See

Issue 15 Autumn 2023

inside for more...

Independent

x

SIBA

Brewer

Haffmans QC Equipment In-line, At-line, Laboratory, Packaging & Monitoring • Reliable & comparable measuring results • Reduced product loss & faster reaction time • Consistent product quality • Increased process efficiency • Accurate measurement of: air, CO2, O2, N2, TPO, foam and turbidity FOODANDBEVERAGE.PENTAIR.COM Phone: +44 (0) 1905 797 280 Email: Sales.uk@pentair.com Understanding Quality. FOR LIFE.

As we go to press on this issue of the magazine we are just exiting the most topsy-turvy Summer we’ve had for a while and moving from bizarrely muggy mid-September madness to the first few cooler days of Autumn.

This time of year brings with it a lot of new things - the harvest, the new school year, new uniforms and a new start. And that is no different for us at SIBA Independent Brewer.

A big thank you to all of you who responded to SIBA’s member survey over the summer, it gave us a lot of really valuable feedback on how we are doing, and we have picked up on some of

the areas you wanted us to focus on in this issue of the magazine.

Firstly, we have introduced a new regular feature section in the magazine in collaboration with Pellicle Magazine. This is in response to members asking us to feature breweries that are less well known and flying a bit under the radar. In our first collab with Pellicle, editor-inchief Matthew Curtis meets up with Caroline and Toby McKenzie from RedWillow in Cheshire (see pages 22-25) for a very personal piece which looks at the brewery’s foundation but also examines how it sits within its local community. In future magazines we will be featuring similar pieces from a series of writers on the wider Pellicle team.

Our second new feature for this issue is again in response to member requests for more focus on technical innovation and the practical side to new developments. Our regular Innovation In-depth section examine such innovations through the eyes of the breweries who are leading the way, and we start this new series with a fascinating deep dive into Gipsy Hill’s world-leading work on achieving carbon negative production, including using hops twice in its brewing process to help minimise its carbon footprint. Hear all about the technical side of this project from Gipsy Hill founder Sam McMeekin on pages 50-55.

Society of Independent Brewers PO Box 136, Ripon, North Yorkshire HG4 5WW Tel: 01765 640 441

www.siba.co.uk

Email: office@siba.co.uk

in this

And finally, for the first time in this issue, we feature an interview with one of our Homebrewer Members, Sam Thakker-Jones (see pages 42-47) who walked away with the top prize in this year’s SIBA Homebrew Awards and enjoyed a brew day at Quantock over the summer as part of his prize, which saw his winning beer made on an industrial scale for distribution to selected outlets across the UK. Find out more about this year’s competition on page 49.

Elsewhere, we bring you a report from this year’s Indie Beer Scotland event on pages 1213, feature Wilde Child Brewing Co in Leeds for our Business Profile on pages 34-39 and bring you the highlights of our SIBA Salary Report on pages 32-33.

Happy reading! And please do keep sending me your press releases, updates, news and views to caroline.nodder@siba.co.uk so that we can share your experiences, thoughts and successes in future magazines – the deadline for submissions for our Winter edition will be November 2nd

Caroline Nodder Editor SIBA Independent Brewer Magazine

Editor: Caroline Nodder (caroline.nodder@siba.co.uk)

Published by: Media Alive Limited

Produced on behalf of SIBA by: Media Alive Limited, 2nd Floor, The Red House, 119 Fore Street, Hertford, Hertfordshire SG14 1AX. T: 01992 505 810

Creative Director: Darren Kefford (darren@wearema.co.uk)

Studio Manager: Jon Hardy (jon@wearema.co.uk)

Advertising Manager: Claire Rooney (claire@wearema.co.uk)

Managing Director: Dan Rooney (dan@wearema.co.uk)

photocopying, recording or

is accurate and up-to-date, neither SIBA nor Media Alive Limited take any responsibility for errors or omissions.

those of their respective authors and not necessarily shared either by SIBA or Media Alive Limited.

3 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023 Editor’s comment

rights reserved. No part of this publication

be stored in

system

otherwise,

the prior

every effort is made to

information

expressed in editorial contributions to

publication

All

may

a retrieval

or transmitted in any form or be any other means, electronic or mechanical,

without

permission of SIBA and/or Media Alive Limited. Whilst

ensure that the

publication

Opinions

this

are

Printed by: Stephens & George Print Group Goat Mill Road, Dowlais, Merthyr Tydfil CF48 3TD

Welcome to the Autumn edition of SIBA’s Independent Brewer Magazine.

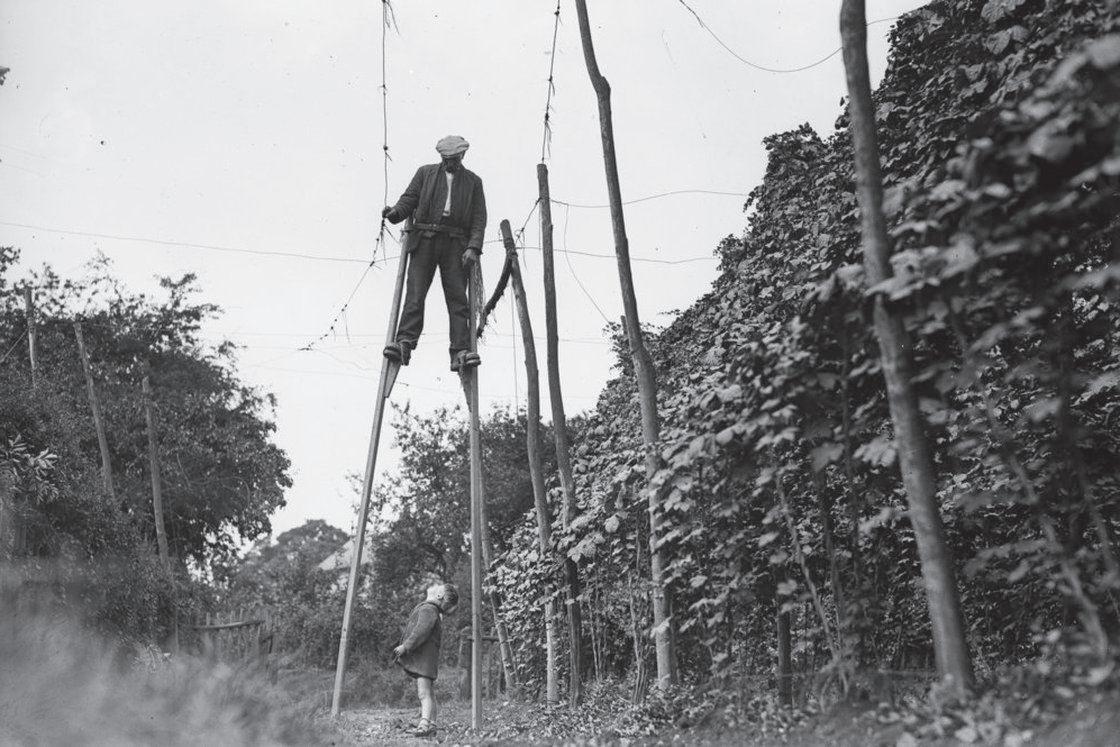

The best hops from the world’s best producers. sales@brewersselect.co.uk 01733 889100

