ROYAL SERIES 2023 COLLECTION DESIGNED FOR IMPACT

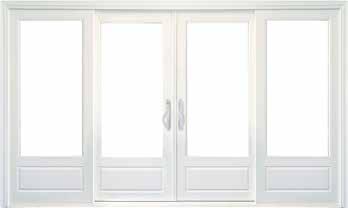

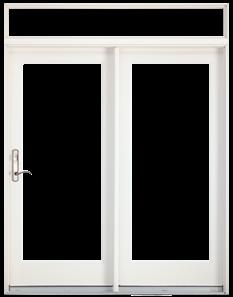

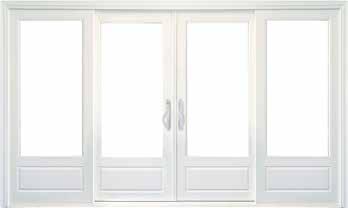

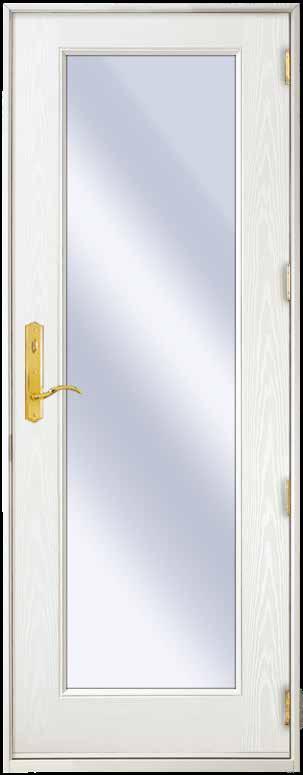

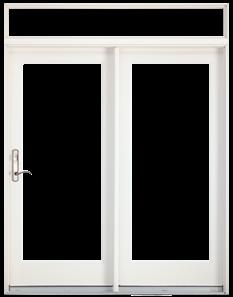

Double Hinged Full Lite Doors

Smooth White Finish | LoE366 Glass

About Neuma Doors

Neuma Doors stands apart as the industry leader in quality and design innovation. Backed by the strength of Nan Ya Plastics Corp. USA, our vertical integration incorporates comprehensive quality control measures through each step of the production cycle, from the manufacture of raw materials to the final door assembly. Our dedication to production excellence and environmental preservation has been recognized with ISO 9001 and ISO 14001 certifications.

Whether your patio door is the gateway to backyard recreation and relaxation, or a busy access point to your home, Neuma Doors’ blend of function and style will provide years of enjoyment with minimal maintenance.

