22 minute read

Product Feature

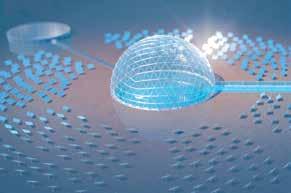

NEOM Adopts Pioneering Solar Dome Technology for Sustainable Desalination Project

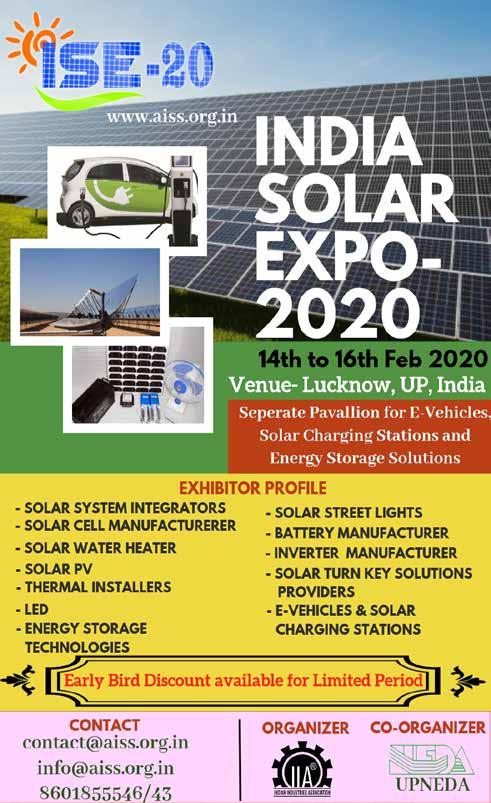

Advertisement

D-HVPE Technological Breakthrough Will Reduce the Time to Make a Solar Cell

NEOM will now adopt pioneering solar technology to produce low cost, environmentally friendly water, strengthening its reputation as an emerging hub for innovation and conservation. The company has signed an agreement with U.K.-based Solar Water Plc. to build the first ever “solar dome” desalination plants in NEOM, located in northwest Saudi Arabia. The pilot project promises to revolutionize the water desalination process, helping solve one of the world’s most pressing problems – access to freshwater. Work will commence in February and is expected to be completed by the end of 2020. At an estimated $0.34/m3, the cost of producing water via “solar dome” technology will be significantly lower than desalination plants using reverse osmosis methods. The technology will also significantly reduce the impact on the environment by producing more concentrated brine, a potentially harmful byproduct of the water extraction process. Solar Water’s ground-breaking approach, developed at the U.K.’s Cranfield University, represents the first use, on a large scale, of Concentrating Solar Power (CSP) technology in seawater desalination. The process sees seawater pumped into a hydrological “solar dome” made from glass and steel, before it is superheated, evaporated and eventually precipitated as fresh water. The “solar dome” desalination process, which can also operate at night due to the stored solar energy generated throughout the day will reduce the total amount of brine that is created during the water extraction process. Typically, the high salt concentration in brine makes it more difficult and expensive to process. The solar dome process helps prevent any damage to marine life as no brine is discharged into the sea. With over one billion people around the world lacking access to clean water every day, NEOM’s solar desalination project will serve as a test case for other water scarce countries that are struggling to generate environmentally safe and sustainable sources of fresh water. NEOM, the flagship project of Saudi Arabia’s post-oil diversification plan, is being built on a 26,500 km2 area in northwestern Saudi Arabia. It offers unique investment opportunities in economic sectors and real-estate development.

Covestro’s Insqin Technology Granted Solar Impulse’s Label

Covestro’s waterborne technology called Insqin for sustainable textile coating has been granted the Solar Impulse Efficient Solutions Label by the Solar Impulse Foundation. The label signifies its credibility and a guarantee of quality for those looking for clean solutions. The project has been proven economically profitable and environmentally protective.

Covestro’s solar-powered greenhouses for drying food to preserve it have also got the Solar Impulse Efficient Solutions Label. With its Insqin technology, Covestro significantly increases the sustainability of textile coating. The technology is based on waterborne polyurethane coatings, making textile production more eco-friendly and easier to handle. Using Insqin, the production of coated fabrics also requires up to 95 per cent less water and 50 per cent less energy.