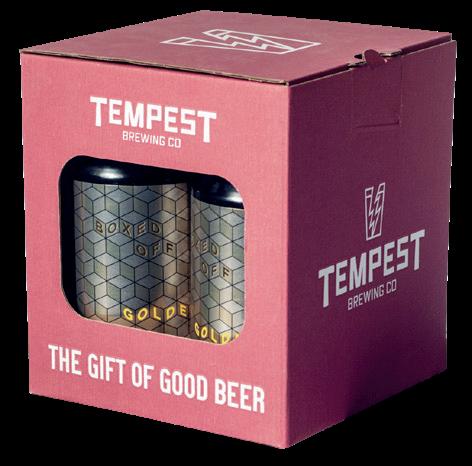

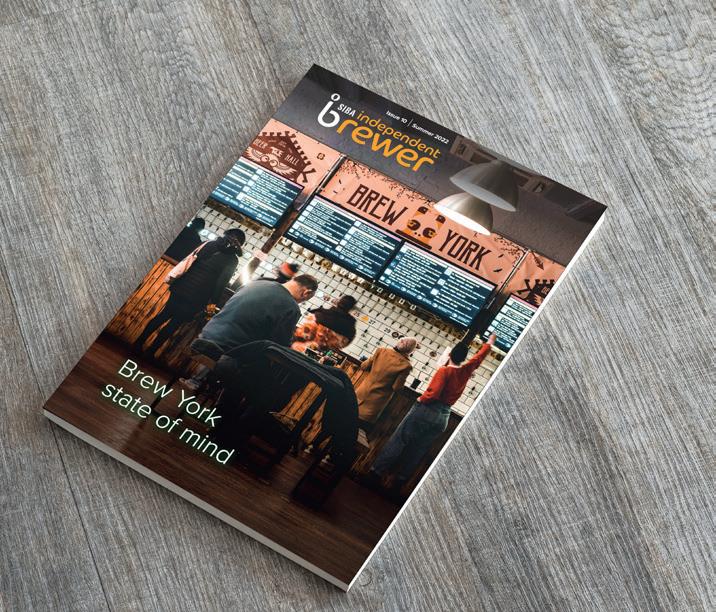

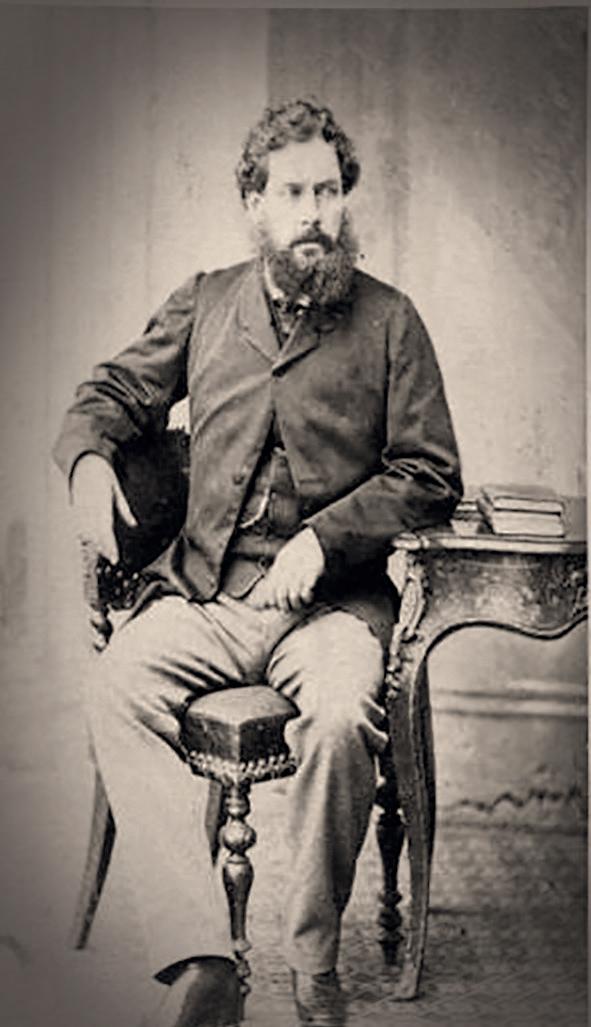

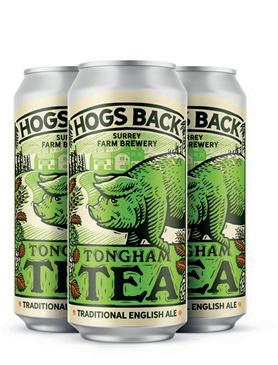

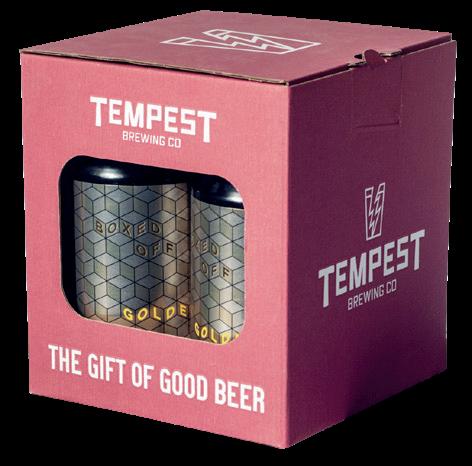

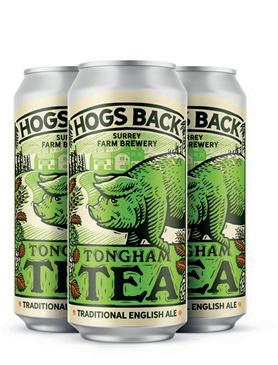

Cover

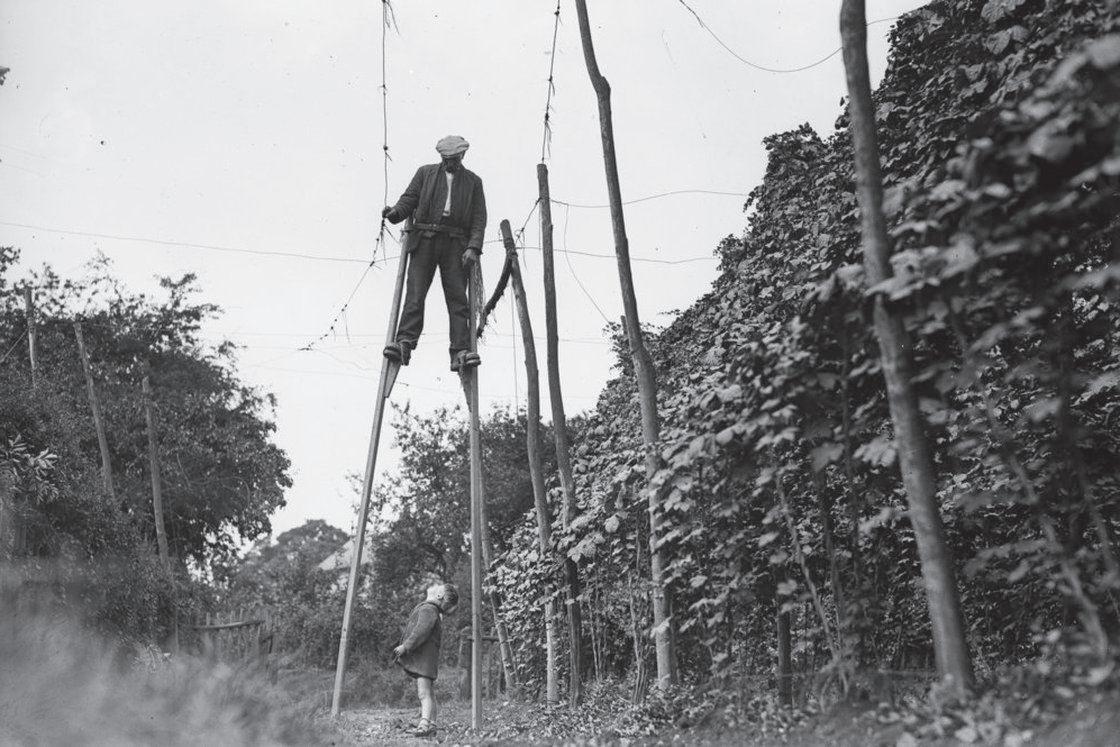

The cover image for our Autumn magazine showing RedWillow’s Toby and Caroline McKenzie was taken by Pellicle’s co-founder Matthew Curtis, the author of our very first SIBA Independent Brewer x Pellicle collab piece.

Comment

Features

5 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023 Contents

Read

9-15 SIBA News All the news from SIBA HQ 78-81 SIBA Regional Beer Competitions Results from the Midlands and Scotland 83-91 Brewery News The latest from our Brewing Members around the UK 94-103 Supplier News Updates from SIBA’s Supplier Associate Members

the full article on pages 22-25. News

CEO’s Update Andy Slee, SIBA’s Chief Executive, on sector confidence 8 Chairman’s Comment National Chair Richard Naisby speculates on the weather 16-17 The View From Westminster Our regular political update 28-29 Homebrew In Focus Andy Parker from Elusive Brewing looks at The Porter by Anspach & Hobday 69 Technical Focus Brewlab’s Dr Keith Thomas on caffeine 71 Supplier Viewpoint Tomasz Lenartowicz from Collective Motion Brewing on the strategy for net zero 73 Supplier Viewpoint Adam Drawwater from Moorgate Finance offers advice on energy saving 93 Supplier Viewpoint Steve Ellis from FPE Seals gives his views on how technology can support industry

7

18-19 Membership Update The new package of membership benefits and services for SIBA Members 22-25 SIBA Independent Brewer x Pellicle Our brand new collab feature series kicks off with RedWillow 27 Meet The SIBA Team New team members Emma and Pip tell us about their new roles 31 Taproom Focus Featuring the Amity Brew Co taproom in Leeds 32-33 SIBA Salary Report Exclusive analysis of current salary levels in craft brewing

Business Profile Wilde Child Brewing’s founder Keir McAllister-Wilde tells us about his Leeds-based operation

Meet The Homebrewer We catch up with SIBA’s first ever Homebrewer Award winner Sam ThakkerJones

Innovation In-Depth Our first regular innovation focus looks at Gipsy Hill’s world leading sustainability programme

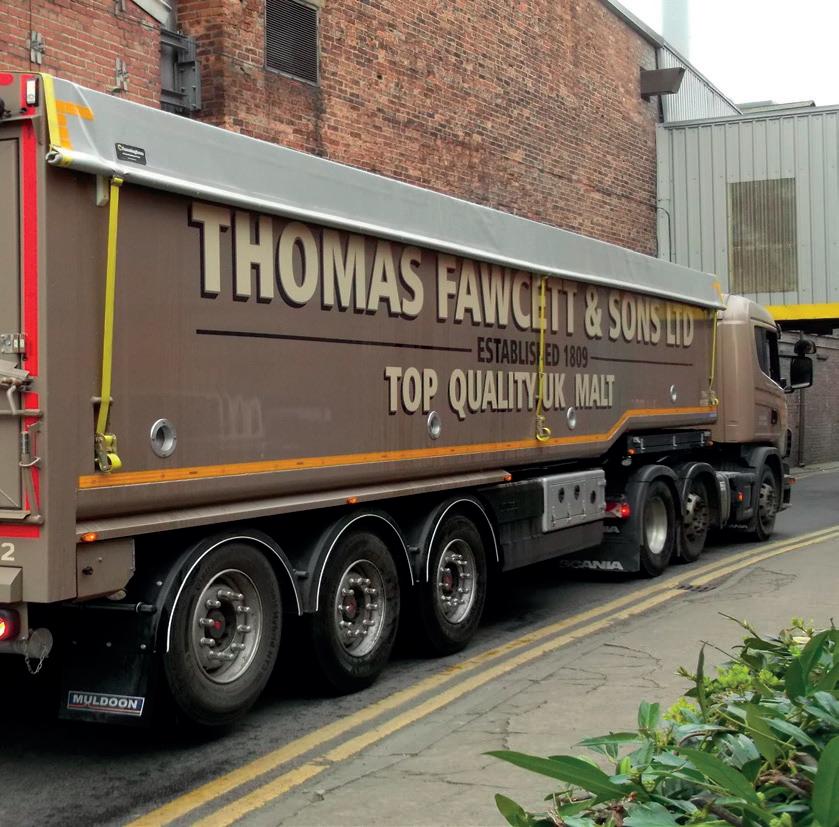

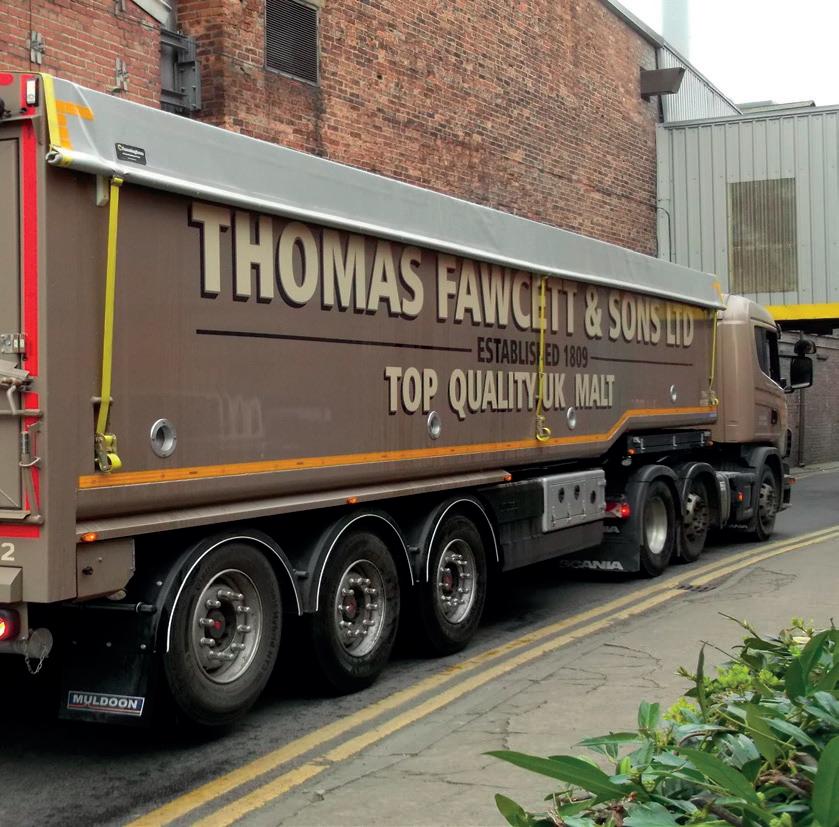

Trend Report The Brewers Association’s Lotte Peplow looks at matching beer with food cooked over wood 61-67 Business Advice Legal, intellectual property, brand & marketing and consumer insight 74-77 Gold Members Close Brothers and Thomas Fawcett and Sons 104 Gold & Silver Members Listing of our key sponsors 106 Contacts Key SIBA contacts Issue 15 Autumn 2023 See inside for more... SIBA Independent Brewer x 57-59 42-49

34-39

42-49

50-55

57-59

Confidence in the future

SIBA’s CEO Andy Slee looks at the issues that unify the SIBA membership, the reasons that independent brewers have to be cheerful, and how SIBA is planning to build confidence in the sector… Confidence is a critical element of success in all aspects of life. On the sports field, in academia and especially in business. And the confidence of staff, customers, consumers, and investors is vital for business success – not necessarily in that order!

Speaking to a senior member of Government recently, he opined that every time he speaks to the hospitality trade, we seem to talk ourselves down. “If you haven’t got confidence in yourselves, how can you expect anyone else to?” was the gist of his message, as part of a conversation on a lack of bank funding for the sector.

This got me thinking. What are the reasons for confidence in independent brewing and how can we project a more positive image of ourselves?

On my travels, brewers I speak to tell me that business over the summer has been ahead of expectations, though profitability remains a challenge. The same holds true for lots of businesses in Britain’s post-Brexit, postCovid era.

Central to the challenge at SIBA has been for independent brewers to enjoy the share of the market that their beers deserve.

SIBA recently asked 3,000 people what they thought of independent brewing. The response was very supportive. Comments like, ‘high quality’, ‘value for money’ and ‘made by real people’ stand out as reasons for consumer confidence in what we do.

I see clear evidence of this in the vibrancy and passion on show wherever I go but especially at the Indie Beer Scotland event in Glasgow earlier this month (see pages 12-13 for a full report on the event). A fantastic festival promoting vibrant, innovative beers in a market that has always been tough to access.

