloy selections.

For abrasive material. For feed with a lot of fines. Used for large CSS settings. Good top-size control. Can be combined with a CC moving plate.

For very abrasive material. Less top-size control. Fixed plate based on our HD pattern with an extra 30 mm thickness for longer wear life. To be used with the CC moving plate.

Contact your local Sandvik rep to help you select the right plate combination for your application.

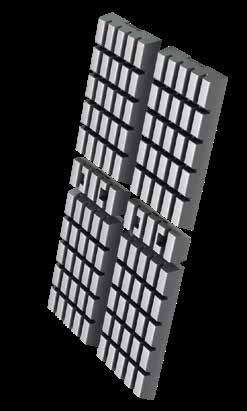

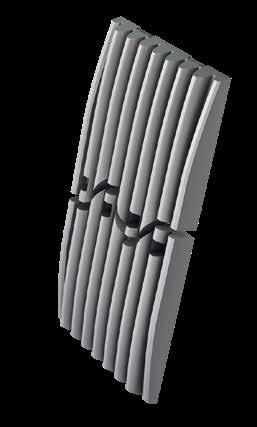

Sandvik offers a range of jaw plate configurations – from one-piece for our smaller models all the way up to six-piece ones for our largest crusher.

One-piece jaw plates offer safer, easier and faster exchanges and require the use of a two jaw die-lifting tool due to the component weight. The plates should be rotated more than three times during their life length to maintain the nip angle and to utilize the manganese steel maximally. A delayed flip of the plate often results in a poor nip angle, which often leads to a higher wear rate leading to premature replacement. The end result is a higher cost per ton for the wear liners alone.

Our two-piece plate configuration creates one large piece when fastened on the crusher. You can then flip this “one-piece” – as described above – to maintain the nip angle and ensure even wear.

Our three-piece jaws are lighter and offer a longer lifetime, lower wear rate, lower cost per ton, and require lower wear part inventory. However, installation of these jaws takes more time and must be done carefully to lock both two-pieces to the middle wear plate fastener (the third piece). Don’t forget to rotate the top and lower plates to maintain the nip angle.

Our six-piece jaws are designed for our largest jaw crushers. They are like our three-piece design however each piece is half the size after considering safety, weight and manufacturing aspects. Four single-component wear plates are fastened to two middle wear-plate fasteners, creating one robust jaw plate. You get the same benefits as with our three-piece plate configuration.

The feed material is crushed between two rigid surfaces – one stationary and the other moving. Moving jaw plates last 50 to 100 percent longer than fixed jaw plates. This is because the crushing movement has a direction that is more favorable for the moving jaw than for the stationary jaw in terms of wear. The rock does not slip against the moving plate, rather there is more sliding on the fixed side where the feeder sits.

This type of sliding increases the wear rate without much crushing effect. In order to increase the lifetime of your liners and make wear more even, you should:

1. Turn jaw plates frequently

2. Choose the right jaw pattern

3. Use the right nip angle, CSS and shim plates

4. Use the right feed arrangement/procedure

5. Choose the right alloy

• Worn jaw plates reduce capacity

• Turn jaw plates to get even wear

• Don’t wear down jaw plates until they break

Worn out Jaw plate change

Jaw plates should be changed when one or more of the following happens:

• When capacity drops off

• When the teeth are gone

• When a hole appears on the jaw plate surface

• When plates are worn down to 15 mm above the clamping bars

Cheek plates do not wear as fast as the jaw plates themselves. The lower cheek plate lasts roughly twice as long compared to the fixed jaw plate. And the upper cheek plate lasts twice as long compared to the lower cheek plate.

The feed arrangement has a direct impact on the lifetime of the deflector plates, which are designed to protect the crusher. The life span can be one to two years if the feed material makes regular contact with the deflector plate. If very little contact is made, then it can last the lifetime of the crusher itself.

All jaw plates are one piece unless otherwise stated.

CHEEK PLATES

Upper plate BG01473832 Lower plate BG01473842

DEFLECTOR PLATE 400.3136-001

CRUSHING CHAMBERS

CORRUGATED (C)

Suitable for less abrasive material. For feed with a lot of fines. Good for small CSS settings. Good top-size control.

SHARP TEETH (ST) HEAVY DUTY/COARSE CORRUGATED (HD/CC)

JAW PLATES

All jaw plates are one piece unless otherwise stated. CHEEK PLATES Upper plate 10-314-386-000 Lower plate 10-314-404-000

DEFLECTOR PLATE 10-314-479-000

CRUSHING CHAMBERS

WIDE TEETH (WT) CORRUGATED (C)

For flaky feed material with a lot of fines. Good gripping ability. Very good top-size control. Highly recommended if the AI is not too high.

For very abrasive material. Used for large CSS settings. Good top-size control

Good wear resistance. For feed with a lot of fines. Can be used on both fixed and moving sides.

Suitable for less abrasive material. For feed with a lot of fines. Good for small CSS settings. Good top-size control.

All jaw plates are one piece unless otherwise stated.

CRUSHING CHAMBERS

CRUSHING CHAMBERS

Good wear resistance. For feed with a lot of fines. Can be used on both fixed and moving sides.

Suitable for less abrasive material. For feed with a lot of fines. Good for small CSS settings. Good top-size control.

For abrasive material. For feed with a lot of fines.

Good wear resistance. For feed with a lot of fines. Can be used on both fixed and moving sides.

