Going Beyond the Basics to Ensure Quality

IndustrialMachineryDigest.com | Q4 2022 The Industrial Machinery Digest Robotics & Automation Quarterly Resource! Special Purpose Machine Manufacturer Invests in Renishaw Alignment System to Expand Its Capabilities Emerson Bearing Company of Boston Shares Tips on How to Prevent Costly Breakdowns and Extend V-Belt Life & Efficiency Ovention® Upgrades Drives on Fast Cooking Oven Lines Faster programming and commissioning are achieved with five-minute assembly time reduction, improved safety and easier service in the field from the use of Siemens drives.

Collaborative

Potential dangers can arise when manufacturers use cobots for tasks that would be better performed by industrial robots.

The High Price of Misusing Low-Cost

Robots

DRILL. TAP. REPEAT. Engineer ed Tough for Year After Year Relia bility H Y PNEU M AT. C O M • 414 - 423 - 740 0 Automatic Drilling and Multiple Spindle Heads

manufacturers air tools for use with

systems.

Disc

and

Tools are

our

product

to air tools, we offer accessories and abrasives for complete process solutions with

to

demonstration on any product in our line. WE LISTEN. WE OBSERVE. WE OPTIMIZE. ABRASIVE POWER TOOLS & PROCESS SOLUTIONS SINCE 1969 Dynabrade, Inc. | 1.800.828.7333 | dynabrade.com | AUTOMATION SOLUTIONS DYNABRADE ROBOT- ATTACHABLE AIR POWERED TOOLS

Dynabrade

automation

Random Orbital Sanders, Finishing Tools, Grinders,

Sanders,

Abrasive Belt

just a sample of

new

offering for robotics. In additional

the know-how

get the job done right. Ask about a no-obligation

4 | IMDQ | Q4 2022 DEPARTMENTS 6 EDITORIAL DIRECTIONS 8 INDUSTRY NEWS 32 PRODUCT SHOWCASE 44 BUYER'S GUIDE FEATURED 49 SURPLUS GUIDE FEATURED 52 SURPLUS BUYING & SELLING 56 CLASSIFIEDS 57 ADVERTISER INDEX ON THE COVER Cover Photo: Courtesy of Siemens FEATURES 14 CASE STUDY Special Purpose Machine Manufacturer Invests in Renishaw Alignment System to Expand Its Capabilities 16 COMPANY PROFILE Emerson Bearing Company of Boston Shares Tips on How to Prevent Costly Breakdowns and Extend V-Belt Life & Efficiency 18 INTEGRATIONS Ovention® Upgrades Drives on Fast Cooking Oven Lines 22 MACHINES The High Price of Misusing Low-Cost Collaborative Robots By Josh Tuttle 28 SOFTWARE/CLOUDWARE Going Beyond the Basics to Ensure Quality By Lindsey Padilla, Director of Quality, Bison Gear & Engineering TAblE OF CONTENTS

Customized Safety Lifting Devices For Any Application SAFELY Lifts Up To 500 lbs! Ergonomic Portable Lightweight Meets OSHA & ASME 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com Available in both CHAIN & CABLE Configurations

Welcome to Q4 of 2022! It’s hard to believe 2022 has reached its end. And while this season is certainly merry and bright, manufacturers around the country are gearing up to meet end-of-year demands ahead of a busy holiday season.

Reaching the end of the year means something else, too, for you – our readers. It’s time for another quarterly edition of Industrial Machinery Digest.

In this issue, you’ll find a case study on specialist machine manufacturer Metecno Oy, who worked with global engineering technologies company, Renishaw, to implement a geometric error measurement systems and ensure it could deliver the best results for large-scale customer projects.

We’ve also featured a company profile on Emerson Bearing Company of Boston, in which they share tips on how to prevent costly breakdowns as well as on how to extend V-belt life and efficiency.

And on the topic of innovative technologies, you’ll find an article by Josh Tuttle, a business development manager at Aerobotix, on the high price of misusing low-cost collaborative robots and how potential dangers can arise when manufacturers use cobots for tasks that would be better performed by industrial robots.

Lastly, you’ll find an article by Lindsey Padilla, the director of quality at Bison Gear & Engineering, on how quality management software enables manufacturers to conveniently (and reliably) track return goods flow and data retention.

As we look ahead to 2023, I’d love to hear from you to learn about which topics you’d like to see covered here between the covers of IMD, as well as who you’d like to learn more about in our features and departments that include case studies, company profiles, expert technical articles, trade show coverage, Q&As, and so much more. Please do not hesitate to contact me with any questions or insight.

Until next time, we hope you have a wonderful holiday season and a productive start to the new year!

William Strickland

Publisher, Industrial Machinery Digest wstrickland@indmacdig.com

North America’s Manufacturing Resource for Industry Professionals Since 1986

36 YEARS

William C. Strickland III, Publisher william.strickland@indmacdig.com 800-366-0676 ext. 103 | Fax: 866-826-5918

Anna Claire Howard, Editor-in-Chief achoward@indmacdig.com 800-366-0676 ext. 104 | Fax: 866-826-5918

Shane Bell, Creative Director sbell@indmacdig.com

SALES

Lisa Hanschu, Sr. Account Executive lisa@indmacdig.com 785-965-9159 | Fax: 785-965-7199

William C. Strickland III, National Sales 205-903-9178 | fax 866-826-5918

Adrienne Gallender, Media Adviser agallender@indmacdig.com 888-407-7737

Susan Strickland, Accounting susan@indmacdig.com 205-542-1098 | Fax: 866-826-5918

CIRCULATION & SUBSCRIPTIONS

IMD, 3590-B Hwy 31 South, Suite 233, Pelham, AL 35124 circulation@indmacdig.com | Fax: 866-826-5918 REPRINTS To

6 | IMDQ | Q4 2022 EDiTOR' S CHOiCE SERVING AMERICAN MANUFACTURERS FOR OVER

purchase article reprints please call 800-366-0676 ext. 103 or email wstrickland@indmacdig.com source media llc 360 A PUBLICATION OF: Source 360 Media LLC 3590-B Hwy 31 South PMB #233 Pelham, AL 35124 INDUSTRIAL MACHINERY DIGEST (ISSN 1542-5223) is published 12x per year by Source 360 Media. POSTMASTER: Please send change of address to INDUSTRIAL MACHINERY DIGEST, 3590-B US Hwy 31 South, PMB 233, Pelham, AL 35124. Printed in the U.S.A. SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the U.S. to qualified individuals. Publisher reserves the right to reject nonqualified subscribers. Oneyear subscription to nonqualified individuals in the United States: $9600. Single copies available (prepaid only) $2000 each. Alabama Automotive Manufacturers Association

28 sales@carellcorp.com • www.carellcorp.com sales@eaglebendingmachines.com • www.eaglebendingmachines.com Visit Us Online or Call: (251) 937-0947 Section Bending Machines MEMBER Stradivari 3D CNC Get the Competative Advantage with State-of-the-Art, Reliable Forming Machines Plate Rolls 20 Ga to 6” Capacities, 80 Models CNC Options Angle Rolls 1” to 10” Capacities, 30 Models Custom Machines CNC Options Machines for any job or budget • Superior PLATINUM Warranties Full CNC + Direct Radius Input 1" to 4" Capacities,15 Models, Bar Twist, Scroll & CNC Options Designed for Rapid, One Pass Production! MEMBER SUPPORTER

of Mexico

Representatives from ANCA and Fravic Daunert recently witnessed the signing of the contract at IMTS 2022

Fravic Daunert, a specialist in the distribution and commissioning of machine tools and accessories was developed with the union of two companies, the Fravic Group and Daunert Machine Tools. The first is a company that is established in the industrial sector that focuses on distributing machine tools including turret lathes, Swiss lathes, machining centers, CNC grinding machines, and much more. The second is a Spanish company, based in Barcelona that has specialized in the distribution of machine tools and accessories in a variety of industries for over 105 years.

According to Guillermo Ramirez, the CEO in Mexico of Fravic Daunert, the partnership between Fravic Group and Daunert Machine Tools was established a year ago to "serve the Mexican market with brands that Daunert represents in Europe." To ensure proximity to local industry, Fravic Daunert has two offices in Mexico, one in Sahagún City, Hiladgo state and another in Queretaro State.

With a 2020 manufacturing output of $232 billion in Mexico, ANCA knew that they wanted to grow the company’s presence in the country. ANCA President, Russell Riddiford said, “ANCA is already established in the Mexican market, with over 160 machines installed around the country, but we know that the manufacturing industry in Mexico is a strong market for us, and we want to make sure we focus on continued growth in the region.” What better way to continue that growth, then to partner with a company you trust?