In talking to members across the land about what would help support their growth and success, the same themes emerge:

• Improved access to market

• Lower rates of taxation

• Better access to capital and labour

• Less red tape – starting with a unified DRS scheme for the UK

• Help to become more sustainable. And if we are agreed on what issues are important then finding unifying solutions becomes much easier.

The team at SIBA has been working on the development of a three-year plan over the summer which addresses these issues in a constructive, cost-effective way. This plan will hopefully gain Board approval next month and will be ready to share with you early next year at regional AGMs.

SIBA is the only organisation set up to fight on your behalf, so I take confidence in the

recent members poll in which you rated us 8/10 for the things that matter to you most. That suggests you have increasing confidence in us, albeit with room still for improvement.

The ultimate test of your confidence is that over 9/10 members said they would recommend SIBA to a friend. If you are speaking to one, please do so - because the more brewers we represent, the stronger our lobbying power and the more we can get done on your behalf.

This edition of Independent Brewer is full of articles and ideas for the future. I hope you enjoy reading it as much as the team has enjoyed putting it together.

Thanks for your ongoing support.

Chief Executive SIBA

7 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023

CEO's Update

Unreliable forecasts

There is something comfortingly British in writing about the weather. Our trade papers are full of headlines bemoaning the slow-down in sales caused by this year’s damp and unreliable summer.

After a scorching 2022, a return to a more normal pattern of weather was always likely, and so it has proved. Some foreign types are bemused by our national obsession with the weather, but it is its essential variability that makes it of interest. Climate change may be inevitable but the unreliable, changeable British weather will be with us for a long time yet. A cooler summer favours cask brewers, a true scorcher favours those who major in keg and can. All of us suffer when it rains. Forecasting comes in many forms and the Bank of England may be looking at the Met Office with some envy. While inflation may have peaked for now, it looks as though the high interest rate regime is here to stay. We are very long way from the BoE's November 2021 prediction of inflation declining from 5%. High interest rates work by subduing demand and discretionary spending – and beer certainly falls into the category – is hit hard. At the same time, any company with variable rate borrowing is facing costs not seen since Tony Blair was Prime Minister. A nasty double blow.

Rishi Sunak, the current Prime Minister, put in a surprise appearance at the trade session of the Great British Beer Festival. I cannot recall a sitting prime minister ever attending before, and the somewhat odd picture of a teetotal PM drawing a pint, itself drew plenty of comments. I suppose it is a measure of the importance of our industry and the monumental changes now

occurring, that the photo-shoot happened at all. As we go to press the full consequences of the changes in alcohol taxation haven't fully manifested themselves. For some the direction of travel is clear. We had already seen some significant ABV reductions from the global brewers. The latest notable brand to jump on the 3.4% bandwagon is Greene King IPA - and many regional brewers are rolling out their own low-gravity low-duty new releases. The shortfall in revenue to HM Treasury from these changes will be huge. SIBA will, of course, continue to fight for the independent breweries for whom a lot of the changes are a largely unneeded distraction. Anecdotal evidence points to some HMRC inconsistency and confusion –especially concerning when it applies to agreed covid-era repayment plans.

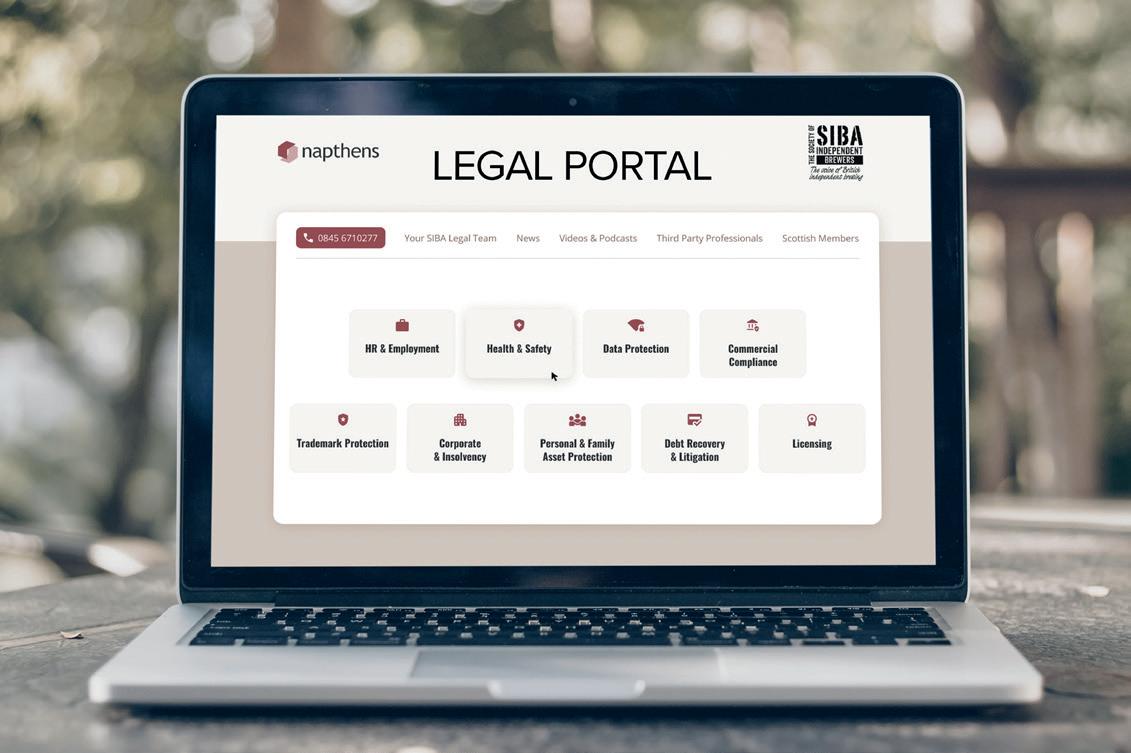

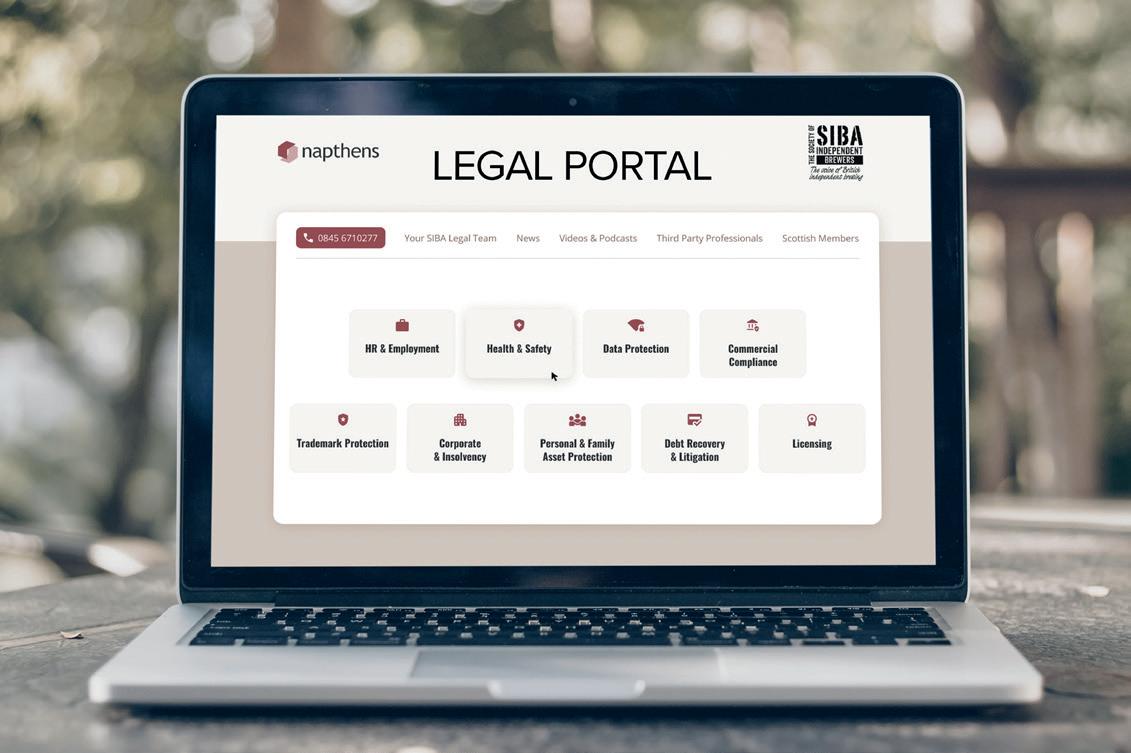

For those SIBA members who are suffering from the combined effects of the weather and duty changes; a reminder that there is help available within the Toolbox – whether it is practical things like labelling guides and compliance or links to professional help (such as the Napthens legal helpline, free for the first hour)– these SIBA benefits are real. We are constantly being advised that early action would mitigate a lot of the problems that can later get out of hand. The issues around the morality of pre-pack administrations are an issue for businesses of all stripes but are particularly felt in the highly-taxed, competitive world of brewing. This is a subject that I'm sure we will return to many times over the coming months. Global events will continue to have repercussions which will be felt in the UK brewing scene. The viability or otherwise of Ukraine grain deals; the uncertainty over the El

Nino phenomenon which could cause major crop disruptions around the world; geopolitical events in Europe and the Middle East - all could cause trouble in the months ahead.

SIBA continues to work for our members' interests whatever the political climate or the weather throws at us.

Richard Naisby Chairman SIBA

Richard Naisby Chairman SIBA

8 Autumn 2023 | SIBA Independent Brewer | www.siba.co.uk Chairman’s comment

SIBA UK Brewery Tracker: UK brewery number rises second quarter of

Despite a high number of reported brewery closures and tough trading conditions, the total number of breweries in the UK rose in the second quarter of 2023, according to the SIBA UK Brewery Tracker.

Covering the period from the start of April 2023 to the end of June 2023, the SIBA UK Brewery Tracker shows the net brewery number across the UK grew slightly (by two) over that three-month period.

Andy Slee, SIBA Chief Executive, said: “Seeing the net brewery number rise across the UK is not only a sign that confidence in the sector remains, but that the demand for quality locally made beer continues to rise. However, there has been a significant number of brewery closures and changes of ownership, with some consolidation and buyouts alongside new businesses opening. So whilst modest growth is ahead of expectations and common perception, it’s not quite the overly positive picture that the headline figures paint.”

The new opening figures highlight the consumer demand for craft beer and the growth in popularity of brewery taprooms, with recent consumer polling showing eight out of 10 people believe a well-run independent brewery has a positive effect on its local community*and that community-spirit is a sentiment shared by brewers, with 98% of SIBA brewers saying they consider their local community to be important to them.

2023

Andy Slee added: “We are still seeing more and more people discovering the importance of supporting their local businesses, and in particular their local brewery taproom, which in many areas are a hugely important community asset. All of this said, trading remains challenging with input cost inflation running ahead of prices and the other well documented issues facing the broader hospitality trade.”

The South East saw the largest +3 increase in brewery numbers, with the Midlands and the East of England also in growth with a +2 rise in both regions, and Wales had a modest +1 rise overall. The North West, West of England, and South West all ended Q2 with no net change in brewery numbers, whereas Scotland had the largest decrease with -3, followed by Northern Ireland on -2 and the North East on -1.

The SIBA UK Brewery Tracker is compiled by full-time professional staff employed by SIBA and is cross-referenced by SIBA Regional Directors in each of the eight SIBA Regions across the UK. The organisation considers a number of factors and data-sources alongside its own data analysis and extensive research, including, but not limited to, HMRC registrations.

*YouGov Consumer polling commissioned by SIBA for the SIBA Craft Beer Report 2023

The SIBA UK Brewery Tracker can be viewed via www.siba.co.uk/brewerytracker

SIBA UK BREWERY TRACKER Q2, 2023

Covering period 01/04/23 - 31/06/23

UK TOTAL: 1826 (+2)

Scotland: 142 (-3)

Northern Ireland: 27 (-2)

North East: 262 (-1)

North West: 209 (-)

East: 182 (+2)

Midlands: 286 (+2)

West of England: 71 (-)

Wales: 108 (+1)

South East: 334 (+3)

South West: 205 (-)

The above shows the new total number and net change compared to 31.3.23

The SIBA UK Brewery Tracker can be found at www.siba.co.uk/brewerytracker

Save the date: BeerX is returning to Liverpool for 2024!

