RAIL PRODUCT CATALOGUE

Overhead Contact Line Systems

Overhead Contact Line Systems

Elcowire is a sustainable partner for companies that are key to the ongoing energy transition and electrification of our society.

With an annual capacity of 300 000 tons Elcowire is one of the largest manufacturers in Europe of copper wire rod, wires, stranded conductors, profiles and overhead catenary systems made from copper, copper alloys and aluminium.

Elcowire can offer Low-carbon Copper, standard materials and customized solutions aiming to support our customers in meeting their specific targets.

Our high quality products offer a range of benefits, such as reduced energy loss, increased efficiency, enhanced reliability, longer lifespan and recyclability. These benefits make Elcowire an excellent choice that meets the energy needs of the society while minimizing environmental impact.

As of today, we offer products less than half of the global average CO2 emissions, as confirmed by the International Copper Association (ICA), and we also see a large potential both in terms of improved efficiency in the processes and the increased use of renewable energy sources such as solar, wind and hydropower capacity.

Elcowire Rail develops and produces products for contact lines of electrically powered rail and also road bound transportation systems. With its product range, Elcowire Rail covers catenary wires, contact wires, dropper wires and earthing wires consisting of standard materials based on Cu, CuAg, CuSn and CuMg. On top, Elcowire Rail offers innovative and customized solutions to support its customers in achieving their sustainability and efficiency goals.

The copper business is not just about the products at Elcowire. Our dedicated colleagues are like family, and many of Elcowire's staff is second or third generation. Every day, we strive to adopt more environmentally sustainable workplace practices, to fulfill corporate social responsibility, and because sustainability makes business sense in terms of improved employee health and well-being.

The tradition of more than 200 years of knowledge is a torch that gets passed down from one generation to the next and we wish you will join us on our continuing journey to reach net zero carbon emission.

Let us get ready for the most sustainable solutions.

elcowire.com

As Northern Europe's leading provider of copper wire products, Elcowire is devoted to supporting our planet's shift to greener energy sources and raw materials.

We focus on developing solutions that enable electrification of transportation, expanding solar and wind power sources and the widespread growth of a modern and sustainable infrastructure.

We are a dynamic international group with strong attention to our customers' needs.

We work directly with you, providing excellent customer support, the highest quality products, reliability, a focus on detail and a close technical partnership.

- The focus is sharp and strong on sustainable products and solutions.

ELCOWIRE AB, SWEDEN

ELCOWIRE GMBH, GERMANY

ELCOWIRE RAIL GMBH, GERMANY

With three production sites we can offer flexibility and a reliable supply chain.

Elcowire Rail benefits from its groupwide access to 3 Elcowire sites, all of them performing specialized production technology and providing capacity for its international rail business.

Elcowire Rail produces products for contact lines of electrically powered rail and covers a wide product range: contact wires, catenary wires, dropper wires and earthing wires consisting of standard materials based on Cu, CuAg, CuSn and CuMg.

AS ONE OF THE LEADING EUROPEAN SUPPLIERS OF COPPER PRODUCTS, ELCOWIRE IS COMMITTED TO SUSTAINABLE COPPER SOURCING.

MINING

URBAN MINING

Elcowire is working with the eco-friendliest mines in the world, together we are finding solutions to minimize the climate impact of our supply chain.

Our contact wires power electrified trucks at the mine, as well as the trains that deliver copper to our production sites.

We produce and deliver sustainable products with high quality and low CO2footprint to our customers, and when the final application needs to be replaced, the copper is returned to a recycling process and reused in our copper production: A new product with high quality and low CO2footprint is produced and delivered to our customers.

Producing new products from existing copper products in applications that needs to be replaced, instead of taking raw material from the mine, is what we call: Urban mining.

LOW-CARBON COPPER with less than 50% CO2

Smelters are powered by electricity from renewable sources, mainly hydro power. Excess heat from smelting process is transferred to the cities´ heating system.

Our lean manufacturing takes in account the use of renewable energy sources, low waste and negligible use of chemicals.

With the input of conducting material, delivered from Elcowire, our customers produce their own products with an already significantly lower

WITH SUSTAINABLE SOLUTIONS

We ensure the loop continues to go around and around and around...

WE ARE DEVELOPING ADVANCED TECHNOLOGIES TO PROVIDE OUTSTANDING ENERGY SAVING PRODUCTS WITH MAXIMUM USEFUL LIFE TO ENABLE SUSTAINABLE SOLUTIONS – TAILOR-MADE TO OUR CUSTOMERS' NEEDS.