SHARP TEETH (ST)

For flaky feed material with a lot of fines. Good gripping ability. Very good top-size control. Highly recommended if the AI is not too high.

Suitable for less abrasive material. For feed with a lot of fines. Good for small CSS settings. Good top-size control.

DUTY (HD)

For very abrasive material. Less top-size control. Can be combined with a CC moving plate.

abrasive material. For feed with a lot of fines.

HEAVY DUTY/COARSE CORRUGATED (HD/CC)

For very abrasive material. Used for large CSS settings. Good top-size control.

All jaw plates are one piece unless otherwise stated. CHEEK

DEFLECTOR PLATE BG00643389

CRUSHING CHAMBERS

CORRUGATED (C)

COARSE

CRUSHING CHAMBERS

COARSE CORRUGATED (CC)

SHARP TEETH (ST)

HEAVY DUTY (HD)

For abrasive material. For feed with a lot of fines. Used for large CSS settings. Good top-size control.

HEAVY DUTY/COARSE CORRUGATED (HD/CC)

For flaky feed material with a lot of fines. Good gripping ability. Very good top-size control. Highly recommended if the AI is not too high.

For very abrasive material. Less top-size control. Can be combined with a CC moving plate.

Suitable for less abrasive material. For feed with a lot of fines. Good for small CSS settings. Good top-size control.

For abrasive material. For feed with a lot of fines. Used for large CSS settings. Good top-size control.

For flaky feed material with a lot of fines. Good gripping ability. Very good top-size control. Highly recommended if the AI is not too high.

For very abrasive material. Used for large CSS settings. Less top-size control. UT fixed plate offers longer wear life.

For very abrasive material. Used for large CSS settings. Good top-size control.

All jaw plates are one piece unless otherwise stated.

*Two pieces

CRUSHING CHAMBERS

For abrasive material. For feed with a lot of fines. Used for large CSS settings. Good top-size control.

HEAVY DUTY/COARSE CORRUGATED (HD/CC)

For flaky feed material with a lot of fines. Good gripping ability. Very good top-size control. Highly recommended if the AI is not too high.

For very abrasive material. Less top-size control. Can be combined with a CC moving plate.

All jaw plates are one piece unless otherwise stated. *Two pieces **Four

CRUSHING CHAMBERS

COARSE CORRUGATED (CC)

SHARP TEETH (ST)

HEAVY DUTY (HD)

For abrasive material. For feed with a lot of fines. Used for large CSS settings. Good top-size control.

HEAVY DUTY/COARSE CORRUGATED (HD/CC)

For flaky feed material with a lot of fines. Good gripping ability. Very good top-size control.

recommended if the AI is not too high.

For very abrasive material. Less top-size control. Can be combined with a CC moving plate.

For very abrasive material. Used for large CSS settings. Good top-size control.

For very abrasive material. Used for large CSS settings. Good top-size control.

Sandvik’s top-of-the-line CS cone crushers are specifically built for your secondary applications where resizing is the key objective. Our high-capacity CS crushers have a large intake opening and a tall crushing chamber, ideal for crushing large feed sizes and processing high tonnage. They allow the material to be processed within your crushing plant and the quality of the product isn’t usually measured in this stage, unless railway ballast is produced.

Our CS crushers come equipped with the hydraulic Hydroset system, which provides safety and setting-adjustment functions. And each crusher has a robust design with an adjustable eccentric throw and a constant intake opening.

The size distribution of the raw material is called the particle size distribution, or PSD for short. It is commonly referred to as the gradation. The PSD of the feed can be expressed as F90 (90% passing square hole size) or F100 (100% passing square hole size), for example. The feed opening determines the maximum feed size for your crushing chamber.

In a CS cone crusher, the feed opening is equal to the distance from the mantle to the concave at the top of the crusher on its open side. As wear occurs in the crushing chamber, the upward movement of the main shaft (and the mantle) maintains the feed opening and performance during the entire service life of the liners.

The closed side setting (CSS) is the smallest distance between the concave and the mantle. It is the last crushing zone and this setting defines your reduction ratio, with a significant effect on the product curve (P80) –your resulting product – crusher capacity, and power draw.

The open side setting (OSS) is the largest distance between the concave and the mantle. The space created here allows the product to fall through the crusher to the next processing stage. The OSS is determined by adding the CSS to the eccentric throw.

The reduction ratio is the particle size reduction you get from your crusher. It is defined as the ratio between the feed size and the size of the outgoing product, usually measured at the 80% passing point. The feed to the crusher (F80) is divided by product size (P80) giving you the reduction ratio.

A typical reduction ratio in a secondary application is in the 1:4 - 1:6 range. This ratio is affected by the feed material’s bulk density, crushability, size distribution and moisture content – among other factors – and will affect the crushing chamber performance.

In our Sandvik CS cone crushers, crushing occurs between a fixed concave and a gyrating mantle that is mounted on the main shaft assembly. The acceleration of the mantle is high as it makes between four and six revolutions per second depending on the size of the crusher. There is also interparticle crushing which happens when the stone grinds against stone inside the crushing chamber.

The main shaft is supported at both ends – a so-called “spider design” – allowing the top of the main shaft to rotate and creating a pivot point. This support at both ends generates an extremely powerful crushing force.

The crusher’s drive motor rotates the eccentric assembly at a constant speed through a gear transmission. This causes the main shaft to move like a conical pendulum, crushing material by compressing it multiple times against the concave on the sides. The eccentric mechanism that moves the mantle – coupled with the Hydroset pressure that pushes the mantle upwards – is what generates the force with which the material is crushed.

