Green technology

Being motivated by the commercial value of sustainable manufacturing

Being motivated by the commercial value of sustainable manufacturing

Morten Wierod from ABB explains why electrification is leading the way on the path to sustainability

Improving efficiency and increasing investment in humans and innovation

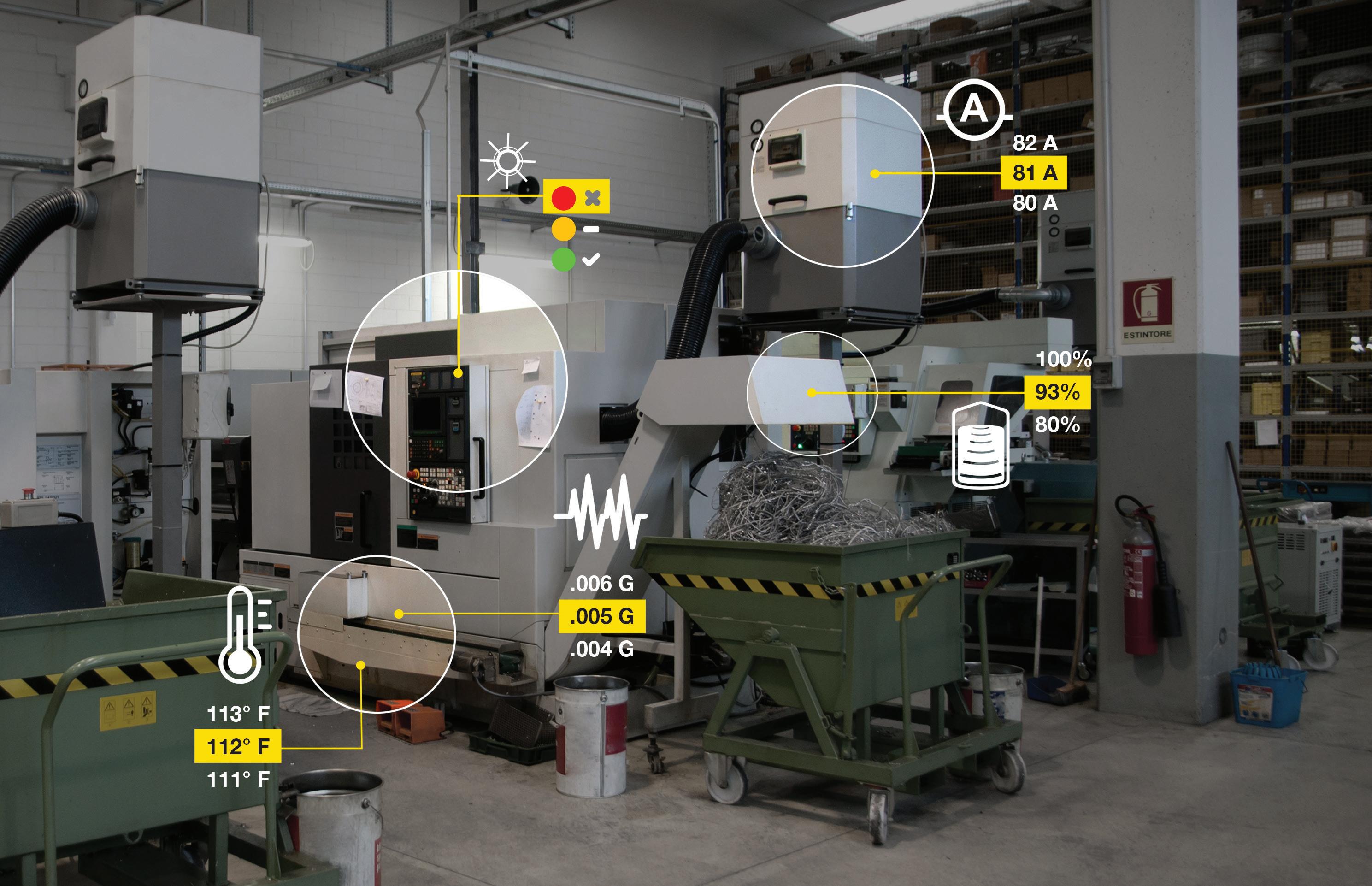

More than an IT challenge, digitalization includes multiple perspectives

Increase Asset Utilization

Predict Maintenance Needs

Improve Quality

Reduce Material Waste

Group COO Joe Woolsgrove

Creative Consultant Tom Vince

Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Alex Caesari, Danielle Champ, Annabelle Crook, Steven Dobinson

Editorial Administrator Amy Gilks, Afiya Lucombe Davis

Creative Lead Lee Protheroe

Managing Art Editor Fleur Daniels

Art Editors David Howard, Charlie Protheroe, Amy Robertson

Artwork Administrator

Rochelle Broderick-White

Sales Director Alasdair Gamble

Project Directors

Philip Monument, Joy Francesconi

Head of Content Management

Adam Blanch

Project Managers Lewis Bush, Natalie Griffiths, Jo-Ann Jeffery, Ben Richell, Laura Thompson

Content Managers Johanna Bailey, Mark Cowles, James Fuller, Jeff Goldenberg, Melanie Joyce, James Page, Wendy Russell, Richard Saunders

Media Sales Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

General Manager Florida Division

Ryan Finn

Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

Hello and welcome to the February issue of Manufacturing Today. In this month’s magazine we’ve asked some important questions, such as - why do you need to invest in automation and, why is sustainability key to manufacturing’s future? Our expert authors make their cases on pages 18 and 30 – have a read and let me know if you agree with their arguments! We also discuss production efficiency, digital transformation and carbon net zero – these topics are frequent flyers in MT’s pages, because we know our readers are keen to learn more about streamlining, digitizing and increasing their green credentials. But if there is a new subject you would like to see in the mag, don’t hesitate to let me know.

© 2023 Finelight Media Group

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

T: (312) 854-0123 T: +44 (0) 1603 274130

www.manufacturing-today.com

US Office 2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426

T: (561) 778-2396

the insights of Morten Wierod, President of ABB’s Electrification Business Area, and he explains why electrification is an unsung hero. Turn to page 8 to learn more.

With 25 years’ industry experience under his belt, Morten Wierod, President of ABB’s Electrification Business Area, joined ABB straight out of university. With lengthy stints in his native Norway, and China, and now with over ten years in Zurich at ABB’s headquarters, he feels fortunate to have worked within sales, technology, and operations. From industrial automation to keeping the world turning with energy-saving, pioneering drive technology, Morten is now settled in Switzerland, heading up the organization’s Electrification business.

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated.

Under Morten’s leadership, ABB Electrification is a global technology leader in electrical distribution and management, collaborating with customers and partners to develop innovative products, solutions and digital technologies that enable energy efficiency and a low-carbon society.

“For me,” Morten begins, “a vitally important aspect of my work is the impact it has on the bigger problems of our time, which has become increasingly relevant in the last few years. I have been committed to energy efficiency and to improving life and societies with better electrical solutions throughout my career. Over the last three-to-four years, however, it feels as though the rest of the world now has that same understanding.

“We experienced the importance of having a stable electricity supply first-hand during the onslaught of the pandemic. Likewise, the outbreak of war in Ukraine reinforced the importance of energy, supply and management, and not just from

the perspective of engineering, but as a matter of national security.

“Our business seeks to answer many of the bigger questions we have surrounding continued quality of life and protection of the earth’s resources,” Morten continues. “With sustainability on everyone’s agenda, electrification, more often than not, is the answer that comes to the fore. We have over 105,000 people working within ABB to make a more sustainable future possible. Our people are increasingly engaged and the pride in their work is evident.

“Electrification is the unsung hero of everything we do. Most people tend not to think about it on a daily basis: generally, only when it doesn’t

work. In terms of networks, it’s not easy to store energy, so, it’s very much a balance of supply and demand, especially at peak times to ensure a reliable grid and supply. Our job is to make that fine balance more stable, and then, of course, to ensure it is generated in the right way to make the green transition possible. We have a very motivated and committed team here at ABB. I work with great colleagues, who collectively, want to make a difference,” he enthuses. This type of engagement doesn’t happen by chance. Indeed, Morten is a firm believer in leading by example. “You need to talk about leadership expectations and the types of behaviors you want to see,” he explains. “This then has to be modelled, because simply delegating or telling people what you

want won’t build and embed a culture. Of course, it requires engagement organizationwide. Similarly, transparency is important: what do I expect from my team members but also what can they expect from me.

“At ABB, we talk a lot about the four Cs: Care, Courage, Curiosity and Collaboration. This encompasses how we interact with each other, take care of each other and the language we use. This sets an organizational standard that needs to be followed, but also provides a safe space in which people are encouraged to speak up when they see behaviors that are not acceptable. We often talk about feedback with good intentions, which is about improved performance, and improved behaviors. We operate in 100 different countries, each with its own culture.

Acceptable behaviors in one place may be deemed offensive or inappropriate in another. Alongside this awareness, we also educate people around unconscious bias, which aligns with how we talk to and about others. I am the executive sponsor for the LGBTQ+ community, championing diversity, equality and inclusivity. We want everyone to develop, to become better leaders, better people and better employees for the company and more importantly, for themselves.”

Even before the disruption from the pandemic and current geopolitical tensions, Morten believes the manufacturing industry started to face a three-fold challenge. “The global supply chain has been strained for some time,” he expounds. “Increasingly, organizations are moving to a regional set up, which is adding complexity because prior to today, we had been on a 20-year journey of globalization, and now, we are seeing those opened trade barriers start to lock down.

“A further complication is the shortage of skilled labor. The population is getting older, and by 2050, a quarter of the population in OECD countries will be aged over 65. This problem is further compounded by an increasing disinterest in factory and shopfloor work as a profession.

“The third challenge facing the entire industry is energy transition. Manufacturing is carbon intense, and while every company needs to embark on its own journey to carbon neutrality, obviously the more carbon there is to omit, the tougher that journey will be,” he states.

“If it comes down to a choice between having the perfect plan of action or the perfect team, from my perspective, there is no choice. I think Mike Tyson said it well, when he suggested that ‘everyone has a plan until they get punched in the face.’ Best laid plans don’t always come to fruition. Recent circumstances are a case in point. In my view, capability and resilience planning offers a more appropriate approach.

It’s a matter of building an organization that is flexible and agile. A decentralized business model that empowers local teams drives faster decision-making. This bolsters organizational capability, both in terms of competence but also mindset. While we can identify some long-term trends and mitigate accordingly, history has taught us that things will happen that we cannot always predict.”

Morten continues: “We are in the midst of an energy and digital transformation. We have apps for everything, and society will only become more connected and centralized in terms of operational execution. This transformation is already affecting how people live in cities, and buildings, as well as how they work, and travel. Against the backdrop of sustainability, we have some clear longterm trends that we have to adapt to as a company, and we can use our technology and experience to help organizations on their journey to sustainability.”

It is in helping organizations to face these bigger challenges that ABB’s technology and expertise come into play. “We are able to understand a customer’s problem and find a resolution,” Morten continues. “In tackling the issue, stepby-step, and working with local channel partners and distributors, we can help our clients achieve their goals. We often use

a pilot project to demonstrate our approach prior to rolling-out measures on a larger scale. For example, if we’re looking at energy efficiency measures, we will look at monitoring local usage and analyzing that data for more informed decision-making. In this way, it’s possible to drill down to the most appropriate next step in terms of cost efficiencies.

“We took this approach with one of the large global hotel chains; assessing a single site, analyzing everything from lighting controls to heating and cooling systems, upgrading accordingly and then outlining how these measures could be replicated in multiple sites around the world. We boast a network of global partners, technical distributors and system integrators. Together, we are able to deliver our technology to best serve our customers’ needs.”

On the path to sustainability, electrification is leading the way. “While it may currently seem most prominent in transportation,” Morten adds, “in reality, by 2050, up to 50 percent of final energy consumption will be electric. Today, we are at around 20 percent. Green buildings, amongst many other applications, will need to become commonplace to facilitate this shift to energy efficiency.

“In terms of industry, we will see more investment in electrification for renewable energy generation, with more on-site production, consumption and storage. While this will reduce the pressure on the grid, in terms of demand, the green transition will require greater stability. As more coalpowered plants are disconnected, and greater reliance is placed on alternatives, such as solar and wind, we are more vulnerable to instability, from both a commercial and consumer perspective. Implementation

of the requisite technology is high on the agenda for utilities, and we may see a trend of continued personalized usage. This process can be further automated, and at ABB, we are working on the technology that will take the time and effort out of monitoring and scheduling usage to work towards achieving carbon neutrality without compromising commerciality or quality of life.”

While it would seem there is an overwhelming commitment to sustainability, what Morten would like to see more of is a sense of urgency. “Every facility at ABB is on track to be a carbon neutral operation before 2030. This is our Mission to Zero programme. It has involved significant investment in how we run our operations, and also how we choose those organizations with which we partner. We are asking our suppliers to do the same and are helping them accordingly. When it comes to sustainability, actions speak louder than words. It’s not about pushing people but rather, inviting them along on the journey. After all, we are all working towards the same goal. It is too important an issue to make optional, but by using the right technology, we can help to minimize the impact of change for a safe, smart, and more sustainable future,” he concludes. ■

Like many other industries, the pandemic significantly accelerated digital transformation in the manufacturing sector. Manufacturers had to cope with major disruption to both the workplace and supply chain, with many finding they could no longer rely on local spreadsheets and applications for effective operations. Consequently, digital transformation plans that had been several years away suddenly became a top priority.

The concept of digital transformation in manufacturing is relatively simple to understand but deeply complex to implement. Manufacturers are applying technology to reduce costs, increase agility, enhance quality, and ultimately maximize revenues, with use cases ranging from workforce productivity to asset utilization.

Digital transformation requires organizations to rethink how they are delivering to customers and stakeholders. It’s not enough to use more technology for existing processes. Instead, it requires a fundamental shift in how enterprises leverage technology, operations, and people to optimize performance.

Rapid technology development also helps to drive advanced applications such as artificial intelligence, data analytics,

automation, edge computing, and decentralized management. To ensure success in the future, manufacturing technology leaders must spend time exploring the drivers and benefits of their digital transformation strategies now.

We’ve seen dramatic shifts in the ways people work. This includes team-based remote and hybrid models and an overall focus on business agility. These shifts highlight the need to move beyond thinking of digital transformation as just an IT challenge.

The disruptions of the past few years highlighted the need to improve business continuity and resilience. Global disruptions, from pandemics to political tensions, are a fact of life. While preparing for every eventuality is impossible, a manufacturing organization must have systems and processes to respond to events and continue operations.

Data generated from manufacturing and design can help improve product designs and factory efficiencies. However, the

main value is in strategic planning. Leaders can use real-time data to make decisions that impact the organization in the short and long term. Data can reveal insights and opportunities in operations, processes, suppliers, and materials that accrue to the bottom line. Manufacturing organizations may be able to develop digital products and services. This can be done as separate revenue streams or as supplements to existing lines of business.

• Agility

Paper-based systems and spreadsheets hold organizations back from leveraging the digital productivity advantage. Moving a digital workflow enables a company to automate many processes through artificial intelligence and rules-based machine learning. Manufacturing

companies will be better able to match production cycles and product demand for greater operational agility.

Organizations that have successfully navigated digital transformation challenges take a holistic view of the process. It should be an interdepartmental, strategic initiative that examines the enterprise from these perspectives.

• Culture

This aspect must be in place before any technology implementation is even considered. In a recent study, 46 percent of companies identified culture as an barrier to transformation. The pandemic accelerated the adoption of cultural changes that would have taken much longer to realize. However, keep

in mind that employees must be trained or hired with the requisite skills to fully make the most of the technology. Engineers must be involved in designing and implementing systems, and data analytics experts are needed to prepare, process, and analyze the flow of information flowing from the systems.

Simply overlaying technology to automate or digitize existing processes and products isn’t the answer. Companies are finding that digitization efforts reduce expenses while enhancing customer engagement at lower costs. For some companies, the plan has shifted from boosting profits to enhancing business continuity, resiliency, and agility.

Many companies fail to modify business processes or optimize connectivity solutions for broader applications, leaving significant value unrealized. Before technology decisions

are made, organizations must review the procedures already in place. Automating inefficient or outdated processes will only lead to the failure of the transformation initiative.

Technology is perhaps the least complicated aspect of digital transformation after the other elements are in place. Adopting the cloud computing model for enterprise IT helps establish a platform for digital transformation. It pairs with edge computing capabilities through IoT (Internet of Things) sensors and rugged mobile devices on factory floors and warehouses that tap into real-time data flows for unprecedented visibility into various processes. The introduction of 5G networks can help companies implement or upgrade robotics and supports bandwidth and speeds to make decentralized decisions on the factory floor.

In the space of just a few years, digital transformation has gone from a nice idea to a critical requirement for manufacturers looking to future-proof themselves against unknown challenges and disruption. As the pandemic proved, business leaders that aren’t willing to adapt and embrace digital innovation in a timely fashion can quickly find themselves on the back foot when the unexpected happens. For those that haven’t done so already, it’s time to embrace digital transformation. ■

For a list of the sources used in this article, please contact the editor.

Tom Baldwin www.getac.com/enTom Baldwin is Sector Lead for Manufacturing, Transport & Logistics at Getac. Since 1989, Getac has been providing rugged computing solutions for demanding professionals in extreme environments. Getac serves a wide range of vertical markets including military & defense, law enforcement, public safety, emergency services, utility, natural resources, oil and gas, telecommunications, transportation and industrial manufacturing.

By Gautam Moorjani

By Gautam Moorjani

Interest rates are rising, credit availability is shrinking, and Covid policies and geopolitical conflicts have caused numerous supply chain issues. The 2022 economic outlook hasn’t panned out as positively as many of us hoped - however, times like these often present opportunities for change and accelerated innovation.

Periods of economic contraction have historically been followed by longer periods of expansion. Most recently, we saw the pandemic unleash unprecedented levels of innovation out of necessity: speeding up digitalization efforts by several years to meet consumer needs; quickening R&D timelines to develop a vaccine in under a year, bucking the usual ten-year timeframe from concept to approval; and hastening availability of financial assistance from governments for struggling small businesses and citizens in record time.

