Thanks to early career researchers like Janet Reid, New Zealand’s future research, science and innovation system is in strong hands. Summer internships at Scion help to foster the next generation of talent, providing a platform for university students to grow while advancing research important to Scion and our research partners.

Discover how our 2022-23 summer students are contributing to projects that support New Zealand’s transition to a circular bioeconomy on page 62.

We’re excited to share that this bumper edition of Scion Connections will be released at the Scion Symposium on a Transition to a Circular Bioeconomy in Wellington on 22 February. Scion has been working to enhance the prosperity, wellbeing and environment of New Zealand for 75 years. As part of this anniversary we are bringing together innovators, policy thinkers and influencers for an in-person panel discussion and networking opportunity. We’ll give you all the insights from this event in the next edition of our magazine in June. Climate change is impacting all of us and science that supports efforts to mitigate its effects are needed now more than ever. Our scientists care deeply about this issue and are committed to finding solutions to the climate change crisis. It’s a crisis that needs to drive major behaviour changes and new ways of thinking about how we shape New Zealand’s future around a circular bioeconomy. We’re using this issue to share stories about how scientists across our Rotorua and Christchurch campuses are leading the way with innovative research and technology. We’re also highlighting how partnerships and collaborations are at the heart of how we work. We’re delivering science that matters and our stories demonstrate how our research offers hope for a greener economy and a more sustainable future. Stay connected to Scion by visiting our website. We also welcome engagement with you on our social media channels. We hope you take some time to enjoy this very special publication.

03 Time critical on climate change action

06 Rotorua to host international remote sensing forestry conference

08 Reducing emissions: Magnifying New Zealand’s impact

12 Kawenata honours spirit of partnership

15 Where’s my drone?

16 Packaging a punch

24 Ticking all the boxes

26 Nursery responds to SOS from Timaru

28 Accessible information vital in extending knowledge of wildfire risk

31 Educating next-generation scientists

32 Marine biofuel to support sustainable shipping

34 Ecogas opens flagship bioenergy facility

36 Getting to the guts of gas

37 Kete of work underway to combat myrtle rust

40 Science recruits target myrtle rust species

42 Genomic tool for radiata pine –a game changer

44 Forestry’s bright future

46 New roadmap for forestry and wood processing sector

48 Biosecurity in safe hands

49 Biological control of giant willow aphid recognised

50 Flexing creativity through innovation

52 Clothes to roads: Innovation explores untapped resource

54 New approach to predict growth of forestry tree species

56 Small things add up

58 Scion develops R&D solution to tackle plastic waste for nurseries

Time critical on climate change action

www.scionresearch.com

60 Scion gets salty with marine biology

62 Creating new science leaders

64 Excellence rewarded

66 Roadmap for Oceania

67 Celebrating research excellence

68 Wood in super resolution

69 Photography exhibition celebrates 75 years of impact

COVER:

As recently as January 2023, we were reminded about the devastating impact of climate change when floods ravaged Auckland and parts of the North Island. As repeated extreme weather events take their toll on communities, infrastructure and our environment, there are growing calls for greater climate change action. At Scion, we are rising to the challenge and leading the way with research that supports the growth of our forestry sector and the development of new technologies that use trees and other renewable materials to create products that can replace those made from fossil fuels.

Forestry is already recognised as a vital means of tackling climate change. It plays its part in two ways. First, it will help achieve New Zealand’s net-zero target by removing CO2 from the atmosphere. That’s essential to our climate change response as sequestration of carbon by vegetation is the only viable technology to reduce and offset the carbon that we’ve already put into the atmosphere. Sustainable plantation forestry also has a role in reducing our gross CO2 emissions by substituting products, fuels and energy made from fossil fuels with renewable wood and fibre-based alternatives.

Forests collectively – both production and long-standing indigenous forests – are a massive renewable resource with the scale needed to provide New Zealand with low-emissions materials and fuels. As a country looking to avoid further catastrophic outcomes, we must invest in research and innovation that unleashes the power of forestry for its ability to mitigate the effects of climate change and chart a course for a low-carbon, circular bioeconomy future.

The challenge for our sector is addressing how to accelerate this work. Scion strongly supports the vision set out in the government’s Forestry and Wood Processing Industry Transformation Plan (ITP) launched by the Minister of Forestry Stuart Nash last year at Fieldays. The ITP’s five goals feature actions to transform the forestry and wood processing sector in New Zealand. It’s a plan that reinforces the relevance of Scion’s Strategy to 2030: Right tree, right place, right purpose, and the leadership role that we have in research that will drive development of new manufacturing sectors and low-carbon products. The ITP has underlined the opportunities for industry, iwi and New Zealand when we all work together to maximise the potential of fibre and trees.

That vision and mission-focused approach is also central to the Te Ara Paerangi – Future Pathways process that the Minister for Science, Research and Innovation, Dr Ayesha Verrall, set out in a white paper launched last November.

We’re excited by the vision and policy directions outlined in the paper as they illuminate a pathway to build a research, science and innovation (RSI) system that supports wellbeing for all New Zealanders. We’re looking forward to working with MBIE to bring that vision to reality.

Scion is kickstarting 2023 with an event in Wellington to bring people together to stimulate conversation about the circular bioeconomy and its critical importance for New Zealand. We care deeply about ensuring that the ‘take, make, waste’ linear economic model is replaced by one where the word ‘waste’ is redundant. Our Strategy to 2030 is leading New Zealand in this transition towards a model where waste from one process becomes feedstock for another. The concept aims to design out waste, keep materials in use for longer, and regenerate ecosystems.

As well as helping New Zealand and the world meet its climate change targets, a forest-based circular bioeconomy is a $30 billion economic opportunity that will provide a mosaic of activity for regional New Zealand to thrive, through emerging bio-based manufacturing, and the creation of new high-value products from what we currently consider waste.

Integral to our success are partnerships with industry, the wider research sector, government and iwi. In this issue of Scion Connections, we’re showcasing the breadth of Scion’s research capabilities in packaging and we highlight how our science activity in forest health, biosecurity, genetics and bioenergy is having a positive impact. You can also read about the growing relationship that Scion has with tangata whenua at the site of our Rotorua campus, through the signing of a Kawenata between Scion and Ngāti Hurungaterangi, Ngāti Taeotu and Ngāti Te Kahu (Ngā Hapū e Toru).

Our mission is to enhance New Zealand’s prosperity, wellbeing and environment through trees. We have great confidence that our excellent science and research, supported and empowered by a coordinated RSI system, will lead the transition to a circular bioeconomy and put New Zealand firmly on track to a sustainable, productive and inclusive low-carbon future.

DR. JULIAN ELDER. CEO, SCION.

Kia ora,

What’s inside

Scion’s 75th anniversary year continues, and it’s clear that the future of forests and forestry are fundamental to New Zealand’s future wellbeing and prosperity.

instagram.com/scion.research linkedin.com/company/scion twitter.com/scion_research youtube.com/user/scionresearch

your Scion Connections delivered by signing up at www.scionresearch.com/subscribe

2230 - 6137 (print)

2230 - 6145 (online)

2023 New Zealand Forest Research Institute Limited, trading as Scion. C000000 From responsible sources MIX

Sign up online Get

ISSN

ISSN

Copyright

04 Endeavour funding success

Scion Connections ISSUE 42 | FEBRUARY 2023 3

Healthy root structure in the baby giant redwood tree. (Champagne tree story, page 26).

Endeavour funding success

Two innovative Scion research projects will receive investment funding totalling $1.9 million over three years through the Ministry of Business, Innovation and Employment’s 2022 Endeavour Fund.

Scion scientists will also contribute their expertise to a further six projects involving other research organisations that secured Government support from the Endeavour Fund – New Zealand’s largest contestable research fund.

Endeavour funding was announced in September 2022 for the two successful Scion projects and will come from its Smart Ideas investment mechanism. Smart Ideas is intended to catalyse and rapidly test promising, innovative research ideas with high potential for benefit to New Zealand.

One pioneering Scion project, in partnership with the University of Cambridge, Implanted sensors monitoring tree health and carbon capture efficiency, will receive $1 million over three years to design sensors to measure the nutritional status, vitality, carbon capture efficiency and microbiome fitness of growing trees.

