23 minute read

PRODUCT SHOWCASE

PRODUCTSHOWCASE

WANT TO BE FEATURED?

Send your latest product information to editorial@indmacdig.com

IMD's Product Showcase features the latest from some of the manufacturing industry's top suppliers.

Dynabrade Introduces New 3” Diameter Dynorbital Extreme Random Orbital Sander.

The commitment to quality continues. Dynabrade, Inc is proud to introduce the New 3” Diameter Dynorbital Extreme Series of Random Orbital Sanders.

Improving on what they do best, the Extreme Random Orbital Sander is an American Made Air Tool delivering the best horsepower rating of all Industrial Orbital Sanders in its class. The new 3” diameter model is available in Non-Vacuum and Central Vacuum models. A 3/16” diameter orbit is offered for general sanding applications. A 3/32” diameter orbit is also available for ultra-fine sanding. The Dynorbital Extreme Random Orbital Sander features an Ergonomic design with a tactile soft grip overmold for a comfortable feel. The 12,000 RPM motor features an improved rotor design for enhanced power. The unique motor V Seal protects bearings from contaminates while maintaining lubrication and reducing bearing temperature; resulting in longer tool life. The full range throttle is featherable. A speed lever is also standard. A full line of Abrasives, replacement Sanding Pads and various accessories are available to keep your tool in peak performance. No-obligation demonstrations are available on this sander or any tool from Dynabrade. Please call for details. Dynabrade has been supplying quality, American made industrial abrasive power tools for use in industries worldwide for over fifty years

ABB Offers Customized Digital Tools and Start-Up Service As The World Gets Back To Work ABB’s Robotics and Discrete Automation business has launched a special package of digital solutions as well as virtual and field service support initiatives to help businesses restart production lines that may have been idle for weeks or months during the COVID-19 pandemic. As well as helping customers to troubleshoot and fix issues related to robots and operations lying dormant, the offer includes several ABB digital tools to help customers optimize processes and be more proactive in maintenance activities, which will help reduce costs in both maintenance and production areas. ABB Ability Connected Services is ABB’s remote services offering, monitoring the health and performance of more than 9,000 robots in over 1000 factories worldwide. It enables customers to securely integrate and aggregate their data, apply predictive analytics, and generate insights to help drive performance and productivity improvements.

» For more information, visit www.abb.com

Beaumont Machine Offers Improved Response Time on Fast Hole EDM Beaumont Machine has updated its core fast-hole EDM machine, the FH40, with added features, including faster response time. According to company President Ed Beaumont, “Fast-Hole EDM has changed in the past five years from primarily producing cooling holes to the needs on shapes and diffusers. The additional need for a lower recast and virtually no microcracking has become the standard in aerospace. As a result, Beaumont Machine has been working on answers for our customers, focusing on the ability to work REALTIME with our power supply to control interconnection and closed-loop features. Doing so aids in delivering better overall quality for our process.

» For more information, visit www.beaumontmachine.com

BIG KAISER Releases Two New Chip Breaker Inserts For Finish Boring Long chips that are difficult to evacuate can lead to poor surface finishes when chips are dragged around by the tool. Insert life can be severely reduced if these chips are re-cut by the insert, and in smalldiameter applications, stringy chips can wrap around the tool to the point where a crash occurs. The exclusive FLM 3D chip-breaker design is used on PCD-tipped inserts ideal for finishing of aluminum components, where traditional flat-top inserts may produce a large continuous nest of chips that is difficult to remove from the bore and/or tool, even with high-pressure coolant.

Combi-Ventilate – Turning One Ventilator Into Multiple Engineered Ventilation Stations The Irish manufacturer Combilift, best known for its range of space-saving forklifts and other handling solutions, has drawn on its expertise in engineering and software design to develop the Combi-Ventilate, a splitter device which turns one ventilator into multiple ventilation stations. Designed to address the requirements of medical professionals in the current Covid-19 emergency, the Combi-Ventilate was developed by a team of mechatronic and software engineers in the past five weeks with a unit currently undergoing laboratory tests with Ger Curley, Professor of Anesthesia and Critical Care at Royal College of Surgeon’s in Beaumont Hospital.