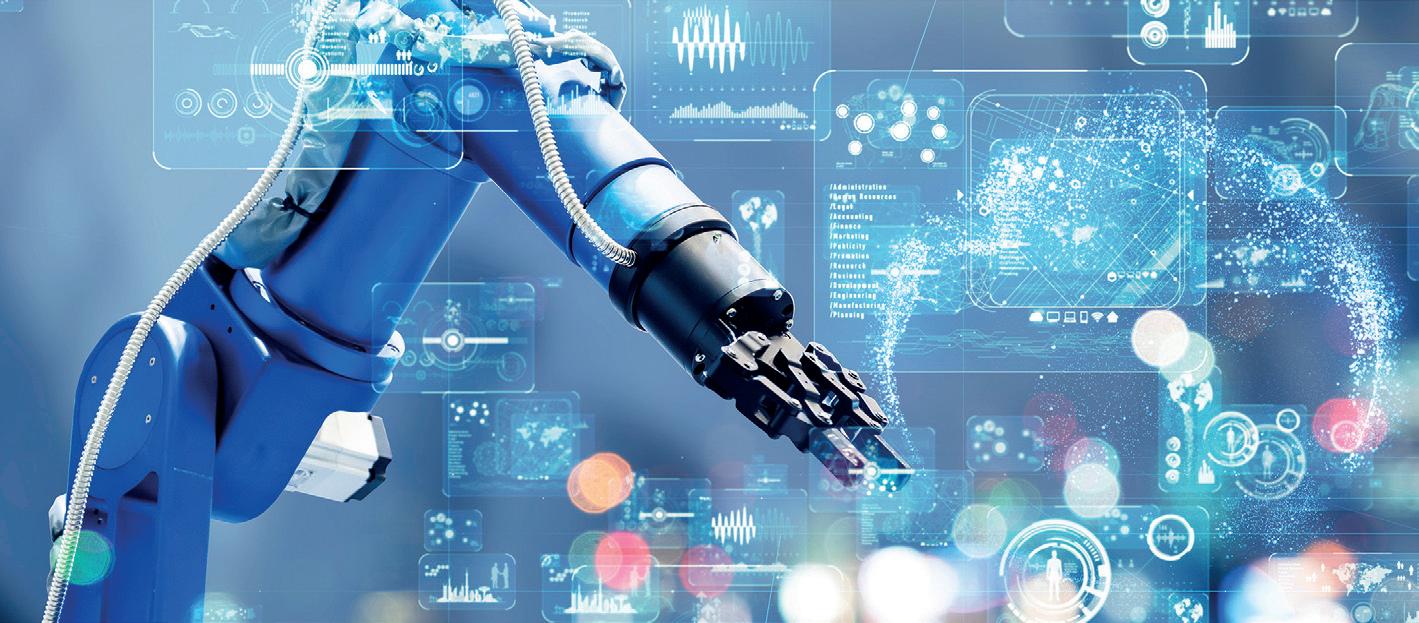

The looming economic downturn and growing skills gaps present another opportunity to drive innovation. Accelerating digitalization will help businesses overcome the slowdown and address talent shortages.

Businesses that are failing to innovate and upskill employees risk losing their long-term market share, consumer loyalty, and growth potential in a shortsighted effort to weather the storm. When faced with volatility and financial downturns, it is understandable to cut costs instinctually: ceasing projects, curbing discretionary spending and reducing spending on human capital. However, this puts the business’ post-crisis viability on the line.

Consumers are usually more hesitant to spend during downturns, making investments to meet their needs and expectations essential. Customers and clients will naturally be drawn to companies whose offerings, products and services are paired with quality and an accommodating experience. The businesses best positioned to meet changing consumer needs, spur innovation, and deliver more than just lip service are those using intelligent automation to service these goals.

Digitalization enables businesses to mitigate fallout and foster agility and resilience, making future volatility easier to withstand. Digitalization boosts productivity and efficiency, improves supply chain management, customer experience, and resource visibility.

No-code automation platforms ease the burden of reskilling employees to use advanced automation technologies. Robotic Process Automation (RPA) can then be used to automate timeconsuming, repetitive tasks, which are often error prone. Pairing this advanced technology with Artificial Intelligence (AI) allows for scalability and decision-making capabilities within business process automation.

Even implementing a simple automation solution like intelligent document processing is a powerful step towards digitalization. It has the potential to save tens of thousands of hours, including those spent on rework for mistakes, and create immense value. US companies spend an

astonishing $5.3 billion annually on wages for manual document processing. By automating processes like this, resources can be redirected to improve other key business objectives, such as customer and employee experience.

Digital transformation is amazing and exciting, but only if done right. Too often, companies get swept up in something most of us are familiar with – FOMO, the ‘fear of missing out.’ They get sold on all the wonders of digitalization and jump the gun on implementing solutions.

This is an avoidable obstacle. Businesses need a well-considered digital transformation plan. This is often done most successfully with the right digital transformation partner who can help them mine processes for automation, select the right solutions, integrate automation into their existing infrastructure and upskill existing workers or, if preferred, maintain their new digital infrastructure on their behalf.

Vendors offering a platform of solutions will be better able to help businesses find the right digitalization plan for their unique needs. Rather than working with five different vendors to implement five advanced automation technologies in a piecemeal fashion, a single vendor strategy enables businesses to integrate their digital solutions cohesively. In an integrated scenario, these advanced technologies work together, maximizing value as intended.

Subject matter expertise is another key differentiator because a vendor offering in-depth knowledge of your sector will understand your pain points and which business process automation will add the most value to your operations.

Another common trap businesses fall into is not investing in the cultural transformation needed to make any digital transformation successful. To get the most

out of business process automation, you need to upskill engaged workers with an aptitude for such training. It would help if you also educated all workers on the purpose of a digitalization plan. Why should they care? How are they going to benefit? These are key questions and if your employees don’t know the answers, you’re already positioning your plan to fail. Workers play a significant role in overseeing digitalization implementation; if they feel antagonistic about it, their chances of success diminish.

Estimates suggest that for every dollar businesses spend on licensing an automation solution, they spend five times more trying to figure out how to implement and scale automation. This is an avoidable waste of resources, especially when many can’t afford it.

The world doesn’t stop during downturns, so you can’t either. A Harvard Business Review study that looked at the outcomes across three recessions found those most likely to flourish post-downturn were the ones that successfully balanced improving efficiency with investing in the future. That is the power of advanced automation technologies: they improve efficiency and free up resources for innovation and human capital investment, paving the way for long-term success. ■

Gautam Moorjani is Head of Product at SS&C Blue Prism. SS&C Blue Prism provides leading enterprise intelligent automation technology worldwide. It empowers customers to reimagine how work gets done with a secure and scalable intelligent digital workforce. A digital workforce increases efficiency, reduces operating costs, and returns millions of hours to staff to focus on the things that matter most.

Gautam Moorjani www.blueprism.comCarbon net zero in manufacturing: seven steps in seven years?

The appetite for carbon capture and clean-tech projects to accelerate progress to net zero in line with UN targets, is substantial.

The UK government has shortlisted 20 carboxn capture, usage and storage projects for potential support, while the European Union is investing more than €1.8 billion in a variety of initiatives ranging from battery manufacturing and low-carbon cement production to synthetic sustainable aviation fuel.

The signs may look encouraging, but markets are experiencing significant energy price and supply volatility which

adds to the difficulties of planning for a more sustainable manufacturing industry. How should asset-intensive, high-energy-consuming industries such as aerospace, fertilizer or steel production, navigate towards a low or no-carbon future employing new technologies?

Digitalization and the use of advanced software will be utterly essential to build into plans for the new technologies that reduce, remove, recycle or sequester carbon. For these reasons, businesses need to effectively capitalize on the enormous growth in volume and complexity of data in energy-intensive industries.

They can then can deploy sophisticated modelling techniques to chart the way forward, making extremely important strategic decisions on the basis of evidence and accurate forecasting. This will achieve the right balance between carbon reduction and profitability. Businesses can also factor in energy security requirements, which have become more pressing in the last 12 months, given the Ukraine war.

Sooner or later all major manufacturing organizations will face the challenges of decarbonizing, so it is worth outlining a series of steps enabling them to grasp the full potential of processes for CO2 reduction or capture.

Many businesses lack precision when it comes to knowing what they emit or use. They need a real-time view. They must be able to identify the bad actors emitting or generating significant amounts of CO2. Once an organization has achieved this, it should use solutions, including digital predictive models, to explore the options for reductions, using insights that support effective realtime decisions. What is important is that any solution must be auditable to meet the requirements of regulators and investors. Advanced software makes this simple, transparent and credible despite the complexities.

Energy-efficiency is the lowesthanging fruit and closer examination frequently reveals that companies

have not executed as well in this area as they thought. Using digitalization to make energy use more efficient will deliver further gains of up to 20 per cent, both reducing CO2 and increasing margins.

This is another significant step that can deliver another 20 per cent in reductions. One option is point-source carbon capture and storage (CCS), removing carbon from flue gases. Another is direct air capture (DAC), which takes carbon out of the atmosphere at specialized plants using huge fans and chemistry. This is at lower concentration than carbon capture, but whereas CCS take a company to zero, DAC could, by removing more carbon that a company emits, take it below zero (called ‘carbon removal’ by the UN). Currently, however, carbon capture is expensive, and transport, storing and monitoring the captured carbon (sequestered in former North Sea oil and gas fields, for example) are all challenging. Subsidies and carbon offsets currently make the costs acceptable, but embedding digital technology is likely to lead to economic breakthroughs.

Low-carbon inputs are an obvious source of reductions for manufacturing, especially through bio feedstock

utilizations. Here is it possible to drive emissions down another ten percent in typical chemical and refining settings.

This step is for organizations running equipment on diesel, natural gas or the conventional power grid. They can plan to switch to green electricity or geo-thermal energy, potentially delivering another 15 or 20 per cent reductions in plants that are energy intensive, such as refineries.

“

“

““

Hydrogen is an exciting prospect as a clean alternative to fossil fuels

Organizations need to use renewables such as solar and wind energy from their own sites or from industrial producers. Microgrids have also become a significant feature of green energy. These are small electricity distribution grids where the site is directly managing and optimizing its own sources, making best possible use of electricity and ensuring manufacturing continues if public power grids go into brownouts or blackouts.

Hydrogen is an exciting prospect as a clean alternative to fossil fuels, but the economics remain challenging. Will organizations be prepared to pay a green premium for it?

Europe has moved more slowly on this than several other parts of the world such as the Middle East, India and Australia.

All these steps are achievable, although electrification of very high energy processes such as ethylene cracking or steel production could be more long-term. Regulatory uncertainty about emissions is also a factor that inhibits investment in new sources of energy along with differences in definitions of bio feedstocks between trading blocs.

We can also see how the UK and Europe are at structural and demographic disadvantages compared with many Asian economies. The retirement of skilled workers in the UK and Europe is a factor, whereas south Asia and the Far East have larger skills bases, agilely form consortiums and feature growing manufacturing capacity.

“

“

““ Regardless of location, all industries will have to shorten innovation cycles

Regardless of location, all industries will have to shorten innovation cycles. The picture will be different once organizations are more fully digitalized and can for example, run thousands of different ideas through digital twin design technologies, modelling far faster than the months it takes to build a pilot plant.

Subsurface modelling is a good example of how highly advanced technology can transform the viability of sequestering carbon in former oil and gas fields. Digitalization will transform how manufacturing adapts and incorporates radical new carbon reduction techniques – from conceptualization to design, implementation and monitoring.

None of these steps can by itself take care of carbon-reduction, but it is certain digitalization will be essential as manufacturers strive to maintain profit levels as they chart their individual paths towards UN targets for carbon reduction. ■

Ron Beck

www.aspentech.com

Ron Beck is Senior Director, Solutions Marketing at Aspen Technology (AspenTech) a global leader in asset optimization software. Its solutions address complex, industrial environments where it is critical to optimize the asset design, operation and maintenance lifecycle. AspenTech uniquely combines decades of process modelling expertise with artificial intelligence. Its purpose-built software platform automates knowledge work and builds sustainable competitive advantage by delivering high returns over the entire asset lifecycle. As a result, companies in capital-intensive industries can maximize uptime and push the limits of performance, running their assets safer, greener, longer and faster.

Suzy Skehan discusses why sustainability is key to manufacturing’s future

For many sectors across the UK, the path to net zero can seem clear and attainable. Due to minimal direct emissions from their operations, in addition to our electricity system becoming increasingly decarbonized, the majority of businesses will likely see a reduction in their total emissions without the need for significant up-front investment. Unfortunately, this is not necessarily the case for the UK’s manufacturing sector. Many of the companies we certify and advise here at Planet Mark are operating with significant direct as well as upstream and downstream emissions exposure and the sector as a whole accounts for 12 percent of the UK’s total greenhouse gas emissions.

However, despite its climate change impact, manufacturing will continue to be vital to the UK economy as it employs over 2.5 million people and accounts for roughly 45 percent of total exports. It is therefore no surprise that reducing the sector’s emissions (integral for achieving the UK’s 2050 net

zero target) while maintaining productivity is core to the government’s Industrial Decarbonisation Strategy. The Strategy, which sets out an ambition for the industry to reduce carbon emissions by at least 67 percent by 2035 and by at least 90 percent by 2050, represents a decarbonization line in the sand and will guide policy thinking and government investment in the years ahead.

Although these targets are certainly admirable, exactly how they will be achieved without a reduction in growth or output can seem, at least initially, to be a bit of a head scratcher. Helpfully the recent Net Zero Review, released only a few weeks ago [at time of writing] is brimming with excellent ideas and suggestions for government on how it can turn these targets into reality. Published by former Energy Minister Chris Skidmore, the review advises on how the UK can tackle climate change alongside reaping the economic benefits of leading the global low carbon transition.

The review provides ample consideration to ‘turbocharging growth’ and decarbonization across the UK’s core sectors, including manufacturing. It recognizes that emissions reductions within the sector will be delivered through greater energy and resource efficiency, fuel switching to low carbon fuels and through the adoption of yet to be commercialized decarbonization technologies such as hydrogen and carbon capture and storage (CCUS).

While it is encouraging to know what the solutions are on paper, achieving their widespread adoption without disrupting overall output and commercial opportunity poses a potentially significant challenge, particularly for manufacturers operating at smaller and more dispersed sites. These manufacturers are already facing high energy costs on top of the cost of decarbonization and a lack of tailored

policy and funding solutions to help them prepare for the years ahead. This contrasts with their larger counterparts clustered within already established manufacturing and industrial areas, who will be more easily connected to the future CCUS, hydrogen and electrified grid systems that will be vital for bringing net emissions down to zero.

While the review sets out useful recommendations to government, such as accelerating and unlocking the decarbonizing potential of energy efficiency investment as well as incentivizing on-site generation by Q2 2024, it likely offers little comfort to manufacturers today that are concerned about how they can secure their place in the rapidly accelerating net zero transition of tomorrow. Fortunately, there are already available solutions whose short-term adoption can deliver long-term emission reductions and a route to net zero, in addition to very necessary energy and operational cost savings.

Many of these such solutions have been embraced by one of our members, Lancashire based Evans Vanodine International. The developer and manufacturer of cleaning and hygiene products has completed a range of projects that address its environmental impact, and which aim to achieve a more productive, safer and streamlined working environment. These range from simply converting lighting to LED in its office spaces, to optimizing and changing the mixing times of the products it makes to save as much energy as possible during the manufacturing process. Looking beyond just immediate emissions reductions, it has also changed how it cleans its manufacturing vessels to minimize the water required and has been optimizing formulations and improving products to use lower impact ingredients where possible. The company is also looking to invest in ambitious upcoming projects such as using heat capture technologies, in combination

with its production boiler, to save heat being lost. It is also investigating opportunities for on-site generation through a solar array.

Evans Vanodine International isn’t alone in this exciting journey. According to recent research by Make UK and Siemens, nearly half (46 percent) of manufacturing companies aren’t waiting around for government policy and are already implementing decarbonization plans, citing rising energy costs, the rising cost of raw materials and more generally the need to do the right thing as factors in accelerating their efforts. Manufacturing companies are better positioned than most to adopt new measures and procedures to realize emissions savings as many thrive on making their processes more and more economical.

Sustainability should therefore be seen by everyone in the sector over the coming years as a metric of success, rather than simply a government target or impenetrable policy proposal, as it signifies the optimized use of materials, reduction in waste and greater overall efficiency. Ultimately, a more sustainable manufacturing company will be more competitive, especially when putting its products into the global market. Therefore, although the route to net zero is harder for manufacturing when compared to other sectors, the commercial success that can potentially be secured as we march on to a net zero future should be a highly motivating factor for the entire sector. ■

Suzy Skehan

www.planetmark.com

Suzy Skehan is Sustainable Business Manager at Planet Mark. Planet Mark is an internationally recognized sustainability certification which recognizes continuous progress, encourages action, and builds an empowered community of like-minded individuals. It is awarded to businesses, properties, new developments and projects that are committed to reducing their carbon emissions.

No sooner has the Covid dust settled than the threat of recession now looms, forcing manufacturers throughout the supply chain to realize that a precarious, post-pandemic market requires a radically different mindset. Before Covid, manufacturers were finally beginning to face the demand for changes brought about by regulation and customer demands. Typically, this was seen in areas such as sustainability, inventory availability and speed of delivery, or increased visibility throughout production. When it came to the production efficiency behind these capabilities, what was once dipping toes into the waters of digital transformation, became a full on diving contest.

In the face of these different headwinds, savvy manufacturers are realizing there are two key elements to a successful strategy:

1) The considered alignment of separate business units, rationalized for efficiency, then integrated with a common backbone

2) Ensuring that this new, integrated organization is fully customer-centric

One of the earliest lessons has been that both of these aspects demand a substantial amount of data, but also create an opportunity for huge improvements in efficiency, both within and beyond the production environment.

Rationalized and integrated business units lead quickly to economies of scale that arise from smarter procurement and manufacturing. This is often misunderstood. Savings are not only made by removing duplicated effort across multiple business units, but also in solving multiple instances of the same issues. Common constraints typically include manual processes that taken together, can create a strong appetite for the adoption of new technology.