Precision forestry uses remote-sensing tools such as satellites and drones, combined with sophisticated sensors, to detect subtle variations in plant health, nutrient and water status.

Monitoring the physiological processes inside trees in real time is the only way to fully understand how trees are responding to the environment around them and to future-proof their resilience to climate change.

To implement this in practice, Scion will develop sophisticated low-cost bioelectronic sensors which can be implanted inside trees. These types of sensors have been used in biomedical research – but rarely used inside trees for forestry. Their use in New Zealand radiata pine will be pioneering.

Data generated by these sensors will be transmitted from the trees via a wireless network in the forest.

Fusing data from remote sensing together with physiological sensors within trees, combined with genome and climate data, can provide the most complete insights into a growing forest anywhere in the world.

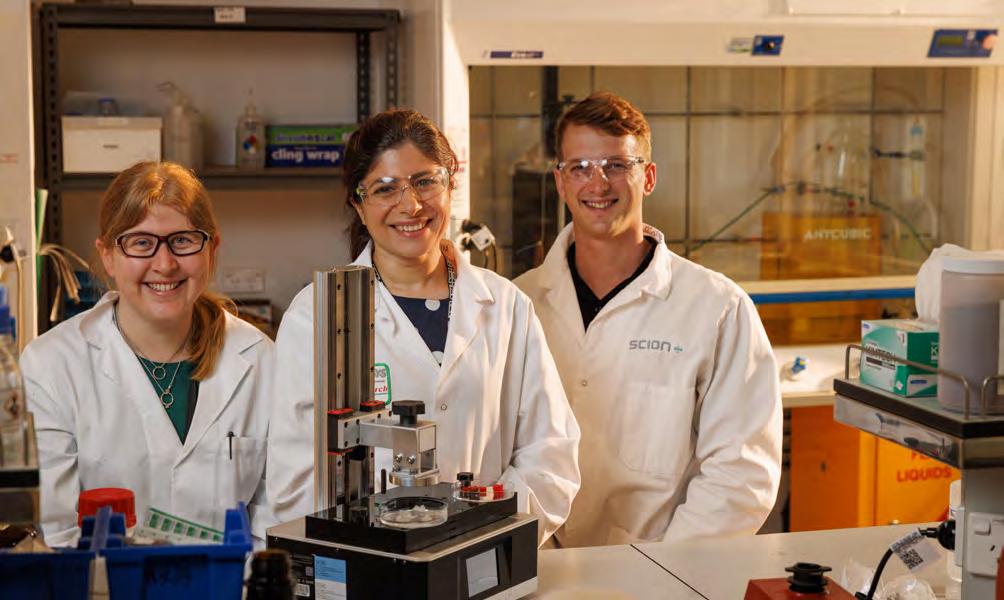

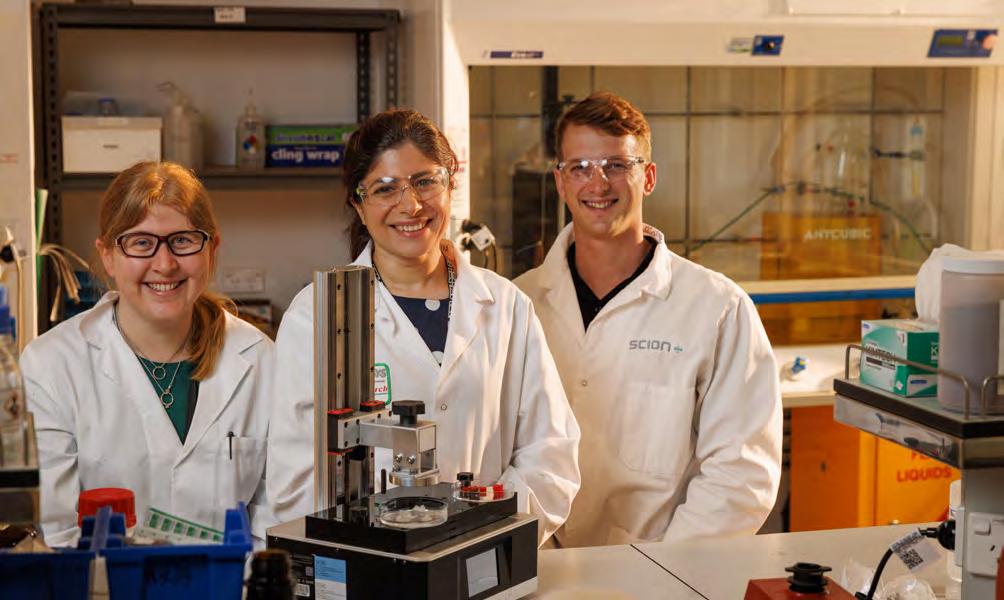

Successful too, was the Scion proposal Plant-inspired 3D-printed scaffold for tissue culture. Awarded $900,000 over three years, Scion scientists will explore new technology that aims to improve the tissue culture technique that makes clonal forestry possible in conifers.

Commercial forestry relies on producing vast numbers of trees – often elite clones. Somatic embryogenesis is the tissue culture technique that is used to create embryos for this purpose, but it has some limitations.

Somatic embryos can have trouble maturing on a flat surface – effectively when they are sitting on a dish on a laboratory bench. In nature, these embryos would mature in a complex three-dimensional structure as they interact with other cells and respond to different gradients and signals of temperature, mechanical force, nutrients and plant hormones. Replicating this environment is extremely challenging in the laboratory, yet it is the key to successful tissue culture. This project will adopt sophisticated 3D printing techniques using hydrogels to create a scaffold with gradients of hormones, nutrients and porosity along its length. To visualise this scaffold, imagine a large cardboard tube with round holes in the sides and complex gradients of hormones and nutrients along its length. While the immediate application is in the forestry industry, the same technique can be applied to other plant species, mammals and create new biomedical opportunities. Scion’s project team will collaborate with Massey University and Terasaki Institute in the US.

Science leaders at Scion will also contribute to six collaborative projects that received a total of $5,754,700 from the Endeavour Fund. They involve joint research with the University of Auckland, WSP Research NZ, Manaaki Whenua – Landcare Research, Lincoln University, Auckland University of Technology and Massey University.

Scion chief executive Dr Julian Elder says the Endeavour funding acknowledges the value of forests and their contribution to a more prosperous economy and healthier environment.

“Forests will be at the heart of a low-carbon future New Zealand. At Scion, we’re proud to lead research that will unleash the power of forestry, tackle climate change and help transition New Zealand to a circular bioeconomy.

“We look forward to supporting our teams as this important research gets underway.”

The Endeavour Fund supports excellent research with the potential to positively transform New Zealand’s economy, environment and society. This year a total of $236.5 million has been allocated to 71 projects.

CLOCKWISE FROM ABOVE:

A Scion research team is exploring new technology to improve the tissue culture technique that makes clonal forestry possible in conifers. Pictured (from left) is cell biologist Tarryn Saggese, principal investigator Roya Rezanavaz and design engineer Karl Molving. Multi-material 3D-printed prototypes, the first step in a three-year Endeavour funding project.

• Scientist Yi Chen is taking a lead role at Scion in a project partnering with the University of Cambridge that explores the benefits of inserting bioelectronic sensors in trees to generate information about tree health and carbon capture.

Small sensors are being inserted into pine trees only one or two years old. The first stage of the research project is measuring the tree’s wound response.

Small sensors are being inserted into pine trees only one or two years old. The first stage of the research project is measuring the tree’s wound response.

Scion Connections ISSUE 42 | FEBRUARY 2023 5 4

Rotorua to host international remote sensing forestry conference

Rotorua and Whakarewarewa Forest will be the backdrop to a global forestry conference that is set to attract up to 500 remote sensing specialists to the city from 9–13 September 2024.

Scion has successfully secured a bid to host ForestSAT 2024, the most prestigious international conference on the application of remote sensing technologies for forest monitoring and modelling.

Previous conferences have been held in Germany, USA, Chile, Italy, Spain, France, Sweden and Scotland. For the first time the conference will be in Australasia over five days in September 2024. Scion’s general manager for Forests to Timber Products, Henri Bailleres, says the event will be an incredible opportunity to showcase New Zealand and Scion.