This gyration of the main shaft moves the CSS/OSS around the inner circumference of the concave at any given point. When the distance decreases, the material is crushed through multiple compressions. Then when the mantle moves away from the concave, particles move and shift down through the chamber – or crushing zones – before being crushed again. The combination of mantle and concave needs to have the right geometric match in order to reduce unnecessary wear, and result in maximum output.

The eccentric assembly is the part of the crusher that determines the eccentric motion, which in turn creates the conical pendulum movement. The assembly is made up of the eccentric bushing, which allows you to choose the eccentric throw setting, and the eccentric, which secures the bushing in place. To increase capacity in your CS crusher, use the eccentric throw settings, not the concave, to adjust capacity. By turning the “keys” on the bushing, you can easily change the eccentric throw to one that suits your operation better.

The A-dimension is the distance between the underside of the spider hub and the top of the head nut. The CSS setting is determined based on the A-dimension value –or the vertical position of the main shaft.

With frequent manual or automatic calibrations, the A-dimension gives you an indication of the status of your liners. A large A-dimension indicates that the liners are new and/or the crusher is running with a large CSS.

A small A-dimension indicates that the crusher is operating at a small CSS and/or the liners are worn. This means it’s time for a liner change. It also indicates that there is a volume of oil below the piston. This determines how much the main shaft can be lowered to open up the crushing chamber if tramp metal enters.

When the minimum A-dimension is reached, it’s time for a liner change. However, the chamber could be worn out before the minimum A-dimension is reached depending on your CSS and eccentric throw settings. A visual inspection of the crushing chamber is the recommended way to decide when the liners need to be changed.

You should not exceed the minimum A-dimension even if there appears to be more wear life in your chamber. Raising the main shaft beyond the minimum A-dimension can cause damage to the spider hub and head nut.

When selecting your mantle and concave, you’ll get the most out of your crushing chamber when you can achieve the right fit between three important factors: the feed, the eccentric throw, and the closed side setting (CSS). Balancing these three elements in the right way will give you the output you want, and will maximize the wear life of your crusher.

Knowing your feed size and feed-size opening is the most important of the three factors. It will help you select the right mantle and concave combination – and allow you to properly adjust the eccentric throw and CSS settings to ensure the right output.

Determining the feed size is done by checking one of several parameters. For instance, the CSS setting of the jaw crusher; the maximum grizzly gap (GG) in the grizzly feeder; or the maximum square hole (SH) size on the screen deck.

Note that separations above about 150 mm are too large to be realistic on a normal screen with square holes, but the SH value can still be used for comparison purposes. To best maintain your crusher and get the fit right, do not select a coarser chamber (i.e. concave) then necessary.

The eccentric throw is one of the parameters that gives your crusher its capacity, and the pendulum movement (or eccentric throw) affects the fit between your mantle and concave. The eccentric throw together with the CSS will determine which mantle is best to use for your application.

The mantle and concave have the right match when they are perfectly lined up at the bottom. And the right match between the mantle and the eccentric throw ensures optimal output and an even wear pattern.

In the closed position (CSS), the bottom of the mantle should be aligned with the bottom of the concave. If, for example, the mantle is hanging below the concave in the closed position, you will get a bulge with uneven liner wear and your crusher won’t perform optimally.

Once you know your feed size and eccentric throw, you can determine the right CSS in order to achieve the final product you want. In some cases, the CSS and eccentric throw will have to be balanced with each other simultaneously in order to achieve the right output.

The CSS setting is determined based on the A-dimension value – or the vertical position of the main shaft.

Some mantles (e.g. A-mantle) have the wear zone higher up in the crushing chamber, meaning that the main shaft does not need to be pushed up significantly to reach a small CSS setting. The resulting larger A-dimension allows for more utilization (wear life) of your crushing chamber, as there is more distance to push the main shaft upwards.

Some mantles (e.g. B-mantle) have the wear zone lower in the crushing chamber, which allows the crusher to be run with a large CSS setting. With this mantle selection, the Hydroset piston has sufficient oil underneath it to allow the main shaft to drop, protecting the crusher against tramp iron. This is especially important with new liners.

There are several important design features on all Sandvik CS cone crushers that ensure you maximize your productivity and performance – and get the lowest cost per ton.

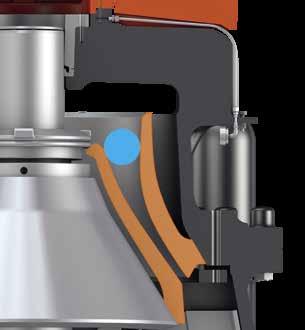

The Hydroset System is a safety and setting-adjustment system that allows you to change key settings – like the CSS, power and pressure – in order to give you maximum productivity and to compensate for liner wear.

The system consists of a robust hydraulic piston, which supports the main shaft at the bottom and adjusts its position. By moving the Hydroset piston up and down, the CSS and indirectly the OSS – as well as power and pressure settings – can be changed, thereby changing the size of the crushed material. These settings can be adjusted at any time and even when a full load of material is in the crusher.