The balancing act here is to implement consistent technology both across and within the business units or brands, whilst maintaining individual identity and the best results that arise from the autonomy of those operations. Cultural issues such as the ‘identity’ of the business can become a significant obstacle to integration and derail efficiency programs if not handled sensitively.

However, it is the second perspective – using customer data to align output to demand and creating a customer-centric organization – that has the final say.

As recessionary fears continue to take hold, sustainability has evolved rapidly

from an exercise in greenwashing, to a key focus on operational efficiency in every department. For production, concerns around energy use and raw material consumption are no longer about saving the earth or the right thing to do – they are about saving costs and ensuring business survival.

The zenith of this idea is that as a business, nothing is produced (or indeed, no activity is undertaken) that is not then part of a tangible, specific demand. No goods are produced that are not already sold. No travel is undertaken that does not tie into clear benefit such as a new or increased order. Buffer inventory is eliminated. Staff are focused on the highest value tasks as defined by the business.

There have been attempts at this kind of thinking before: lean manufacturing, zero waste projects and so forth. What makes the current situation different is the presence of technology that can not only track the necessary variables throughout the business, from energy use to production output, but also the connection to customer data.

Two main questions then arise: firstly how a manufacturer can undertake a project that pulls together so many different business disciplines into a cohesive whole and secondly, just how far can it take these projects to yield improvements?

Implementing a customercentric strategy that includes production efficiency (and indeed, efficiencies throughout other areas of the business) is no small feat.

The first phase is discovery –assessing the current state of play and getting a clear picture of the status quo. This typically involves a lot of

stake holder interviews, data gathering where possible, and then looking for the most pronounced pain points.

From this, a set of recommendations follow to address these issues, that then feeds into a strategy that can outline business models and architecture. From this the roadmap can be developed, that will oversee investments to be made.

In terms of an order of priorities, this will of course differ from company to company, but any decent discovery process will quickly reveal the most pressing concerns.

Our own assessment then takes into account two factors – the effort demanded to make necessary changes and the impact that those changes will have. Of course, low effort / high impact changes will look attractive, but typically it will be those changes that are less effort but less impactful that will see the most agreement.

Production efficiency improvements (and some associated areas such as logistics) usually do demand a little more effort but they also do have a much more pronounced impact – so it is important at this stage to secure full buy in from senior figures to ensure changes will be implemented and supported.

Which then brings business leadership to the second question – how far can these changes go? Or rather, how far should these changes extend?

The immediate boundary is that of commercial relevance and benefit. If any changes to improve production efficiency – or any other aspect of a manufacturer – does not yield tangible improvement, then it should not be pursued.

But even here, there are degrees.

The cost of a change program, in terms of money, time, human resources and host of other factors can – and arguably

should – put the brakes on. This is especially true of programs in departments that might not be directly customer-facing.

But in those departments that do interact with customers, it can often pay to be a little more flexible, in the search for the next series of data points that can feed into the business to make it more efficient from the customer-centric perspective.

Beyond this, there really is no limit to the efficiencies and changes that manufacturers can explore, even within solely the production environment – although such an approach would of course limit the return made on the investment. Production efficiency demands change and change is an organization-wide mandate to any manufacturer looking to emerge victorious in the current climate. ■

Matt Fearon www.bmldigital.com

Matt Fearon is Senior Consultant at BML Digital, a consultancy that demystifies technology and digital transformation. It delivers focused, powerful, pragmatic, and effective change to some of the biggest names in business. Its unparalleled insight and expertise leads to tangible transformation that creates actual results.

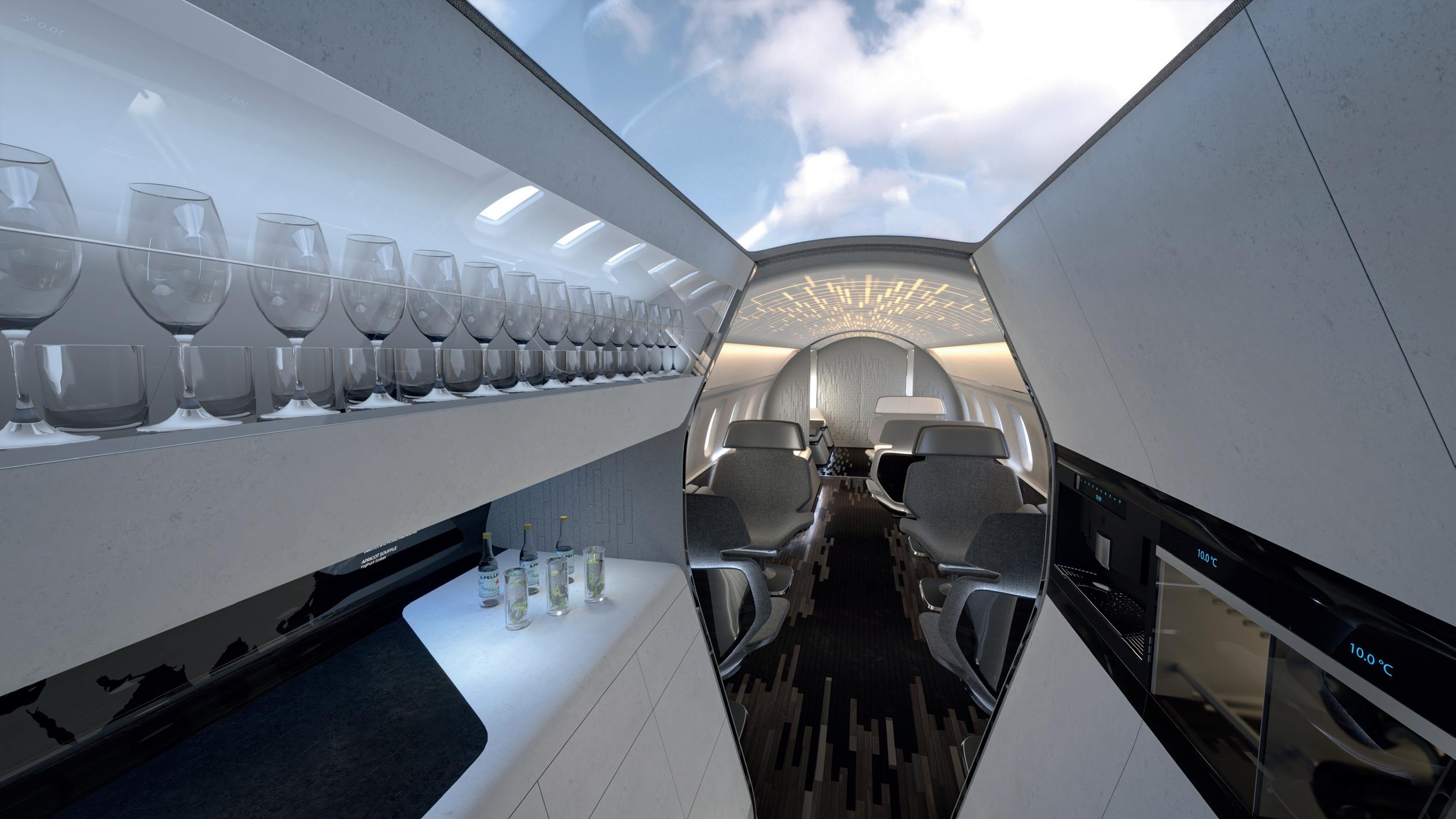

Franz List Snr gave his surname to F/LIST when he founded the business in 1950. With its original home situated in a heavily wooded region of Austria, the business is rooted in master carpentry, craftsmanship and cabinet making. In 1962, his son, Franz List Jnr, took the reins, became the youngest master carpenter in Lower Austria, and added the F to the company’s name. Today, the enterprise also has locations in Brazil, Germany, Dubai, the US, UK and Canada, and applies its age-old knowledge and techniques to a plethora of different industries.

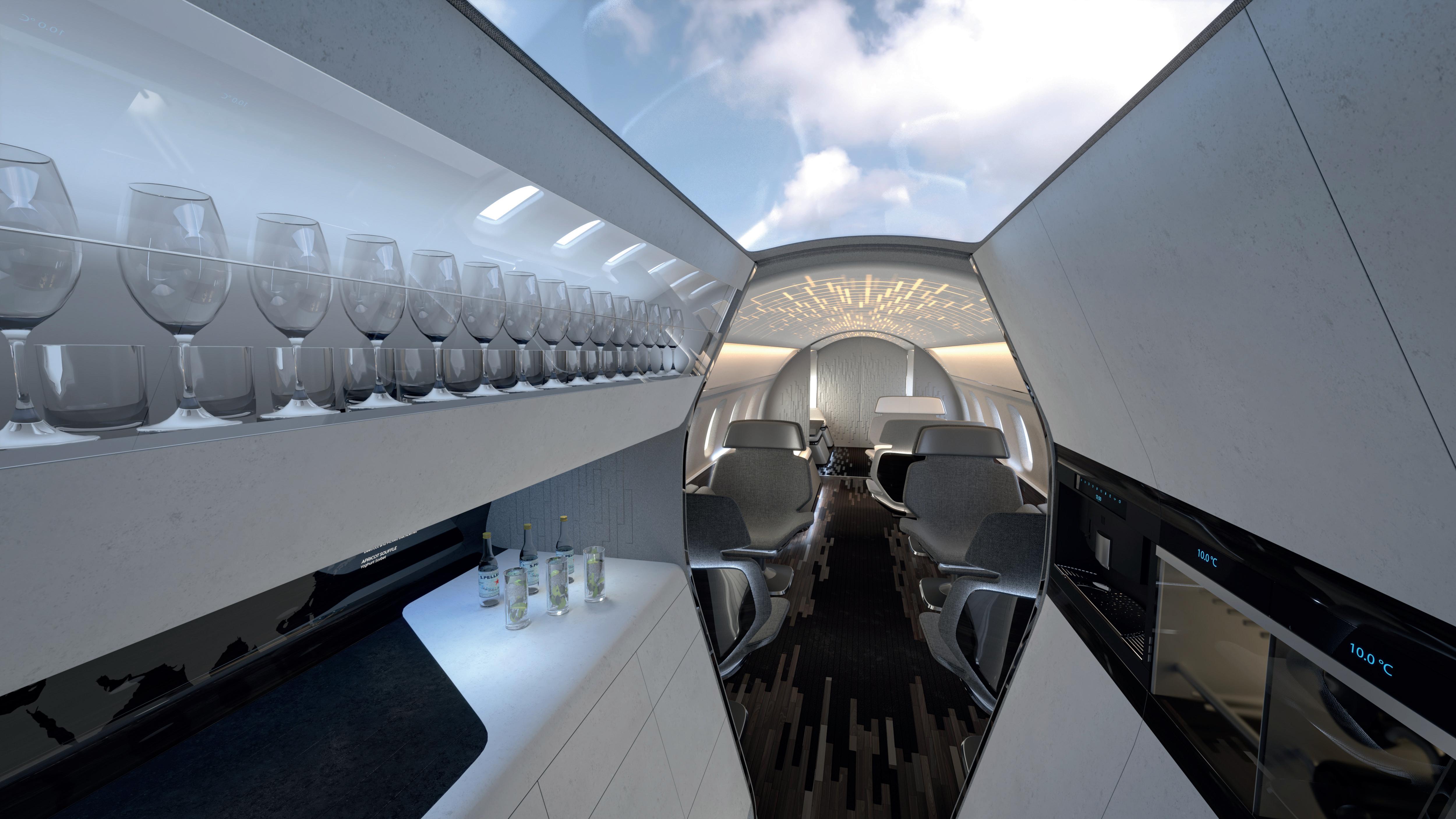

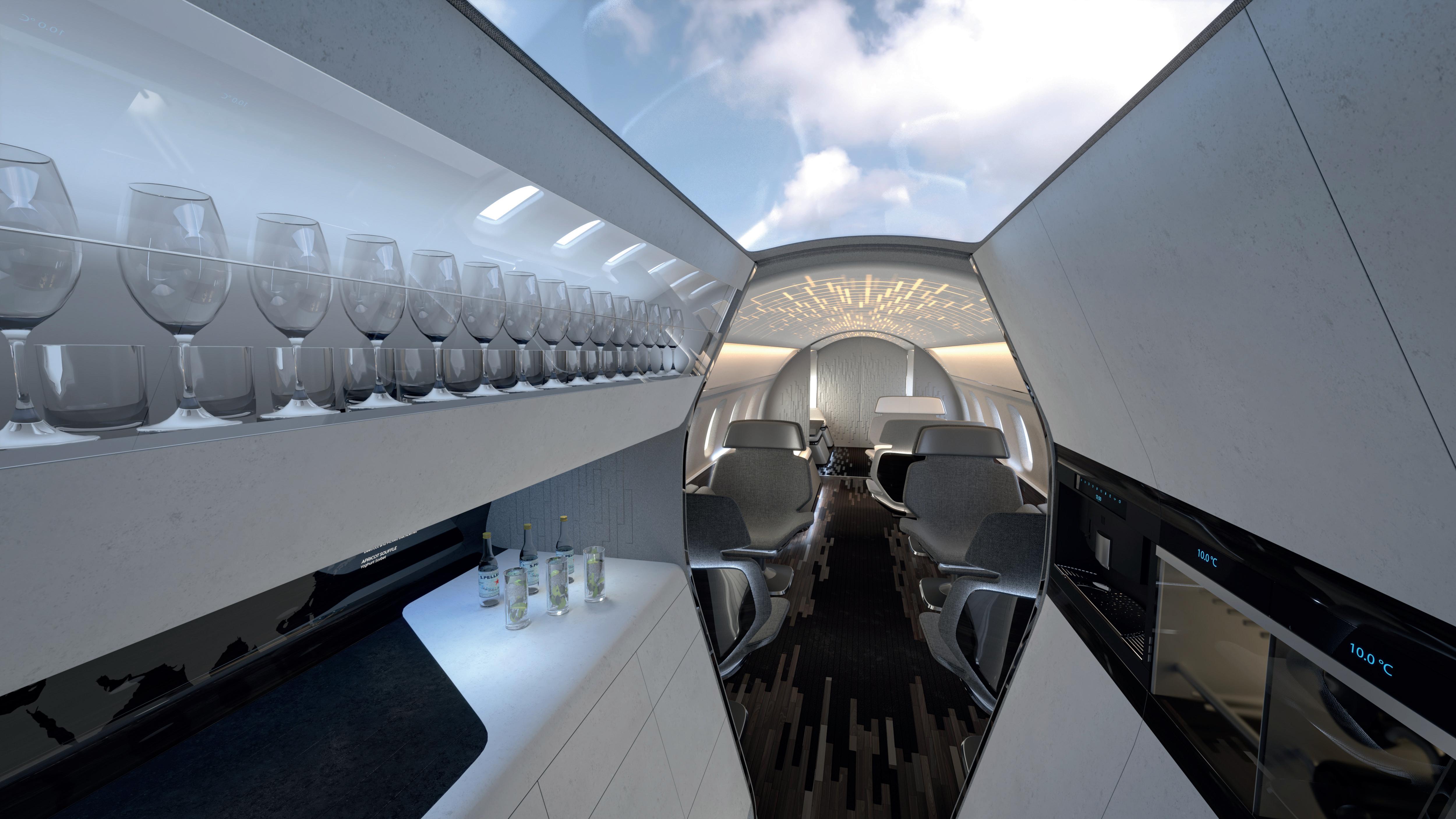

“It’s been a labor of love for the List family for three generations, with Franz List Jnr’s daughter Katharina List-Nagl representing the most recent,” begins Derek Gelinas, Managing Director of F/ LIST Canada Corporation. “The company has been steadily branching out over the last thirty years. In 1992, we delved into the luxury yacht industry, which is a huge line of business over in Europe, and then in 2004, when Katharina joined, she established our Research and Development (R&D) department. This spurred on our expansion into lightweight construction, which was closely followed by our entry into the aviation business. Ultimately, when it comes to luxury interiors, we’ve got land, sea, and air covered.

“We initially started working on Bombardier Learjets, 40s and 45s, but our work within the wider industry soon took off. By 2009, we had an aftermarket division that led to our involvement with in service aircraft in locations all over the world. Katharina became our CEO in 2017, then I joined our Canada site the following year. We are now three years into Katharina’s 15-year vision, which is a strategy to develop F/LIST’s focus on innovation, sustainability, and technology. We’ve been debuting our ideas at multiple conventions. It’s an exciting time for us.”

High quality products and customer satisfaction have always been at the top of F/LIST’s agenda, underpinned by its family-

based focus on providing a supportive and educational environment in which its people can flourish. An example of this, is the way that the company mirrored its Austrian-based technology in the Canada location when it was established. Although it seemed like a difficult and cumbersome approach at the time, to load everything onto boats and transfer it across the Atlantic, the business had two key reasons for doing so.

“Firstly, it was due to the familiarity that the Austrian teams had with the kit, and it was those colleagues who came over to get things up and running,” Derek explains. “This was the most effective way for them to bequeath their skills and craftsmanship

to our Canadian-based workforce. We were very lucky to be taught how to use the machines by the people that know them the best. The second reason became apparent once we started to interview new hires. All of our equipment is top of the line, and a lot of it is not readily available in North America, so you can only imagine how prospective employees’ faces light up when they see the toys that they get to play with.

“We also house a lot of contemporary technologies, but what’s more exciting to me is the time that the teams spend experimenting with our tools to see how

far we can stretch their capabilities,” he continues. “There is a certain curiosity that trickles down from our artisanal heritage of hand crafting and traditional methodologies, which when applied to our new lines of machinery, creates the most incredible feats of engineering. Imagine taking a master carpenter of 25 years, based in Austria, and dropping him into an aerospace project to see how his skills can be transferred. It’s amazing!”