INDUSTRY NEWS

ANCA has been well represented by Daunert in Spain for many years. The partnership is already established, and proven, so the decision to partner with them in Mexico was simple. The partnership between ANCA and Fravic Daunert in Mexico has been in the works for months, but it was finalized in September at IMTS 2022 in Chicago, IL. Fravic Daunert will distribute the entire range of ANCA products, including ANCA’s world class CNC tool and cutter grinders, as well as the accessories that accompany them.

Present at the signing was Mr. Riddiford, as well as Mr. Ramirez, and brothers Fritz and Max Daunert, from Fravic Daunert. Fritz is the vice president, while Max holds the position of general manager. Sales representatives will promote and represent ANCA products in San Luis Potosi, Guanajuato, Queretaro, Aguascalientes, Puebla, State of Mexico, Mexico City and Tlaxcala in conjunction with ANCA regional manager, Denny Smaic.

This partnership with ANCA is significant because it is, "A great opportunity, since in the Mexican market ANCA machines are widely used in the automotive, aerospace, medical and electrical industry for companies to manufacture their own tools." This allows a reduction of costs, as well as greater efficiency and probability. Ramirez concluded, "This in the long run has a very positive impact on the economy and productivity."

8 | IMDQ | Q4 2022 iNDUSTRy NEwS

WANT TO BE FEATURED? Send your press releases to editorial@indmacdig.com www.IndustrialMachineryDigest.com Streamlining Credential Processes Bringing Global Technology to a Local Level Manufacturing IndustrialMachineryDigest.com October2021 MANUFACTURING SHOWCASE: FEATURED STORIES: Cincinnati, Inc. IMPACTING DROP ZONE Wildeck Provides Increased Safety for Moving Palletized Loads the » Empowering Employees » Surpassing Energy Savings Manufacturer in Oxnard, CA experiences the benefits of Green Hydraulic Power Units » Lifting Higher Combi-PPT - A High Capacity Powered Pallet Truck Streamlining Control Siemens Offers Optimized Control Panel Construction to Machine Tool Builders IndustrialMachineryDigest.com March 2019 IndustrialMachineryDigest.com June2021 ESTABLISHED IN 1986 AND IS THE INDUSTRY’S Most Extensive Industrial Publication. GETTING BACK TO WORK!! 2021 INDUSTRIAL MACHINERY DIGEST’S

industrial Machinery Digest's industry News features the latest news and press releases from some of the industries top companies.

Fravic Daunert signs contract with ANCA to distribute its products in portions

TEXTILE

is exclusively distributed in the US and Canada by Do you often move loads with surfaces that require protection? Then it is essential to avoid damage by lifting means at all costs. The solution: the new TXP-Texolution-Point. Its round sling reliably protects high-quality surfaces. Damaging contacts between lifting means and load surface are practically no longer an issue. And that with guaranteed total WLL. This preserves values and increases efficiency.

WORLD’S FIRST! First textile lifting point with tested and guaranteed total WLL. THE NEW TXP-TEXOLUTION-POINT.

MEETS STEEL. solutions.rud.com

InspecVision Planar: A High Speed Integrated 2D and 3D Measurement System

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, represents Planar from InspecVison. This 2D inspection machine allows manufacturers to simply and quickly verify product quality by performing 2D inspection, CAD comparisons and reverse engineering in seconds.

Planar is ideal for shop floor use, requires minimal operator input and increases production throughput across a wide range of applications. These include flat and folded/formed sheet metal components, gaskets and seals, laminations, O-rings, paper acetate and electronic drawings and other opaque and semi-transparent flat materials.

A standard feature on every Planar system is 2D reverse engineering. Existing parts can be reverse engineered quickly, creating dxf or dwg CAD files. The software allows the user to edit and clean the data such as standardization of hole sizes and clean edges and eliminates the need for hand measurement and CAD programming. Physical parts or even paper, acetate or electronic image files can be reverse engineered to create CAD files. Furthermore, reverse engineering processes can also be carried out in 3D using optional 3D modules. For full 3D capability, users simply add Opti-Scan 3D, while the SurfScan module extends Planar to 2.5D.

Opti-Scan 3D is a non-contact white light scanning system that uses a high speed, high resolution camera and an LED DLP projector to scan the surfaces of an object. Patterns of light are beamed from the projector onto the part, recorded by the camera and used to create a 3D point cloud of the scanned surface. The Opti-Scan 3D outputs the ultra-high resolution points into a number of different file types which can be used in virtually any 3D inspection or reverse engineering software package.

SurfScan integrates seamlessly with the Planar 2D automatic inspection software to allow accurate inspection of both the part’s 2D shape and its 2.5D features with a single click. The SurfScan is a high resolution projector which mounts onto the existing Planar vertical column. The projector shines structured light on the part which is then imaged by the Planar’s camera to create a 3D scan of the upper surface of the part. The point clouds created by the system can then be loaded into free and readily available 3D inspection software for comparison against a 3D solid CAD model. Point clouds are also compatible with Geomagic Control, Control X, Polyworks, etc.

InspecVision Planar offers fully automated one click inspection with machine sizes ranging from 500m to 3000mm. The machine is scratch resistant, features no moving parts, has simple calibration and minimal maintenance, requires minimal training and offers rapid return on investment.

Bruce Williams Starts New Chapter at Exact Metrology

Formally the president of Accurate Pattern Inc., a Wisconsin patternmaker, Williams works as a trainer for the company’s educational initiative

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, has hired Bruce Williams at their Brookfield, Wisconsin location to help customers with their metrology applications.

His educational background includes attending Milwaukee Area Technical College and Phoenix University (Brookfield, Wisconsin). Williams’ first job was in 1974 at J.P. Pattern Inc. (Butler, Wisconsin). For eleven years, he had several roles in the company including patternmaking journeyman, sales and supervisor. In 1985, Williams started working at Premold Corporation (Oconomowoc, Wisconsin), working sales and as a general manager. From 1985 to 2021, he was the founder/president of Accurate Pattern Inc. (Butler, Wisconsin). They specialize in wood, metal and plastic patterns. Although Williams decided to retire in 2021, he works as a manufacturing adjunct instructor at Waukesha County Technical College (Pewaukee, Wisconsin).

Once he decided to “retire,” Williams reached out to Greg Groth, Exact Metrology applications engineer and Dean Solberg, vice president of metrology, both of whom he has had long business relationships with. He commented that “I have always admired Dean and Greg in their technical expertise and the culture they promote.” He is excited to work as an Exact Metrology trainer, specializing in 3D Systems Design X reverse engineering software.

Exact Metrology offers training options on all hardware and software options related to digitizing, reverse

10 | IMDQ | Q4 2022

engineering, measurement and metrology. In his role, Williams will lead the recently implemented educational initiative for the company. This will involve working with schools of all types as well as multiple trade associations to help educate the current and future workforces on the application of advanced metrology, especially robots and cobots, CT technology and advanced laser scanning in the quality area at all types of companies across America. The educational initiative means that, “The training is specific to each customer with small in-person classes. The instructors are experts in the field and use practical examples including the customer’s own parts and data.”

Describing the experience, Williams commented, “This is a great place to share my years of pattern/tooling experience in combination with the latest technologies in metrology and modeling. It is satisfying to see customers and colleagues succeed as we help each other.”

In the future, he plans to keep learning and growing with others through his teaching, work at Exact Metrology and industry involvement.

Gaubert Oil Launches New Website

Gaubert Oil Company, Inc., a leading provider of fuel, lubricants, chemicals and related services to industries in the Gulf South, announces the launch of their new corporate website, gaubertoil.com.

“We are excited to share Gaubert Oil’s new website with our customers,” said Ron Gerlach, Director of Marketing for Gaubert Oil. “The transition from the former website to our enhanced platform was carefully strategized and implemented to ensure our visitors receive an even better experience.”

Founded in 1926, Gaubert Oil provides comprehensive, on-time delivery with a full range of storage, handling, and on-site lubrication services. The new website features a full redesign with updated content, all-new navigation and important information for Gaubert Oil’s customers and partners.

“The new website provides a convenient platform for seamless interaction, quality information and expert advice,” Gerlach said.

Gaubert Oil Company, Inc. invites visitors to gaubertoil. com to experience all-new market and product-specific content, products and services, company history and more.