Coxreels ® Shipping Program Coxreels goal has always been to listen to customer’s needs and the challenges they face. The third generation, family-owned business, has listened to your feedback and has worked tirelessly to deliver the products and services that will help you grow your business. Coxreels has launched “Coxreels Ship Ready”. With more than 80 SKU’s included, Coxreels Ship Ready Program ship all confirmed orders the next business day after you place your order, and if at any time Coxreels can ship it the same day, they will do their very best to make this happen.

» For more information, visit www.coxreels.com/shipready.html

Dillon Fast-Trac Jaw Nuts Provide Quick Change Capability The Fast-Trac Jaw Nuts convert standard chucks into quick change chucks, reducing jaw change time by 50 percent or more. This proven system allows users to preassemble the jaws required for the next operation while the machine is running a separate job. This minimizes jaw change time while maximizing productivity and profitability. Quick change capability allows more productivity per square foot of manufacturing space by productively using machining time, which is ideal for facilities operating with fewer employees due to social distancing requirements. They are ideal for workholding applications requiring durability and high strength such as high-speed machining.

» For more information, visit www.dillonmfg.com

Cutting Tools for Maintenance and Repair (MRO) The team at Dormer Pramet has created a specific selection of cutting tools and accessories aimed at the MRO professional. The brands within this offer are Precision Twist Drill (PTD), Union Butterfield and Dormer. Targeted at delivering MRO professionals an offer that is easy-to-select and comprehensive for their needs, our experts have identified drills, taps, dies, reamers, end mills and rotary burrs that will deliver reliable and cost effective results in portable and machine applications in a wide range of operating conditions in various materials.

ESAB Cryo-Shield Ni9 Flux Cored Wire Offers Crack Resistance, Lowers Total Cost For Lng Fuel, Storage Tank Applications This modified 625-type wire offers excellent crack resistance and is superior to conventional NiCrMo-3 wires. Mechanical properties are similar to Hastelloy ENiMo-13 flux cored wires but at lower purchase price because of its modified formula. Further, because it uses 100% CO2 shielding gas instead of an argon blend, it lowers operating cost. The wire carries approvals from the ABS, BV, DNV GL, KR, LR and CCS classification societies. ESAB offers Cryo-Shield Ni9 in 1.2 mm diameter and packaged on 300 mm wire baskets or plastic spools.

TheBestTool Cabinet You Will 1 0 0 % M A D E I N T H E U S A EverBuy

GUARANTEED I N E V E R Y W A Y

MADE BY AMERICAN CRAFTSMEN IN THE USA WWW.STORLOC.COM • 1-800-STORLOC 1-800-786-7562 sales@storloc.com

No Drip Spray Nozzles Sanitize, Clean and Cool While Conserving Liquid EXAIR’s new 1/2 NPT No Drip External Mix Air Atomizing Spray Nozzles work in the same way our standard atomizing nozzles do,but have the added benefit of positively stopping liquid flow when compressed air is shut off. External Mix Air Atomizing Spray Nozzles have the highest flow rates and allow the air and liquid flow to be adjusted independently. They can be used on liquids above 300 centipoise. The patented No Drip design requires no additional airline to control the No Drip feature. Like any of EXAIR’s spray nozzles, these are ideal for sanitization, decontamination, cooling, cleaning, dust mitigation, coating or humidification.

» For more information, visit www.exair.com

HEIDENHAIN’s Rugged New GAGE-CHEK Now Available for Today’s Basic Metrology Applications With its rugged industrial design, HEIDENHAIN’s new shop-floor hardened GAGE-CHEK 2000 evaluation electronics box is now available. Offered as a plug-and-play embedded system along with HEIDENHAIN-brand encoders including length gages, this solid metrology unit provides reliable basic measurement of 1D values. The new GAGE-CHEK 2000 is well suited for positioning tasks on many applications, from typical measuring rooms to a harsh production environment. Built on HEIDENHAIN’s next generation DRO software and hardware, the GAGE-CHEK 2000 offers a simpleto-view readout and up to 3-axis inputs.