Table of Neuma Benefits

Design Options

Products

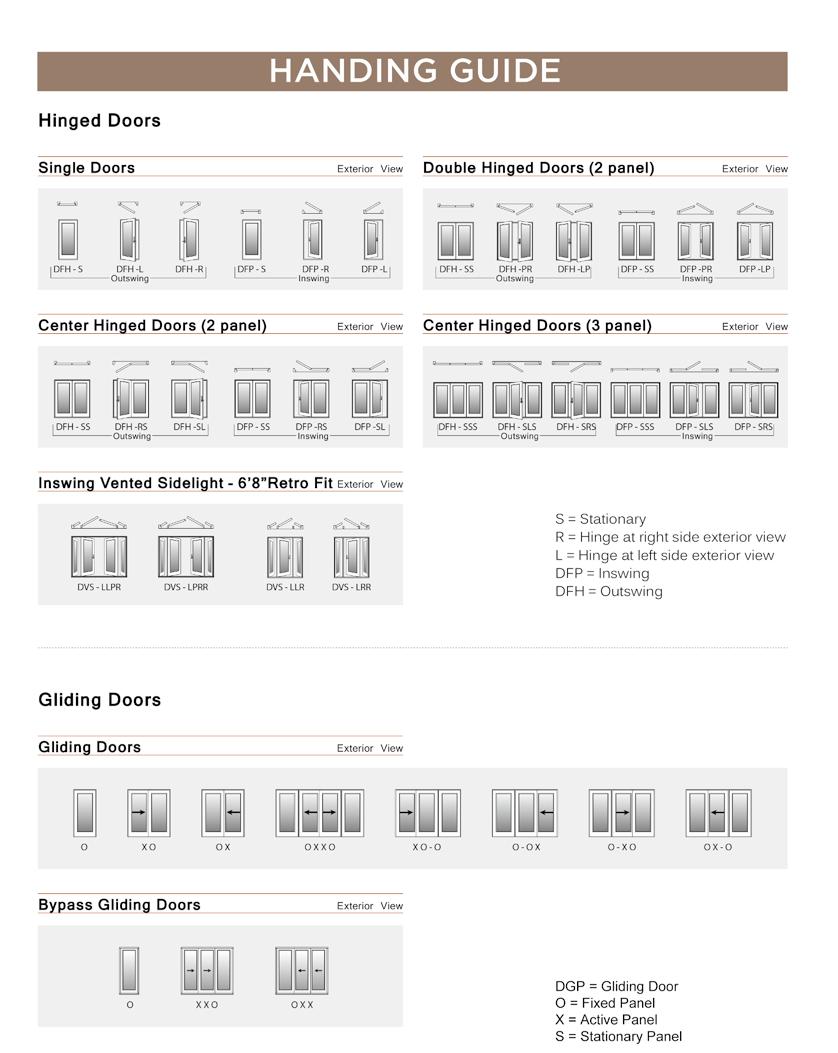

Guides *** Colors and finishes in this publication are not actual representations. Contents 06 Impact Options 08 Complete Door System 10 Energy Efficiency 12 Door Design 14 Hinged Series 20 Hinged Units and Dimensions 30 Vented Sidelight 32 Vented Sidelight Units and Dimensions 33 Hinged Transom Units and Dimensions 35 Hinged Test Results 38 Gliding Series 44 Gliding Units and Dimensions 50 Gliding Test Results 52 Bypass Gliding Series 56 Bypass Gliding Units and Dimensions 57 Bypass Gliding Test Results 58 Transom and Sidelight Options 63 Glazing Options 64 Blinds Between The Glass 66 Finish Options 68 Hardware Options 71 Additional Options 72 Product Details 73 Door Design Specifications 75 Handing Guide 76 Painting Guide 77 Staining Guide 78 Oxidation/Chalking Cleaning Guide 79 Maintenance Guide 80 Ideal Construction 82 Warranty