“Scion has a strong remote sensing group with international outreach and a wide industry network within the New Zealand forestry sector,” he says.

“The hosting of ForestSAT in Rotorua by Scion highlights the excellence, standing and reputation of our science with our global peers, as well as showcasing Rotorua as a premier tourist destination.”

Scion principal scientist Dr Michael Watt, who leads many remote sensing areas including modelling of forest carbon capture and use of hyperspectral imagery, presented at ForestSAT 2022 in Berlin.

He was impressed with the overall quality of presentations at the event and thought that New Zealand had a reasonable chance of hosting the next conference. Working closely with Tourism New Zealand, the Scion team, led by Watt and Bailleres, submitted an application that was unanimously approved by the ForestSAT board of directors.

“What New Zealand and Scion does is unique globally,” says Watt.

“Our group’s research is competing on the global scene and is attracting interest from many overseas forestry companies and research organisations.”

Global heavyweights in remote sensing for forestry are expressing their excitement about the opportunity to visit New Zealand in September 2024.

Founder of ForestSAT and former conference chair, Dr Juan Suarez, says Rotorua is one of the most important innovation hubs in forestry science worldwide.

“Hosting the conference will enable Rotorua to cement its global reputation in this area, connect academia with a forestry industry actively embracing new tools and technologies and attract new practitioners that can lead the transition to 21st century forestry.”

Canada’s research chair in remote sensing, Dr Nicholas Coops, from the University of British Columbia, says he’s looking forward to attending ForestSAT for its stimulating talks and impressive field tours, with the added benefit of enjoying New Zealand’s scenery.

“The conference has a strong history of bringing together leading practitioners and academics working in this field from across the world. After a very successful meeting in Germany, it is fantastic to know that this event will be held in New Zealand who are leaders in the application of spatial analysis technologies to forest management.”

Whakarewarewa Forest and its diverse range of exotic tree species and native undergrowth is renowned for mountain biking and walking. Uniquely, it also forms part of the largest production forest in New Zealand, which is monitored using state-of-the-art remote sensing methods.

Puruki Forest is also likely to capture the attention of conference participants. About half an hour out of Rotorua, Puruki is a nationally significant experimental forest. Data and models from Puruki underpin almost every management decision New Zealand’s forestry companies make today. As planning for the next rotation begins, there is an opportunity to design new sets of trials and create an internationally important forestry science resource.

“Allowing international delegates the chance to visit this forest could provide opportunities for co-design of the next forest,” says Bailleres.

“There is the potential for Puruki to be linked in with other international experimental forests and for a digital forest of the estate to be generated so lessons and the future forest can be shared beyond New Zealand.”

Planning underway

Work to organise the conference, planned for 9-13 September 2024, is now underway. The conference committee includes Scion’s portfolio leader, Claire Stewart, and key members of Scion’s Data and Geospatial Intelligence group. Collectively, they will provide attendees with several technical sessions and field trips that explore world-class recreational and productive forests.

For more information, please contact michael.watt@scionresearch.com.

Principal Scientist Dr Michael Watt co-led a bid for New Zealand to host ForestSAT 2024.

Scion Connections ISSUE 42 | FEBRUARY 2023 7 6

Remote sensing specialists will descend on Whakarewarewa Forest and Rotorua in 2024.

Reducing global emissions:

Magnifying New Zealand’s impact

A change in market attitudes and needs, leveraging strong local and international relationships, and a new way of thinking have enabled clean-tech start-up Cetogenix to bring world-leading science out of the laboratory and into actuality.

Cetogenix is addressing the most significant challenges presented by disposal of the world’s 1.5 billion tonne per year organic waste streams: value recovery, environmental impacts, and processing cost. This is being achieved by focusing on modular, retrofittable systems for conversion of organic biomass feedstocks to energy, nutrients, and bio-based products, that ensure ‘no waste is left behind’.

From foundational science to a new market

Cetogenix builds off a significant R&D foundation generated as part of an ongoing waste-to-value programme created by the company’s executive leadership team while they were all based at Scion. This work demonstrated the benefits of the core concept – conversion of organic wastes into bioeconomy feedstocks, which was translated into a valuable intellectual property portfolio.

The company’s lead investor, Pacific Channel, obtained exclusive global rights to this Scion IP in 2019. In 2021, Pacific Channel approached the original development team to step back in and realise the potential of the IP within changing market channels.

Over the past year, Cetogenix’s leadership team has pivoted the core platform to specifically target its application to renewable natural gas production, modularity and as a complementary and retrofittable system to the established and high-growth anaerobic digestion market.

While anaerobic digestion is relatively new in New Zealand, internationally it is a $26 billion per year capital investment industry, which produces the majority of the world’s biomethane – a sustainable replacement for fossil-derived natural gas.

One limitation of anaerobic digestion is that a high proportion of the original waste material does not break down into biogas –meaning lower production efficiencies, higher operating costs, and potential environmental impacts through disposal of the leftover material.

Cetogenix specifically uses this leftover material – digestate – as its feedstock, increasing gas production of the plant by 40%, eliminating the need for digestate disposal, ensuring recovery of nutrients, and destroying any contaminants.

It is a disruptive value proposition that has successfully attracted $4.5 million in seed capital investment over the past year and may generate up to $120 million each year in revenue for Cetogenix when fully commercialised.

Partnership in practicality

Scion and Cetogenix have signed a Memorandum of Understanding (MOU) to bring about significant impact benefits.

As an example of the MOU’s value, Scion was recently successful in securing a significant grant from the BioResource Processing Alliance to help scale up the Cetogenix technology.

Cetogenix is also headquartered at Scion’s Te Papa Tipu Innovation Park, where it now has 12 staff, a dedicated laboratory, and a pilot-scale prototyping system. This co-location reflects the company’s belief that strong science-commercial partnerships will accelerate innovation and deployment.

Scion’s general manager of Forests to Biobased products, Florian Graichen, says science is the foundation for change, but it is not enough in isolation.

“Our purpose as a Crown Research Institute (CRI) is to partner with companies to achieve the impact we want to see for New Zealand through science. It’s imperative we have commercial partners to be able to take our science and technology out into the market.

Scion Connections ISSUE 42 | FEBRUARY 2023 9 8

Power in partnership: The Cetogenix team (back row) Dr Trevor Stuthridge, Dr Daniel Gapes, Marcel van Leeuwen, Rahul Dhiman. (front row) Dr Ursula Hosking, Rob Lei, Alex Stuthridge, Ciara Griffiths, Dr Donya Novin and Dr Okey Nwadigo.

“This is about opportunities that go beyond Scion. Part of our mandate is also to incubate new opportunities that then create assets for high-value jobs and regional growth, particularly around cleantech and a circular bio-based economy.”

Cetogenix managing director Dr Trevor Stuthridge says Cetogenix is a real partnership success story in terms of a CRI/ industry dynamic and highlights a paradigm shift in the way workable innovation can be brought to market.

“It’s always been a challenge bringing new technologies out of the laboratory, as science has traditionally worked in isolation of the end-user. Our team has been lucky to be highly engaged with both industry and Scion throughout the development of this technology.

“It’s taken some time for the market to catch up to our value proposition, for the people involved to have the confidence and experience to take things forward, and for the investment community to be comfortable investing in the cleantech space in New Zealand.

“It has been a convergence of journeys to get to this point and we are privileged to have a strategic partnership with Scion that will hopefully also be an exemplar for others.”

The power of pivoting

Stuthridge says 10-plus years ago, when the technology’s principles were first developed, it was in response to lowering the costs and impacts associated with bio-based waste ending up in landfill. Now, the waste management industry has pivoted towards adding value to that waste material and creating energy security, particularly around renewable natural gas production, as decarbonisation policies and energy security challenges increase worldwide.

“In setting up Cetogenix, we saw the connection between the old technology’s strengths and potential, a fundamental change in market thinking, and we knew the time was right to bring this technology back to the table.

“It was a convergence of a number of things: our personal career experience, growing consumer demands, improved investor understanding in this type of technology, and the global regulatory imperatives to meet macro-trends on climate change, circularity and reduction in our dependence on fossilderived products.