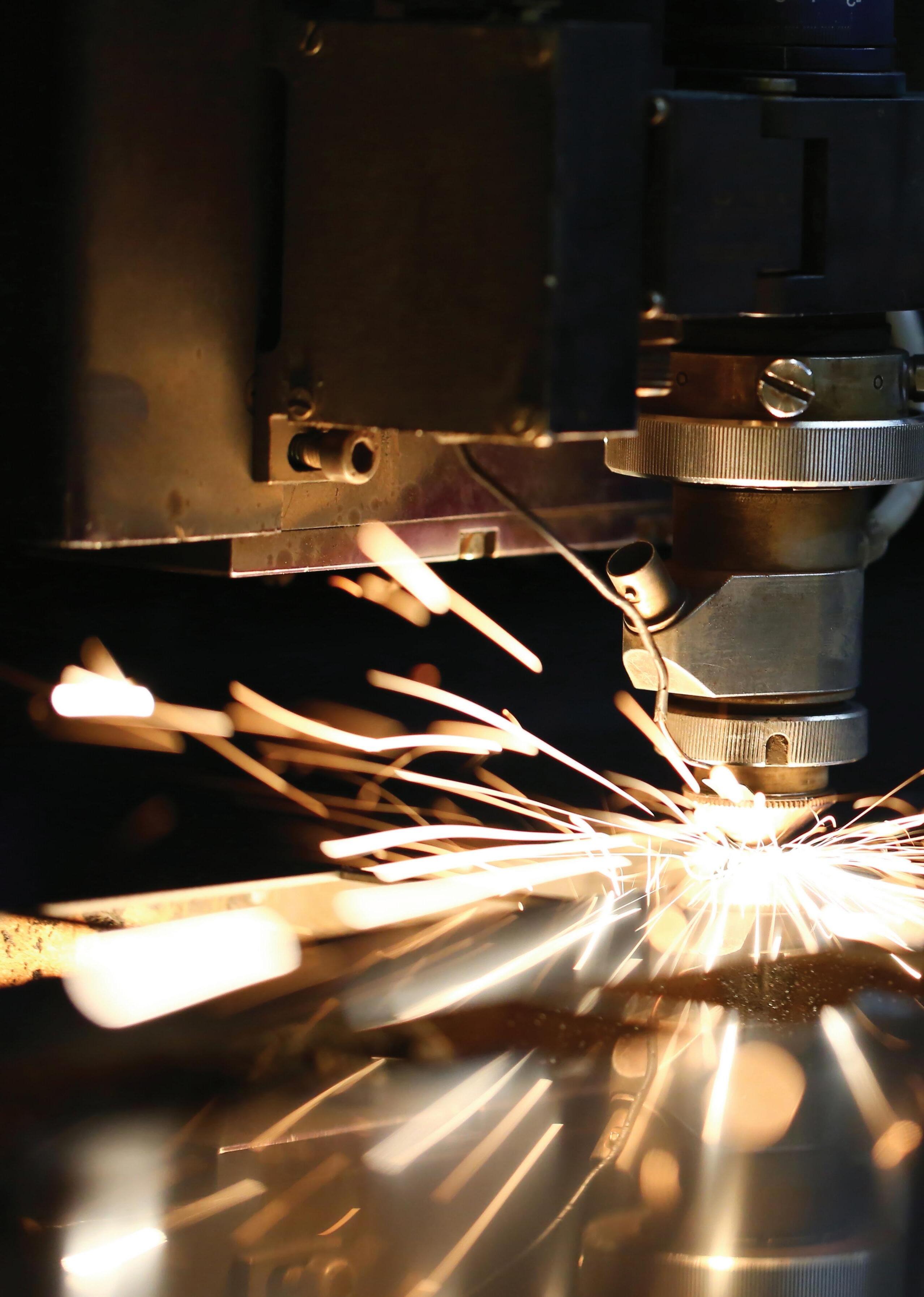

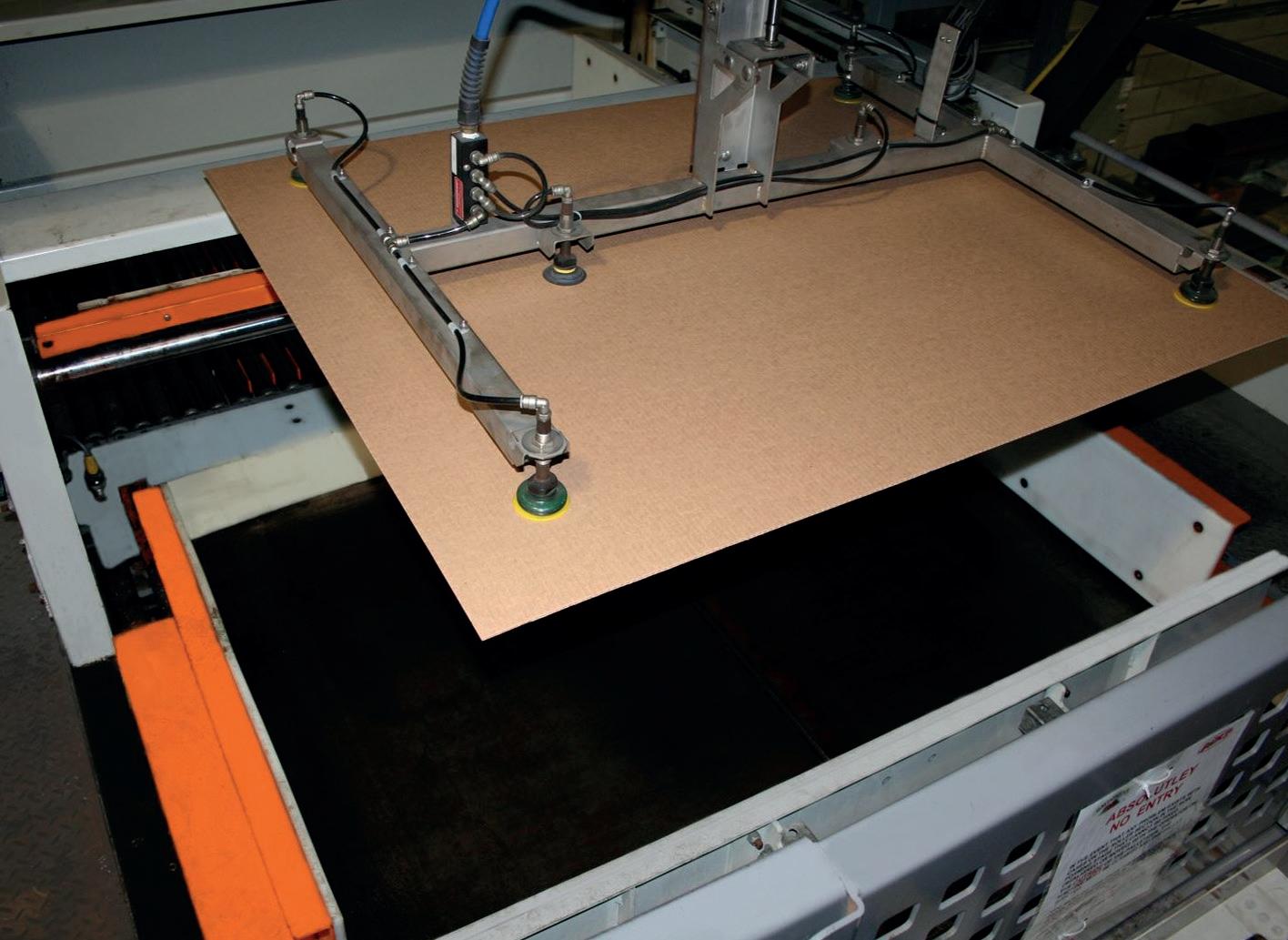

The Canada site initially focused on raw material veneers, but it wasn’t long before F/LIST realized that it needed to address the needs of local consumers for full scale manufacturing. The three key sectors in which it now operates are aerospace OEM, aerospace in-service and aftermarket, and residential. To serve the aircraft interiors segment, the location features a large format five-axis CNC machine, veneer cutting and joining machinery, pressing machinery, cabinetry pre-production equipment, two spray booths, a separate glue booth, an upholstery workshop, a flammability lab and a recently added large format laser cutting machine. It also falls on Derek and his team to bridge the innovations developed by the R&D department, now called the F/LAB, at the headquarters in Austria, over to the North American market. The Austrian locale

eight sites, with a few more in the pipeline.

“As we move forward with Katharina’s vision, the two major principles that we have chosen to address are sustainability and innovation,” says Derek. “Sustainability is an obvious one into which we, as a species, should be doubling our efforts as it means to survive. We are utilizing our infamous flair for innovation and design skills to provide solutions. We’re known for challenging the status quo and achieving feats our industry hasn’t seen before, for a customer base that thrives on having the best of the best.

“We are continuing to push the boundaries in providing solutions for our future clients, with a particularly exciting avenue being that of our sustainable decorative materials. WHISPER Leather for example is a new generation of leather, which is manufactured from plant-based raw materials. However, it has been developed in such a way that it not only meets the expectations of the traditional animal-based alternative but exceeds its functionalities and places-of-use too.”

Derek cites the organization’s method of managing supply chain relationships as being inherited from its European roots. F/LIST bonds with its vendors, suppliers and customers, in what he refers to as eye-level partnerships. The

great value of these connections come from strong, long-standing relationships, in which all parties practice the utmost honesty and support for one another. “Some of the actions I’ve seen at this company would boggle the minds of those working elsewhere in North America,” Derek goes on. “I have witnessed senior specialists notice imperceivable defects in products that have already been signed off by customers and proceed to contact them immediately about fixing the fault.

“We also like to consider our closer competitors more like neighbors, as we regularly help each other out. We would rather share our inventory stock, given that the lead times for some of our European components can be two to three weeks, so that everyone can avoid disruptions. I believe this to be a far more advantageous approach to navigating your supply chain than conventional dualsourcing or strategically holding stock around the country. We still practice the latter to a small extent but thrive more so on feeling like we belong to a community where everybody helps each other out.

One of the main factors that Derek states attracted him to his role, is the emphasis that F/LIST places upon its people and working culture. The company strives to facilitate learning and career progression by creating a fun and encouraging atmosphere in which people are proud to work. “The Head of People & Culture, Monika Putz, has been over from Austria recently, workshopping our new culture guide with the teams. Another company-wide initiative is promoting international opportunities for employees on a long- or short-term basis. For example, this year F/LIST Canada is hosting two employees on long-term assignment from Austria and will be sending three of its top employees over to a new developing location to share their expertise. This is a real point of pride for people.

“We like to celebrate first-time delivery of a new, or really well executed product or service, as well as stage a family day, a summer BBQ, occasional food trucks, a Halloween costume/pumpkin carving contest and a Christmas event every year. In keeping with our Austrian heritage, there’s also our “F/LIST Canada” version of an Oktoberfest potluck every autumn. The social element is so crucial to sculpting a workplace that gets the most out of everybody. As a result of all the orchestrated events that we host, the employees have formed their own summertime tradition, organizing a barbecue every Friday afternoon in our parking lot to get everyone together. I always say that I’m trying to run Hotel California, as I want everybody to retire here!

“We aim to stand out from our competitors, by being what we hope makes us an employer of choice,” Derek concludes.

“Looking forward, I want to see us grow the reputation of a worldwide high-end luxury interior brand, all within a culture that celebrates people who love what they do.” ■

www.f-list.at

Axioma Metering (Axioma) is known as a worldwide pioneer in the metering industry. First set up in 1992, the company began with the creation of an innovative ultrasonic heat meter; since then, it has gone on to develop and manufacture myriad ultrasonic heat, water metering, and data management Internet of Things (IoT) devices, with sales increasing exponentially over the last two decades.

Sitting down once more with CEO, Ignas Vosylius, we get an insight into the company’s growth trajectory. By the end of the year, Ignas expects turnover to reach a staggering 80 million euros – not bad for a company that, prior to its mass market expansion in 2019, was turning over an eighth of that. “I think we need to give props to the market and the people who are now paying more attention to the global problem of water scarcity,” he

. . . we want to implement good, innovative technology in a new way – one that will create a cost-effective and more accessible end product

begins. “That has driven a majority of the demand, but then, of course, underpinning that is our innovative methodology.”

For Axioma, innovation is key; it is one of the core tenets driving growth. As a trail blazer, there is no alternative way of being. The new and the novel are fused to the company’s sense of identity.

“We have a long track record of creating specific solutions for persistent problems,” notes Ignas. “It can be something like

investigating how to use ultrasound as a means of measurement. You see, we have the luxury to play around in numerous areas of interest. Combining a rich company-wide bank of knowledge and industrial expertise concerning niche segments and market trends puts us ahead of the competition.

“But make no mistake: our goal is not necessarily that of creating a new product that has never been seen before,” he goes on. “Rather, we want to implement good, innovative technology in a new way – one that will create a cost-effective and more accessible end product. People want innovation but without all the nonsense that can oftentimes be attached to it. Indeed, smart meters are installed in lots of different locations: all kinds of basements, inside, and outside in various environments.”

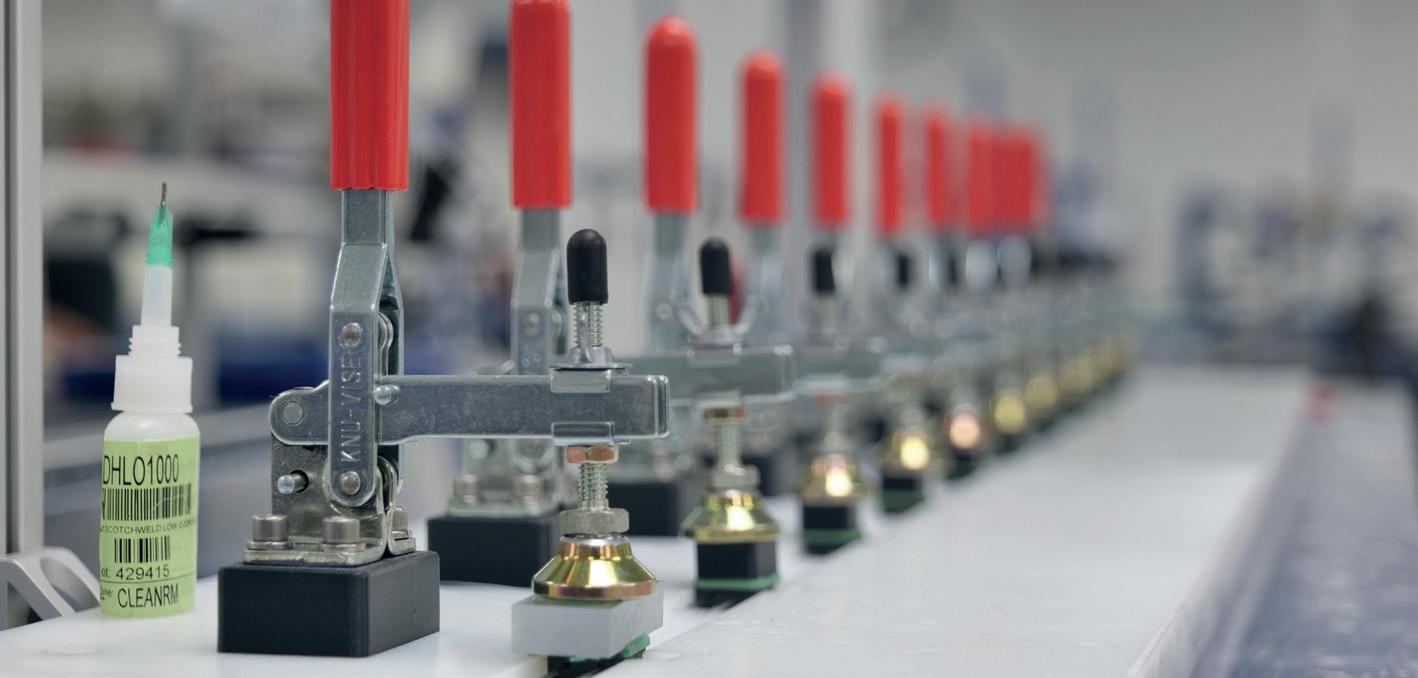

Consequently, to create professional, high performing products that work in a variety of settings, Axioma has invested significantly in automation. Ignas is keen to point out a core difference between his company and others.

“When people consider automating processes, it typically comes from an ambition to minimize the overall costs associated with manufacturing and production,” he explains. “Whereas, at Axioma, the more important goal for us is applying automated technologies that can perform operations otherwise impossible to manually carry out. The result is an increase in our standards and – eventually – our end product.”

Focus, dedication, and long-term planning are key – and no one knows that better than Ignas. He is a firm believer that, together, these are a necessary remedy to the ongoing issues concerning the supply of electronic components like semiconductors, which Axioma is heavily dependent on.

As Ignas informs us, the company was handicapped for almost a year, running at just under 20 percent of

its full capacity. But that didn’t stop Axioma. “Though hampered, we refused to stop moving forward,” he says. “We ploughed on with an array of strategic investments. Yes, it was a painful financial period, but we knew it was a short-term problem. We didn’t want to just maintain our capacities, we wanted to double them.”

In October 2022, as Ignas mentioned, Axioma was running at a low capacity. But by putting this optimism and determinism into a practical action plan, the company managed to significantly turn the tables in just a matter of weeks.

November saw that figure rise to 50 percent and by the end of the year Axioma was back up to a 75 percent operating capacity. That’s a staggering increase in just three months. For Ignas, it was essential

By 2026, the total investment value will sit at around 70 million euros

that the company maintained its quality standards during that period of flux.

“It has been a very intense and challenging time, and I am thrilled with the results we have seen. However, I am even more proud of our team, who accepted this challenge and put in huge amounts of effort, showing exemplary cooperation to make this happen. We have proven that with the right level of dedication we can conquer the most ambitious targets!”

Axioma has invested around 30 million euros so far into its factory, which was built back in 2018, effectively doubling its production capabilities. “A couple of

months ago, we started construction on a new factory, which will be located in a neighboring lot; it will be twice as big as our current facility and will triple our total floor space,” reveals Ignas.