Sandvik Coromant and NAIT Renew 15-Year Partnership

Sandvik Coromant and NAIT celebrate the renewal of a long-standing 15-year partnership through 2025 Sandvik Coromant and NAIT (Northern Alberta Institute of Technology) recently celebrated a 15-year partnership with a new contract extension that will be in effect until Dec. 31, 2025. The partnership was officially signed and agreed upon before an awards ceremony hosted by Sandvik Coromant and NAIT in Edmonton in October. Representing Sandvik Coromant during these proceedings were Magalie Jackson, Canada General Manager, Alex Durkovics,

Channel Marketing Manager, and Jim Cordoviz, Sales Regional Manager.

“Education has always been at the forefront of Sandvik Coromant, whether with the customer, with our partners and even in the academic space, in order to develop the future of manufacturing,” said Alex Durkovics, channel marketing manager for the Americas. “We're proud to have a positive influence in Western Canada through our long-term and continued partnership with NAIT, empowering students with the tools, knowledge and passion for a positive impact on the future of industry.”

The three-year agreement includes gifts-in-kind for equipment and digital machining applications, as well as a robust scholarship program. A total of 12 scholarships are available to students each year for the five-year period. Eleven awards per year are available to first- through fourth-year students, which are awarded based on academic achievement. The twelfth award is the Sandvik Coromant Leadership award, which is granted to the top student who demonstrates initiative, creativity, leadership with their fellow students and enthusiasm, in conjunction with academic achievement.

“Together, Sandvik Coromant and NAIT have always provided students with a healthy and fair competitive environment to help them grow in every facet of life for almost 15 years,” says Magalie Jackson, Canada General Manager. “As the most recognized school in Western Canada, we are so proud to partner with them. We have given equal opportunities to all our students so that they realize their true potential and get ready to face the outer world once they complete their studies. And we are so pleased to see the recipients of these awards performing and excelling in their respective areas of interest year after year.”

“We are so grateful to Sandvik Coromant for their generosity in providing equipment and educational resources for both the students and staff,” said Vance Monaghan, 2022 recipient of the third-year academic achievement award. “It lifts a huge burden, knowing that we no longer need to be fixated on the cost of tooling. Because of your gifts, we can take creative risks and grow our skills further than what we could imagine possible. Your dedication to and sponsorship of us — the students — has incentivized many people I know to join skilled trades, or at least further appreciate the dedication and skills tradespeople bring that keep our world turning.”

As part of the partnership, the state-of-the-art NAIT Sandvik Coromant Centre for Machinist Technology facility is available for use by all machinist programs for hands-on training, machine time and coursework. Within the Centre are four CNC machinist labs, a metrology lab and a centralized tool crib, as well as smart classrooms, computer labs and office space for both instructors and support staff.

“Sandvik Coromant’s ongoing commitment to NAIT goes above and beyond,” adds Matthew Lindberg, Dean, NAIT School of Skilled Trades. “Not only is Sandvik Coromant a trusted industry partner, they support NAIT’s

INDUSTRIA L MACHINERY DIGEST COM IMD | 11

vision through their support of our students. Because of the contributions of Sandvik Coromant, together we can provide an exceptional learning experience for students and advance our goal to be a leading polytechnic.”

“On behalf of our students, the School of Skilled Trades and NAIT, I offer my sincerest thank you to Sandvik Coromant. I look forward to all that our continued partnership will bring in the coming years.”

Starrett Appoints Director of Operations and Continuous Improvement

The L.S. Starrett Company, a leading global manufacturer of precision measuring tools and gages, metrology systems and more, has recently appointed Mr. Matthew Wells as Director of Operations and Continuous Improvement. In this new position based at Starrett Headquarters in Athol MA, Mr. Wells is responsible for Production, Planning, Production Control and Purchasing, Inventory Management, Warehouse and Shipping, Quality, Manufacturing Engineering, Facility, EHS, Maintenance and Continuous Improvement. Wells reports directly to Mr. Emerson Leme, Vice President, Starrett Industrial Products, North America.

“We are very pleased to have Matt join the Starrett team,” said Leme. “He brings to Starrett a broad range of manufacturing and production expertise that will be vital for the company’s operations.”

Mr. Wells, a Western Massachusetts native, has over 25 years of manufacturing experience in the U.S.A. and Canada, including extensive experience with Toyota Production Systems, Lean Manufacturing and Six Sigma during his tenure at a Toyota motor manufacturing company and The Schaeffler Bearing Group, among other manufacturing enterprises. He has a bachelor’s degree in Mechanical Engineering and a Master of Business Administration, both obtained at Western New England University. He currently resides with his family in Central Massachusetts.

Orbital Wrapper Manufacturer Increases Made in USA Components to 90 Percent

In-House Parts Production Speeds Lead Times for TAB Wrapper Tornado

Orbital wrapping machine manufacturer TAB Industries, LLC, Reading, Pa. (www.tabwrapper.com), has increased the amount of component parts that are “Made in USA” in its TAB Wrapper Tornado line of pallet wrappers to 90 percent. Now manufacturing more than 40 different parts per orbital wrapper in its Reading, PA facility, the company increased the use of in-house and locally sourced components as a key part of its business strategy to help insulate production from global supply chain disruptions and permit faster lead times. Recent investments in fabricating, welding, automated laser cutting, and CNC machining equipment have eliminated reliance on outside suppliers and accelerated lead times by approximately two weeks. Current lead times for the standard model wrapping system are at eight weeks.

First manufactured in 2011 using only [40?] percent of component parts that are “Made in USA”, the TAB Wrapper Tornado orbital wrappers today feature heavy gauge steel wrapping rings, laser cut machine guarding, a variety of latches, clips, and plates, and advanced electronics, all designed, manufactured, assembled, wired, and programmed in-house and delivered ready to plug in and operate. The company's streamlined production capabilities also promote fast delivery of replacement parts.

The TAB Wrapper Tornado line of orbital wrapping machines automatically apply stretch wrap 360 degrees around and under the pallet and load to create a sturdy, secure, unitized load in seconds without banding, boxing or strapping. Testing is offered using customer-supplied pallet loads to verify performance.

West Ohio Tool Gives Back to West Ohio

Continuing its tradition of strong family and deep community roots, West Ohio Tool is paying its success forward. For every new product sold, the company provides 10 meals to families who are struggling to put food on the table. Since the initiative began Sept. 1, the company has donated the equivalent of 950 meals to Feeding America, a national organization with local resources for Ohio families who live in Auglaize and Champaign counties as well as Logan County, which is home for the company.

Kaci King, CEO of West Ohio Tool, has always appreciated how much her parents sacrificed for her. For instance, whether it was factory closings or building the family business that is now West Ohio Tool, King is fully aware that as a child she never went hungry, but her parents did.

“I watched many days that groceries were either stacked on credit cards or Mom and Dad went to bed hungry because starting the business took hard work and money,” recalls King. An organization like Feeding America that lifts up my neighbors goes deep into my soul.”

The West Ohio Tool family of employees have also allocated work time as volunteer time for Second Harvest Food Bank that serves people experiencing food insecurity in Logan County.

Further, King encourages employees to follow their personal passions for service. West Ohio Tool provides up to two paid days off to team members who volunteer with area community service organizations.

“When any of us invest our time with an organization in our community, it means we are putting feet to our fire,” King said. “And I want the warmth of the fire to spread in our community.”

12 | IMDQ | Q4 2022

SAVE THE DATE | MAY 10-11, 2023 OREGON CONVENTION CENTER PORTLAND, OR INNOVATION. TECHNOLOGY. GROWTH. OWNED & PRODUCED BY: FOR EXHIBITING INFO, CONTACT JOYCE LORTZ: JLORTZ@FACILITIESEXPO.COM | (410) 598-3535 REGISTER AT: MACHINETOOLEXPOS.COM

Special Purpose Machine Manufacturer Invests in Renishaw Alignment System to Expand Its Capabilities

To ensure that it could deliver the best results for large-scale customer projects, specialist machine manufacturer Metecno Oy worked with global engineering technologies company, Renishaw, to implement a geometric error measurement system. By investing in Renishaw’s XK10 alignment laser system, Metecno Oy was able to bring more quality assurance processes in-house, meeting specifications for new customers, whilst expanding its capabilities to deliver high-quality machines.

Background

Founded in 2008, Metecno Oy is a Finnish, family-owned special purpose machine manufacturer with expertise in CNC machines, automation design and robotic integration. Its team of 12 people provides companies with customised machine and automation solutions on a turnkey basis, designing and building production machines that enhance companies’ production, including machine tools, machining centres and milling machines. Because the company supplies solutions to any manufacturer in need of a specialised production machine, Metecno Oy has worked with various industries, including nuclear, metal, rubber, mining and food production.