The solar greenhouse dryer is an efficient, decentralised, cost-effective and sustainable solution for reduction of post-harvest losses in agricultural products. The high efficiency of the dryer is achieved through the use of polycarbonate for construction of a parabolically shaped greenhouse. The material is transparent to visible and in particular infrared light and shows good thermal insulating properties, allowing the dryer to heat up quickly.

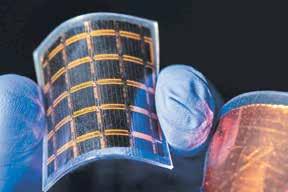

www.solarquarter.comwww.solarquarter.com The scientists successfully integrated an aluminum source into their hydride vapor phase

epitaxy (HVPE) reactor, then demonstrated the growth of the semiconductors aluminum

indium phosphide (AlInP) and aluminum gallium indium phosphide (AlGaInP) for the first

time by this technique.

III-V solar cells—so named because of the position the materials fall on the periodic

table—are commonly used in space applications. Notable for high efficiency, these types

of cells are too expensive for terrestrial use, but researchers are developing techniques to

reduce those costs.

One method pioneered at NREL relies on a new growth technique called dynamic hydride

vapor phase epitaxy, or D-HVPE. Traditional HVPE, which for decades was considered

the best technique for production of light-emitting diodes and photodetectors for the

telecommunications industry, fell out of favour in the 1980s with the emergence of MOVPE.

Both processes involve depositing chemical vapors onto a substrate, but the advantage

belonged to MOVPE because of its ability to form abrupt heterointerfaces between two

different semiconductor materials, a place where HVPE traditionally struggled. That’s

changed with the advent of D-HVPE.

The earlier version of HVPE used a single chamber where one chemical was deposited on a

substrate, which was then removed. The growth chemistry was then swapped for another,

and the substrate returned to the chamber for the next chemical application. D-HVPE

relies on a multi-chamber reactor. The substrate moves back and forth between chambers,

greatly reducing the time to make a solar cell. A single-junction solar cell that takes an hour

or two to make using MOVPE can potentially be produced in under a minute by D-HVPE.

Despite these advances, MOVPE still held another advantage: the ability to deposit wide

band gap aluminum-containing materials that enable the highest solar cell efficiencies.

HVPE has long struggled with the growth of these materials due to difficulties with the

chemical nature of the usual aluminum-containing precursor, aluminum monochloride.

The researchers always planned on introducing aluminum into D-HVPE, but first focused

their efforts on validating the growth technique. The scientists used an aluminum

trichloride generator, which was heated to 400 degrees celsius to generate an aluminum

trichloride from solid aluminum and hydrogen chloride gas. Aluminum trichloride is much

more stable in the HVPE reactor environment than the monochloride form. The other

components—gallium chloride and indium chloride—were vaporized at 800 degrees

Celsius. The three elements were combined and deposited on a substrate at 650 degrees

Celsius.

Using D-HVPE, NREL scientists previously were able to make solar cells from gallium

arsenide (GaAs) and gallium indium phosphide (GaInP). In these cells, the GaInP is used

as the “window layer,” which passivates the front surface and permits sunlight to reach

the GaAs absorber layer below where the photons are converted to electricity. This layer

must be as transparent as possible, but GaInP is not as transparent as the aluminum

indium phosphide (AlInP) used in MOVPE-grown solar cells. The current world efficiency record for MOVPE-grown GaAs solar cells that incorporate AlInP window layers is 29.1%.

With only GaInP, the maximum efficiency for HVPE-grown solar cells is estimated to be

only 27%.

Solar Project Operators Turn to Autonomous Drone Technology for Efficient and Secure Solar Energy Production

Sunerg Solar Introduces BIPV Monocrystalline Panel in Different Colours

Renewable energy is the key to a cleaner, brighter energy future. And solar is one of the most promising global sources of renewable energy. It’s cheaper (and arguably cleaner) than nuclear, coal, or combined cycle gas turbines. Yet, large-scale operations in the harsh environments most suitable to solar electricity production are challenging. Remote, geographically dispersed and sparsely manned, project construction and O&M are complex and costly. The components of solar power generation systems are surprisingly fragile – subject to mechanical and technical failure, wear and tear, and even vandalism and theft.