Neuma Royal Series

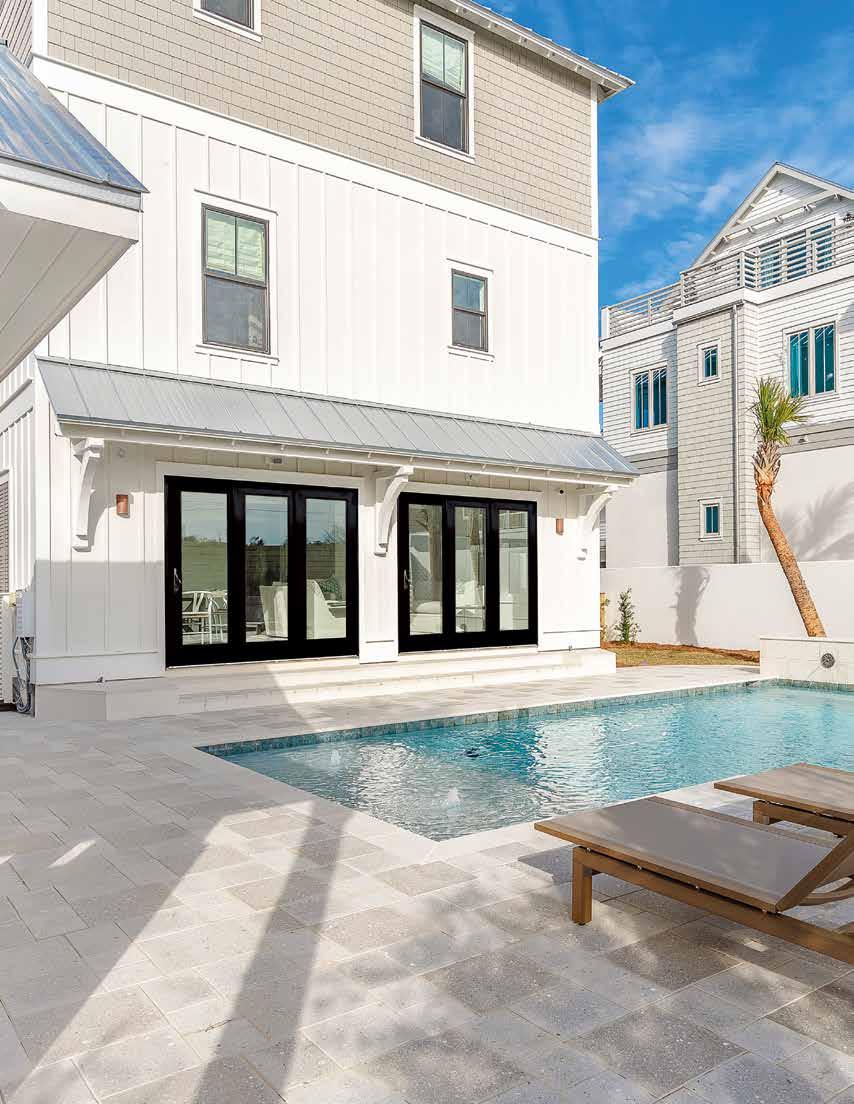

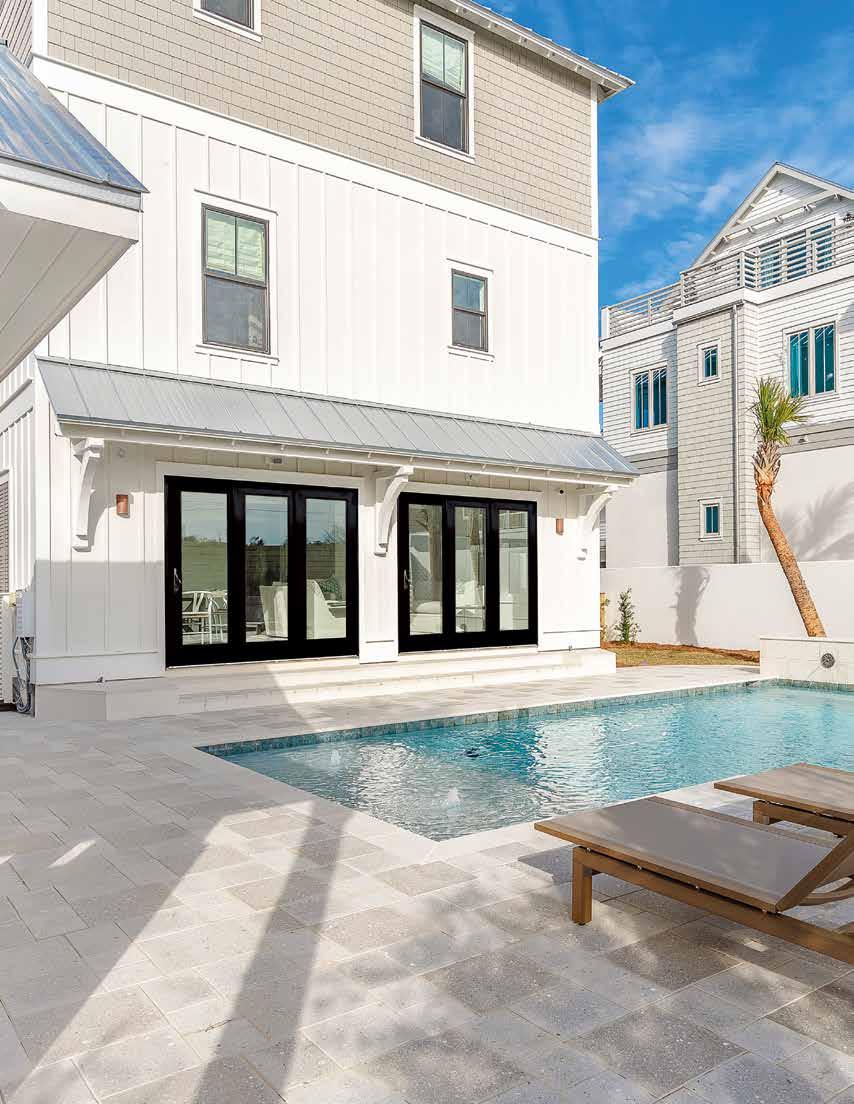

Visual Impact

Something as simple as a door can have a dramatic Visual Impact on your home. The right door brings out the best qualities in your home and can be the focal point of your indoor-outdoor patio space. Clean lines, rich textures, and tall glass panes provide your home with a strong atmosphere of elegance. Low maintenance fiberglass is easy to clean should you chose to let the standard finish shine and easy to paint or stain, allowing you to add a personal flair.

Extend your living area with a Neuma Patio Door and create a flexible space that accommodates the way you live. Open or closed, you can appreciate expansive, unobstructed views and create a space that is open to the outdoor views and infused with natural light with all Nemua Door systems. Our patio doors are designed with visual impact in mind, offering flush glazed windows, realistic woodgrain patterns, and a wide range of transoms and sidelights. With customization options such as color, lite pattern, and configuration, your door will be a true reflection of your style and leave a lasting impact on all of your guests.

Designed to Last

As an entry point to your home, it is essential that your patio door provide safety and security as well as protection against incoming weather. Neuma Doors are designed to withstand the impact of extreme weather conditions. Our precision engineered door units protect your home against water infiltration and stand up against extreme heat and cold.

Neuma Doors offers a variety of impact rated door options for added protection. Designed to safeguard people and property, Neuma Impact Doors are built to stay strong during high wind events that can hurl debris at the door. The high impact fiberglass panels with a dense foam core and laminated impact glass work together to keep the effects of extreme weather from penetrating the door. For safety and security, the laminated glass in an impact door contains a cut resistant vinyl interlayer that remains intact and adheres to glass fragments should the glass ever be broken.