BeerX UK 2024 will take place in Liverpool on March 13th and 14th 2024. Planning starts early and we are already looking to provide a wider range of seminars and events on such topics as brewery fund raising and succession planning. Bob Pease from the American Brewers Association will be our keynote speaker. Watch this space for more details as they are confirmed!

Brewing in Brief distribution list

We are getting increasing numbers of brewers reading our Brewing in Brief email update each week. This is a reminder that as part of your SIBA membership we can send it to as many of your team as you would find useful. If there is anyone you would like adding onto the Brewing in Brief distribution list, simply advise membership@siba.co.uk and they will make sure that happens.

9 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023 SIBA news

Greater sales via SIBA Beerflex

Beerflex gives SIBA members access to outlets that would otherwise be closed to supply by independent brewers.

This year, SIBA Beerflex is trading over 10% up on last year, with the price paid for each firkin well ahead of that. This growth has been helped by the newly developed Order Portal, from which publicans place their orders.

To ensure your brands are marketed to their full potential we recommend your brands are regularly updated via Beer Manager, this may be specials/seasonals or new beers.

Please contact SIBA HQ office@siba.co.uk should you have any questions.

SIBA appoints Pip Young as Events & Marketing Officer

Navigation Brewery and Attic Brew Co. named best in the Midlands at SIBA Independent Beer Awards 2023

Navigation Brewery in Nottingham and Attic Brew Co. in Birmingham have taken the overall Gold awards in SIBA’s Midlands Independent Beer Awards in Cask and Keg beer – making them officially the two best beers in the Midlands for 2023.

The awards are run by SIBA and are hosted by the Rail Ale Festival at the Roundhouse, near Chesterfield. The competition saw a huge range of beer styles judged across cask and keg format, from traditional Bitters, Stouts and Porters, to New England IPAs, Lagers, Speciality and Sour beers.

It was Navigation's deliciously fruity Golden Ale 'Rebel' that wowed judges in the cask competition with tropical fruit and citrus flavours and a clean bitterness in the balanced finish. Craig Nightingale, research and development brewer at Navigation, was on hand to collect the Overall Champion Cask Beer award on behalf of their three-person team. He said: "I'm over the moon to win, I love this beer, it is one of my favourite beers, and it’s the one I drink in the pubs at night. So it's great to see it win as it's the first time it has been in the running for awards as well. The beer is based around citra hops and it's just super sessionable, super easy drinking, really crisp and really flavourful."

The other big award was the Overall Champion Keg Beer, which went to Attic Brew Co.'s 'Signals' IPA, which impressed with big citrus and strone fruit flavours of grapefruit, apricot and blackcurrant.

Attic Brew Co.'s Business Development Executive John Nowacki accepted the prestigious award, saying: "It's amazing to win the award, we think we're brewing some really good beers but it's nice to have that backup to know that we're on the right track. We brew really hop-forward but really drinkable beers, with loads of body and not too much bitterness so you can enjoy a few different beers."

SIBA Chief Executive Andy Slee was on hand to dish out the top awards in the Midlands, he commented on the quality of the entries: “Huge congratulations to all of this year's winners and in particular our Overall Champions who not only won their style categories but went on to be named the best of the best in what was an extremely hard fought final round judging. The quality of beers in the competition was superb and I want to say a huge thank you to the Rail Ale festival for being such fantastic hosts and for ensuring all of the beer was served in such superb condition."

For the full list of winners from the Midlands competition see pages 78-79.

SIBA has appointed Pip Young as its new Events & Marketing Officer, joining the organisation’s Marketing and Events Team in promoting independent craft beer across the UK. Pip joins SIBA from SALT/Ossett brewery and brings with her a wealth of events experience, not least in her work founding and growing The Coven, a project from 30SIXCo, aiming to increase diversity and inclusivity within the beer industry. Most notable is their work creating the role of the Wellness Officer; Good Vibe Guardians for beer festivals– ensuring all attendees and participants are safe, considered and welcomed.

The newly-created Events & Marketing Officer role centres on delivering and further improving SIBA’s Independent Beer Awards and Regional Meetings, as well as events sponsorships and partnerships across the UK promoting independent craft brewers.

Neil Walker, SIBA Head of Comms & Marketing, said: “I’m delighted to be welcoming Pip into the marketing team here at SIBA and look forward to seeing the positive influence she can bring to SIBA events and beer competitions. Her huge amount of experience in the beer industry, particularly in her work at The Coven, makes her perfectly placed to help us deliver even better events across the whole of the UK.”

Pip Young said: “I am extremely proud to be joining such an esteemed organisation within the beer industry and I am excited to keep the success and momentum going at SIBA. No doubt building on my work with 30SIXCo and The Coven. Now with SIBA, playing my part in creating a more just, safe and successful beer industry.’’ Find out more about Pip in our Meet the SIBA Team section on page 27.

11 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023 SIBA news

Indie Beer Scotland 2023

Scotland’s biggest craft beer festival, SIBA’s Indie Beer Scotland, moved to Glasgow in September this year with double number of beers.

After a hugely successful launch in Edinburgh in 2022, Indie Beer Scotland returned in 2023 at the brand-new event space ‘Clyde Rooms at Edmiston House’ in Glasgow, running from Friday the 8th until Saturday 9th September.

The event was sponsored by Kegstar, and with double the number of beers on offer compared to 2022, it is now the country’s largest craft beer festival, featuring over 200 different cask and craft keg beers from some of Scotland’s best independent craft breweries, plus cider and spirits from independent Scottish producers.

Indie Beer Scotland is organised by Scottish brewers from SIBA, with festival organiser Fiona MacEachern, from Loch Lomond Brewery, saying the new venue has really taken the event to the next level. She said: “We’re really excited to be working with Edmiston House to present Scotland’s only National beer festival, featuring exclusively Scottish independent craft breweries, cider producers, and artisan spirits, again from independent producers only. The Clyde Rooms at Edmiston House is a superb modern event space with ground floor access, just a short walk

from the tube and with great connections and transport links.”

Indie Beer Scotland also aims to offer great value for money, with a huge number of session beers including cask and craft keg frozen at last year’s prices, available from just £4 a pint. “Beer should be enjoyed by everybody, which is why we work really hard to ensure we offer great value for money as well as the best possible range of beers in huge variety of styles and strengths – from hoppy IPAs and Pale Ales, to craft lagers, pilsners and stouts. No matter what styles of beer you enjoy we have got something for everyone, and all cask and keg beers up to 4.5% are available for just £4 a pint or £2 a half,” Fiona added.

Indie Beer Scotland is also the home of the SIBA Scotland Independent Beer Awards 2023, with judging taking place to name Scotland’s very best beers prior to the festival opening to the public – making festival-goers the first to try Scotland’s official best beers, with all this year’s winning beers available over the three sessions Friday to Saturday. Beers ranged from session strength lagers and pale ales of 4%, to barrelaged imperial stouts and scotch ales which tip the scales at a punchy 10% ABV or more.

12 Autumn 2023 | SIBA Independent Brewer | www.siba.co.uk SIBA news

Massive congratulations to all of the winners from Indie Beer Scotland. The quality was superb across the board.

Andy Slee SIBA’s Chief Executive

Broughton Brewery’s ‘Old Jock’ Scotch Ale and Swannay Brewery’s Orkney Porter named Scotland’s best independent craft beers

Broughton Brewery’s ‘Old Jock’ Scotch Ale was named Scotland’s best cask beer at the SIBA Scotland Independent Beer Awards 2023, which took place at Indie Beer Scotland, with Swannay Brewery’s Orkney Porter being named Scotland’s best in keg.

Broughton Brewery’s Old Jock Scotch Ale impressed judges with big roasted malt flavours and a balanced sweetness.

Broughton Brewery’s Christie Slater had this to say when accepting the award: “It’s absolutely fantastic to be here and win the overall cask beer award for Scotland. Old Jock’s been around for a while, it’s a completely unpretentious beer, a true Scottish ale with not too many hops and a lot of big malt flavours – but at 6.7% it does pack a real punch.” Christie Slater, Borughton Brewery.”

The SIBA Scotland Independent Beer Awards are blind-tasted by expert beer judges, beer sommeliers, and master brewers from elsewhere in the UK, with the winners of each beer-style category going through to a final judging table where the overall Champion Gold, Silver and Bronze are selected. Swannay Brewery’s 9% Orkney Porter took competition’s other big award, being named Overall Champion in the SIBA Scotland Keg Beer Awards, wowing judges with berry-fruit and big smokey malt flavours.

SIBA’s Chief Executive Andy Slee said: “Massive congratulations to all of the winners from Indie Beer Scotland. The quality was superb across the board so to take away an award from such tough competition is something to be truly proud of. This is especially true of our Overall Champions, Broughton and Swannay Brewery, who not only won their categories but then went on to be named our Overall champions – the very best of the best in Scotland for 2023.”

Find the full list of winners from the Scottish competition on pages 80-81.

13 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023 SIBA news

Go West WARMINSTER MALTINGS LTD Traditional Maltsters robin.appel@warminster-malt.co.uk Tel: 01985 212014 ...For Better Barley, For Better Malt

SIBA Homebrew Competition Winner’s beer goes national

The competition was open to Homebrew Members of SIBA. Neil Walker, Head of Comms at SIBA, joined the brew day and had this to say on Sam’s award-winning beer: “The quality of beer being brewed by the best homebrewers in the UK really is astonishing and we were blown away by Sam’s beer when it was judged. The brief was to best showcase Yakima Chief’s new experimental hop and his deliciously hoppy, hazy pale ale did exactly that. Huge congratulations to Sam and I look forward to trying his beer in a pub near me very soon!”

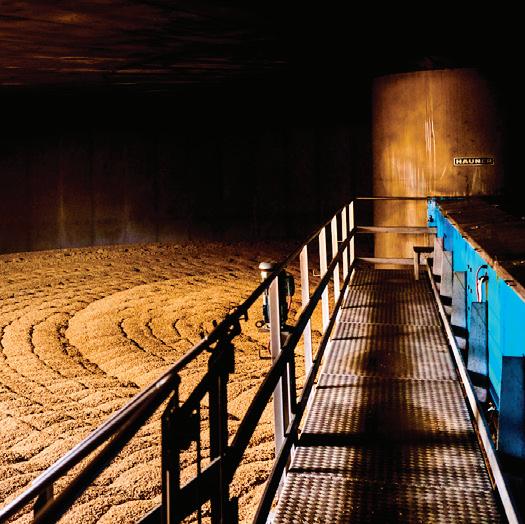

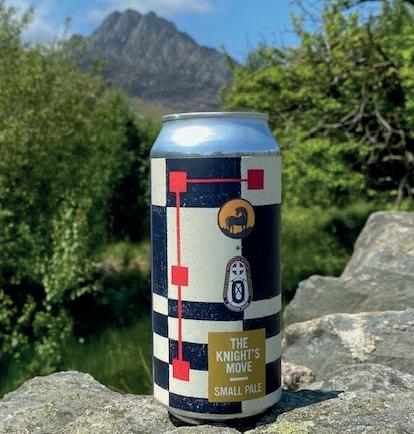

The hazy pale ale “Push the Button” was named as a tongue-in-cheek jibe at the differences between homebrewing and commercial brewing, where the much larger scale means some elements have to be automated. The brew makes use of an experimental new American hop ‘HBC 586’, making the finished beer “hugely aromatic and hoppy with aromas and flavours of tropical and stone fruit, backed up with citrus notes and a soft mouthfeel”.