“We had very clear principles from the start around what sort of technology we wanted to create, such as adding value to the entire waste stream, avoiding environmental harm, and integration of multi-disciplinary science/engineering concepts – and because of that, I think we and Scion have always been ahead of the game.

“It took some time for the end-user and investment market to catch up, but now is the right time.

“We have deliberately designed a technology that is complementary. We are not in competition with current bioprocessing plants, which means our target market already includes more than 15,000 potential clients across Europe and North America alone.”

The potential for wider impact

Creating local, regional impact is a driving factor for both Scion and Cetogenix.

Developing New Zealand’s bioeconomy is one way in which to do that, according to Scion’s portfolio lead for Distributed and Circular Manufacturing, Marc Gaugler.

“One of the critical challenges for New Zealand that could be aided by a bioeconomy is the need to create higher value, futureproofed jobs in our regions.

“If you couple that with the fact that the resources needed in a bioeconomy are geographically spread out and seasonally diverse, there’s a great opportunity to do things differently and process material where it’s available, rather than transporting everything into one centralised hub.

“Not only does that help to create regional jobs, but it also helps keep the regional identity behind the material, depending on the application. Having start-up companies like Cetogenix in the regions also helps demonstrate how we can get innovation developed inhouse at Scion out and what that innovation looks like.”

Globally, there has been a big market shift in recent years towards ‘process local, use local’.

Stuthridge says New Zealand’s impact on climate change is smallscale, producing less than 1% of greenhouse gas emissions, but international deployment of our home-grown innovation is where we can pack a powerful punch and where we have the potential to see a huge global impact for change.

“Our New Zealand technology is our greatest contribution to environmental issues on the world stage and, as a country, we need to be thinking globally in the first instance when it comes to developing our technologies.

“International demand for local production and investment in climate-positive energy sustainability is expected to increase ten-fold over the next 10 years. It takes courage to think globally and New Zealand may be small, but our contribution counts.”

Future proofing the innovation ecosystem

Stuthridge says partnerships between start-up companies like Cetogenix and organisations, such as Scion and New Zealand universities, are a hugely valuable vehicle for the development of future technologies.

“Working closely with CRIs and universities allows us to explore some of the riskier tech concepts that industry may not necessarily have the budget, time or capacity for. Let’s use that intellectual firepower through the likes of scholarships, secondments, and internships, to push the boundaries because that’s where the real gold is found.

“As a start-up with a global market, we can be one of those pathways for developing new ideas, concepts, and IP, and take them somewhere. We can also help equip current and future scientists with real-world experience in the challenges of science/technology translation to the market.

“Taking science out of the lab is surely the ultimate goal. The relationship between Scion and Cetogenix provides an incredibly valuable working example of how that can happen in reality.”

As a start-up with a global market, we can be one of those pathways for developing new ideas, concepts, and IP, and take them somewhere. We can also help equip current and future scientists with real-world experience in the challenges of science/ technology translation to the market.

DR. TREVOR STUTHRIDGE, CETOGENIX

Scion Connections ISSUE 42 | FEBRUARY 2023 11 10

Cetogenix is working to reduce global emissions through advanced waste-to-renewables technologies.

honours spirit of partnership Kawenata

The growing partnership between tangata whenua and Scion was formalised by the signing of a Kawenata / Memorandum of Understanding in a special ceremony last year.

The Memorandum of Understanding signing in August 2022 between Ngāti Hurungaterangi, Ngāti Taeotu and Ngāti Te Kahu (Ngā Hapū e Toru) and Scion was a significant event for all parties who were pleased to see a journey that started decades earlier come to fruition. It was appropriate that the signing of the Kawenata in both te reo Māori and English occurred at Te Whare Nui o Tuteata – the Great House of Tuteata. In October 2020, Ngā Hapū e Toru had gifted the name of their ancestor, Tuteata, to Scion for its headquarters in Rotorua to signify the importance of the partnership that they were building together.

The Kawenata and gifting of the name Tuteata are two of the many positive outcomes to emerge from conversations that started many years ago involving Ngā Hapū e Toru, including the late Ben Hona and George Mutu. Kōrero focused on a collective vision to restore their physical connection to the whenua around Whakarewarewa Forest.

Ngā Hapū e Toru trustee Veronica Butterworth explains that when the land was used by the Crown as a forest nursery from 1898 and then for forestry research from 1947 onwards, physical connection of the hapū to this land was severed. The spiritual connection, however, remained.

Historically, it had been a site where whānau lived and cultivated the land for kai, such as kūmara and aruhe (fern root). Birds, fish and other food sources were abundant.

“Land is the basis of identity and wellbeing for our people,” Butterworth says.

“We are genealogically connected through our whakapapa to the land itself, which ties us to various parts of the natural environment. These are fundamental aspects of our culture and our lives. Whakapapa and whanaungatanga give rise to obligations to look after the land, the waters and the environment on behalf of our ancestors and ourselves for future generations.”

Butterworth adds the signing for Ngā Hapū e Toru was a significant step forward in the partnership with Scion, which in turn was a step towards strengthening the mana of the land and hapū.

“This land is part of our rohe, our tūrangawaewae, and is the basis of identity and wellbeing for our people.”

Moving forward

Working together, the hapū and Scion will honour five matapono (principles) of the Kawenata: whakapapa, kotahitanga, rangatiratanga, manaakitanga and tiakina te mana o te whenua. Scion chair Dr Helen Anderson says the signing marked a significant milestone for the Crown Research Institute and its enduring relationship with tangata whenua.

“We have signalled how Scion and tangata whenua recognise the value of working together in the spirit of cooperation and partnership. We have common principles and an unwavering commitment to protect the waterways, forests and whenua.

“As Scion takes bold new steps with research to support New Zealand’s transition to a circular bioeconomy to help meet our climate change objectives, we have committed to a set of principles that will underpin our close relationship with tangata whenua and help us navigate the challenges and opportunities ahead.”

For Tamara Mutu (Ngāti Hurungaterangi, Ngāti Te Kahu) Hunga Whakahaere Matua – Operations Manager, the Kawenata represents a major step forward in efforts to align the kawa (protocol) and tikanga (customs) of the hapū within Scion and normalise hapū values.

Her role at Scion was created in 2021 to build relationships with Ngā Hapū e Toru. The role was established by Scion, Te Uru Rākau, New Zealand Forest Service, and Timberlands – key tenants on the 114ha site, known as Te Papa Tipu campus, where Ngā Hapū e Toru are tangata whenua.

In her role, Mutu is focused on strengthening partnerships between the three hapū, Scion and other tenants, looking for mutually beneficial opportunities.

Scion board chair Dr Helen Anderson (left) and Veronica Butterworth (right), representing the three hapū - Ngāti Hurungaterangi, Ngāti Taeotu and Ngāti Te Kahu with the Kawenata that was signed in a formal ceremony surrounded by the hapū, Scion board, staff and guests.

Scion Connections ISSUE 42 | FEBRUARY 2023 13 12

Strengthening connections

The Kawenata signing was followed by the launch of a new permanent visitor display in the building’s atrium. This shares the Kawenata and connection that Ngā Hapū e Toru have to the whenua, while also explaining the significance of forestry science and innovation to New Zealand and the world. Co-funded by Scion and Te Uru Rākau, New Zealand Forest Service, the displays are a creative bilingual storytelling experience that explore the history of tangata whenua, forestry and the future.

One display describes Ngāti Hurungaterangi, Ngāti Taeotu and Ngāti Te Kahu. It explains the deep connection to the whenua, with historical pā, kāinga (settlements), cultivations and wāhi tapu (sacred sites), as well as looking to hapū aspirations –including partnership and tino rangatiratanga.

The other display documents the history of New Zealand’s forestry industry, starting in the late 19th century when the first exotic trees were planted in a nursery at the Whakarewarewa Forest. The storytelling explains the value of radiata pine, along with the importance of forests to New Zealand for timber production, biodiversity, biomaterials, tourism and to tackle climate change problems the world faces.

Where’s my drone?