ELCOWIRE CAN OFFER STANDARD MATERIALS, LOWCARBON COPPER, RECYCLED COPPER AND CUSTOMIZED SOLUTIONS AIMING TO SUPPORT OUR CUSTOMERS IN MEETING THEIR SPECIFIC PURPOSES.

KNOW HOW

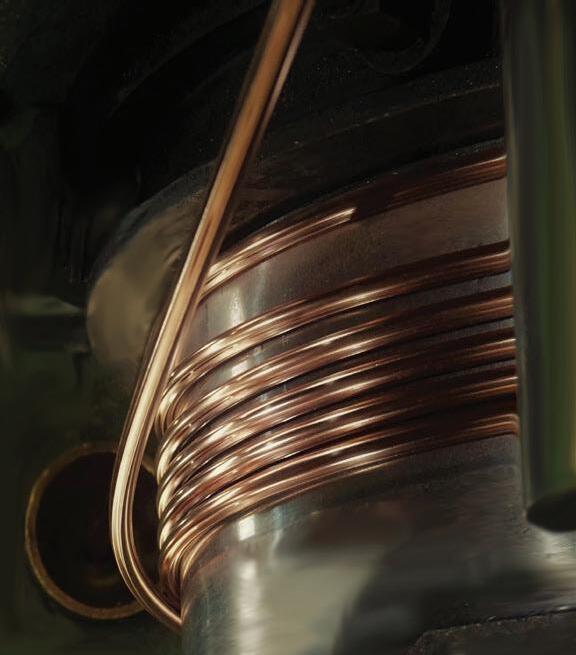

Elcowire’s contact wires and catenary wires primarily rely on Elcowire’s brilliant know how and expertise in producing rod material of 8-22 mm as pre-material (Cu-ETP, CuSn alloys and CuAg alloys).

Furthermore, Elcowire Rail provides an own upstream technology to produce rods of different CuMg alloys. Using different production steps, like rolling, drawing and stranding we finally produce an enormous wide range of different contact wires with different profiles and catenary wires and flexible cable conductors with various design configurations. This wide range of products derives from the several options to combine a chosen alloy, a specific contact wire profile or stranded wire configuration, a required cross-sectional area and finally the demand for special properties like mechanical strength and electrical conductivity.

Fulfilling these complex demands of European and International standards as well as specific customer requirements is the unique competence of Elcowire Rail. It is a part of our mission to support our customers to finalize their own sustainable projects in railway applications.

Today we are a leading supplier in Europe, in the aspect of casting, rolling, drawing and stranding. We have all the test equipment needed to check fulfilment of the requirements of common standards for contact wires and catenary wires, such as EN 50149, IEC 62917, DIN 48201 and IEC 63190. Our activities, our business processes and structures are based on well-established management systems for quality ISO 9001:2015, environment ISO 14001:2015, energy ISO 50001:2018 and health & safety ISO 45001:2008.

Today’s modern rail applications put special requirements on the components and materials used in overhead contact lines. In particular, contact and messenger wires used in these applications require increased tensioning forces, highest possible electrical conductivity and the maximum possible fatigue strength. Elcowire has developed a comprehensive portfolio of products designed to meet these challenging demands.

For railways with high speed up to 400 km/h, we offer the VALCOND CuMg0,2 and CuMg0,5 contact wires. These have been specially developed to ensure maximum tensile strength with minimal wear, while providing high electrical conductivity.

For high-speed rail at speeds of 300 km/h and below, our VALCOND CuSn0,2 contact wires provide excellent tensile strength and conductivity.

Elcowire’s copper alloy VALTHERMO CuSn0,1 is an economically and ecologically smart replacement for contact wires and stranded conductors made from copper and copper-silver alloys. It is typically suitable for applications of speeds up to 250 km/h.

VALTHERMO products provide the maximum possible electrical conductivity and high tensile strength, with wear rates far below those of conventional copper or copper-silver solutions.

Half of the carbon emissions over its production processes, compared to the global average footprint for standard copper.

Low-carbon Copper is made possible through production that has undergone a substantial transformation due to electrification and automation of various stages of the process.

The Low-carbon Copper has also been made possible by a very efficient ore concentration process and a world-class green energy mix. The result is copper wire that has a low impact on nature and the climate.

The significantly lowe r CO2 emissions of the Low-carbon Copper are verified through several validation processes. The reporting protocol that is used for verification is the Greenhouse Gas Protocol – Product Life Cycle Accounting and Reporting Standard.