Robbie Harrigan, from Yakima Chief Hops, also joined the brew day: “It’s been brilliant to be involved, growing our engagement with the homebrewing community, who we feel are one of the most passionate brewing communities across the globe. Many of our commercial customers around the World started out as homebrewers, so to keep engaging with these guys, and doing projects such as this one is extremely valuable and really good fun! HBC 586 is one of the latest and most exciting trial varieties from the Hop Breeding Company and is a firm favourite of everyone at Yakima Chief Hops. We were honoured to work with SIBA and Quantock to bring this trial variety to a wider market."

The UK’s best homebrew beer hit bars across the UK following the SIBA competition, with a prize to brew it on a commercial scale.

Originally brewed by champion homebrewer Sam Thakker-Jones for the SIBA Homebrew Beer Awards, the recipe was upscaled for commercial production at Quantock Brewery in Somerset and had a Limited National release.

Sam joined the team at Quantock, along with awards organisers SIBA and Yakima Chief Hops, to brew his beer on a commercial scale.

Sam said of the experience: “It’s been amazing brewing here at Quantock, really in-depth, really friendly, getting closely involved in every part of the process - from milling the grain this morning, to mashing in, adding hops, right through to the end of the brew day. I’ve loved every second of it.”

Statement from SIBA responding to the delay of the Scottish Deposit Return Scheme (DRS) until 2025

SIBA’s Jamie Delap said: “Small independent breweries have been clear from the start that the gold standard for the Deposit Return Scheme is for it to have the same scope and be introduced at the same time across the whole of the UK. Doing so will ensure it works more effectively, reduce its costs, and avoids impact on consumer choice.

“The announcement from the Scottish Government today that the scheme will be delayed until October 2025 and they intend to remove glass moves us towards achieving this goal of a joined up scheme across the UK, but there are still questions about differences in Wales and it’s inter-operability. We have seen how positive engagement with Industry in recent months can improve the scheme and make it more workable and it is important for all governments to work together and with industry to achieve the best scheme for the whole of the UK.”

As well as being available in Quantock’s taproom and specially selected venues across the UK, including Sam’s home town of Bath, a limited amount of the beer also went into cans and was available via the Quantock webshop.

Quantock Brewer Daniel Enticott was on hand to ensure a smooth brew day: “The recipe itself is really interesting as it’s pretty much the same process as we use here for our hoppy pale ales, so transitioning the recipe from a homebrew batch up to a commercial kit has actually been pretty easy. We’re going to be selling the kegs through wholesalers nationally so there’s no limit as to where it might end up, and will also be putting the beer into can as well so it will available on our website and of course in the taproom too.”

Find out more about Sam and his winning beer in our Meet the Homebrewer feature on pages 42-49.

Launch of SIBA Exclusive Member Services

June saw the launch of the new Exclusive Services package available to SIBA Members.

In addition to current Benefits, Brewing Members in particular can now access a range of exclusive services and offers from SIBA Gold, Silver & Supplier Associate Members.

Members can view the services and offers in the Toolbox portal in the new Member Services section.

If you have any questions or are supplier looking to launch an exclusive service for members please contact membership@siba.co.uk

15 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023 SIBA news

The view from Westminster

I hope that everyone managed to get their heads around the new alcohol duty changes that went live on 1 August. From my discussions with breweries of all different sizes, calculating hectolitres of pure alcohol (HLPA), determining when production takes place and the new takeaway beer rules were the most problematic areas. If you’re still confused don’t forget that SIBA has produced a guide and calculator as well as recorded several webinars which are all available on the Toolbox to help you. I’m also always available to answer any questions on this topic where I can.

One particular issue that reared its head at the last moment was the transition from Small Breweries’ Relief (SBR) to Small Producer Relief (SPR) and this raised a wider issue of how small breweries have been interpretating SBR rules for more than 20 years. Luckily SIBA managed to work with HMRC to get this changed before the new system came online.

In HMRC’s view breweries should be paying the relief rate for when the beer was produced rather than when it passes the duty point. Therefore it believed that, for the transition from SBR to SPR, the old SBR rate should apply for everything that was produced before 1 August even if it was in duty suspense and released on or after 1 August. Such a move would have meant operating a messy and confusing dual system, with breweries having to maintain two sets of records and completing two sets of figures on the EX46 form. It’s also not the system that small breweries have been using for the last two decades. Again in HMRC’s view, when moving to a new small brewery year in January under SBR the previous relief rate should be paid for everything produced in December or earlier. I haven’t spoken to any brewery that has been doing this under SBR or expected the new system to work in this way and certainly the old EX46 was not designed to work in this way. It wasn’t only breweries that were also impacted by this – cidermakers that only make an autumnal product suddenly found that the

16 Autumn 2023 | SIBA Independent Brewer | www.siba.co.uk The view from Westminster

One particular issue that reared its head at the last moment was the transition from Small Breweries’ Relief (SBR) to Small Producer Relief (SPR) and this raised a wider issue of how small breweries have been interpretating SBR rules for more than 20 years

new SPR didn’t apply to anything they had produced in the previous year.

SIBA convinced the Exchequer Secretary to introduce emergency legislation to ensure that on the 1 August the new rate applied to anything that was produced. This didn’t prevent anyone with beer in duty suspense from constructively removing it to duty paid which could have helped those with stronger beers above 8.5% ABV.

However, this is not yet a permanent fix. The Minister has not yet applied this change to the transition to the next SPR year. Breweries will have to recalculate their beer duty on 1 February every year in HLPA when the new small producer year starts. Under the new rules, as they are currently written, small breweries will have to use the relief rate for when it was produced. So if you produced some beer in January and it was still in duty suspense in February it would pay the January rate rather than the new February rate. SIBA is working with HMRC to try and get this changed to what small breweries are used to and expect so that it’s the rate when

it crosses the duty point and not when its produced.

We also continue to have discussions with the Government on the takeaway beer issue which impacts many of your customers. Under the new system any pub wishing to do takeaway beer, such as in growlers or crowlers, must purchase from a brewery a cask or keg that has not had the draught relief applied to it. I.e. one where you have charged your higher small pack duty rate rather than the lower draught rate. The liability for this rests with publicans with breweries required to indicate on their invoice or delivery note that the container has not benefitted from the draught relief. Only those with a brewing licence or a warehouse licence can decant from a draught relief container to a smaller vessel and then pay the duty difference to HMRC. This means that breweries can still do takeaway beer from their taprooms from draught relief containers but pubs cannot. I’ve spoken to a number of bottle shops and pubs that have taken the decision to stop selling takeaway

beer because they have struggled to buy nondraught relief containers from wholesalers or breweries.

Although discussions continue, unfortunately there are few solutions that HMRC will accept. It does not want the draught relief to apply to beer that is sold from pubs for consumption at home and is fearful that supermarkets will start to sell growlers and crowlers to benefit from the lower duty rate. Finally – don’t forget that a great way to speak to your MP is by having your beer served in Parliament. Having your cask ale chosen as a guest beer in the Strangers’ Bar is a great opportunity to come down to Parliament, have some photos taken to send to the local press and lobby your local MP for changes. Please contact me if you’re interested in this.

Barry Watts is Head of Public Affairs and Policy at SIBA. He covers political relations and policy for SIBA members. He can be contacted at barry.watts@ siba.co.uk or 07977837804.

17 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023 The view from Westminster

Is your Brewery missing out?

Offering a range of Membership benefits from as little as £150 per year, SIBA, the Voice of British Independent Brewing is the one stop shop for Independent Craft Breweries. SIBA are committed to ensuring that our Members’ are equipped with the Tools, Legislative advice, access to market and insight data required to run a successful Brewing business. Look out for the * to see what you could be saving by joining SIBA.

See how SIBA Membership can help your Brewing business

SALES

Various opportunities for increasing sales within the on and off trade accounts through direct delivery, resources or exclusivity at prestigious events

PROMOTION Exclusive access to promote your beers at prestigious events such as the British Guild of Beer Writers Awards, BeerX and much more. Access to the BGBW event would cost a single brewery *£4k, with other events costing much more.

INDEPENDENCE CAMPAIGN Standing out from ‘big beer’ by increasing visibility on bottled products with Independent Crown Caps and independence badges for beer labels – assuring consumers that they are buying from an Independent Craft Brewer.

BEERFLEX An option for all SIBA members to develop on trade sales by supplying to large pub operators at a price band of your choice and with favourable payment terms. The average Beerflex Member generating *£15k turnover.

INTEL

Raising the bar for your brewery and beer by obtaining invaluable industry information and data

INDEPENDENT BREWER MAGAZINE Featuring Industry News, guest articles, meet the brewer profiles and much more. Independent Brewer is your portal to the wider world of independent brewing, delivered to your business quarterly.

CRAFT BEER REPORT Data insight and analysis on brewing businesses and the industry from qualified contributors and academics, providing invaluable data for your business planning.

BREWING IN BRIEF Weekly email newsletter, containing member news, Industry news and upcoming events. A snap shot of the week in brewing.

LOBBYING Securing Support & Advice via Political representation with a user friendly synopsis of Government Legislation available to members.

GOVERNANCE Eligibility to take a seat at the table of SIBA Board Directors, helping set the strategic direction of the trade association.

REGIONAL MEETINGS Access to quarterly meetings, with presentations from industry experts and members of the SIBA Management Team, with complimentary food and beer for you and your fellow brewers.

18 Autumn 2023 | SIBA Independent Brewer | www.siba.co.uk Membership Update

CoveringEngland,Scotland,Wales &NorthernIreland

SIBA LEGAL HELPLINE: 0845 671 0277

BUSINESS

From Legal issues, to user friendly calculators and Tools, SIBA has its members covered in all areas with the Business Benefits, potentially saving each member a substantial amount of time and money.

LEGAL ADVICE Members can contact the dedicated SIBA Legal Helpline, facilitated by Napthen’s Solicitors for 1 hour FREE advice. With legal specialists not only covering England but Scotland, Wales and Northern Ireland ensuring no eligible SIBA member goes without. There is no limit on the number of times members can contact the helpline. Potential saving of *£200 per call

*

Unlocking access to exclusive SIBA Member Benefits, resources and everything SIBA, via the SIBA Members Toolbox, whether it be entering Awards to accessing the legal portal, potentially saving each member in excess of *£5000

LEGAL PORTAL Taking away from our members the stress and pressures of being kept up to date on Legislations. The SIBA Legal Portal, in collaboration with Napthens Solicitors contains every day legal documents tailored to Brewing Businesses. *New to 2023

INDUSTRY SUPPLIERS From Brewery Equipment, to Ingredients, to Business Saving experts and Promotional items. Members can find a SIBA Supplier Associate Member for every business need from the SIBA Trade Directory.

BEERX Owners of the UK’s largest Independent Brewing Trade Show, Members can access SIBA’s flagship event FREE. A forever expanding Trade Show showcasing the best beer industry suppliers and packed seminar schedules, from workshop to informative seminars led by key industry personal – saving of *£65, based on 2x Delegate Passes

HR & EMPLOYMENT Covering all areas within HR & Employment, SIBA Members have access to an array of Templates to customise to their own business branding. Estimate value exceeding *£3000

DEBT RECOVERY & DISPUTES Debt recovery & insolvency are hot topics at the moment and members can access free of charge template letters to customise and issue. Saving on average *£500

COMPLIANCE Assisting members with legal compliance, a number of Tools are available for Members to customise to their own business needs. From HACCP and traceability tools to a H&S guide and practical guide to labelling your draught and packaged products, with a value in the region of *£3000

ALCOHOL DUTY In addition to ensuring Independent Brewers voices are being heard in Government, SIBAs Political team supply members with user friendly guides and simplified Duty calculators.

COSTING TOOL A Tool aimed at smaller brewers whom perhaps are unable to justify the expense of accounts personnel. Members can access at any time the Brewery Costing Tool to ensure that your sell price is calculated to run a sustainable business.

