4 minute read

Wind it Up

Getting your winch in working order

By Peter Symons, AKA Mr Winch

Advertisement

“P ETE, it’s Tom Jones here. You fitted a winch to my new 4x4 a few years ago and on a recent trip up to Moz I noticed it didn’t seem to have as much power as usual. I’m going to Sodwana in two weeks’ time ... can you look at it for me?”

I get literally hundreds of these calls every year, and my stock answer is largely as follows: “Sure Tom. When was it fitted, what winch is it and what vehicle is it on?”

Bear in mind that I fit at least 100 vehicles a year and can’t remember every fitting I have ever undertaken. In addition, most modern 4x4 vehicles used by the ski-boating fraternity have their winches mounted in such a way that they are virtually hidden from view behind the vehicle’s front grille with only the fairlead rollers and winch hook visible.

For this reason I first try to establish when the fitting took place as that’s usually just after the vehicle was purchased.

“Ja, Pete, it’s a XXX double cab that I purchased in 2014 so it must have been fitted soon after that. I don’t know what model winch it is … it’s the one you recommended. To be brutally honest I have never even seen the winch and I can’t find the handbook you must have given me. All I see is the hook and the remote toggle and cable to make it work.”

“Tom, I’m not trying to be funny, but I presume your vehicle gets serviced every 15 000km in line with the manufacturer’s requirements?”

“Yes, for sure. And you don’t need to rub it in … I know what your next question is going to be — When did you last have your winch serviced? The answer is never!”

Having made my point, we arranged to have Tom’s winch properly serviced to ensure he wouldn’t have any winch problems on his tip to Sodwana Bay.

I would say about 90% of the guys I fit winches for, after deciding on the make and model required, never physically see that winch again. So long as it keeps working they let “sleeping dogs” lie.

On average a recreational ski-boater uses his winch about 30 to 40 times a year and for the other 330 days it lies hidden underneath the vehicle’s bonnet but exposed to all the elements — sea sand, salt, desert dust, bush leaves etc. All these play havoc with the electrics and gears of a winch that has to pull up to 10 000 lb when put to use.

So often I see recommendations on how to service your winch, and I recently watched a YouTube video on this. According to this video you just have to pull out the cable, clean it and respool, then put some lubricant spray on the hook and fairlead rollers. Sure, it’s better than nothing, but this is only 10% of what a service should entail.

Another big factor is that ski-boaters generally only pull out sufficient cable to reload their craft — about 6- to 8 metres at the most. The rest of the 28 metre cable is left spooled on the drum, gently rusting away unseen and unnoticed.

In the old days when a ski-boater’s winch was mounted on a bull bar in front of the vehicle’s front grille the winch itself got a lot more attention. Being fully visible, they were adequately washed down with fresh water after each use and, with a bit of luck, they also got an overall squirt of Q20 or similar lubricant muti.

However today most winches are hidden away, stewing in their own juices until something goes wrong and they stop pulling. Then they’re sworn at and called all the names in the skippers’ vocabulary including “the rubbish I was sold”.

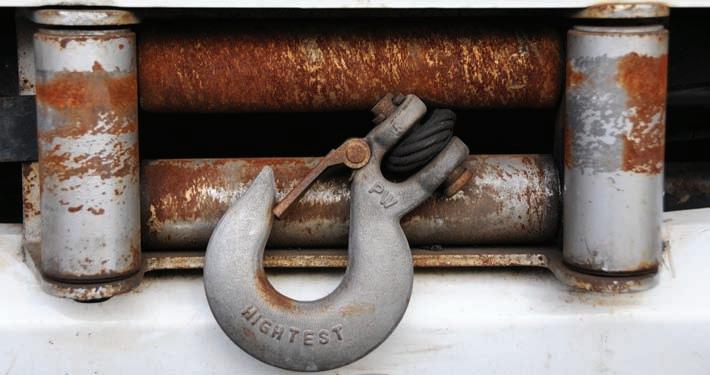

Drum before cable removed — note the galvanised and salt deterioration on the cable beneath the rusted cable that was in continual use.

To clarify what your winch really needs, I’ve set out below all the detail I go to when a winch comes in to me for a service. I largely do these services myself and personally test the winch after the service and again after remounting it in its hiding place within the confines of the 4x4 vehicle.

1. Strip the winch from the vehicle, then inspect all the supporting brackets that allow for what is the anchor point of the winch when exerting 10 000 lb of force during operations.

2. Totally strip the winch down to expose all the components.

3. Clean and check every mechanical part and all the electrical components.

4. Shot blast all areas of corrosion.

5. Respray all the components.

6. Lubricate the parts and reassemble the winch.

7. Bench test the winch.

8. If the cable is worn or rusting normally I suggest the owner replace the cable. Alternatively I soak and relubricate the cable ensuring the lubrication gets through to the centre of the steel cable, then I rewind it back onto the drum.

9. Remount the winch ensuring that the electrics are perfect and the bolts holding the winch are tightened correctly and coated with rust prevention products.

10. I personally fully test the winch once it is reinstalled on the vehicle.

I stand by the guarantee I put on my workmanship which, after 35 years in the business, speaks for itself.

If you have any specific queries about your winch give me a call on 031 312 4004.