Metecno Oy is one of the very few manufacturers in Finland that designs and builds bespoke CNC machines. As a result, the business has grown rapidly since its inception, with a record turnover of €1.2 million in 2021 and a promising outlook.

Challenges

A manufacturer approached Metecno Oy with requirements for a customised CNC machine that was much larger than the systems that the team at Metecno traditionally builds. The customer also had very specific tolerance and surface quality requirements.

Accuracy is vital when developing machinery - the operation of the machine could be affected if it is built incorrectly. For example, milling machines feature linear guides to manoeuvre the machine table across each axis. If errors occur when assembling the machine frame to other parts of the machine body, it could move the guides out of tolerance. While minor inaccuracies might not impact product quality, it could reduce the lifetime of the machine. Additionally, once manufactured, the team at Metecno Oy mounts the machine to the floor at the customer site, which can impact the rest of the machine.

As well as ensuring the axes are accurate, CNC

manufacturers such as Metecno Oy must consider the perpendicularity of the spindle. If this is not square, it will leave cutter marks on the workpiece, negatively affecting the surface finish of machined parts.

“All the special purpose machines we manufacture must pass strict quality management processes before they are delivered to the customer,” explained Mikko Similä, System Design Engineer at Metecno Oy. “To ensure we deliver accurate and reliable machines, we typically outsource quality checks to a subcontractor. While this works for our smaller machines, when we received the brief for the larger project with tighter tolerance requirements, we knew we wanted to find a way to measure in-house so that we could deliver a high-quality machine and correctly predict its lifespan.”

Solution

After reviewing different market options, Metecno Oy concluded that the Renishaw XK10 alignment laser system would be the best, most cost-effective solution.

The XK10 system has been developed to measure geometric and rotational errors of machine tools. Using the system alongside its machine tool fixturing kit enables faster and easier measurements compared to traditional methods, such as dial gauges. Measuring geometric and rotational errors during machine build, maintenance and service enables accurate alignment and adjustment of machine axes to achieve optimum performance. This

14 | IMDQ | Q4 2022 CASE S TUDy

reduces time during machine assembly processes and on-site service, including regular maintenance or following a collision. The XK10 can also measure the angle at which a spindle or chuck is pointing, ensuring accurate alignment through a complete 360° rotation.

“The XK10 system has enabled us to improve our measurement processes for larger machines,” explained Similä. “During this project we used the XK10 to measure the machine during assembly to check the axes are straight along the axis of travel and measure the machine once installed. With more familiarity of the process, we can monitor external factors that can influence the measurement, such as the effect of environmental changes. We can easily input test parameters into the XK10 display unit and use the versatile fixturing kit to simply check a range of measurements. We have also identified where we can use the XK10 system on future machinery.”

“While using a subcontractor enables Metecno Oy to ensure all its bespoke machinery delivers quality, when speaking to the team, we knew that bringing some measurement processes in-house could benefit the manufacturer and its customers,” explained Isto Tuomisto, Renishaw’s Area Sales Manager for Finland. “The XK10 was developed to make building machines easier. The team got to grips with the system very quickly after installation, which will enable the Metecno team to deliver this machine quickly and efficiently. Checking

alignment during construction on this project ensures that any errors are identified and adjusted before the machine is built, when they are much more difficult to correct,” continued Tuomisto.

Results

“Investing in the XK10 enables us to validate machine accuracy at multiple points,” stated Similä. “This was particularly useful during this project because, once complete, we will have to disassemble the machine to transport it to the customer site. After rebuilding the machine on the shop floor, we can use the XK10 to check the machine again, reassuring the customer that they have received an accurate machine.”

“While this project is still ongoing, we have already seen positive outcomes from investing in the XK10 alignment laser system - we have noticed improvements in accuracy, time savings and a reduction in costs. As a result, we have already seen a return on our investment. Additionally, we can now accept more large-scale projects with the confidence that we can deliver quality and accuracy. Now that we have seen the capabilities of the XK10, we plan to explore how we can use other Renishaw systems to bring more quality assurance processes in-house,” concluded Similä.

For more information visit, www.renishaw.com/xk10

•

•

INDUSTRIA L MACHINERY DIGEST COM IMD | 15

IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

CNC MILLS | CNC LATHES | CNC PLASMA TABLES | CNC ROUTERS | INDUSTRIAL ROBOTS | AUTOMATIC FEED BANDSAWS NEED A SECOND OPS PART MAKER OR A PERFECT PROTYPING MACHINE? Make one-off and small batch parts in-house while your bigger machines handle production.

With its compact size, the 1100MX sneaks into unexpected places. With servo motors and a BT30 spindle, it’s built to mill anything. Set it up, make chips, and cut parts.

•

Our

runs on our intuitive and easy-to-use CNC controller, PathPilot®. A short learning curve is a real dealmaker.

1100MX

Feel free to build out the machine you want because it’s modular, so you can include options like an ATC, PathPilot Operator Console, or a microARC 4 4th Axis table whenever you want. Learn more and build yours at tormach.com/1100MX/IMD

Emerson Bearing Company of Boston Shares Tips on How to Prevent Costly Breakdowns and Extend V-Belt Life & Efficiency

Choose the right V-belt and properly install it to help maximize your component's longevity and reliability.

Often undervalued, an important component of many industrial and manufacturing systems is the V-belt. Optimizing V-belts is critical for extending their life, increasing system efficiency, reducing the need for frequent maintenance, and preventing costly breakdowns.

V-belts are versatile components that transmit power in mechanical systems between sets of grooved sheaves or pulleys. They feature a trapezoidal cross-section and are the most popular belt drives. Their unique geometry, which causes the fit in the sheave or pulley to tighten with increased tension, is a big part of the reason for their widespread use.

When wedging the belt into the groove, there's an increase in friction between the belt's surface. This allows for the transmission of high torques. The increase in friction also prevents slippage, which would otherwise cause a greater loss of power. Additionally, in applications where V-belts often slip, many operators find that their bearings prematurely fail. Increasing V-belt life will also increase bearing life because it eliminates slippage and the accompanying frictional heat.

Why Properly Maintained V-Belts Matter

Steve Katz, president of Emerson Bearing Company, provided information from preferred supplier, Bestorq,

about V-belts. According to Bestorq, there are several reasons that may cause a belt to fail prematurely, such as the size of the pulley being too small, debris in the drive, under belting, or if the incorrect belt is used in the pulley.

The top reasons for belt failures that Bestorq faces include:

» Belts that are not tensioned correctly

» Worn pulleys

» Misaligned pulleys

» Belts that have been rolled on

There are many signs that can be observed before a belt fails. They will start cracking, delaminating, or there are other noticeable signs of belt wear. Belts may also make squealing, slapping, running, grinding, or other abnormally loud noises that indicate there is a problem.

It’s crucial to notice these signs and take the appropriate action. Bestorq says that if all safety precautions are not taken appropriately, someone can be seriously harmed if hit with a broken piece of belt or metal.

Properly maintained V-belts will provide longer overall belt life, allow for more energy efficiency, and experience less downtime. To extend V-belt lifetime and boost overall

16 | IMDQ | Q4 2022 COMPANy PROFilE

quality, Emerson Bearings Company of Boston suggests implementing the following best practices.

Use Correct Installation Procedures

While you may initially consider saving time by rolling the V-belt onto the drive to install it, this comes with certain risks if installers neglect first to loosen the motor. This installation method presents a safety hazard, potentially damaging sheaves and belts, and putting heavy loads on the belt and the system's shafts and support bearings.

Choose the Right-Sized Belt

There have been certain technological advancements in V-belts regarding their materials, tensile cord advancements, construction methods, and cross-section profiles. They're available in a range of profiles, sizes, and widths. To optimize their performance and prevent V-belt damage, you'll need to select the ideal V-belt for your specific application. If your belt is loose-fitting, this will lead to decreased efficiency and life, which is why it’s so important to ensure the V-belt is the right fit.

Regularly Check Sheaves for Wear

V-belt users often replace these components while neglecting to check for signs of wear on the sheaves. These signs may include polished, ridged groove sidewalls, or groove sidewall cupping. If the sheaves display signs of wear, it's best to replace them, because worn sheaves can reduce the V-belt’s lifetime by as much as 50 percent.

Tension the Belt Properly

The best method for tensioning belts and maximizing their longevity is to use a belt tension tool. Relying solely on touch to gauge tension can make it more challenging. Too much tension will increase the risk of the band breaking while greatly reducing bearing life. Conversely, too little tension will cause the belts to slip over time due to high temperature and noise levels.