“We will begin with just one production line, but will soon equip it with four,” he concludes. “By 2026, the total investment value will sit at around 70 million euros; it’s all part of our growth plan. Indeed, within the next year, we are planning to quadruple in terms of volume, and we have put a very clear framework in place to achieve that. We are moving fast – hopefully we can catch up soon and tell you how we did!” ■

www.axiomametering.com/en

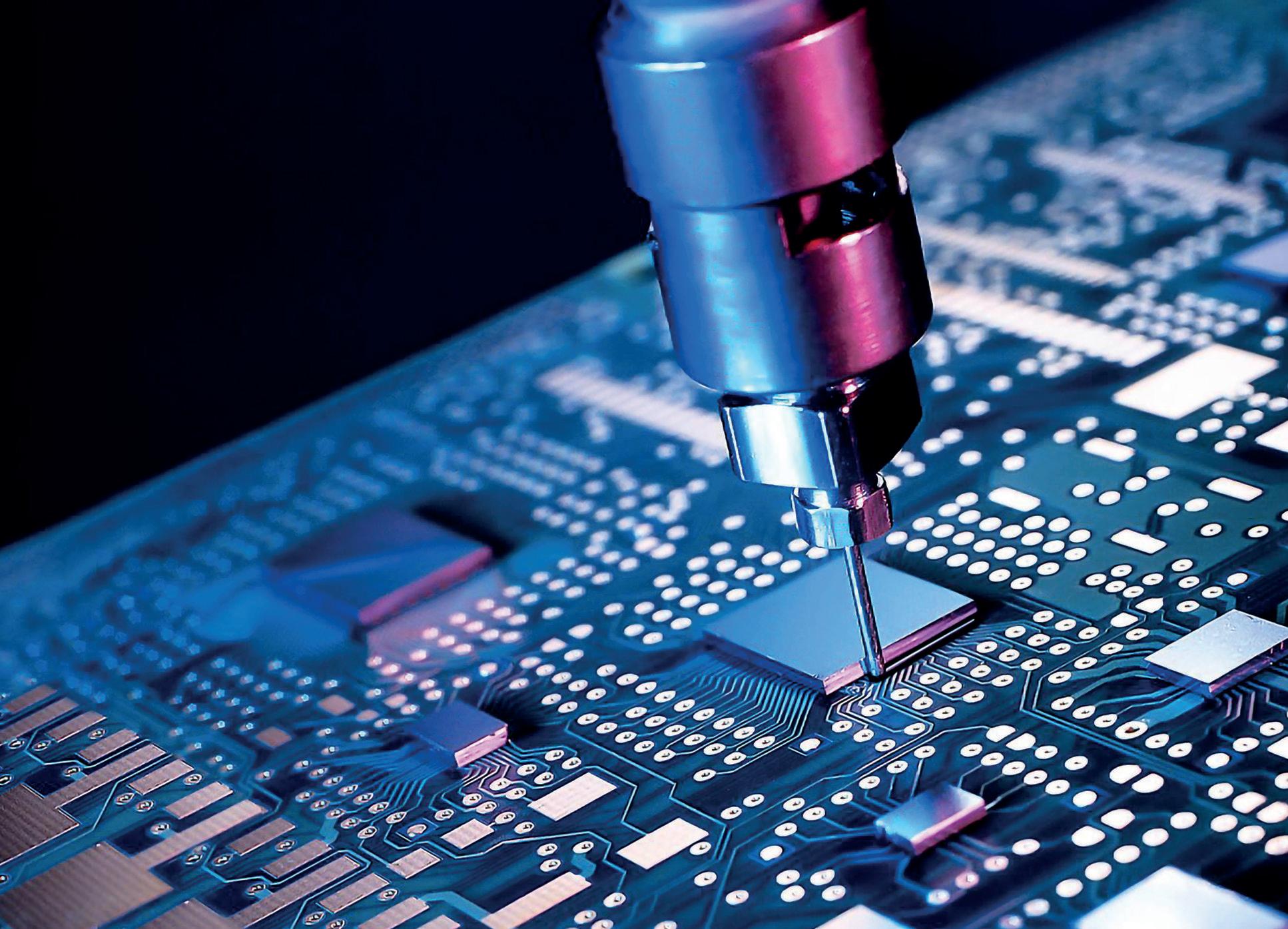

With the aim of supplying the rapidly growing UK electronics industry, Ronnie Hetman and two peers set up V Tech SMT (V Tech) in 1997. IBM, Compact, Hewlett Packard, Motorola - all these huge technology players were scaling up operations across England and Scotland at the time, and capable, trusted electronics suppliers were in high demand.

As Ronnie aptly points out, many of these companies have since moved on, establishing operations in more cost-efficient territories overseas. But V Tech remains

here – and it’s still going strong. Indeed, since 1997, the business has grown year-on-year with balance sheets firmly in the positive.

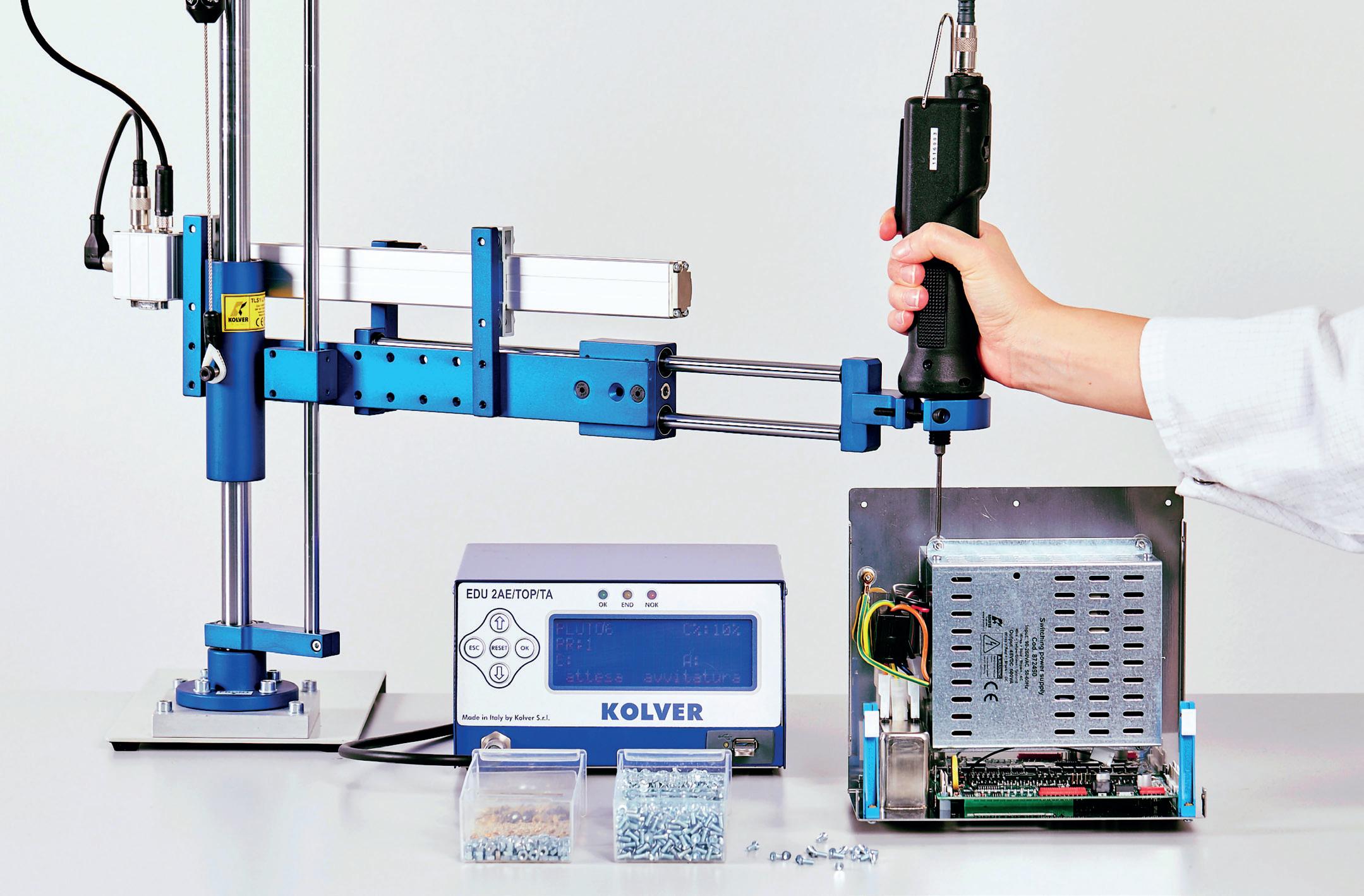

Accredited to ISO 9001 and 14001, V Tech specializes in the supply and worldwide distribution of equipment and consumables to the electronic assembly industry.

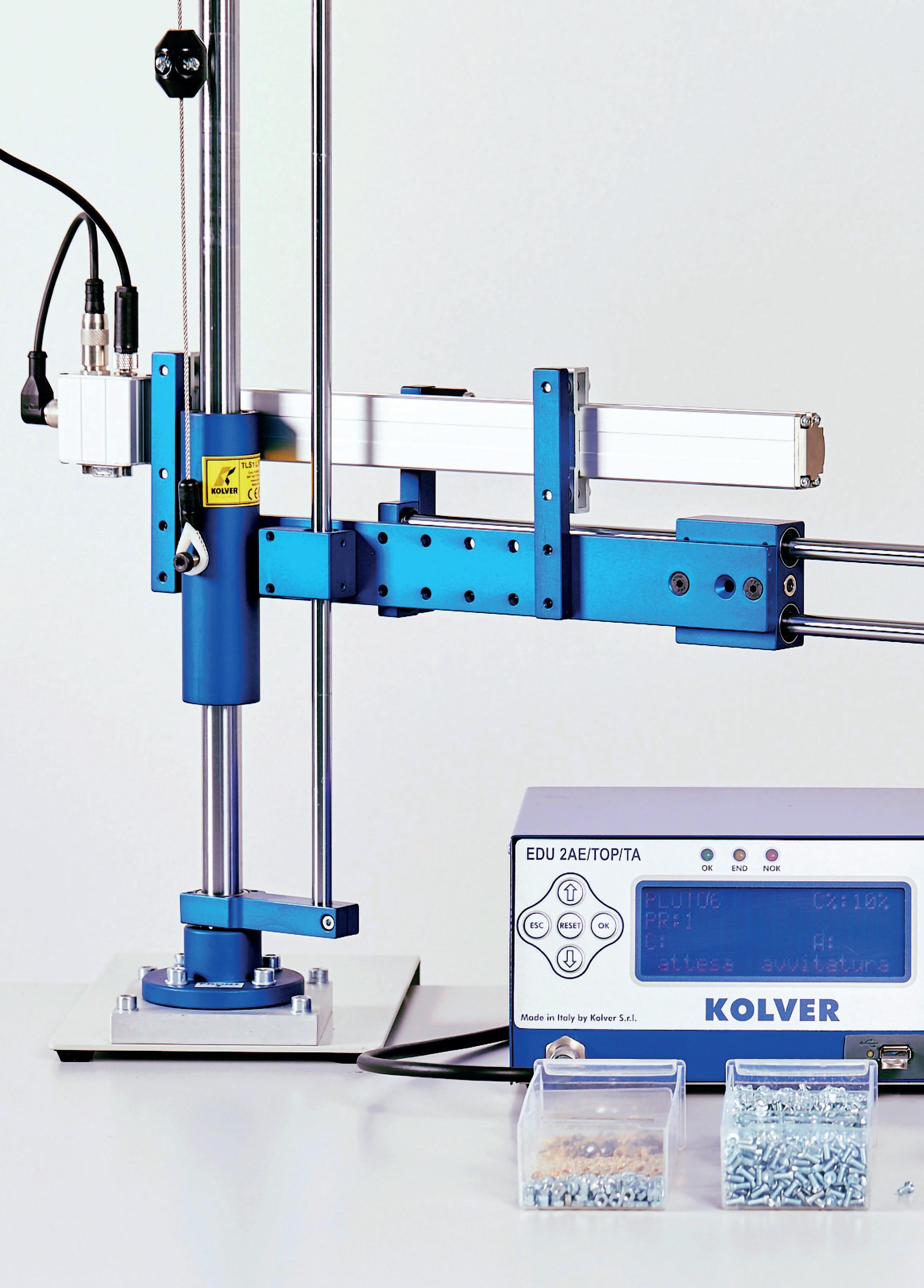

Specialist adhesives, UV curing, underfill, SMT adhesive, electronic kits, silicones, JBC soldering equipment and accessories, fume extraction, lasers, 3D printing, Kolver torque drivers, Vision inspection equipment, various production consumables - the product portfolio at V Tech is extensive. Even that feels like an understatement. Services also include downpacking, repair work,

The company is made by its people, not the directors. I think it’s a really good culture

site visits, demonstrations, product trials, and vendor managed inventory.

To get a better idea of how V Tech arrived in this esteemed position, we ask Ronnie about some of the key milestones behind the business. But the answer we get – at least initially – is not one we expect.

“Unfortunately, it doesn’t really work like that,” he begins. “In a way, it’s much simpler: you just focus on the key accounts, and then you go from there. The way we used to work was our engineers would spend one or two days with a company, make as many contacts as possible, and then go on to bring in the big accounts. Since many larger companies have moved abroad, we must work with a lot more companies to generate the same level of volume.

“We finished 2022 with record numbers,” Ronnie reveals. “The reason behind this is probably taking on new products, as well as

expanding into new, previously untapped markets. We like to think of ourselves as a one-stop shop for everything. One of our biggest accounts is Honeywell, and there is only one in Scotland, but they have given us access to look after other Honeywell site in the UK, which is definitely a broad one – from aircraft equipment and non-consumables to repair and workshop services. Yet, looking back over the last 25 years or so, there have been no key milestones to speak of – just lots of hard work.”

Naturally, the backbone of all that hard work has been built by V Tech’s people. “All our employees have been here for quite some time,” says Ronnie. “The company is made by its people, not the directors. I think it’s a really good culture. People have

always come to us after joining and said it’s not like this anywhere else!

“It’s also important to point out that I’m not the boss; instead, our boss is the customer and our entire workforce believes in that,” he goes on. “If an employee has a job to finish, usually they will stay after work and get it done.”

Picking up on Ronnie’s assessment of V Tech as a one-stop shop, we are eager to find out a bit more about what goes into the business and how it aims to deliver multiple services and products to customers, thus creating a holistic and diverse offering for its range of clients.

“At V Tech, our main product line is specialist adhesives,” Ronnie details. “Which have to be stored at -40C or have very long lead times which we manage for our customers,

so we are dealing with sophisticated products. Within the electronics space, this is becoming an increasingly diverse line, and we intend to capitalize on that.

“Moving on, we then supply everything that goes on a bench to manufacture or repair a printed circuit board,” he adds. “So, that means we are supplying the benches, microscopes, fume extraction, tools, soldering equipment, inspection equipment, as well as anything else that a client will need to carry out an array of circuit board manufacturing processes.

“Furthermore, we have our very own bespoke tool room that can make jigs and fixtures with a quick turnaround time. So, for instance, if someone wants a jig or a fixture, then we can produce one in as little as three days; whereas many other companies can take as long as four weeks to carry out the same task.”

For Ronnie, another important aspect that sets V Tech apart from the competition is the company’s acute focus on customer service and aftersales support. “Our customers know that they can call us at any time,” he says. “Rather than using up to 20 different companies, our partners understand that they can rely on us to do it all under the one roof.

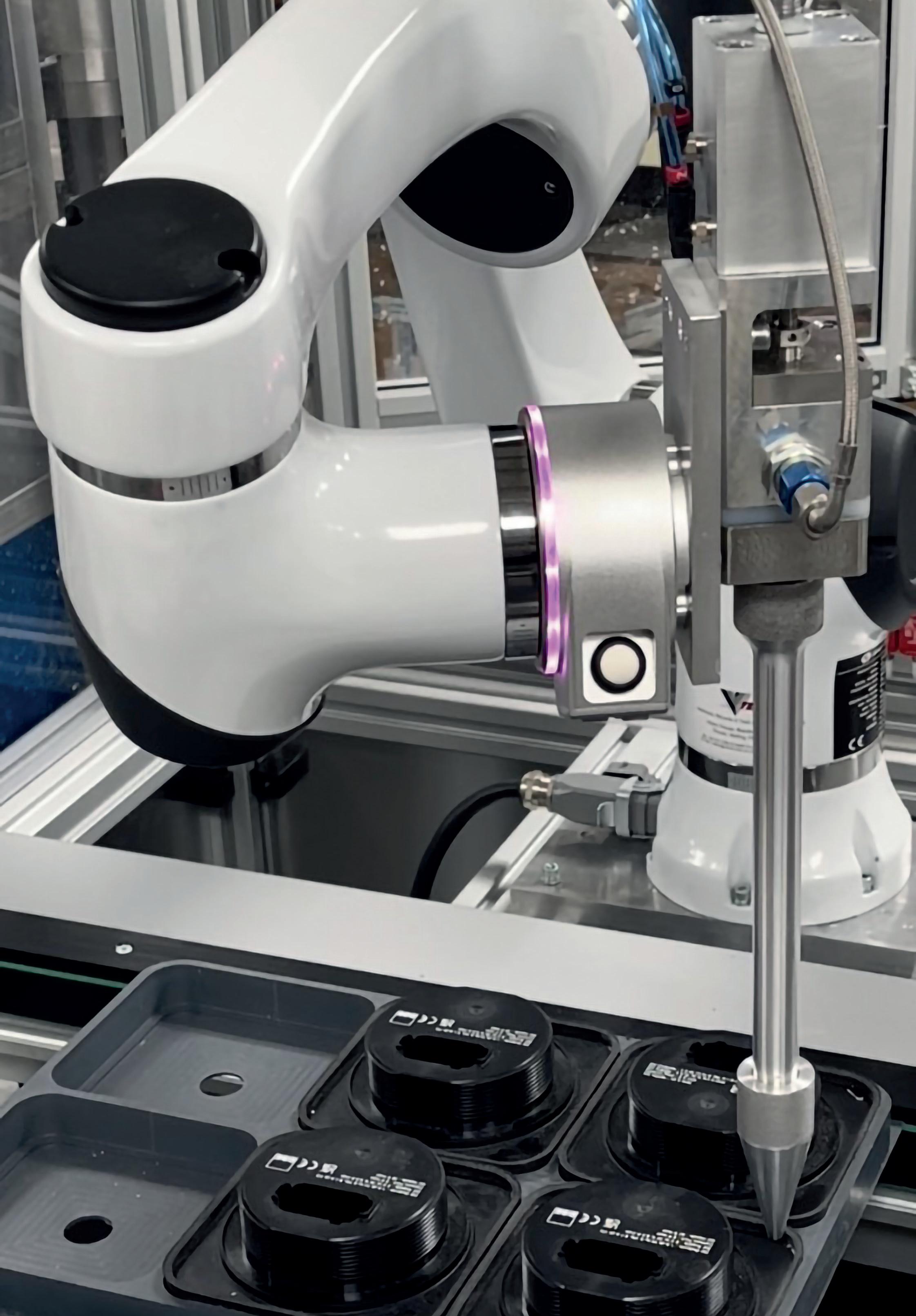

“Another unique selling point for the company is our appropriation of cuttingedge technology,” Ronnie continues. “We sell cobots and robots, but we don’t just supply them; rather, we will specifically configure the units to do exactly what the client wants. That means we always have software engineers on hand to integrate a cobot, which, for those that don’t know, is a unit that can work with no guarding on a bench alongside a human.”