» For more information, visit www.heidenhain.us

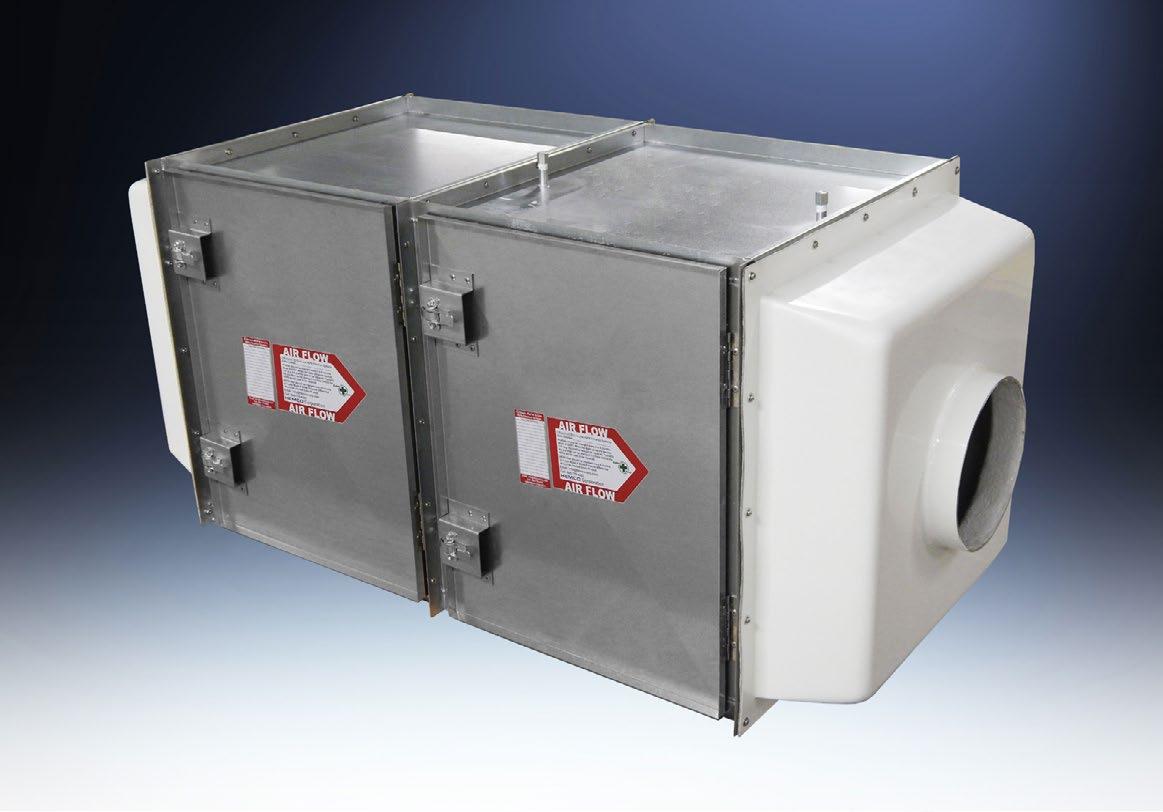

Clean Aire HEPA and Carbon In-Line Filter Paks CleanAire HEPA and Carbon Filter Paks are designed to be mounted inline in the exhaust ducting from a fume hood or contaminant source up to 1500 cfm. The filter pak includes a galvanized steel housing with hinged and gasketed access door for filter change-out and molded composite resin inlet and outlet plenums with duct connection collars sized to meet specification. Both filters include a 30% pleated prefilter and can be paired together for applications that require particulate and fume removal.

Electrically Heated Pit Furnace L&L Special Furnace Co., Inc. has manufactured a fourth high-uniformity, pit-style furnace used for annealing. This furnace has been supplied to an industry leader that manufactures aerospace fasteners and supplies to a worldwide client base. The annealing process occurs when the parts are evenly heated to 1,400°F / 760°C and held for a predetermined amount of time. Temperature uniformity is critical to this process, and both ambient and load temperature must maintain ±10°F throughout the cycle. There is a five-horsepower, air-cooled turbo convection fan included to aid in temperature uniformity.

Mate Precision Tooling Announces Availability Of Custom Press Brake Tooling Mate Precision Tooling now offers modified standard and custom Press Brake Tools that supplement its extensive range of standard hardened and precision ground Press Brake Tools (PBT). While Mate’s standard tools fulfill the needs for most fabricating operations, bending variations may require modifying the angle of a standard punch or die a few degrees. Sometime the angle of the standard punch or die needs to be modified. This is easily accomplished because the induction hardening depth is 3mm-4mm (.118 in - .157 in). This allows material removal to modify an angle or change a radius without jeopardizing the structural integrity of the tool.