A permanent visitor display in the building’s atrium shares the history and connection that Ngā Hapū e Toru have to the whenua, while also explaining the significance of forestry science and innovation to New Zealand and the world.

Ground-breaking research aims to advance technology in forestry

Forest environments are notoriously difficult for drone (unmanned aerial vehicle – UAV) operations. Aside from the trees themselves, hilly terrain and remote areas provide challenges for drone operators. Add in the complexity of technical and regulatory considerations in a forest environment, operation of UAVs when visual contact is not maintained is considerably more difficult.

A recently published review article showed how these challenges can be overcome using beyond visual line of sight (BVLOS) UAV operations.

There are many applications of unmanned aircraft within planted and indigenous forests. These include wildfire monitoring and suppression, inventory and health assessments of forestry plantations, wildlife research, spraying of herbicides to kill invasive plant species, and dropping poisons and traps for pest control.

UAV operations internationally are governed by aviation rules that restrict their range to areas in which the pilot can maintain visual line of sight with the craft to manage potential risks.

The article was authored by Robin Hartley (Scion), Isaac Henderson (Massey University School of Aviation), and Chris Jackson (Jackson UAS Limited). Each author provided their unique contributions of expertise related to forestry, aviation safety, and unmanned aircraft operations.

Lead author Hartley has been researching the area of BVLOS in forest environments for years. Most striking was the absence of solid information that can be found in one place for practitioners or researchers to access, he says.

“Collaborating with Isaac and Chris has been great as between us we have been able to pool our collective resources into an article that will be a very useful starting point for others who are wishing to follow in our footsteps.”

The article emphasises how BVLOS UAV operations help overcome the challenges of operating in the forest environment. Having flown UAVs in a variety of forest environments for more than six years, Hartley has an incredibly good understanding of the frustrations that can come with trying to maintain visual line of sight.

“It is standard practice to do a desk-based assessment of an area, or even a field trip prior to accepting the work to see whether it will even be possible to capture data there with a UAV.

“We have experimented with various methods for maintaining visual contact by raising the pilot up into or above the canopy, however, this is not always possible and so BVLOS has always appealed as an effective way to apply UAVs to almost any site.”

The article also outlines the international regulatory environment related to BVLOS UAV operations and some of the technological and operational factors that must be considered when taking a risk-based approach for conducting such an operation.

Massey University’s Henderson says most literature related to BVLOS UAV operations is focused only on technological solutions that may help to safely conduct such operations.

“This article also helps advance the importance of understanding airspace requirements, risk assessment, and human factors related to fatigue, multi-crew operations, training and competency requirements, among others. In this sense, this article appears to be the first to make a holistic appraisal of BVLOS operations.”

The full article is freely available here

This land is part of our rohe, our tūrangawaewae, and is the basis of identity and wellbeing for our people.

VERONICA BUTTERWORTH, NGĀ HAPŪ E TORU

The

Read the English version here Read the Te Reo Māori version here

Kawenata and its principles can be viewed on our Scion website.

Scion Connections ISSUE 42 | FEBRUARY 2023 15 14

Operating a UAV in a forestry environment can be challenging. Pilots use various methods to maintain visual contact, such as being raised above the canopy on a platform.

Packaging a punch

New Zealand packs a punch well above its weight in the packaging science space, with Scion hosting a unique and world-class set of capabilities and infrastructure for commercial testing, research and development.

It’s not a small coincidence that one of the world’s most advanced packaging research and testing facilities exists in New Zealand. With a $63 billion contribution to GDP in 2021, we are an exporting nation. Dairy, meat and fruit are among our largest export earners. Each of these food items exported needs to comply with a myriad of global food safety, sustainability and environmental standards. With growing global demand and requirements for recyclable, reusable and compostable packaging, the eradication of singleuse plastics and significant challenges around food waste, supply chain logistics and differing market compliance around recyclability, being part of the wider conversation has never been more important for us as an export nation.

Scion Connections ISSUE 42 | FEBRUARY 2023 17 16

Testing box performance inside the WHITE Room.

Scion invests $1 million in research and testing facilities

Scion is a global leader of fibre-based and plastic-based packaging research. As the packaging landscape rapidly changes, Scion has recently invested over $1 million in research and testing facilities, in order to ensure global packaging commitments can be met for New Zealand products.

Recently completed upgrades include doubling capacity for commercial testing of box performance in chilled supply chain conditions, called the WHITE Room (an acronym for weight, humidity, intervals (time), temperature experiments); doubling the capability of testing facilities for industrial disintegration to determine the compostability of packaging and products; and the purchase of a pilot-scale moulded fibre thermoformer machine to assist in the development of fibre-based packaging solutions. Individually, these facilities are considered unique in the world, being among merely a handful of similar systems, but having all three on one independent site is, currently, the only one of its kind globally.

Of course, there is more to packaging than the above; digital packaging for traceability, food contact compliance and the development of bioplastics are also key research areas for Scion and assist in shaping the wider story of packaging in New Zealand.

Scion’s general manager of Forests to Biobased products Florian Graichen says for New Zealand, packaging is mission-critical.

“For an export nation like us, packaging is absolutely vital. And it’s much more than just the material itself; what packaging enables is also significant.

“All our export markets are moving to reusable, recyclable or compostable packaging so it’s become much more than merely protecting the goods. Without sustainable packaging, you have severe risk to market access for all our brands and producers; hundreds of billions of dollars is underpinned by that.”

New Zealand also has its own aspirations around emissions mitigation, zero waste and creating a circular climate – none of that can be achieved without addressing packaging.

The wider context –packaging and food waste

In our ever-maturing awareness of how modern society impacts the environment, single-use plastics is controversial. But there’s much more to the story: food waste. According to the UN, as much as 30% of food produced worldwide is wasted. If global food waste was a country, it would be the third-largest emitter of greenhouse gas on earth. Big problem. Bigger than even plastic waste.

The conundrum facing many working in this space is that packaging plays a vital role in helping to reduce food waste and making sure products are in a fit-to-eat state by the time they reach the fridge.

Different markets also have different regulations around what constitutes sustainable food packaging, as well as different endof-life infrastructure, meaning there is currently no one-size-fitsall solution.

So how do you create packaging that in and of itself is not an issue, while maintaining it’s still fit-for-purpose? If merely reducing packaging contributes to food waste, how can these two issues be similarly addressed?

This is the multi-billion-dollar question.

Work is already underway in many areas of the food production cycle here and overseas.

The Office of the Prime Minister’s Chief Science Advisor recently released a working report on combatting food waste, detailing what New Zealand is currently doing and what work is still needed.

The report, titled Food waste: A global and local problem, published in July 2022, highlights how the entire circular system needs to be taken into account – packaging design and manufacture, as well as end-of-life systems and end-market infrastructure.

Combatting food waste here and world-wide will require collaboration from many different stakeholders, including research, government and industry.

Individually, these facilities are considered unique in the world, being among merely a handful of similar systems, but having all three on one independent site is, currently, the only one of its kind globally.

FLORIAN GRAICHEN, SCION

Scion Connections ISSUE 42 FEBRUARY 2023 19 18

The Kiefel moulded fibre thermoformer allows Scion to support industry to make the transition into alternative packaging by researching different materials and fibre blends.

Scion’s role in the global conversation

So how does Scion fit into the global conversation?

Graichen says Scion brings together a unique number of elements to the packaging party.

“Where Scion packs a collaborative punch is with our decadeslong experience in packaging research, science and innovations, our world-class facilities, and wide-reaching existing relationships both here and overseas.

“That means we can do true packaging research that is closely aligned with industry, which is absolutely unique.

“We are able to do the actual science behind packaging –including materials and performance – and then link it back into industry through the hundreds of small to large companies we work with. That capability doesn’t exist anywhere else.”

He says Scion’s knowledge has come full circle in terms of its historical work in the pulp and paper space.

“The need for fibre-based packaging is increasing rapidly. We can use the work done in the past and re-package it to make it relevant for the future, particularly as we already have the recycling options for paper-based products.

“The two opposing factors of single-use plastics and food waste will require significant ingenuity to combat – at policy level, science level and company level. Scion has those relationships already on which to draw from.”

Scion packaging research leader Kate Parker says increasing capacity for commercial testing and in-house research and development is critical for supporting New Zealand’s primary industries.

