earth bound

This project is an exploration of my roots, in the land where I was brought up and where I belong.

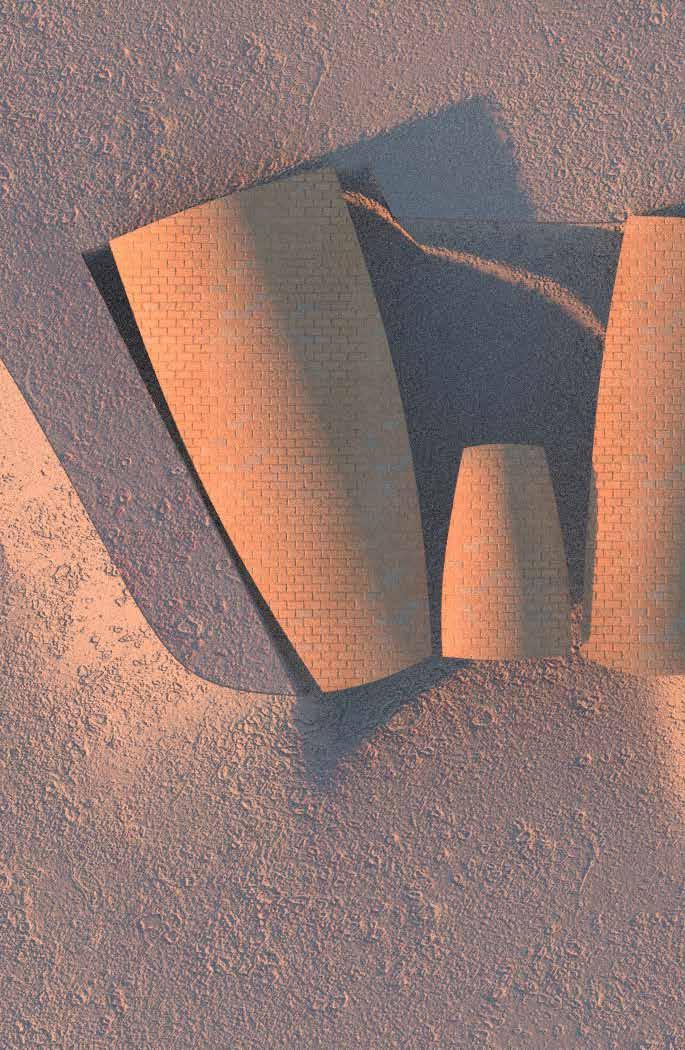

It is an attempt to understand this landscape and its remnants, what it consists of. I look at it not through its heavily traced political borders and conflicts, but as a unifying entity. The architecture that comes out of this project is one that looks back and learns from the vernacular but has a desire to move forward. It exists very close to the ground, adding and substracting within a threshold of -2 m, + 2 m.