» For more information, visit www.mate.com

IF YOU HAVE AN EDGE… WE HAVE A TRIM!

Let Us Help You Find the Right Trims and Seals

Burnishing Tools for Varied Applications Easy-to-Use Tools Eliminate Secondary Operations and Set-Ups Monaghan Tooling Group presents the full line-up of Elliott Tool Technology burnishing tools, which produce a 4 to 8 Ra surface finish in one pass, thus eliminating secondary machining operations and their requisite set-up time and costs. With tooling to burnish ID, OD, ID/OD and flat surfaces, Monaghan has the capability to handle virtually any burnishing project. By improving surface irregularities and tool marks, these easy-to-use tools also eliminate secondary machining operations such as grinding, honing and polishing, thus cutting project costs and lead times. Fast cycle times mean that burnishing projects are measured in seconds, not minutes.

HEADQUARTERS

6855 HERMOSA CIRCLE BUENA PARK, CALIFORNIA 90622

MIDWEST MANUFACTURING

1642 GATEWAY COURT ELKHART, INDIANA 46514

WWW.TRIMLOK.COM INFO@TRIMLOK.COM

New Norton Disc Grinding Wheels Offer Over 30% Longer Wheel Life and Consistent, Superior Perfomance. Saint-Gobain Abrasives new Norton Stellar inserted-nut grinding wheels for double and single disc grinding offer improved wheel life, increased parts per wheel and lower cost per part. The new grinding wheels are ideal for a wide range of industries including automotive, bearing, tool manufacturing, compressors, knife blades and job shop/ general machining. The new wheels also have an improved material removal rate of more than 15 percent. Norton Stellar wheels are available in Norton's range of high performance grains and bonds, including the most cutting-edge ceramic grains and advanced bond technologies.

» For more information, visit www.nortonabrassives.com

Ultrasonic Finishing Tool from Palmgren The Ultrasonic Finishing Tool from Palmgren is perfectly designed for micro filing and polishing solutions. With its lightweight and ergonomically designed ultrasonic handpiece and powerpack, it can polish and deburr in hard to reach, intricate places. The handpiece on the #9650004 utilizes an advanced high-performance oscillating unit and features a removable curled power cord for easy storage. The powerpack provides a wide range or operational frequencies. The tool comes with an optional finishing kit featuring a complete selection of diamond files and ceramic polishing stones. Now observing its 100th anniversary, Palmgren is a C.H. Hanson brand.

OPEN MIND to Feature Advanced hyperMILL ® CAD/ CAM Software Suite The latest versions of hyperMILL ® encompass a wide range of user-friendly enhancements and important new machining

strategies, further advancing the capabilities for accurate, efficient

3D and 5-Axis machining. Developed with Industry 4.0 in mind, hyperMILL ® VIRTUAL Machining features a VIRTUAL Machining Optimizer which provides innovative solutions over and above

simulation and identifying error conditions. These capabilities improve toolpaths that are traditionally calculated in the CAM engine, and incorporate knowledge of the part model, tooling, the toolpath calculation and collision check engine, and the machine tool model with its physical constraints.

» For more information, visit www.open-mindtech.com

Rockford Systems Introduces New Line of Cough and Sneeze Shields The COVID-19 pandemic is causing businesses to take extra precautions for the well-being of employees and customers. Rockford Systems is helping organizations protect employee health and safety by launching its new GermBlock™ line of cough and sneeze shields. GermBlock shields limit the spread of airborne droplets resulting from coughing, sneezing or speaking from reaching a nearby person, therefore helping to mitigate possible COVID-19 infection. Constructed of heavy-duty clear 3/16" polycarbonate and 16-gauge 304 stainless steel ¾" framing with full penetration welds, the shields are offered in tabletop, floor standing and extended-leg versions in popular sizes.

» For more information, visit www.rockfordsystems.com

Schweiss Doors Rolls Out Updated Brochure on Bifold Doors Schweiss Doors has published a new brochure designed to help contractors, architects and building owners make the best decisions when it comes to bifold and hydraulic doors for their projects. The 36-page brochure covers door comparisons, liftstrap bifolds, strap latches, greaseable hinges, hydraulic doors, hinges, power units, wind pins and remotes. Schweiss Doors is the premier manufacturer of hydraulic and bifold liftstrap doors. Doors are custom made to any size for any type of new or existing building for architects and builders determined to do amazing things with their buildings, including the doors. Schweiss also offers a cable to liftstrap conversion package.