“With these machines, you can carefully and accurately lay down an adhesive onto a board. It is a very fine and delicate process; tiny amounts are dotted along the board, and these dots are so small that they are hard to see with the human eye. These cobots can be quickly reengineered to do other sophisticated tasks such as soldering, screwing, encapsulation, handling and many more things”

As Ronnie goes on to explain, to promote full traceability, V Tech ships out all its technology with a unique barcode on every internal part (as well as the overall boxed shipment). The purpose of these individual barcodes is to ensure that customers, after scanning the item, can access a wealth of information, including how the part integrates within its wider system,

its expiry date, and its storage instructions (for instance, it might have to be kept above/below a certain temperature).

Entering 2023 off the back of a record year is a motivating time for V Tech, and Ronnie remains very optimistic despite the news that often clamors through our media devices. “We have recognized the trends: people are negative; things aren’t going well,” he concludes. “It is very difficult, but we now have more staff than ever, the phone is ringing more, and increasing numbers of orders are coming in. So, though Britain is going to get hit somewhere along the line this year, we are proudly bucking the trend. Looking ahead, we want to accrue more and more new customers and continue on our growth trajectory.” ■ www.vtech-smt.co.uk

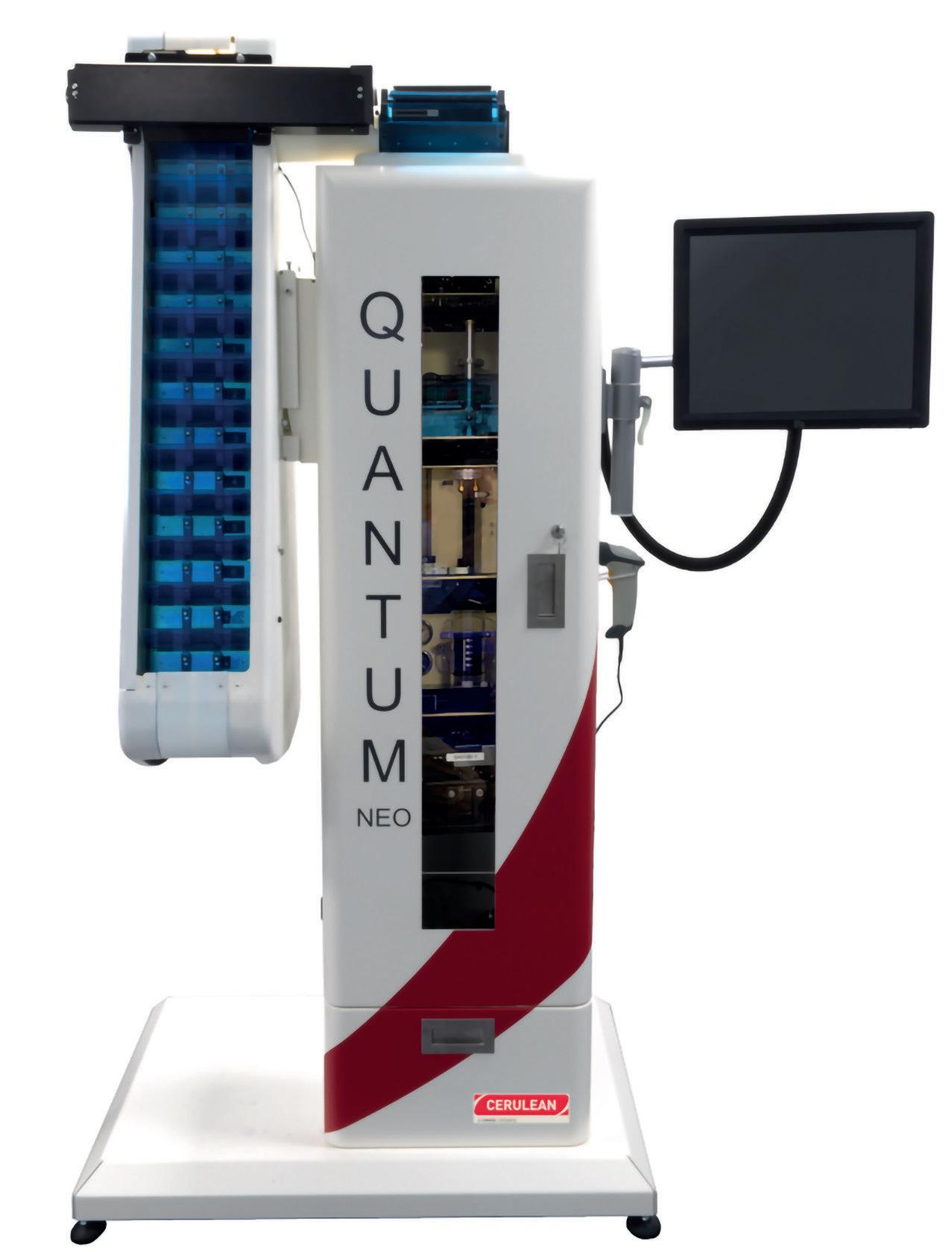

How global testing company, Cerulean, is experiencing tremendous success in unfamiliar markets

Established in 1945, and renamed in 2001, Cerulean is a worldleading provider of control, testing and measuring equipment. Having started exclusively in the tobacco industry, the company has gained a global reputation for innovation and precision, while providing excellent customer service.

Since its foundation, Cerulean has experienced tremendous growth and has successfully expanded into new markets beyond tobacco, such as food, chemicals,

and industrial goods. Steve Frankham, Managing Director at Cerulean, discusses the company’s growth, its innovative capabilities, and plans for the future.

Steve begins: “Originally, the business was part of Filtrona, the largest global manufacturer of cigarette filter rods. There was no testing kit on the market for those cigarette rods, so Cerulean was born as a division to fulfill testing requirements, initially for in house produced rods. It then grew rapidly, as other cigarette manufacturers

began to invest in testing kits for their own products. The division was sold to Molins Plc at the turn of the 21st century, and again in 2017 to Italian engineering company, Coesia. We are still dedicated to tobacco testing products, but we are now involved with other consumer products too.”

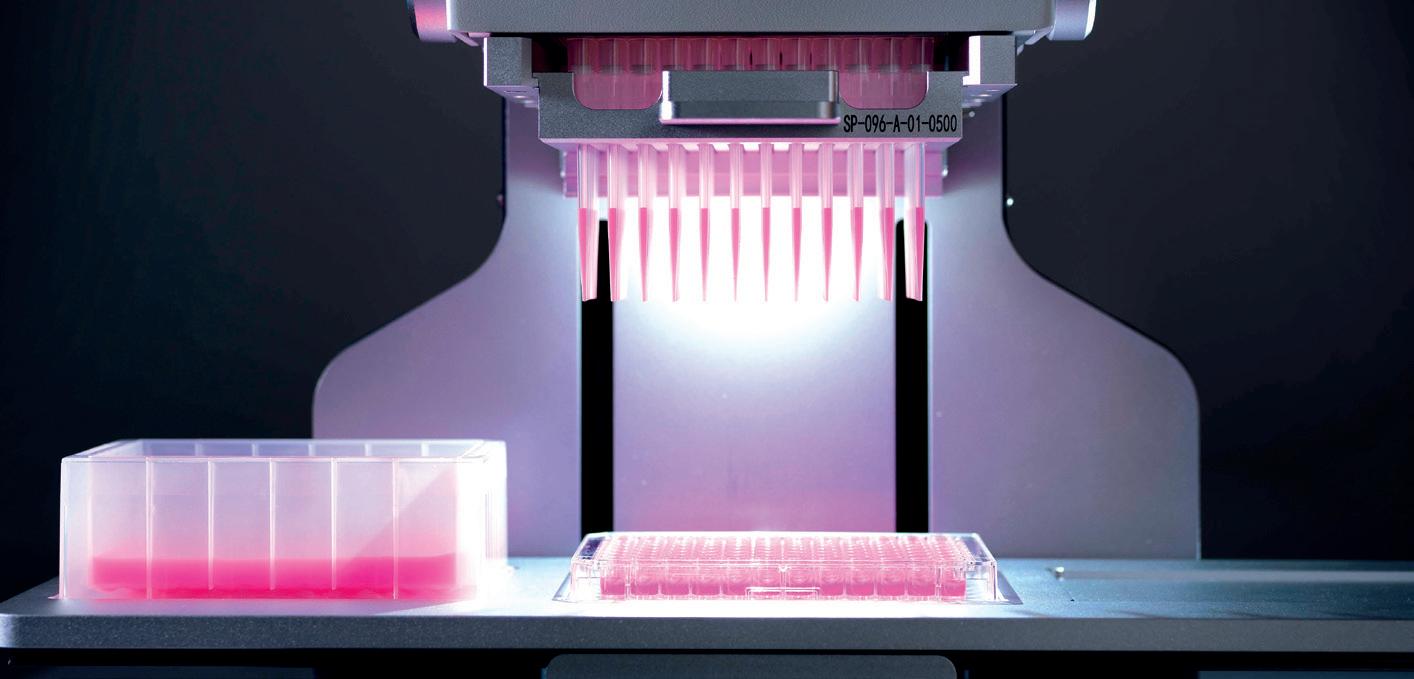

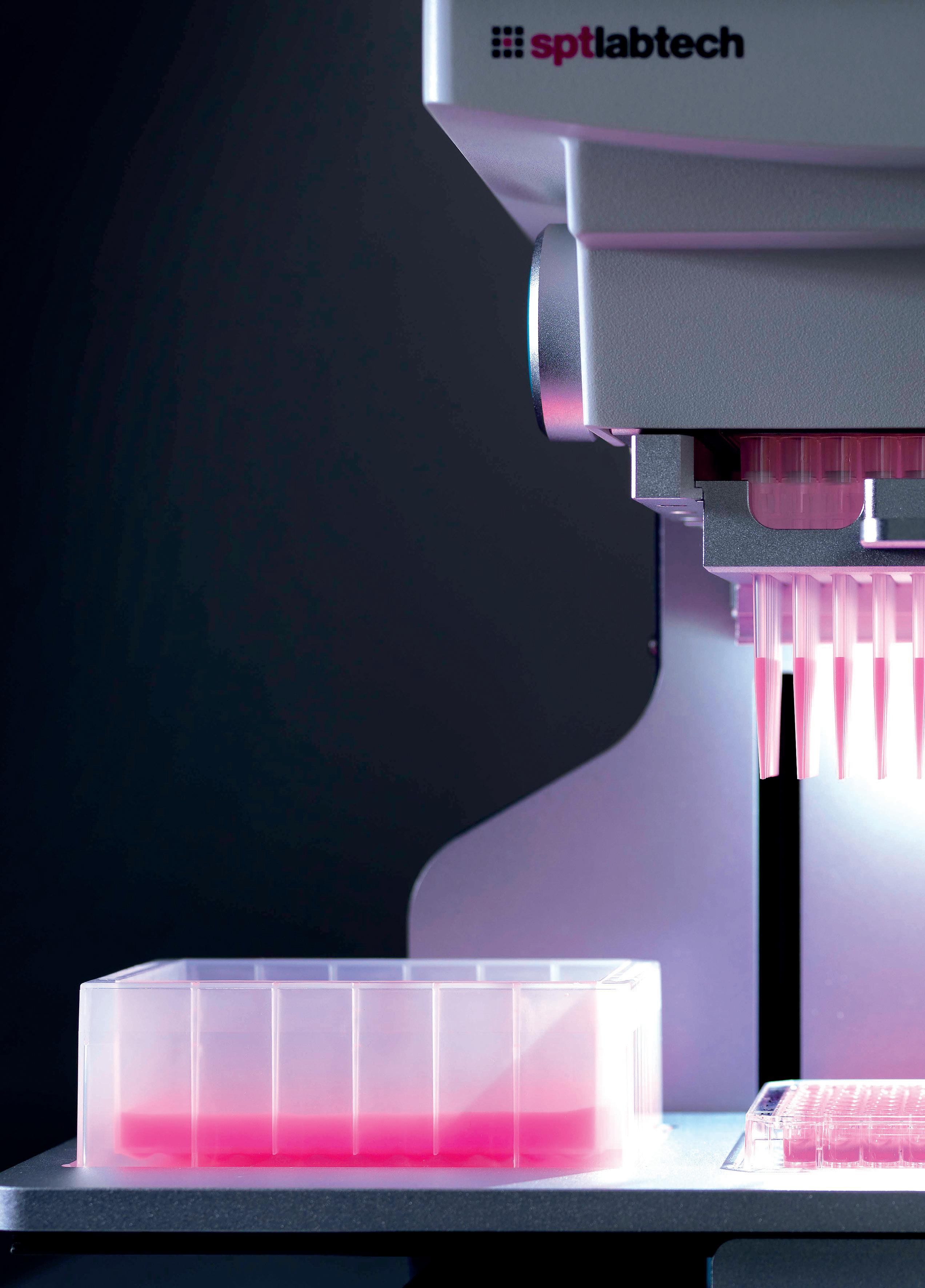

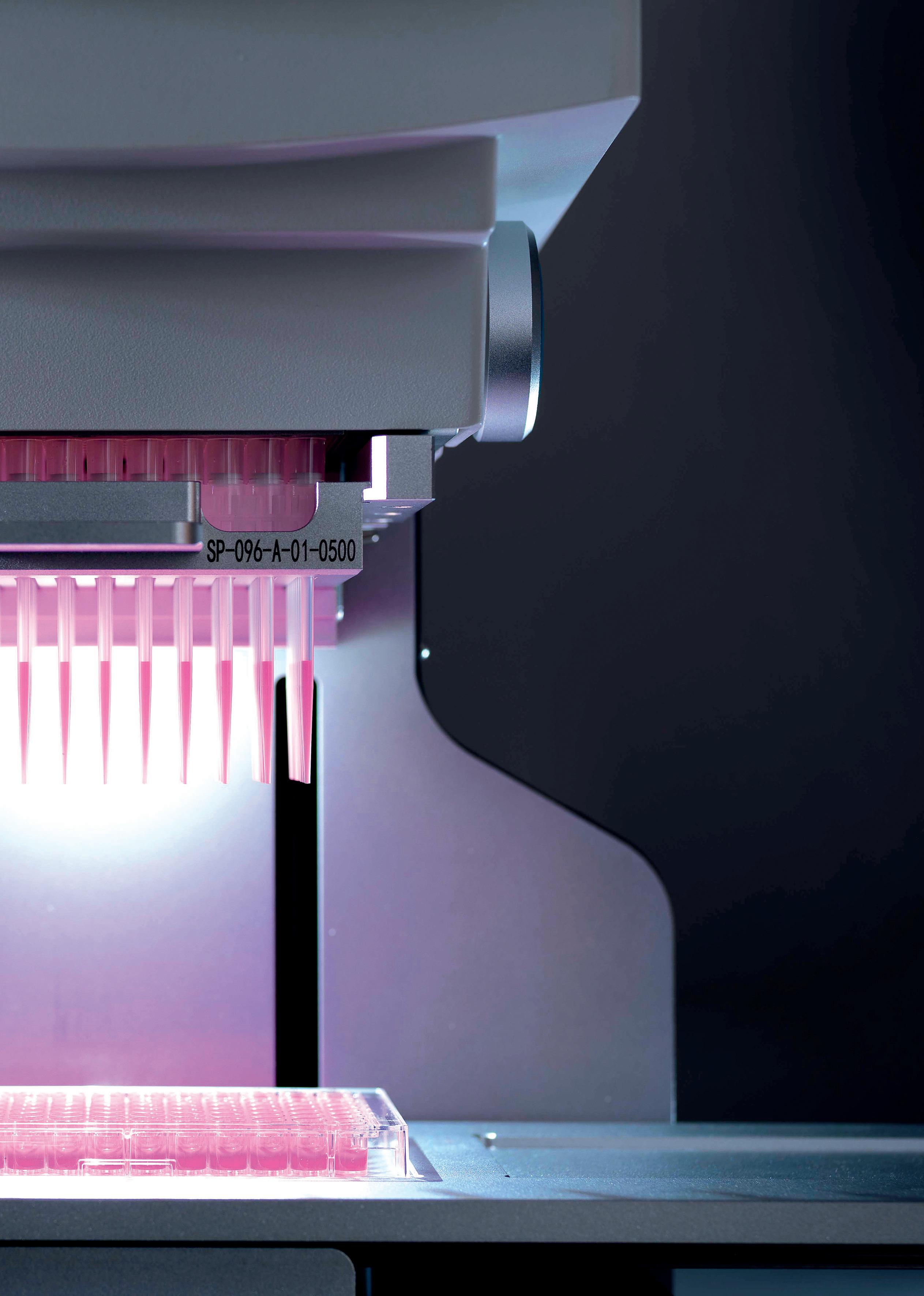

As Steve highlights, the company no longer operates exclusively in the tobacco industry, instead boasting a large array of solutions and capabilities for numerous markets. It has designed an air sampling range, for example, to detect enzyme and