earth bound

1. Introduction

Abstract

Project site

Project proposal

Working hypothesis

Construction sequence

2. Context

Fields of extraction

Problematic relationship with earth / an opportunity to redefine it

Site geology/geography

The landscape of the Beq’aa

Local construction history - a village in the beq’aa

Construction precedents

3. Site analysis/ earthen geological layer

Materiality

Climatic conditions

4. Manipulation of earth

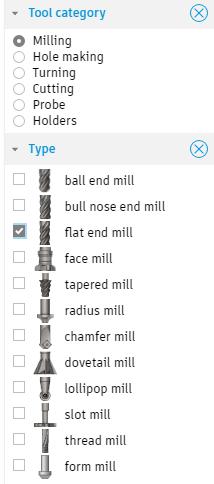

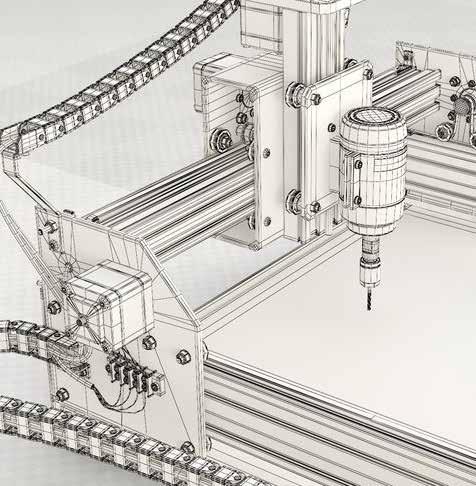

Tools

Clay extraction/processing

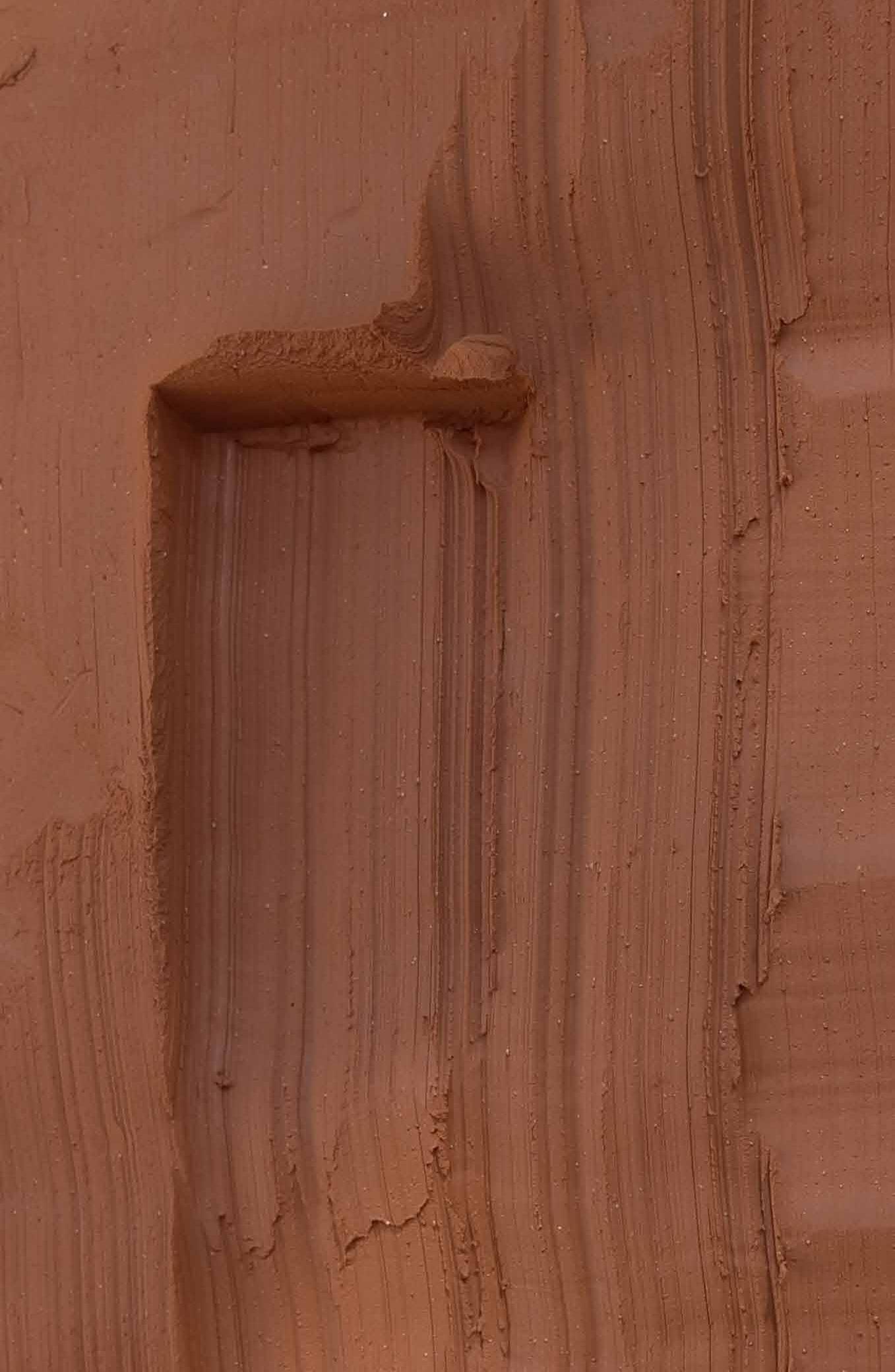

4.1 Removal of earth ( - )

an earth enclosure

Design intent

Notation

Shifting

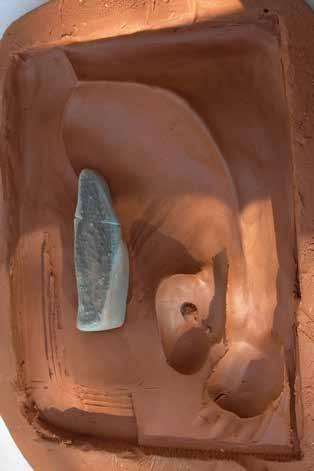

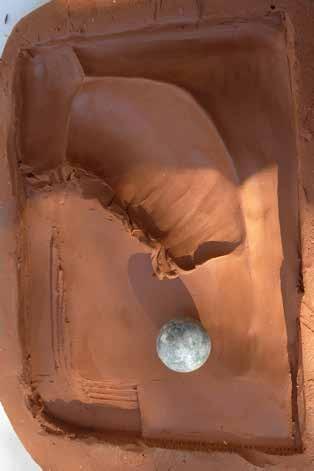

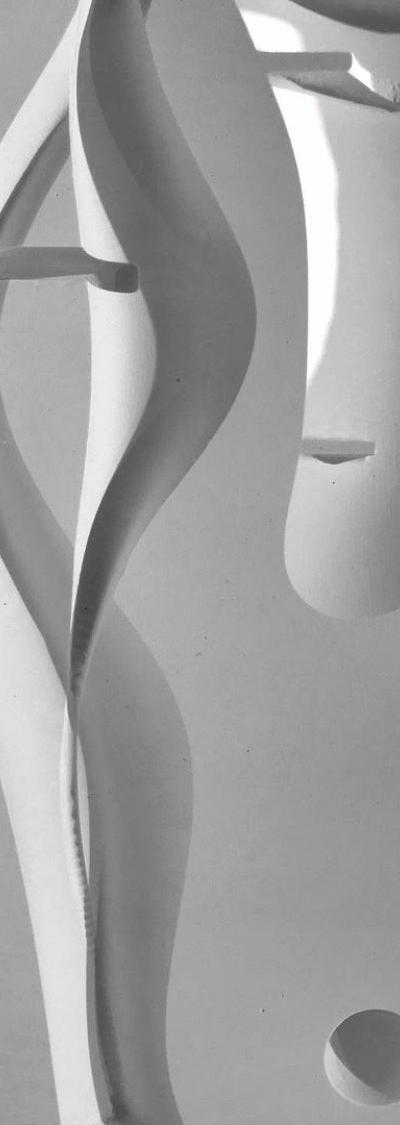

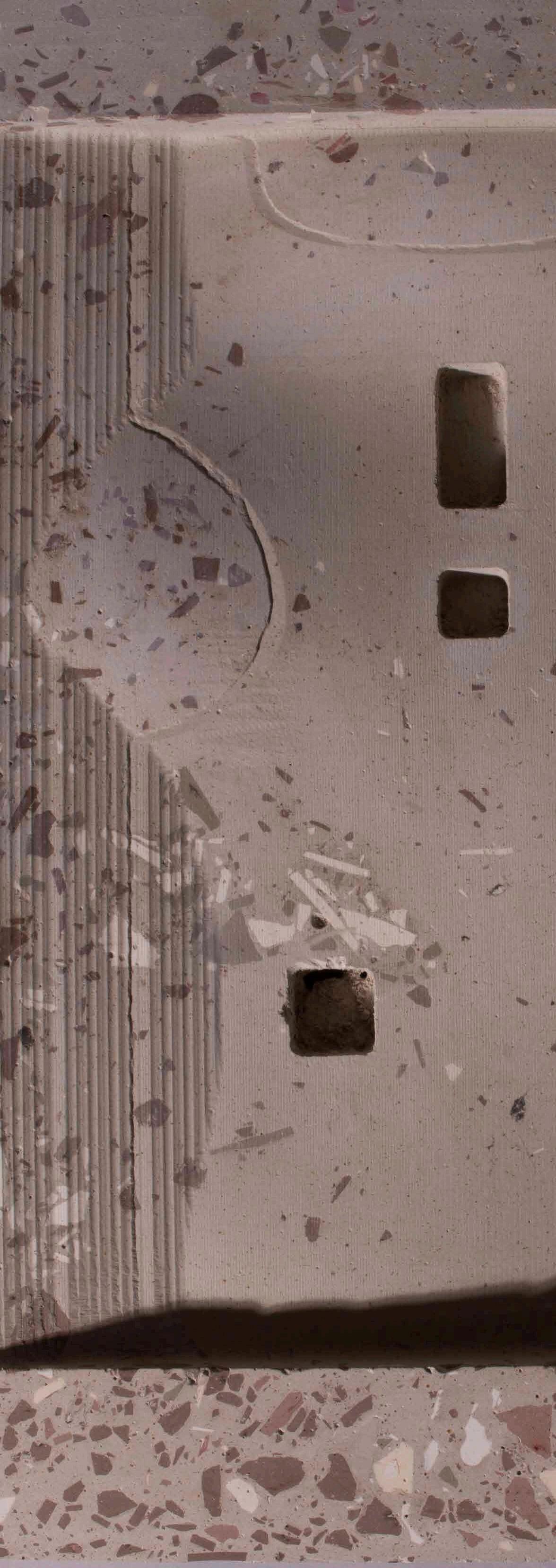

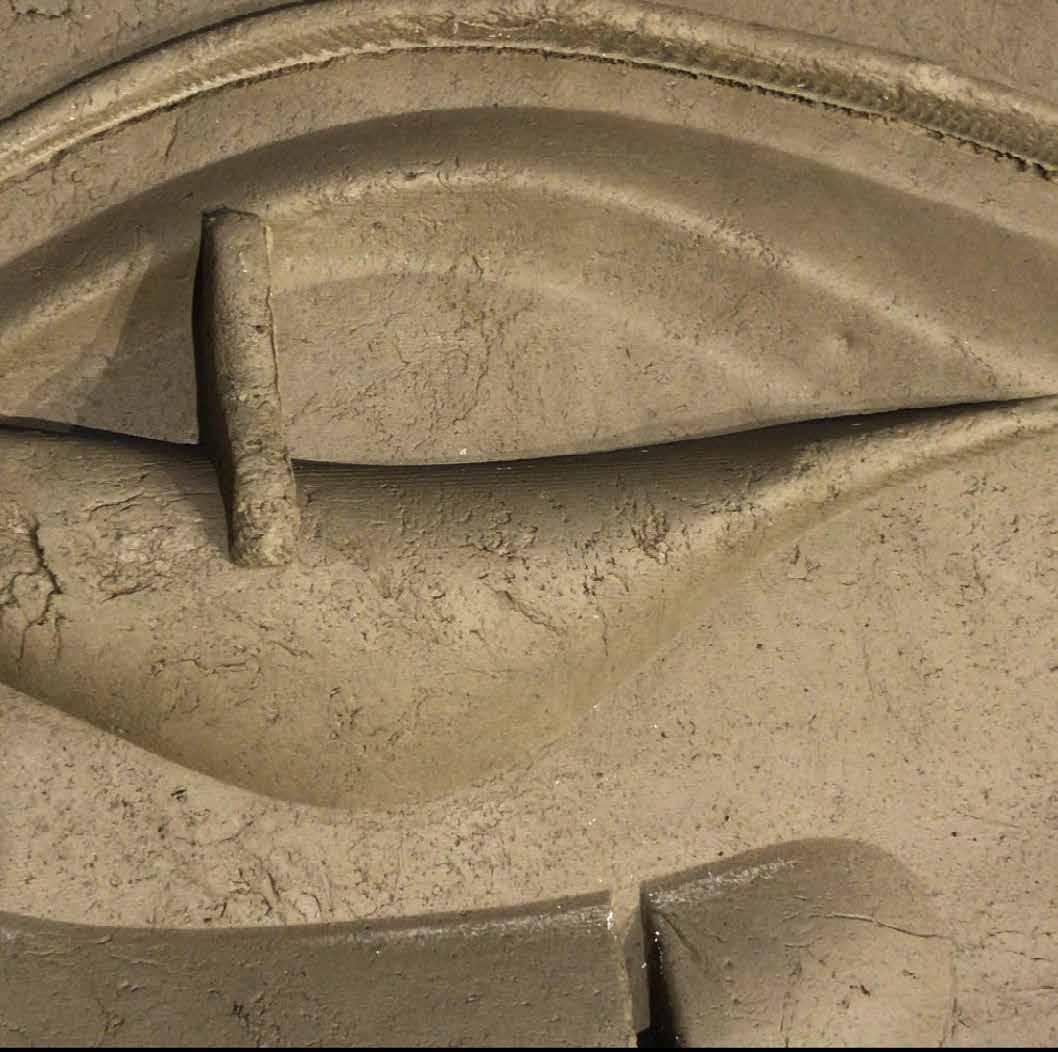

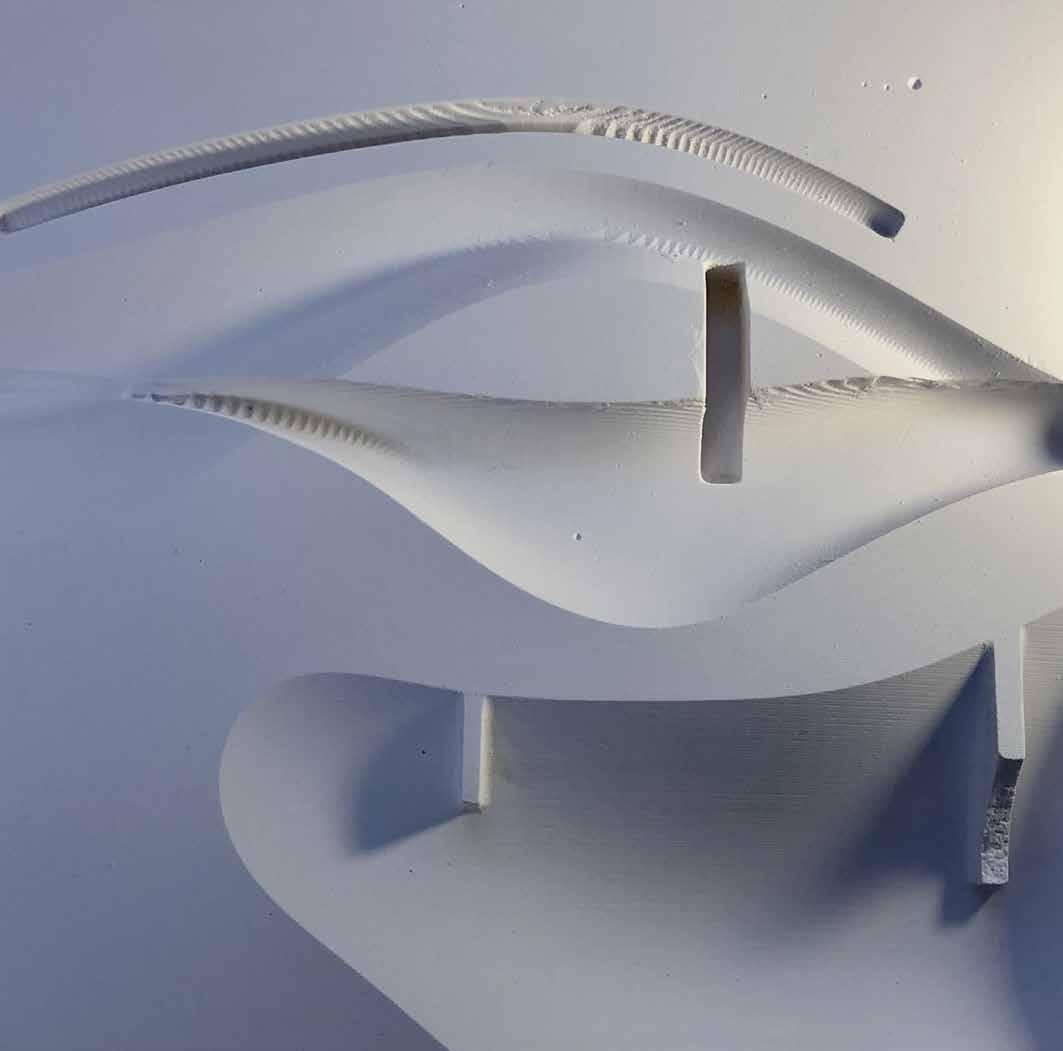

Subtraction tests cnc machine

Subtraction tests hand tools

Ground tools

Case studies

Refuge proposal

4.2 Addition of earth ( + )

a ground condition to inhabit

Design intent

Quantities

Earth constructions

Building with bricks

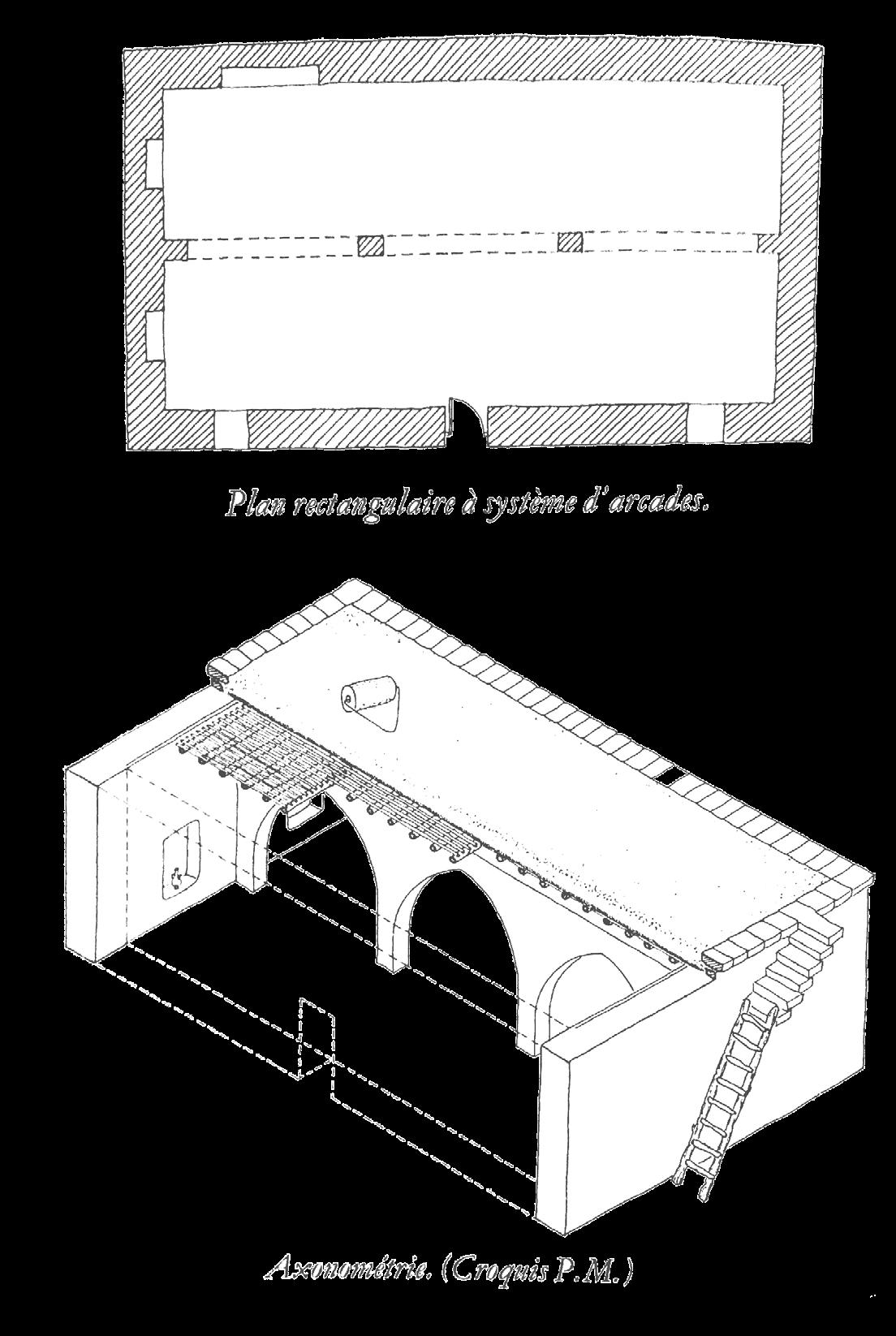

Timbrel vault constructions

Case studies

Centering tools

Understanding vaults

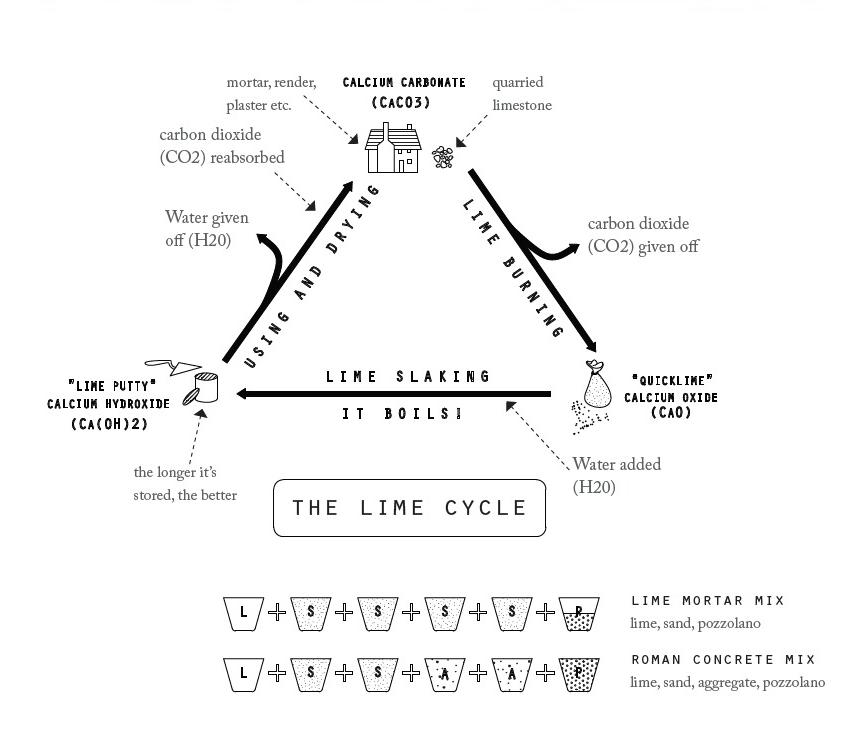

Mortars

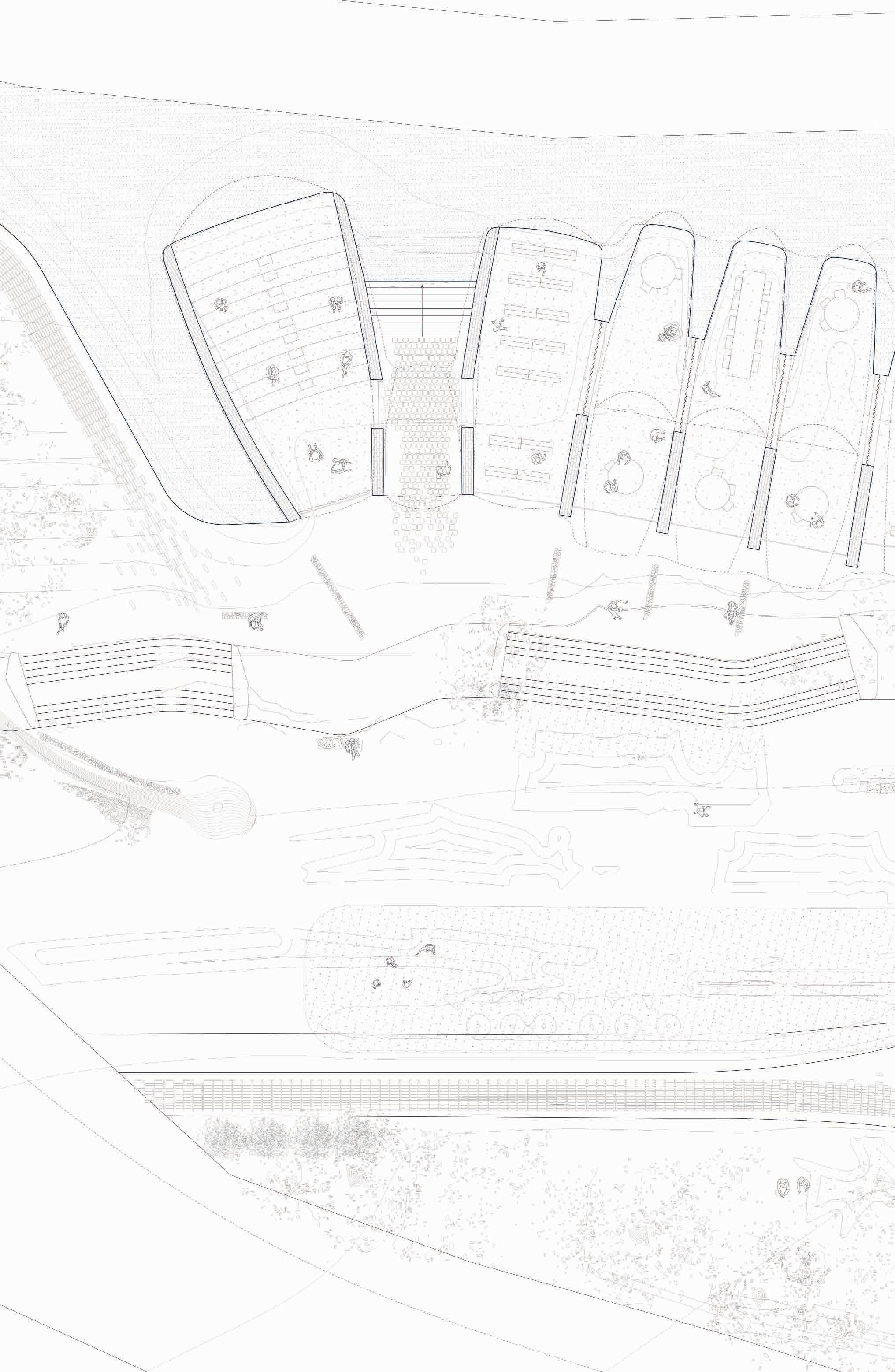

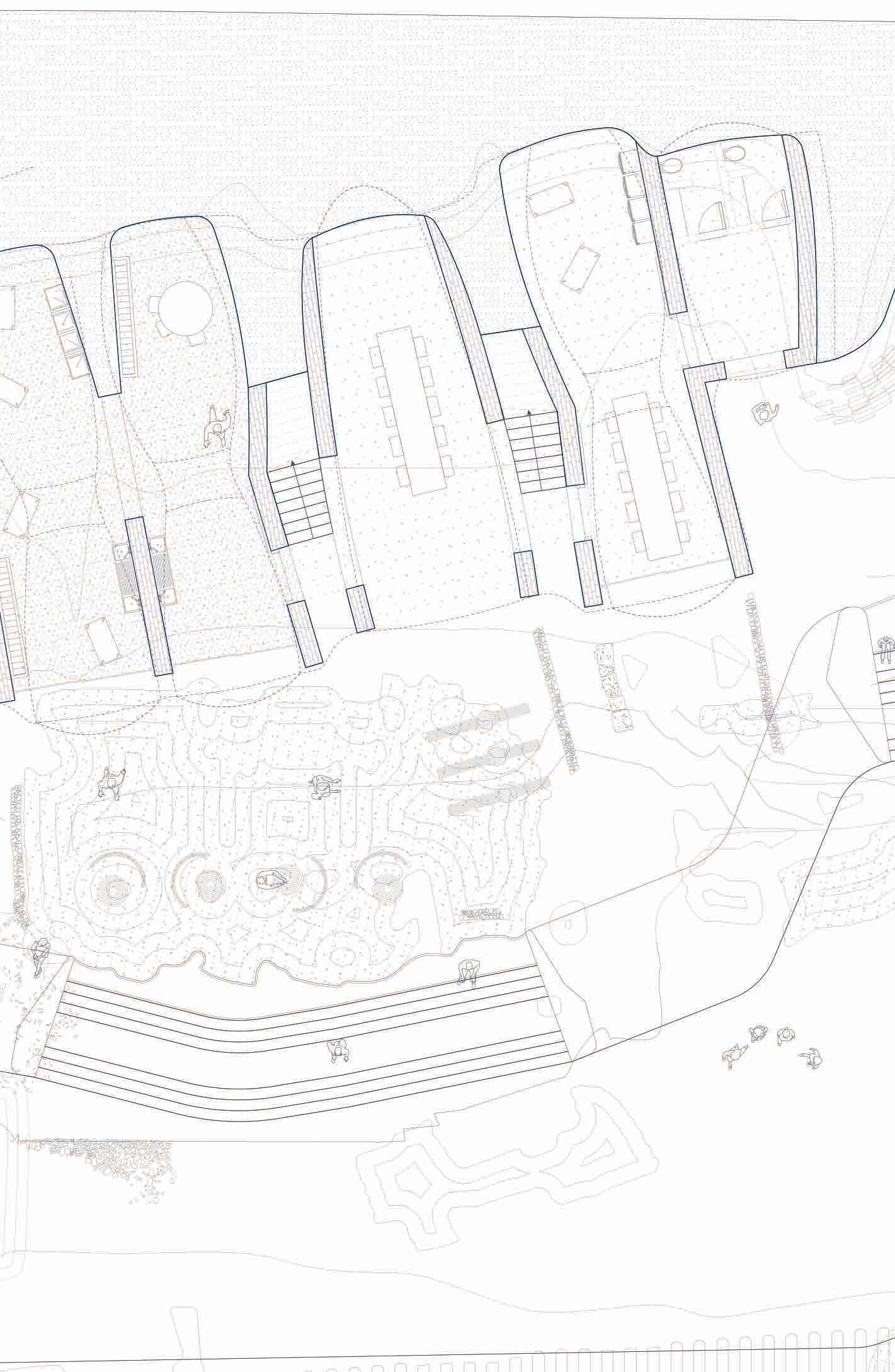

5. Proposal

The refuge

The bakery

The public square

ABSTRACT

PROJECT SITE

PROJECT PROPOSAL WORKING HYPOTHESIS CONSTRUCTION SEQUENCE

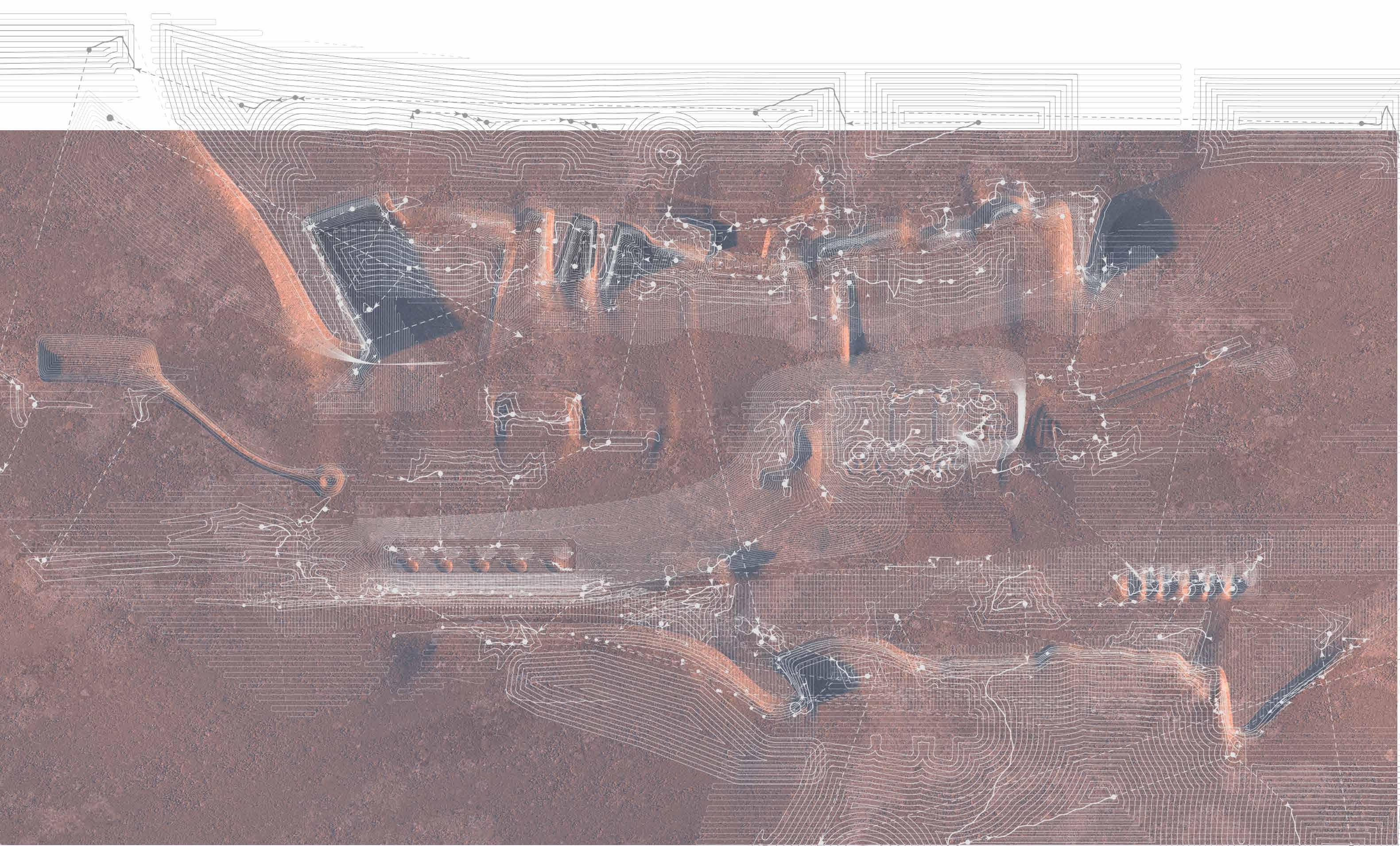

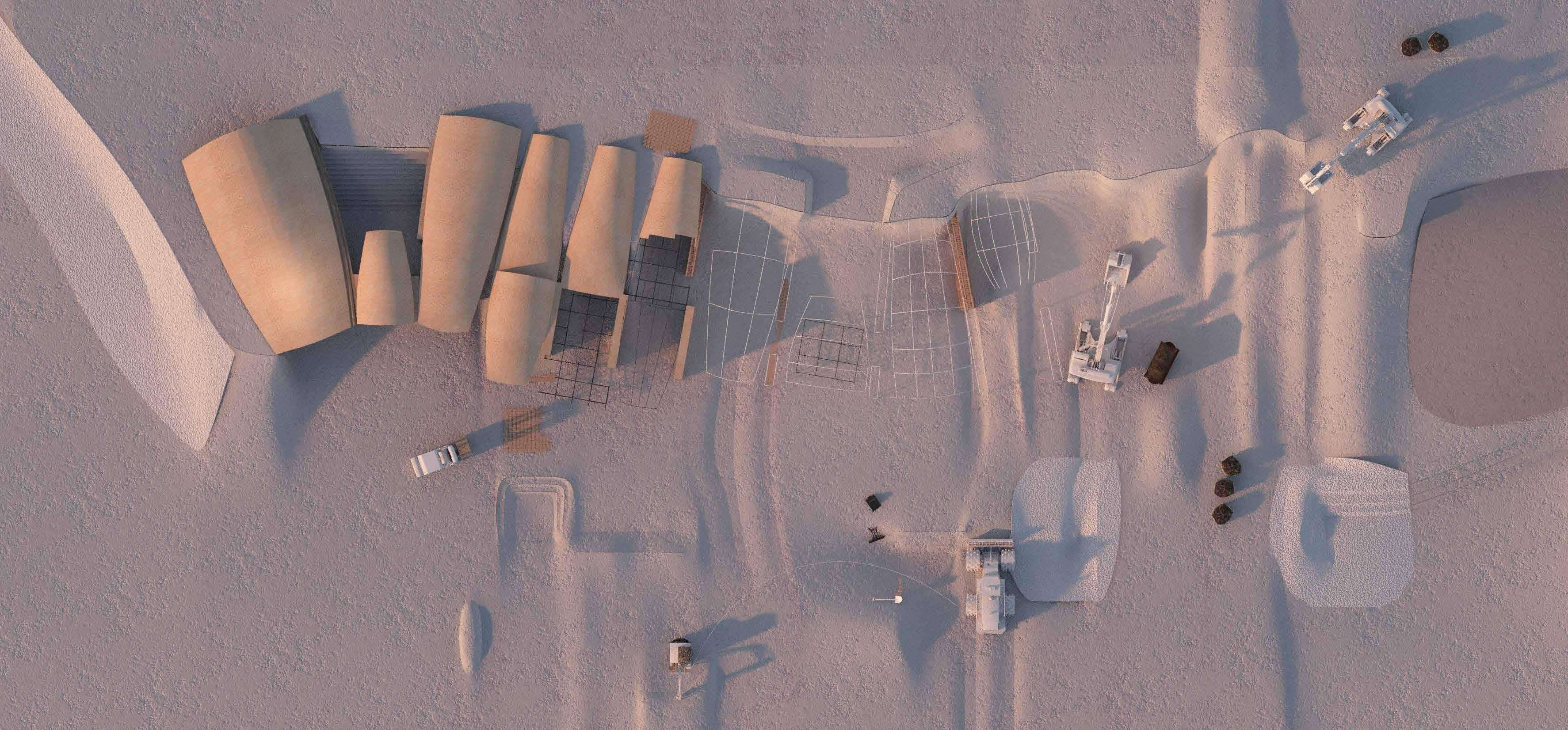

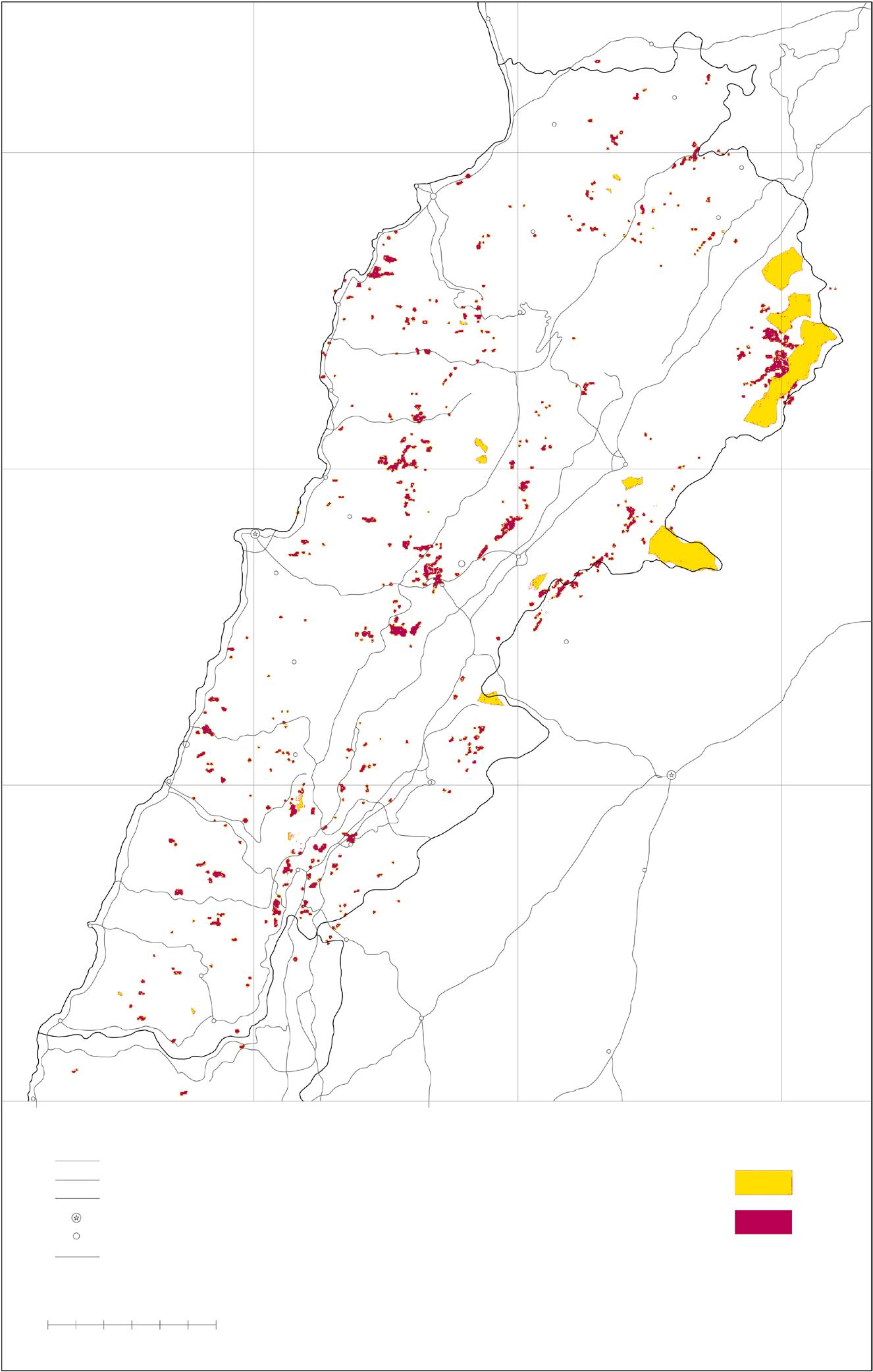

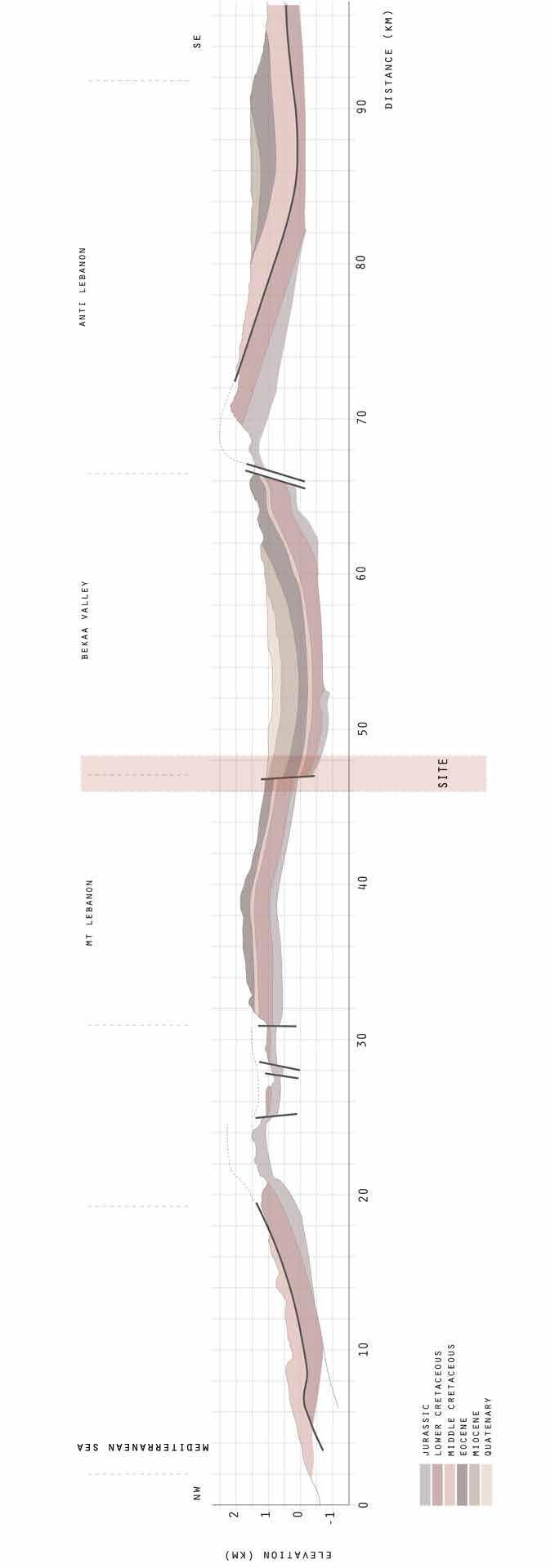

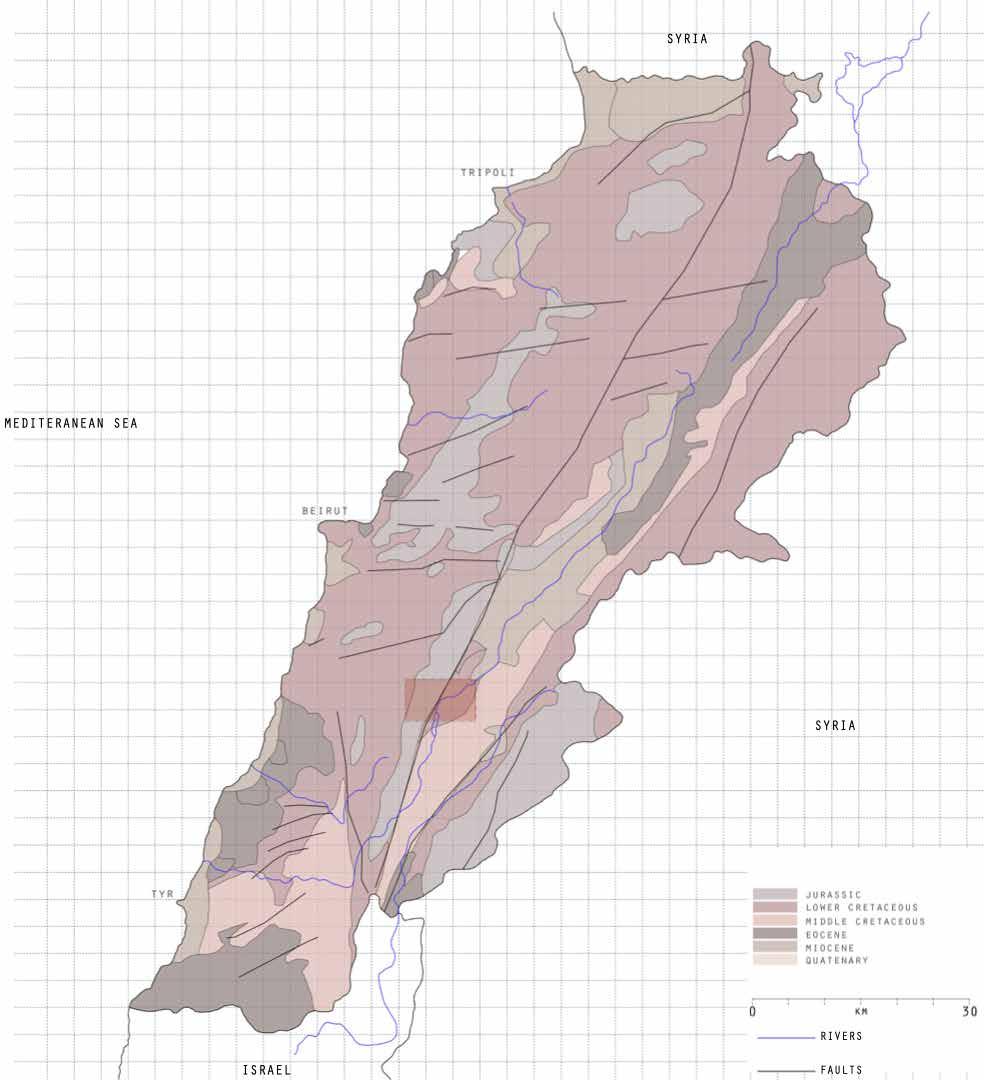

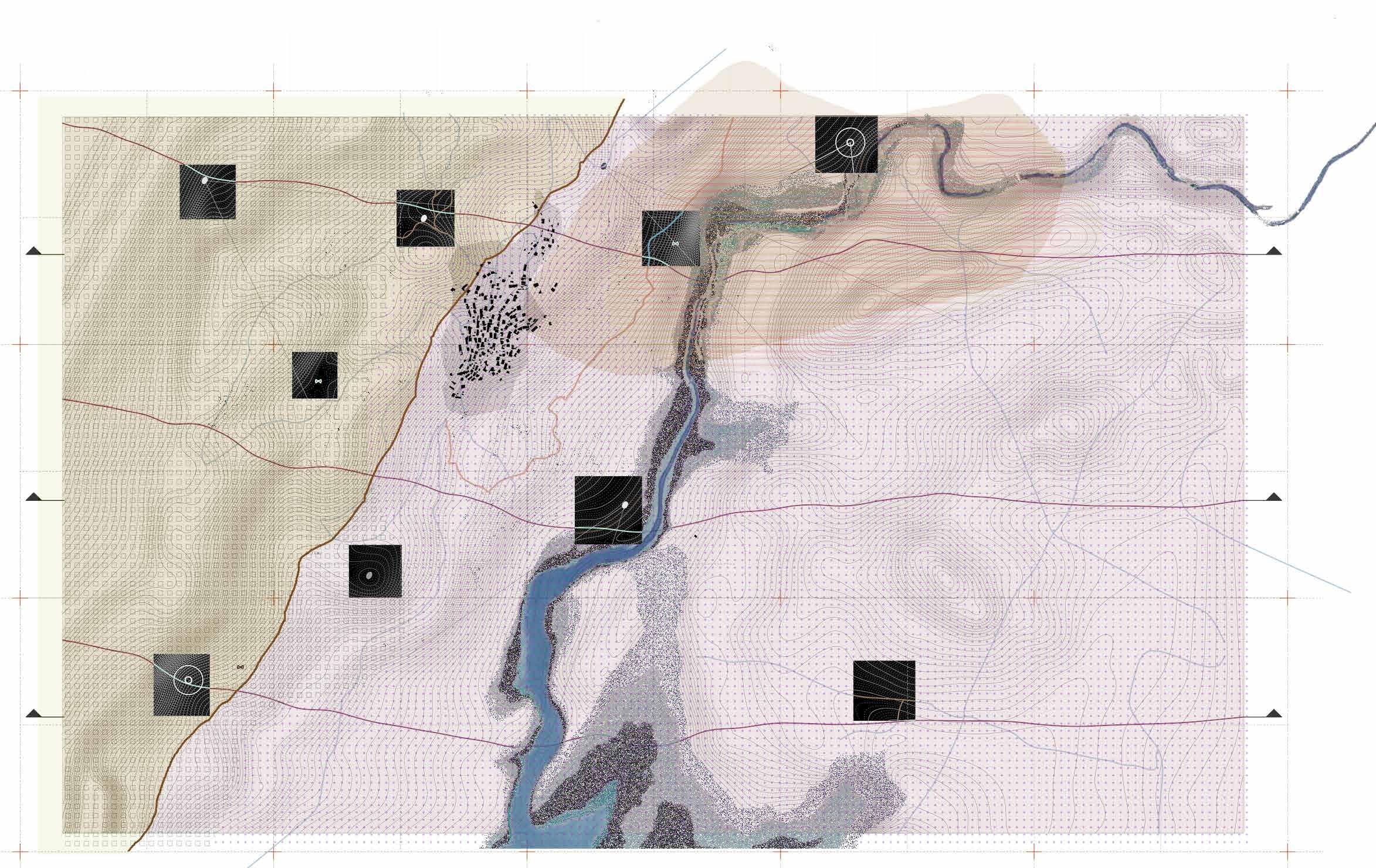

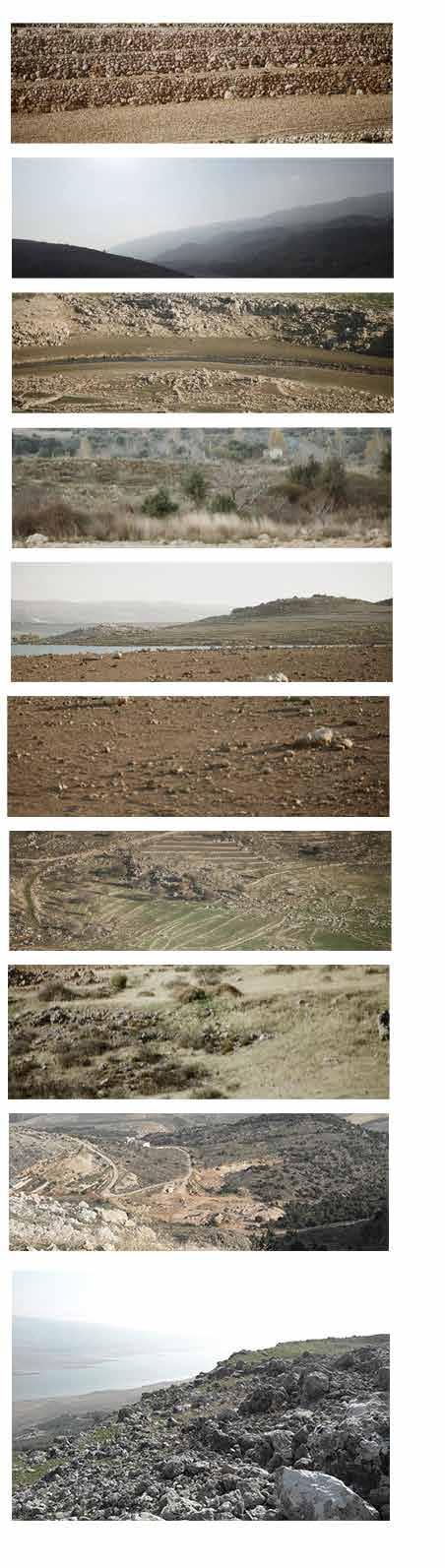

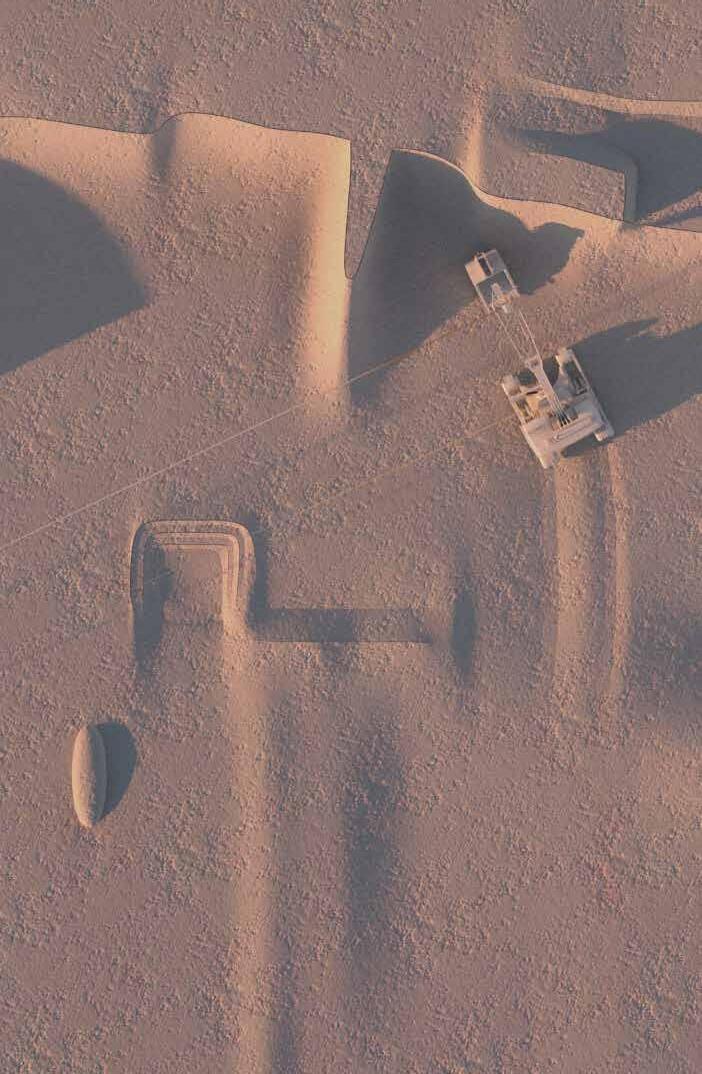

In this project I conduct field research in the landscape of the Bekaa region in Lebanon. Firstly in geological terms, and secondly in the geology’s subsequent cultural influence. Observing and measuring the forms and materiality of the slow forming landscape as well as the traces and clues embedded in it which allow natives to navigate and recognise points in time as well as inspired them to build the way they do.

The terrain consists of limestone karst with different formations determined by the Yammouneh fault, covered with a sedimentation of soil rich in silt and clay.

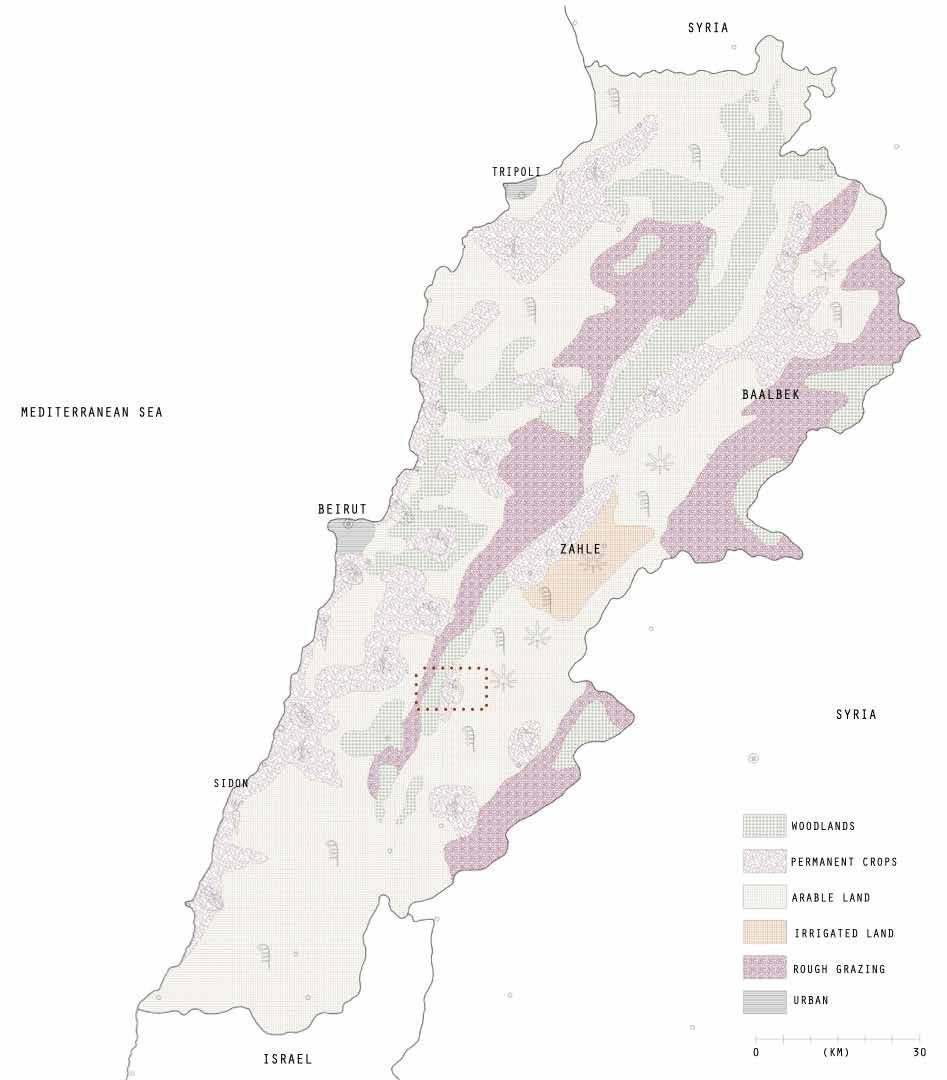

I am looking at material culture and technology as part of understanding the rural community, and how the landscape and geology have played a role as a decisive characteristic and engine of its local history. Construction technique is often the bridge between people and place, and evidence of the use of clay can be found on site from the modern days dating back to the roman era. This is a specific example of how decisively construction technique has informed the appropriation of environments by humans, and then as an essential factor in the construction of relationships between humans. By Identifying their surrounding as useful material, to extract, build with or within, the people became geological agents, developing a method that allowed a social development and cultural manifestation through their architecture.

An inevitable part of the project is about recognising the social, economic and political shifts that are affecting the Lebanese landscape. Following a massive rural exodus in the 90’s, there is currently a movement back to the countryside. One of the many consequences of that exodus was the abandonment of traditional earth construction methods for rural housing in the Bekaa. Clay was always used in its raw form, as mud bricks, covering mixtures for stone walls or earth roofs on a wooden structure. They was replaced with concrete structures for reasons of maintenance and cost. I am trying to borrow from the lost techniques of the past whilst preserving the benefits of the techniques that became popularised. Consequently exploring further potential of clay as building material.

I will study the housing conditions and domestic equipment of earthen houses of rural life in a village, in order to pinpoint why these traditional construction methods were lost, and whether it is desirable to bring them back in a meaningful way.

Bringing back these lost techniques and materials will have cohesive social effects, by integrating public program. As well as reconnecting the people of the village with their earthy landscape.

A landscape of Clay away from the urban densities of Lebanon in a village in the beq’aa valley, that has, like many villages across the mediterranean been subject to rural exodus and permanent leave.

‘In the settlers mind, land was property, real estate, capital, or natural recources. But to our people, it was everything: identity, the connection to our ancestors, the home of our non human kinfolk, our pharmacy, library, the source of all that sustained us.’ Braiding sweetgrass Robin Wall Kimmerer

The project is trying to reconnect the people of the area of the bekaa in Lebanon through secular means. The secular approach I have chosen would be through the finding of a new common ground for people to come together in a context that is at the periphery of the village and the landscape, accessible to all inhabitants.

With inteventions at different scales, the proposal encourages a reading of a landscape, through walks, refuges nestled in the territory and rediscovering a forgottent earthen architecture and repurposing it.

(1) reclaimed and retrofitted old abandonned earth house - turned into a bakery main public space - a square surrounded by - a library (2) - 400 m2

- a communal cooking area ( 3 ) - 300 m2

- a laundrette ( 4 ) - 70 m2

- a hammam / relaxation area ( 5 - 150 m2

Village municipality

litani river

Can fostering a relationship between the people and their geology be achieved by developing tools and toolpaths for manipulating earth at the scale of the landscape?

Extracting, moving, scraping, moulding, smoothing, compressing, extruding, compacting, forming earth.

In other words, can we bypass the middle man which is the quarry site and create a contextual ecosystem of material construction methods?

Subtracting from the earth ( - ) in order to inhabit it and build up with the excavated material ( + )

This project explores the earthen geological layer and the construction methods that allow an inhabitation of it.

Earth is brought to the domestic realm to be used for cultural and traditional costums and building constructions. I propose to go to the earth, moving it, moulding it to create inhabitation and Implode the domestic realm.

It is an attempt at blurring the boundary between the urban and geological fabric, suggesting that the people of the town might be able to rethink their place within the country at a time of turmoil by understanding their place in the landscape.

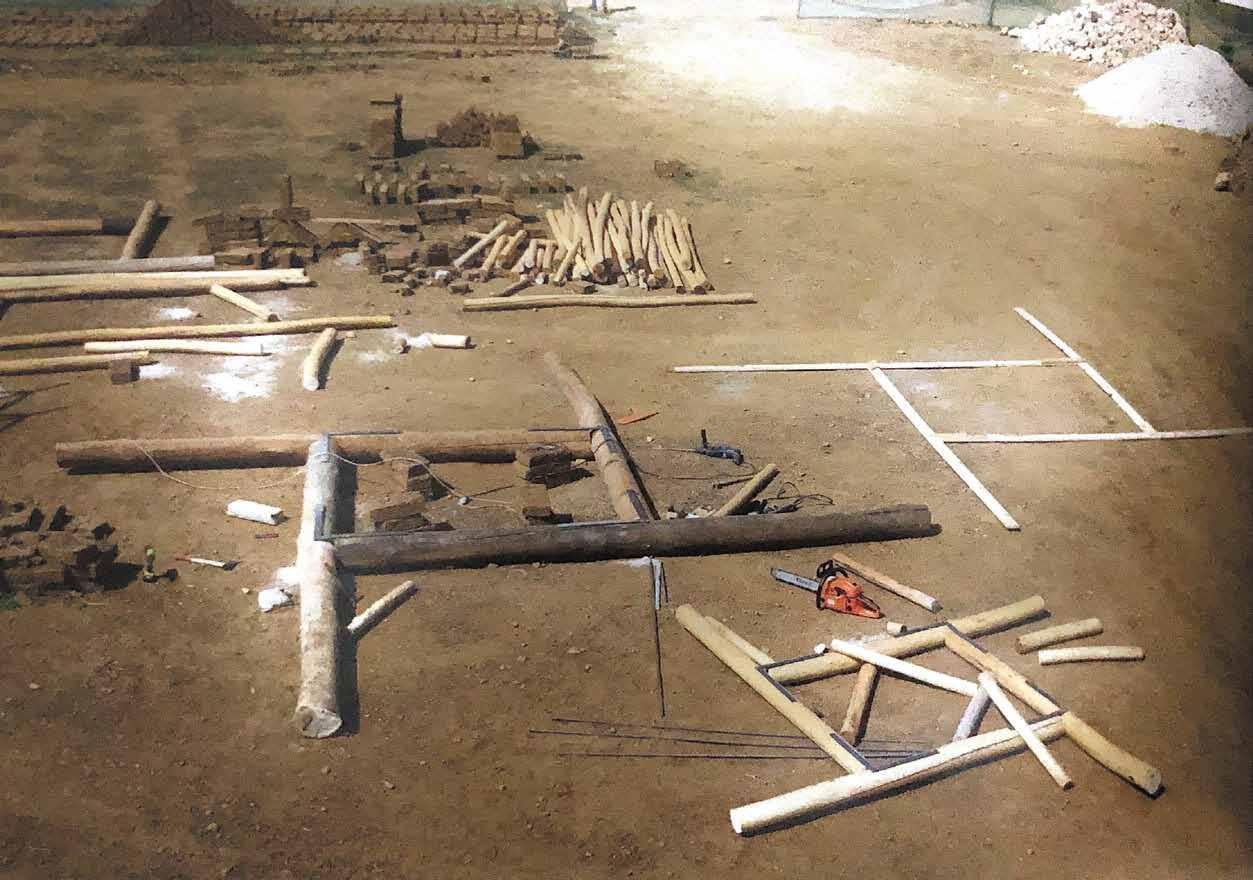

The construction sequence begins EXCAVATION ( - )

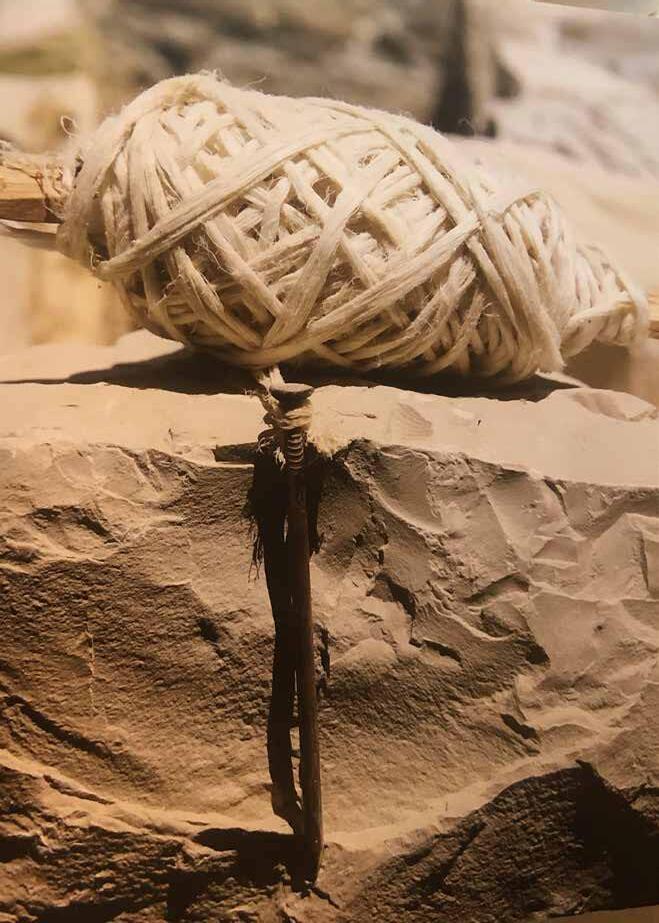

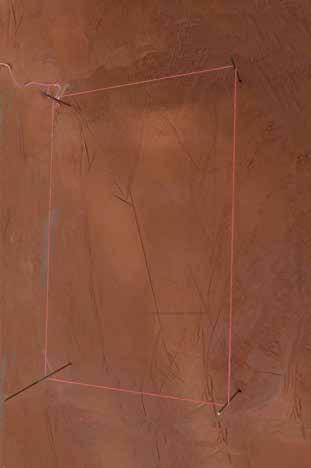

(1) Careful marking of the terrain/ with simple tools borrowed from the vernacular: threads and nails as instructions of digging in order to start with the excavation

Situated on a slope of 12 o, the construction of the project will begin at the top of the slope. After analysing the quality of soil and concluding its richeness in clay, a construction method conscious of it’s geology will be suggested.