AWARDS With Beer Competitions for Cask, Keg and packaged judged by beer sommeliers and Business Awards judged by Industry Leaders, Members have unlimited entries into SIBA Competitions with winners having the opportunity to exclusive events promotion events and opportunities to facilitate with buyers and retailers across the UK *£450 (based on three entries into similar awards)

FREE ADVERTISING Forget Facebook Market Place –SIBA Classified Ads is the place to advertise everything and anything Brewery related. From job vacancies, to equipment for sale or a Wanted section, all as are free to place by members, with non members charged a fee of *£75

JOINT PURCHASE SCHEMES From glassware to beer mats, to bar runners – SIBA are able to offer its members promotional items at competitive rates.

CASK REPATRIATION INC ORANGE LABELS

Protecting your assets with cost effective semi-permanent labels to affix to containers – keeping track of your containers across the country!

19 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023

ACCESS NEW TO2023

SIBA Independent Brewer x Pellicle Collab

XThe spirit of collaboration is a hugely positive part of the independent brewing sector, with brewers regularly collaborating with their peers on new beers, and indeed ideas. Collaboration makes both parties stronger, through the exchange of knowledge and ideas, or by opening up new routes to market. It’s in this spirit, that SIBA Independent Brewer is launching a new regular feature series in collaboration with the team at Pellicle, a title we have huge admiration for. Over the next 12 months each issue of Independent Brewer will feature a brand-new piece written by one of the regular Pellicle contributors on a brewery that is doing great things, but maybe hasn’t had the coverage that some of its peers are getting. A hidden gem waiting to be discovered by a wider audience. As ever, the Pellicle team will be writing in their own very personal and informed style and we are excited to welcome these new voices to the SIBA magazine.

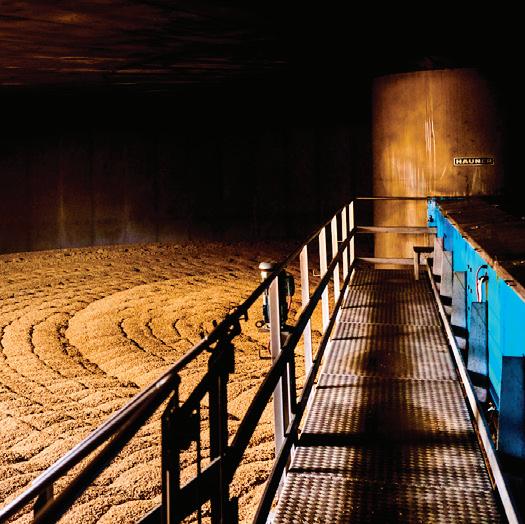

RedWillow Brewery Macclesfield, Cheshire

To kick off our new collab, Pellicle’s co-founder and editor-in-chief Matthew Curtis speaks to Toby and Caroline McKenzie from a brewery close to his heart, and indeed his home, Macclesfield’s RedWillow…

“There was a level - I want to say selfconfidence, but ego is probably the right word - of ‘how hard can it be?’,” Toby McKenzie tells me. “Turns out it's a lot more difficult than you think it is.”

In 2012, Toby had it pretty much made. He was working in bioinformatics, and latterly as a director of professional services for a large IT

firm. The money was good - so good in fact that his wife Caroline could leave her position as a research scientist at pharmaceutical firm AstraZeneca and focus on raising their two children. But it also required regular commutes from his home in the northwestern market town of Macclesfield, Cheshire, to London. Those two hour rail journeys between work and home gave him plenty of time to think, much of which was largely dedicated to his two main passions: food and drink. Toby had aspirations to cook professionally, but he also confides that, deep down, he knew he would never end up as a chef. What he did find, however, were parallels between his love of cooking, and his other hobby, homebrewing.

Matthew Curtis is a freelance writer and photographer based in Manchester, England. He specialises in writing about beer, pubs and the culture that stems from them, and in 2019, he founded online magazine and podcast Pellicle with his friend Jonathan Hamilton, for which he is editor-in-chief. His latest book, Manchester's Best Beer, Pubs and Bars (CAMRA Books), is due to be released in October 2023. www.pelliclemag.com

22 Autumn 2023 | SIBA Independent Brewer | www.siba.co.uk

“I ran money projects, I had big teams, and it’s still very difficult to pinpoint one thing where I can say that was 100% me, or even 80% me,” he says. “Brewing was something I felt I could do and I could have fun doing it. I wanted that completeness of being able to say: ‘I can do something, and this is me, this is what I’ve done.’”

When their daughter was born, Toby and Caroline decided on Willow as a middle name, after one of their favourite characters from popular 90s TV show Buffy the Vampire Slayer. A couple of years later when their family was completed by the birth of their son, they asked their infant daughter what their newborn's middle name should be. ‘Red’ was her decision, and shortly afterwards ‘RedWillow’ became the name of Toby’s blog, which he used to keep a record of his homebrewing activities, “mainly for my own interest and records,” he tells me. By 2012, Toby’s hobby was beginning to get out of hand. In September the same year, the project had expanded from a leisurely pastime into a full-blown professional pursuit. They acquired a small warehouse site a 10 minute walk from Macclesfield town centre, a 10 hectolitre brewing kit, and by the time Christmas came around they had begun selling casks into the trade.

“I was still working part time while also brewing three days a week,” Toby says. “I think

The incredible breadth of styles Redwillow now brew includes a wide range of lagers, which were initially born out of necessity in 2013 when the brewery opened its first bar in Macclesfield town centre.

my old company thought I would do it for a year, maybe 18 months, and viewed it as a sabbatical/midlife crisis. If I’m honest, I don’t think any of them expected me to carry on in that direction.”

In early 2013, signs of the craft beer revolution that had spent the past decade or so taking the United States by storm were beginning to wash ashore in the UK. Inspired by the vibrantly flavourful and powerfully hopped beers emerging from North America, new breweries such as London’s The Kernel, and (the now sadly defunct) Summer Wine in Holmfirth, Yorkshire, were opening with increasing regularity. Toby cites beers such as Racer 5 from California’s Bear Republic and 90 Minute IPA from Delaware’s Dogfish Head as direct influences on his own brewing style; strong, powerfully hopped ales, the latter leaning as heavily on the sweetness of crystal malt as it does the potency of modern US hop varieties.

Despite these influences, RedWillow was initially a cask only brewery, and one located in a part of the country that was deeply wedded to pale and hoppy real ales. Locals were no stranger to the citrus-accented flavour of North American hops thanks to existing breweries such as Pictish in Rochdale, and already popular US-hopped beers such as Yankee from Yorkshire’s Rooster’s Brewery.

Toby, sensibly, decided to lean into this, and RedWillow’s first commercially released beer was a 4.2% cask golden ale called Directionless. Perhaps named as a nod towards the fact he had left the security of a well paid job, deciding instead to lean head first into what he repeatedly refers to as a “mid-life crisis”.

“[It] had more crystal in it than you would put in that style of beer at the moment,” he says. “The strongest beer we made at the time was Ageless, a 7.2% IPA which was a little bit out there for the UK market when we started making it.”

“It was! We weren’t selling the casks of it,” Caroline interjects.

Continued on page 25

23 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023 SIBA Independent Brewer x Pellicle Collab

Issue 15 Autumn 2023 See inside for more...

Cover story

SIBA Independent Brewer x

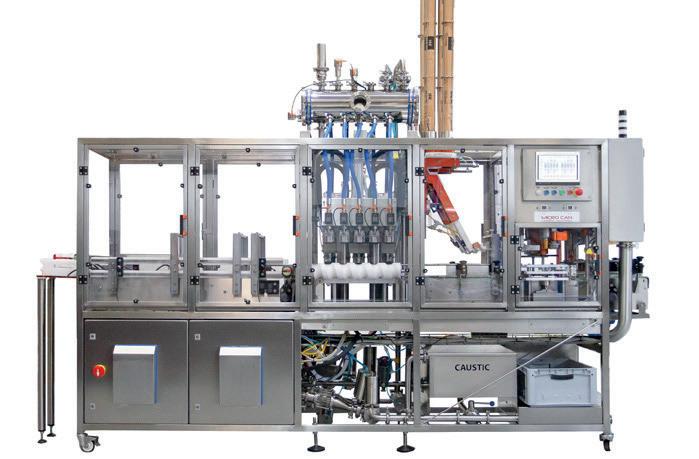

Rizzolio’s automatic and economic Compactblock filler and capper added to our bottling range.

The Rizzolio Range - For carbonated & still drinks

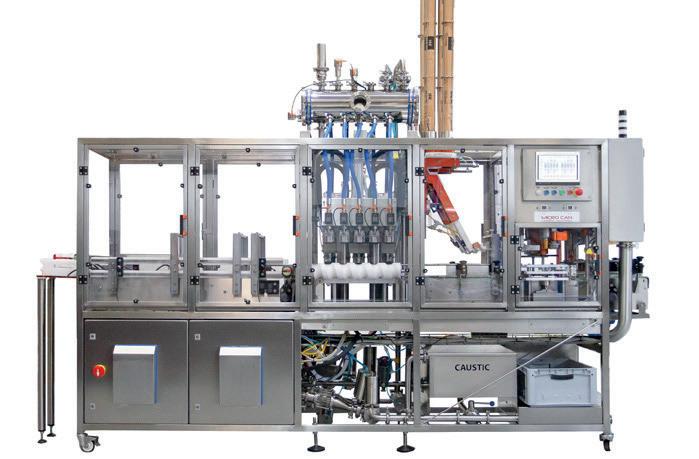

Having sold Rizzolio’s semi-automatic counter pressure fillers to brewers and cidermakers for over 4 years, we’re pleased to now offer Rizzolio’s Automatic Compactblock Counter Pressure Filler and Capper. With an output of 700 to 900 bottles per hour, you can fill and cap carbonated and non-carbonated products, including beer, hop water, kombucha, and soft drinks. The Compactblock is a great stepping stone between Rizzolio’s semi-auto fillers and CIMEC bottling lines. Options are available for single/double pre-evacuation of oxygen for low DO pickup values. As with all the lines we supply, these machines are installed, commissioned and supported by our team of engineers.

energy efficient chillers

With energy saving features to help reduce power consumption & operational costs.

Quantor chillers include features to save energy and reduce CO2 footprints by means of higher efficiency and optional heat-recovery features (reversible via heat-pump for producing hot water). Our engineers install complete systems with bespoke ringmains for controlling product and/or air temperature.

Call

ongoing support

6 ways we support you and your Vigo equipment before, during & after sale

We wouldn’t be here today, 39 years on, without the level of support we offer our customers. Our Engineering Team of 9 install, make technical adaptations, service, repair, manufacture and UKCA mark where necessary. Read the Case Studies online for what our customers say about the support and backup we give.