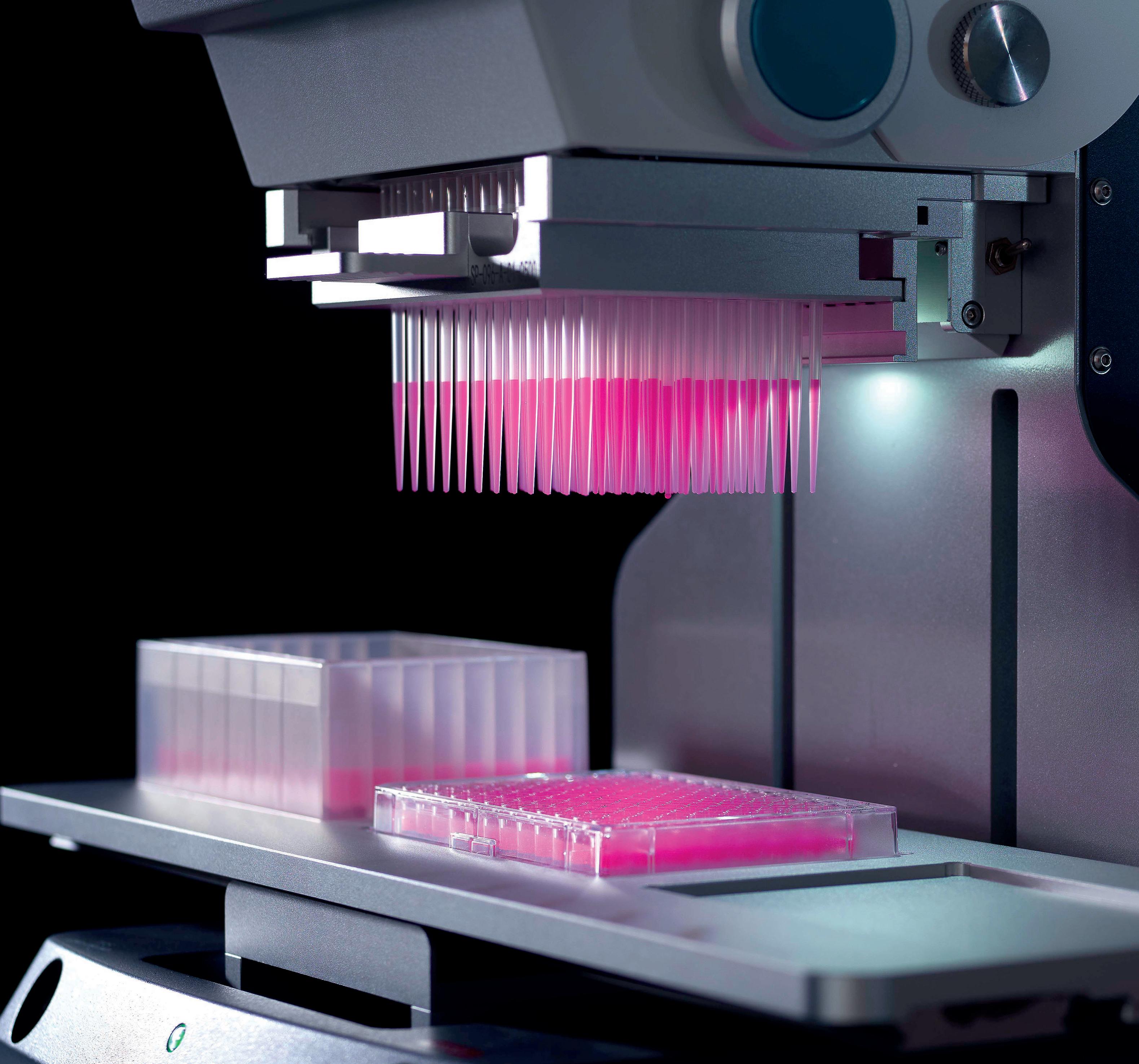

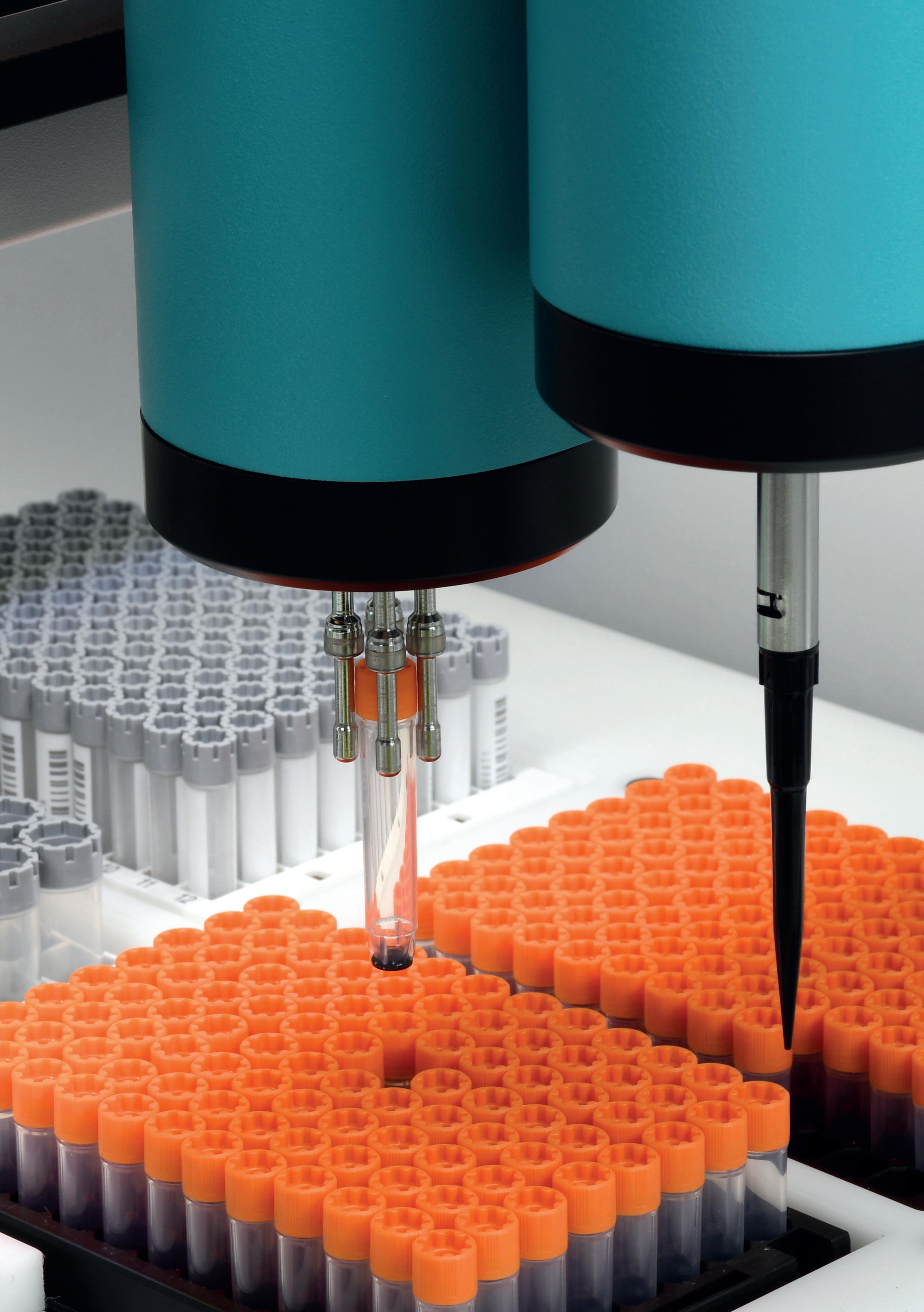

dust levels in specific environments such as detergent factories. Cerulean also offers a range of automated robotic systems for laboratory environments, particularly for the healthcare and pharmaceutical industry.

Additionally, the business has expanded into product testing machines for the cosmetics and personal care sector. Specifically, it has developed bespoke machinery for packing and testing unfilled tubes, such as those used for toothpaste and ointments. With machines for identifying leaks, inspecting packaging, and automatically checking caps and seals, Cerulean is revolutionizing the tube testing process by enhancing both its efficiency and accuracy. The company has also recently developed Celsius, a range of products designed for food temperature testing in the chilled and frozen food markets.

“The standard way of

measuring food temperatures is either using an infrared thermometer, which only measures surface temperature, or by probing the food to get a point measurement,” Steve explains. “But neither of these methods provide an accurate average temperature of the product. Celsius overcomes this issue by measuring naturally emitted microwaves that come off the product, which provides an average temperature.

“The product itself looks similar to a traditional microwave, but instead of heating food, the cavity is used for the measurement process,” he continues. “It is primarily used in the food industry during dispatch, so that the company or person in charge can demonstrate that the food was the correct temperature at the time of dispatch. It’s a real sustainability tool for the industry because it reduces food waste; products must be thrown away if a probe is used. It can also be used in food factories for process optimization, specifically to reduce energy being wasted on the cooling process. We have also developed software packages that enable all the data to be added to a database, which can be manipulated, downloaded, or used in exactly the way the manufacturer requires.”

He continues: “Our customers want information, not just a big piece of equipment, so the database we provide is just as important as the machines. Software

Our customers want information, not just a big piece of equipment, so the database we provide is just as important as the machines

is the biggest complexity within the business, and there are two elements to our software. Firstly, the physical workings of the machine; the valve needs to open and close at the correct time, for example. Then there is the data handling side, which includes managing the database, comparing results against specification, and producing reports.”

Returning to the tobacco industry, Steve explains the company’s work with heated tobacco products.

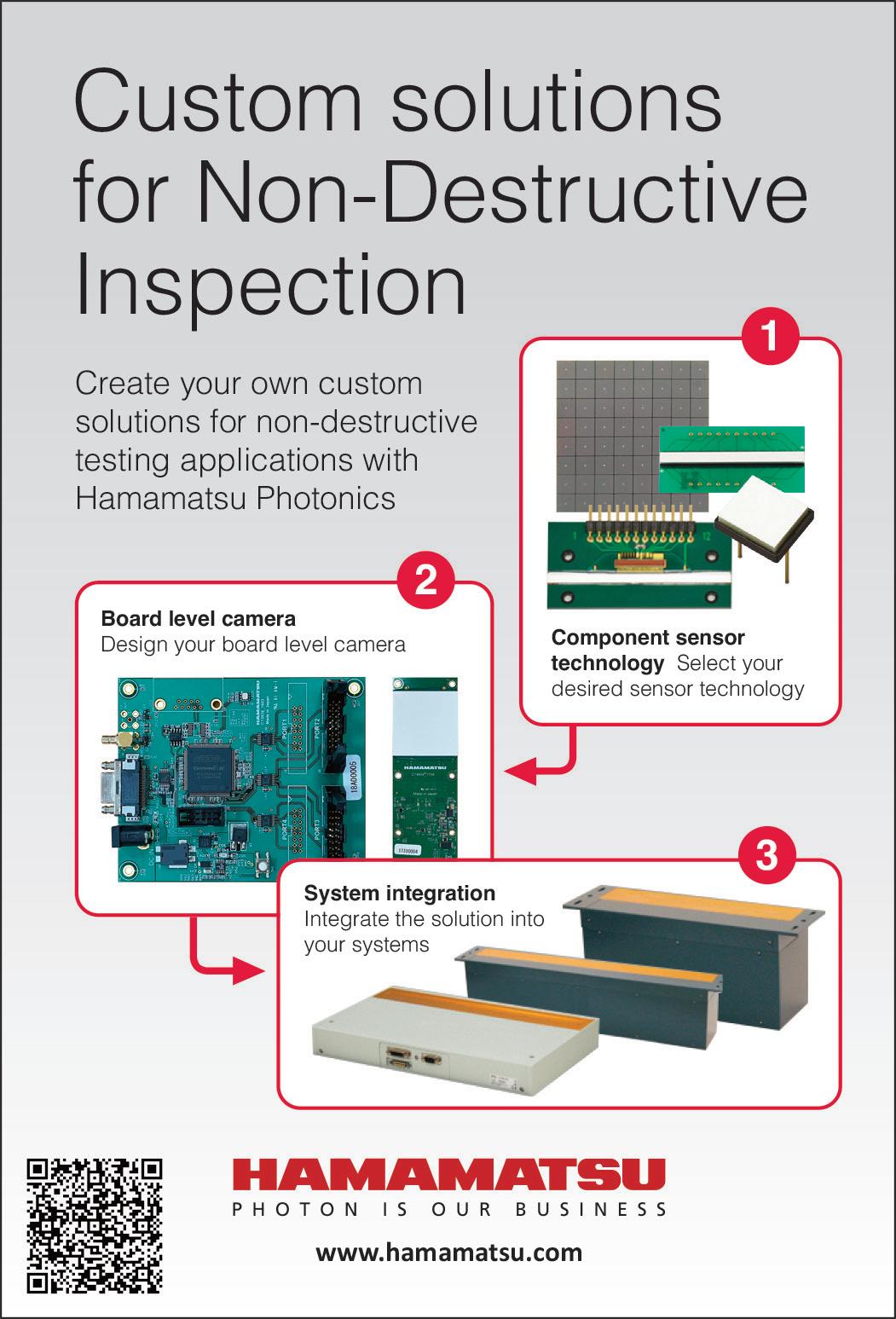

“These look like small cigarettes, but they are placed in a heater and the nicotine is released without the tobacco being burned, meaning the consumer gets the nicotine they want without the chemical combustion and residue associated with burning tobacco,” he describes. “These products have intricate internal features that need to be tested, but because they also can contain metallic materials, you cannot access the internal parts through ultrasound or microwave. Instead, we used X-ray technology to examine the product in various dimensions. In this case, we also worked closely with Hamamatsu, who developed an applicationspecific camera for us that not only fulfilled our measurement requirements but is also a cost-effective solution.”

Despite its constantly growing work in unfamiliar markets, Cerulean remains committed to its roots in the tobacco industry. It supplies physical property test instrument stacks, which “measure a myriad of things; weight, circumference, pressure drop, moisture content, or resistance to compression,” says Steve. These individual measurements allow the manufacturer to assess the physical properties of the product.

Turning to the people side of the business, Steve describes: “We are of a size where everyone knows each other and that shapes our inclusive culture. We encourage entrepreneurial attitudes and innovation, with everybody understanding

and respecting the framework in which this is managed. We are not a particularly hierarchical company, so everyone’s ideas are equally valued. Overall, we are friendly, hardworking, innovative, and flexible. We support our employees in taking their career in whichever direction they desire, helping them to grow and develop, both personally and professionally.”

Steve reflects on how Cerulean has navigated supply chain challenges, transforming potential problems into avenues of success. “It’s forced us to be more innovative,” he says. “We have used the supply chain difficulties to drive entrepreneurial and innovative culture within the business, encouraging the team to find available solutions to our shortages.

“We have been able to reengineer products by using available resources,” Steve continues. “We are fortunate that the

breadth of the business has grown outside of tobacco and into other industries because this allowed us to increase the supply and technology base of the business, which in turn helps fuel the innovative culture, and of course grow our overall turnover and make the business less dependent on one sector.”

Looking ahead, Steve concludes: “I hope that we can further spread our wings to engineer more growth and add to our platform of services and capabilities for existing clients, as well as new ones. Typically, it’s a lengthy process to gain new repeat customers, as it takes time to build up a rapport based on quality and trust. We must accept that this dynamic exists and strive to grow our customer base year-on-year.” ■

www.cerulean.com

How CarnaudMetalbox Engineering is using its growth and expertise to meet consumers’ demands for sustainable packaging solutions