“There is a huge global push to make packaging recyclable, reusable or compostable, with many countries introducing legislation and targets around what they are and are not willing to import.”

Scion’s capability also enables New Zealand to be part of the conversation around creating international standards.

“Part of upgrading our facilities enables us to create good tests for fibre recyclability, because there are currently no universally accepted standards; they’re all focused on plastics. Currently, countries have their own set of standards, which means every market is different.

“New Zealand needs the capability to be able to test to those standards here, as well as support our primary industries to be able to meet market requirements and recycle more fibre onshore,” says Parker.

For New Zealand, our largest export markets are Europe, China, the US and Australia – all of which currently have different regulations around packaging and recyclability.

Parker says part of the work Scion does is not only about giving New Zealand industry options, but also helping them understand differing compliance.

Fibre-based R&D

Scion’s recent investment in facilities has allowed it to research new bio resources for packaging and waste.

“As we look at working with new bio resources to create packaging, it’s also a way of engaging with producers of agrifibre waste across New Zealand and supporting more recycling of fibre,” Parker says.

“We still have big waste streams in New Zealand because we don’t have the products to turn it into. Using what’s considered waste residue and turning it into new material resources that can be used is a big part of what we do.

“With the global push for more fibre packaging, many companies are looking at what options are available. Our role is to support New Zealand industry to move into that new space.

“Our upgraded facilities also mean we can take into account the bigger circular bioeconomy picture. We’re able to consider the full life cycle analysis of current and emerging new materials – feedstock, water, energy, transport – plus performance and what happens at end-of-life.”

Our upgraded facilities mean we can take into account the bigger circular bioeconomy picture. We’re able to consider the full life cycle analysis of current and emerging new materials – feedstock, water, energy, transport – plus performance and what happens at end-of-life.

KATE PARKER, SCION

Scion Connections ISSUE 42 | FEBRUARY 2023 21 20

Industry engagement: Dr Kelly Wade explains to visitors attending Scion’s packaging conference how the thermoformer functions.

Forming a new path –the new Thermoformer

Scion’s Kiefel moulded fibre thermoformer arrived in June 2022. Paper and cardboard – dissolved in a water bath – create the raw material, known as pulp. Through application of pressure most of the water is removed and the wet basic form is created. In the next step, the remaining moisture is removed and the basic form is dried by applying high pressure and temperature. The combination of the applied heat and pressure results in a very robust material for packaging.

The pilot scale industrial machine enables different pulps to be trialled rapidly for packaging with relatively small volumes of material needed, 1-2kg of dry pulp being sufficient.

Scion has trialled different pulps in the thermoformer, with the ability to collect data such as how much energy and water is used to create trays from each different pulp, as well as the percentages of recycled fibres that can be used in pulp before structure and performance is affected.

In the short term, the goal is to support industry to make the transition into new alternative packaging.

Long term, Scion sees its role in this space as researching different materials and fibre blends for those alternative packaging products, improving performance through lightweighting and mould design, as well as being able to offer an alternative use for recycled fibre waste in New Zealand. Non-standard fibre streams, for example, which would not be available in sufficient volumes for papermaking, such as hemp hurd or agricultural residues, could be a valuable resource in this context.

Box it up baby

Validating new technology and materials is a crucial part of R&D and that’s enabled by the WHITE Room, which simulates supply chain conditions such as temperature, humidity and weight. Imagine apples, kiwifruit or dairy products being exported to northern hemisphere markets. These food items are packed in boxes for weeks, need to cross the equator and withstand being crushed by boxes stacked on top of them.

Scientist Dr Kelly Wade says the WHITE Room gives the packaging team the ability to create a model, then make packaging based on that model and test it in real-world conditions to understand performance.

“Traditionally, boxes are specified based on their shortterm crush strength and safety factors to ensure they don’t fail, which can lead to over or under-specification.

“Now, with supply chains so stretched the world over, it’s become more important to minimise weight, size and transport costs, while still maintaining performance. Better understanding of long-term box performance offers the potential to optimise box specifications.”

Wade says ultimately, the goal would be to re-design the cardboard box with the knowledge gained and continue to test within industry to make sure it’s viable.

“Box performance is no simple thing. Paper composition and how it is converted into board, how the box is cut, glued and taped, printing technique and handle placement can all affect performance of the box itself. Other factors such as filling of the box, stacking arrangement and environmental factors like temperature and humidity can further influence the response of the box.

“And they’re all on the table as things we can test using the WHITE Room. Ultimately over time, all boxes eventually fail. We want to understand the science behind that.”

The WHITE Room is also used for commercial trials by companies wanting to further optimise their own systems and packaging. Despite capacity doubling with the recent upgrade, it is still booked up with clients for months in advance.

Compost your cappuccino

As new packaging and materials are developed, it is essential they live up to their compostability claims. Do they in fact disintegrate? And what happens to the compost once materials have broken down?

Scion’s newly upgraded biodegradation facility allows compostable and fibre-based packaging to be tried, tested and certified, as well as provide knowledge and information about the wider impact of biodegradable packaging on the environment.

“In terms of compostability, we aim to support the transition of materials to being compostable,” says Parker.

“It’s becoming more important that packaging materials are actually certified compostable and it’s important for New Zealand industry to be able to have access to that type of testing facility. The closest other facility of its kind is in Thailand.

“We work with the Ministry for the Environment, for example, to support them in moving New Zealand towards a new circular bioeconomy, and the phase out of single-use plastics.”

Parker says as well as industrial disintegration tests, which take around three months, the facility enables both Scion and commercial clients to undertake biodegradation tests (measuring the conversion of carbon in the original material to carbon dioxide) and ecotox testing (where the resulting compost generated during original material breakdown is still viable in terms of seedling growth and worm health).

Wrapping up

In a [sustainably packaged] nutshell, Scion is committed to working towards how New Zealand can do things better and smarter.

Bringing together industry, infrastructure, R&D and legislation, as well as ensuring dissemination of information and ongoing collaboration, is the only way to combat the challenges we find ourselves wrapped in.

Talk to our packaging team to find out how Scion’s research can support your organisation’s sustainability goals. For more information, please contact alec.foster@scionresearch.com

The WHITE Room is also used for commercial trials by companies wanting to further optimise their own systems and packaging. Despite capacity doubling with the recent upgrade, it is still booked up with clients for months in advance.

Scion Connections ISSUE 42 | FEBRUARY 2023 23 22

Pilot plant engineer Garth Weinberg inside the WHITE Room.

Ticking all the boxes

Challenges for industry

Over the years, investment in research through the Government’s Strategic Science Investment Fund has built up Scion’s capabilities within its sustainable packaging programme, and now many food exporters and packaging companies come to Scion for advice on using new sustainable materials.

Zespri has benefitted from Scion’s guidance since partnering on research to commercialise its biospife – an industrially compostable version of Zespri’s iconic polystyrene spoon-knife.

Scion developed the biospife formulation by combining kiwifruit skins with a bioplastic. But before Zespri could share its biospife with kiwifruit lovers around the world it needed to meet food safety standards and pass vigorous compliance tests.

Gaugler set up testing capability at Scion for the biospife project as well as other internal research and product development. She upskilled by attending conferences, webinars and talking to global experts.

In testing for food contact, we wanted to know we were measuring the right things.”

Information-sharing supports research

Miruna Petcu joined Scion’s Zespri packaging team three years ago, bringing with her research experience with plastics, knowledge of how to get products approved and has experience dealing with the European Food Safety Authority.

Together, Gaugler and Petcu tap into global networks where new regulatory information is shared, ensuring they stay across the latest developments, technologies and substances of concern.

Gaugler is a member of the Australasian Pulp and Paper Technical Association and serves on its food contact materials committee. Through Scion’s involvement as a research partner with the New ZealandChina Food Protection Network and the New Zealand Food Safety Science and Research Centre, Gaugler secured funding in 2018 to travel to China. The visit was an opportunity to exchange valuable knowledge with scientists in China which, at that time, had adopted new food contact material regulations.