Current technology is good, but not enough. There is technology out there to assist solar farm operators in monitoring key points of failure – some created especially for solar power generation, like smart metering. Others include piloted drone solutions or solutions that facilitate or document manual inspection. Yet these solutions lack the accuracy and scope that enable project operators to keep a finger on the pulse of multiple sites comprising hundreds of thousands of moving parts.

Autonomous drones make solar energy farms more productive, more cost-effective, and more secure. An on-site autonomous drone system facilitates continuous and automatic oversight of the full range of solar park operations – even hard-to-reach or remote areas in unmanned facilities. Percepto’s new paper, “Autonomous Drones for Efficient and Secure Solar Energy Production,” presents an in-depth use case for autonomous drone systems in solar parks. Here are just a few of the reasons many solar project operators and stakeholders are turning to advanced autonomous drone technology:

Safe, continuous and efficient site construction

Ambitious and binding renewable energy targets have resulted in massive construction of solar farms, and contractors are under pressure to complete construction and move to production in record times. Facility commissioning dates are fixed, and delays in solar farm qualification and acceptance can result in high penalties. Autonomous drones drive CAPEX savings during solar farm setup, enabling safer and more efficient construction, and facilitating site delivery and acceptance by:

� Monitoring actual progress on a daily and hourly basis to optimize construction

� Detecting safety issues during complex construction involving multiple workers and heavy equipment

� Providing aerial data during construction and positioning of solar panels, surveying and terrain mapping

� Providing timely alerts of construction bottlenecks to enable corrective action that minimizes delays

Continuous monitoring of site productivity

O&M for industrial solar farms is complex and costly. Where the need to control CAPEX in the construction phase is clear, tighter operational monitoring and control can have a major impact on the OPEX of solar energy production. Autonomous drone systems offer better maintenance and fault detection at a lower cost — reducing overall site OPEX and turbocharging ROI. For example, Percepto’s autonomous drones feature a dual payload that enables combined visual, thermal, and radiometric solar panel monitoring and detection for:

� Ensuring optimal temperature, angle and reception

� Conducting frequent inspections – regular, pre-planned or ad-hoc

� Enabling 24/7 monitoring without additional pilot expenses

� Minimizing electrical component failure by conducting regular checks of multiple individual cells, diodes, junction boxes, modules, strings, combiners, trackers (ensuring correct panel tilt or angle) and inverters

www.solarquarter.comwww.solarquarter.com Italian solar panel manufacturer, Sunerg Solar has developed a BIPV monocrystalline panel suitable for residential projects on rooftops and facades in a range of different colors. The Sunerg X – Color module, which is produced in a standard size of 275 W with an aluminum frame and backsheet in the chosen colour, is available in mahogany brown, reddish brown, bottle green and black-grey. These colours according to the manufacturer offer a wide range of options to better match the architectural vision and the design of a building. The PERC module was created for a niche BIPV market, in which blue polycrystalline or black monocrystalline modules cannot satisfy aesthetic requirements. Furthermore, the company offers the possibility to add dummy modules with the same coloured glass, frame and backsheet that can be attached to the building envelope and adjusted to the size and dimension of the roof. For rooftop applications, the module is available in two versions: a fully building integrated panel or a partially integrated module through a “floating architectonic structure” on top of the roof with waterproof asphalt roofing underneath. Around 52 kW of these modules in reddish brown color were recently installed in a residential building in Copenhagen, Denmark. Sunerg added that the reddish brown colour of the modules do not perfectly match the surrounding red tile roofs in the Danish project, but it explained that a lighter red colour would reduce the efficiency to 240-250W. Lauri admitted that these modules are not as efficient as traditional monocrystalline modules, due to the extra colour coating layer on the glass. He stressed however, that their efficiency can match that of polycrystalline panels. The module price is around 50% higher than standard mono modules. The durability and maintenance costs of PV systems with Sunerg coloured modules are similar to those of a normal passive glass façade.

France’s SCP to Deploy Floating PV Installation with Solar Tracking Systems

Société du Canal de Provence (SCP) plans to deploy a floating PV installation with a solar tracking system on the Barjaquets reserve in Rognac, in the Bouches-du-Rhône region of Southern France.

The plant, which will be commissioned by the end of this year, was awarded a fixed tariff in a special tender for innovative PV projects held by The French Energy Regulatory Commission (CRE) in February 2018.