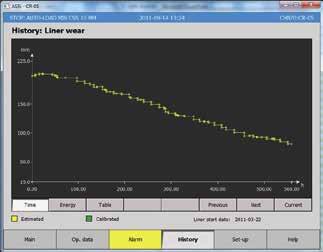

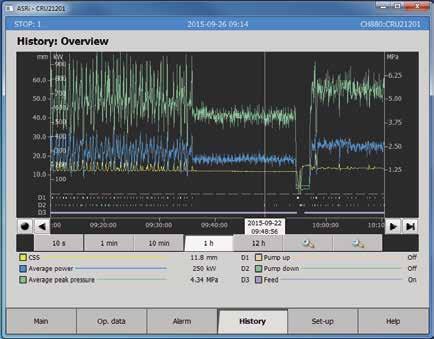

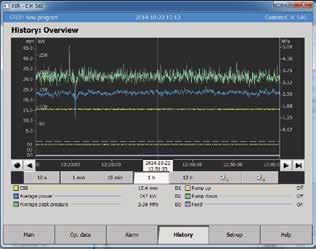

The Sandvik Automation and Connectivity System (ACS) and the Sandvik Automatic Setting Regulation Intelligent (ASRi) system, optimize the performance of the crusher without overloading it, allowing you to get the most out of your crusher.

The setting regulation functionality constantly monitors the Hydroset pressure, motor power draw and the position of the main shaft, and adapts the crusher’s settings in real time to match feed curve variations and variations in the hardness of the process material. The design allows you to adjust the CSS within a wide range to promote capacity, product size – or both.

Both systems offer a simple push-button, metal-to-metal calibration, which can be done within seconds, even from the control room. Instead of having to do it manually, the system will automatically adjust your crusher settings to compensate for crushing chamber wear – ensuring consistent product size.

IMPORTANCE OF CONCAVE SELECTION

The crushing chamber is mostly determined by the concave (or outer liner) selection, consisting of a one-piece lower concave and the upper concave – either one piece or made up of individual segments. There are two to three different standard concave choices for each crusher model (see chart), and each has a specific application area.

Use the top size of the feed to determine the right concave to use, and do not select a coarser concave than necessary as this will lead to uneven liner wear. Also remember to use the eccentric throw settings, not the concave, to adjust capacity.

STANDARD CS CONCAVES

Concaves are specified as extra course (EC), coarse (C) and medium coarse (MC).

LOWER CONCAVE COMPATIBILITY WITH A WORN UPPER CONCAVE

Faster wear in the lower concave section is quite common since the CS crusher is not always choke fed. An upper concave usually lasts as long as two lower concave sets. The lower concave needs to be replaced more frequently to maintain capacity, and maximize upper concave and mantle wear life.

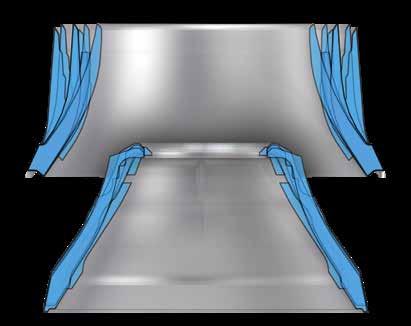

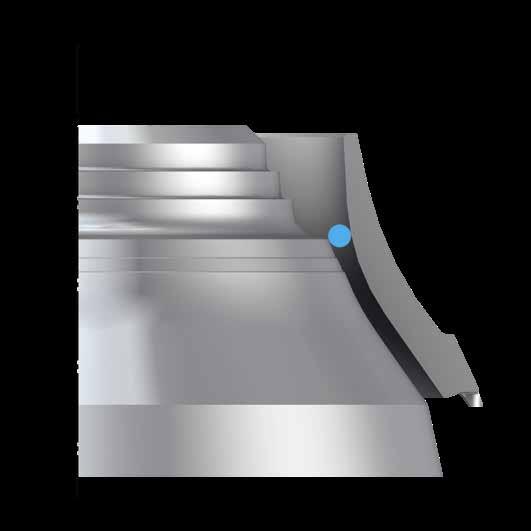

Sandvik offers a second lower concave ring designed to match a half-worn upper concave on our CS430, CS440 and CS660 models (left image). The crushing chamber nip angle is maintained because the second lower concave has an adjusted profile (which takes into account the half-worn upper concave) and is cast and therefore does not alter the geometry of the crushing chamber.

If installing a new lower concave against a half-worn upper concave, an unwanted edge is formed between the new lower concave and the used upper concave (right image). This edge affects the geometry of the crushing chamber and if no remedial actions are taken, causes a temporary but significant drop in performance. This capacity drop can be as much 25% for 15% of the lifetime of the crushing chamber. A standard remedial action is a blow-torched chamfer, but this can affect the crushing chamber’s nip angle, impacting the performance and creating worker safety issues.

We offer three different standard mantles: A, S and B – and the key differences are the positions of the crushing surface in relation to the contact surface of the head center. Each mantle has a specific application area, so not all mantles are available for all crusher models. You can determine which mantle to use by looking at the combination of eccentric throw, CSS and top feed size. Sandvik’s PlantDesigner software can help you select the right mantle profile for your application. Contact your local Sandvik representative for more information.

Regardless of the mantle selected, there will be oil underneath the Hydroset piston to allow the main shaft to drop, protecting the crusher against tramp iron.

However, with the correct mantle selected based the CSS setting, there will more oil underneath the Hydroset piston thereby allowing the main shaft to be lowered even more. This is especially important with new liners.

Both the A- and B-mantles have the same profile, so there is no difference in the crushing chamber. The position of the crushing surface in relation to the contact surface of the head center is where they differ.