As part of a secondment that started in July 2022, the scientists are working to deepen Zespri’s knowledge and understanding of food contact regulations to ensure its packaging remains all-market compliant for export. Their work is pivotal in keeping the kiwifruit exporter up to date with global sustainability trends for packaging and changing regulations across multiple markets that Zespri ships to. This informs Zespri’s decision-making and ensures innovation efforts are aligned with global realities, securing its ongoing commercial success.

Lack of compliance is a huge risk that, if left unmanaged, could lead to product delivery delays or, in extreme cases, loss of whole export markets.

The responsibility that comes with the role isn’t lost on Gaugler who learned the art of reading regulations and determining what tests are required to meet them while working as a chemical engineer in Germany. It’s a skillset that requires strong attention to detail and a curious mind.

“We examine the regulations for food contact compliance for each country, working out what’s different between them and determining what tests each market needs for the packaging to be certified as compliant,” says Gaugler.

“It’s like being a detective and we love it.”

Standards for the materials that come into contact with food (known as food contact compliance) differ from country to country. Rules around the chemicals and substances used in food packaging can also change over time as new information about their safety becomes available.

Gaugler says the food contact regulatory environment is incredibly complex and there is no such thing as a one-size-fitsall approach.

“Most markets have a list of allowed substances, but markets might differ on how much of each substance can be used in plastic packaging; there can be different limits. We usually find there are requirements for testing those substances. But we’ve learned that even if a lab can do a test, it doesn’t mean it’s always the right test with the right settings.

“Testing must be very fit-for-purpose for the product, the market and its application.”

For Zespri, having support to navigate the complexities associated with global food regulations has been valuable.

Zespri’s head of global quality and technical, Farzana Adams, says the secondment ensures that not only does any new packaging being explored meets Zespri’s desire to be more sustainable, it also meets all regulatory requirements, including materials that can be used for direct food contact.

“The expertise Scion has provided has meant we’ve been able to better develop our knowledge and explore potential solutions efficiently, accurately and cost effectively.”

While having the testing capability at Scion, external partners like Zespri use certified laboratories for food contact testing, relying on Scion’s team for testing recommendations and guidance. The team is in high demand, as more companies are wanting to reduce their environmental footprint by developing more sustainable packaging.

However, Gaugler points out that while there is a global drive for more recyclable, sustainable packaging from consumers and industry, food contact regulations in many countries have been slower to respond to this changing environment.

“You can’t just assume that hemp fibre will be ok to use in a packaging product – you need to check to make sure it’s on the list of permitted substances in the country you are exporting to, and in what quantities it is allowed.

“For these reasons, some products that use new fibres and substances in packaging are taking quite a long time to enter the market. There’s a lot involved first in getting these products approved.”

It’s also important to note that just because a substance can be safely consumed or applied to skin, its use as a food contact material may not always be permitted, she says.

“One of the biggest challenges facing packaging producers right now is finding more sustainable water-repellent materials, as some traditional plastic products contain substances that are getting banned.

There’s a move to use more fibre-based food contact products, but how do you still get these to have all the properties that you need to repel water, store well and preserve its quality through the supply chain?

“Product developers everywhere are researching alternatives that perform a certain way, are cost-effective and meet the food contact regulations,” says Gaugler.

“Over the years we’ve made strong connections with people and there’s a lot of information sharing, which we pass on to industry. We regularly attend workshops and technical seminars, so across all the connections we’ve made, if industry has any new questions, we’ll do our best to find the answers.”

Building capability

During the secondment, Gaugler and Petcu have gained an appreciation for Zespri’s logistical and shipping challenges throughout the supply chain.

“Working closely with Zespri has given us insights into the commercial realities they face; there are good reasons why they do what they do. We understand those realities which help us to adjust our advice and solutions to any market challenges,” says Gaugler.

“The partnership with Zespri is very valuable. Not only are we making sure that Zespri’s packaging meets its obligations for food contact compliance, we’re building Scion’s capabilities all the time.”

For more information, please contact alec.foster@scionresearch.com

Scion’s Zespri Packaging Team includes scientists Eva Gaugler (centre) and Miruna Petcu, as well as (from left) Garth Weinberg, Robin Parr and (far right) Kelly Wade. The team was recognised for their impactful collaboration with Zespri at Scion’s Employee Recognition Awards in 2022.

Zespri has previously partnered with Scion on research to commercialise its biospife –an industrially compostable version of Zespri’s iconic polystyrene spoon-knife. Scion developed the biospife formulation by combining kiwifruit skins with a bioplastic.

With talent for scrutinising complex regulations and a desire to support New Zealand businesses to meet their sustainability goals, Eva Gaugler and Miruna Petcu are in their element working in Scion’s Zespri Packaging Team.

It’s like being a detective and we love it.

Scion Connections ISSUE 42 | FEBRUARY 2023 25 24

EVA GAUGLER, SCION

Nursery responds to SOS from Timaru

Scion’s nursery team is celebrating after successfully preserving the genetics of a landmark giant redwood tree felled due to property development in Timaru.

Cuttings from the felled tree, known to Timaru locals as the Champagne Tree, have been propagated by Scion in Rotorua where nursery staff discovered early signs of healthy root structure in a young plant eight months after branches were sent to them.

Their mission now is to grow at least one plant into mother stock that can provide further cuttings and repatriate these to Timaru.

Scion’s nursery operations manager Kelly Turner says the result is a major win for her team.

“Branches from the tree were salvaged, put into bags of water and sent up to us in boxes on ice about four days after the tree was felled. It wasn’t an ideal start, but we cracked it.”

She credits their success to the expertise of nursery technician Trish Moke-Pouwhare who took cuttings from the branches, and the Ellepot paper pot technology used in Scion’s nursery to accelerate plant propagation.

“At Scion we mostly propagate the coastal redwood species and Trish handles all of our cuttings after mastering the art. This tree is a mountain redwood and grows roots very slowly. It can usually take up to 12 months, so to see healthy roots after eight months is a real testament to her skill and the effectiveness of the paper pots to speed up the plants’ growth.”

Earlier attempts to preserve the tree’s genetics through tissue culture techniques were unsuccessful.

Scion has been using the Ellepot technology for three years.

“Taking cuttings is quite an old method but what’s new is the paper pot technology; that’s what we’ve found with the redwoods,” says Turner.

“Before using paper pots, it could take six months to get coastal redwood cuttings to root. Now, it takes three months or even six weeks under the right conditions. The cuttings love it.”

Roots grow faster in the paper pots and plants can be easily transferred into bigger pots or put straight into the ground.

Turner says her team’s goal is to return healthy trees to the Timaru community and to the descendants of the woman who was gifted the redwood in the mid-1850s.

“With their permission, we’d like to keep some cuttings at Scion so we can learn more about this particular species. We’re hoping we can accelerate the cuttings process and achieve a result faster than eight months after discovering more about the conditions that it likes.”

The felling of Timaru’s Champagne Tree took some people by surprise, including descendants of the tree’s first owner.

However, it followed many months of discussion between owners of the property where it grew and a neighbouring company that sought professional advice about its health and the safety of nearby properties. The 34m tree sat near the boundary of land they planned to subdivide. Efforts to formally protect the tree fell short, as it could not be listed as a notable tree under Timaru’s District Plan until 2023.

After the tree was cut down on March 31 2022, descendants gained permission from the property owners to get cuttings, with half going to Scion and the rest to a South Canterbury nursery for propagating.

The tree dates back to the 1850s when George Rhodes gave a seedling to his wife Elizabeth, and it first grew at the site of the present Timaru District Council building.

After her husband died, Elizabeth remarried, and the tree moved to her new husband’s home off Wai-iti Rd in 1873. The tree was then in poor shape and a bet was made, for a case of champagne, that it would not survive.

It thrived and became known as the Champagne Tree, towering over Timaru for 150 years. It was also home to the town’s Christmas star from 2003 until 2020.

The tree is a Sequoiadendron giganteum, otherwise known as giant sequoia or Wellingtonia tree. One of three species of coniferous redwood trees, it grows more commonly in colder climates or mountainous terrain. In its natural habitat on the western slopes of the Sierra Nevada mountain range in California, it is listed as an endangered species due to the threat of global warming, drought and fire. It’s believed fewer than 80,000 trees remain.