04

Double Hinged Full Lite Door with Sidelight Smooth White Finish | LoE366 Glass

Double Hinged Full Lite Door with Sidelight Smooth White Finish | LoE366 Glass

We believe that doors should be beautiful and durable, protecting your family while maintaining exceptional style. Neuma Doors undergo rigorous testing to help ensure that each door meets our highest standards, meets building code requirements and withstands the test of time without compromising beauty.

Designed to perform well for years to come, Neuma Doors are tested in accordance with the following test standards:

ASTM E 283

ASTM E 331 / E 547

ASTM E 330

ASTM E1886 / E1996

AAMA 1304

TAS 201

TAS 202

TAS 203

NFRC 100 / 200 / 500

ASTEM E90 / STC / OITC

AAMA 920

AAMA / WDMA / CSA 101 / I.S./A440 (NAFS)

Air infiltration

Water resistant

Uniform structural load

Impact / cycle test

Forced entry resistance test

Impact test

Air / water / structural test

Wind pressure cycle test

Energy efficiency

Sound transmission

Operating cycle test

North America fenestration test

DESIGNED TO PROTECT

Impact Options

Designed to protect people and property during violent storms, Neuma’s Impact Rated Doors provide the ultimate storm protection for your home and include the following standard features:

High impact fiberglass panels for strength and durability

1” insulated laminated impact glass for extra security and protection against broken glass

Multi-point lock for added security

HPVD (High Physical Vapor Deposition) for additional protection in harsh environments

Storm damage can be caused by debris that is picked up and hurled towards your home in high winds. These objects, set on a collision course with your home, can penetrate doors and provide an entry point for water, high winds and additional debris. Our Impact Doors stand up to the harshest conditions and are more resistant to denting than traditional metal doors.