(2) Planned excavation/ according to needs, the terrain will be excavated, earth will be moved, compressed, creased, piled, smoothed

(3) The excavated material will be:

a/ displaced down in order to flatten the slope of the site to cater for a public square with easy acess and fluidity compressed, shaped, manipulated, treated to design the public square

b/ used for the making of earthen components

( the components will be made and air dried on site using brick making tools and moulds using various techniques, and will be transported to a nearby kiln for firing )

brick tiles for shells

bricks for foundations and walls tiles for floors

(4) Preparing the ground/ Smoothing, compressing, grading the ground for it to be ready for construction at pre defined depths Defining entrances and stairs

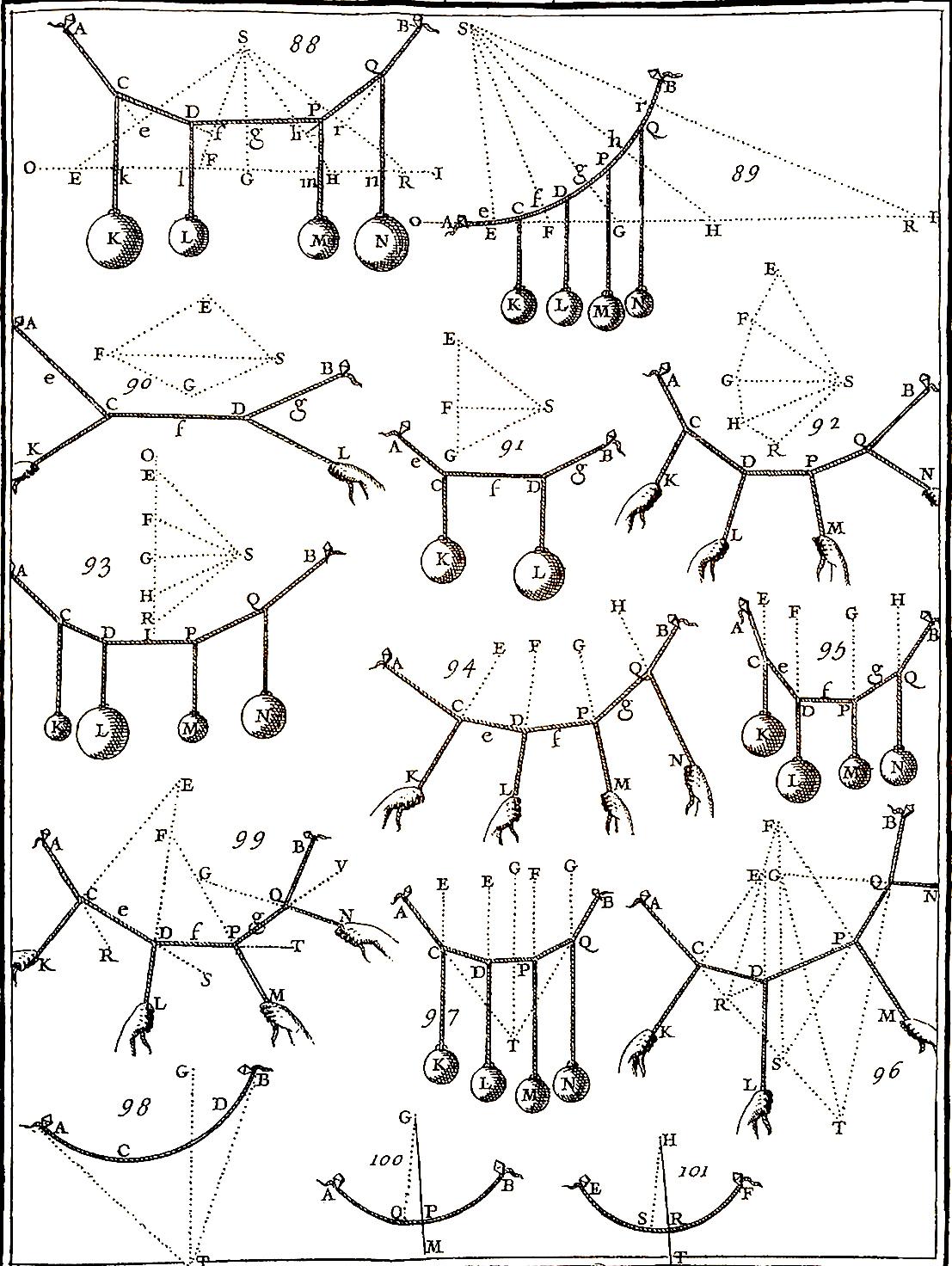

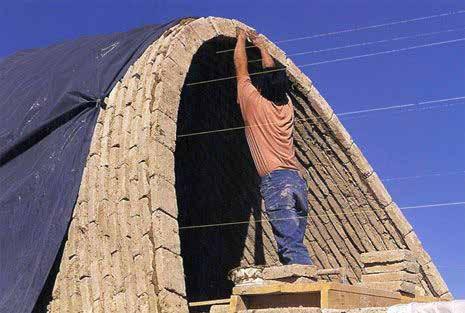

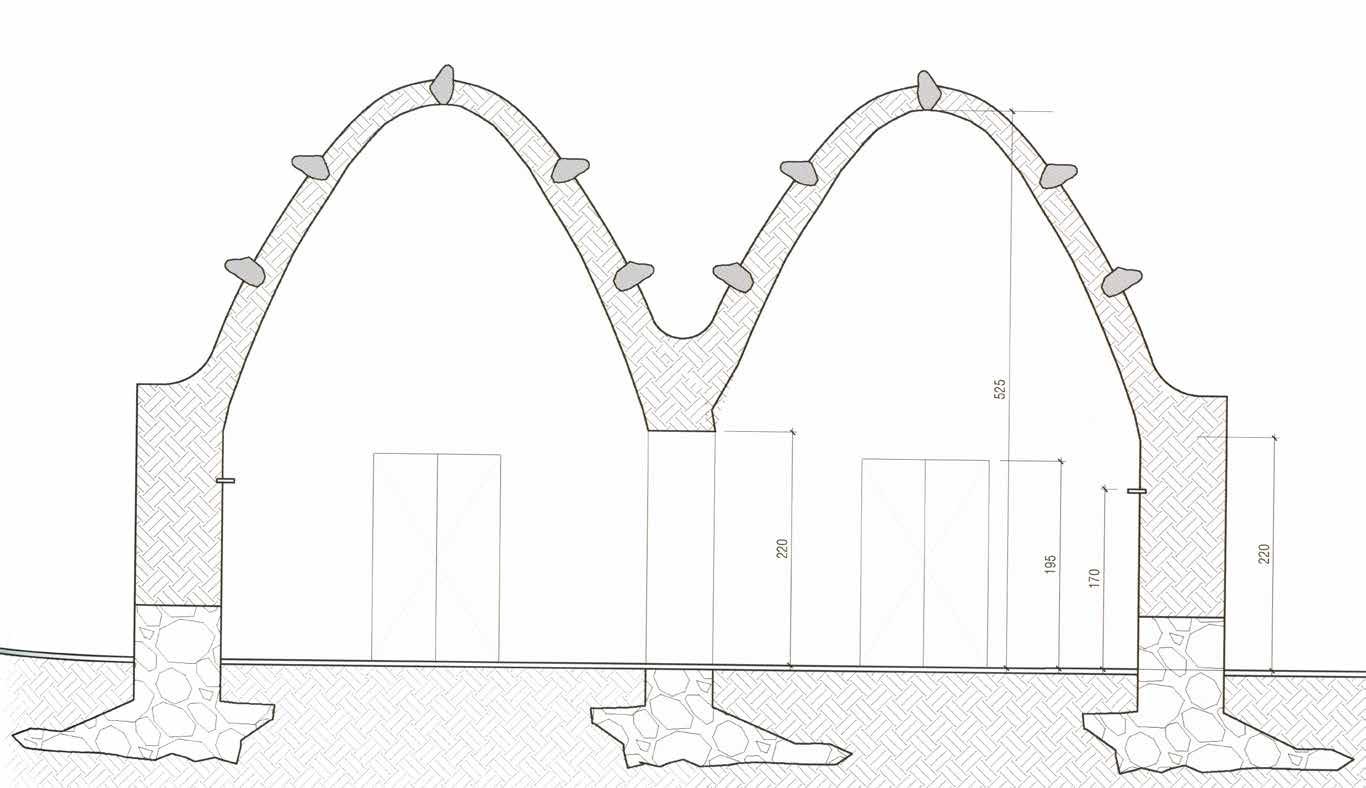

(5) Marking the positions of the walls and vaults/ Using scaffolding and bent metal wires for the outline of the designed vaults

CONSTRUCTION ( + )

The assembly of bricks begins incrementally from left to right as the ground begins to be ready for construction

(7) Construction of brick foundations and walls

(9) Ground works continue, with a similar process

(6) After firing, the bricks and tiles are brought back to site

(8) Construction of 3 layered brick tile vaults, assembled with fast setting mortar

The construction of the vaults needs very little centering, support and markings to get the shape right and scaffolding for the builders to be steady at various heights

(11) Earthen mixes are applied to different zones for delineation, waterproofing and flooring (made on-site)

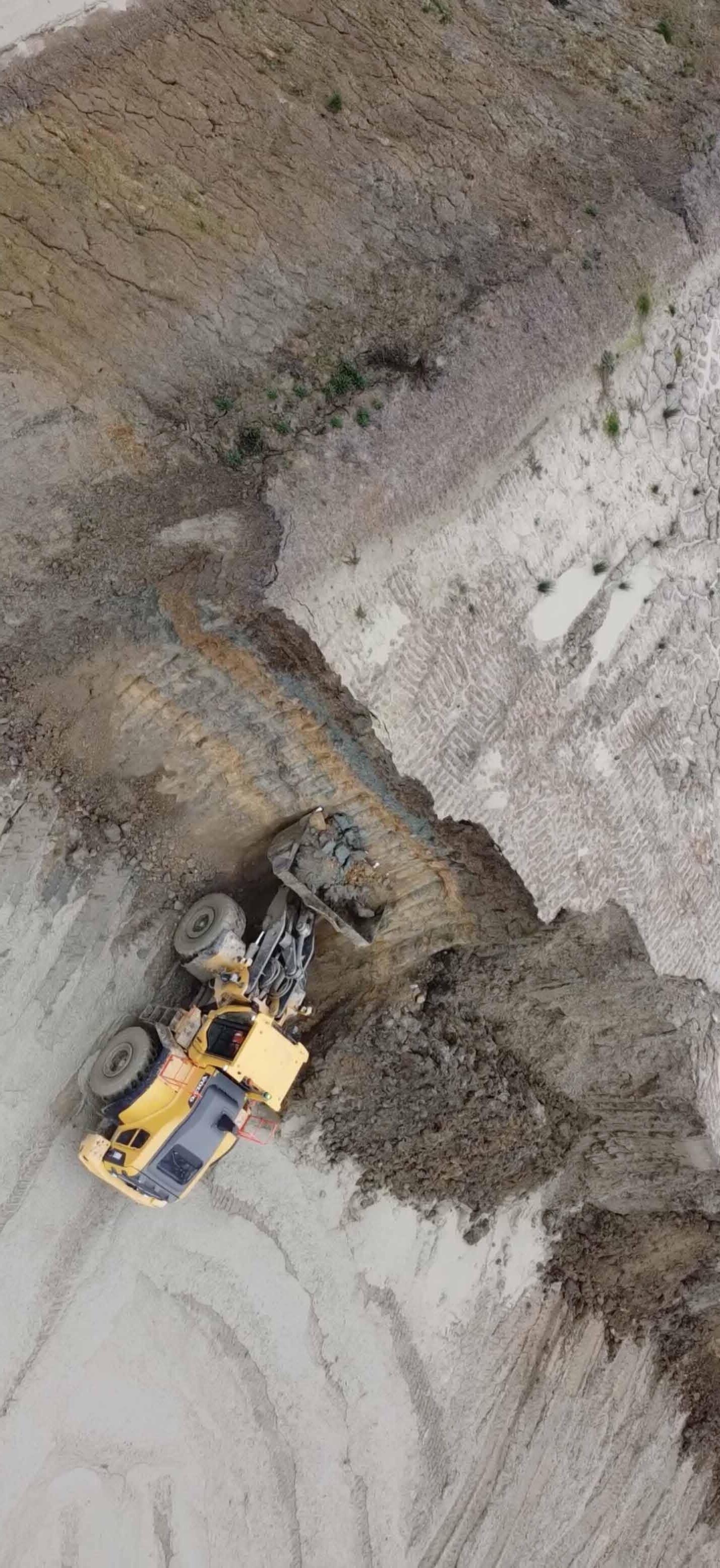

FIELDS OF EXTRACTION

PROBLEMATIC RELATIONSHIP WITH EARTH / AN OPPORTUNITY TO REDEFINE IT SITE GEOLOGY / GEOGRAPHY THE LANDSCAPE OF THE BEQ’AA LOCAL CONSTRUCTION HISTORY / A VILLAGE IN THE BEQ’AA CONSTRUCTION PRECEDENTS

https://www.sciencemag.org/news/2005/03/outdoing-mother-nature

Mining and quarrying extract a wide range of useful materials from the ground such as coal, metals, and stone. These substances are used widely in building and manufacturing industry.

Mining and quarrying involve investigating potential sites of extraction, then getting the required material out of the ground, and finally processing with heat or chemicals to get out the metal or other substance of interest.

Gravel, clay, sand, and limestone are quarried in vast quantities for use in building materials like concrete, cement, and glass. Crushed stone from quarries is used in large amounts to build roads. A mile of a motorway could require nearly a quarter of a million tons of crushed stone.

Mining and quarrying can be very destructive to the environment. They have a direct impact on the countryside by leaving pits and heaps of waste material. The extraction processes can also contaminate air and water with sulfur dioxide and other pollutants, putting wildlife and local populations at risk.

The industrialization of architecture has been a major proposition of the modern movement. The synergy between modernist architects and industry enabled to provide housing for millions and to improve the quality of life for people experiencing poor living conditions, sufering relocation after the war or following decolonisation. But the standardization produced by building codes and the industralisation of architectural elements has also resulted in the homogenisation of the built environment and the architect’s role being gradually reduced to project management and product specification submissive to industrial interests. The environmental and socio-political implications of this condition in construction, similar to the agricultural and garment industry, are quite profound.

‘Human reality resides in its smallest details. More than anything else, technology shapes our culture; it influences our intellect, our very way of being, and our existence. Technique is not only constrained and in opposition to the spontaneous but it also embeds a fundamental philosophical dimension that relates to ideas of freedom, men’s capacity to invent their lives, knowledge and existence.’

Gilbert SimondonOnce very in tune with the geology around it, borrowed earth, over time through instrumentalisation of earth through trade and more efficient techniques, and consistancy of doing it through larger monopolies meant that people build with earth from somewhere else.

As a result of this, contribution to the cycle but also lost relationship with their own land.

I suggest a hyperlocal approach to material provenance, a geologically aware construction method that will allow us to be in tune with our surroundings.

‘Humans now move an order of magnitude more earth than all natural processes combined’

fundamental problems

“Traditional and contemporary art of raw earth construction are both absent from even the most recent books on architecture, disregarding its due importance, and its true diversity, quality and modernity. With some notable exceptions, this ignorance had produced a lack of reliable information about the future uses of this natural resource as a locally sourced and ecological- ly sustainable building material. The dearth of information is the result of a sustained and profound crisis of cultural amnesia. Remedying this missing knowledge would allow a wide range of arcitectures to be built in situ, in both emerging and industrialised countries”.

Inhabiting the Earth Jean Dethier, The Architectural Review, Feb 2020

POLITICS

the makeup of soil, which differs from one place to another, makes it difficult to create material standards for earth. An important consideration in the processing and selling of building materials. This does not bode well for earth’s role in a capitalist society. Increasingly, it is illegal to build with earth because of building codes that are enforced by municipalities.

PREJUDICE - inferiority complex

AESTHETIC

Earth construction is usually not taken into account as a viable alternative to common industrialised materials just because we are not used to earth buildings. With our point of view too often influenced by the modernist aesthetic of white pristine walls we are skeptical about the earth option. The first (...)“today it is overlooked as a building material. When earth is used, by architects rather than the many hands of craftsmen and builders, it is often the sour- ce of controversy”.

problem is about getting used to a different, much richer, more colourful and warm aesthetic.

LACK OF KNOWLEDGE

“One of the major reasons is likely to be a lack of knowledge. Although ram- med earth itself is old, our research is quite a new field compared with other more traditional construction materials like concrete, steel, masonry and tim- ber. Unfortunately, a lack of research means a lack of understanding of the material and its structural properties”.

local problems

lost craft in Lebanon

Ignorance of an abundant material , fogotten recource

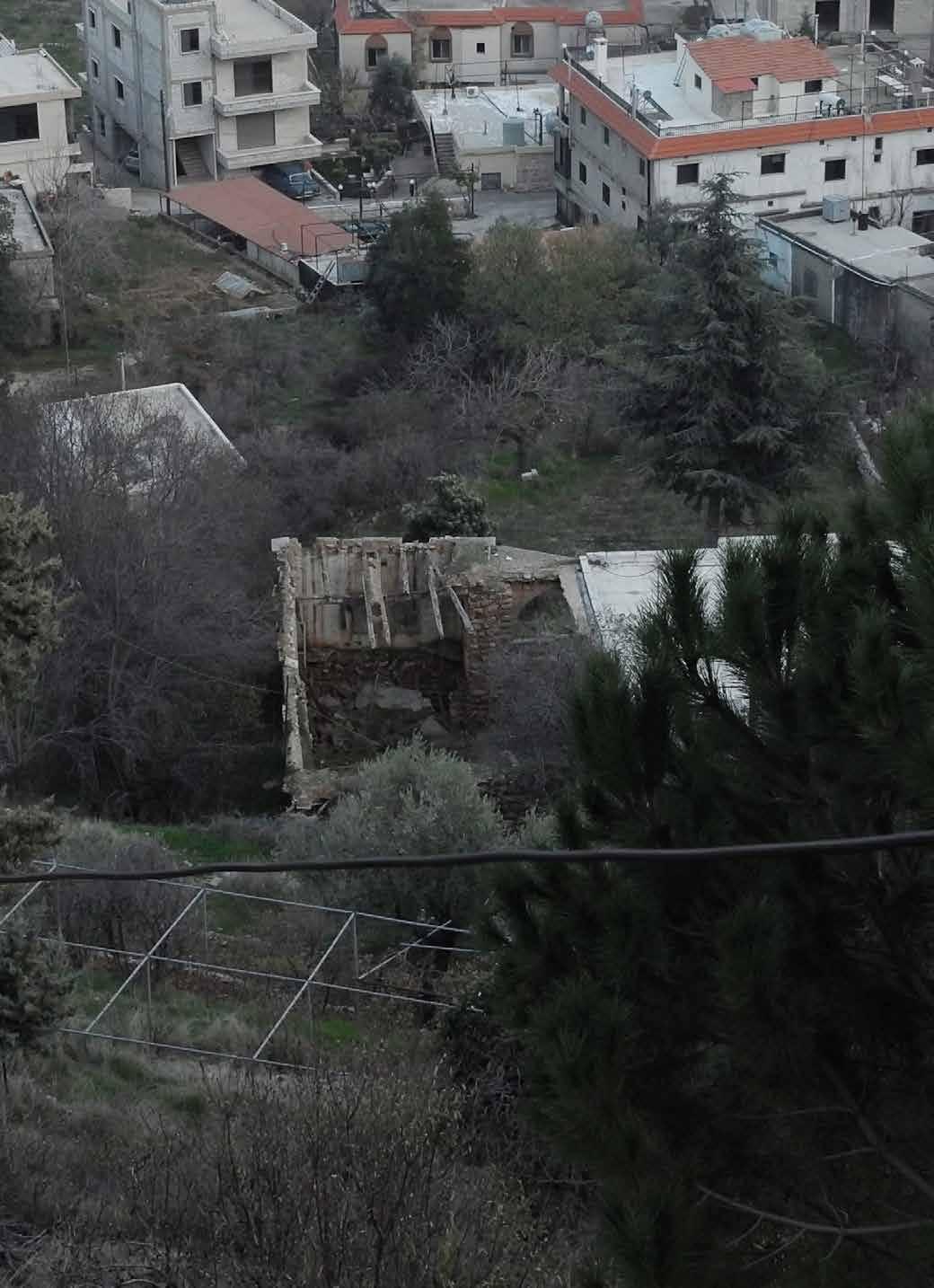

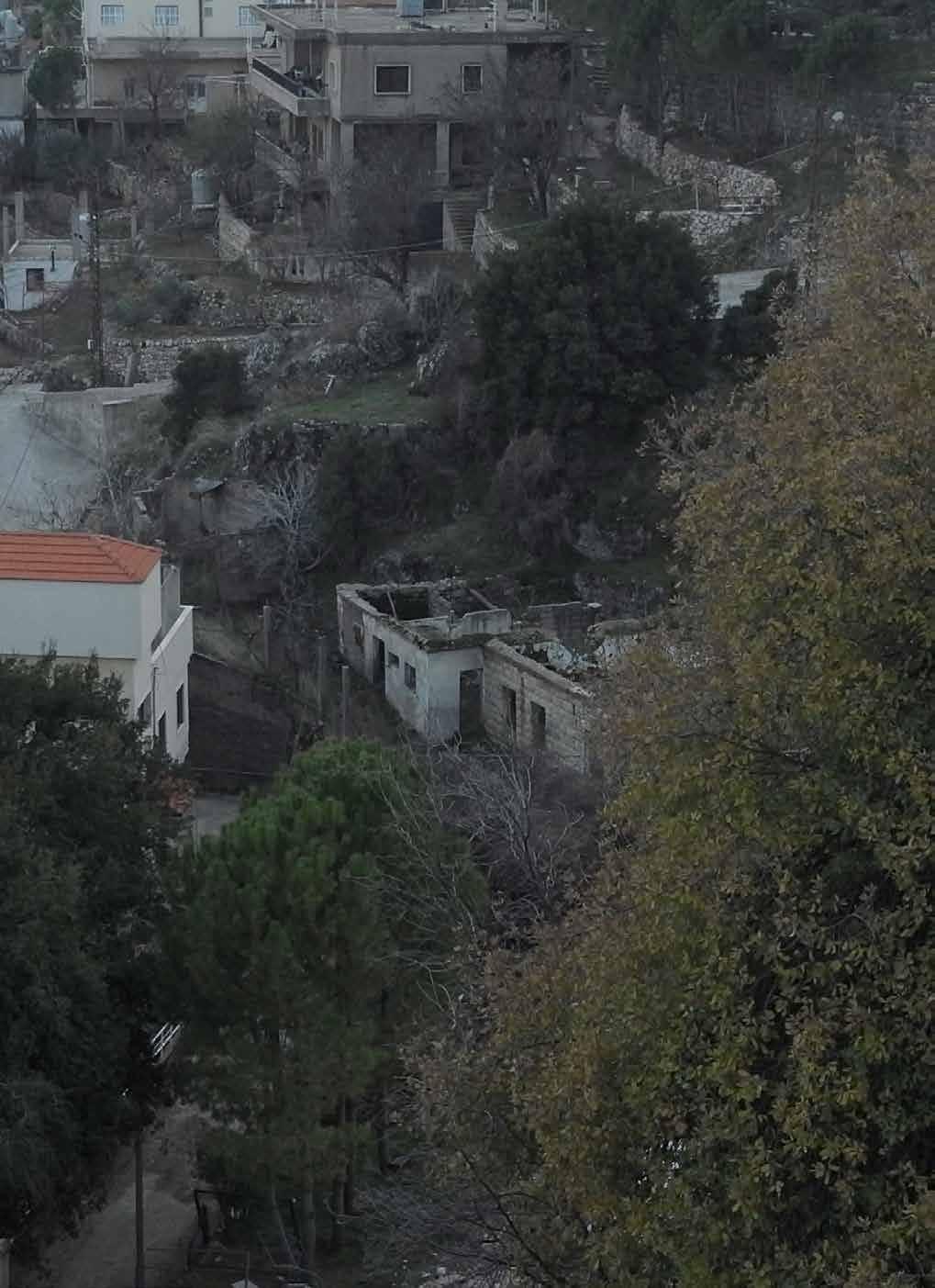

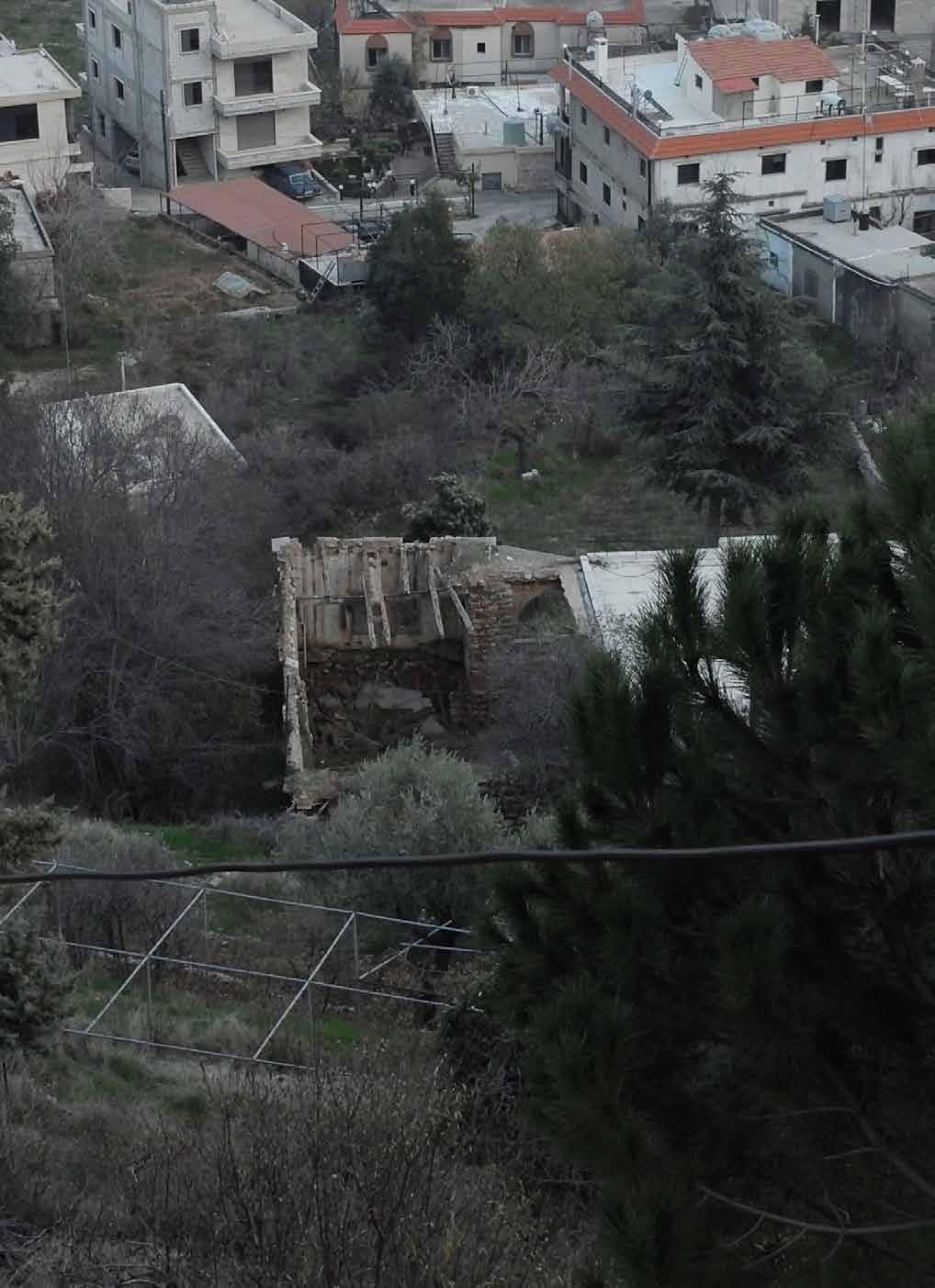

The earthen architecture which was, in the last century, the mode of construction in use in certain regions of Lebanon and particularly in the Bekaa valley, no longer exists today except in a state of reminiscence in many villages.

One of the social causes of the switch from earth to concrete was the raised standards of living This traditional architecture suffers from a devaluation, with very little being proud of it, as it is associated with poverty and synonym to misery.

Another reason is the rural exodus towards the Capital and big cities, especially definitive emigration to far away countries, emptying out the villages of their inhabitants. Civil war They are often reduced to the state of ruins because without upkeep and maintenance they deteriorate, especially the roofs. They collapse and hardly survive the harsh winters particularly where the snow is abundant.

Earth is one of the few materials on the planet that has not been subject to large scale industrialisation. The heterogenoity of soil has allowed earthen building techniques to be technologically and contextually supple. While many machines have been devised to ‘advance’ the state of the material, earthen architecture remains largely a specialised and traditional practice, unchanged for thousands of years. Yet the advancements of the industrial revolution have brought about technologies that, when appropriately coupled with earth techniques can result in ingenious hybrid forms of construction.

DIRT - that most ancient of building materials - is experiencing a popular resurgence, one of the world’s oldest building products has now become one of the most sustainable building materials. The earth houses within are as aesthetically pleasing as they are ecologically sound.

It is estimated that between a third and half of the worlds population - approximately three billion people on six continents - lives in buildings constructed of earth. The ground we walk on and cultivate our crops in is the most widely used building material on the planet.

Ronald Rael, earth architecture

There are perhaps twenty different methods of employing earth to construct walls, floors, and roofs of varying dimensions and form. The adaptability of the material has allowed it to respond to a wide range of contexts, cultures, and epochs, including the spectrum of architectural history from antiquity to the modern era.

Vitruvius felt that the primary qualities architecture should represent were firmitas, utulitasi, and venustas - durability, usefulness, and beauty. Inherently, earthen architecture represents this triad of values, and he wrote extensively about the topic.

The typologies of earthen architecture, extend beyond buildings for living, and include structures for working and worshiping, as well as the countless forms of earthen architecture that are not inhabited by humans, such as agricultural buildings, city walls, and monuments.

In India there are estimated to be as many as 80 million dwellings made of earth, and in China the number of people living in earthen homes is estimated to be 100 million. In France 15 percent of rural buildings are made of rammed earth, and the united states is the leading consumer of mud bricks in the industrialized world. This makes the ground we walk on and cultivate our crops in the most widely used building material on the planet, Dirt.

ECOLOGY - Earth is an inherently ecological material. Earth has excellent thermal mass properties, which can maintain comfortable interior temperatures without the need for mechanical heating and cooling. The utilisation of earth requires little embodied energy and structures made of it are highly recyclable.

Earth by this definition is simply clay, gravel, sand, silt, or other friable soils, in which organic materials sometimes exist. Because of the ubiquitous availability of appropriate soil, buildings constructed of earth can also be found everywhere - in almost every terrestrial biome on the planet.

DEMOCRATIC ACCESSIBILITY - earth is everywhere

“As we construct thickness and inhabit the depths, as we burrow and excavate, we carve a space for ourselves on this third planet: we reconnect with the soil to stretch the confines of time”

journey through the landscape as an act of mapping / understanding the territory and material movements SEPTEMBER

Marls and thin bedded carbonates, Hammana formation (albian C3)

Limestone and dolomite limestone Kesrouane formation (Jurassic J4)

Limestone, Marls and Marly limestone Sannine formation, Cenomanian (C4)