The product is also validated and reviewed against the general principles in ISO 14064-3 Standard.

Environmental declarations

Environmental declarations have been developed for Elcowire’s products, including Low-carbon Copper. Our footprint is verified through mass balance-based self-declarations for Low-carbon Copper Wire Rod and Low-carbon Copper Profiles, as per the framework in ISO 14021.

This is a first important milestone for Elcowire and the next step is to perform calculations of the carbon footprint for drawn wire products.

Elcowire aims to be a sustainability leader in its business, and therefore the carbon footprint is strategically important.

For more information, please visit our website; elcowire.com

Cu-ETP, CuAg, CuMg and CuSn according to EN 50149 - IEC 62917

Our products can be manufactured according to european (EN), international (IEC), or individual specifications our customers are asking us for.

AREAS OF APPLICATION:

Contact wires for all ranges of speed on main and side lines, for all electrical systems AC or DC, as well as for Metros, Trolley buses and Mining.

PACKING:

Different drums according to the specific application.

All values refer to new unworn contact wires at a density of 8.890 kg/m³

Overview of materials and speed range (selection)

(high tensile strength)

Values based on a cross section of 120 mm² according to EN 50149 and IEC 62917. All values refer to new unworn contact wires. For non-standard products the technical and commercial availability should be inquired.

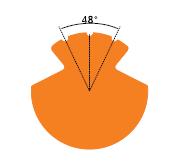

Contact wires made of copper-magnesium alloy have three identification grooves on the top of the wire.

VALTHERMO contact wires have two identification grooves, one offset at an angle of 24° and one in the middle of the curve at the top of the wire (by agreement).

1) Calculated with minimum cross section.

2) Different tensile strength on request.

3) Calculated at wind 1 m/s, sun radiation 1000 W/m², 35°C ambient temperature, max. permanent operating temperature 80°C, new contact wire. All values refer to new unworn contact wires. For non-standard products the technical and commercial availability should be inquired.

Values for CuAg0,1 alloy (normal tensile strength)

Values for CuAg0,1 alloy (high tensile strength)

1) Calculated with minimum cross section

2) Different tensile strength on request

Values for VALTHERMO CuSn0,1 alloy (high tensile strength)

1) Calculated with minimum cross section.

2) Different tensile strength on request.

3) Calculated at wind 1 m/s, sun radiation 1000 W/m², 35°C ambient teperature, max. permanent operating temperature 100°C, new contact wire. All values refer to new unworn contact wires. For non-standard products the technical and commercial availability should be inquired.

1) Calculated with minimum cross section.

2) Different tensile strength on request.

3) Calculated at wind 1 m/s, sun radiation 1000 W/m², 35°C ambient teperature, max. permanent operating temperature 80°C, new contact wire. All values refer to new unworn contact wires. For non-standard products the technical and commercial availability should be inquired.

1) Calculated with minimum cross section.

2) Different tensile strength on request.

3) Calculated at wind 1 m/s, sun radiation 1000 W/m², 35°C ambient teperature, max. permanent operating temperature 100°C, new contact wire.

4) Improved electrical properties of VALCOND CuMg0,5 are based on 72 % IACS. IEC 62917 requires 70 % IACS only for high conductivity CuMg0,5.

All values refer to new unworn contact wires. For non-standard products the technical and commercial availability should be inquired.

Ask us for your product of choice - standard, VALUE or customized!

STRANDED CONDUCTORS CHARACTERISTICS ACCORDING TO DIN 48201

1) According to EN50119 guide values for ampacity are calculated at max. temperature 80 °C for Cu-ETP and 100 °C for Bz II and Valthermo. wind 1 m/s, sun radiation 1000 W/m², 35°C ambient temperature. All values refer to new stranded conductor..Other specifications according to international standards and customer requirements on request. For non-standard products the technical and commercial availability should be inquired.

BzII (CuMg)

Overview Cable conductors made of pure copper (Cu-ETP) according to DIN 48201 part 1

Overview Cable conductors made of bronze BzII (CuMg) according to DIN 48201 part 2

1) Guide values for ampacity valid up to 60 Hz at wind speed of 0,6m/s and sun radiation of 1000W/m², ambient temperature of 35°C and permanent conductor temperature of 70°C according to DIN 48201-1. Calculation for other conditions on request.

2) All values refer to new stranded conductor. For non-standard products the technical and commercial availability should be inquired.