» For more information, visit www.bifold.com

IF YOU HAVE AN EDGE… WE HAVE A TRIM!

Let Us Help You Find the Right Trims and Seals

Scotchman Industries Introduces New PressPro Hydraulic Press Line Scotchman PressPro Hydraulic Presses are industrial-grade and ideal for fabrication, bending and forming, straightening, assembly, maintenance operations, testing and quality control. The open side frame design allows for material to pass through and provides flexibility to work on the longest work pieces. The adjustable H-frame bed height offers increased versatility with its ability to raise and lower the table for the best working distance possible. Equipped with a pressure regulator, 3 ram speeds, and an easy to use joystick operation; Scotchman PressPro shop presses provide fine control for precision pressing for many years of productivity.

HEADQUARTERS

6855 HERMOSA CIRCLE BUENA PARK, CALIFORNIA 90622

MIDWEST MANUFACTURING

1642 GATEWAY COURT ELKHART, INDIANA 46514

WWW.TRIMLOK.COM INFO@TRIMLOK.COM

Seco Tools New Duratomic ® TM Grades for Stainless Steel Turning The expanded range of TM inserts also includes new geometries with chipbreakers optimized for finishing and medium-roughing applications in stainless steel. TM1501 is designed for the highest level of speed, productivity and wear resistance in stable continuous cut applications for austenitic stainless-steel components. The firstchoice grade for any low to medium-alloyed stainless steel, TM2501 excels as a general grade that provides long tool life and toughness across the widest application area. And a brand-new grade for the toughest high-alloyed stainless steels, including duplex and superduplex stainless steels, TM3501 also offers good performance across all stainless-steel applications.

» For more information, visit secotools.com

Suhner Offers Newly Designed Version of BEX 15 Suhner Industrial Products introduces its machining unit BEX 15 with maximum spindle speed up to 23,000 RPM, thus offering higher speeds and improved production inline. Standard variations are equipped with electric motors of 0.55 kW, 0.75 kW and 1.5 kW. An adapter flange is designed for the installation of multiple spindle heads and angle heads. A new style timing belt drive multiplies the motor speed up to 13,050 RPM spindle speed. An AC inverter drive is used to increase the spindle speed up to 23,000 RPM at 87 Hz.

New Sinamics G120 Smart Access Wireless Module Simplifies Drive Commissioning, Parameterization and Maintenance Siemens has expanded its Sinamics G120 drive series to include an option for wireless commissioning and service. The new Sinamics G120 Smart Access module enables wireless connectivity of mobile devices such as tablets, smartphones and laptops over Wi-Fi to Sinamics G120 and Sinamics G120C drives. The module is setup in a few easy steps using a standard web browser and any standard operating system. Its built-in web server functionality eliminates the need to download additional software, and with its intuitive user interface and menu, the Smart Access module offers users outstanding convenience.

» For more information, visit www.siemens.com

With TAB Wrapper Tornado, Each Operator Gets Own Controls To minimize worker contact and support compliance with social distancing guidelines in the workplace, packaging machinery manufacturer TAB Industries, LLC has unveiled an optional, wireless, remote control package on its TAB Wrapper Tornado orbital wrapping systems that assigns a single, personal remote control to each forklift driver who operates the wrapping machine. Synching multiple remote controls to the same orbital wrapper, the new capability ensures each hand-held device remains with each operator at all times to prevent transfer from person to person and virtually eliminate the potential for cross-contamination.

» For more information, visit www.tabwrapper.com

New Quickpierce Consumables From Thermal Dynamics ® Reduce Piercing Time By Up To 40 Percent On Thick Steel Thermal Dynamics ® Automation has upgraded its 400-amp cutting system — featuring Ultra-Cut ® 400 XT high-precision power source, XT torch with QuickPierce consumables and iCNC

Performance Controller — to reduce piercing time by up to 40 percent on mild steel thicknesses ranging from 1.25 to 2.0 (30 to 50 mm). Faster piercing time reduces cycle time, especially for plates with a complex parts nest. Thermal Dynamics further improved consumables life by adding pierce-on-the-fly and pierce-puddleavoidance routines within its iCNC Performance Control. Piercepuddle-avoidance also extends consumables life by preventing the front end of the torch from touching the puddle during arc start.