WATER LEVELS

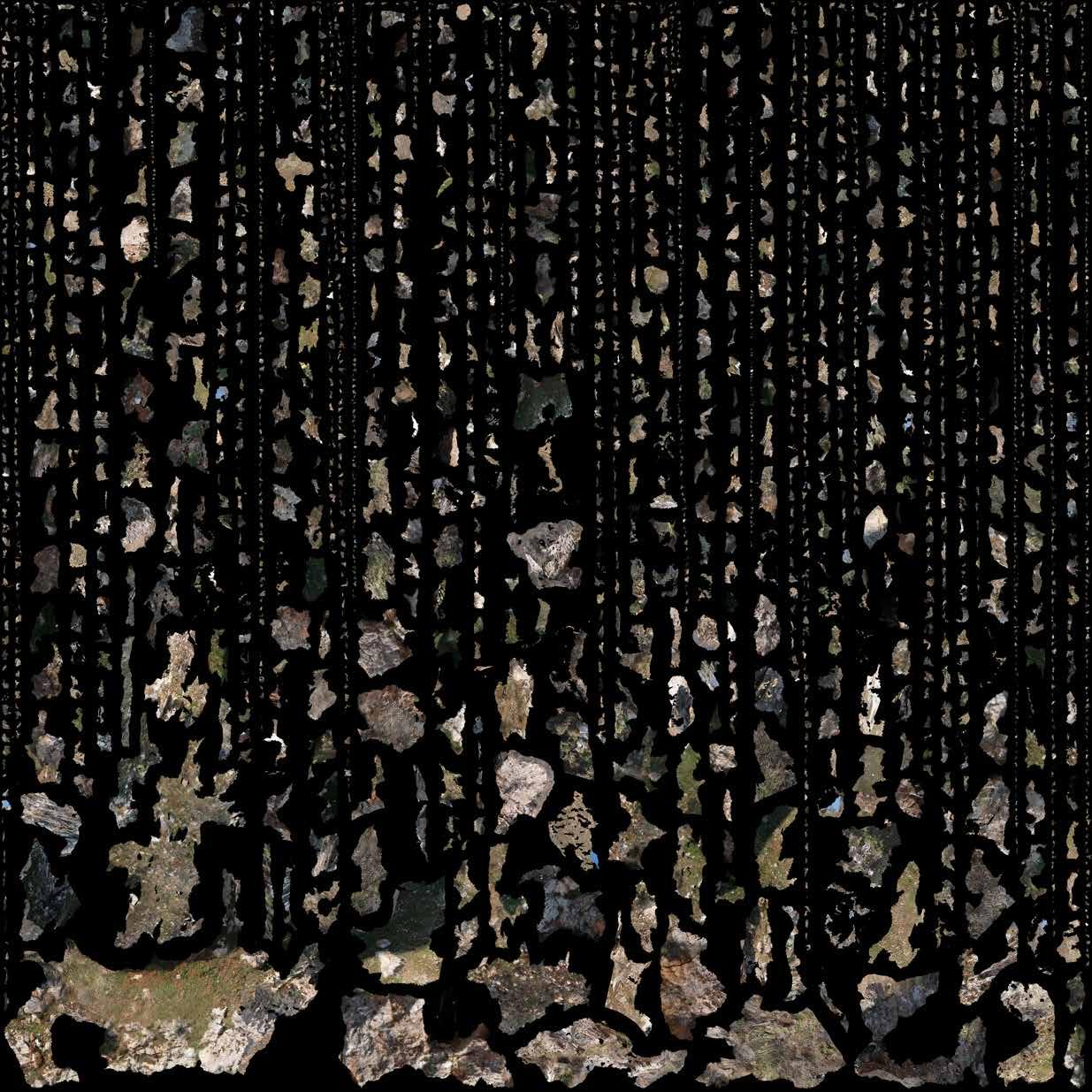

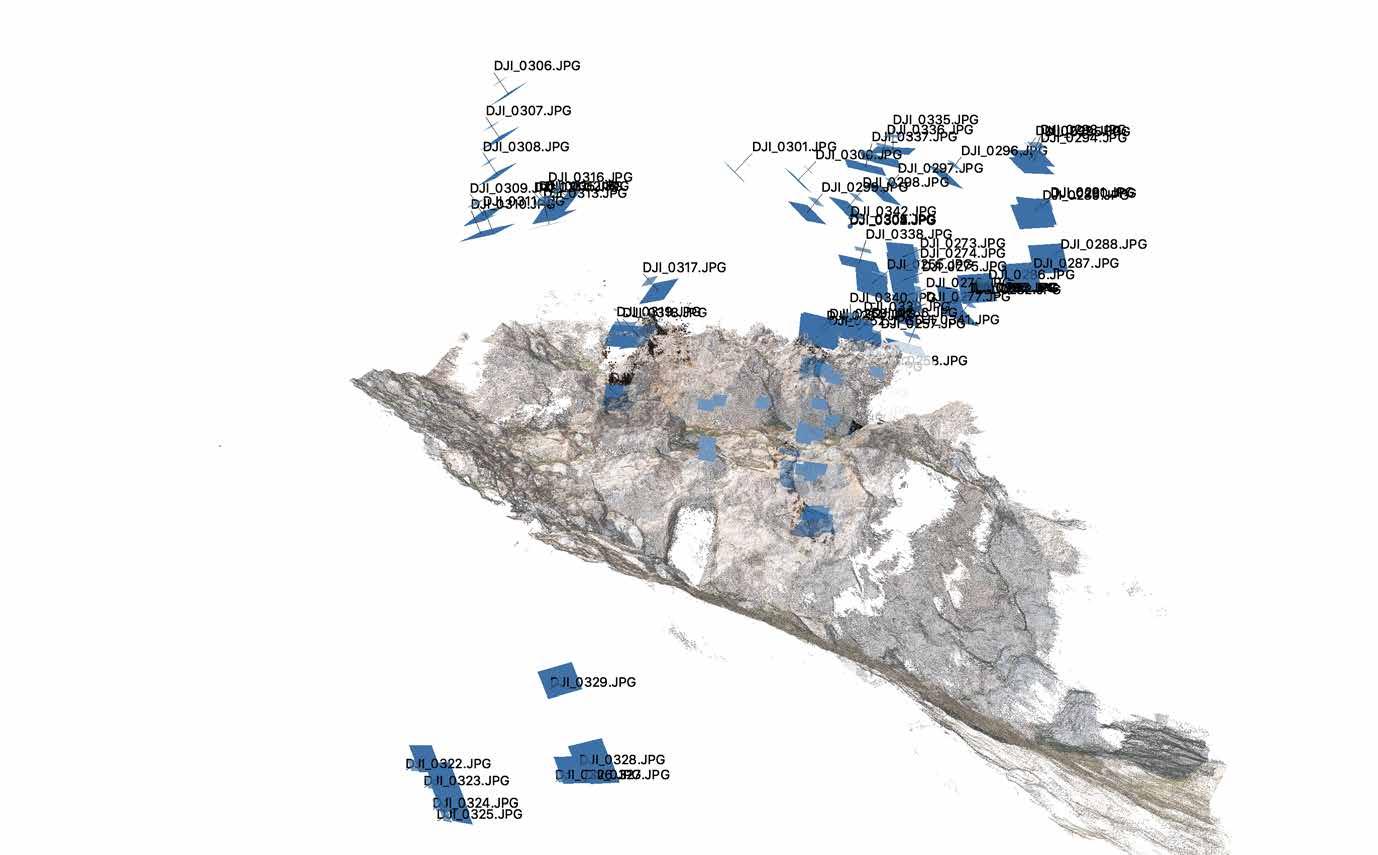

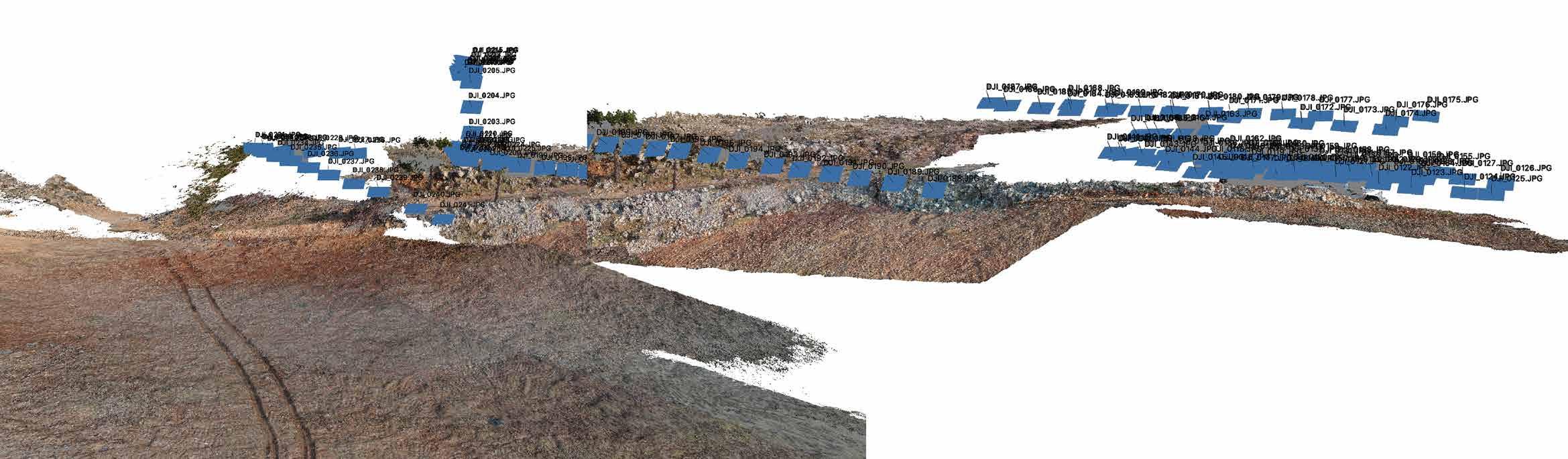

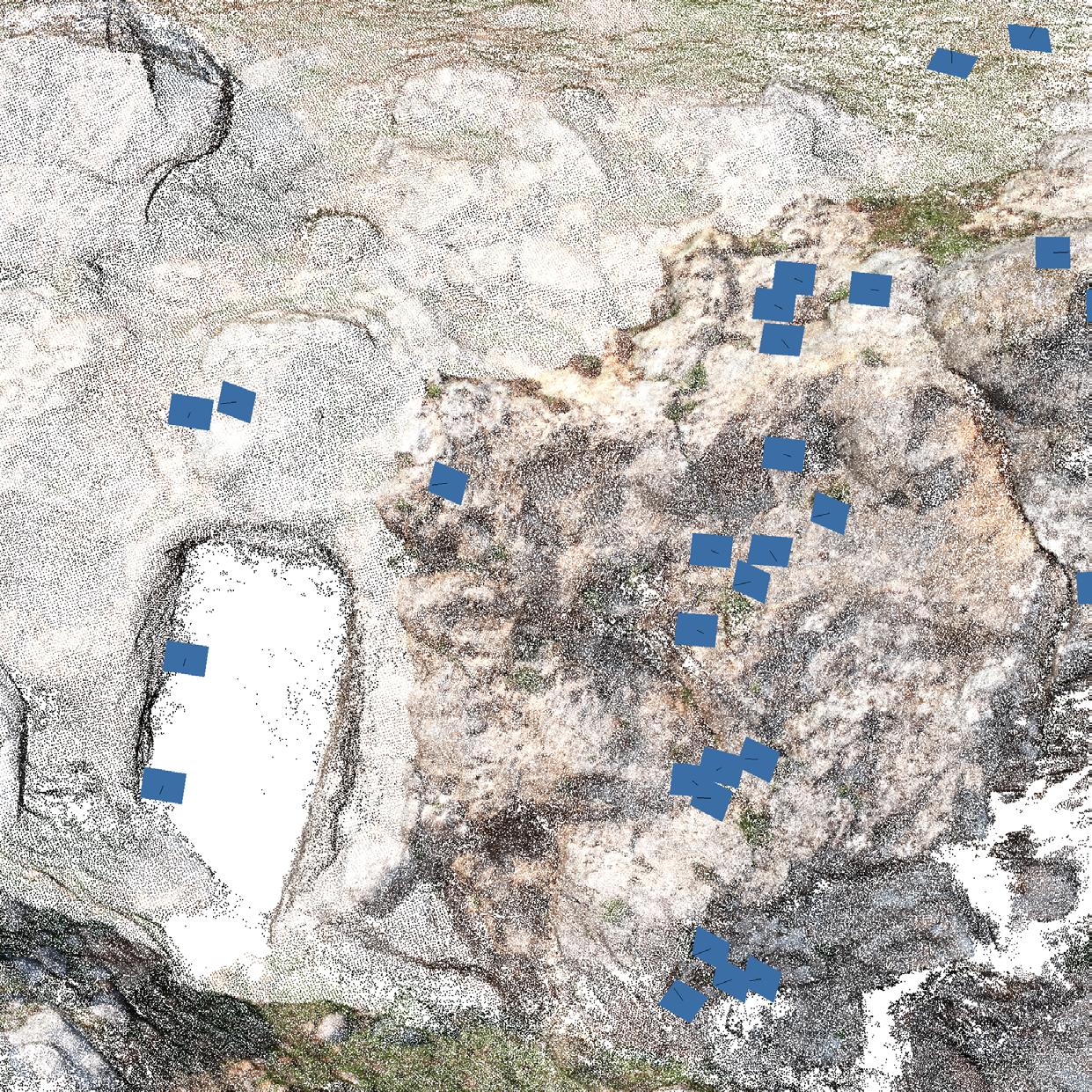

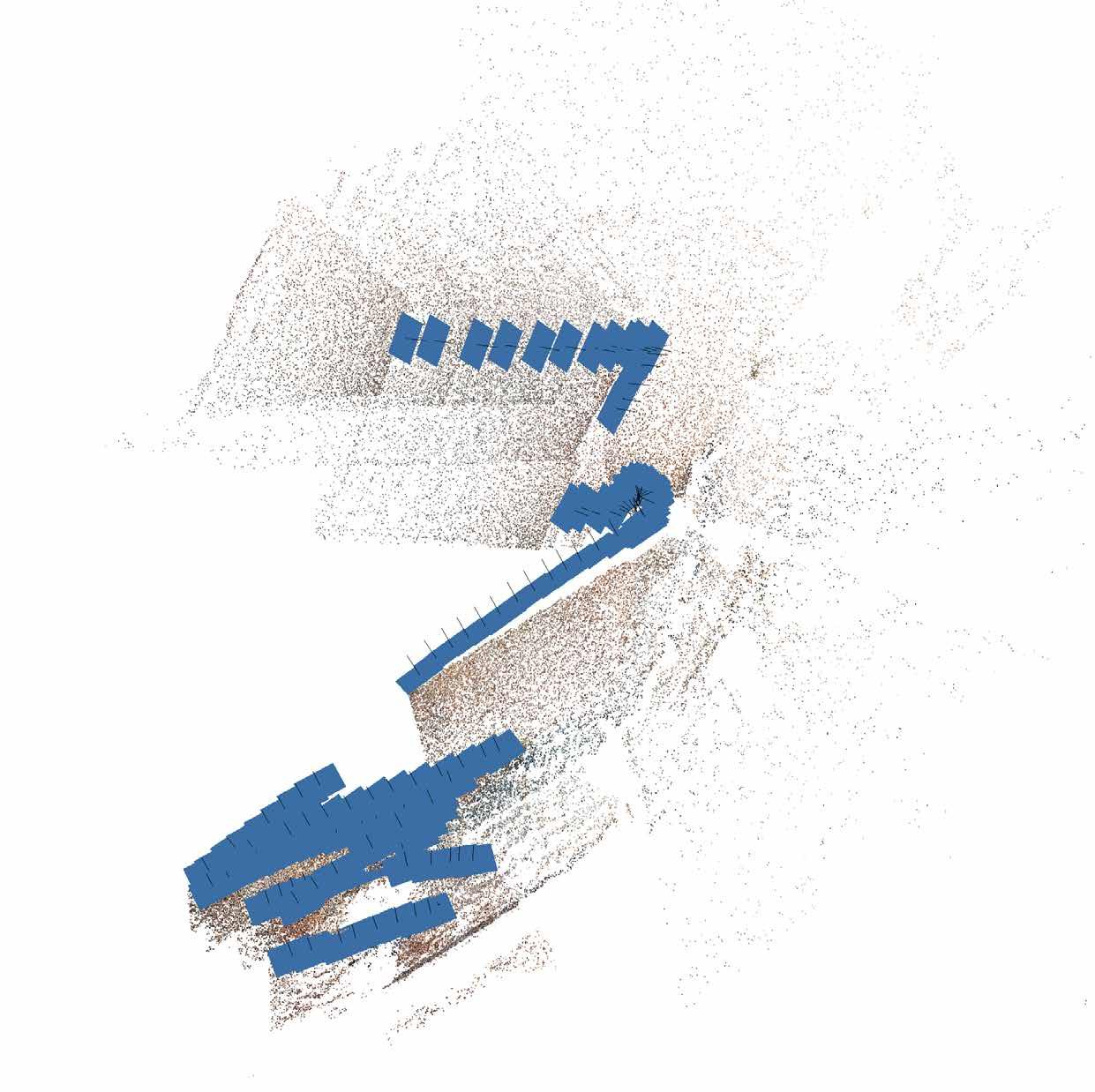

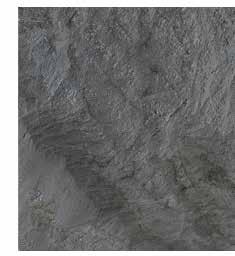

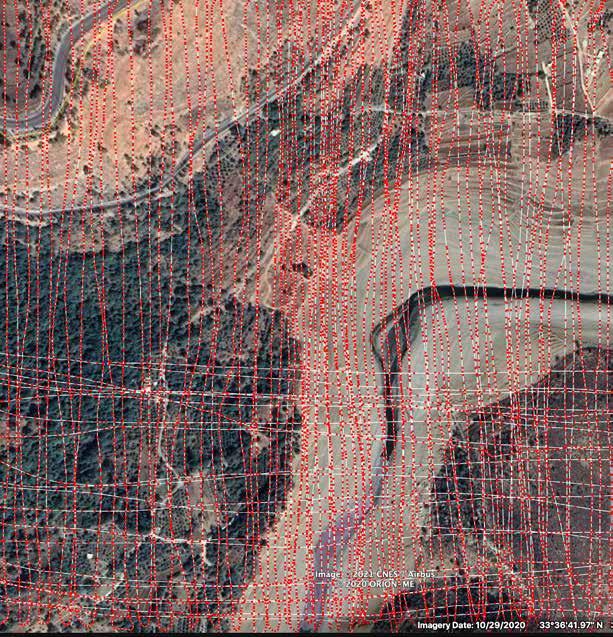

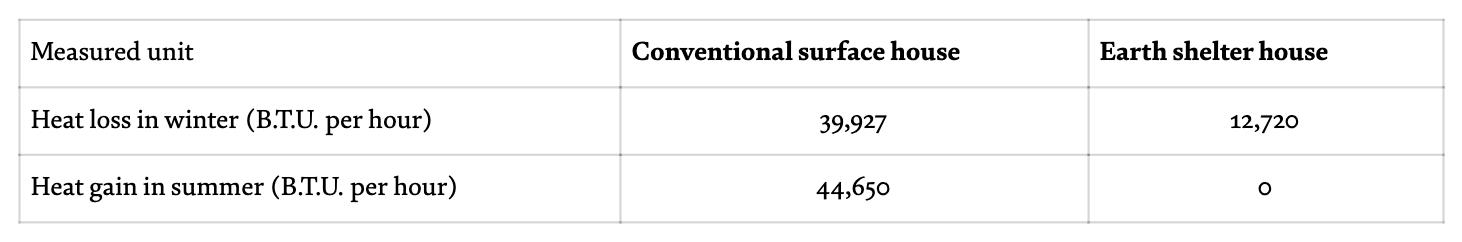

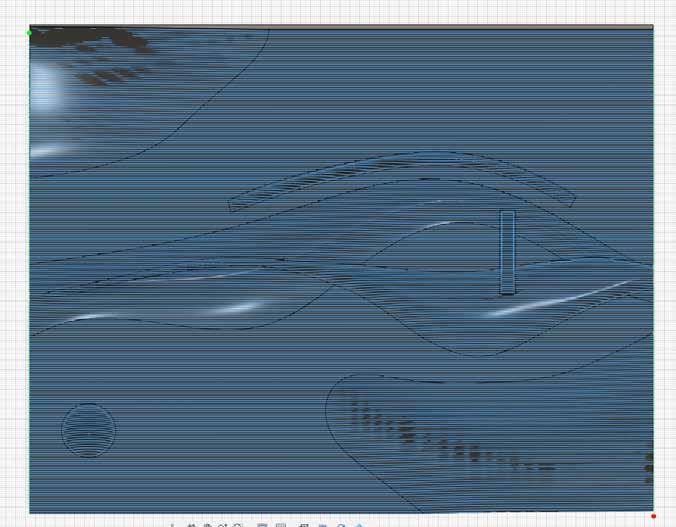

3d scanning as a means of observing and collecting data from the surrounding landscape, in order to recreate it digitally and extract textures and topography information

The blue square represents the photo taken, in each scan, the blue squares , taken at ddifferent angles and positions are stitched together to get a wide span and replicate the landscape digitally.

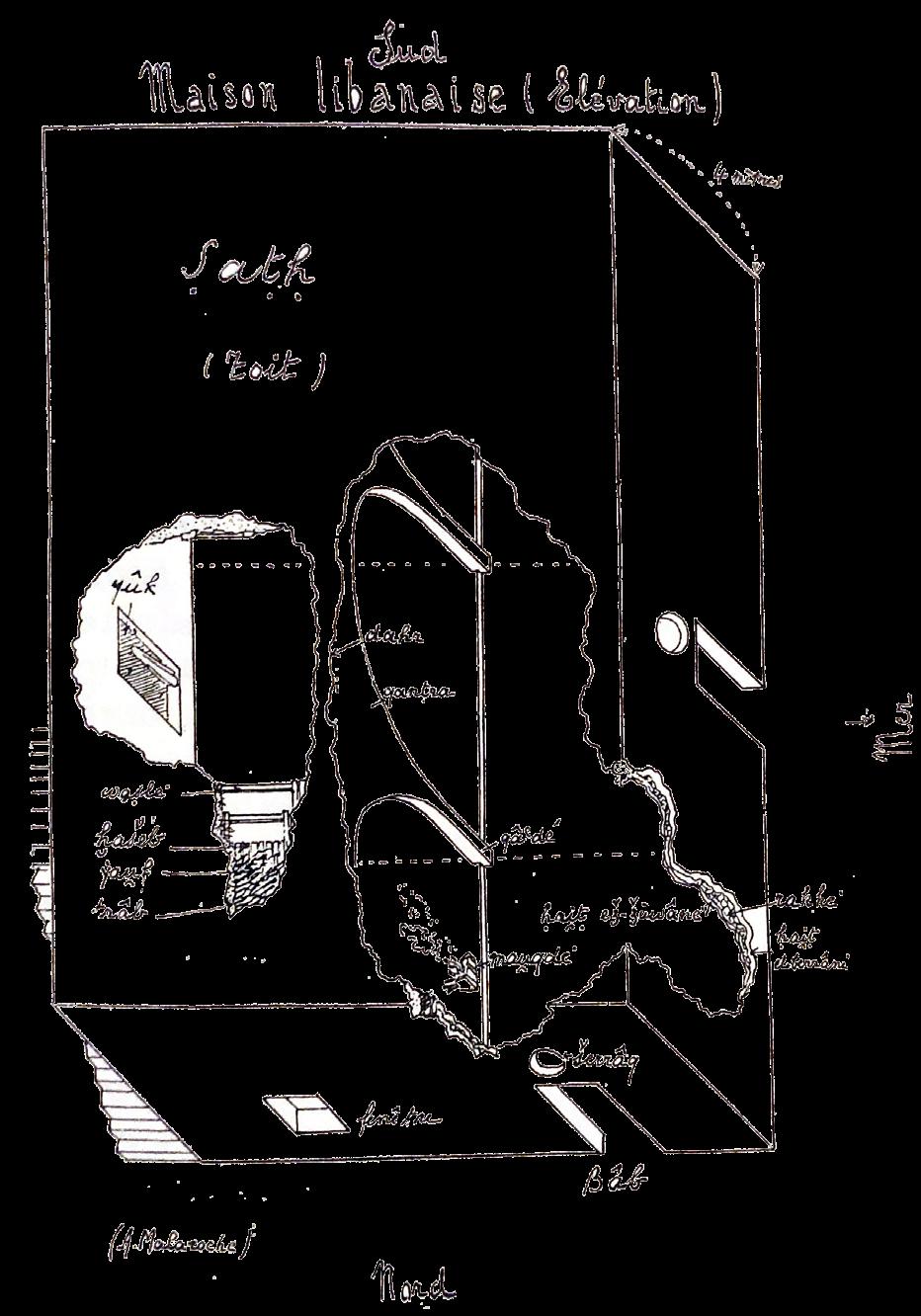

LOCAL CONSTRUCTION HISTORY EARTH CONSTRUCTION IN THE BEQ’AA

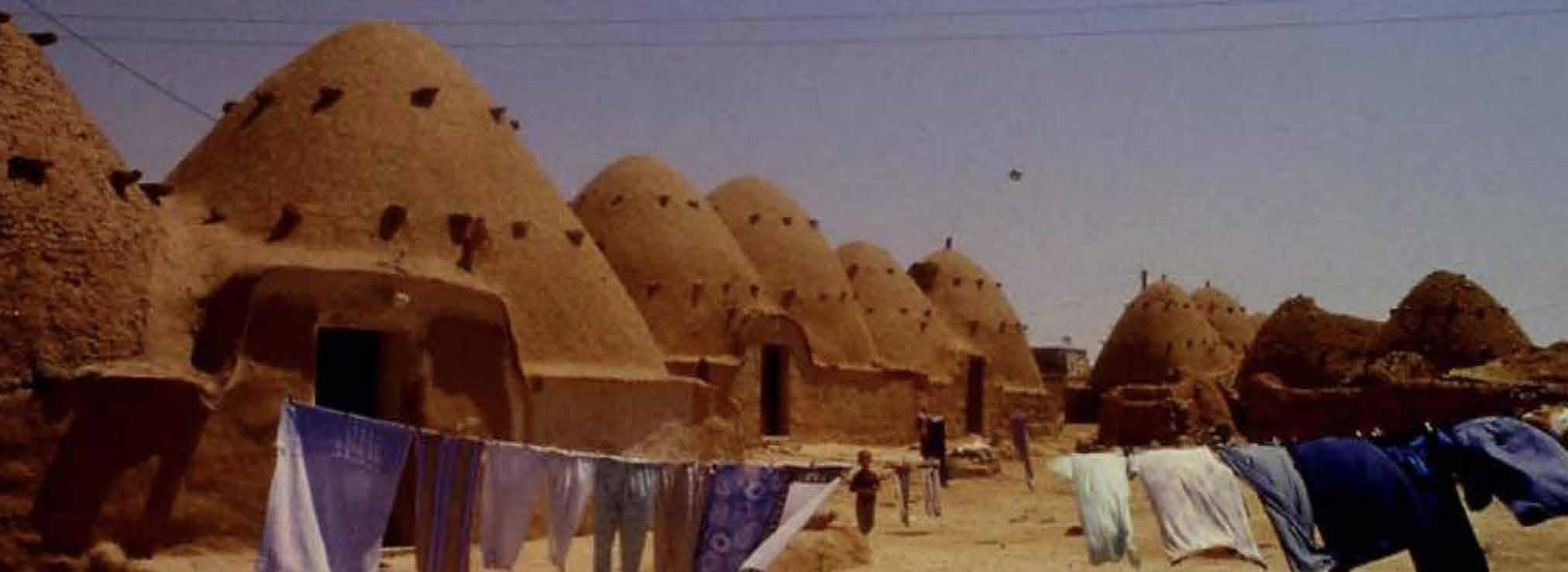

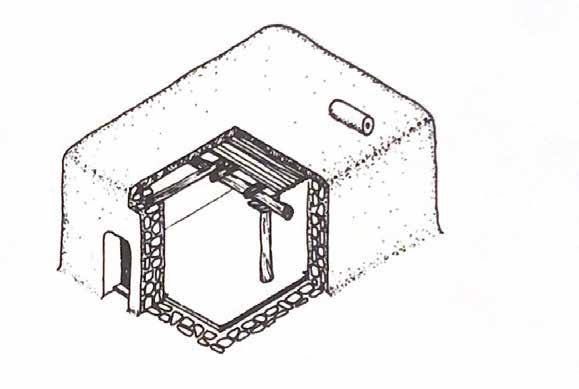

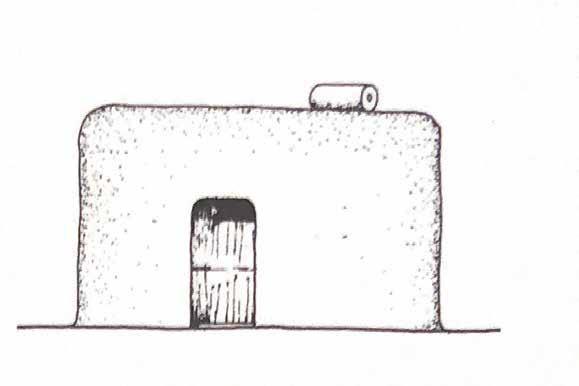

The Beq’aa is a historic area of implementation of raw brick construction. The construction techniques are exclusively made of earth in the valley and mixt, rocks and earth in the more mountainous areas that overlook the plain where the risk of snow is higher.

The earthen architecture which was, in the last century, the mode of construction in use in certain regions of Lebanon and particularly in the Bekaa valley, no longer exists today except in a state of reminiscence in many villages.

One of the social causes of the switch from earth to concrete was the raised standards of living. Another reason is the rural exodus towards the Capital and big cities, especially definitive emigration to far away countries, emptying out the villages of their inhabitants. Civil war They are often reduced to the state of ruins because without upkeep and maintenance they deteriorate, especially the roofs. They collapse and hardly survive the harsh winters particularly where the snow is abundant.

The combination of very few and derelict earthen houses found and the few documentation on this architecture leads us to the hypothesis that the most beautiful specimens of this architecture has disappeared and those that remain are only the pale witnesses of an art of building which once had its letters of nobility.

February 1992 is an important date in the material turnaround, during the harshest winter - the whole of February- the earth roofs collapsed due to the heavy snow and lack of maintenance.

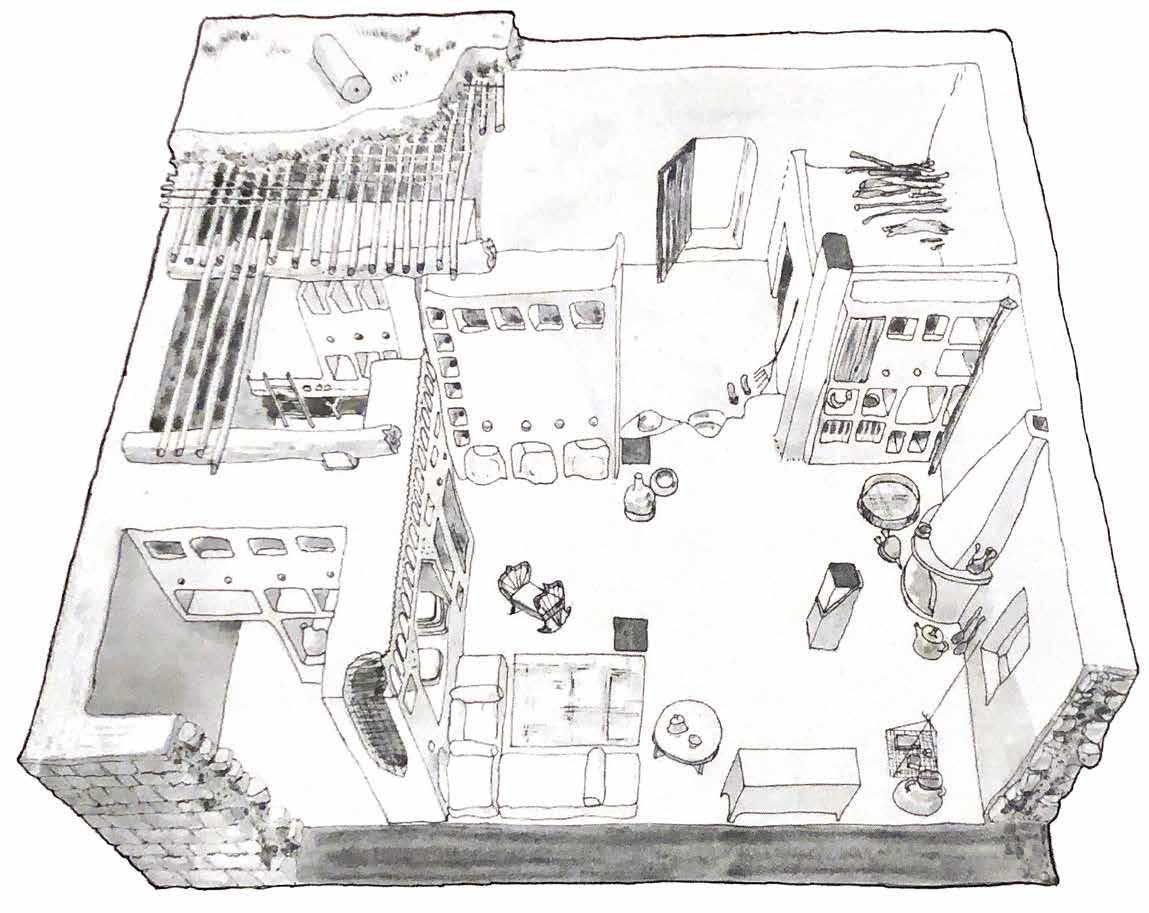

A gradual re interpretation and adaptation of the elements that make up the house is the transitory stage which precedes their elimination. From the niches to the fireplace to the grain silos, the elements were replaced with standardised ones. For various reasons, be it aesthetic, functional or workforce.

Devaluation of the traditional habitationThis traditional architecture suffers from a devaluation, with very little being proud of it, as it is associated with poverty and synonym to misery.

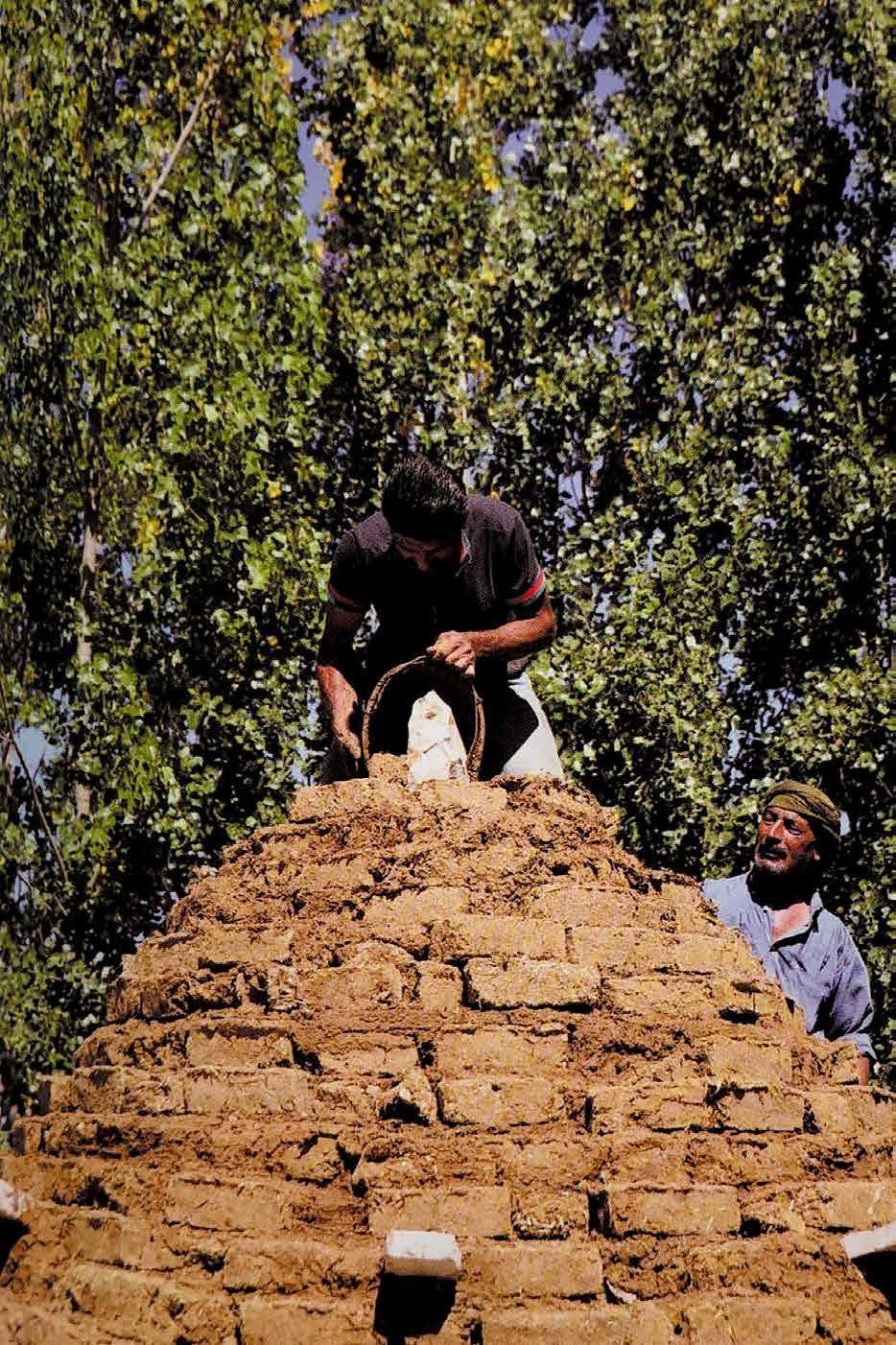

Tools for the brick-making stage

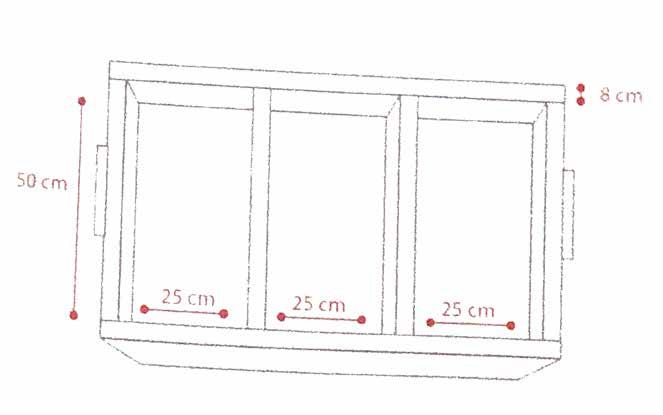

Frame or casting mold

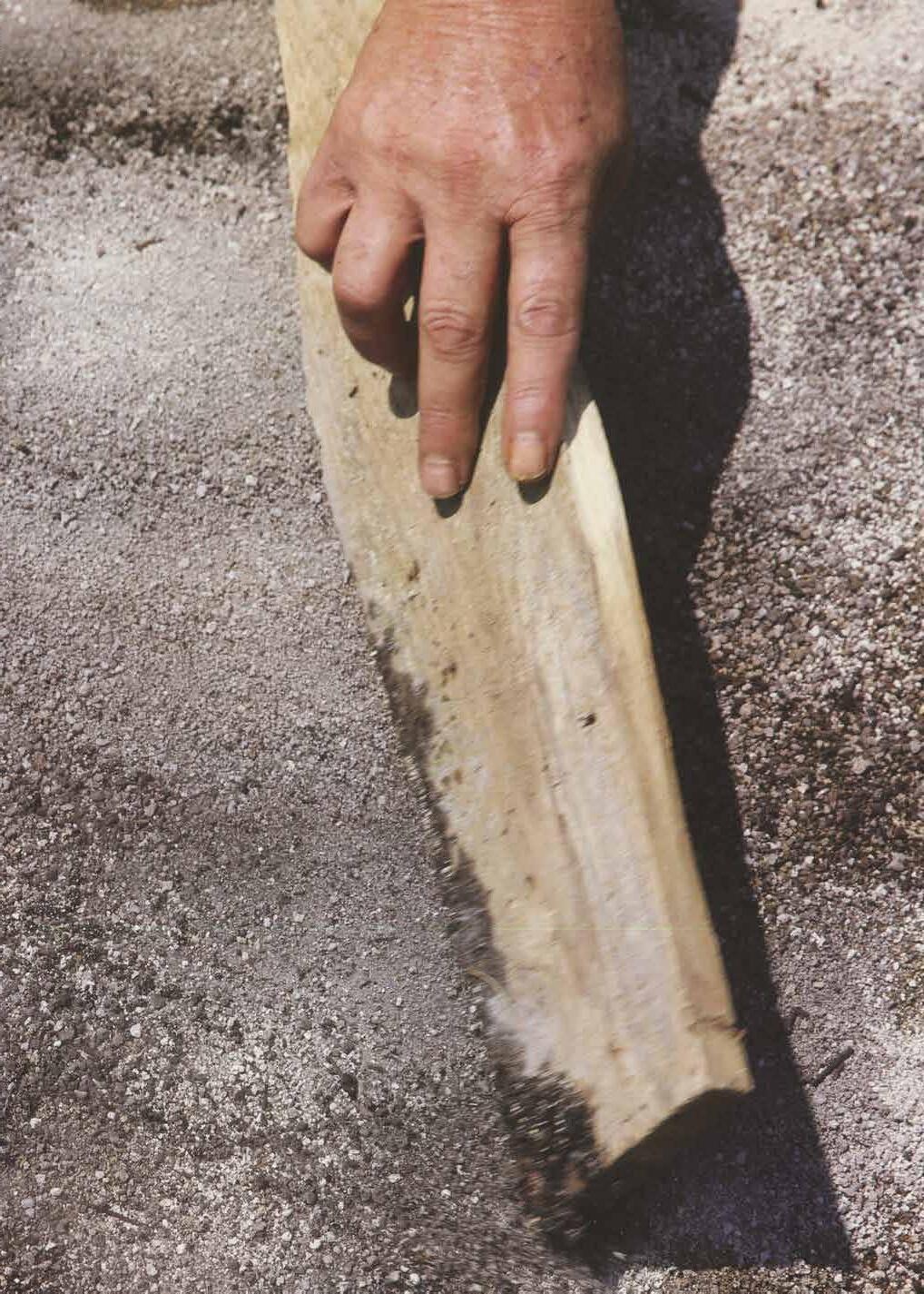

qâleb,literally mold and casting mold, or cutter of mud bricks, designates the bottomless frame used for the manufacture of mud bricks and which is essential for builders to benefit from bricks of homogeneous shapes and sizes. It can be made of metal, but manufacturers generally favor wooden frames which are lighter, easier to handle and less expensive. Their low cost and the ease of their manufacture explain the fact that they can be quickly produced on site by the inhabitants. The wooden frames are made of planks with smooth walls that make it easier to extract the brick. The manufacturer provides them with two handles which make it easier to grip when removing it after molding. To go faster, the builders use several frames, or else they make a double frame they call jawzeh, double, which allows them to simultaneously cast two bricks, or a triple frame, moutallateh, to cast three at the same time.

This is certainly the most specific tool on the job site since it is specially designed for the occasion. While other tools may find subsequent use in a different context, this will only be used in the making of bricks and, once this step is completed, will be put away for an identical use.

Tools for mixing

The shovel

Used essentially to knead the mixture and fill the wheelbarrow with it but also to pour the mortar over the walls when the height of these is still within the reach of the builder.

Sieves

Used at several stages of the site and of various sizes, sieves, ghourbâl, were formerly made by the gypsies who went from one village to another to sell them to the peasants. They were then composed of a wooden frame and an organic mesh, the preference going to goatskin which is the most resistant. The distance between the meshes was a function of their use. Nowadays, screens are purchased from specialist vendors and made of a metal or nylon mesh that corrodes less easily.

Gloves

At all stages of the construction of a home, from the manufacture of bricks to the installation of the finishing plaster, builders have always worked with bare hands.

Scaffolding

In the past, builders did not use scaffolding but relied on manual transport of bricks, mortar and plaster according to the human chain system described above. Currently, two empty barrels and an oblong wooden plank are used as makeshift scaffolding. If you want to speed up the pace of the site and activate the work by doubling the number of masons and if several barrels are available, two to three scaffolds will be put in place.

Fabrics made of hemp,

To wash the mold when making bricks or when laying plaster and to wipe tools, we used to use pieces of torn clothing, of strips or pieces of jute bags, kheych. The use of a sponge, sfengeh, currently makes it easier for workers.

Tools for construction

For foundations workers break stones with a heavy hammer called muhaddah.

For masonry

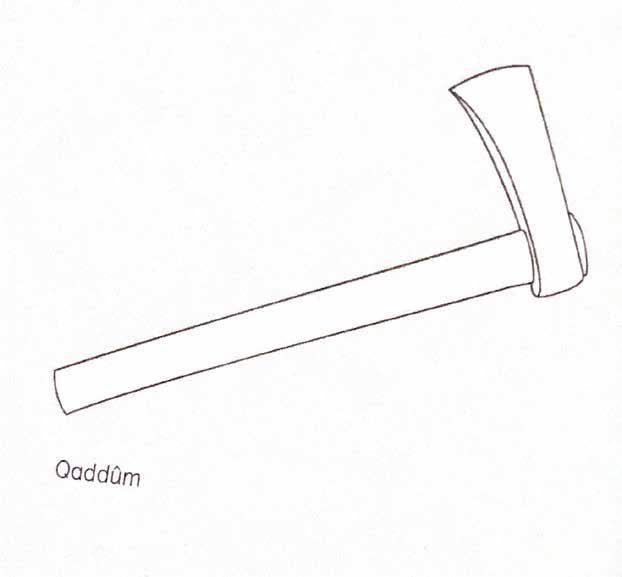

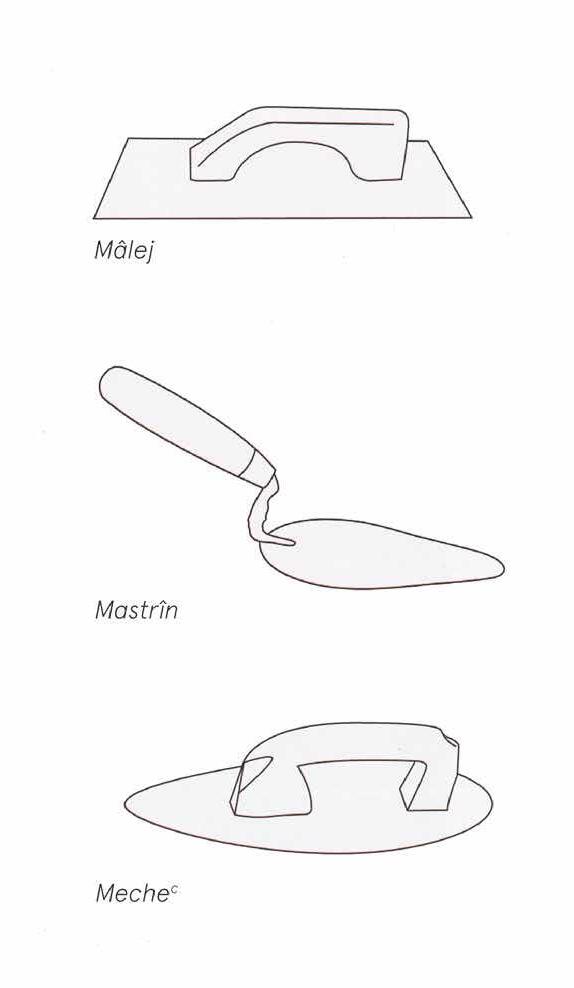

the tools of master masons were reduced to wire and plumb line, belbol ( Later replaced with the spirit level), flat hammer, qaddûm, and a trowel, mastrîn.

The wire which was used to take the measurements and the plumb line to ensure the verticality of the walls will be used especially at the time of the foundations and the construction of the walls.

The master mason will take a few wooden planks to consolidate the angles. The qaddûm It is, after the mold, the second tool intended for construction. It is mainly used to "cut" that is to say to resize the bricks.

If the builder uses the bricks as they are, he sometimes has to work them, sculpt them as they go to give them the desired size and so that they come to fit together in the whole, occupying precisely the place that they want. is vested. Sometimes the mason has to remove small excess parts, other times he breaks them to shrink them.

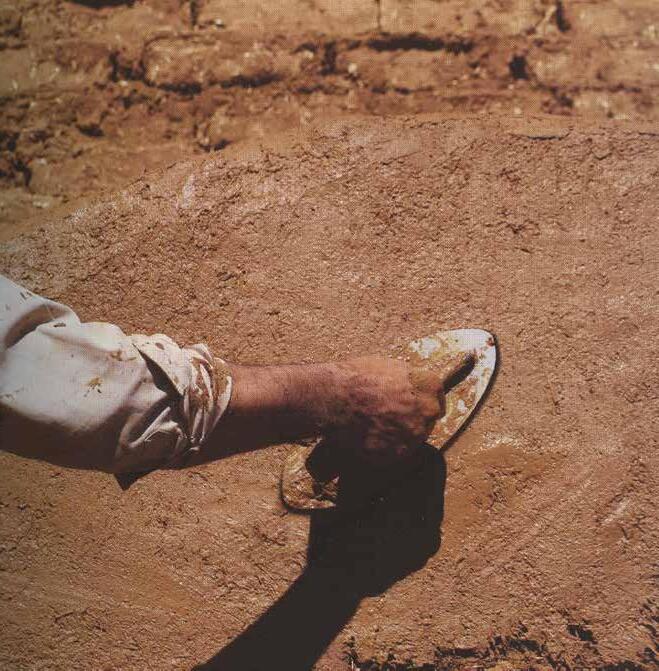

Trowels

When they use cement in their foundations, masons make great use of it, a sort of rectangular stainless steel trowel with which they smooth the floors, with a rounded end, which has the shape of a palm.