Our research nursery provides specialist seedling growing services and support to commercial forest growers. For more information, please contact kelly.turner@scionresearch.com

Nursery technician Trish Moke-Pouwhare successfully propagated cuttings from the famous Champagne Tree.

Before using paper pots, it could take six months to get coastal redwood cuttings to root. Now, it takes three months or even six weeks. The cuttings love it.

KELLY TURNER, SCION

Scion Connections ISSUE 42 | FEBRUARY 2023 27 26

Accessible information vital in extending knowledge of wildfire risk

Climate mapping, risk models and 170 best-practice recommendations for mitigating wildfires by Scion are now being used by fire authorities to keep communities safer, while also winning a national award.

Wildfire frequency and severity are accelerating globally, including in New Zealand. The Lake Ōhau fire, which destroyed 48 homes in October 2020, is evidence of this, taking firefighters nine days to extinguish the 5,000ha fire. Fire and Emergency New Zealand (FENZ) regards this event as one of the worst in our country’s modern history. For several years, social scientists from Scion’s Rural Fire Research Group have been working to understand where climate change is increasing the risk of wildfire, where communities are most exposed, and how best to communicate that risk.

Findings from the group’s latest research, Adapting and mitigating wildfire risk due to climate change: extending knowledge and best practice, and their corresponding recommendations, have been widely communicated.

Agencies have used the information to plan for and reduce the growing risk of wildfires, as well as improve wildfire risk awareness and mitigation among homeowners and communities in New Zealand, especially in areas where residential houses are near or intermixed with flammable vegetation like mānuka, gorse and pine.

The research team includes Lisa Langer, Simon Wegner and Andrea Grant, and former employees Grant Pearce (now FENZ) and Nathanael Melia (now Climate Prescience). The team’s comprehensive effort in making the research readily available and easily digestible has been recognised by an Emergency Media and Public Affairs (EMPA) award for delivering published research that advances emergency communication.

Scion senior social scientist Lisa Langer says that research outputs need to be clear for research to be understood and implemented by the desired end-user.

“Not everyone has the time or the ability to comprehend indepth scientific papers, so for us, it meant taking the lessons from our research and translating it into as many forms as possible, so it becomes a valuable source of information for a variety of audiences.”

The researchers’ findings and recommendations have been communicated through articles, blogs, online workshops, conference presentations, radio interviews, technical reports, and academic papers, all of which have had significant influence for FENZ, regional and local councils, primary industry land managers and investors, and property owners.

Uptake of innovative mapping by agencies

The latest high-resolution climate models overlaid with Scion’s mapping of New Zealand’s growing residential housing in rural areas and on the fringe of urban areas will assist FENZ and other agencies in prioritising community engagement and risk reduction efforts. The highly detailed climate model simulations describe future wildfire danger projections in every 5x5 kilometre grid cell across the country. This technology has found that climate change is predicted to substantially increase the wildfire risk for many regions, increasing the frequency, severity, and season length of fire weather conditions until at least mid-century.

The magnitude of these risks is linked to the success of climate mitigation efforts, making it important for fire managers to ensure communities become more aware of high wildfire risk environments and communicate knowledge appropriately to successfully prepare and mitigate against wildfires.

Understanding community complexities

Social findings from a community case study and a national survey undertaken by the researchers have enabled firerelated agencies to plan better and use more effective communication methods.

Langer says understanding the level of wildfire comprehension between permanent residents and visitors is essential.

Permanent residents from the small community on the northern side of Wānaka, including Mt Iron, where climate, wild vegetation and development factors have combined to create extreme wildfire risk, were engaged in a case study. This involved interviews, focus groups, and workshops with 64 key end-users and residents to identify wildfire risk awareness and mitigation actions.

Following this, Scion undertook the country’s first national quantitative assessment of wildfire risk perception and mitigation among residents in New Zealand, guided by lessons learnt from the case study.

The case study found that many permanent residents of Mt Iron exhibit high wildfire awareness and anxiety, amplified by the Lake Ōhau wildfire 70km away. Permanent residents also perceived a lack of awareness among short-term residents and tourists who continued to engage in activities such as using braziers and lighting fireworks. This limits the effectiveness of risk reduction efforts carried out by those permanent residents who are aware of the risk and undermines the impact of awareness campaigns by authorities.

Permanent residents from the small community on the northern side of Wānaka, including Mt Iron, were engaged in a case study.

Permanent residents from the small community on the northern side of Wānaka, including Mt Iron, were engaged in a case study.

The latest high-resolution climate models overlaid with Scion’s mapping of New Zealand’s growing residential housing in rural areas and on the fringe of urban areas will assist FENZ and other agencies in prioritising community engagement and risk reduction efforts.

Scion Connections ISSUE 42 FEBRUARY 2023 29 28

Wānaka case study area with survey zones discussed during a community engagement day.

Most concerningly, the national survey showed that awareness of and concern about wildfire risk was only weakly correlated with taking action to mitigate risk.

Langer says simple awareness campaigns will not be enough to spur people into action; there are likely to be practical or social barriers to mitigation that need to be addressed.

Wildfire mitigations for homeowners and communities

One of the research components recognised by the EMPA award resulted in 170 best-practice recommendations for agencies, communities, and individuals, supported by international literature to create an easy-to-use resource, Wildfire Mitigations for Homeowners and Communities.

The recommended mitigations have been divided into five categories that apply to people at different stages of preparation and response: building or remodelling a home, landscaping or designing outdoor spaces and property infrastructure, making a wildfire plan, preparing for the start of each wildfire season and when a wildfire occurs.

Recommendations from around the world have assisted firerelated agencies in understanding and categorising wildfires from the early stages when the thought of wildfires has yet to come into planning, right through to a wildfire emergency.

FENZ has developed a Wildfire Safer Housing Guide, which drew on Scion’s house construction recommendations to promote mitigation action among builders and homeowners. For FENZ Southland, the Mt Iron survey provided useful research data and helped all agencies understand the level of knowledge around wildfire, and the complexities that exist within communities.

Community readiness and recovery advisor Sally Chesterfield says the project identified clear groupings to allow agencies to understand and respond to their different needs.

“The research will be invaluable for measuring the success in reducing wildfire risk and improving resilience from a community and agency perspective in the future.

“It’s data that is usable for all agencies involved in the Mt Iron project and will help to strengthen each agency’s area of responsibility with evidence-based research.”

Extreme wildfire programme launched

Social research has suggested that most engagement surrounding wildfire comes too late, long after housing developments have been designed, homes have been built, and landscaping planted, when substantial changes are complex and costly.

Langer explains that individuals from the Mt Iron community faced challenges like these, with their concerns focused on factors such as restrictions to removing the protected but highly flammable kānuka vegetation around their properties, and the flammability of cedar cladding of their houses. This community’s difficulties led to a new research direction from preparing and mitigating against future wildfires at an individual property scale to national and local government and developer planning to prepare to live with wildfire.

Educating next-generation scientists

House of Science, a charitable trust, was awarded the 2022 Royal Society of Chemistry’s (RSC) Horizon Prize for Education in November for their entry Equity and Excellence: Bilingual Science Resources for NZ Primary Schools. The award acknowledges the development of a vast library of hands-on, bilingual science resource kits that enable thousands of primary school teachers across New Zealand to deliver life-changing science lessons.

Forty science resource kits have been rolled out over the past eight years, 15 of which have a strong chemistry focus.

Jane Hoggard from the House of Science developed the kits in conjunction with Eva Gaugler at Scion, Laura Kearney at the NZ Agricultural Greenhouse Gas Research Centre and Mike Bunce, Ham Davidson and Vanessa Crow from the NZ Environmental Protection Authority.

Specific kits that showcase chemistry in the circular economy include A Load of Rubbish with activities focused on sustainable ways of making and remaking new products with a focus on designing out waste. Gaugler was the Scion lead in the kit’s development, launching it in July 2022 at Te Whare Nui o Tuteata in Rotorua.

Other kits include Climate Change which features eight interactive activities to help students become better informed and empowered to care for our planet, and Who’s Been There – a kit which explores the composition and structure of DNA and highlights its use as a biodiversity monitoring tool.