The advantage of using a tracking system with this type of installation is still to be studied, as it is still unclear if technical and climatic constraints (notably wind) can be compensated by the yield increase provided from the trackers.

A similar project relying on trackers is currently under development in the Netherlands by Floating Solar B.V. The project is planned for a drinking water treatment plant owned by Netherlands-based water utility PWN – Waterleidingbedrijf Noord-Holland – and consists of 15 floating solar plants with a combined capacity of 25 MW.

The solar installations will be based on Floating Solar’s tracking system technology, which ensures rotation towards the sun during the day. The system is based on an algorithm said to be able to gradually adjust panel position and increase system yield by approximately 30%. The specially engineered floating structure has been successfully tested under the most severe near-shore conditions.

Ingeteam Launches its Latest Battery Inverter with Two Solar PV Inputs

Ingeteam is finalizing the launch of its latest INGECON® SUN STORAGE 1Play TL M hybrid inverter. This highly versatile inverter features a battery input and two more inputs for PV panels. Each PV input has its own maximum power point tracking system, making it ideal for harnessing the maximum amount of energy on roof-mounted, self-consumption PV installations, with the PV solar panels positioned in two different orientations. A further advantage is that the INGECON® SUN STORAGE 1Play TL M hybrid inverter features an EMS (Energy Management System), making it possible to implement advanced operating modes, such as self-consumption, and facilitating system monitoring through the INGECON® SUN Monitor smartphone application. Moreover, there is an application to easily and remotely set-up and upgrade the inverter firmware via PC, tablet or mobile phone. Moreover, the system commissioning and the inverter’s firmware update can be performed remotely with the application via PC, tablet or smartphone. This new inverter is suitable for both grid-connected and stand-alone systems. In this latter case, the hybrid inverter is responsible for generating the grid. For grid-connected systems, the inverter features a back-up functionality so that, in the event of a grid outage, the critical loads can be powered from the batteries and PV panels. Production of this new inverter is set to start in May and it will be available with two power outputs: 3 kW and 6 kW.

GoodWe Winner of the 2020 “Best Inverter Award” of the PV Magazine

GoodWe has been selected as a winner in the category of best inverter by the PV Magazine for the innovation and design of our newly developed A-ES storage inverter. The A-ES Series is GoodWe’s innovative adaptation of the internationally successful ES energy storage solution inverter. This inverter is a solution for situations of grid failure and its comprehensive functionality was conceived for boosting self-consumption. It is available on a power range of 5 and 10kW with as many as 4 MPPTs, and with its UPS function has the capacity to provide all the power that home-owners may need in situations of emergency. It features a 50% of oversizing capability and also boasts a Zero Export function. GoodWe is advantaged with an R & D team of approximately 200 solar researchers, that our company has reached a position of leadership in the complex and expanding energy storage market segment. This team is GoodWe’s secret weapon not only for securing patents and awards but for expanding a large network of customers all over the world, that are loyal to our energy storage inverters for their great quality, design and superb functionality.

LONGi Sets Another New World Record for Module Efficiency

LONGi, the world’s leading solar manufacturer announced that it had achieved a new world record of 22.38% conversion efficiency for its monocrystalline module. The record was verified by the global independent certification agency TÜV Rheinland. “LONGi has continuously pushed the modules efficiency limits of our high performance monocrystalline products to further improve the price-performance ratio. This breakthrough once again confirms the development headroom of monocrystalline module technology. With continuous R&D investments in technologies and processes, new innovations can be rapidly applied to large-scale production, thus promoting the energy transformation led by solar energy. LONGi has always focused on the improvement of cell and module conversion efficiencies. In the past few years, LONGi’s mono-crystalline cell and module products have broken conversion efficiency world records many times. As a global leading solar technology company, LONGi has the confidence and commitment to lead the global energy transformation with technological innovation. The large-scale production of high efficiency module validates LONGi relentless focus on technology.

Aegeus Technologies plans to launch Waterless Robotic Panel Cleaning Technology in the Middle East

After all the R&D and successful tests of Waterless Robotic Panel Cleaning Technology on commissioned projects in India, Aegeus Technologies that holds technology Patents in India, plans to launch its Robots for Ground Mount and Rooftop projects in the Middle East at the World Future Energy Summit 2020 in Abu Dhabi. According to the ASU Renewable Energy Center, unwanted pollutants that obstruct sun rays from hitting the solar panel can impact electricity generation significantly. In fact, pollutants like dust can reduce solar panel efficiency by approximately 50 per cent.