The hand

For the laying of the plaster, they sometimes use the malej but especially the wick, an oval-shaped trowel with rounded ends also with a handle in the middle. It is with the help of this wick that the mason adds the mortar evenly on the bricks. He uses it to spread the mixture, apply it and cover the bricks on all sides and between the rows to fill in the gaps.

The mixture

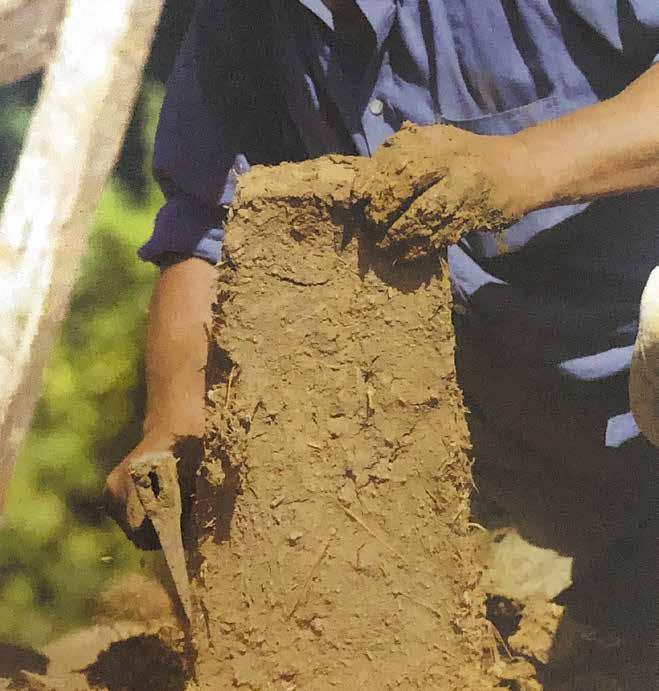

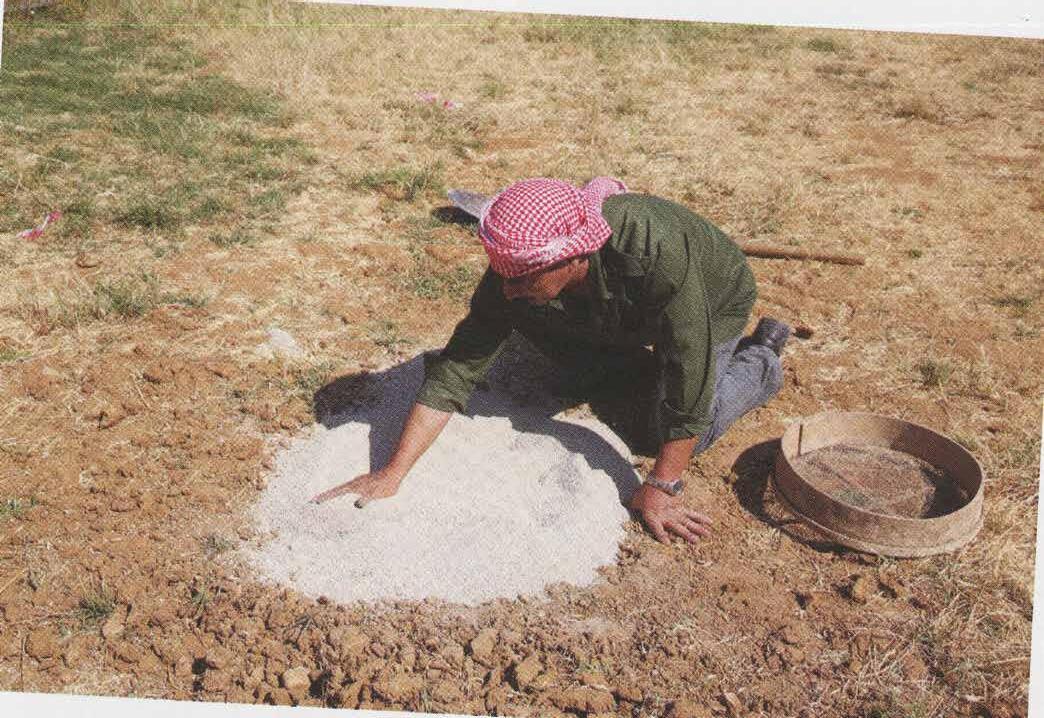

The soil intended for construction must be extracted under the topsoil at a minimum depth of 30 cm, in order to avoid, on the one hand, the depredation of arable land which farmers have greatly needed and on the other hand to be able to have a land with the least possible plant elements.

Knead the mixture

• Take a pile of soil, add wheat straw in 5 cm stalks, ‘tebn gameh’, and mix them dry with a shovel and a fork.

Create a crater in the center of this mixture and drown it entirely in water overnight.

• The morning of the next day, break up the mixture which has hardened a little overnight, then knead it again with the shovel and fork. Repeat the operation with their feet, at length and in depth, rehydrating the mixture with water as they go and adding wheat straws again, but this time with a length of 10 cm.

LOCAL CONSTRUCTION HISTORY

EARTH CONSTRUCTION IN THE BEQ’AA

The house in it’s environment

Far from being the crucible of a unique architectural model, the administrative region of Bekaa brings together a multitude of types of dwellings, reflecting the diversity of its climate and the relief that makes up its landscape: plains, sinkholes, mountains, areas steep, arid zones… The material and climatic conditions, the diversity of the fauna and the environment have, as everywhere else, condition the choices of the builders, leaving their mark on the living space.

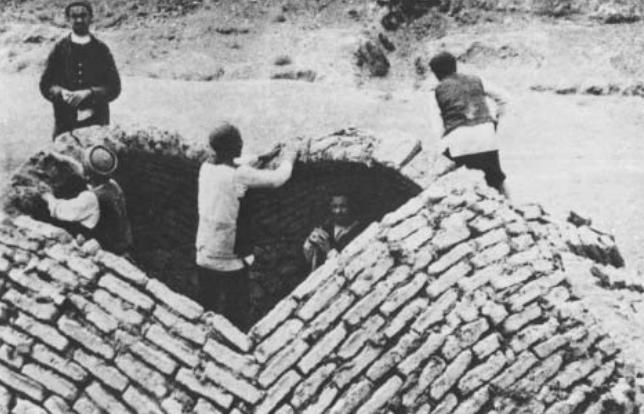

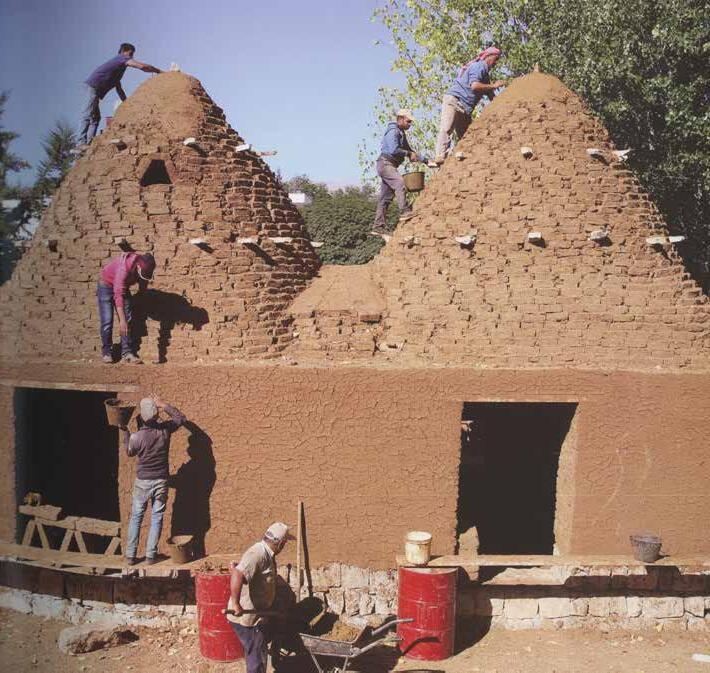

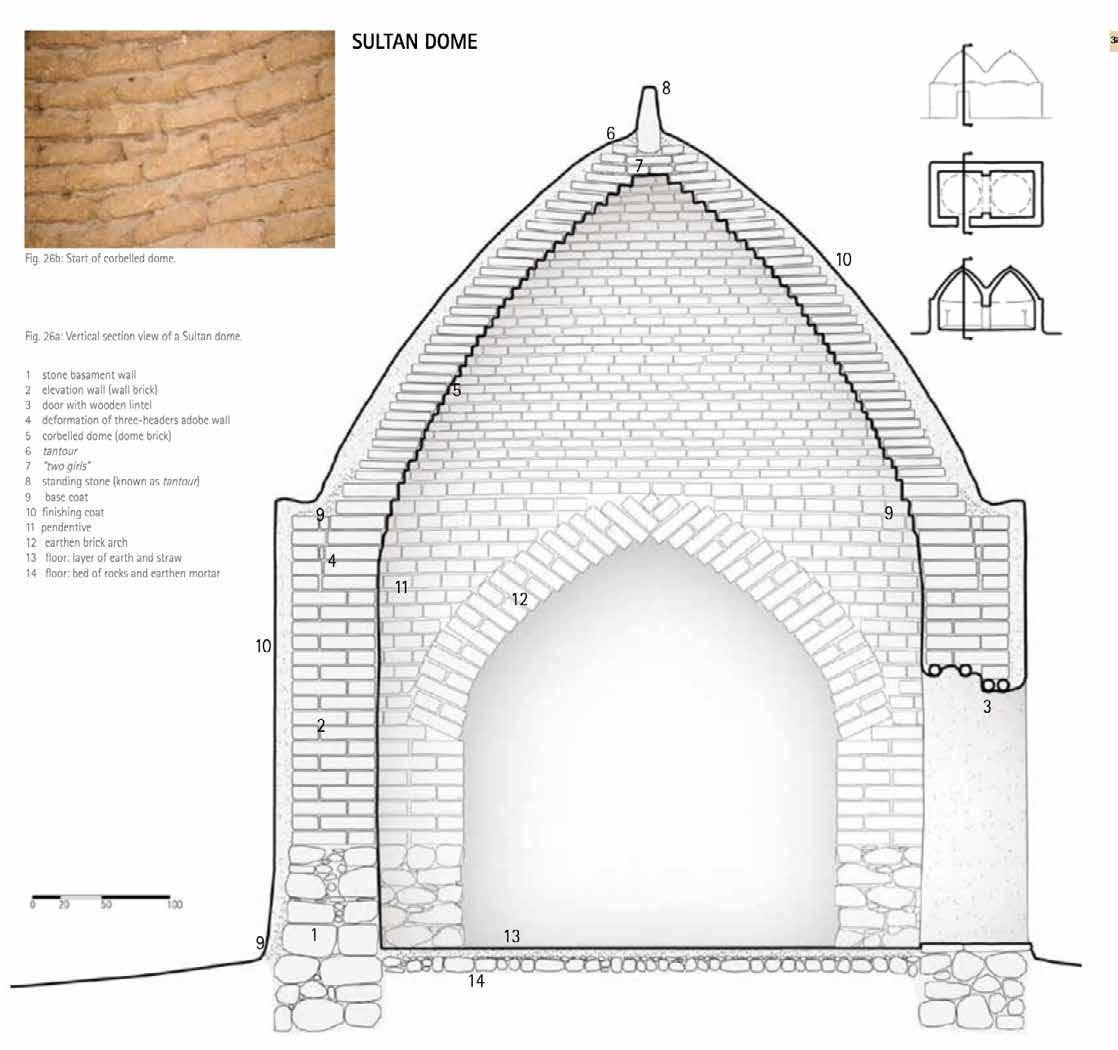

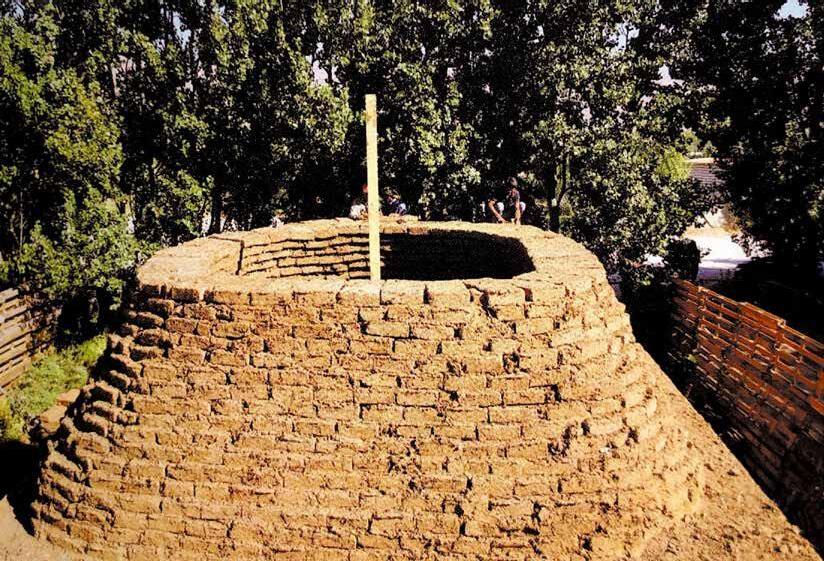

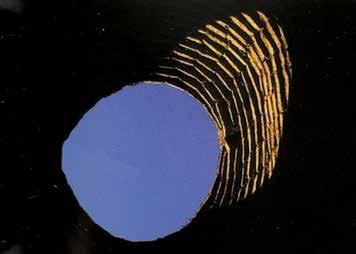

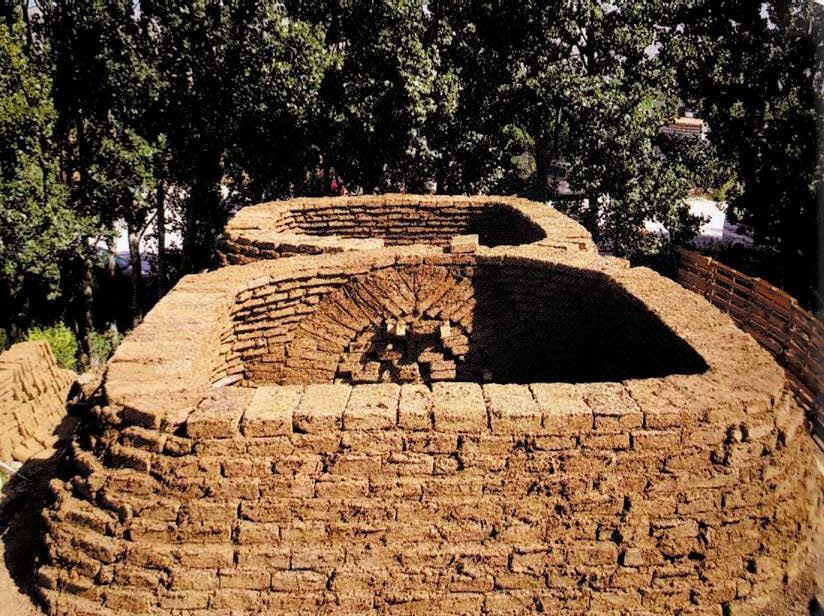

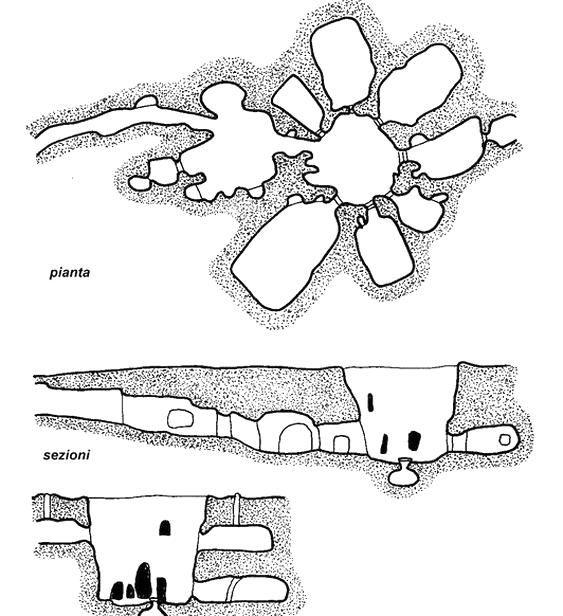

The construction of the dome is naturally the most difficult phase. It requires concentration, study and precision. The corbelled dome elevation method also requires the team to exercise patience as a dome cannot be built in one fell swoop and it is imperative not to skip steps if one is to achieve a solid construction. The laying of the first course of bricks, is decisive. The success of the construction depends on it, because if the calculations have been correct, the cupola will turn and coil appropriately and justly and will automatically begin to take its oval shape. Construction of the dome without arch.

Unlike arches, the construction of which requires the installation of a hanger made of jute bags or more generally of earth bricks, the corbelled dome constructed using bricks placed overhanging horizontally one above the other, does not require the installation of a hanger and is done without scaffolding.

Sealing and closing of the dome

The master mason completes the last rows and prepares to seal the dome by place four bricks in the shape of a cross and insert vertically, in the center of this cross, a stone 35 cm long, 10 cm wide and 10 cm thick. He consolidates it by surrounding it with half-bricks and plaster the whole with mortar. Some builders skip the laying of this stone and seal the dome only with earthen bricks.

To save time, two masons are sometimes called upon to erect the domes. And since it happens that, to go faster, they use their fingers rather than the tape measure to measure the advance of the bricks and that the dimensions of their hands are not identical, the dome risks being somewhat distorted. This is why it is preferable that a single master mason officiates on the same dome.

The dome rests on the walls of a cubic base. To move from square to circle, the master mason begins to raise it from the corners, so that he can roll it up, laff, and rotate it, which he does by moving his rows of bricks gradually towards the interior. It shrinks and collects, in the form of a spiral or bracelets until the dome is formed.

In order to facilitate the process of rotation, stones or small flat beams are added in the four angles of this cubic base, which serve to break the angles.

Then, the builders begin to narrow the perimeter of the given shape and make turns to form the circle of the dome. To do this, he advances circularly, leaving part of precisely protruding, he moves each row, of mud bricks cantilevered inwards from the lower row, proceeding as follows: he folds back his four fingers tightly pressed on his palm and inserts his hand which thus serves to take the measurement of the adequate constriction and which corresponds to approximately 5 cm. By reducing the perimeter by 5 cm each time on a 50 cm brick, it keeps 45 cm in the back of the structure, which consolidates its building.

It must not exceed these 5 cm otherwise the rest of the brick will be more loaded towards the front and the advanced part will not be able to support the weight, will break and break the whole brick. Thus, the first medmâk will protrude by approximately 5 cm and the following row in the same way and so on until the top of the dome and its closure. To take his measurements, the master mason can use a tape measure, but generally he assesses the distance with his hand. And each time that by completing a row of bricks he wants to initiate the next, he takes the measurements by relying on a vertical axis placed in the center of the cell brick. More From a height of one meter, the construction of the dome becomes more and more difficult and the work more arduous.

Drying time and number of rows per day

One of the basic rules of building a domed house is not to hurry but to move forward gradually in order to guarantee the solidity of the building.

The construction of the base, the walls and especially the dome must be done gradually, taking into account the constraints and above all by marking the stops essential to respect the drying time.

When the work is done in the middle of summer, the high temperatures facilitate drying but not enough to be able to ignore the respect of waiting times. This is why the stage of construction of the dome itself takes time.

The masons must therefore as the construction progresses wait until the bricks they have placed are completely dry and that they have fully adhered to each other before continuing. These, depending on the weather, need a day or two to dry thoroughly.

In cases where the temperatures are moderately high, masons erect four to five rows of bricks per day. But since they usually work in the middle of summer, they ride six to seven daily. If it takes 1 cm of mortar per brick and if each brick is 8 cm thick, this means a total of 54 or 63 cm in height for each intervention

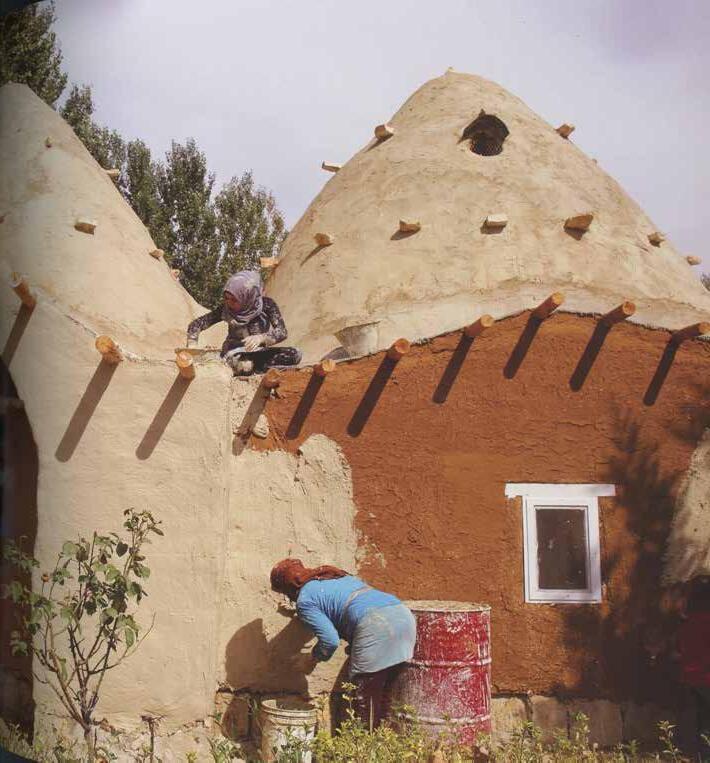

three earth coverings using two different types of earth from the region

RED EARTH ‘delghani’, نياغلد

Tt is the earth used for the preparation of the bricks. But for this purpose, it is worked a bit more in order to be more malleable.

The mix ‘jableh’ is made near the site, it has a life of 3 days.

It is the same mix as the brikc mix, adding to it a step of sifting to get a smooth clay mix, 4mm sift Add barley straw instead of heat straw added to the brick, much thinner therefore facilitated the smoothing operation

Leave the mix until the next day for it to ferment, and bind as a whole.

The fermentation process allows the barley straw to liberate a sticky cellulose that will allow the mix the be waterproof

Before it’s application, one needs to make sure all the window, door frames as well as electrics are in place.

Thickness of 2 to 3 cm. It is important to humidify the bricks before the application of the coating in order for the bricks not to absorb the water from the coating.

Coat from top to bottom, ‘taltich’ شتلت operation wait 3-4 days for it to dry, if some cracks fix them then apply second coating of white earth

WHITE PLASTER BODY ’huwwara’ ةراوح

On the sides of mount Lebanon and Anti-Lebanon, we can find white earth composit. water, white earth, barley straw, 15% fine lime ‘kels’ with a bit of salt for reinforcement

It is a lumpy mix, better leave it overnight for the lumps to dissolve as a way of fermentation, this phase can take up to 15 days depending on the size of the lumps.

Application from top to bottom, smoothing an equalising the surface at each height. For harsh winters it is better to put a mesh in between the red and white mix

FINISHING COAT liquefied ‘huwwara’.

The purpose of this coat is for a light color finish, white and dazzling. To illuminate the habitat, inside out. Furthermore, this coating, when humidified emanated a strong smell that eliminates bad one. It also serves as a filter to oxygenate and freshen the ambient air and gets rid of dust.

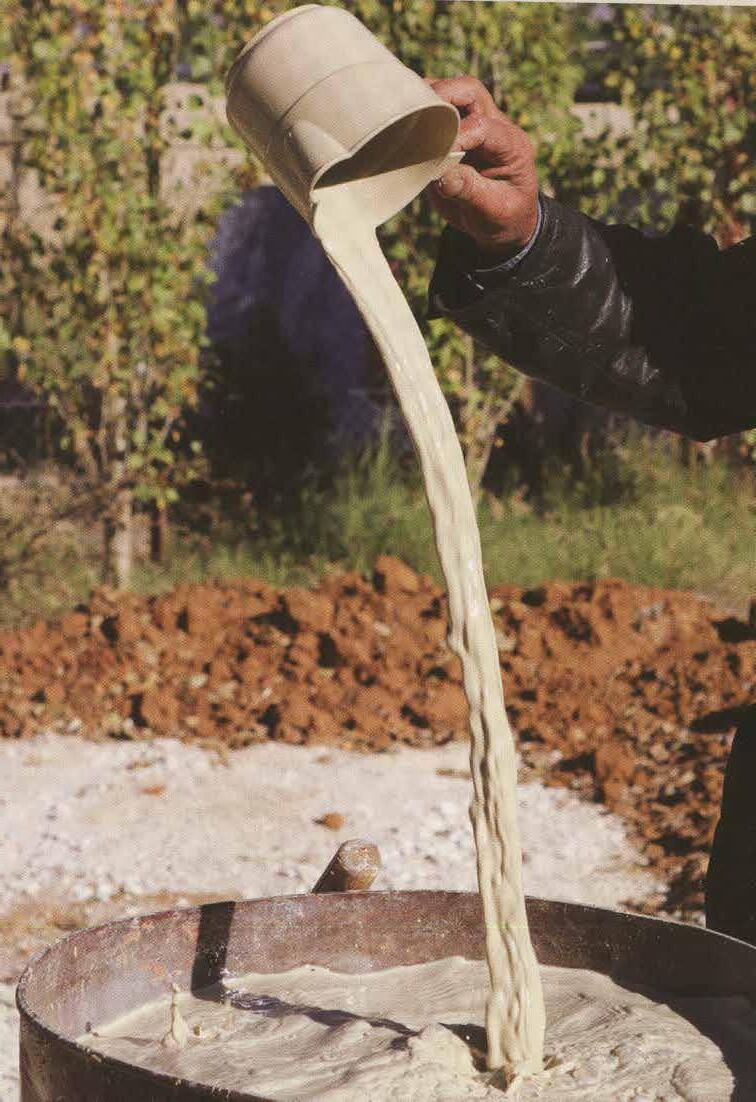

For it’s implementation it has to be completely liquefied. Soaked in water for 2-3 days then sifted with a 3-4mm sift to get rid of all lumps. The mix is considered ready to use when it gets to a radiant white colour and a completely smooth texture, like yogurt, but still keeping a certain consistency to be able to apply it nicely on the vertical wall. The mix is sprinkled then applied with a sponge Once a year it has to be repainted, symbolic, new season new life

LOCAL CONSTRUCTION HISTORY EARTH CONSTRUCTION IN THE BEQ’AA

floor coverings

Builders in Syria use a type of white clay soil, solid and very hard named joss. In Lebanon situated in Britel, nab chit and Ersal.

It is mainly used to insure the sealing of the floor It allows people to clean their floor multiple times, even with a pressurised hose without risks of water absorption, it is also an air freshener and emanates a good smell when vaporised Combustion process to attain its optimal state After extraction the clay has to be very finely sifted.

The fuel usually used is some kind of animal manure.

The duration of combustion varies depending on the village, weather and direction of the wind. In some villages, the builder leaves the mix to consume itself for only a day, in others up to 5 days.

Sometimes, the process is repeated more than once to get the desired consistency, when the first batch of manure is complete, you can add another one.

The earth has to cook very slowly in order to get to its desired state, as solid and robust as concrete is.

The sign that the process is successful is the change of color from white to brown after combustion ‘yinahess’ is the expression used to describe the final result.

LOCAL CONSTRUCTION HISTORY

EARTH CONSTRUCTION IN THE BEQ’AA

maintenance tools

Snow scraper

Roof edge tapper metal handle for roller the small wooden pieces (2) between the handle ends and the roller

The roof is built up of a layer of crushed stone over a thick layer of earth. The layer is carried by a vaulted stone or timber structure. The roof requires regular maintenance for compacting the earth to stop the penetration of rain. This is achieved through dragging a stone roller (mahdalleh) over it to close any cracks that may appear.

The roof tops were and are to this day an important part of the house. The long and hard winter months made September a busy month due to the necessity of stocking up the house with foodstuff (mouni). The short availability and high cost of food in winter was turned into an art of conserving, drying and pickling all sorts of fruits and vegetables by the villagers. Small bunches of sticks and pine cones for use as fire wood were dried on the roof. Figs, raisins, apricots, pine kernels, tomatoes, green beans, burgul and kishk were dried for the mouni. Burgul is cracked wheat while kishk is burghul marinated in yogurt. The making of kishk is a highly laborious process. The women frequently collaborated in the preparation of their stocks. To prepare kishk, they would ask the single men and women of the village to help them, providing them with an opportunity to meet. In September, the roofscape of any village in Lebanon is like an oriental carpet rich with patches of color and texture.

interior spaces

LOCAL CONSTRUCTION HISTORY EARTH CONSTRUCTION IN THE BEQ’AA

the importance of the roof

The choice of a flat and accessible roof, therefore functional, is motivated by the agricultural activities of the farmers.

In rectangular houses with flat roofs, this one, far from being a simple blanket, is a complementary working space. it is ...One of the essential elements of rural activity, it is on the roof that the crops are dried, cheese, sorghum, dried vegetables, that the burghoul is spread out in the sun , that we pile up the provisions of wood; it is even on them that one settles during the summer nights: one sleeps there cooler than inside overheated and badly ventilated. The roof surface with multiple functions, is therefore in turn used as a work, rest and communication area. The inhabitant accesses this terrace via a wooden ladder. Seat of its agricultural activities. It is this link that connects the bottom and the top of dwellings with deep interdependence.

The reciprocal dependence between the two spaces is such that a direct access from the roof to the interior of the house and the silos is provided by a temporary opening called Qaffa’a which allow an easy transit of the goods from the roof to the interior of the silos where they will be stored.

failure of the roof

Buildings are subject to a permanent process of physical degradation due to their use and under the influence of the external environment. Buildings, despite their really solid appearance, and their different components are very sensitive to the action of climatic factors (sun, rain, cold or heat) and all other natural actions. User action is also one of the causes of the progressive deterioration of the various elements.

From the earth house to the white house the archictectural development of the villages of the bekaa, took place outside any urban plan. Concrete buildings have invaded, in disorder and like everywhere else in Lebanon, the whole of the plain. If the economic development and the enrichment of the population obviously have direct repercussions on the forms and the techniques of construction, the genesis of this measure finds its origin however in the local traditions which make of the dwelling the reflection of the prestige of the dominant family and the symbol of the economic and social situation of the owner.

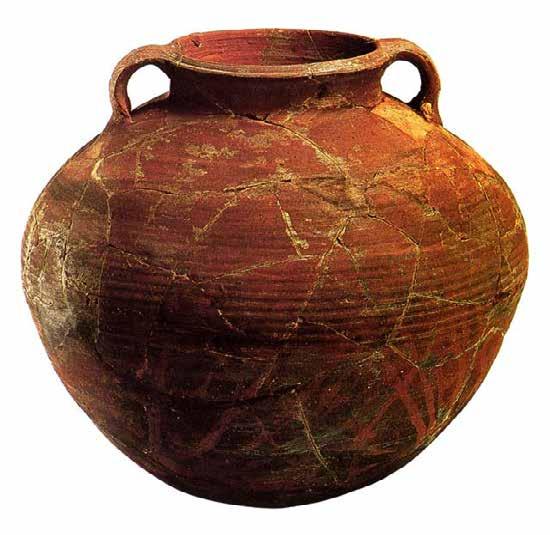

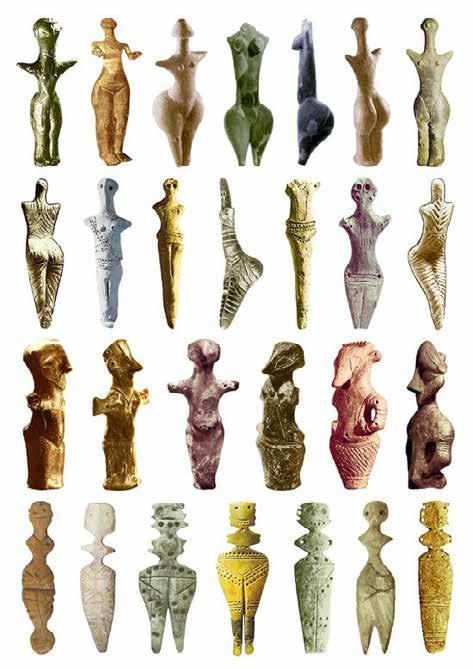

6,000 - 4,0000

Archaeologists found Ceramic figurines used for ceremonial purposes dating back to 24000 B.C.

The first use of functional pottery in vessels for holding/storing water and food is thought to be around 9000 or 10,000 B.C.

24,000 B.C.Ceramic figurines used for ceremonial purposes

14,000 B.C.First tiles made in Mesopotamia and India

9000-10,000 B.C.Pottery making begins

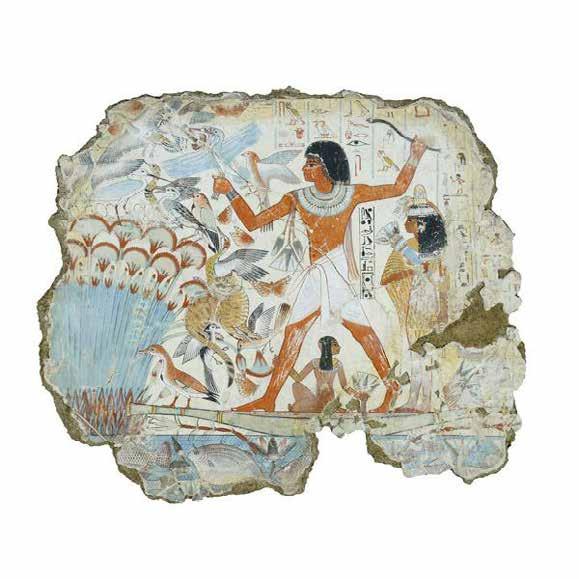

5000-8000 B.C.Glazes discovered in Egypt

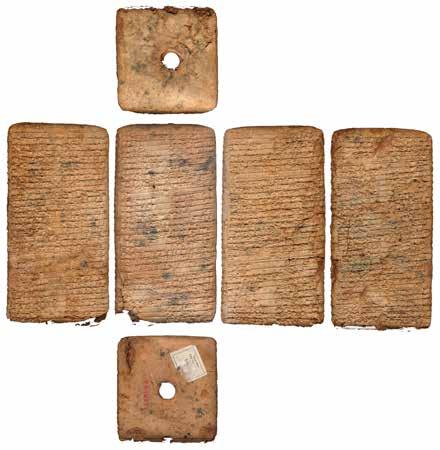

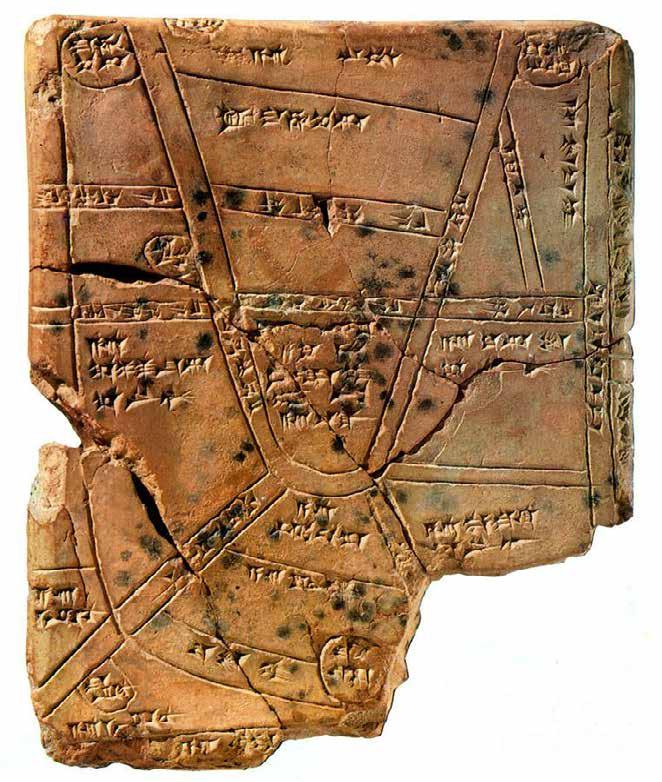

3200-3000 B.C Cuneiform writing

1500 B.C.Glass objects first made

10,000 - 7,000 B.C Pottery is created with handbuilding techniques in Japan

14,000 B.C

First clay tiles are made in mesopotamia and India

29,000 - 25,000 B.C

The oldest known ceramic artic le in the world, Venus of Dolni Vestonice, is created

Sumerian tribes would pick up a lump of clay big enough to fit in their hand, in fact about the size of a modern smartphone, would take a piece of weed cut into the shape of a wedge. the oldest cuneiform tablets come from the city of Uruk and date to the late 4th millennial.

Around the 32nd or 31st century, consisted of pictographs so everyone could understand, used to keep track of everyday things

OLDEST AND MOST WIDELY USED MATERIAL ON THE PLANET

it is estimated that between a third and a half of the world’s populationapproximately three billion people on six continents- lives in buildings constructed of earth. The typologies for earthen architecture, however, extend beyond buildings for living, and include structures for working and worshipping, as well as the countless forms not inhabited by humans such as agricultural buildings, city walls and monuments. this makes the ground we walk on and cultivate our crops in the most widely used building material on the planet dirt. This does not include, nor should be confused with, other materials that come from the ground, such as stone, cement, or metals derived from ore.

Earth, by definition, is simply clay, gravel, sand, silt, or other friable souks, in which organic materials sometimes exist. Because of the ubiquitous availability of appropriate soul, buildings constructed of earth can also be found just about everywhere - in almost every terrestrial biome on the planet.

Earth buildings are commonly perceived to be used only by the poor or found only in ‘developing’ countries, but there are earth buildings of almost every architectural type in use by every economic and social class in both the industrialised and non industrustrualized worlds.