What to Look for in V-Belts

Finding the appropriate V-belt for your specific application is essential, according to Katz, president of Emerson Bearing Company. He says: "We are dedicated to helping customers not only find the right V-belt solution for their application, but to provide tools and information necessary to help enhance performance and extend service life.”

ABOUT EMERSON BEARING BOSTON

Founded in 1957, Emerson Bearing Boston specializes in bearings for niche markets nationwide and is the sister company of Action Bearing which serves the New England market. The company provides solutions to a variety of industries including: aggregate, concrete, mining, machine tools, electric motor repair, marine, material handling, metal processing, packaging, food processing, paper converting, printing, wind/power generation, recreation, heavy construction, robotics, automation, transportation, wood products, wastewater treatment, pump, compressor, and oil field.

More About Bearing Failure

Often a component of V-belt and pulley systems, bearings play a critical role in many industrial devices and equipment. While bearing failure is unavoidable, it is possible to minimize the negative impact of failure on company operations. The key is understanding what causes a bearing to fail and how to prevent it from causing premature failure.

There are many reasons why bearing failure may occur, such as improper lubrication. This is the reason for the majority of bearing failures and can occur if the wrong lubricant is used, if not enough lubricant is applied, or if the bearing has been exposed to excessive temperatures that have caused the lubricant to degrade. A properly installed, right-sized, and well-maintained V-belt can help eliminate those excessive temperatures.

Contaminants such as dirt, sand, water, and chemical compounds can also cause numerous issues in bearing assemblies. For example, they can degrade the lubricant or corrode/erode bearing surfaces, all of which can lead to premature failure.

While some bearings can handle minor misalignment between the shaft and bearing housing, not all of them can. Typical causes of misalignment include bent shafts, contaminated components, and improperly positioned shafts and locking nuts. These issues can lead to uneven load distribution and excessive vibration generation, which can further hasten failure.

Fatigue, or spalling, refers to the fracture of bearing surfaces and the subsequent breaking off of pieces of material. As fatigue spreads, it will lead to failure as well.

Knowing why bearing failure occurs makes it easier to implement appropriate measures to avoid the causes. Selecting the right bearing, correct installation, and proper lubrication can help you avoid premature bearing failure.

INDUSTRIA L MACHINERY DIGEST COM IMD | 17

1986

IMD – North America’s Manufacturing Resource for Industry Professionals Since

Ovention® Upgrades Drives on Fast Cooking Oven Lines

Faster programming and commissioning are achieved with five-minute assembly time reduction, improved safety and easier service in the field from the use of Siemens drives.

Recently on its line of Matchbox, Shuttle, MiSA and conveyor ovens, Ovention® (Sturgeon Bay, Wisconsin), a company owned and operated by foodservice equipment powerhouse Hatco® Corporation, was presented with an improved drive technology by its motion control component supplier, Siemens, in tandem with the local distributor, Standard Electric Supply. The goal, according to Ovention Project Design Engineer, Tom Dulak, was “to allow us the opportunity to upgrade our drives with a newer technology, one that featured Wi-Fi connectivity for remote testing purposes, a built-in display for field parameter verification as well as a much easier programming operation.”

Ovention ovens are designed to prepare a variety of dishes with recipes based on time, temperature, and independent blower control, which offer the end-user maximum cooking control that works great for high volumes. The cooking surface moves into the cavity and is subjected to one of up to 1,000 unique cook settings that

The programming,

18 | IMDQ | Q4 2022

ABOVE : The SINAMICS V20 drive from Siemens is now used for the motion control on the blower motor systems found on various fast cooking ovens manufactured by Ovention. The drive can be entirely programmed offline, by use of a self-powered parameter loader and SIM card for full drive functionality. Remote monitoring is offered by the smart access module, plus the end-user can quickly determine any drive errors on the digital display.

iNTEgRATiONS

BELOW:

installation and assembly time of the Siemens drive onto the Ovention oven have all been reduced, according to Tom Dulak, project design engineer at the company.

The Best Tool Cabinet You Will Ever Buy GUARANTEED 100%MADE IN THE USA INEVERY WAY WWW.STORLOC.COM • 1-800-STORLOC 1-800-786-7562 MADE BY AMERICAN CRAFTSMEN IN THE USA sales@storloc.com

can be loaded through a USB port, then shuttled out of the oven. This is all done in a ventless environment which provides a 30% higher yield and consumes a third less energy, according to the manufacturer

This advanced cooking technology requires an airflow control system of considerable power, flexibility, speed and self-monitoring. That is precisely what Siemens brought to Ovention in its SINAMICS V20 drives.

ABOVE : Matchbox 1718/1313 ovens by Ovention represent a new level of automation and control in the food industry, due in part to the improved motion control technology onboard.

BELOW: Unique Ovention Shuttle ovens can be used as both a conveyor and as an automatic load/unload closed cavity oven.

In tandem with this improved drive technology from a performance standpoint, the assembly and commissioning time for each oven was reduced by up to five minutes, according to Dulak. “Due to the process speed of the V20’s parameter loader and smart access module, compared to our previous drive product, we can perform commissioning, operational simulation and diagnostics remotely, plus the improved safety factor is also an advantage.” Dulak further notes that the initial cost of the new drive was lower, while offering Ovention several new easily implementable features.

“In addition to the reduced assembly time with the quick-mounting hardware, we’re seeing much faster programming time and the ability to quickly troubleshoot on newer oven design concepts in ways we couldn’t in the past.” From a service perspective, Dulak also points out that the digital display on the SINAMICS V20 is much easier for a technician to diagnose and troubleshoot a drive error than the previous unit’s blinking lights. For getting his team up to speed on the new drives, Dulak credits his Siemens contacts Fabrizio Galbiati, plus the team from the local distributor, Standard Electric Supply, comprising Doug Heitpas, Trent Reimer and Mike Ubl.

Commenting on the safety aspect of the new drive, Tom Dulak notes the two parameter sets on the previous drive lines were transferred into a single parameter set on the V20 without the need of an external power supply connection during programming. The new additional customized parameters could be easily integrated, including defining a limiting blower percentage to auto-enable/ disable operation on the oven. Using the Smart Access Module (SAM), wireless commissioning, operation and diagnostic work in the factory or field via a mobile device or laptop with web-server module can be performed. This feature substantially reduces the time needed to commission the specific models being built in the factory.

During installation, the Ovention production personnel are provided the drives, which then get mounted into the oven and tested. The builder has tracked a five-minute

reduction in the commissioning and assembly time for each oven, which translates into ongoing and substantial savings for the company. Further, the WiFi connectivity for remote testing purposes and built-in digital display for field parameter verification were cited as significant areas of savings and ease of service on the Ovention ovens, both in the factory and field.

The new SINAMICS V20 drives are currently used on the Ovention MiSA-a12, Matchbox 1718/1313, M360 and other shuttle and conveyor ovens. They have been in use on all the models for more than one year. Tom Dulak observes, “We have been using V20 drives on both new and legacy units built at Ovention without any issues, so we’re extremely pleased.”

SINAMICS V20 drives are found on a variety of commercial kitchen appliances, including convection and impingement ovens, automated cookers, mixers, washers and exhaust systems.

20 | IMDQ | Q4 2022

Matchbox M360 auto-load and unload ovens likewise feature Siemens V20 drive technology for blower motor control.

The High Price of Misusing Low-Cost Collaborative Robots

Potential dangers can arise when manufacturers use cobots for tasks that would be better performed by industrial robots.

By Josh Tuttle

By Josh Tuttle

Recently, a young boy at a chess tournament in Moscow was injured by a chess-playing robot – a dramatic warning of the potential dangers of collaborative robots. What should have been a fun, engaging experience with the machine instead became a very painful one for the child. Though this wasn’t an industrial robot, manufacturers who use robots should be taking note.

Industrial robots vs. cobots

Collaborative robots, also known as a cobots, are intended for direct human interaction within a shared space, but ironically, they often have different safety features than industrial robots, which work independently from humans. In actuality, the chess-playing robot, despite being used to interact and play games with humans, isn’t collaborative, in the traditional sense of the word, at all. Instead, if the machine had been safer, with features like additional sensors (i.e., power and force limiting devices) and an

automatic brake release mechanism, this event could have been avoided.

Cobots don’t have the power and speed of industrial robots, but they are well-suited to slower, specialized work and can be safe — if they’re a quality unit that’s used correctly, and within the parameters of a proper risk assessment. But potential dangers can arise when manufacturers, intent on using cheaper units, instead use cobots for tasks that would be better performed by industrial robots, or when a proper risk assessment isn’t performed before using a cobot to attempt tasks for which it is not suited.