Solar panel cleaning is the process of removing accumulated particles including atmospheric dust, bird droppings, ashes from wildfires and other debris from the panel surface. The process is adopted to improve the power conversion capability of these modules as these agents act as an obstruction to the sunlight falling on the panels. These methods are utilized across almost all the applications owing to their effectiveness in enhancing panel efficiency and therefore providing high power output.

AMP Energy India Launches One of the Largest Behind-the-Meter Distributed Generation Project with L&T Metro Rail Hyderabad

AMP Energy India, one of the fastest growing integrated renewable energy solution provider has launched one of the largest ‘Behind-the-Meter distributed generation projects in India’. The project is an 8MW solar project supplying power to L&T Metro Rail Hyderabad on an OPEX basis under a power purchase agreement (PPA)for 25 years. The 8MW solar power project is spread across 25 metro stations, 5 depots out of which 2 depots have ground mounted solar system and 3 depots have roof mounted solar system and 1 carport with elevated solar system.

SunSource Energy, a leading provider of solar-based energy and storage solutions to commercial and industrial organizations, has announced the commissioning of its 1.2 MW Solar Power Project for Shivamrut, a leading co-operative milk producer’s union in Maharashtra that provides self-employment to over 40,000 rural families in Maharashtra. The project was inaugurated by Hon’ble Former Chief Minister of Maharashtra (CM), Devendra Fadnavis at Solapur, Maharashtra. The project will supply clean energy to Shivamrut for a period of 10 years and is expected to offset over 15 million kg of CO2 emission over the course of its lifetime.

Tata Power Solar Awarded 250 MW PV Project from NTPC

Tata Power Solar Systems, has won the 250 MW solar project tender under the central public sector undertakings (CPSU) scheme, according to a letter of award from stateowned utility NTPC Ltd. The CPSU scheme provides viability gap funding support for Indian state-run power generators to set up 12 GW of grid-connected solar PV power projects using domestically made equipment. The capacity is to be built in the next four years. This project is going to be the biggest single order from a third party. It is in line with the government’s ‘Make in India’ mission.

Hartek Solar Bags 1-MW rooftop solar projects in Daman

Hartek Solar, the rooftop solar division of the Hartek Group with operations in more than 10 states, has marked its presence in the newly merged union territories of Dadra & Nagar Haveli and Daman & Diu by bagging around 40 rooftop solar projects to the tune of 1 MW in the industrial category in Daman. Grabbing the opportunities presented by the solar policy of the recently merged UTs, that makes it mandatory for industrial units to install rooftop solar plants, Hartek Solar, which develops and provides complete rooftop solutions, right from installation of solar panels and inverters to supply, design, engineering and commissioning, has bagged these substantial orders by riding on its expertise in the rooftop solar domain and track record of keeping up high project execution standards.

Adani and Azure Bag ManufacturingLinked Solar Tender Floated by the Solar Energy Corporation of India for 7 GW

Adani Green Energy and Azure Power have won the first of its kind manufacturing-linked solar tender floated by the Solar Energy Corporation of India’s (SECI) for 7 GW of solar capacity. Adani and Azure won the bids for developing 2,000 MW of projects with 500 MW of manufacturing capacity. The winning tariff quoted by both the companies was ₹2.92 (~$0.04)/kWh. The ceiling tariff for this tender was fixed at ₹2.93 ($0.041)/kWh. The tender also elevated an option for greenshoe where the companies could opt for an additional capacity to both develop and manufacture. Adani, under the greenshoe option, has offered an additional capacity of 1,500 MW solar cell and module manufacturing and 6 GW generation. The total capacity allocated for Adani now becomes 2,000 MW of solar cell and module manufacturing and 8 GW of generation capacity.