ShamsArd: With Dirt And A Vision

ShamsArd is a young Palestinian architecture firm that has designed several buildings constructed of dirt that respond to both the environmental climate (keeping the house cool in the summer and warm in the winter), and the political and economic climate. An Israeli company that exports the vast majority of cement used in the occupied Palestinian territories, suddenly stopped the supply for almost a month because of cement shortages in the Israeli market. A few months later, the price of cement sold to the Palestinians also increased, making alternative construction techniques, a beautiful design solution. It also responds to history as Jericho, the location of their most recent design, is home to the oldest earth building traditions in the world. Hear and read more about ShamsArd on National Public Radio and in an Al Jazeera article.

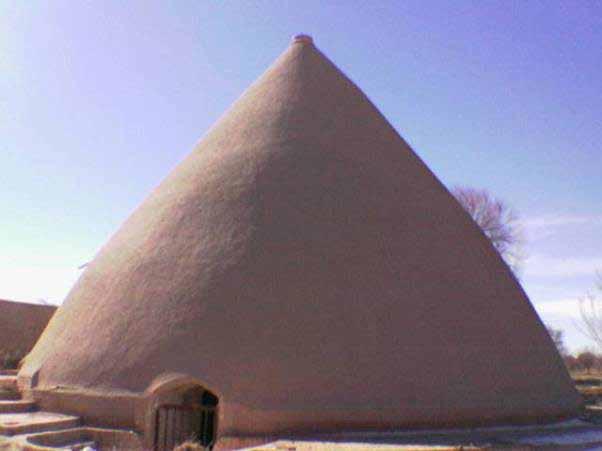

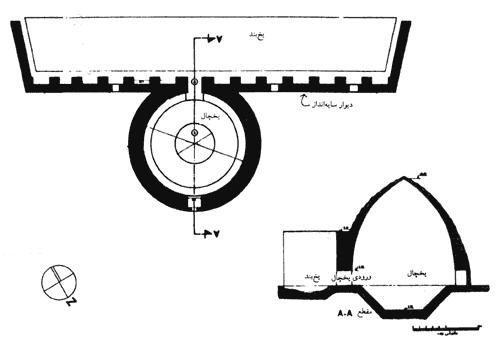

Yakhchal: Ancient Refrigerators

Yakhchal in Yazd Province

By 400 BC, Persian engineers had mastered the technique of storing ice in the middle of summer in the desert. The ice was brought in during the winters from nearby mountains in bulk amounts, and stored in a Yakhchal, or ice-pit. These ancient refrigerators were used primarily to store ice for use in the summer, as well as for food storage, in the hot, dry desert climate of Iran. The ice was also used to chill treats for royalty during hot summer days and to make faloodeh, the traditional Persian frozen dessert.

Aboveground, the structure is comprised of a large mud brick dome, often rising as tall as 60 feet tall. Below are large underground spaces, up to 5000m³, with a deep storage space. The space often had access to a Qanat, or wind catchand often contained a system of windcatchers that could easily bring temperatures inside the space down to frigid levels in summer days.

The Yakhchal have thick mud brick walls that are up to two meters thick at the base, made out of a special mortar called s?rooj, composed of sand, clay, egg whites, lime, goat hair, and ash in specific proportions, and which was resistant to heat transfer. This mixture was thought to be completely water impenetrable.

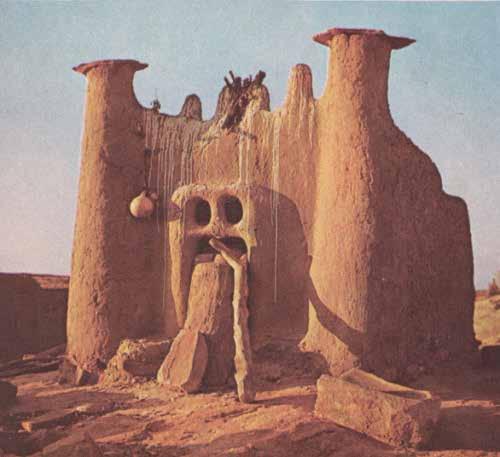

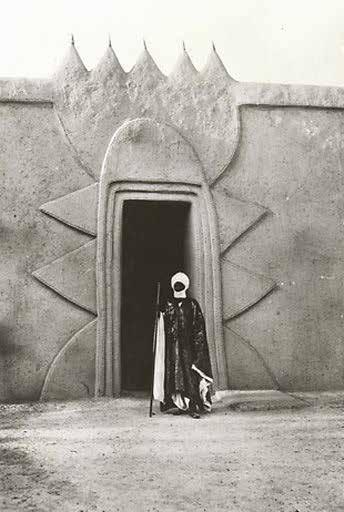

CONSTRUCTION PRECEDENTS in sync with their geology

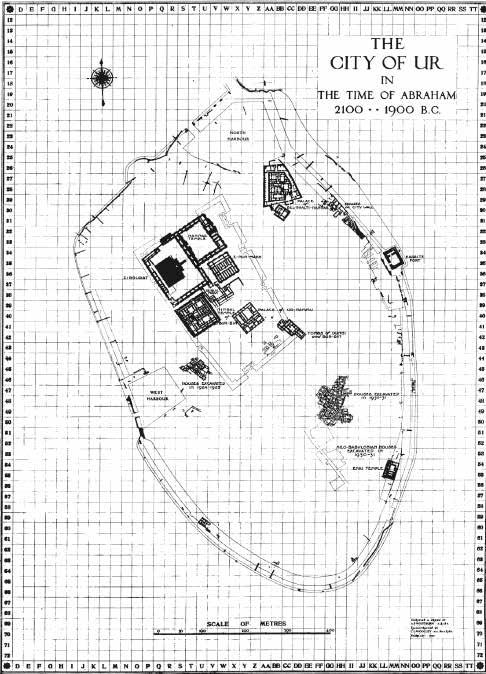

Old mesopotamia, now southern iraq

The land is essentially nothing but a flood plain, between two rivers, tigres and euphrates, made of clay and silt, poor in natural recources, no metals to be mined and virtually no stone.

The riverlands werent suitable for the hunter gatherer lifestyle,the first nomadic hunter gatherers began to settle there around 10000 BC

The Sumerians were the people of southern Mesopotamia whose civilization flourished between c. 4100-1750 BCE

The people of Suma are one of the candidates for the first ever technological human civilisation, over the course of millenia they built a society that would form the blueprint for all that followed after, they rose to invent writing, mathematics and the wheel and built the largest cities that humanities have ever seen

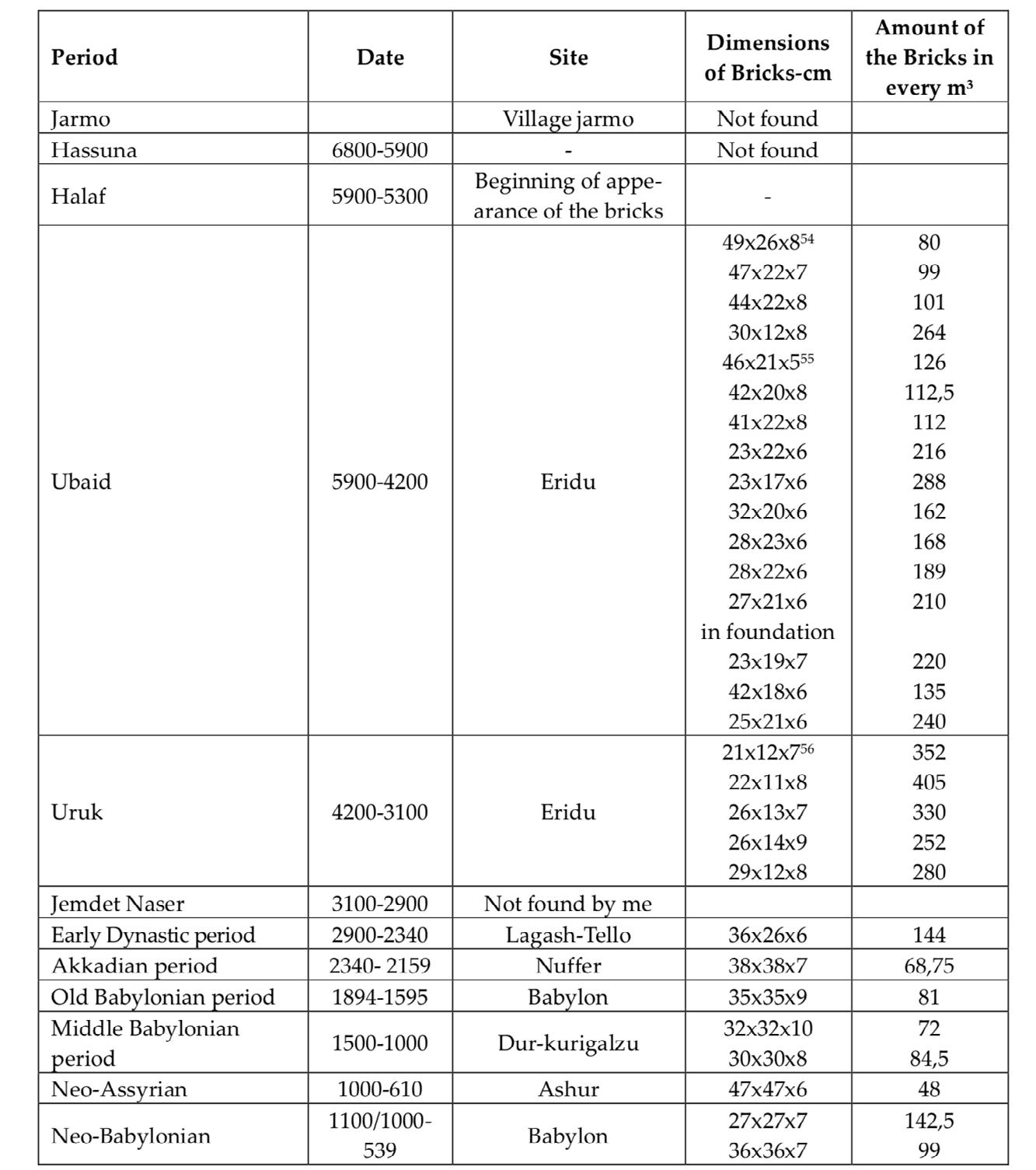

Clay brick masonry is one of the oldest and most durable construction techniques used by mankind. It was a fundamental building material in the Mesopotamian, Egyptian periods. Despite several modifications of the clay brick uses, shape and manufacture along thousands of years of continuous evolution, the simplicity that made it successful remained the simple manufacturing process based on fired clay, a raw material available in large quantities all over the Earth. Its wide use proved that the clay brick was an effective construction material that could provide both resistance to prevalent climatic conditions and insulation from both cold and heat. It is known that the properties of ancient clay brick masonry rely essentially on the properties of the brick units, which depend on the quality of the raw materials used, together with the manufacturing process technology.

Clay bricks are products of a dough consisting of clay soil and water, pure clay or a mix with other materials such as straw. Bricks were formed primitively, naturally dried and fired in the kilns in the workshop.

The history of bricks is almost as long as that of human civilisation.

CONSTRUCTION PRECEDENTS in sync with their geology

The cave houses, also known as troglodyte houses, offer protection against the extremes of summer and winter in the arid desert. They are created by digging a large pit in the ground, and then around the sides of the pit caves are dug to be used as rooms. The open pit functions as a courtyard, and are sometimes connected to other “pit” courtyards nearby through trench-like passageways forming a large underground maze.

Soil

Matmata’s terrain is hilly and the small valleys between the lime stone mountains contain deposits of loess (almost 20 meters deep), which are composed of clay with enough gypsum to act as a binding agent. This provides a firm and stable but easily worked material for excavating ro- oms (Kempe, 1988). The softness of the soil material is both the reason for troglodytes being possible, and for never becoming very old.

Thermal performance

The troglodytes are isothermal; their temperatures are warm in winter and cool in summer, and stay relatively constant year round, as earth as a bu- ilding material stabilizes the extreme temperature swings, both daily and seasonally.

The ceilings are usually vaulted, to bear the loads of the soil above it and to accommodate day lighting and ventilation needs.

The typical dimensions of the rooms in Matmata are 4 to 5 meters wide and 8 to 10 meters long with a height of about 3 meters for the large rooms, and between 3 to 4 meters wide and 4 to 5 meters long with a height of 2.5 meters for the smaller ones.

The soil cover from the ground level to the room ceiling in Matmata ranges from 6 to 7 meters. Such thickness eliminates any potential for water leakage caused by possible heavy rainfall and it significantly reduces the heat gain and the heat loss rates into and out ofthe building (Golany, 1988).

Usually there is a cistern in the middle of the courtyard for gathering rainwater. The courtyard is protected from the rainfall by building a short fence around its circumference using the clay that resulted from the excavation.

The entrance of the dwelling is above the ground and is about 10 meters away. To ensure the safety and protection of the unit, the entrance is fortified and sloped downwards to the central courtyard through an excavated tunnel.

Building materials such as stone and gypsum are available from thesurrounding environment and they are used for the finishing coats of the internal walls and for the fixed furniture (beds and storage cabinets)

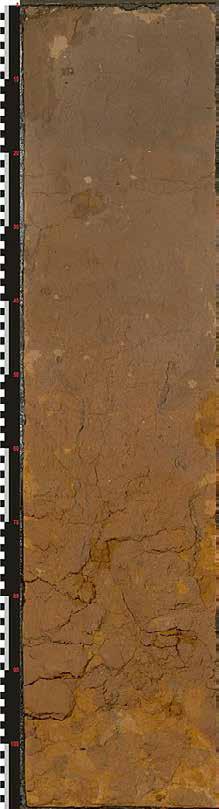

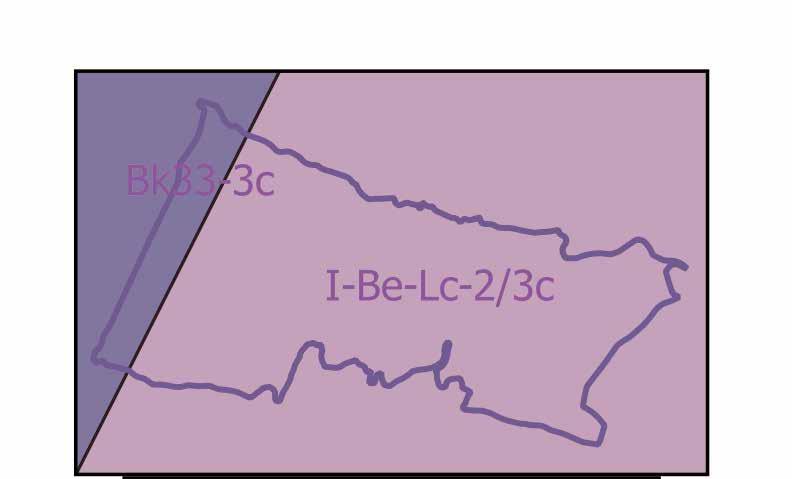

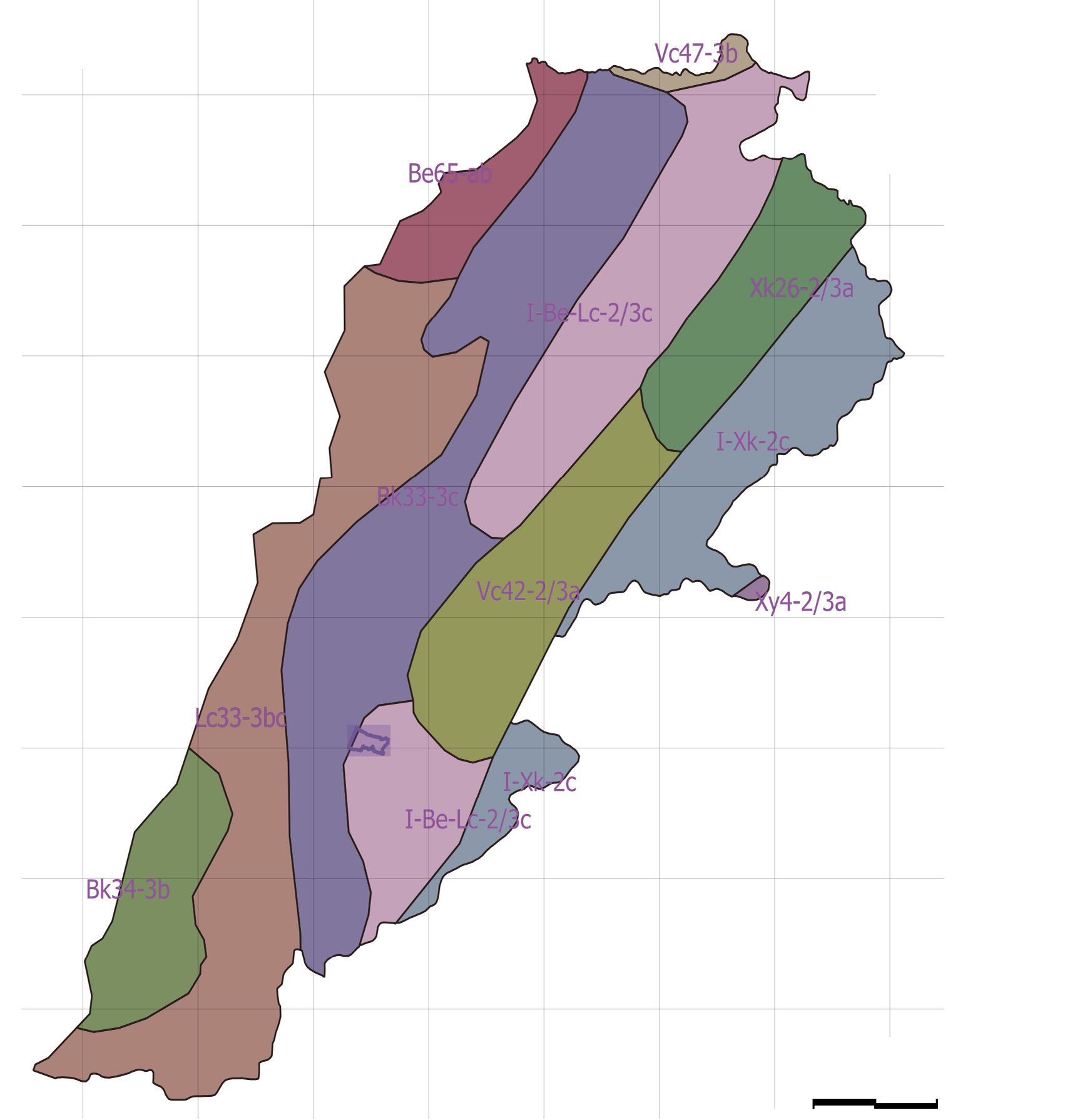

soil map unit symbols

Be: Eutric Cambisols

I: Lithosols

Le: Chromic Luvisols

Material properties and contraints composition of soil

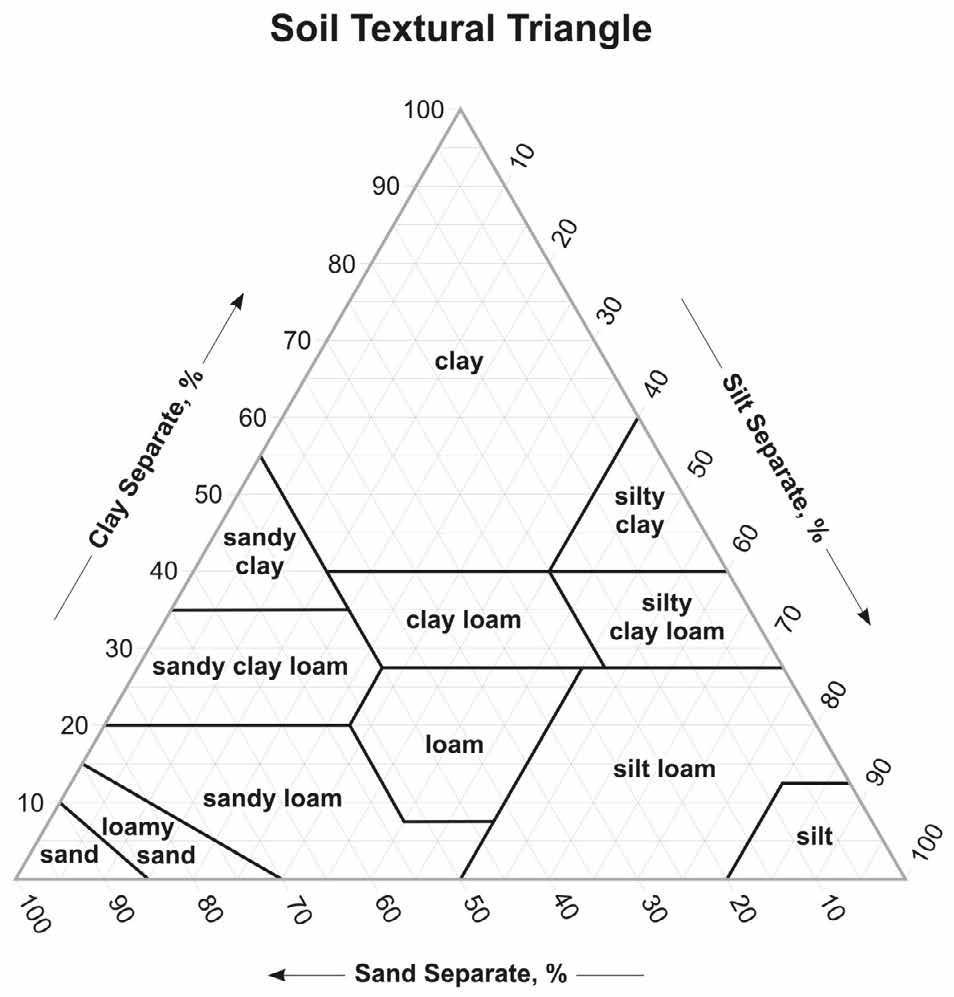

Texture classes reflect the relative proportions of clay (fraction less than 0.002mm), silt (0.002 - 0.05mm) and sand (0.05 2mm) in the soil.

Three textural classes are recognized:

coarse (1): sands, loamy sands and sandy loams with less than 18 percent clay and more than 65 percent sand; medium (2): sandy loams, loams, sandy clay loams, silt loams, silt, silty clay loams and clay loams with less than 35 percent clay and less than 65 percent sand; the sand fraction may be as high as 82 percent if a minimum of 18 percent clay is present; and fine fine (3): clay, silty clays, sandy clays, clay loams, with more than 35 percent clay.

When information on the texture of the surface layers (upper 30 cm) of the dominant soil is available, the textural class figure (1, 2, 3) follows the association symbol, separated from it by a dash. Where two or three groups of textures occur that could not be separated on the map, two or three figures may be used, separated by a slash each is taken to apply to 50 or 33 percent respectively of the dominant soil unit..

Texture Class in Map is 2/3

Three slope classes are distinguished:

(a) level to gently undulating, with generally less than 8 percent slope,

(b) rolling to hilly with slopes between 8 and 30 percent and

(c) steeply dissected to mountainous, with more than 30 percent slope .

Where two or three slope classes are indicated, each is taken to apply to 50 or 33 percent respectively of the dominant soil unit. The slopes of component soils (associations and inclusions) and dominant soils when not indicated in the mapping unit, were derived from the Composition Rules in Table 6 (FAO, 1978, with five soil units updated):

Slope Class in Map is "c"

SOIL FORMATION

Main soil forming process is time

Classification of soils consists of the division of soils into classes based on their genetic, textural, chemical, mineralogical, physical, or geotechnical characteristics. The nature of the parent rock influences the composition of the resulting soil

Soil is classified into four types:

Sandy soil. Silt Soil. Clay Soil. Loamy Soil.

The strength and stability of soil depend on its physical properties. Soil with good structure is more stable. Clay textures are often more stable than sand textures because they have better structure. However, a mix of particle sizes (and pore sizes) is best for engineering (just as it is best for growing crops)

Lithosol

aka skeletal soil: any of a group of shallow azonal soils consisting of imperfectly weathered rock fragments.

Eutric Cambisols:

silicate clays sesqui(hydr)oxides as result of weathering of primary minerals

Starts 25 to 100 cm below surface

More clay than underlying horizon as evidence of transformation, weathering.. up to 40% clay One of the most widespread soils, covering some 1.57 billion ha or 12.5 % of the Earth’s land surface, mainly in temperate and boreal regions, in desert regions, and in mountainous areas.

Chromic luvisol:

They are widespread, especially in temperate climates, and are generally fertile. Luvisols are widely used for agriculture.

The base-rich Luvisols (from Latin, luo, to wash), with a distinct clay accumulation and argillic horizon with a high base saturation;

Acid Podzols (from Russian, pod, under and zola, ash), with a bleached eluvial horizon over an accumulation horizon of organic matter with aluminum and iron (spodic horizon); Large clay component

ARGIC: General description. The argic horizon (from L. argilla, white clay) is a subsurface horizon which has a distinctly higher clay content than the overlying horizon.

General description. The argic horizon (from L. argilla, white clay) is a subsurface horizon which has a distinctly higher clay content than the overlying horizon.

General description. The argic horizon (from L. argilla, white clay) is a subsurface horizon which has a distinctly higher clay content than the overlying horizon.

Gravel > 2mm

Sand 2 to 0.02 mm

Silt 0.02 to 0.002 mm Clay 0.0002mm

from the laboratory of the american university of Beirut - Angele Kesrwany. De terre et de main d’hommes Houda Kassatly

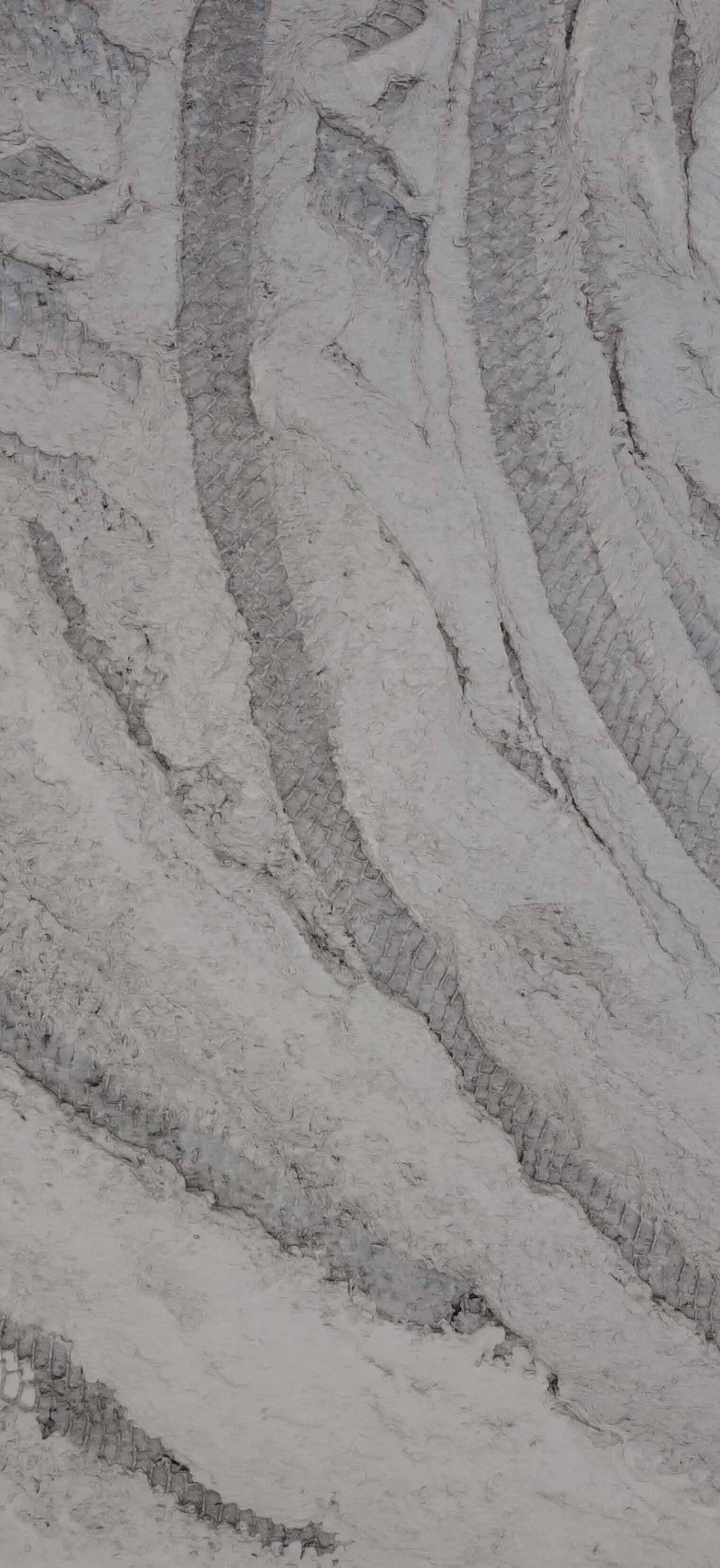

The Red earth is a ground clay rich in sesquioxides (ground fersiallitic ) and red, made of clays decarbonization on calcareous outcrops in Mediterranean regions, particularly on hard and crystalline limestones . The red earth is also identified as consisting of clays decalcification.

Erosion in limestones occurs by infiltration of water into the numerous cracks or joints in the rock. They undergo decarbonation by surface leaching (dissolution of calcium carbonate by runoff ), which releases a residue formed from the insoluble impurities of limestone (impurities made up of clay minerals and iron hydroxides concentration and dehydration of the latter producing the phenomenon of reddening). These processes form a residual red clay concentrated mainly in cavities of karst origin in Mediterranean regions with a warm climate.

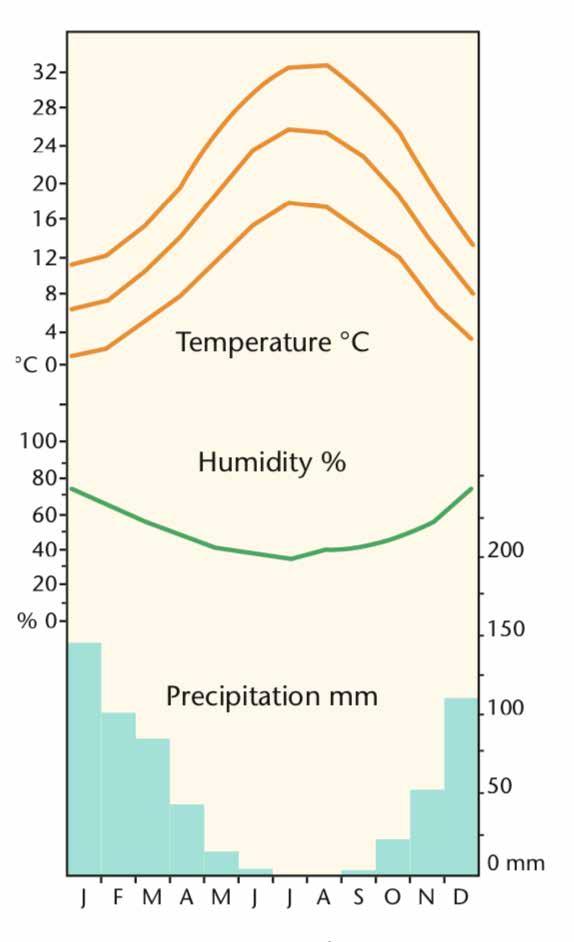

The yearly climatic cycle in Lebanon consists of rainy winters with snow down to 1000 meters. early spring with the last rainfall in May, four hot, dry summer months, and a mild autumn with little rainfall. According to the geographic structure, four climatic zones may be distinguished: coast, western slopes, high mountains and the beq’aa plain.

The high plaine of the bekaa, lying between the mount lebanon and anti lebanon ranges, has alluvial characteristics. The deep soil is excellent for farming, and irrigation ensures a sufficient water supply. Because of the altitude of the plain (averaging 1000 m) the adjacent mountains do not seem very rugged. The presence of clay and water in combination with a fairly dry climate allows the use of mud brick (adobe) construction. The mountains of lebanon were originally the most densely wooded area of the near east. This wealth has been almost totally lost. For centuries, timber for construction has been limited to poplar, willow, walnut and maple, which grow along the riverbanks. In some areas there are also fairly large groves of pine trees. In swampy soots we find reeds, which have always been used with mud in construction. Another material is chaff, the residue from primitive threshing methods using sleighs. Mixed with clay or mud it acts as a binding agent which prevents the formation of cracks.

The graph shows the monthly number of sunny, partly cloudy, overcast and precipitation days. Days with less than 20% cloud cover are considered as sunny, with 20-80% cloud cover as partly cloudy and with more than 80% as overcast.

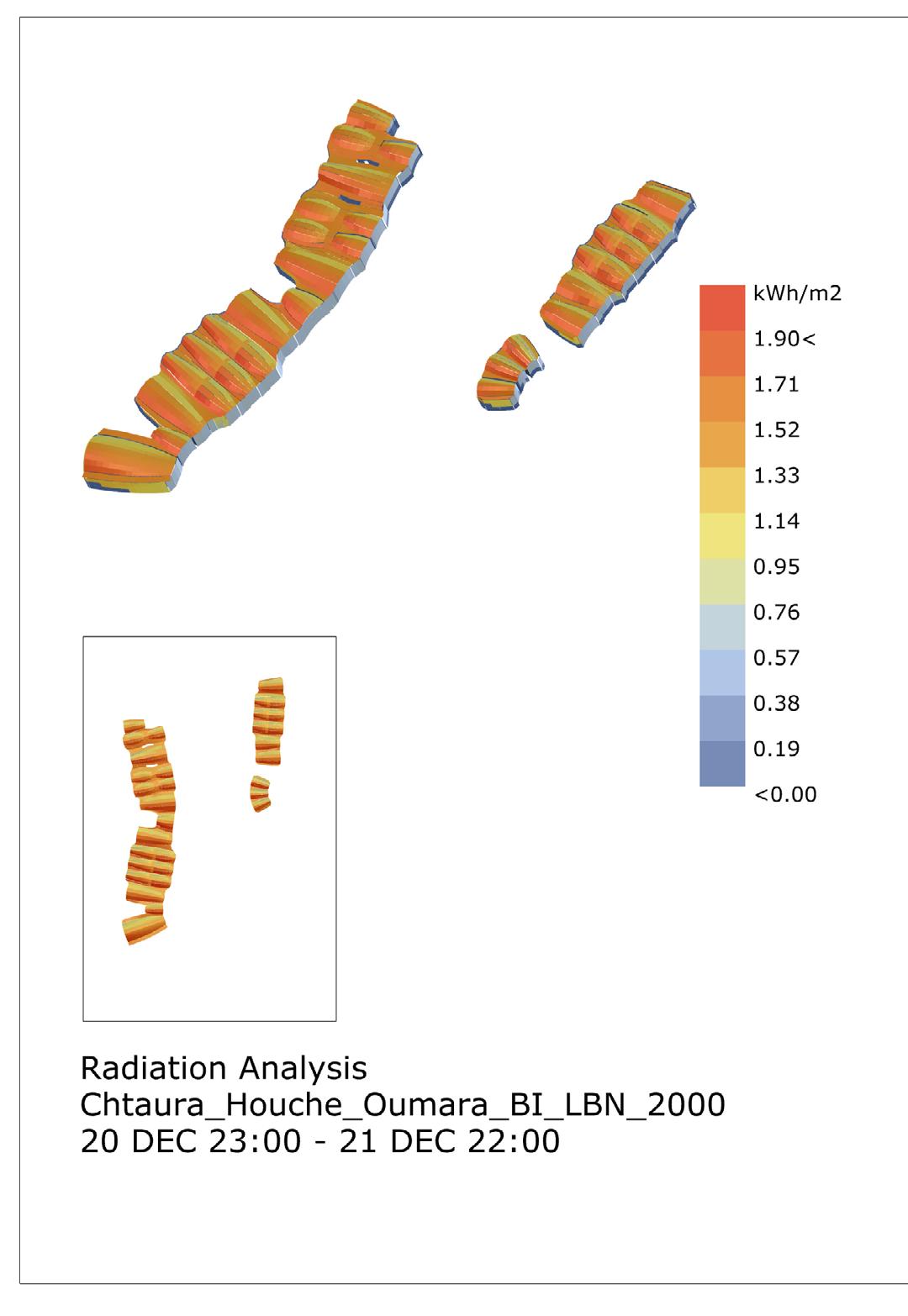

Solar studies

Sun path analysis using ladybug/ grasshopper plug in

Considering that bricks and earth is the main material for the design, it is important to consider the possibility of passive energy production systems. This might also inform the internal spatial layout. The building, facing east allows morning sunlight in from it’s facade and afternoon light from the back. Being half buried, The opening of the vaults to the West side is crucial in allowing sunlight and wind in.

The maximum temperature diagram for Saghbîne displays how many days per month reach certain temperatures.

The "mean daily maximum" (solid red line) shows the maximum temperature of an average day for every month for Saghbîne. Likewise, "mean daily minimum" (solid blue line) shows the average minimum temperature. Hot days and cold nights (dashed red and blue lines) show the average of the hottest day and coldest night of each month of the last 30 years.