Unfortunately, as cobots have grown in popularity and availability — and some robot sellers have looked to make quick sales — proper integration has many times been abandoned so that cobots can be put to work more quickly.

Often, it’s less of a matter of negligence by companies buying and operating them and more an issue of proper education in how to comply with safety systems. In many

22 | IMDQ | Q4 2022 MACHiNES

carburizing (case hardening), SCM415 is normally used. requirements for harder material, SNCM220 and/or SNCM420 is determined by production condition. hardness value is informed in a quotation of gears. precision grade table : equivalent grades are for reference only. completely match each other. 15/05/21 14:20:18 259 Elm Place, Mineola, NY 11501 Phone: 516.248.3850 | Fax: 516.248.4385 Email: info@khkgears.us Largest selection of in North America Stock Metric GEARS

cases, machines that robotics and engineering students at U.S. colleges and universities have worked with previously are often cobots rather than industrial robots — and this can heavily influence their robot purchasing decisions after graduation. While these units are familiar to those just entering the workforce, when they are put into operation on the shop floor, they often cannot succeed in the tasks that they are designated to complete.

Safe robots pay for themselves

While it’s true that industrial robots can have larger upfront costs than cobots, they still deliver cost efficiencies and can pay for themselves over time. Moreover, it’s false economy to buy a cheaper cobot and, for example, recklessly strap a sander or welding gun to it.

To begin with, that could impact a company’s insurance eligibility. Insurance companies will often refuse to issue policies to businesses and organizations whose robotic systems fail to comply with regulations and industry best practice. Cobot-related safety incidents can also potentially result in worker injury or death, insurance claims being rejected, civil or criminal prosecution, and/or a manufacturer having to cease operations.

That’s why every robotic system should have a risk analysis performed.

The benefits of working with an integrator

A robotics integrator affiliated with the Robotic Industry Association (RIA) can help a manufacturer choose the right robot for a task and perform a risk assessment to ensure the robot will meet RIA standards for collaborative and non-collaborative systems.

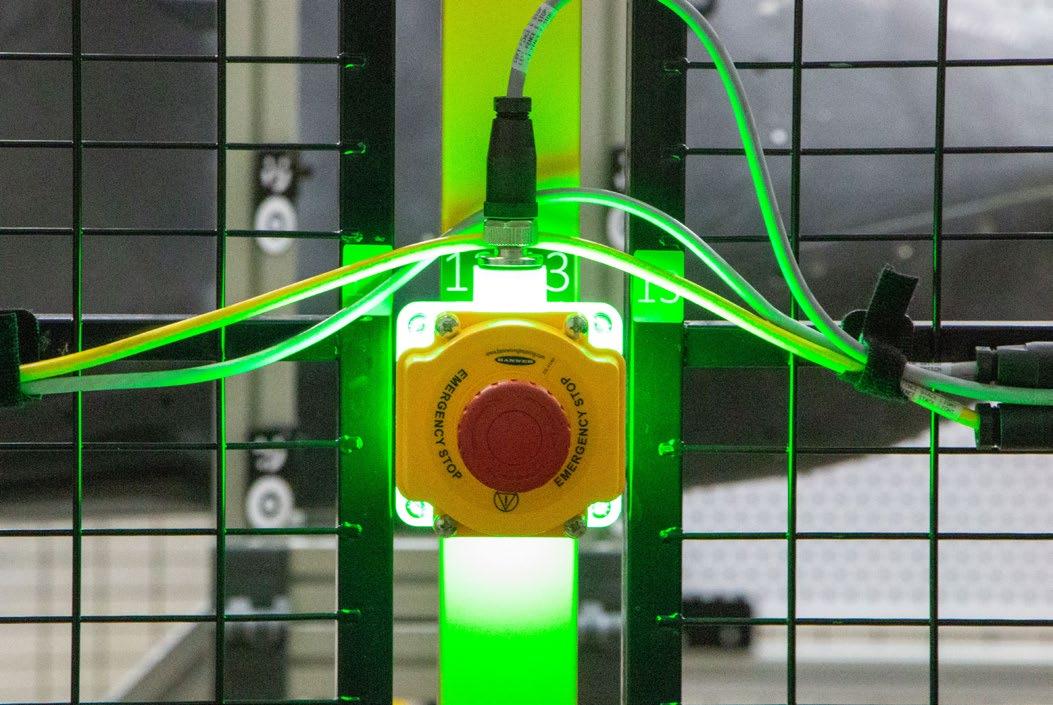

Among the best practices eLearning educator LabMidwest recommends for workplace standards include:

» Fencing off robots — with a fence height of at least six feet

» Extra sensors

» Walk-through safety beams

» Emergency stop buttons

» Safety mats that stop a robot when someone is standing, or not standing, on the mat as designed

» Sensing scanners that know where humans are in certain areas

These measures can be a sizable investment, perhaps as high as $15,000 for a robot that sells in the $50,000 to $60,000 range, but the insurance costs, legal liability, potential for shutdown of operations, and most importantly, the risk of injury or death to humans is not worth the associated risk.

Final thoughts

Fortunately, the Russian child referenced earlier in this article was able to return later in the chess tournament and finish play but every incident involving unsafe robots and humans will not have as lucky an ending.

Companies that skirt safety are engaging in a perilous venture that often ends in bigger costs than if they had just purchased the right robot, worked with the right collaborator, and integrated both their machine and practices the right way early in the operational process.

It’s the right — and safer — thing to do. And, in the end, it will cost you far less time, energy and money.

ABOUT THE AUTHOR:

Josh Tuttle is a business development manager at Aerobotix, an innovative leader in robotic solutions for the aerospace and defense industries. Headquartered in Huntsville, Alabama, the company specializes in the creation of cutting-edge automated robotic solutions for high-value, high-precision components, aircraft and vehicles.

24 | IMDQ | Q4 2022

For over 50 years! www.betenbender.com Call for a free catalog! Phone: 319-435-2378 | Fax: 319-435-2262 | sales@betenbender.com Hydraulic Shears: 1/8” (10GA), 3/16”, 1/4”, 3/8”, 1/2”, 5/8”, 3/4”, 1” and 1-1/4” Press Brakes: 50-Ton to 550-Ton C-Frame Presses: 40-Ton to 200-Ton Custom Designs: for Custom Applications Retrofit Backgauges: for Shears and Press Brakes. Made to fit most machines with minimum modifications. Precision Knife Sharpening AMERICAN-MADE SHEARS & PRESS BRAKES

ABRASIVE POWER TOOLS AND PROCESS SOLUTIONS

Since 1969, Dynabrade has been a global leader in the innovative design and manufacture of industrial abrasive power tools and related accessories. We’ve earned an outstanding reputation and position of leadership in the pneumatic tool market and have been supplying high quality, American Made power tools to customers through a worldwide network of professional distributors.

Discover The Dynabrade Difference...

SALES SUPPORT

– Factory-trained experts on tools, air systems, accessories and abrasives.

– “Process Solutions” approach: sales personnel outfitted with tools, accessories and abrasives for on-site demonstrations.

COST SAVINGS

– Let us analyze your air system with our Performance Assurance Kit.

– “Same Day/Next Day” shipping on most USA orders.

– USA Flat Rate Repair Program offers quick repairs by factory-trained experts.

– End-user conversion programs.

TRAINING

– On-site tool training clinics to educate your personnel.

– USA Mobile Training Units bring products directly to the workplace.

– Online demonstration videos available.

CUSTOMER SERVICE

– Talk with a trained Customer Service Representative.

– Discuss tool specs and applications with an experienced Technical Support Person.

– Utilize our online literature library.

PROUDLY DESIGNED, ENGINEERED, AND BUILT IN AMERICA SINCE 1969 Dynabrade, Inc. | 1.800.828.7333 | dynabrade.com | WE LISTEN. WE OBSERVE. WE OPTIMIZE.

“The Original” Dynafile® Pipe Belt Finisher PROUDLY DESIGNED, ENGINEERED, AND BUILT IN AMERICA SINCE 1969 Dynabrade, Inc. | 1.800.828.7333 | dynabrade.com | WE LISTEN. WE OBSERVE. WE OPTIMIZE.

Going Beyond the Basics to Ensure Quality

By Lindsey Padilla, Director of Quality, Bison Gear & Engineering

Product quality is a critically important consideration when purchasing electro-mechanical components, such as electric gearmotors. But what does quality mean and how do you evaluate it as a customer?