Tata, Waaree, Inkel Win Bids For Kerala’s 46.5 MW Rooftop Solar Auction

The KSEBL (Kerala State Electricity Board Limited) has given the tender of its 46.5 MW Rooftop Solar Auction to Tata Power, Waaree Group, and Inkel. As per the sources, Tata power has won a total capacity of 35 MW, in all categories which includes projects less than 10 kW, 11-100 kW, or more than 100 kW. Waaree Group, has won a total capacity of 6.5 MW, and Inkel which is a Kochi-based developer has bagged a capacity of 5 MW. It was mentioned by the source that out of the five bidders only three were selected for this project as the other two didn’t match the financial and experience criteria according to the tender document.

Trina Solar Commence Manufacturing New Multibusbar Modules With 210mm Wafer

Trina Solar has officially started manufacturing its first large-size module using silicon wafers with 210 mm side length. The new multi-busbar product uses an innovative 1/3- cut design, said the Chinese vertically integrated PV module producer. Trina claims this will pave the way for compatibility and integration of large-size, high-power modules and downstream systems. The move will greatly accelerate time-to-market for large-size modules. Large-sized wafers are said to help the modules generate more power thus enabling an overall reduction in costs. Tier-I manufacturers are increasingly introducing larger wafers for their cell/module products.

JinkoSolar Leads as a Top Module Supplier In 2019

With solar panel shipments worth 14 GW in 2019, China’s JinkoSolar Holding Co., Ltd. held on to its top position in PV InfoLink’s Top 10 Global Module Shipment Ranking for 2019. In 2018, JinkoSolar shipped more than 11 GW. JinkoSolar started the year 2019 with a forecast of 14 GW to 15 GW during the year, it later on reduced the forecast to between 14 GW to 14.2 GW. Yet, the 14 GW figure for JinkoSolar is way higher than the second highest volume of over 10 GW that fellow Chinese companies JA Solar and Trina Solar shipped in 2019, as per PV InfoLink analysts. Overall, shipments by all the top 10 suppliers added up to nearly 80 GW, which equals a 65.4% market share out of 121.4 GW shipped globally last year. If ranked by export numbers, the top five module manufacturers – JinkoSolar, JA Solar, Canadian Solar, Trina Solar and Risen Energy – together exported 33 GW to 34 GW of modules in 2019.

Microsoft Pledges To Go Carbon Negative By 2030

The global IT giant has pledged to go carbon negative by the year 2030, which means it will remove more carbon than it emits each year. By 2050, it will remove from the environment all the carbon it had emitted either directly or by electrical consumption since it was founded in 1975. The bold announcement comes with a detailed, sort of, plan as to how the management will go about meeting the target. Microsoft says it will shift to 100% renewable energy supply by 2025 by way of signing power purchase agreements (PPA) for green energy contracted for 100% of carbon emitting electricity consumed by its data centers, buildings and campuses, something it has been doing for quite some time now.

Change in ReneSola Revenue Guidance For 2019

New York Stock Exchange (NYSE) listed solar power project developer ReneSola Ltd. has changed its revenue guidance for the last quarter of 2019 and the full year itself owing to delay in recognizing revenue from the sale of a solar project in Canada. It will expect to complete the project sale and recognize the revenue in Q1/2020. As per preliminary unaudited results, it now expects Q4/2019 revenues to be in the range of $20 million to $25 million, bringing it down from $45 million to $50 million shared previously. Expected gross margin for the period will now be in the range of 27% to 31%, as opposed to 10% to 15% guided earlier. While sharing its third quarter results for 2019, ReneSola guided for full year 2019 revenues to be between $130 million to $140 million with a gross margin of 20% to 25%. Now it has been reduced to $115 million to $120 million as revenues and gross margin is anticipated to be within 25% to 30%.

Engie To Divestment 74%Stake In Indian Solar Assets

French energy company Engie is giving up a 74% stake in its 12 solar assets in India representing 813 MW of operating capacity to Edelweiss Infrastructure Yield Plus (EIYP) and a portfolio company of the latter called Sekura Energy Limited. EIYP is an infrastructure focused fund managed by Edelweiss Group’s Edelweiss Alternative Asset Advisors Limited. The move will help the company reduce its net debt by more than €400 million ($443.7 million) and is part of the company’s business model to develop-build-share-operate (DBSO) under which it partially sells off interest in its EPC projects post commissioning. Engie said it will collaborate further with EIYP under an ‘ambitious strategic partnership’ to expand a growing solar platform with the French company continuing to look after development, construction and operation of present and future solar plants.