On A-mantles, the wear zone is higher up in the crushing chamber, meaning that the main shaft does not need to be pushed up significantly to reach a small CSS setting. The resulting larger A-dimension allows for more utilization (wear life) of your crushing chamber as there is more distance to push the main shaft upwards. An A-mantle should be used to optimize wear characteristics when using a small CSS and eccentric throw.

If an A-mantle is used with large CSS settings, the main shaft needs to be lowered, possibly to the point where the crusher operates with little or no oil below the Hydroset piston. This can lead to mechanical failure if metal objects enter.

On B-mantles, the wear zone is lower in the crushing chamber, which allows you to run the crusher with large CSS and/or large eccentric throw settings. With this mantle selection, the Hydroset piston has sufficient oil underneath it to allow the main shaft to drop, protecting the crusher against tramp iron. This is especially important with new liners.

On the S-mantle, the position of the crushing surface in relation to the contact surface of the head center is in between the A- and B-mantles. Sandvik’s PlantDesigner software can help you select the right mantle profile for your application. Contact your local Sandvik representative for more information.

ECCENTRIC THROW AND MANTLE COMBINATIONS

The position of the crushing surface in relation to the contact surface of the head center is where the A- and B-mantles differ. With an A-mantle (orange), the wear zone is higher up, and with a B-mantle (blue) the wear zone is lower down.

Select our customized liner sets EC/BC or ECC/BC

The maximum eccentric throw setting is the limiting factor if your desired end product is large-size material, such as ballast. In order to increase the CSS opening right from the start, we offer the EC/BC or ECC/BC crushing chamber solutions, which increase the CSS range by 18 mm and 41 mm respectively (compared to our standard EC/B chamber). These specialized liner sets allow you to start producing your end product right from the beginning with your CH440, making your operations more profitable. The increased CSS does come at a cost of lower crushing chamber lifetime.

ECCENTRIC THROW AND MANTLE COMBINATIONS

ECCENTRIC THROW AND MANTLE COMBINATIONS

Our customized liner sets - EC/BC and ECC/BC – have been designed to directly produce large-size product, such as ballast, when newly installed.

CUSTOMIZED A-MANTLE (BG01238109)

This mantle has a specific application area as the wear zone is in between that of an A- and B-mantle. Available as BG01238109-01 (M1), BG01238109-03 (M7), and BG01238109-05 (M9).

ECCENTRIC THROW AND MANTLE COMBINATIONS

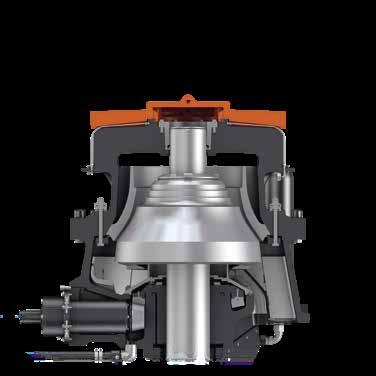

Sandvik’s top-of-the-line CH cone crushers are specifically built for your high-capacity secondary applications, high-reduction tertiary and quaternary applications, and pebble-crushing applications. They come equipped with the hydraulic Hydroset System, which provides safety and setting-adjustment functions. And each crusher has a robust design with an adjustable eccentric throw and a constant intake opening. Choose from extra-coarse crushing chambers with the largest intake to extremely fine crushing chambers – all engineered to be the perfect fit for your application.

The size distribution of the raw material is called the particle size distribution, or PSD for short. It is commonly referred to as the gradation. The PSD of the feed can be expressed as F90 (90% passing square hole size) or F100 (100% passing square hole size), for example. The feed opening determines the maximum feed size for your crushing chamber.

In a CH cone crusher, the feed opening is equal to the distance from the mantle to the concave at the top of the crusher on its open side. As wear occurs in the crushing chamber, the upward movement of the main

The closed side setting (CSS) is the smallest distance between the concave and the mantle. It is the last crushing zone and this setting defines your reduction ratio, with a significant effect on the product curve (P80) –your resulting product – crusher capacity, and power draw.

The open-side setting (OSS) is the largest distance between the concave and the mantle. The space created here allows the product to fall through the crusher to the next processing stage. The OSS is determined by adding the CSS to the eccentric throw.

The reduction ratio is the particle size reduction you get from your crusher. It is defined as the ratio between the feed size and the size of the outgoing product, usually measured at the 80% passing point. The feed to the crusher (F80) is divided by product size (P80) giving you the reduction ratio.

A typical reduction ratio in a secondary application is in the 1:4 - 1:6 range, while in a tertiary/finer application it’s in the 1:2 - 1:4 range. This ratio is affected by the feed material’s bulk density, crushability, size distribution and moisture content – among other factors – and will affect the crushing chamber performance.

In our Sandvik CH cone crushers, crushing occurs between a fixed concave ring and a gyrating mantle that is mounted on the main shaft assembly. The acceleration of the mantle is high as it makes between four and seven revolutions per second depending on the size of the crusher. Between each compression, the particles change position before getting crushed again. And in fine crushing applications, much of the crushing is done as stone grinds against stone – also known as interparticle crushing.

The main shaft is supported at both ends – a so-called “spider design” – allowing the top of the main shaft to rotate and creating a pivot point. This support at both ends generates an extremely powerful crushing force.