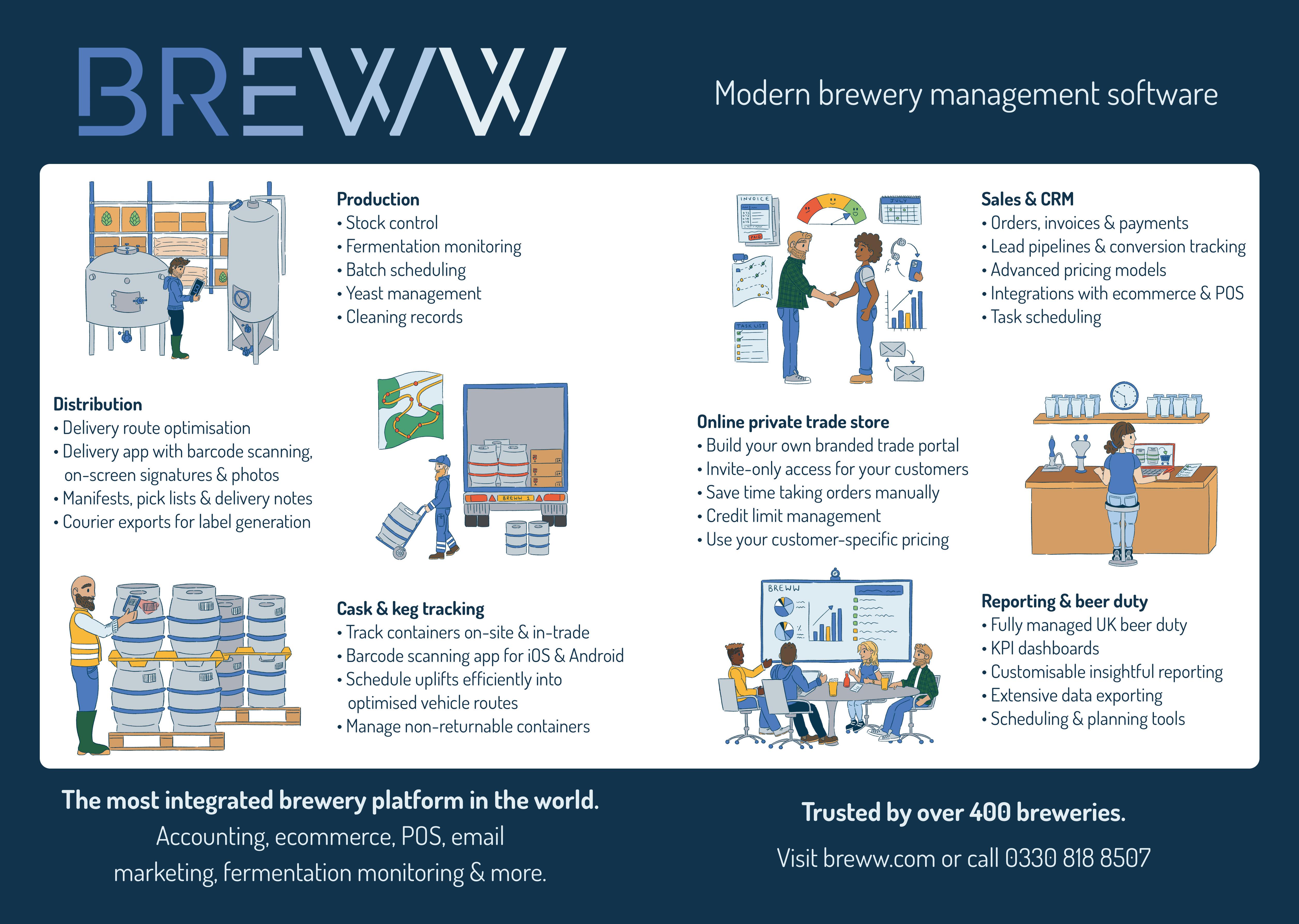

Rawlings are now distributing Dolium oneway kegs in the United Kingdom, Northern Ireland and the Republic of Ireland.

Dolium one-way kegs offer user friendly, cost-efficient, and sustainable alternative to stainless steel kegs. The one-way kegs solve problems many drink producers, particularly breweries, face with the high costs of low-rotation markets and longdistance shipping.

Dolium One-way Kegs

Dolium One-way Kegs

At Rawlings we provide you with the very best glass packaging solutions for your brand. Handling everything from sourcing, design and logistics Call us at Rawlings, Bristol on 0117 960 4141 Email: hello@rawlingsbristol.co.uk or visit www.rawlingsbristol.co.uk

COUNTER PRESSURE filling

us on 01404 892 100 to discuss your equipment requirements or email sales@vigoltd.com

Part of the Packaging & processing equipment from renowned manufacturers, fully supported by our team of 9 engineers @VigoLtd www.vigoltd.com Call us on 01404 892100

Across pretty much the breadth of what beer can be, RedWillow has had a crack at it and usually hit the nail squarely on the head

While it may have been a little bit full on for British cask drinkers at the time, it soon found itself a captive audience in beer venues that were willing to push the envelope such as (the now sadly closed) Mr. Foley’s in Leeds, and Hudderfield’s The Grove. A young, enthusiastic homebrewer called Brian Dickson was working at the latter, and he got a chance to brew a beer with Toby as part of RedWillow’s experimental ‘Faithless’ series of beers. Known initially as Faithless IX (as in the ninth iteration in the series), the black IPA would eventually become a seasonally released beer called Soulless.

“Toby was always one to brew what he found interesting, not necessarily what would be best-selling,” Brian, now the technical director at Leeds’ Northern Monk Brewery, tells me. “His enthusiasm was infectious to me as a 20-something beer nerd and we could chat about beer ideas for hours, so spending a few weeks over in Macclesfield felt like a no-brainer when I was learning the trade.”

Directionless gradually became less popular as RedWillow’s audience developed their palates and began to demand more up-to-date flavours in their beer, as modern North American Hop varieties such as Citra and Mosaic became more fashionable. Wreckless, a 4.8% pale ale, and Weightless, a 4.2% ‘session’ IPA gradually filled the space Directionless previously occupied in its core range. These were bookended by the 3.9% Headless, an accessible cask pale for the traditionalists, and Contactless, a distinctively modern, hazy, 5.2% pale ale.

These pale, and deeply hop accented ales were merely the vanguard of RedWillows ambition, however. There are few styles the brewery has not turned its hand towards, be they historic porters brewed with heritage varieties of barley such as Chevalier or Plumage Archer, or offkilter recipes such as a Thai-inspired wheat beer flavoured with lemongrass and galangal. An eventual, inevitable move into keg allowed them to pursue more contemporary styles, while their cask beers kept traditionalists satisfied.

“Across pretty much the breadth of what beer can be, RedWillow has had a crack at it and usually hit the nail squarely on the head,” Cal Darley, manager at Manchester’s Café Beermoth says. “I can't really think of many others who straddle the line keeping both sides of the market this well catered for.”

The incredible breadth of styles Redwillow now brew includes a wide range of lagers, which were initially born out of necessity in 2013 when the brewery opened its first bar in Macclesfield town centre. These include Guileless, their signature pilsner, and a stronger helles style beer called Godless. Much like their propensity to experiment within the boundaries of other styles, specials have included smoked lagers, and even a cask Vienna lager - the appropriately named Meaningless (should you be a fan of Midge Ure and Ultravox, at least.)

“We considered that we could just buy lager in, or we could make our own,” Caroline says. “That’s evolved into a whole new thing that’s just grown for us, and we’re now doing almost as many of those kinds of beer as we are cask ales.”

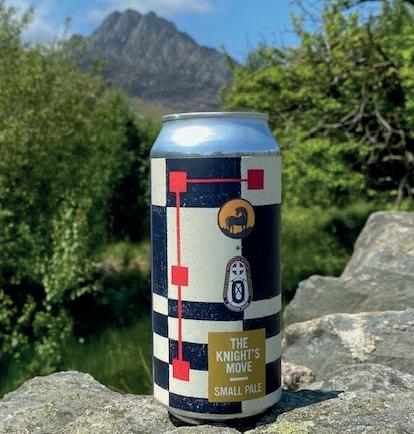

RedWillow’s mastery over pretty much every style they turn their hand to was demonstrated in March 2022, when Perceptionless, a 6.6% New England IPA, deliciously accented with flavours of fresh peach and apricot, was named SIBAs champion beer at its annual BeerX awards ceremony. Not only did the beer win outright in the Northwestern regional final, but it went on to become champion in both the keg and can categories in the national competition.

Toby recalls how he heard about his beer’s success while on the way to host a meet the brewer event at Stockport’s Petersgate Tap. As brewer Tom Lewis went on stage to collect the prizes, Toby was met with a flood of congratulatory text messages, making it difficult to focus on the task at hand.

“I just laughed like a lunatic. It took me quite a long time to actually calm down enough to make any sense at the meet the brewer,” he says. “People kept asking me questions and I just kept looking at my phone and thinking ‘holy shit!’”

The success of Perceptionless is testament to both the quality of RedWillow’s beers, and the conviction that Toby, Caroline and their small team carry with them. They have, without question of a doubt, developed into one of the finest breweries in the North West, if not the UK as a whole. Proof, if it was ever really needed, that Toby and Caroline taking the plunge and leaving the security of their well paid jobs was, in fact, a very good idea indeed.

25 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023 SIBA Independent Brewer x Pellicle Collab

X

We're keeping kegs simple. Scan Free Fixed Fee Integrated Tech Simple Logistics Keep in touch: 0800 534 5000 rent@kegstar.com kegstar.com Stainless steel keg & cask rental

Meet the SIBA team

The SIBA team was delighted to welcome two new members to head office this summer, so we caught up with them to find out a bit more about their background and new role on the team…

How long have you worked at SIBA and what did you do before?

"I joined the SIBA Team in July 2023 as a Membership Services Assistant. Prior to this I have held roles within hospitality and more recently distribution industries, where I developed skills that have enabled me to easily transition into this new position."

What does your job with SIBA involve?

industry trade show; Beer X. There is already a buzz in the office about the event, and I understand it to be really good fun. It’ll also be a great opportunity to meet people from the industry, and understand a bit more about the production side of beer."

What do you like to do outside of work?

Name: Emma Guneyogullari

Job title:

Membership Services Assistant

Contact details: emma.guneyogullari@siba.co.uk

"Based at SIBA HQ in Ripon, my role is very varied, but mostly consists of handling incoming calls and emails whether this be customer service enquiries, or taking orders from pubs with the addition of supporting colleagues in other areas as and when required."

What are you most looking forward to in your role this year?

"I’m especially looking forward to SIBA’s flagship event and the UK’s biggest brewing

How long have your worked at SIBA and what did you do before?

"I started working for SIBA in midAugust 2023, and so am very new to the organization. However, having worked in the beer industry for around eight years, I am familiar with the work SIBA engages with and the benefits offered to the membership. My most recent role was as Brewery Manager for SALT Brewing, at their Saltaire site.

Name: Pip Young

Job title: Events and Marketing Officer

Contact details: pip.young@siba.co.uk

Describe your role at SIBA.

"Planning, facilitating and promoting events organised and sponsored by SIBA. This is a new role to consolidate event tasks and provide members and associate suppliers with one go to person. Enabling smoother communication and implementation of regional meetings, competitions and any other event that SIBA is involved with."

I am hugely passionate about beer and keen to ensure the brewing industry has a sustainable future. I believe this will be achieved and supported through increased diversity and equity within the industry worker’s demographics. Some of my spare time is donated to the running of a project from my business 30SIXCo: The Coven. Where we platform and promote beer from marginalised brewers and owners. We also offer 1st aid services to beer festivals, ensuring all in attendance feel welcomed and safe."

What inspires you about your job?

"I am excitedly awaiting the chance to meet more folk from the brewing industry, to learn about their unique stories and understand

"My family and friends are extremely important to me, and so I spend a lot of time socialising with them. Going for long walks in the Yorkshire countryside or having a few drinks in a beer garden is a typical weekend for me."

If you could drink any beer anywhere in the world what would it be and where?

"I would be in a hot country, definitely sat on a sandy beach, drinking something light and fruity. Possibly a fruited IPA or hopped lager."

why they too love this crazy industry. I really want to understand the members and really embrace how SIBA can help them. I want to be part of affecting positive change for their businesses and the wider beer and brewing world."

What’s new in your department for 2023?

"My role!"

If you could drink any beer anywhere in the world what would it be and where?

"I would absolutely love to have a Duchesse De Bourgogne, in the brewery itself of Verhaeghe Vichte, Belgium. It can be a dividing beer, and one that once sipped expanded my journey through beer into new areas. Tasting of balsamic vinegar, with notes of strawberry and cherries, and hints of milk chocolate; The Duchess is a red brown Flanders Ale and is double fermented and matured in oak casks. An ancient process linked to the region of the southwest of the province of West Flanders and it’s hard not to admire the brewery for keeping this heritage alive."