If the glass on a Neuma Impact Door is broken, our standard 1” insulated laminated impact glass maintains its integrity thanks to the vinyl interlayer which remains in the door frame. This vinyl interlayer stays intact and prevents broken glass fragments and additional debris from entering the home. Unlike most other doors on the market, Neuma Doors’ unique removable glazing bead allows for glass replacement without the added expense of purchasing an entirely new unit.

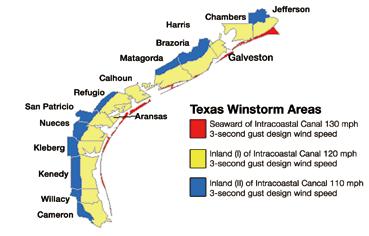

Neuma’s Impact Rated Doors are certified by the Texas Department of Insurance and Florida Building Code, with HVHZ options available for use in High Velocity Hurricane Zones. Neuma Doors Impact Hinged Inswing and Gliding Doors can withstand windstorm of over 145 mph and our Hinged Outswing can withstand windstorm as high as 170 mph. (AAMA / NWWDA / CAS101 / I.S. 2 / A440-8)

With a variety of door styles, design options and configurations, Neuma Doors are an affordable option to expensive and unsightly roll-down or accordion style shutters.

Our Impact Series helps preserve the house’s envelope to minimize the damage from the storm’s elements.

If a home has been breached through a broken door or window, wind can then enter. This causes an increase in pressure that can lift the roof and push the walls outward.

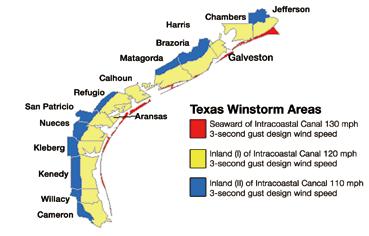

Note: The wind zones are approximate. Please refer to the International Building Code for precise locations.