» For more information, visit www.thermal-dynamics.com

Wildeck, Inc. Launches 2-Day Shipping for Guarding Products Wildeck, Inc. is pleased to announce effective June 1, 2020, stocked guarding product orders less than $5,000 (list price) will ship in two days. Simply place your order prior to 12 PM CST and that order will ship on the second business day. Customers may contact their Wildeck sales representative directly for quick-ship options for orders greater than $5,000 (list price). Wildeck manufactures a full line of guarding products, including steel guard rails, end-ofaisle protectors, rack upright protectors, bollards, shelving guards, machine guards and much more. All products are made in the USA.

» For more information, visit www.wildeck.com

New Thread Former From Walter for High Production With a Lower Cost Per Thread Walter has introduced the TC470 Supreme solid carbide thread former, an innovative approach to thread forming that combines a new geometry with more forming edges than comparable thread formers. The new thread former features a new coating and surface treatment for better tool life, higher productivity, and increased process reliability in large batch and high-volume production while achieving a lower cost per thread. Intended for blind hole and through hole threads and thread depths up to 3.5 x DN in steel, it has also shown good results in machining cast iron and aluminum.

» For more information, visit www.walter-tools.com

YAMAHA Intelligent Machinery Expands Industrial Robotics Line-Up The YAMAHA industrial robotics group of the Intelligent Machinery Division announces the addition of the new YK610XE-10 (610mm arm length) and YK710XE-10 (710mm arm length) models to the YK-XE Series of SCARA robots. The two new models build on the high motion performance and low cost of the current YK-XE Series. Both models deliver high performance, with 10kg maximum payload and standard cycle time of 0.39 seconds (YK610XE-10) or 0.42 seconds (YK710XE-10), contributing to higher productivity. Additionally, the accessible pricing for these models enables developing production facilities with high performance at lower cost

DP Technology Announces Support for Additive DED Manufacturing The DP Technology teams are proud to announce the very first commercial version of ESPRIT that includes additive direct energy deposition (DED) cycles. ESPRIT’s additive capabilities are the product of the team’s more than 35 years of experience in toolpath generations, and they include the same intuitive user interface that users expect from the software. The product release includes 3-axis, 4-axis, and 5-axis DED support. Combined with the subtractive processes and embedded into a single software, DP Technology brings a full spectrum of support to hybrid manufacturing.

» For more information, visit www.espritcam.com

Mastercam 2021 is Now Released As more shops continue to rely on streamlined multiaxis cutting for single-setup precision, Mastercam 2021 adds new techniques and strategies. Expanded Multiaxis Pocketing combines efficient pocket cutting with a focus on finishing with Accelerated Finish tools, automatically maintaining the correct tool contact within defined parameters. Mastercam now gives you the ability to analyze and modify the UV direction on surface models, expanding the power and flexibility of multiaxis flowline milling toolpaths. Mastercam Mill-Turn supports collet chucks as individual component types which greatly expands the range of machines that can be directly supported.

KASTO Provides Unmanned Handling of Sheet Metal KASTO’s new and cost-effective sheet metal manipulator is suitable for separating sheets, feeding various processing machines and removing good parts and remnants. It is equipped with a vacuum cross bar, which picks up individual sheets in pre-prepared packages from the storage facility and places them on the table of the respective processing machine. The lasered individual parts and the residual sheet skeleton can also be removed from the working area of the machine using the rake cross bar. This permits unstaffed production at high throughput speeds and relieves staff of the laborious and potentially risky task of handling the large-format sheets.

» For more information, visit www.kasto.com

Starrett Introduces High Throughput Rotary Table Springs Force Tester The system is setup to test multiple springs in a single setup without the need for additional operator input as required when springs are tested one by one. The batch testing volume production approach saves time, and significantly increases test throughput, while freeing up the operator to attend to other jobs. Multiple springs can be loaded and tested in the Rotary Table Force Tester System, and the system will provide a pass/ fail report on each spring. Detailed information on each spring is also available including free length, spring rate, and critical load and distance points.

» For more information, visit www.starrett.com