The crusher’s drive motor rotates the eccentric assembly at a constant speed through a gear transmission. This causes the main shaft to move like a conical pendulum, crushing material by compressing it multiple times against the concave on the sides. The eccentric mechanism that moves the mantle – coupled with the Hydroset pressure that pushes the mantle upwards – is what generates the force with which the material is crushed.

This gyration of the main shaft moves the CSS/OSS around the inner circumference of the concave at any given point. When the distance decreases, the material is crushed through multiple compressions. Then when the mantle moves away from the concave, particles move and shift down through the chamber – or crushing zones – before being crushed again. The com bination of mantle and concave needs to have the right geometric match in order to reduce unnecessary wear, and result in maximum output.

The crushing force is the result when power and pres sure are applied in the chamber. Power is the force creat ed by the conical movement of the main shaft, while pressure is how much force is pushing upward – or the Hydroset pressure. This Hydrocone® design allows for continuous monitoring of the pressure – and the known crushing force inside the chamber.

REACTION FORCE, F1 CRUSHING FORCE, F

REACTION FORCE, F2

REACTION FORCE, F3

The power and pressure variables together exert the crushing force – and they have to be balanced. Power is important during coarse crushing, while pressure is the important factor in fine crushing. For example, too much power in fine crushing applications can result in damage to the crusher. But in Sandvik CH crushers, the Automation and Connectivity System (ACS) and the Automatic Setting Regulation Intelligent (ASRi) system balance the two factors based on your feed characteristics. The crushing force is maximized under controlled conditions to protect the crusher and achieve the right balance for your operation.

During continuous and stable crushing operations with a constant feed, the power draw is linear to the crushing force (and the Hydroset pressure). With coarse crushing, the pressure is lower compared to fine crushing but the power consumption is higher. It is usually the crushing force (or hydraulic pressure) that limits the maximum crusher load during fine crushing, while the power limits it in coarse crushing.

The eccentric assembly is the part of the crusher that determines the eccentric motion, which in turn creates the conical pendulum movement. The assembly is made up of the eccentric bushing, which allows you to choose the eccentric throw setting, and the eccentric, which secures the bushing in place. By turning the “keys” on the bushing, you can easily change the eccentric throw to one that suits your operation better.

When selecting your mantle and concave, you’ll get the most out of your crushing chamber when you can achieve the right fit between three important factors: the feed, the eccentric throw, and the closed side setting (CSS). Balancing these three elements in the right way will give you the output you want, and will maximize the wear life of your crushing chamber.

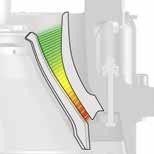

As an example, an eccentric throw of 18 mm will give you 28 crushing zones, while an eccentric throw of 32 mm will give you 20 crushing zones. The fewer zones you have, the more tonnage you’ll get because the rock will go through the crusher much faster. However, a higher throw always gives a coarser product. It is about achieving a balance between desired product size (whether it is a P80 or a target fraction) and tonnage.

The A-dimension is the distance between the underside of the spider hub and the top of the head nut. The CSS setting is determined based on the A-dimension value –or the vertical position of the main shaft.

With frequent manual or automatic calibrations, the A-dimension gives you an indication of the status of your liners. A large A-dimension indicates that the liners are new and/or the crusher is running with a large CSS.

A small A-dimension indicates that the crusher is operating at a small CSS and/or the liners are worn. This means it’s time for a liner change. It also indicates that there is a volume of oil below the piston. This determines how much the main shaft can be lowered to open up the crushing chamber if tramp metal enters.

Knowing your feed size and feed-size opening is the most important of the three factors. It will help you select the right mantle and concave combination – and allow you to properly adjust the eccentric throw and CSS settings to ensure the right output.

The eccentric throw is one of the parameters that gives your crusher its capacity, and the pendulum movement (or eccentric throw) affects the fit between your mantle and concave. The eccentric throw together with the CSS will determine which mantle is best to use for your application.

The mantle and concave have the right match when they are perfectly lined up at the bottom. And the right match between the mantle and the eccentric throw ensures optimal output and an even wear pattern.

As particles move through the crushing chamber, they pass through different crushing zones. The zones change size because of the geometry of the crushing chamber. The zones become narrower as particles move down the chamber, increasing the degree of particle reduction in steps as it moves down. The height of each zone is the distance a particle travels during one eccentric revolution. In mining, the aim is to obtain the highest possible degree of reduction, and the smallest gap between crushing surfaces in the last crushing zone. In aggregate production, however, it’s about getting the proper product shape and a product curve with the target fractions.

When the minimum A-dimension is reached, it’s time for a liner change. However, the chamber could be worn out before the minimum A-dimension is reached depending on your CSS and eccentric throw settings. A visual inspection of the crushing chamber is the recommended way to decide when the liners need to be changed.

You should not exceed the minimum A-dimension even if there appears to be more wear life in your crushing chamber. Raising the main shaft beyond the minimum A-dimension can cause damage to the spider hub and

In the closed position (CSS), the bottom of the mantle should be aligned with the bottom of the concave. If, for example, the mantle is hanging below the concave in the closed position, you will get a bulge with uneven liner wear and your crusher won’t perform optimally.

Once you know your feed size and eccentric throw, you can determine the right CSS in order to achieve the final product you want. In some cases, the CSS and eccentric throw will have to be balanced with each other simultaneously in order to achieve the right output.

The height of each crushing zone is the distance a particle travels during one eccentric revolution. With larger throws, the particles have more room to drop, offering fewer crushing zones compared to a smaller throw.