1) Guide values for ampacity calculated at wind 1 m/s, sun

Calculation for other conditions on request.

All values refer to new stranded conductor. Other specifications according to international standards and customer requirements on request.

ACCORDING TO IEC 63190

Examples of common conductor constructions - selection of characteristic values

S97-C0 Cu-ETP

S62-C4 CuMg

H75-C4 CuMg

1) Designation consists of values for nominal cross-sectional areal, number of individual wires, individual wire diameter, conductivity class and % IACS (e.g. S97 for standard conductivity of 97 % IACS), class of mechanical characteristics (C0 to C7) and material.

2) Any product with a conductivity class higher than standard (S) can be connected to VALCOND. Higher conductivity classes are H (high), E (extra high) and U (ultra high).

3) Calculation of break load according to IEC 63190 deviates from calculation according to DIN 48201 due to considering the stranding factor as well as an additional reduction coefficient.

For non-standard products the technical and commercial availability should be inquired.

(CuMg) according to DIN 43138

APPLICATIONS/VERSIONS:

Bare conductors

Flexible cables

Flexible strands

Jumpers

ALLOYS:

Cu- ETP, Bz, CuAg and other copper alloys according to customer request

DESIGN: Bare, hard drawn, thermally treated

PACKING: Different drums according to the specific application

Overview Flexible cable conductors made of pure copper (Cu-ETP) according to DIN 43138

1) Guide values for ampacity are valid up to 60 Hz at the given wind speed and sun impact for ambient temperature of 40 °C and a final permanent temperature of the conductor of 80 °C.

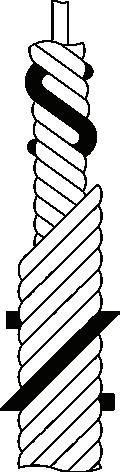

Remark: The outer layer is right-handed (Z).

All values refer to new stranded conductorn.

Other specifications according to international standards and customer requirements on request.

Overview Flexible cable conductors made of bronze BzII (CuMg) according to DIN 43138

Remark: The outer layer is right-handed (Z).

All values refer to new stranded conductor.

Other specifications according to international standards and customer requirements on request. For non-standard products the technical and commercial availability should be inquired.

according to DIN 48201 part 7

APPLICATIONS/VERSIONS:

Anchoring cables

Cable conductors (messenger wire)

Lightning protection cables

Feeder cables

Rail and track connectors

Anchoring systems for street lighting

DESIGN: Bare

PACKING: In coils, on drums made of wood or steel

1) Guide values for ampacity valid up to 60 Hz at wind speed of 0,6m/s and sun radiation of 1000W/m², ambient temperature of 35°C and permanent conductor temperature of 80°C according to DIN 48201-7. Calculation for other conditions on request.

2) The cable weights are calculated on a density of 8.150 kg/m³ for Staku I and II with a conductivity of ≈ 30 % of a wire made of soft annealed copper; on a density of 8.200 kg/m3 for Staku I and II with a conductivity of ≈ 40 % of a wire made of soft annealed copper and a medium regular twist length of lay. The medium regular twist length of lay is defined by the arithmetic average of minimum and maximum values of the values for the regular twist length of lay in the standards concerned.

3) For cables with a nominal cross section of 50 mm² the number of wires has to be specified in the order.

All values refer to new stranded conductor

Other constructions: e. g. Staku II/30, Staku I/40, Staku II/40 or international standards and customer specifications on request.

With pleasure and if demanded, our products can be manufactured according to european (EN), international (IEC) or individual standards our customers are asking us for.

AREAS OF APPLICATION:

Contact wire for all ranges of speed on main and side lines, for all electrical systems AC or DC as well as for Metros, Trolley buses and Mining.

PACKING: Different drums according to the specific application

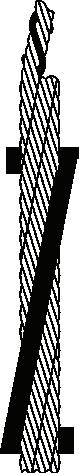

1) other drum specification and seaworthy packing on request, also steel drums

2) We would be happy to give support for the optimization of drum selection for your equipment OVERVIEW WOODEN SPOOLS BASED ON DIN 46391, E. G. FOR CABLE CONDUCTORS

1) Other spool specification and seaworthy packing on request, also steel drums.

2) We would be happy to give support for the optimization of drum selection for your equipment.

The Group has expanded and this has added production capacity, but perhaps even more importantly, sales capacity, technical competence and experience. Capacity is important, but even more so is the knowledge of our Elcowire colleagues.