Obviously, quality involves materials and manufacturing processes that consistently result in high-performing, defect-free products that conform to specifications. That’s necessary, but not sufficient in ensuring that the product performs as needed in the particular application under the particular conditions for the intended lifespan.

Holistic, Proactive and Cross-functional

Ideally, a quality program should be holistic, integrating all aspects of a company. At Bison Gear & Engineering, for example, we see quality assurance as encompassing every aspect of what we do, not only on the manufacturing floor, but also in every department from sales, application engineering, and product development, through

manufacturing, quality control, and customer service. The key is that quality assurance is comprehensive and integrated. Cross-functional teams bring diverse perspectives and challenge assumptions to proactively anticipate potential problems. And we take advantage of quality management system software to track and analyze data from across the company, in order to identify and correct problems in real time and drive continuous improvement.

Going Beyond the Basics

The certification program of the International Standards Organization (ISO) provides helpful general guidelines and imposes a degree of discipline to ensure a systematic approach to quality. The ISO 9001:2015 audits and periodic recertification process ensures that we have a carefully-considered, well-documented, and consistentlyimplemented program. But an effective and comprehensive

28 | IMDQ | Q4 2022 SOFT wARE/ClOUDwARE

Quality Management Software allows for convenient tracking of return goods flow and data retention.

quality program is unique to each industry and Bison’s quality program far exceeds expectations of ISO 9001.

We have also chosen to employ Advanced Product Quality Planning (APQP), the general framework of procedures and techniques developed by the automotive industry and broadly used in other industries.

According to the Automotive Industry Action Group (AIAG), the purpose of APQP is "to produce a product quality plan which will support development of a product or service that will satisfy the customer."

A comprehensive and effective quality program goes beyond these standardized guidelines and frameworks, to include everything from the company philosophy, investment priorities and organizational structure, employee culture and capabilities, to the relationships with suppliers and customers.

Real Time Data Drives Action

Systematic quality programs like ISO 9001 and APQP represent the skeletal framework, and real time data represents the lifeblood of outstanding quality assurance. At Bison, our implementation of web-based quality management (QMS) software has allowed us to better use data through our company and in our relationships with suppliers and customers, resulting in significant, measurable improvement in quality. Access to reliable, real time data has enhanced our efforts to be proactive and preventative.

The QMS software allows us to capture and analyze data, grouped by product, feature or process, to identify problems and to drive improvements. Rather than solving issues in isolation, we are able to apply lessons across customers, across products and across processes. Instead of firefighting — expending resources correcting problems after they have already caused negative impact — resources can be applied far more effectively and efficiently to prevent problems and drive continuous improvement.

For example, at Bison, we measure quality in terms of defective parts per million (DPM), and have been able to reduce our DPM in our DC motors by 68% through analysis of data across multiple products in this category. The manufacturing of these types of motors requires precise pressing of laminations and winding of the wire so that the armature fits exactly in the machine. By analyzing data across varied motor shafts and different lengths of swages, we were able to improve the quality for the entire product category. We were able to standardize the lengths and sizing of the shaft swages to reduce tooling change over in our manufacturing process, thereby improving our cycle time and our ability to respond more quickly to customer orders.

Cross-Functional Teamwork at Every Stage

Teamwork is also essential to quality assurance. Subjecting concepts and designs to early cross-functional reviews is an investment in time and effort, but it pays off in a smoother

INDUSTRIA L MACHINERY DIGEST COM IMD | 29

IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

process and far better quality. From the beginning of the process of developing new products and features or working with new customers and applications, bringing together multiple viewpoints produces better solutions and prevents future headaches.

Often the process starts with application engineers reaching out to customers, or vice versa, to understand the customer requirements. Design engineers and manufacturing engineers join the cross-functional development and review process to evaluate not only the performance of the design, but also the manufacturability. The teamwork continues through the design, prototyping, manufacturing, and customer support stages, with quality engineers.

Quality Involves Partnership with Customers

The teamwork approach also extends to the close working partnership with customers. In one case, a Bison quality engineer helped a manufacturer of commercial ice dispensing machines to identify and correct a problem causing failures in the field, even though it turned out that the root cause was not in the design or manufacture of the gear motor.

The QMS system ensures that any issues that an individual customer may have are analyzed with the benefit of the experience of all customers. Knowledge gained from a problem here, or a solution there, is shared and drives actions internally and throughout the customer base.

And Partnership with Suppliers

Suppliers, too, are well-integrated into the overall quality program. Bison’s documented Supplier Performance Improvement Process (SPIP) exemplifies our data-driven, team approach to doing business. We recognize that our ability to meet customer expectations is dependent on the quality and reliability of our suppliers, and we are actively engaged in systematically evaluating and supporting them.

We send all of our suppliers quarterly quality and delivery scorecards. Among the data we use to assess quality and identify opportunities for improvement is a self-audit survey that our suppliers complete. We often have one of our quality engineers perform an onsite assessment. We find that it is critically important that we establish a close working relationship with at least one counterpart at the supplier, so that we are prepared to quickly address and correct any issues that may arise.

Our incoming parts inspection process identified problems with the hardness of metal bar stock from a supplier. The hardness of the material must be within specified limits to ensure that shafts stand up to the torque applied during the life of the motor. The supplier was applying excessive heat treatment, causing areas of the bar stock to be too hard.

We visited the supplier and met with the quality manager and some of the operators and determined that the type of inspection they were doing was too

30 | IMDQ | Q4 2022

Technician performing final Hipot testing on gearmotor electrical connections.

cumbersome and time consuming. Either they would continue to run products, while the inspection was happening or they would skip the inspection altogether. We identified an easier and quicker method of inspecting, using cylindrical ring gauges that slip on to the bars, which we purchased for the supplier. The ring gauges were effective because an oversized condition is a byproduct of overheating.

Being smart about inspections

Inspections are obviously critical. But you can’t test everything. We do perform final assembly testing for every item prior to delivery — including testing for air leaks, torque and RPM — but incoming parts inspections and in process inspections must be selective and strategic. There are an average of about 50 parts that go into each gear motor, and each product has up to 500 specifications on the print.

Strategic testing means that we do not just test at random. Our QMS software allows us to use data to drive the inspection process. Data analysis is used to identify parts and processes that are especially critical or have a history of failing and points. For example, specific testing protocols are implemented after retooling or other operations that present identified risks.

We will sometimes perform the same tests at multiple points in the process. For instance, we repeat a hipot test (High Potential Test) at various stages because protection against electrical shock is a particularly important safety requirement for electrical motors.

Investing in Quality

Quality assurance requires significant investment in people and equipment. Investing resources in cross-functional teamwork results in an excellent payback in terms of quality and of faster and more reliable delivery, as well as in overall customer satisfaction. Investing in staffing and expertise is also important for ensuring that applications engineers, design engineers, manufacturing engineers, and quality engineers are available to work together as a team and develop long term relationships with customers and suppliers.

Bison also chooses to invest heavily in new equipment that elicits faster production and better quality. Analysis of data derived from the QMS software provides a systematic process for looking out to the future and anticipating investment needs in new equipment and technology, to maintain capabilities and continually improve in both machining and in inspection.

Meeting Customer Requirements

Every company measures quality differently. For us, it is all about meeting customer requirements, specifically defined as delivering more dependable performance, fewer field failures and longer service life. We have found that to achieve this goal requires high commitment and investment and a data-driven, proactive, team-based approach.

INDUSTRIA L MACHINERY DIGEST COM IMD | 31

ACTEKMFG.COM 200% PROOF LOAD TESTED INDIVIDUALLY SERIAL NUMBERED FOR BETTER TRACEABILITY ORDERS SHIPPED SAME DAY RATED LOAD 400 LBS - 250,000 LBS 800-752-7229 | SALES@ACTEKMFG.COM HOIST RINGS ACTEK Forged Street Plate™ Swivel Hoist Rings Side Load Hoist Rings Hoist Ring Kits Pivots180° Swivels360° Drop Forged Hoist Rings Mold Handler™ Swivel & Pivot Hoist Rings Round Base Swivel & Pivot Hoist Rings Forged Swivel Hoist Rings ISO 9001

PRODUCT SHOWCASE

Clever integration: BvL cleaning system in production cell needs less personnel

Several automotive suppliers use decentralised cleaning in their production to reduce personnel hours and costs –these solutions do not have to be complex and expensive.

Everything centres around the process here – literally! In one example, grey-cast iron planetary carriers are first processed in a machining centre and then cleaned. To reduce handling times, a manufacturing cell was designed where the machining centre and cleaning system are supplied by a robot.