The CSS setting is determined based on the A-dimension value – or the vertical position of the main shaft. Mantles (e.g. A-mantle) have the wear zone higher up in the crushing chamber, meaning that the main shaft does not need to be pushed up significantly to reach a small CSS setting. The resulting larger A-dimension allows for more utilization (wear life) of your crushing chamber, as there is more distance to push the main shaft upwards.

Some mantles (e.g. B-mantle) have the wear zone lower in the crushing chamber, which allows the crusher to be run with a large CSS setting. With this mantle selection, the Hydroset piston has sufficient oil underneath it to allow the main shaft to drop, protecting the crusher against tramp iron. This is especially important with new liners.

There are several important design features on all Sandvik CH cone crushers that ensure you maximize your productivity and performance – and get the lowest cost per ton.

The Hydroset System is a safety and setting-adjustment system that allows you to change key settings – like the CSS, power and pressure – in order to give you maximum productivity and to compensate for liner wear.

The system consists of a robust hydraulic piston, which supports the main shaft at the bottom and adjusts its position. By moving the Hydroset piston up and down, the CSS and indirectly OSS – as well as power and pressure settings – can be changed, thereby changing the size of the crushed material. These settings can be ad-

The Sandvik Automation and Connectivity System (ACS) and the Sandvik Automatic Setting Regulation Intelligent (ASRi) system, optimize the performance of the crusher without overloading it, allowing you to get the most out of your crusher.

The setting regulation functionality constantly monitors the Hydroset pressure, motor power draw and the position of the main shaft, and adapts the crusher’s settings in real time to match feed curve variations and variations in the hardness of the process material. The design allows you to adjust the CSS within a wide range to promote capacity, product size – or both.

Both automation systems offer a simple push-button, metal-to-metal calibration, which can be done within seconds, even from the control room. Instead of having to do it manually, the system will automatically adjust your crusher settings to compensate for crushing chamber wear – ensuring consistent product size. Frequent calibration is required for the system to keep good track of the A-dimension. This is particularly important when you are operating the crusher in an auto-CSS mode.

Sandvik crushing chambers are designed to maintain an even shape of the liners to extend your operational life and increase your output. As wear occurs, the upward movement of the mantle maintains both the shape and volume of the chamber, and the size of the feed opening during the entire service life of the liners. This means that wear is evenly distributed over the surface of each liner, so the production rate of the crusher is never reduced as the liners wear.

To get the most out of your crusher, choosing the right chamber based on its application is vital. Our offering covers extra-coarse crushing chambers with the largest intake for high-capacity crushing all the way to extremely fine crushing chambers for high reduction or extremely tough pebble crushing. All chambers are engineered to be the perfect fit for your application.

IMPORTANCE OF CONCAVE SELECTION

The crushing chamber is mostly determined by the concave (or outer liner) selection. We offer between four and seven different standard concaves per crusher model, each of which has a specific application area. They range from extra course all the way to fine. Your top feed size will dictate the correct concave to use, and you can determine this feed size by matching it up with the square hole size or the CSS of the crusher beforehand.

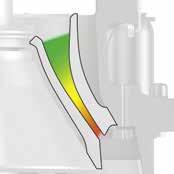

With the right concave, material starts to be crushed at the very top of the chamber, rather than material dropping to the middle or bottom – which can result in uneven wear.

Concaves are specified as extra course (EC), course extra (CX), coarse (C), medium coarse (MC), medium (M), medium fine (MF), fine (F), extra-fine extra (EFX), extra fine (EF) and extra-extra fine (EEF).

We have developed a range of standard “short” chambers to increase the crushing forces within the chamber. To achieve a higher size reduction with smaller feed sizes, our standard EF mantle (see page 73) is used. We offer one to three different concaves per model.

If you use a crushing chamber that’s too big (the feed material is too small), the material is crushed in the lower part of the chamber. This leads to a limited amount of wear at the top of the chamber, and accelerated wear at the bottom. This uneven wear profile shortens the lifespan of your crushing chamber.

ACCELERATED WEAR

When changing your crushing chamber (or concave), you will often move toward a finer chamber – meaning lower capacity at the same throw and CSS. However, you should avoid selecting a coarser chamber to increase capacity. Sandvik’s PlantDesigner software can help you estimate new operating conditions and select the right crushing chamber profile. Contact your local Sandvik representative for more information.

There are five different standard Sandvik mantles – A, S/D, B, HC and EF. Each mantle has a specific application area, so not all mantles are available for all crusher models. You can determine the mantle to use by looking at the combination of eccentric throw, CSS and top feed size. Sandvik’s PlantDesigner software can help you select the right mantle profile for your application. Contact your local Sandvik representative for more information.

Regardless of the mantle selected, there will be oil underneath the Hydroset piston to allow the main shaft to drop, protecting the crusher against tramp iron.

However, when the correct mantle is selected based on the CSS setting there will be more oil underneath the Hydroset piston, thereby allowing the main shaft to be lowered even more. This is especially important with new liners.

Both the A- and B-mantles have the same profile, so there is no difference in the crushing chamber. The position of the crushing surface in relation to the contact surface of the head center is where they differ.

On A-mantles, the wear zone is higher up in the crushing chamber, meaning that the main shaft does not need to be pushed up significantly to reach a small CSS setting. The resulting larger A-dimension allows for more utilization (wear life) of your crushing chamber as there is more distance to push the main shaft upward. An A-mantle should be used to optimize wear characteristics when using a small CSS and eccentric throw.