JAN SIEBERT

Head of BU RAIL

Language: German & English jan.siebert@elcowire.com

+49(0)3476 87 14 10

Mobile +49 (0) 152 5873 4951

SALES & APPLICATIONS RAIL

ROBERT GEHRMANN

Head of Product Management

Language: German & English robert.gehrmann@elcowire.com

Mobile +49(0) 151 2272 7184

RICK SCHULZ

Sales Manager

Markets: Eastern Europe, Russia, Greece, India & Turkey

Language: German & English rick.schulz@elcowire.com

Mobile +49(0) 172 7915 128

CALLE CROONA

Sales Manager

Markets: Sweden, Denmark, Norway, Finland

Language: Swedish & English calle.croona@elcowire.com

Mobile +46 (0)705 300 696

Withsustainabilityinmind,combinedwithwidetechnical knowledgeandexperienceinestablishingnewareasof operationandbusiness,wearelookingforwardtogiveyou answerstoyourquestions...

ELCOWIRE TEAM

JOHANNES KALTENBACH

Product Management

Language: German & English johannes.kaltenbach@elcowire.com

Mobile +49 (0)176 185 08 205

HANS-PETER WIPFLER

Sales Manager

Markets: Western Europe, South-Middle and North America

Language: German, English & Spanish hans-peter.wipfler@elcowire.com

Mobile +49(0) 152 5632 6830

TONY HILL

Application Engineer

Language: Swedish & English tony.hill@elcowire.com

Mobile +46 (0)703 195 366

GIANCARLO SERINELLI

Sales Manager

Language: German, English & Italian Markets: Germany, Austria, Switzerland & Netherlands Giancarlo.serinelli@elcowire.com

Mobile +49 (0) 162 2583 866

KRZYSZTOF KOENIG

Regional Sales Manager - Eastern Europe

Markets: Poland, Czech Republic, Slovakia

Language: German, Polish & English

krzysztof.koenig@elcowire.com

Mobile +48 (0)790 890 350

WALID TOUZI

Sales Manager

Markets: Africa, Middle East

Language: Arabic, English & French

walid.touzi@elcowire.com

Mobile +216 24 326 990

CUSTOMER SERVICE CENTER RAIL

MARIA STRECKENBACH

Head of Customer Service

Hettstedt

Language: German, English & Spanish

maria.streckenbach@elcowire.com

+ 49 (0) 3476 89 2526

NANCY KUSENEWSKI

Hettstedt

Language: German nancy.kusenewski@elcowire.com

+49 (0)3476 87 1431

KERSTIN MEISTER

Hettstedt

Language: German

kerstin.meister@elcowire.com

Mobile +49 (0)3476 87 1433

TINA GERLACH

Hettstedt

Language: German & English

tina.gerlach@elcowire.com +49 (0)3476 87 1464

SARAH ZIMMERMANN Hettstedt

Language: German & English

sarah.zimmermann@elcowire.com +49 (0)3476 87 1439

FAITH MUNGAI

Hettstedt

Language: German & English

faith.mungai@elcowire.com

+49 (0)3476 87 1432

ANDRÉ PRELLER

Hettstedt

Language: German & English

andre.preller@elcowire.com

+49 (0)3476 87 1468

STEFANIE SCHRADER Hettstedt

Language: German, English & Russian stefanie.schrader@elcowire.com

+49 (0)3476 87 1460

FREDERIKE KUMAR Hettstedt

Language: German & English

frederike.kumar@elcowire.com

+49 (0)3476 87 1437

OUR SOLUTIONS ARE AN ESSENTIAL COMPONENT IN THE ELECTRICAL AND INFRASTRUCTURE INDUSTRIES. WITH RESPECT FOR THE ENVIRONMENT AND FUTURE GENERATIONS, WE ARE DEVELOPING ADVANCED TECHNOLOGIES TO PROVIDE YOU WITH OUTSTANDING ENERGY-SAVING PRODUCTS WITH MAXIMUM CIRCULARITY.

Our copper is responsible sourced to prevent abuses of human rights, avoid contributing to conflicts, as well as safeguarding health and safety of miners in the supply chain. Our cathodes are LME Grade A and in accordance with the standard ASTM B115, or EN 1978.

The Low-carbon Copper has less than half of the CO2 emissions per kg copper compared to standard copper. The reduced CO2 emissions of our Low-carbon Copper have been validated scientifically and will play an important role in the transition, to achieve the goal of net-zero CO2 emission by 2050 set by the EU. The carbon emissions reduction by using Low-carbon Copper is based on using copper mines with electrified production, Elcowire's lean production methods, very efficient ore concentration process and a world-class green energy mix.

