2 minute read

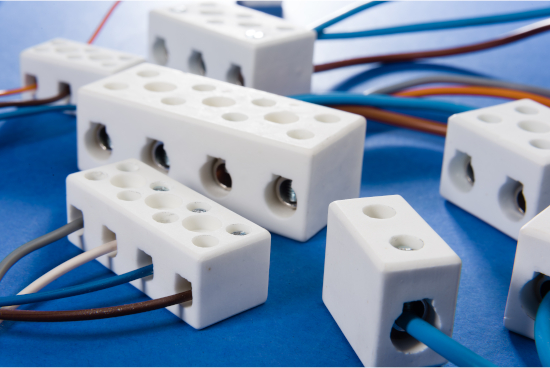

CERAMIC TERMINAL BLOCKS

Types and features to make the best use of them.

The electric terminal block connector, or terminal block, is a device that allows you to organize, connect and isolate a series of electric wires.

The ceramic terminal blocks consist of insulating body and metal inserts made of different materials depending on the use.They are safe, durable and easy to use. When we talk about "contact" (more commonly pole or pin), we refer to the electric contact point inside the terminal blocks.

The number of poles is a fundamental requirement when choosing a product because it allows to evaluate the quantity of connections necessary for a specific project or application.

The contact pitch refers to the distance between each contact, measured from the center of each hole. The contact pitch is directly related to the number of contacts and it is typically expressed in millimeters (mm).

The body is always composed of sturdy materials as porcelain for insulator. The electrical conductors are manufactured in copper and other metals, which differ according to the application and could also resist corrosion.

There is a big range of products and different types of terminal blocks dedicated mainly to the electrical, electronic and industrial sectors. Every specific range of products is different in order to adapt the different technical applications and conditions of use.

Which terminal blocks choose at high temperatures

The technical ceramic insulating body is designed to withstand high temperatures. The ceramic terminal blocks are excellent in electric furnaces, power resistors and where there are high temperatures.

In some particularly heavy temperature and corrosion applications there are terminal blocks with AISI 304 stainless steel contacts. In our catalog you can find special SS and SL terminal blocks suitable for this purpose.