27 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023 Meet the SIBA team

Anspach & Hobday – The Porter

The British Guild of Beer Writers’ Brewer of the Year Andy Parker, from Elusive Brewing, met up with Paul Anspach from London brewer Anspach & Hobday to discuss his passion for porter…

28 Autumn 2023 | SIBA Independent Brewer | www.siba.co.uk Homebrew in focus

Homebrew in Focus columnist Andy Parker

OG: 1.065

FG: 1.014

ABV: 6.7%

Mashed for 1 hour at 67C:

Pale Malt: 5KG

Chocolate: 0.5KG

Amber: 0.5KG

Black: 0.5KG

Hops (60 Min Boil):

EKG 20g @ 60 minutes

EKG 20g, Cascade 20g @ 20 minutes

EKG 20g, Cascade 20g @ 10 minutes

EKG 40g, Cascade 40g @ 0 minutes

Yeast: US-05 11g

Water: London Water, just treated with a bit of campden to knock the chlorine out.

“For Jack and me, learning to brew and learning about beer and its history very much went hand in hand. There is a lovely symmetry between the fact that The Porter was the beer that launched our brewery, and that it was the beer that put London on the map as the brewing capital of the world. In a way it is not at all surprising - if you consider that historically it is the water chemistry of a region that tends to define its beer, then it follows that London based homebrewers just beginning to get to grips with this aspect of brewing would find success with a Porter.

With regards to the beer itself, I think brewing darker beers gives you a better opportunity to properly engage with the malts, in a way that producing Pale Ales and IPAs does not. It’s a great way to learn about the malting process and what it brings to the beer, and given the big, bold flavour characteristics that highly kilned and roasted malts have, it forces you to really focus on balance.

Whenever I visit another country, I want to drink the beers that are from that region. It’s those beers that make the places unique, and in turn it’s those places that make the beer unique.

Ultimately, The Porter connects our brewery to our place in a way that no other style can.”

Whilst no longer your flagship, how did the success of The Porter inform and evolve into Black?

It's certainly true that the London Black has replaced The Porter as our flagship, but it's also true that without The Porter there would be no London Black. It still has a very important place in our range, and we are currently transitioning it to a yearly, vintage release, the first of which will be out in the next couple of months.”

How do you go about selecting the malts to use in your dark beers and how do you achieve such balance?

“The danger with very dark beers such as The Porter is always about losing the balance. Highly kilned and roasted malts such as Chocolate and Black Malt can be extremely powerful and overwhelming, specifically with regards to astringency. This really needs to be kept in check, otherwise things can get a little ashy. As a rule of thumb, the higher the level of kiln/roast, the less of the malt you should be using.

Sweetness also needs to be kept in check. As a brewery, we tend not to brew big, sticky pastry stouts with ridiculously high finishing gravities. These sorts of beers can become cloying and unbalanced, and drinkability can really suffer. As such we’ll make sure we are using a good proportion of simple base malt, and achieve a good fermentation with a high level of attenuation - for example, the FG of The Porter is 1.014, with an apparent attenuation of around 77%.

With the nights closing in and temperatures dropping, many drinkers seek comfort in dark or more malt forward beers. You really can’t beat a delicious pint of Porter or Stout enjoyed whilst sat in an armchair by an open fire in a cosy pub. I chatted with Paul Anspach, who with best friend and business partner Jack Hobday founded Anspach & Hobday in 2012. They launched with The Porter, their homage to the beers brewed in days of old in their London home. This rich and decadent beer is the ultimate comfort blanket and Paul tells us the story of how it came to be, how he approaches brewing dark beers and how it laid the foundation for the incredible success of their now flagship beer, London Black. The Porter was your first ever brew and one that's stood the test of time in your range. What is it you love about the style and its history?

“Being a brewery that led with a dark beer, the comparison to Guinness was often made, right from day one. Obviously, it's a bit of an inappropriate comparison given the strength of the Porter (6.7%), and we always knew it was never going to be a big volume, permanent line kind of beer. As such, we’d often play around with session strength variants, going as low as 2.8% with The Table Porter. This gave us a great foundation when it came to designing the London Black recipe. We had a good understanding of what gets lost when you start dialling back the ABV, and how the balance of the roasted malt character starts to shift.

Very much linked to this has always been the discussion around nitro, and it was only a matter of time before we started experimenting. Ultimately it was the many hours, days, and weeks of reflection and soul searching that the pandemic forced upon us that gave us the impetus to finally give it a go. With regards to the trade, I think that having a good reputation for Porters put us in a strong position when it came to pitching the beer. Moving away from Guinness is a big deal for many pubs, so having the pedigree earned with The Porter helps to make that decision a little easier for publicans.

It’s also tempting to throw as many different varieties of malts at a dark beer as possible, and we’ve certainly brewed beers with some extensive grain bills in the past. Ultimately though, it can be easy to crowd things out, and the characteristics of each individual malt can quickly get lost amongst the noise.

With The Porter things are much simpler. It's very much built from the bottom up, with a large amount of Pale Malt, Chocolate Malt for chocolate and coffee, Amber Malt for some toasty notes, and a pinch of Black for a little top note of roast.

It's also easy to underestimate the importance of hops in darker beers. As beers such as The Porter aren't primarily hop-forward beers, it's tempting to not give too much thought to the hops, or to conclude that you really don't need to use that many at all. In a sense, the opposite is true. Given how bold the malt characteristics can be the hops really have to work hard to make themselves known. Whether you are trying to balance out the malt sweetness with some hop bitterness or add some nice punchy fruit aromas to the beer, it's always worth thinking about how much malt character you are up against. Indeed, The Porter actually has a larger kettle addition than The IPA.”

29 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023 Homebrew in focus

Anspach & Hobday – The Porter

have produced the most ergonomically designed handle hole that is large enough and fully rolled under to eliminate sharp edges.

Precision machined shive inner. Our keystone has a machined inner to help the bung grip and make a tight fit. This is a stronger and more accurate weld. STANDARD CASKS 4.5 , 9 & 18 gallon From stock or bespoke manufacture: ndlkegeurope.com 01142 699080 info@ndlkegeurope.com CRAFTED FOR QUALITY

We

A closely welded finger guard keeps fingers from being caught between the chime and keystone.

Taproom Focus: Amity Brew Co

Taproom focus with with Pip Young

SIBA’s Events & Marketing Officer highlights some of the best taprooms from across the UK…

Name: Amity Brew Co

Founded: 2020

Location: Farsley, Leeds

Taproom Hours:

Open Thursday 5pm-11pm, Friday 4pm-11pm, Saturday 12pm-11pm & Sunday 12pm-8pm

There’s not a better way to start a tenure writing about taprooms than visiting your local, and local is what Amity Brew Co is all about. Community is at the core of what Amity stands for and popping in for a pint at their Farsely brewery tap is like heading round to an old pal’s for a pint and a natter.

The welcoming atmosphere cannot be understated, nor the sense of wholesome playfulness that is on offer across the bar. Brewing modern interpretations of classic beer styles, Amity is known for putting their personality on to all they do, and you can taste and feel it.

Experimentation, quality and standards in both brewing and service is clearly a priority. I opted for a pint of Waterpistol, 4.6% ABV juicy pale, delivering big notes of tropical fruit. A delicious treat in a very session-able abv. The flagship brew was awarded UK Winner of The Best Pale Ale in bottle and can at the SIBA National Beer Awards in 2023.

And when the inevitable call of nature arrived, I was pleased to be greeted with a poster for the ‘all welcome’ beer campaign. Ensuring that marginalised folk and those belonging to minority groups know they are welcome and will be looked after within the venue.

Verity Clarke, Director at Amity Brew co, said: "We set up Amity with the core values of Community, Friendship and Good Beer and we hope to bring these values into everything we do from the beer we create to the atmosphere in our bar. For our taproom, based in the heart of Sunnybank Mills in Farsley, we created a space that is for everyone. We are part of the Everyone Welcome Initiative and want people to feel seen by the little touches we make, including free period products in our bathrooms and our pledge to inclusivity proudly on display. We actively hold events and collab days for different groups, my favourite being a brew day for International Women's Day in collaboration with The Coven. The idea of community has evolved over time as we mean different things to different people, and we absolutely love that."

The venue is simply beautiful, with exposed stone, comfortable furniture and unfussy with a bright and airy vibe. Offering great inside and outside views, either overlooking the brewing vessels or the rest of the converted Sunnybank Mill complex. Amity have extended their community friendliness to their neighbours from the mill, enabling patrons to eat pizza onsite and their brewers to be one of the 1st to hear about upcoming gigs.

Check out their socials for events, games and tap takeovers to entertain yourselves, friends and family with. There is something for everyone and everyone is welcome.

31 www.siba.co.uk | SIBA Independent Brewer | Autumn 2023

Salaries in the craft brewery sector

For the second year, SIBA has published its Craft Beer Workforce Report providing a guide to salaries, diversity, age and qualifications of the people who work in craft beer. The full report is available on the Toolbox. It was produced with assistance from Mr David Tyrrall and Professor Geoff Pugh using data from the SIBA Craft Beer Report. In this piece for the magazine, they explain the background to the data.

The 2022/2023 survey received 188 full responses representing 28% of SIBA’s brewing, as shown in table 1.

The responding firms provide a good cross section of SIBA membership, so we have no reason to suspect that the salaries data is unrepresentative.

Graph 1 provides average salary data by SIBA’s regions across all positions and all sizes of breweries in the UK. In this article, we report simple average (mean) salaries (i.e., not weighted by the number of employees in each category). At first glance the graph looks quite flat, but in fact there is noticeable variation in the average salaries – ranging from £22,000 in the North West, through a national average of £26,000 to £29,000 in the South East – i.e., variation of 12% to 16% from the national average.

For comparison, Graph 2 gives the median annual earnings across all occupations for each UK region in 2022. The patterns are broadly similar: from the northern regions (lowest salaries) through Wales and the Midlands to the South East and London (highest salaries). This is unsurprising, but provides further reassurance that the SIBA results are robust.

More troubling, is the comparison with salaries in the wider economy. At an overall UK level, the estimated median annual earnings for full-time employees in the UK in 2022 are £33,000 (per Office of National Statistics). If we look at the latest mean annual salary for the Manufacturing - Food Products, Beverages and Tobacco sector, the salary is slightly lower at £31,980 per annum. Irrespective of the chosen comparator, the craft brewing sector is clearly showing rather lower levels of annual income than elsewhere in the economy. This probably reflects two pressures in the sector. On the demand side, it is known that the big players in the distribution chain for beer can exert considerable downwards pressure on the prices that the smaller craft brewers achieve for their output (Wyld, J., Pugh, G. and Tyrrall, D., 2010), which is why our research continues to suggest that small brewers’ tax relief should be maintained. However, it is also likely that there also is downward pressure on the supply side, because beer and brewing enthusiasts are prepared to accept lower wages and salaries because of their love for the sector.

Regional and national salaries

Source: SIBA’s members’ survey, 2022/23

Graph 2. Median Annual Earnings by UK region (2022) Median Annual Earnings (GBP)

Source: UK full-time annual salary by region 2022 | Statista

32 Autumn 2023 | SIBA Independent Brewer | www.siba.co.uk

£30,000 £25,000 £20,000 £15,000 £10,000 £5,000 £0 NorthWest EastNorthEast

ScotlandWalesandWest

MidlandsSouthWestSouthEastNational

Graph 1. SIBA members’ national and regional salaries

45,000 40,000 35,000 30,000 25,000 20,000 15,000 10,000 5,000 0 NorthEastEngland Yorkshireandthe Humber NorthernIrelandEastMidlandsWalesNorthWestEnglandSouthWestEnglandWestMidlandsEastofEnglandScotlandSouthEastEnglandLondon

SIBA Salary Report

SIBA membership level Hectolitre production range Responses Level 1 0-999 76 Level 2 1,000-4,999 76 Level 3 5,000-29,999 30 Level 4, 5, 6 30,000-200,000+ 6

Table 1. SIBA membership levels and survey responses

Mr David Tyrrall Professor Geoff Pugh

Next, we turn to variations in salary levels by size of brewery. Graph 3 shows average salaries across all posts according to the different SIBA membership levels.