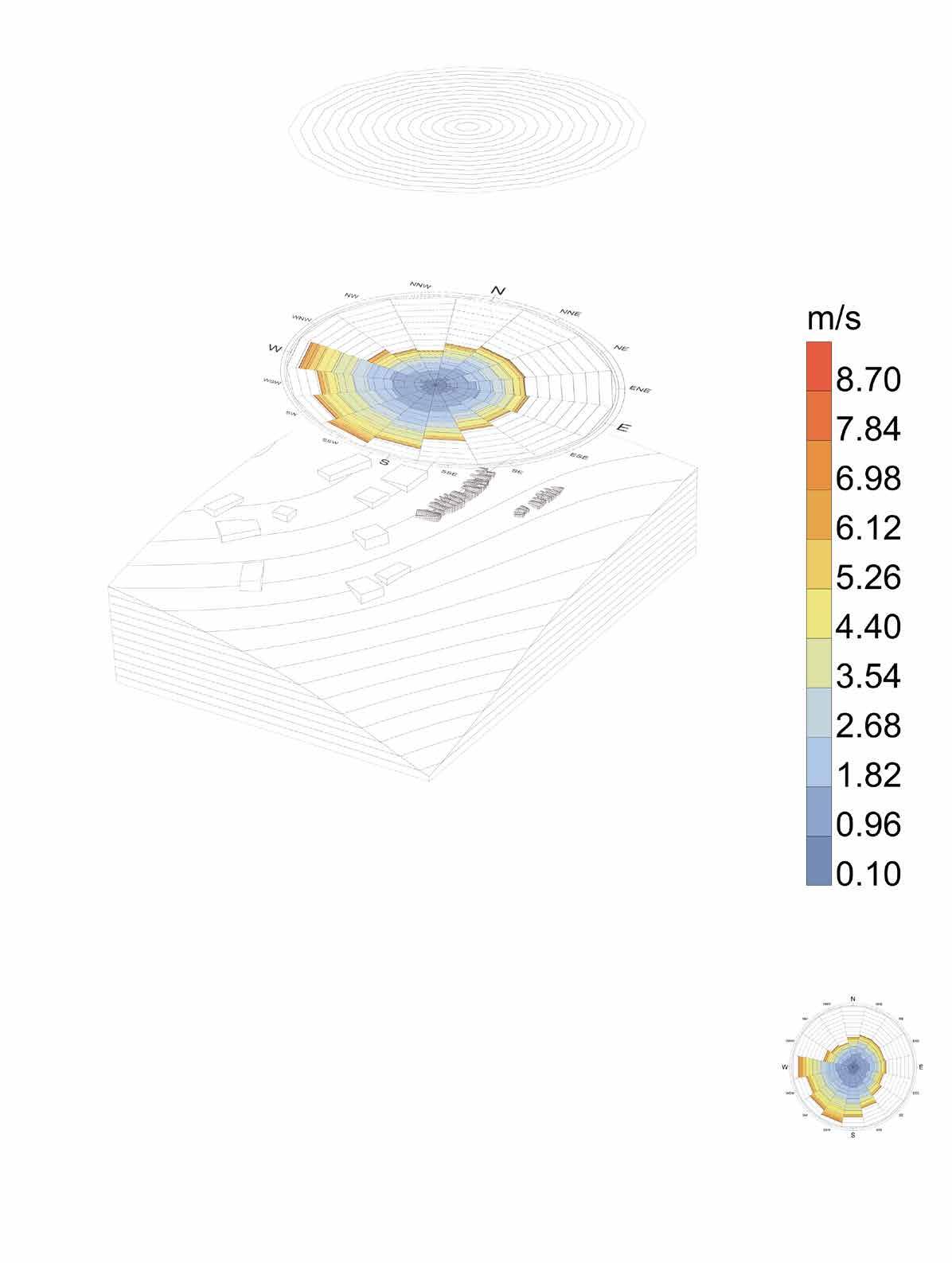

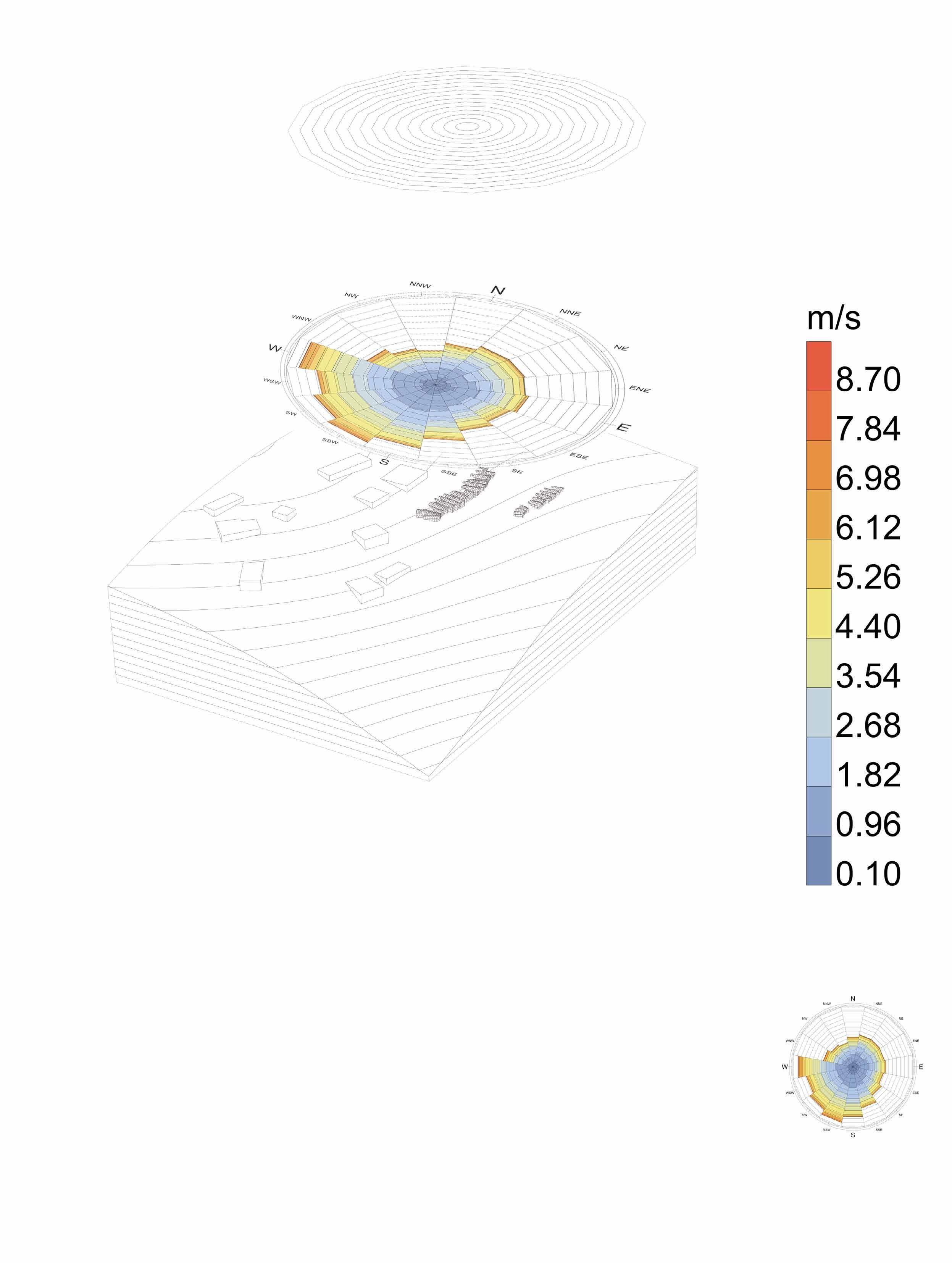

The diagram for Saghbine shows the days per month, during which the wind reaches a certain speed. The wind rose shows how many hours per year the wind blows from the indicated direction.

Climate Saghbîne

The graph shows the monthly number of sunny, partly cloudy, overcast and precipitation days. Days with less than 20% cloud cover are considered as sunny, with 20-80% cloud cover as partly cloudy and with more than 80% as overcast. While Reykjavík on Iceland has mostly cloudy days, Sossusvlei in the Namib desert is one of the sunniest places on earth.

Note: In tropical climates like in Malaysia or Indonesia the number of precipitation days may be overestimated by a factor up to 2. Maximum

The meteoblue climate diagrams are based on 30 years of hourly weather model simulations and available for every place on Earth. They give good indications of typical climate patterns and expected conditions (temperature, precipitation, sunshine and wind). The simulated weather data have a spatial resolution of approximately 30 km and may not reproduce all local weather effects, such as thunderstorms, local winds, or tornadoes.

You can explore the climate for any location like the Amazon rainforest West-Africa savannas Sahara desert Siberian Tundra or the Himalaya

30 years of hourly historical weather data for Saghbîne can be purchased with history+ Download variables like temperature, wind, clouds and precipitation as CSV for any place on Earth. The last 2 weeks of past weather data for Saghbîne are available for free evaluation here

The maximum temperature diagram for Saghbîne displays how many days per month reach certain temperatures. Dubai one of the hottest cities on earth, has almost none days below 40°C in July. You can also see the cold winters in Moscow with a few days that do not even reach -10°C as daily maximum. Precipitation

The precipitation diagram for Saghbîne shows on how many days per month, certain precipitation amounts are reached. In tropical and monsoon climates, the amounts may be underestimated.

Wind speed

https://www.meteoblue.com/en/weather/historyclimate/climatemodelled/saghbîne_lebanon_268424

6

The diagram for Saghbîne shows the days per month, during which the wind reaches a certain speed. An interesting example is the Tibetan Plateau where the monsoon creates steady strong winds from December to April, and calm winds from June to October.

speed units can be changed in the preferences (top right). Wind rose

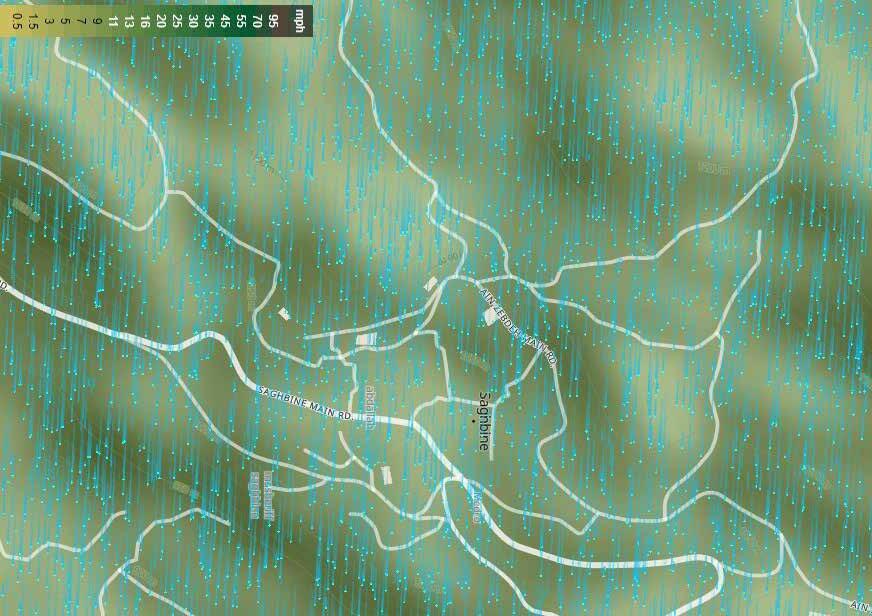

The project responds to the given weather conditions in it’s overall positionning, angles and openings direction taking into consideration the sunpaths, wind direction and precipitation in order to heighten the performance of the building and for it to be as contextual and energy sufficient.

https://www.meteoblue.com/en/weather/historyclimate/climatemodelled/saghbîne_lebanon_268424 6

https://www.meteoblue.com/en/weather/historyclimate/climatemodelled/saghbîne_lebanon_268424

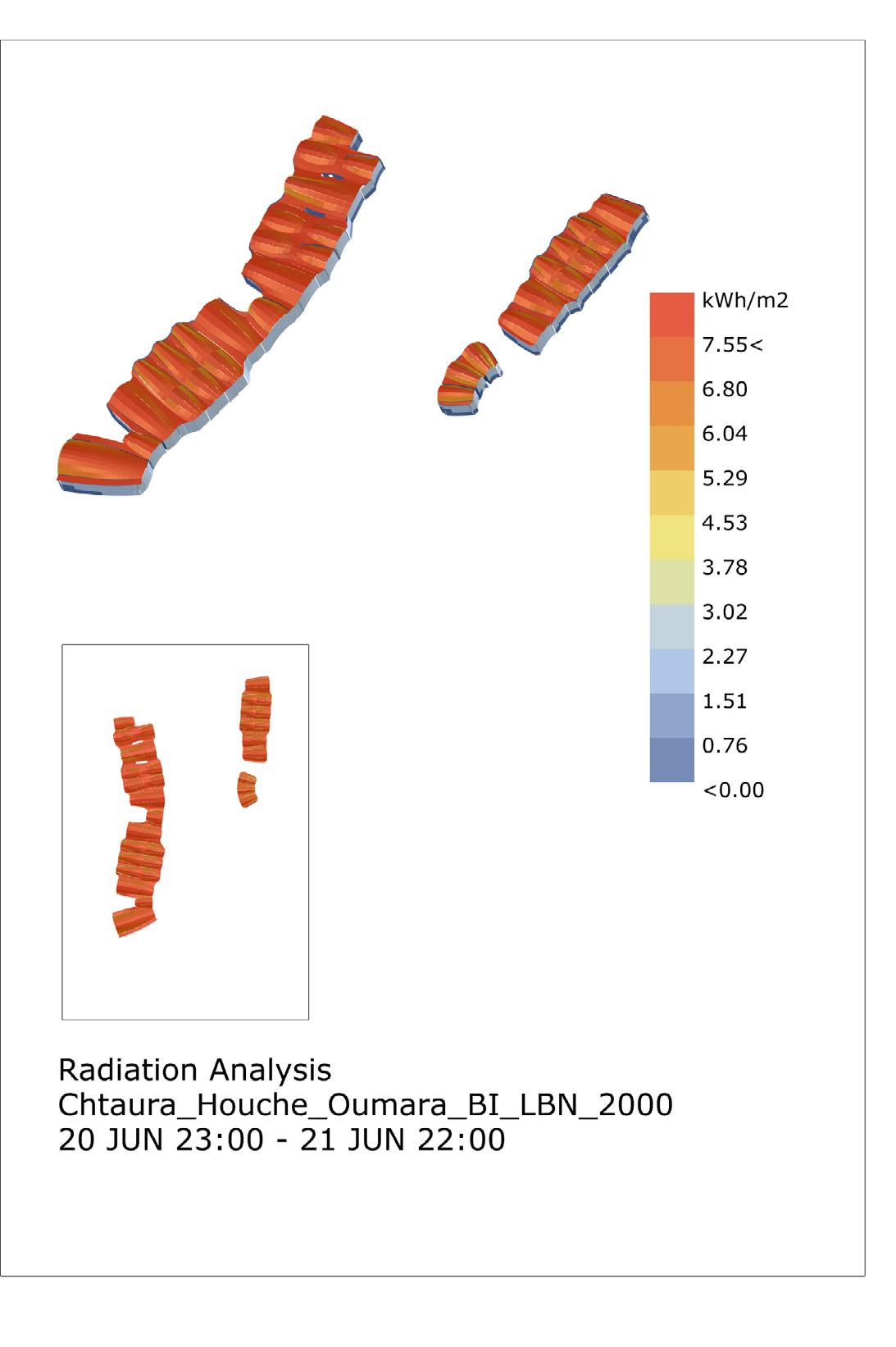

In the context of building energy performance, the ancient wisdom of using the earth as temperature moderator against harsh weather has impressive potential to become a solid solution against the energy inefficiency of Heating, Ventilation, and Air Conditioning system (HVAC) in building

considerations

It is important the roof doesnt have many opening to the sky as it is the surface that receives the most radiation especially during summertime, the vaulted roofs of the scheme will be covered in a vernacular mix of fermented white earth mixed with chalk (cf p.57) in order to mitigate heat gain from the roof through its materiality.

The thermal mass of the earth will minimise radiations going through the roof, as well as the color of the covering being white and relfecting the sunlight, instead of absorbing it.

With rainfalls almost 6months a year it is worth it to consider rain-collection as part of the design in order to be able to provide for the functions of the building. From W.C, to public bath and kitchen facilities.

The Vaulted roofs can redirect the water to the creases where the water can be directed to the back of the building to be collected through edge gutters and soil gutters into the rainwater tank than can be burried in the soil behind.

For the roofs to transfer the water accurately, it will be coated with a waterproof covering borrowed from the vernacular.

https://www.intechopen.com/books/energy-conservation/earth-shelters-a-review-of-energy-conservation-properties-in-earth-sheltered-housing

Building with earth helps greatly in responding to the weather.

Earth is a great moderator of temperature change. When warmed up, it can stay warm a long time without losing much of its heat. Earth does not react as fast to temperature change as air does.

This means that for instance if air surface temperatures ranges from -15°C to 35°C through the year (winter through summer), then about 3 meters below, the temperature of the earth will vary only between 10°C to 15°C. This short range in difference explains the ability of earth to maintain stable temperatures throughout the year. This is a significant energy conservation tendency in the case of reducing the load on home heating and air-conditioning systems

In earth shelter houses, the overlaying thick earthen layer around much of the building effectively eliminates possibilities of infiltration through the building skin (as is the case in conventional above-ground houses). This can contribute significantly in reducing energy loss due to infiltration, except only through the exposed portions of the structure. Apart from the reduction of infiltration, studies identified that the application of thermal coupling of the earthsoil to the building wall places significant values to the thermal conditions of the earth shelter environment in winters. This process allows for improved thermal storage through the soil into the building walls.

With the potential thermal conservation qualities and physical characteristics of earth as a building mass, earth shelters can now be defined as structures built with the use of earth mass against building walls as external thermal mass, which reduces heat loss and maintains a steady indoor air temperature throughout the seasons.

Earthen building are therefore cooler in the summer, warmer in the winter which is a great building solution for the climate of LEbanon, having practically four seasons with warm summers and cool winters.

CONCLUSION

So far, looking at fields of extraction, our relationship with the earth, my proposal looks at being contextual and hyperlocal in material providence.

In Order to achieve that, I first attempted to understand the landscape, it’s materiality, inhabitation, use of technologiees and subsequent influences through surveying and research.

The local construction methods utulise local soil which is rich in clay as well as local limestone. Once the most popular building construction in the area, for various reasons earth houses have disapeared. I am looking at learning from the methods, borrowing mixes for coverings and techniques for measuring and making bricks but not replicating the exact architecture.

Having done an analysis of the soil it is stillimportant to perform percolation test on the construction site's soil to determine the earth shelter soil permeability before construction. Earth structures require natural drainage and therefore permeable soils. The most permeable soils as identified above are the granular type which consists of a fair amount of sand or gravel while soils with high clay content are less permeable as they expand and contract as moisture levels fluctuate.

I have taken environmental parameters into considerations which have helped me understand the weather conditions and how to respond directly in order to reach a better performance.

Earth is indeed an appropriate material to use in the climate of the Beq’aa, used since roman times in the area.

Moving forward, I will explore earth as a material to manipulate in order to create a ground condition, substracting, transforming and reusing this earth locally on site in order to achieve a building in continuity with it’s surroundings,encouraging a relationship with the earth by designing public earthen facilities.

MANIPULATION OF EARTH

tools at a multitude of scales

‘Earth can be moulded ad infinitum – hydrated, pressed, spread, rolled, compacted, thumped, torn, cracked, joined again, dried, ripped and hydrated again. The cycle of the seasons imposes its rhythm and shapes the landscape. Because of its malleability, its endless morphing and moisturising, earth becomes a material of endless possibilities.

exhaust

diesel engine steel tracks

1 m3 capacity bucket

shovel max bucket lifting height 4600 forward 10 km/h reverse 9 km/h glazed cab with all round vision

Dumpers max foward speed: 50 km/h skip with a heaped capacity of 10 m3

These are used for the horizontal transportation ofmaterials on and off construction sites generally by means of anintegral tipping skip. Highway dumpers are of a similar but largerdesign and can be used to carry materials such as excavated spoilalong the roads.

Beneficiation

Compared with other manufacturing industries, far less mineral beneficiation (washing, concentrating, sizing of particulates) is employed for silicate ceramics. Clays going into common structural brick and tile are often processed directly as dug out of the ground, although there may be some blending, aging, and tempering for uniform distribution in water. Silicas are purified by washing and separating unwanted minerals by gravity and by magnetic and electrostatic means.

Plastic forming

Plastic forming is the primary means of shaping clay-based ceramics. After the raw materials are mixed and blended into a stiff mud or plastic mix, a variety of forming techniques are employed to produce useful shapes, depending upon the ceramic involved and the type of product desired. Foremost among these techniques are pressing and extrusion.

Slip casting

A different approach to the forming of claybased ceramics is taken in slip casting, with sufficient water content and the avddition of suitable dispersing agents, clay-water mixtures can be made into suspensions called slurries or slips. After a sufficient thickness of deposit has been obtained, the remaining slip can be poured off or drained and the mold opened to reveal a freestanding clay piece that can be dried and fired. Surprisingly complex shapes can be achieved through slip casting.

Firing

After careful drying to remove evaporable water, clay-based ceramics undergo gradual heating to remove structural water, to decompose and burn off any organic binders used in forming, and to achieve consolidation of the ware. Batches of specialty products, produced in smaller volumes, are cycled up and down in so-called batch furnaces. Most mass-produced traditional ceramics, on the other hand, are fired in tunnel kilns. These consist of continuous conveyor belt or railcar operations, with the ware traversing the kiln and gradually being heated from room temperature, through a hot zone, and back down to room temperature.

Finishing

If fired ceramic ware is porous and fluid impermeability is desired, or if a purely decorative finish is desired, the product can be glazed. In glazing, a glass-forming formulation is pulverized and suspended in an appropriate solvent. The fired ceramic body is dipped in or painted with the glazing slurry, and it is refired at a temperature that is lower than its initial firing temperature but high enough to vitrify the glaze formulation. Glazes can be coloured by the addition of specific transition-metal or rare-earth elements to the glaze glass.

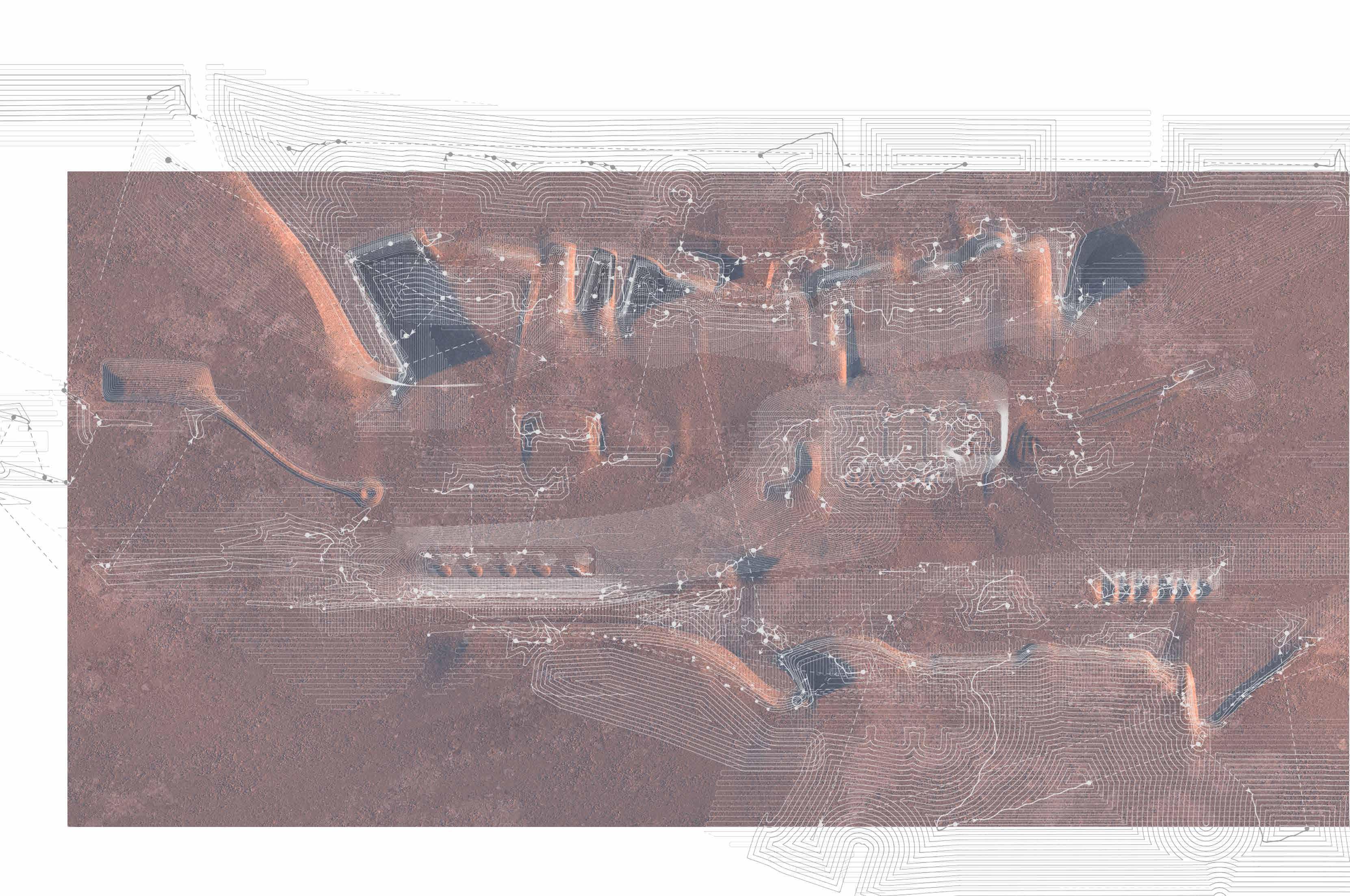

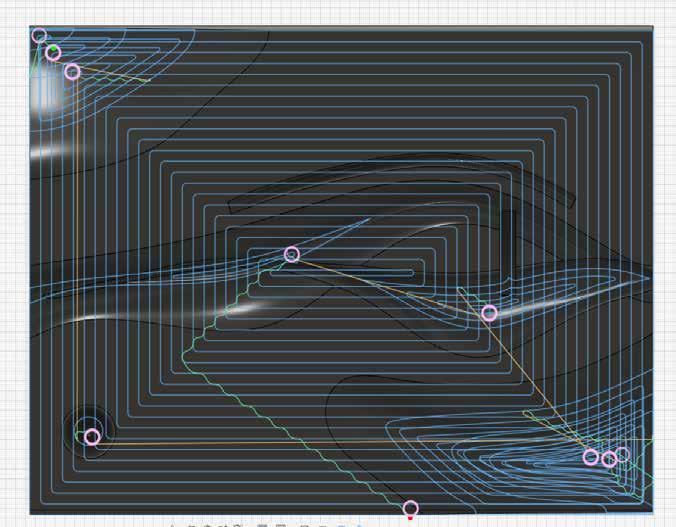

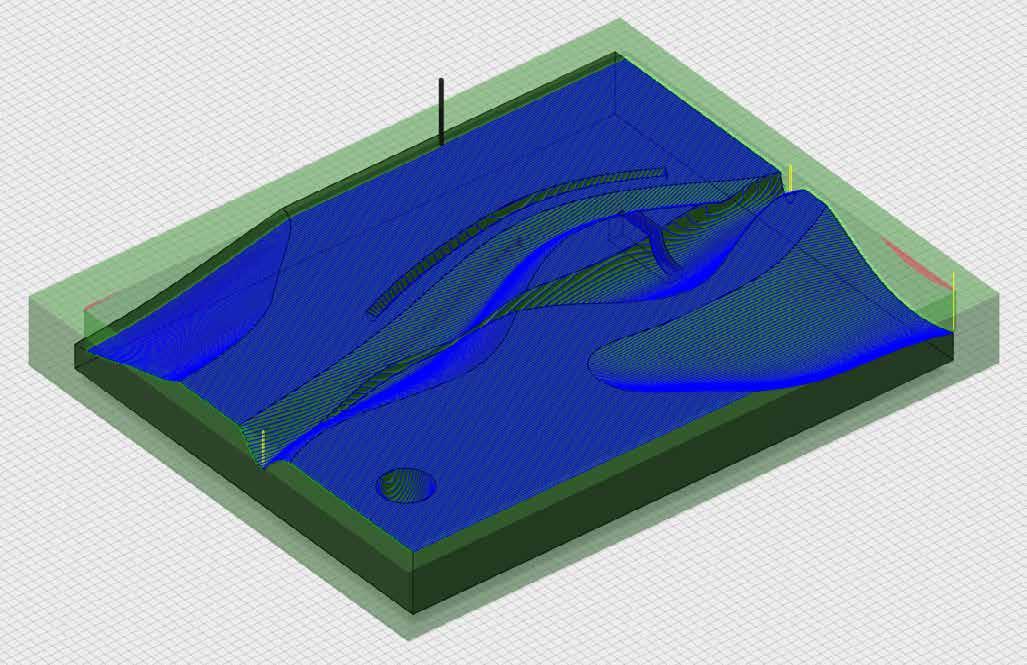

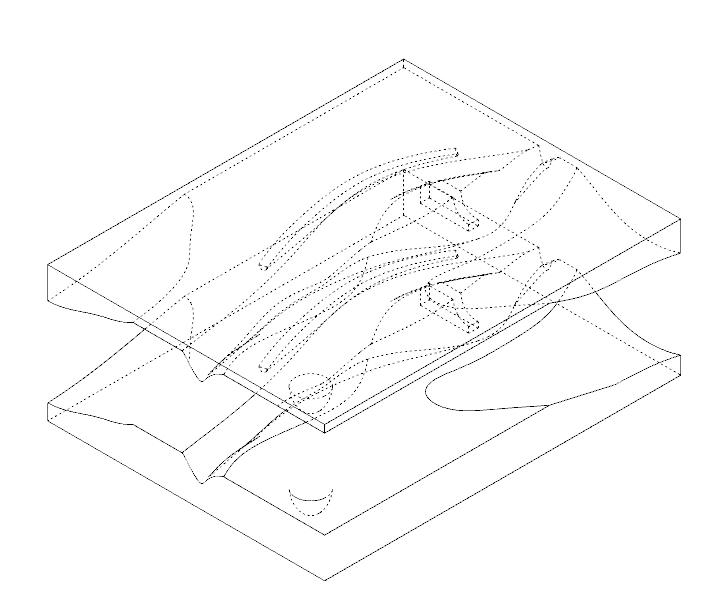

addition substraction programatic zones sloped entrance points scrape outline to 60o building outline to dig - 2m mound creasing

water ponds retaining walls functional cavities

( 1 ) marking with thread and needle

(

2 ) marking by excavating the boundary

(

3 ) bulk excavation - roughing

( 4 ) compressing - smoothing

(

5 ) stair tool - sweep

(

6 ) roughing tool excavating deeper

(

7 ) marble ball stamp

(

8 ) scooping out

(

9 ) stamp of a 3d printed tool

( 10 ) trench

(

11 ) smoothing and arc stamp

(

12 ) stamp of a 3d printed tool

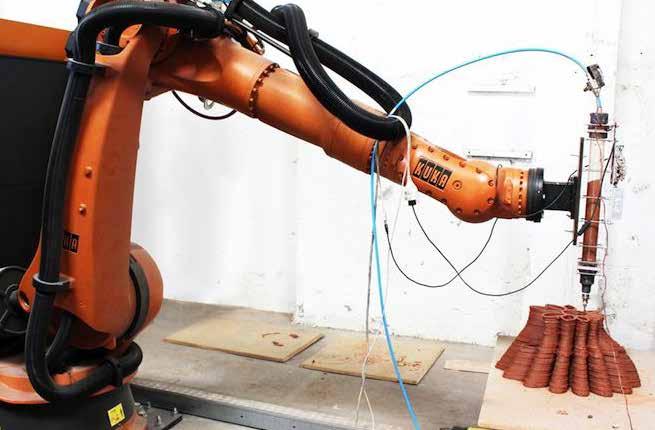

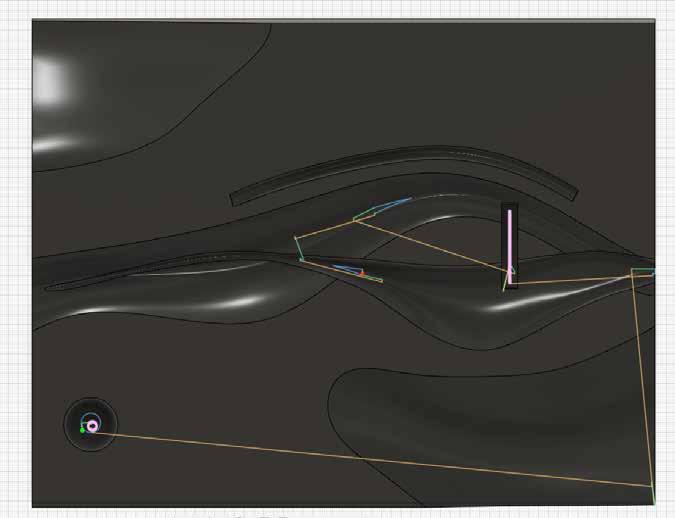

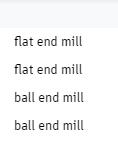

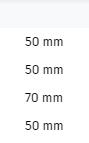

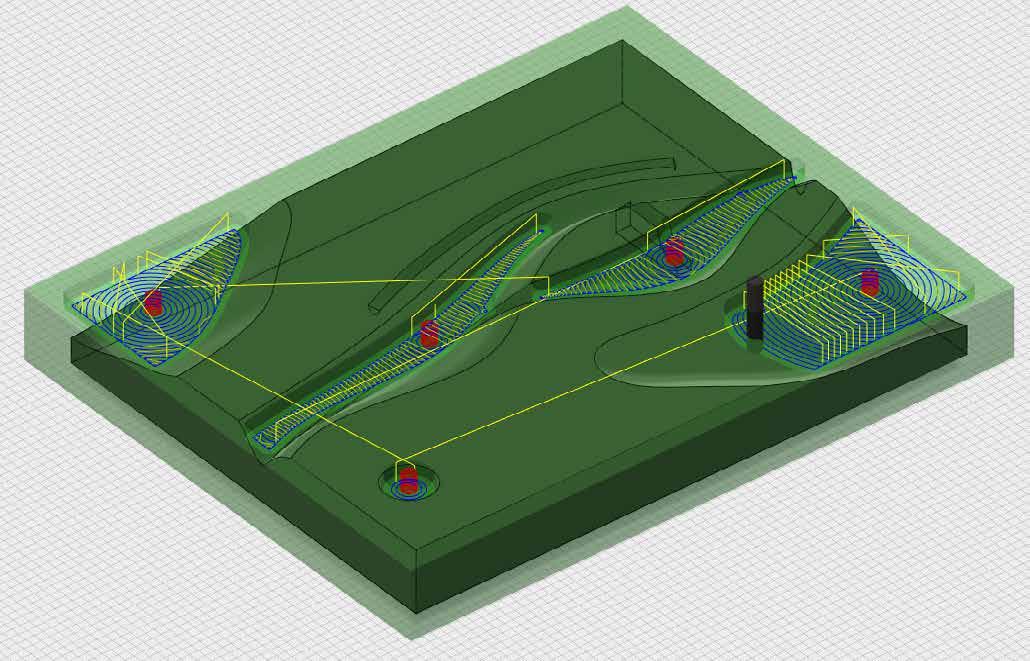

Considering the site and context, robotic tools would only be used as a manufacturing technique at a small scale, ie to produce tiles or moulds for tiles off-site, with clay from the site. As opposed to using a robot to sculpt the ground. Instead the ground condition will be formed and manipulated using mechanical machines, diggers, scrapers, graders, borrowed from the agricultural and building industry. The intention is to add custom endings to be fixed on the tools for custom finishings of the ground.