On B-mantles, the wear zone is lower in the crushing chamber, which allows you to run the crusher with a large CSS and/or large eccentric throw settings. With this mantle selection, the Hydroset piston has sufficient oil underneath it to allow the main shaft to drop, protecting the crusher against tramp iron. This is especially important with new liners.

On the S-mantle, the position of the crushing surface in relation to the contact surface of the head center is in between the A- and B-mantles. Sandvik’s PlantDesigner software can help you select the right mantle profile for your application. Contact your local Sandvik representative for more information.

If an A-mantle is used with large CSS settings, the main shaft needs to be lowered, possibly to the point where the crusher operates with little or no oil below the Hydroset piston. This can lead to mechanical failure if metal objects enter the crushing chamber. It also leads to nose formation of the mantle (see chapter 9), which restricts the outflow of material and provides the wrong readings for the the automatic metal-to-metal calibration.

The HC or heavy-choke mantle is designed to improve your reduction ratio. It has a strangulated intake that reduces material volume in the chamber, and permits crushing at smaller settings. This means you get larger reduction, less recirculating load and better shape in fine fractions (5-8 mm). While it provides a larger feed opening, it also reduces capacity – particularly with new liners.

The A-mantle should be used with small eccentric throws and small CSS settings. As the throw and CSS get bigger, you’ll need a mantle where the wear zone is lower in the crushing chamber (a B-mantle), thus keeping the oil volume under the Hydroset piston at a secure level.

If you have a lot of tramp events, then the B-mantle may also be preferable since it allows for a bigger CSS opening that can let tramp material out of the crushing chamber when the dump valve system is triggered. This is when the main shaft is lowered, opening up the chamber.

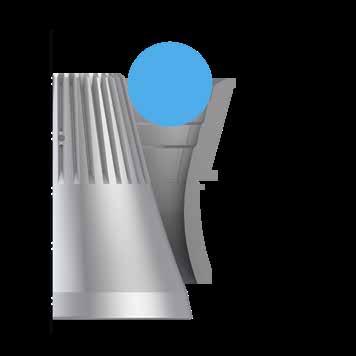

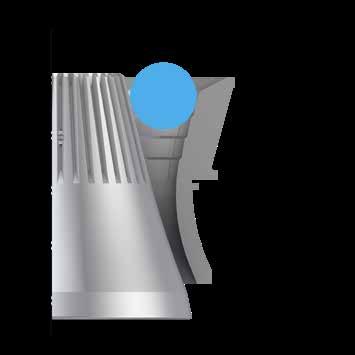

In order to increase the crushing forces within the chamber, the EF mantle has a step design creating a “short” crushing chamber after the final step. Used in finer applications, combining our EF mantle with a suitable concave (MF, F, EFX, EF, EEF) will give you higher reduction and less circulating load (whether it is a P80 or a target fraction) compared to an F concave with a suitable mantle.

Sandvik offers an innovative range of premium chamber solutions that are created based on your needs, and deliver consistently high availability and reliability. These patented solutions offer significant productivity gains and safety improvements in your crushing operations, and improve your bottom line.

Our Flexifeed (FF) mantle – or moving liner – is engineered for your secondary crushing applications, and offers up to a 20% longer lifetime compared to a correctly configured standard chamber. It has a varying feed opening that is ideal if the crusher feed is not calibrated.

Product name FLEXIFEED mantle

Application

Secondary crushing applications.

It has a varying feed opening, ideal if the crusher feed is not calibrated.

Crusher compatibility SANDVIK CH420, CH430, CH440, CH660, CH830i, CH840i, CH860i, CH870i, CH890i.

Concave match EC, CX (CH660), C, MC

Our High Reduction (HR) concave – or fixed mantle – is part of our “short” chamber solutions. It has a unique shelf design that increases the crushing chamber pressure in finer applications. This unique concave with its patented step feature has proven to offer up to 10% more final product compared to conventional designs, and offers up to 19% less recirculating load, creating a more efficient crushing circuit.

Product name High Reduction (HR) concave

Application Finer applications: tertiary or final crushing stages.

It has a unique shelf design that increases the pressure in the crushing chamber giving more reduction.

Crusher compatibility and mantle match

CH430: A, S, B, HC

CH660: A, D, B, HC

CH865i: A, B

CH870i: A, B

CH895i (CH880): A, B, HC

Our Oversize Breaker (OB) mantle is part of our “short” chamber solutions for tertiary or final crushing applications. It is based on our EF-mantle profile design and it has a varying feed opening that is ideal if the crusher feed has a larger proportion of oversized process material than anticipated.

Product name Oversize Breaker (OB) mantle

Application Finer applications: tertiary or final crushing stages.

It has a varying feed opening, ideal if the crusher feed is not calibrated.

It increases the allowable top size in short crushing chambers and helps to prevent bridging from oversized rock/ore.

Crusher compatibility and concave match

CH865i: MF, F, EF

CH870i: MF, F, EF

CH890i (CH880): F

CH895i (CH880): EF, EFX, EEF

CONCAVE, ECCENTRIC THROW AND MANTLE COMBINATIONS

* Filler ring is used between the concave and the top shell n/c = not compatible

Concaves and mantles for Sandvik cone crushers with the C2 top shell (H2000:05) produced before February 1997.