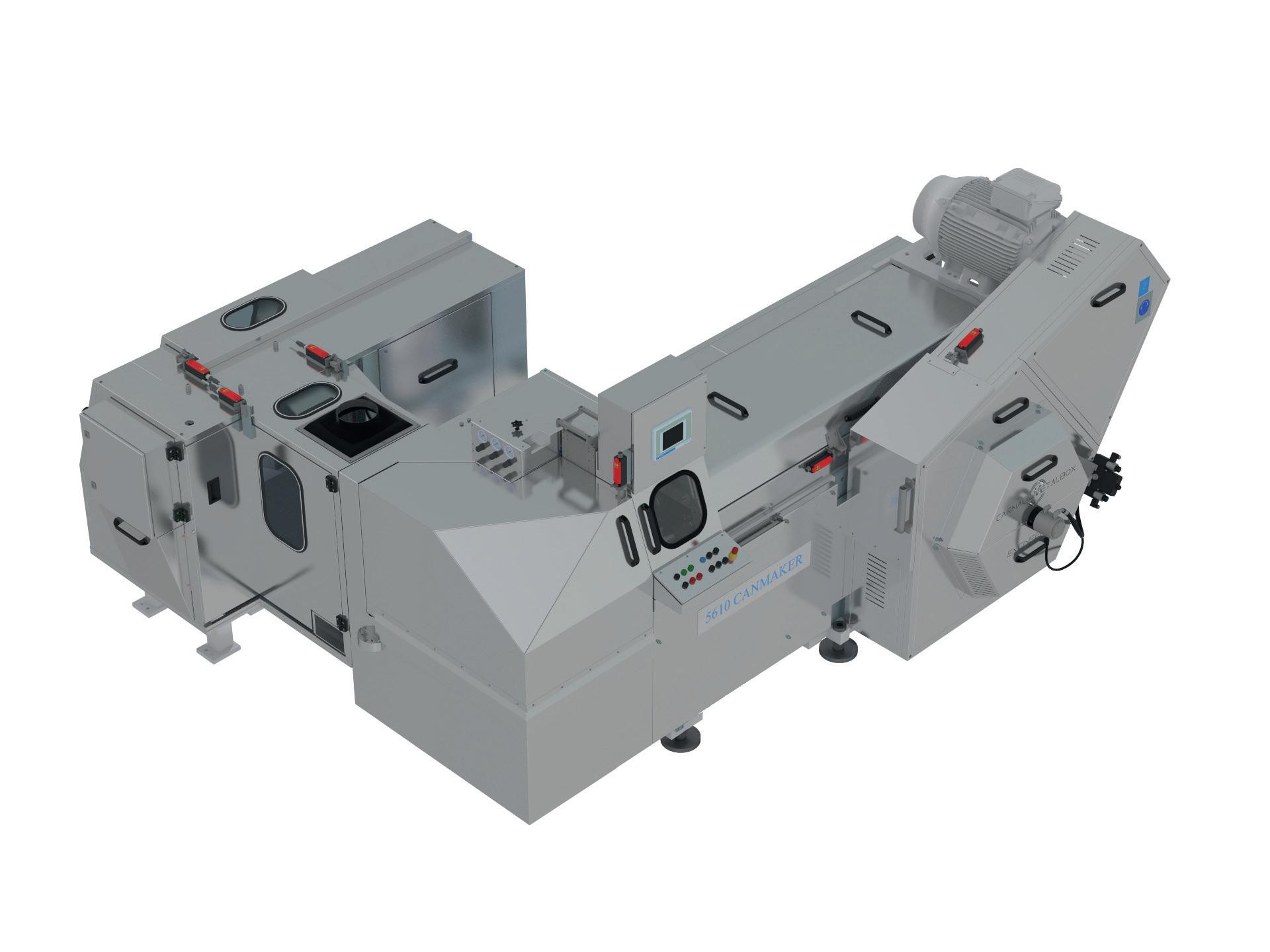

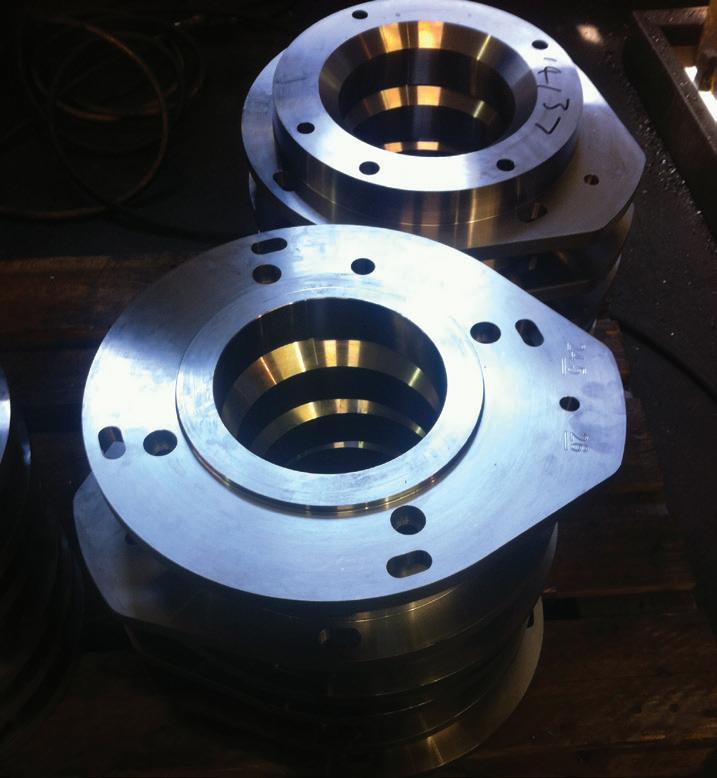

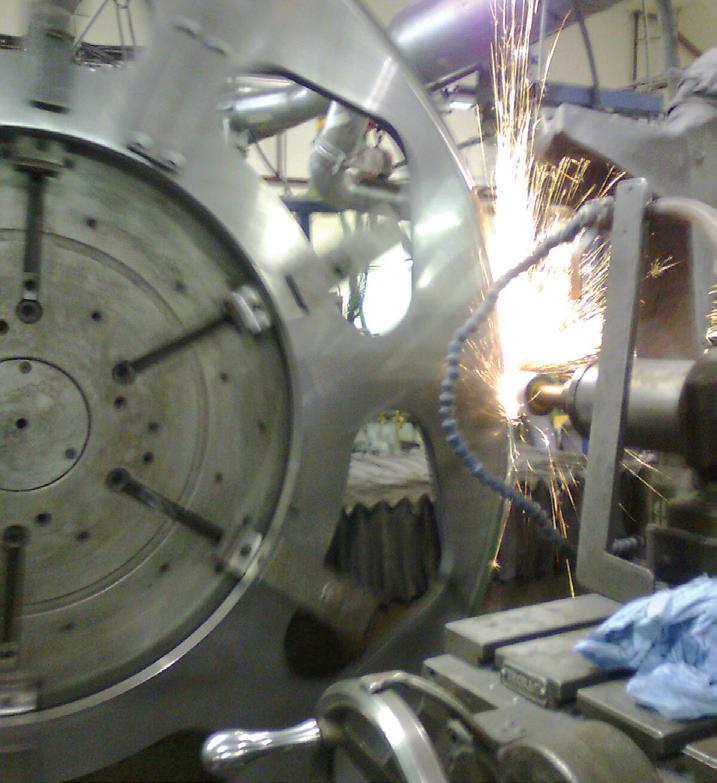

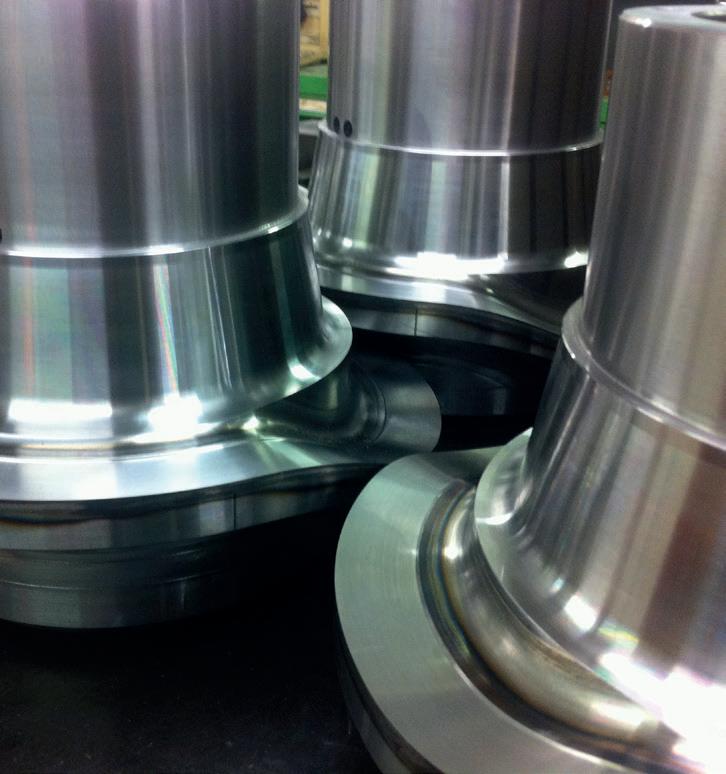

CarnaudMetalbox Engineering (CMbE) is a leading manufacturer of can making machinery and seamer tooling systems. It is a customerdriven operation with equal dedication to efficiency, quality, and sustainability.

As part of Crown Holdings Inc, one of the world’s leading producers of metal packaging, CMbE serves an international market, with offices in the UK, United States and China. Having spoken to Marc Hoche, Vice President at CMbE, in February last year, Manufacturing Today was keen for an update about its continued success and the new facility in Leeds.

“Following on from last year’s article, I still feel people are more aware of packaging, particularly in terms of its sustainability, and the can is one of the most recyclable containers around,” begins Marc. “Production lines can run up to 3400 cans per minute, so you can imagine the amount of engineering that goes into the container and the production machinery that must operate at such high speeds.”

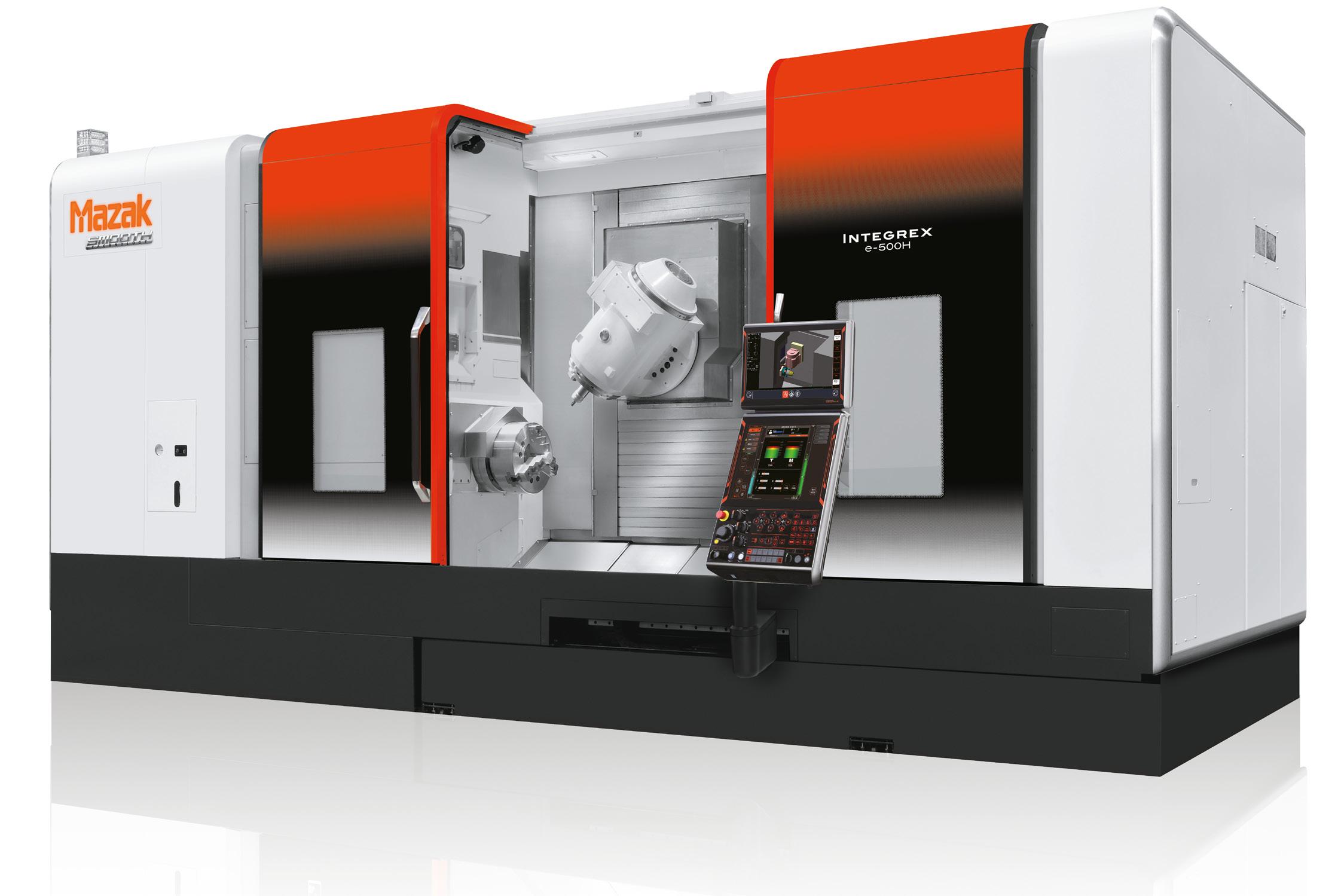

With further investment CMbE now have a world class manufacturing facility, including fully automated Mazak ‘Multi-Tasking’ cells

Founded in the 1930s, CMbE has nearly a century of experience and expertise in cuttingedge metal forming and finishing equipment. In 1986, it won the Queens Award in Technological Achievement for its revolutionary design of a new Spin Necking system. Its precisionengineered machinery, such as the Bodymaker, remains an effective design, as does the Trimmer, and when combined, the two offer a high-speed fully integrated can making machine. Indeed, the business takes inspiration from its history of engineering excellence. Today, it continues to develop innovative can making machines, as well as decorating systems and technology.

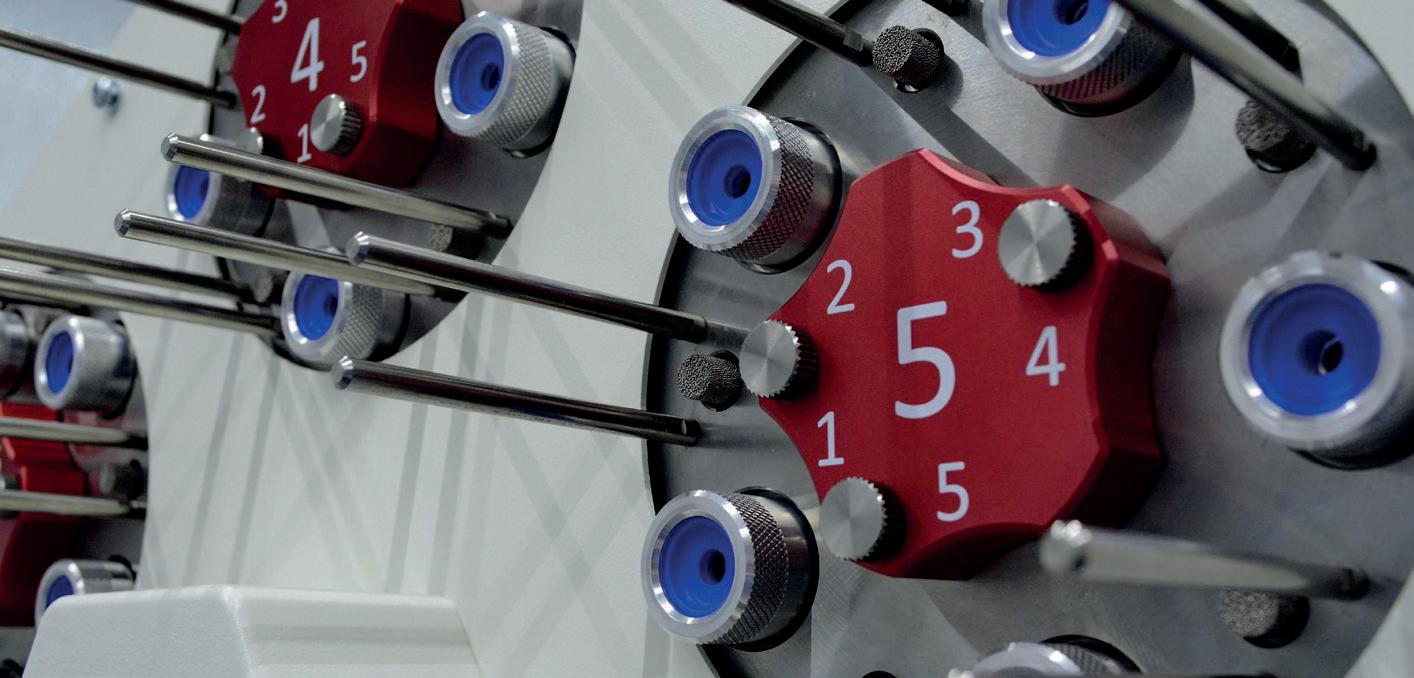

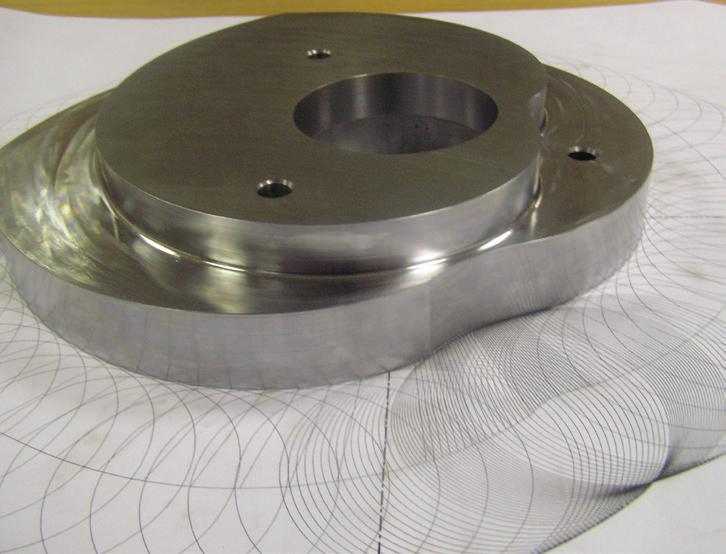

▲ FJW-100/160

▼ Canmaker

▲ FJW-100/160

▼ Canmaker

Its decades of industry knowledge and experience shine through its designs and have enabled its tremendous growth and success.

“We have been in the industry for a very long time,” explains Marc. “We have been manufacturing can making machines for more than 85 years – from the birth of the industry really. In 2024, we will have been at our purpose-built Shipley site for 60 years and we have grown quite considerably in that time, with the recent expansion to the new facility in Leeds. By September 2021, we were laying our first customer machines down for assembly at the new site, having completed an £8 million refurbishment,” recalls Marc, “which was a Herculean effort to achieve and a credit to all the teams involved. 2023 marks some significant milestones in machine production, including the 2000th

Bodymaker, the 1000th Die Necker and the 100th ReformatTM Spray Machine.”

Prior to its new facility in Leeds, CMB Engineering’s headquarters in Shipley included both the manufacturing and assembly elements of the company. Its Leeds site is now home to the assembly shop, which has doubled its capacity and cleared space in Shipley for other developments.

“Our new site has given us the opportunity to reorganize the manufacturing environment. Underpinning the concept for the layout, has been the optimisation of material flow through the complete manufacturing process,” Marc adds. “With further investment CMbE now has a world class manufacturing facility, including fully automated Mazak ‘Multi-Tasking’ cells, benefitting from the complete fusion of CNC turning and a machining center all in one, offering ultimate flexibility and lights out production. Due to the nature of the

product range, the investment in automation has been carefully considered to maximize productivity whilst maintaining flexibility. The flagship of the new investment is a Mazak Versatech vertical milling machine, 37m in length and boasting a maximum workpiece capacity of 9m x 4m x 1.2m, making it one of the largest capacity production machines in the UK. The optimised layout, along with the new manufacturing capabilities and automation, provides CMbE with a fully integrated manufacturing environment taking full advantage of new technologies.”