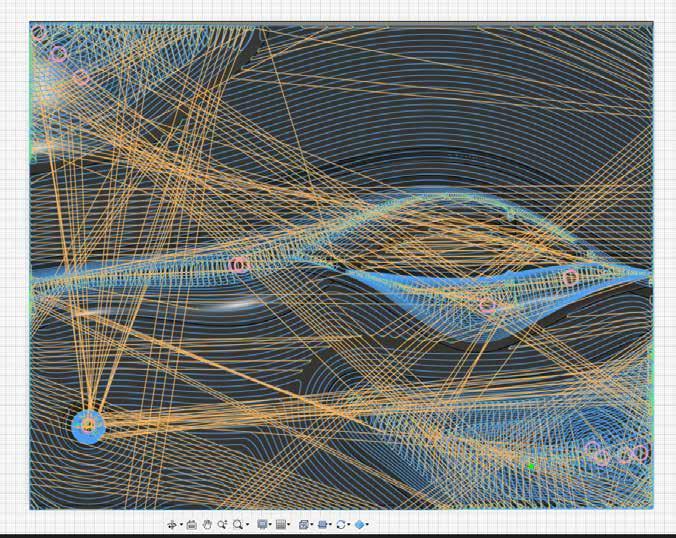

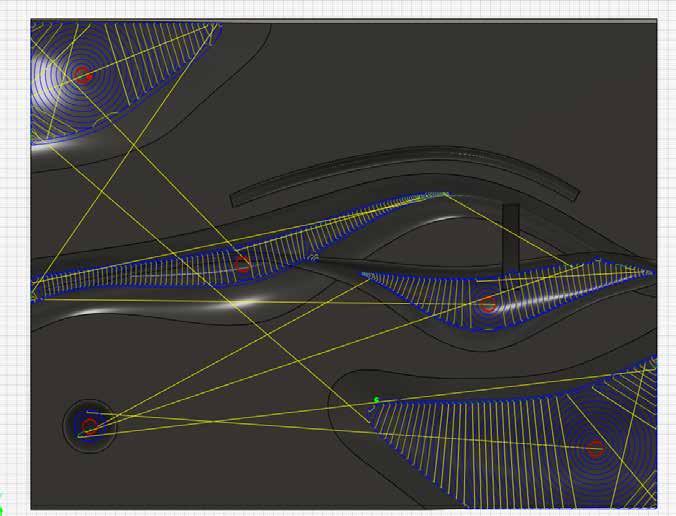

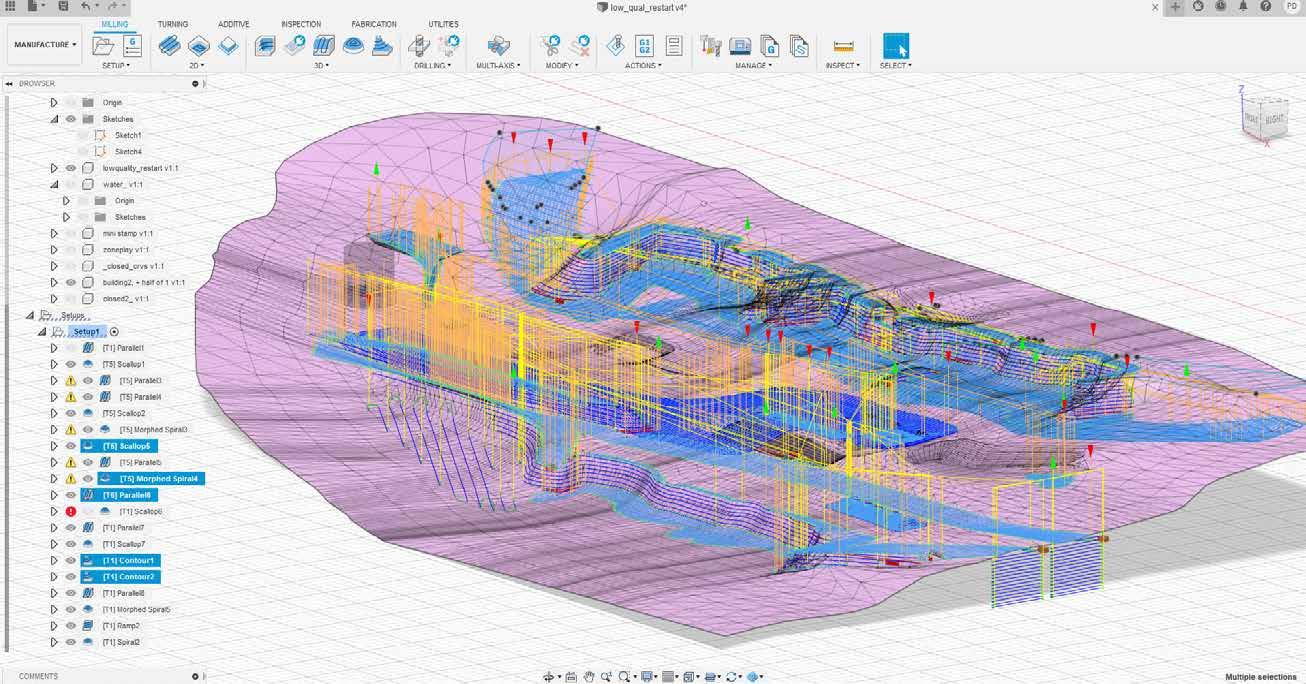

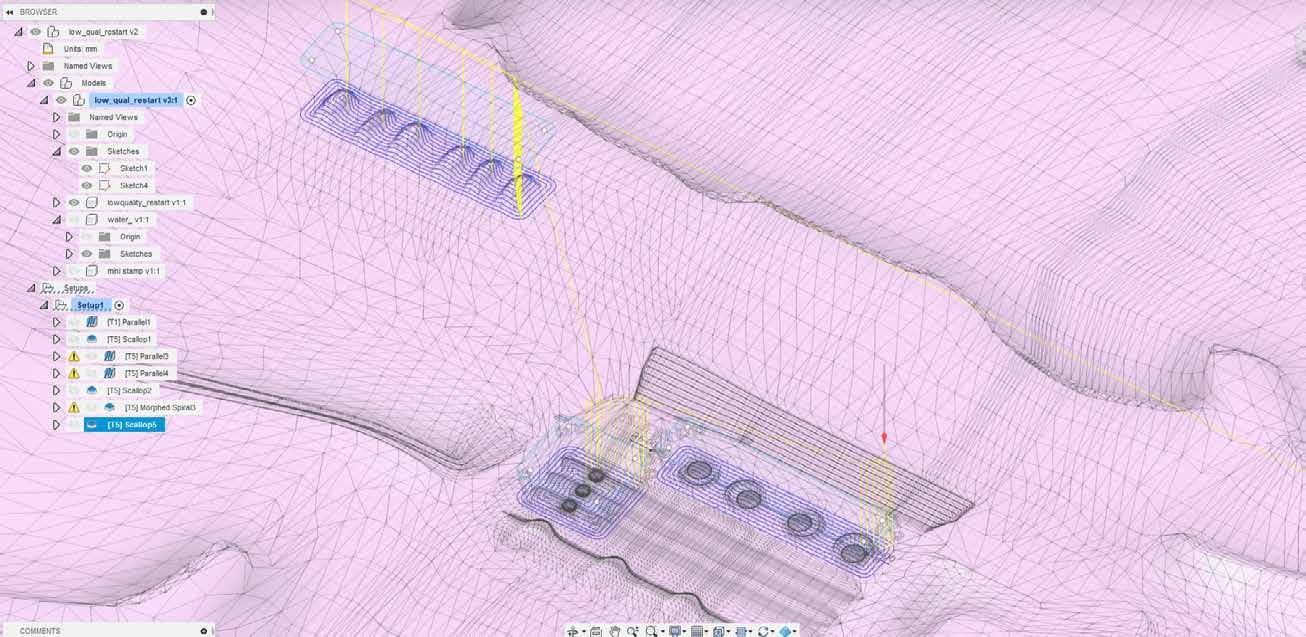

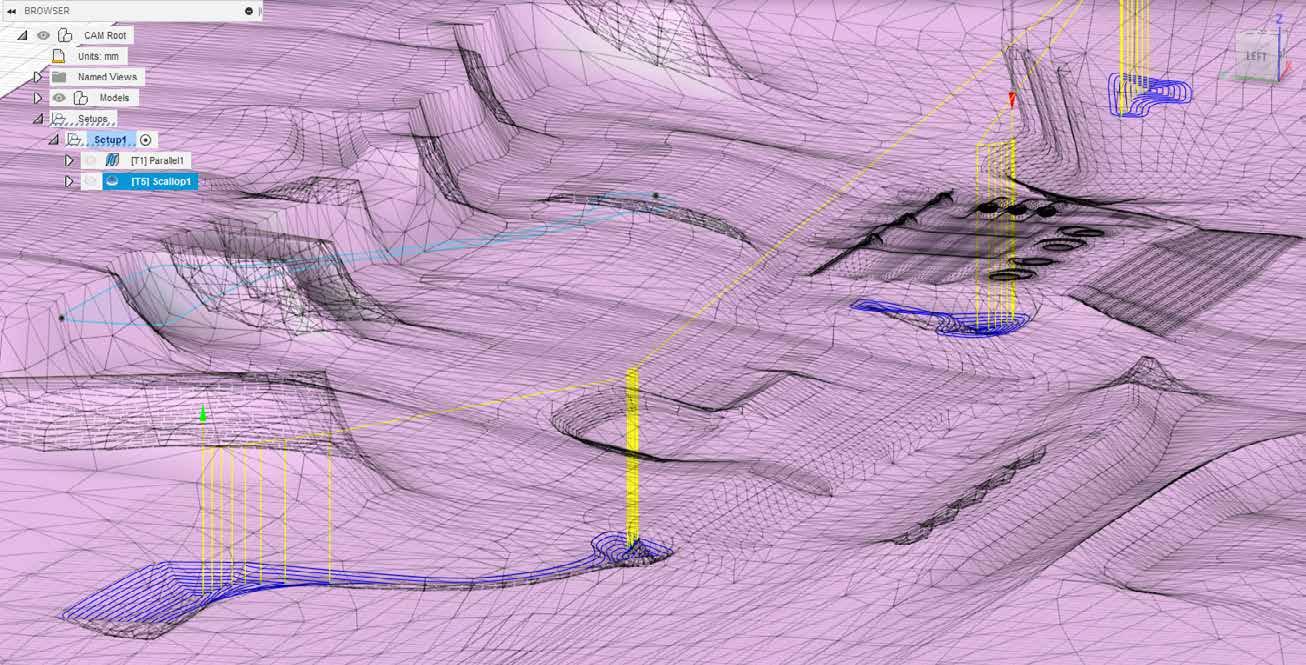

However, softwares to manipulate robotic are used to generate tool paths controlling speed precision and thicknesses. It is a way for me to simulate the ground works. It serves to create notation drawings to inform the sculpting and zoning of the ground. As well as possible routes for one type of digger to follow. A kind of notational map that can be used as an informative construction guide.

In order to construct the landscape, digging operations are determined by the design. Learning from the manipulation of milling machines at a small scale and extrapolating the numerical technique to the territorial scale. Defining toolpaths by scaling up the drill bits of the cnc, according to diggers, arm sizes, textures and diggin depths.

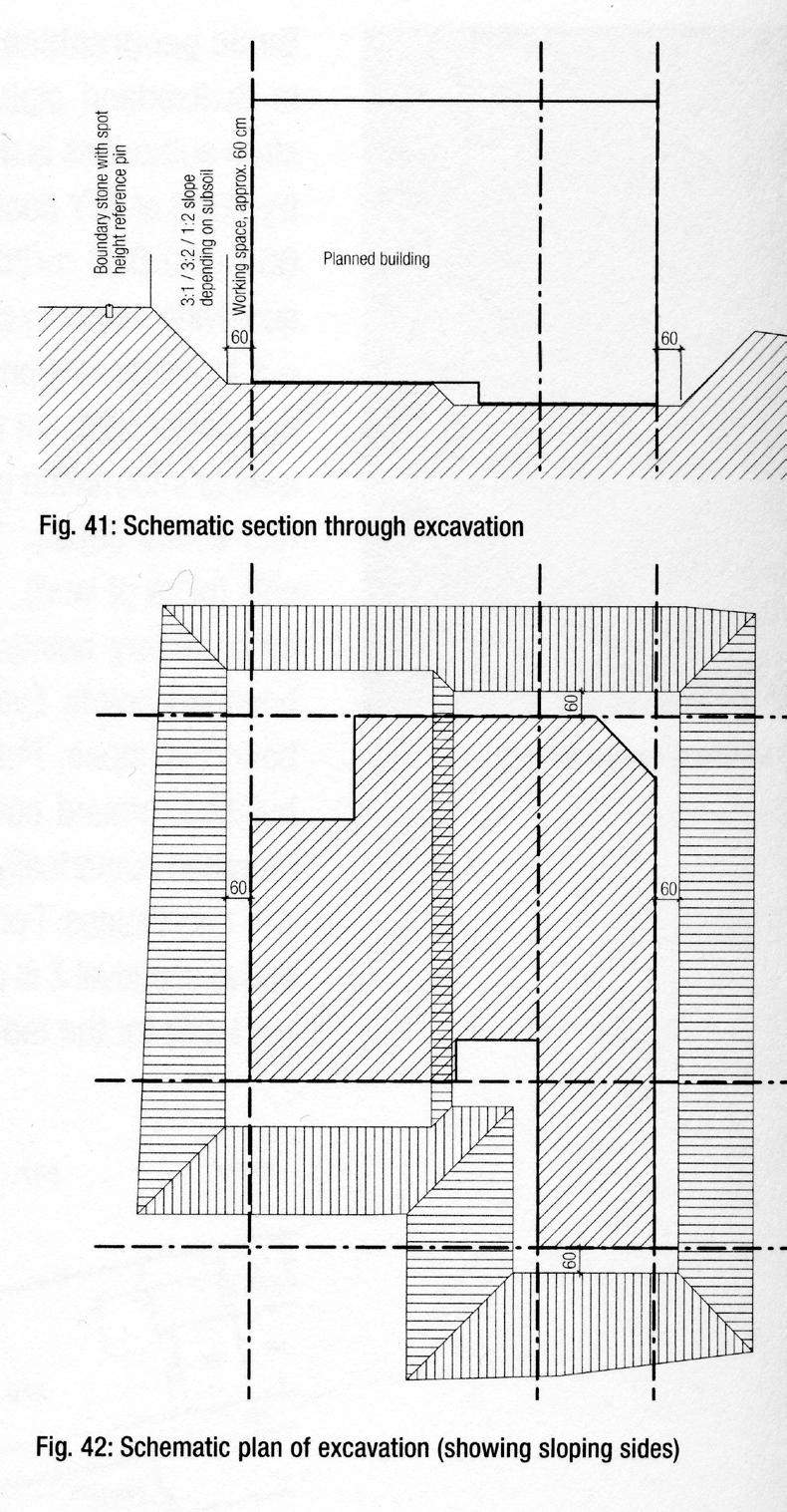

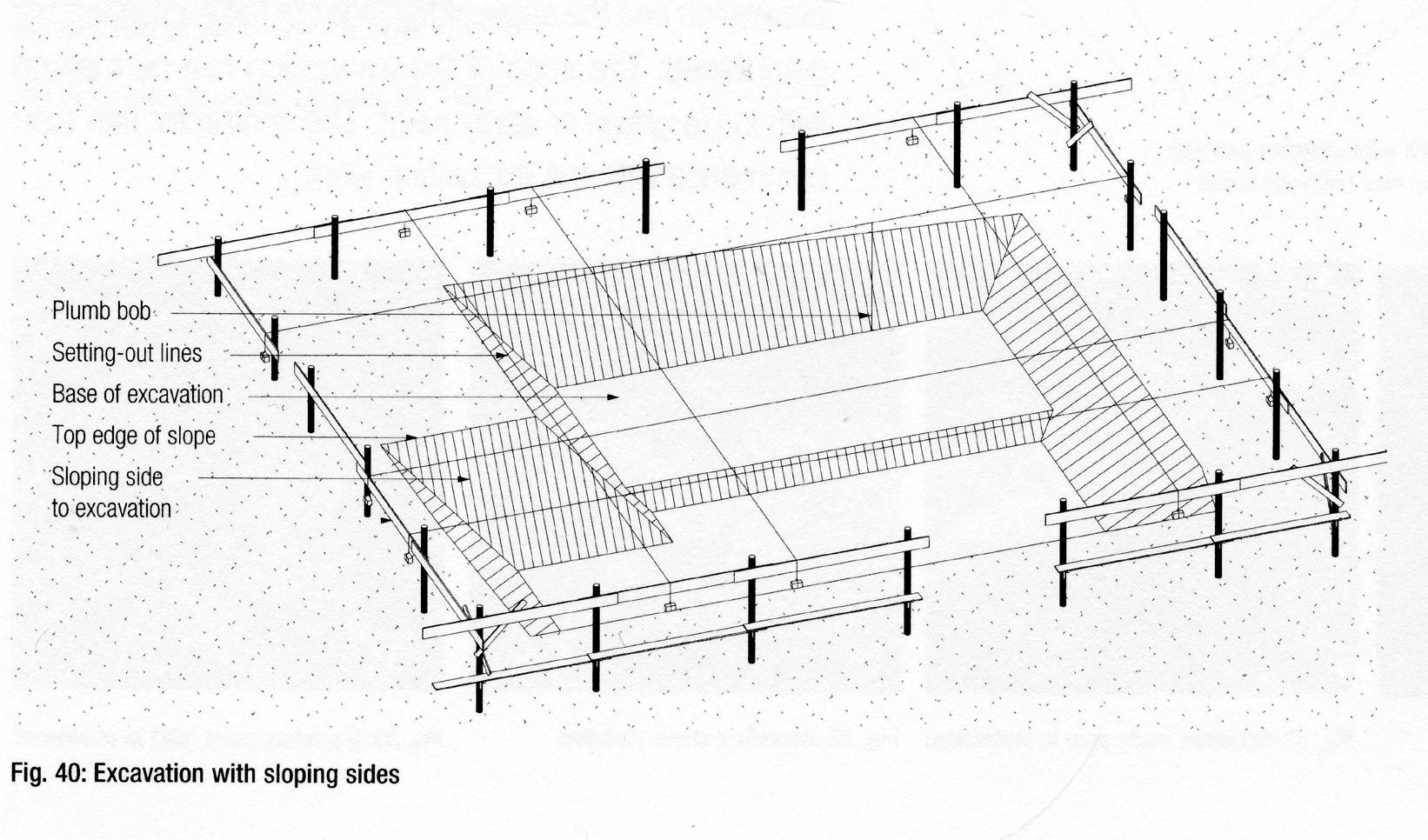

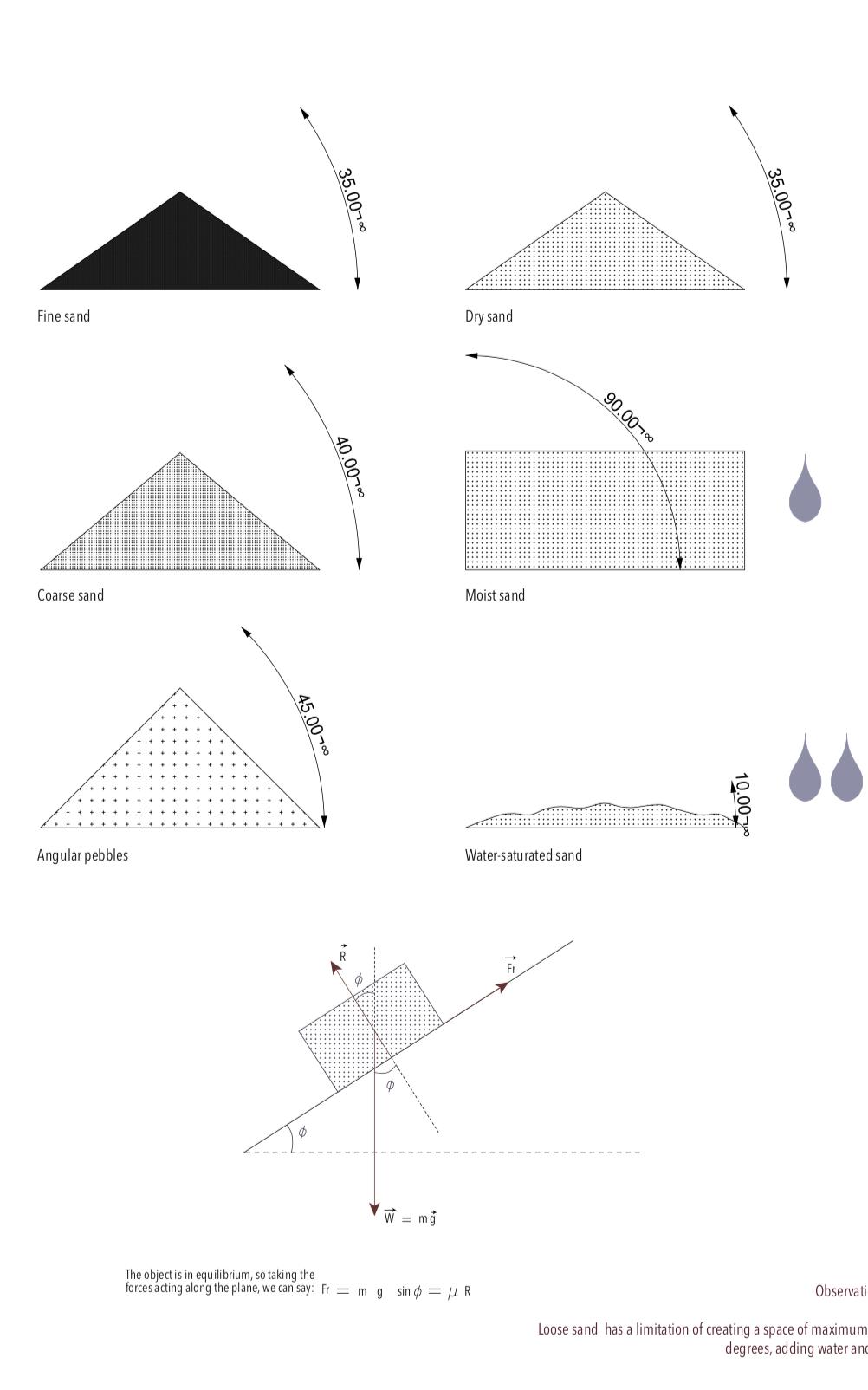

Excavations

The movement of masses of soil is an activity that is difficult to predict, the details of which are normally planned by civil engineers and geologists

Using the results of a soil survey (boreholes), the anticipated quantity of material to be excavated and the strength of the subsoil can be determined. Afterwards, a decision can be made regarding the best type of foundation for the structure. The earthworks contractor initially removes the upper most layer of topsoil and vegetation (approx. 30 cm) with a tractor shovel and retains some of this material on site. Afterwards, the actual excavation work begins in stages.

If there is room on the site or in the immediate vicinity, excavated material (spoil) is retained for backfilling at a later date because the transport of spoil is expensive and should be avoided wherever possible. Working with the excavation plant (excavator, tractor shovel etc.) is a skilled job; the operators have to work to an accuracy of a few centimetres Once the required depth has been achieved, the base of the excavation is covered with a blinding layer of lean concrete (grade PC 150, approx. 5 cm).

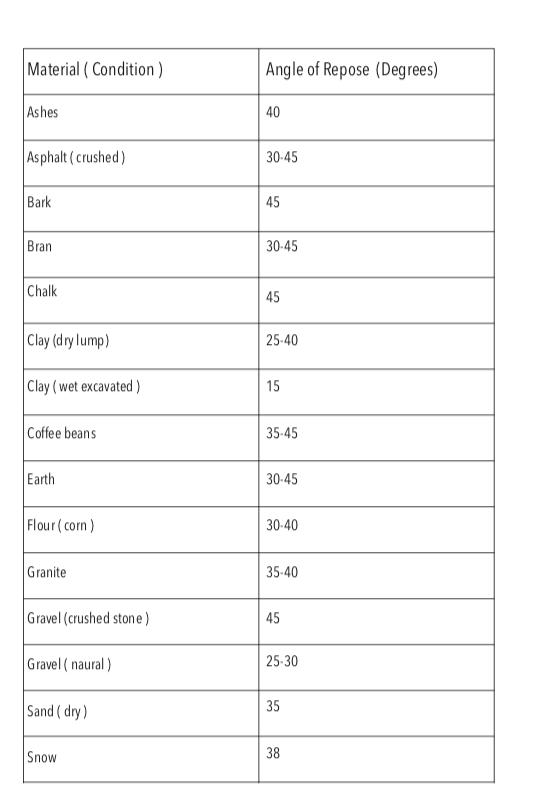

The lean concrete provides a clean base on which to mark out underground services or the foundations. However, on rocky ground the layer of blinding may not be necessary. The excavation should generally be about 60 cm larger than the outline of the building all round; 60 cm provides an adequate working space for the contractor The angle of the sloping sides to the excavation (and if necessary stabilising measures) depends on the properties of the soil. The angle must also be chosen to rule out slippage or collapse and hence guarantee the safety of persons working in the excavation. Depending on the weather conditions and the hydrostatic pressure (slope run-off water or groundwater), any water must be drained away according to the regulations.

The following function provides a ood approximation of the angle of repose by knowing the friction of the material.

tan (a) = x

x being the coefficient of static friction, and (a) the angle of repose

The angle of repose of a granular material is the steepest angle of descent relative to the horizontal plane to which a material can be piled without slumping. At this angle, the material on the slope face is on the verge of sliding. The angle of repose can range from 0 ° to 90 °. Smooth rounded sand grains cannot be piled as steeply as can rough interlocking sands. If a small amount of water is able to bridge the gaps between particles, electrostatic attraction of water to mineral surfaces will increase soil strength

Rough ground mold No largescale formwork

Shotcrete thin layer

The proposed site is carefully prepared. First we excavate or build up the earth, and install drainage, coping and all steel work. The area is then set out with formers and re-bar to shape the material and the concrete is sprayed in place. A pump sprays the concrete onto the transitions using compressed air. We use the ‘sprayed concrete’ method. Curved templates and screeds are used to give a high level of accuracy. Finally the surface is hand finished through several passes reducing the size of steel trowels to give a smooth, durable polished surface. This is the method used by the highest quality skatepark manufactures around the world.

Free-Form Construction

Unlike fitting together pre-cast moulds, freeform construction allows architects the freedom to create progressive designs, especially where one transition merges into another - allowing us to design the park that perfectly meets the requirements of the site, user-group and the local community.

“With pre-cast, every piece has to be mould and cast, it’s heavily engineered, it’s less environmentally friendly because you use about three times the amount of concrete building this way. So that means cost, additional environmental impact and unnecessary limitations on design.”

Jeremy Donaldson, Professional Skatepark Designer and Architect6. Filling foundation for stabilisation of the wall

5. Flipping wall on foundation

4. Casting of foundation and shape

3. Shaped metal rebar inserted

2. Excavation of the soil in a specific shape to cast in

1. Deposit and displacement of soil to create a mound

metal reinforcement

soil concrete

The object is in equilibrium, so taking the forces acting along the plane, we can say:

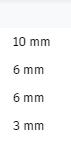

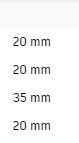

The intention is to have a balance between the ( - ) and the ( + ) The dug out earth will mainly be used for relandscaping, flattening the lamd to accomodate for a public space , and processing it for the making of bricks and tiles. two types of bricks will be produced, the brick tile for the construction of vaults and the bricks for foundation and walls.

Below is a diagram of the construction method that will be deployed across the site, with variations.

The quantity of earth dug out in order to make space for the building at the top of the slope is approximately:

SOIL = 970 m3

Of which 40% is clay (cf p. 39)

After sifting through the earth to obtain the finest particles which are clay,

CLAY = 388 m3

the clay needs to be moulded in two different components

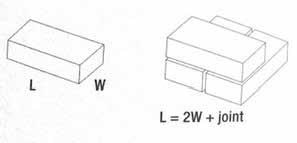

bricks for the structural walls (220 x 110 x 70 mm) and

brick tiles for the vaults ( 300 x 150 x 30 mm)

then dried and fired, ready for assembly for a vault

(considering the vault surface area of 600 x 370 mm)

1.62 m3 of clay

1 tile = 0.001 m3

each layer would consist roughly of 540 tiles 1620 tiles / vault

540 x 0.001 = 0.54 m3

each vault consists of three layers of tiles

3 x 0.54 =1.62 m3

for 17 vaults

1.62 x 17 = 27.5 m3

for 12 vaults

1.62 x 12 = 19.5 m 3

for 3 vaults

1.62 x 12 = 4.62 m 3

total = 51.62 m3

51840 tile bricks in total

-

soil for relandscaping and backfilling = 714 m3

for a wall + foundation (considering the wall 600 x 200 x 44 mm

4.52 3 of clay

1 brick = 0.001 m3

each wall would consist roughly of 2900 brick the foundation 1620 bricks

total = 4520 m3

4520 x 0.001 = 4.52 m3

-

for the floor (considering 500 m2) 15 m3 of clay

The floor is made out of a mix of broken up fired tiles tempered with lime an ancient method used by romans called opus signinum or cocciopesto

for 20 walls + foundation

4.52 x 20 = 90 m3

for 10 walls

4.52 x 10 = 45 m3

total = 135m3

total clay needed for the first building 133 m 3

total clay needed for second bbuilding = 72 m3

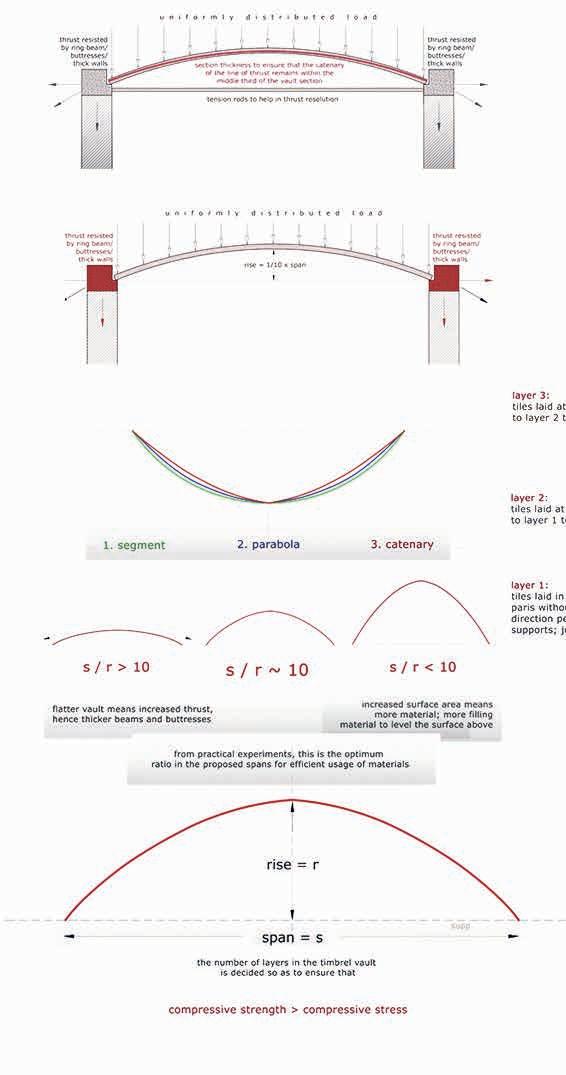

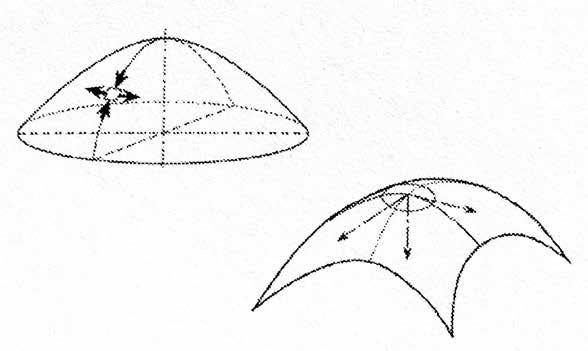

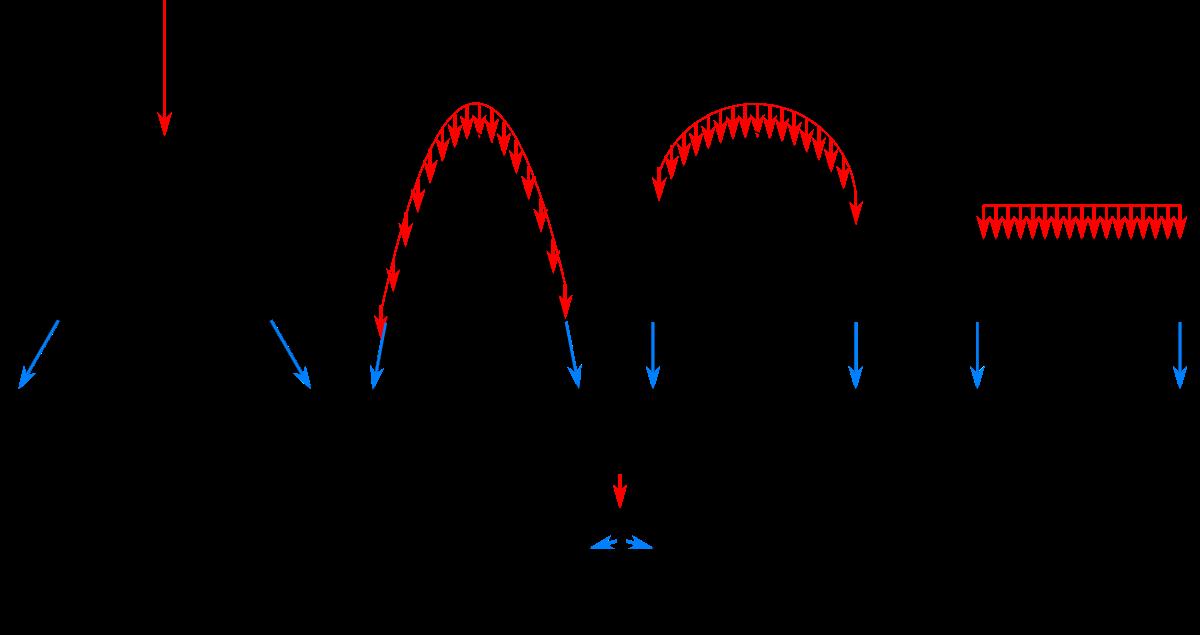

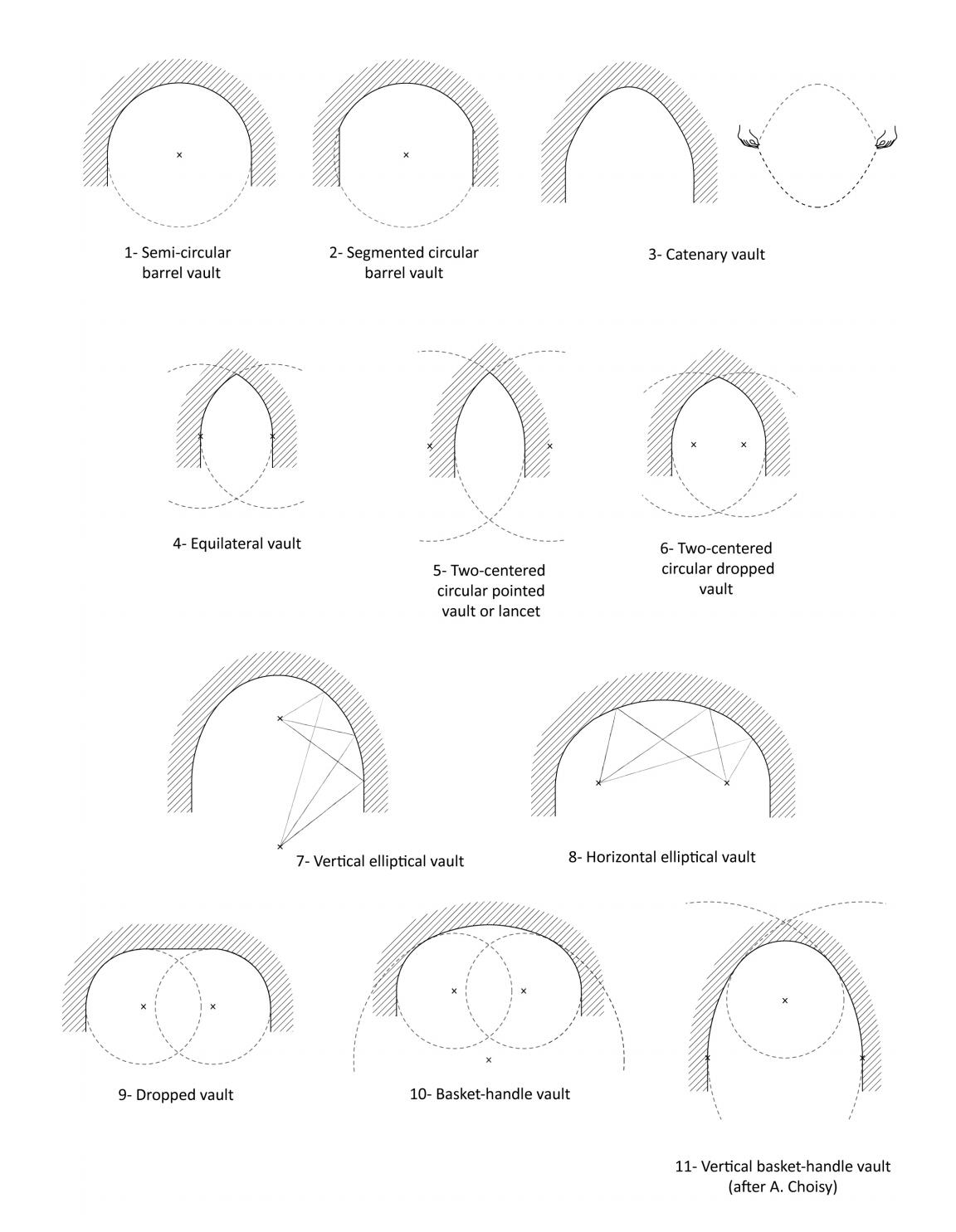

Earth constructions only take forces under compression. The only way of spanning any distances in earth is therefore working with vaults or domes.

The chain formed arch (catenary arch) is a natural shape of a compression only vault.

The oldest vaults known in Egypt, the Nubian vaults, are Catenary arches. The Catenary arch has until recently been the principle basis for all compression only vaults, and the construction techniques have often limited the shapes of the vaults to being symmetrical.

There is an ongoing research being deducted on free form compression only shapes. New ways of interpreting the classic vault are being testes and examined.

In order to construct free form vaults in common bricks or blocks the tile vaulting technique is used. Two or more layers of thin tiles constitute the vault and a more even spread of the forces is enabled.

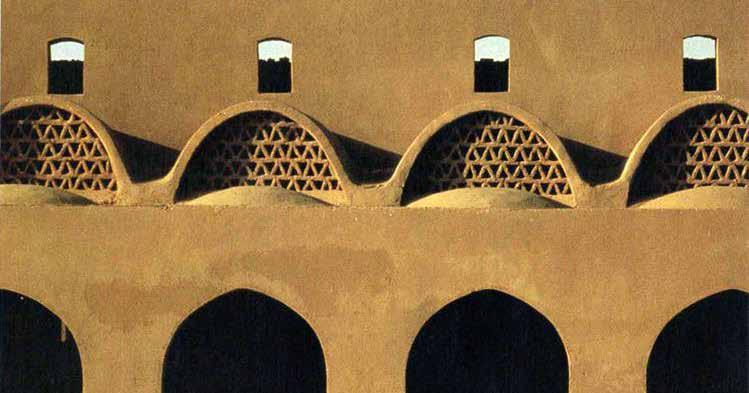

Brick tiled vaults will be used for the roofs of my buildings, the technique is a lightweight yet strural solution to earth building, it requires no or little centering and simple tools and guides for construction.

The tiles will be made from the clay of the site, after extraction, sifting, moulding and firing. Fast setting mortar is to be used to ensure the stability and strength of the brick vaults. Usually portland cement is the chosen mortar but a more sustainable option like lime mortar can be envisaged.

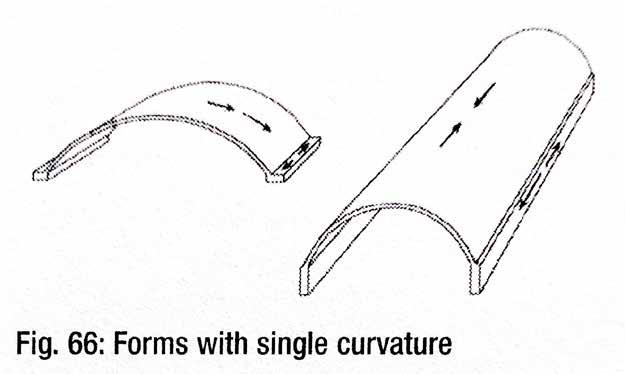

single curvature

double curvature

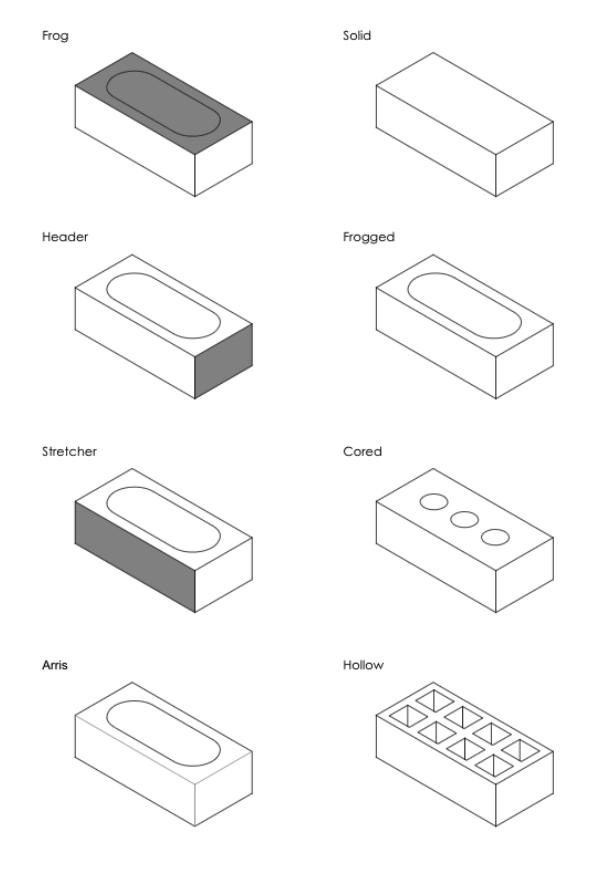

ADOBE BRICKS