Elcowire sets the example by producing semi-finished and finished products that have a low impact on nature and climate.

One of the most significant benefits of copper is its recyclability. Copper is a highly sought-after material in the recycling industry because it can be recycled over and over again without losing its quality or purity. This means that copper can be reused in new products, reducing the need for mining and extraction of new copper ore. Recycling copper also reduces energy consumption and greenhouse gas emissions associated with copper production, making it an environmentally friendly choice. Elcowire's waste management and processing of materials are focused on going from linear flows to circular flows, supporting the core of a circular economy.

End-of-Life materials can be sent back to smelters to be refined inseveralprocesssteps Metals are extracted withlowestpossible impactfrom suppliers' mines

Internalmetalscrap isrecycled

End-of-Lifecoppercanbesentbackto Elcowiretoberecycled

Processscrap from customers canberecycled at Elcowire

Elcowire's circularity process enables our customers to reduce their CO2 emissions.

End-of-Life - At the material end-of-life thereareseveralpossibilities forthematerialtogetanewlife

START OF OPERATION COUNTRY PROJECT NAME OPERATOR

2006 Germany Verkehrsprojekt Deutsche Bahn Deutsche Einheit Nr. 8 HSL

2007 France Paris–Strasbourg SNCF

2008 China Beijing–Tianjin HSL CMRT

2010 Spain Madrid-Valencia HSL ADIF

2011 Finland Seinäjoki–Vaasa Väylävirasto

2011 China Beijing-Shanghai HSL CMRT

2016 Switzerland Gotthard Base Tunnel SBB Infrastruktur

2016 Spain Valladolid-Leon-Burgos HSL ADIF

2017 Spain Antequera-Granada HSL ADIF

2018 Switzerland Cenery Base Tunnel SBB Infrastruktur

2020 Spain Padralba-Ourense HSL ADIF

2020 Malaysia Gemas-Johor Bahru Malaysian Railway

2021 Germany Ulm-Wendlingen HSL Deutsche Bahn

2021 Germany Electrification Südbahn Deutsche Bahn

2021 Austria Mittlern Althofen HBF ÖBB Infrastruktur

2021 Austria Graz HBF ÖBB Infrastruktur

2021 Bolivia Cochabamba LRT Municipality of Cochabamba

2022 Finland Raide- Jokeri Helsinki City Transport

2023 Mexico Maya Train Olmeca-Maya-Mexico

BU Rod has an annual production capacity of 300 000 tons of pure and silver, tin- and magnesium-alloyed copper wire rod.

BU Rod is one of the largest manufacturers in Europe with continuous cast and upcast in rod dimensions 8–30 mm.

BU Rail serves the worldwide market for overhead conductor material, including catenary and contact wires, feeder, stitch, jumper and earthing wires.

Our products are suitable for all speeds of operation and support sustainability in railway design.

Our drawn wire products cover a diameter range between 4,6 mm and 0,05 mm. They are made from Elcowire continuous cast wire rod.

BU Wire & Strands manufactures our wires in compliance with European and international standards.

BU Specials is a leading provider of drawn and extruded profiles used in various applications for energy transmission.

BU Specials is supporting our customers to build up renewable energy transmission systems.

BU High Voltage’s conductor materials are being used in cables for interconnections, off shore wind parks, underground power links and other applications.

ELCOWIRE GROUP

With an annual production of 300 000 tons Elcowire is one of the largest manufacturers in Europe of copper wire rod, wires, stranded conductors, profiles and overhead catenary systems made from copper, copper alloys and aluminium.

BU High Voltage offers our extensive knowledge and products primarily to manufactures of high voltage and extra high voltage cables.

and products primarily to manufactures of high voltage and extra high voltage cables.

ACCELERATE YOUR JOURNEY FOR LOWER

Asoneoftheleading Europeansuppliersof copperproducts,we arecommittedto sustainablecopper sourcing.Weare developingadvanced technologiestoprovide outstandingenergysavingproductswith maximumusefullife toenablesustainable solutions.

Welookforwardto buildingonthis strongfoundation forevenstronger relationshipsgoing forward...

CONTACT

Elcowire Group AB Elektrogatan 20, 251 09 Helsingborg, Sweden

Elcowire Group | LinkedIn elcowire.com