The operator only has to move the floor conveyor into the manufacturing cell and start the process and can then complete other tasks for the rest of the shift. From this point on, a robot carries out the handling. It picks a component from the basket and places it in the processing machine. A machining time of 12 minutes per component is defined. Then the robot transfers the machined or polished component to the cleaning system and places it back in an empty basket after cleaning.

One basket holds 8 components, and the floor conveyor can accommodate 5 baskets. A machining time of 12 minutes means that 40 parts can be machined within an 8-hour shift without worker intervention.

Small but clever: that is the best way to describe the OceanRW cleaning system from BvL. At first glance, it is a small, conventional single-tank cleaning system that uses the turntable principle. The parts to be cleaned are placed on the workpiece carrier at the top and rotate around the horizontal axis during the process. The special nozzle frame is individually adapted to the component to ensure thorough cleaning. Drying is also achieved with individually designed nozzles.

The cleanliness requirements for this intermediate cleaning step were quite modest. The parts had to be free from visible transport and manufacturing residue after cleaning, such as swarf, blasting materials or casting sand.

“It is important to us to design the perfect cleaning system for customers,” explains Bernd Menke, Sales Manager at BvL Oberflächentechnik. “And that includes much more than just looking at the parts to be cleaned. The entire process, the logistics and also the automation

play just as important a role as the satisfaction of the system operators,” says Menke. “In this case, we were able to implement the perfect process with a small cleaning system. That produced an optimum solution that was not too complex and not too expensive – all while relieving the employees in production.” Menke also emphasised, however, that “BvL can implement a great variety of solutions and integrate these in the customer’s production line. Our consulting and competence benefit greatly from a wide range of experiences. Our IT experts have also linked some highly interesting interfaces to a variety of different system types,” he explains.

Many manufacturing companies are currently experiencing a major skills shortage in production.

32 | IMDQ | Q4 2022 PRODUCT SHOwCASE

Industrial Machinery Digest's Monthly Product Showcase features the latest from some of the manufacturing industry's top suppliers.

WANT TO BE FEATURED? Send your latest product information to editorial@indmacdig.com

Manufacturing cells with a workpiece supply for an entire shift can be a practical option for using valued personnel efficiently. Integrating machining as well as cleaning is important for an efficient process and for employee satisfaction. It means that the parts will be ideally prepared for the next production step.

New Cementex Arc Rated Face Shields

Updated face shield provide classic, reliable arc flash protection Cementex, the safety tool specialists, highlights the Cementex 17 Cal/cm2 Arc Rated Face Shield (AFS-180) with hard hat. The AFS-180 features a molded shape to provide minimal distortion with exceptional Visible Light Transfer (VLT). This face shield will be included in the Category 2 Contractor, UltraLite and Feature Series PPE kits. They are in stock and available to ship immediately.

Cementex Arc Rated Face Shields are made of durable polycarbonate with anti-fog and scratch resistant coatings. The long length, chin cup, and sides provide superior coverage and protection around energized equipment. The brow shield deflects impact of Arc Blast and the translucent sides and chin cup provide improved peripheral vision.

This face shield meets the requirements of: NFPA 70E, CSA Z462, ASTM F2178, ANSI Z87.1, ANSI Z89.1, and CSA Z94.1.

The AFS-180 Face Shield is available for purchase

through Cementex distributors. For more information about Cementex’s industryleading products, visit www. cementexusa.com or call 1-800-654-1292.

For more information, visit www.cementexusa.com

Drench Shower

The Drench shower is equipped with a pull rod activated shower and push handle eye/face wash for immediately drenching of personnel that have been exposed to hazardous chemicals. The Shower provides a continuous stream of non-injurious water for 15 minutes or longer, after activation. Combination shower and eye/face wash shall deliver 30 GPM of flowing pressure from the shower head and 8.0 GPM of flowing pressure from the eye/face wash. Drench Shower is ready for installation to water supply and waste systems. Compliant with A.N.S.I. and O.S.H.A. requirements.

For more information, visit www.EmergencyShowerBooths.com

INDUSTRIA L MACHINERY DIGEST COM IMD | 33 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986 www.trimlok.com info@trimlok.com Trim-Lok Corporate 6855 Hermosa Circle Buena Park, CA 90620 Trim-Lok Midwest 5540 Beck Drive Elkhart, IN 46516 CELE B R ATING YEARS CELE B R ATING 80 0 - 663-9507 CALL US TODAY! ® TRIMS AND SEALS S C M Y CM MY CY CMY K 2022 IMD AD final 11-21-2.pdf 1 11/22/22 12:16 AM

NewTek Hermetically Sealed 4-20 mA Position Sensors Offer Consistent Performance with Less Power than other DC-operated LVDTs

NewTek Sensor Solutions offers its Hermetically Sealed Position Sensors with a 4 – 20 mA current loop output that has become the data transmission standard in the process control industry. Offering rugged operations and high performance with low power consumption, Newtek’s HI Series of Hermetically Sealed 4-20 mA LVDTs ensure highly reliable and consistent data output for factory automation, materials testing and packaging equipment applications. Requiring less power than similar DC-operated LVDTs and signal conditioners, these 4-20mA sensors also satisfy low power budgets.

Sustaining accuracy with no errors over long distance transmissions, the 4 – 20 mA current does not degrade over long connections and is less sensitive to background electrical noise. Simple to connect and configure, the 4-20 mA output position sensors offer plug and play compatibility with most PLCs and controllers. Units also require less wiring and connections than other signals to reduce startup costs.

NewTek offers its Hermetically Sealed 4-20mA LVDTs with either a radially- or axially-mounted connector. Units are available in ranges of 0.1” (2.54 mm) to 20” (500 mm). In addition to being sealed to IP-68, windings of the HI series are potted inside the housing with a two-compound epoxy for maximum resistance against harsh environment conditions. Operating temperatures range from -15°F to 185F° (-25°C to 85°C).

For more information, visit www.newteksensors.com

New Norton Cutting and Grinding Wheels for Aluminum Offer Best in Class Performance

Saint-Gobain Abrasives, one of the world’s largest abrasives manufacturers, has introduced its new “Norton for Aluminum” Thin Wheels for the right angle cutting and grinding of aluminum and other non-ferrous soft metals. High quality, extra-friable and self-sharpening aluminum oxide grain and specialized bond technology results in the best cutting and grinding wheel market performance in its class. The new wheels offer aggressive, fast cutting which resists loading and minimizes heat on the workpiece, providing consistent, long-lasting wheel performance.

“As the demand for lighter, stronger materials such as aluminum continues to grow, we are very pleased to offer customers a new, efficient cutting and grinding wheel solution that specifically addresses their application challenges,” said Bradley Povelaites, Manager, Product and Commercial Management, Norton | Saint-Gobain Abrasives. “Norton for Aluminum wheels improve throughput and reduce scrap and downtime, saving costs.”

Norton for Aluminum wheels have a range of features and benefits including a 5/8"- 11" hub for quick, tool-free wheel changes. Helping to keep metal surfaces clean for defect-free, corrosion-free welding, the new wheels have a contaminate-free bond which does not need any waxes or lubricants. Also, a double coarse layer construction adds versatility and life on applications such as back-grinding and notching. Norton for Aluminum wheels construction is strong and safe, exceeding all the strictest Norton American ANSI and international safety standards.

Key markets for Norton for Aluminum include aluminum and metal fabrication, welding, shipbuilding, automotive and transportation, aerospace and construction. Applications include aluminum, cut-off, portable grinding, beveling, notching, smoothing welds and offhand stock removal. The new wheels are available in 1/4" Grinding Type 27, 1/8" Cutting/ Notching/ Grinding Type 27, .045" Right Angle Cut-Off Types 01/41 and 27/42, and Straight Cut-Off Type 01/41.

For more information, visit: www.nortonabrasives.com

PALLITE™ Inc. Expansion to Meet Demand. QUIET Platforms install PALLITE™ PIX™ storage solutions across their warehousing facilities.

PALLITE™, the award-winning international designer and manufacturer of high-density storage bins, has taken on bigger premises in Milwaukee to facilitate the demand in their honeycomb cardboard pick bin units.

34 | IMDQ | Q4 2022

Since launching their strong, flexible warehouse storage solutions in the USA twelve months ago and success following MODEX, PALLITE™ has seen huge demand from a growing number of customers, including QUIET Platforms.

Over its 13-year operating history, QUIET has become the chosen fulfillment provider to the most successful and progressive digitally native companies seeking to maintain their brand identities.

With facilities located in key regions including Boston, St Louis, Chicago, Dallas & LA, working with PALLITE™ they have been able to transform their storage and picking efficiencies.