Neuma Benefits 7

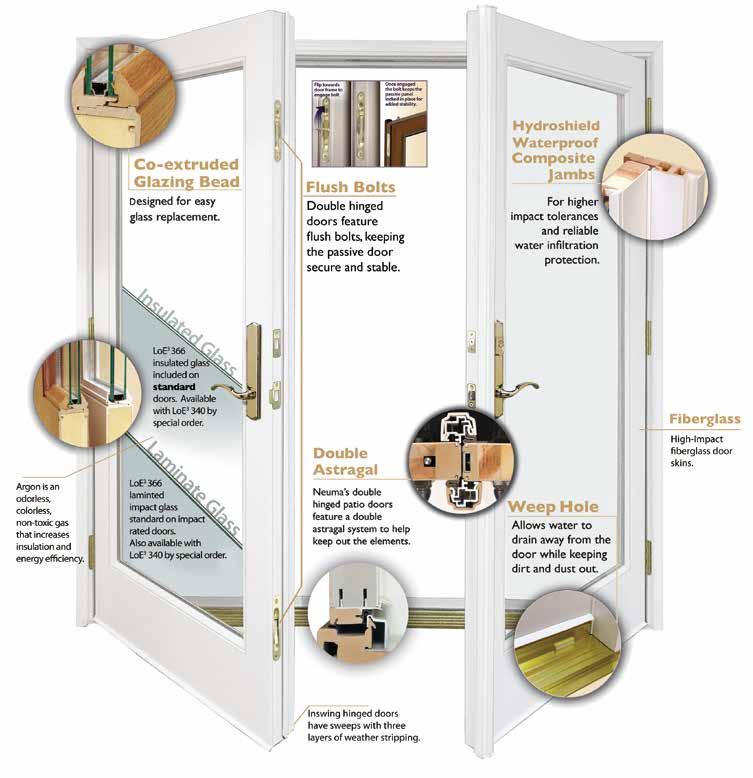

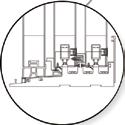

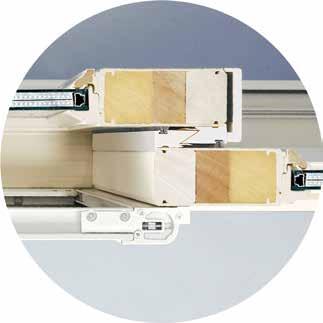

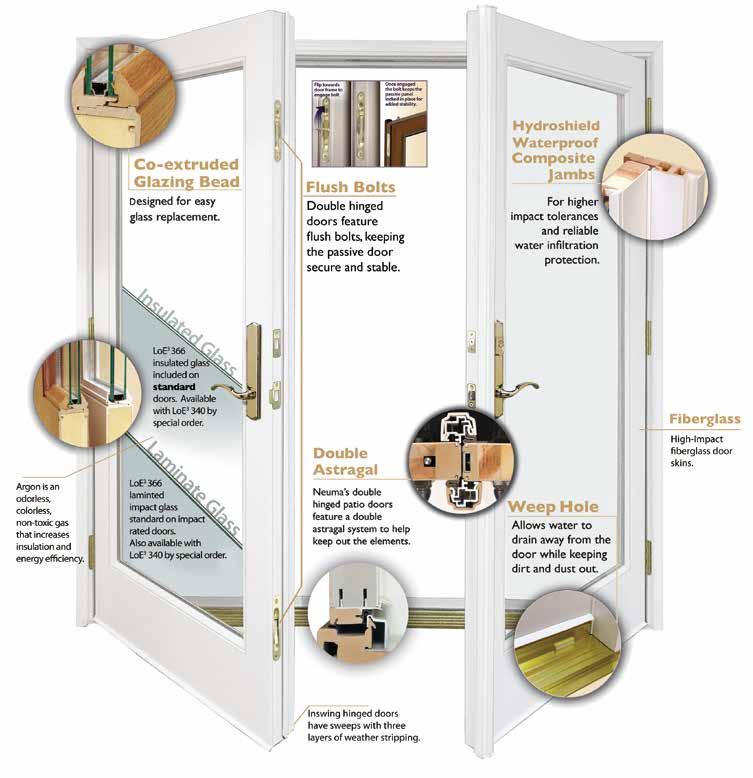

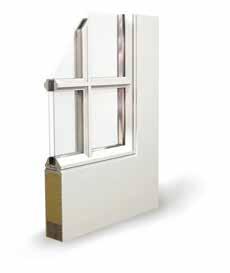

Designed as a Complete Door System

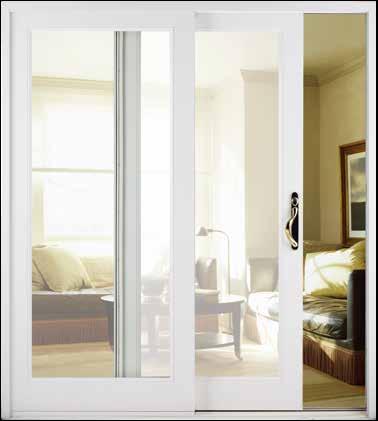

Neuma Doors, designed as a complete door system, are a smart investment in your home due to the outstanding durability and energy efficiency.

Weather Guard System

Neuma Door’s Weather Guard System is designed to provide the best combination of performance, durability, security and appearance.

Neuma Door Systems are precision engineered to guard against water infiltration. The specially engineered composite material will never absorb water, eliminating the problems commonly associated with wood and metal doors.

Designed with a unique double astragal system, Neuma Doors create a weather-proof barrier that keeps rain and wind from penetrating the seal of the door.

Neuma Doors with an insulating CFC-free foam core and LoE glass, guard against harsh heat and UV rays from the sun, protecting furnishings from fading and helping drive down heating and cooling costs.

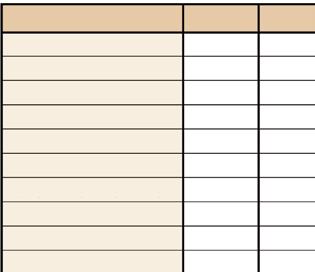

Gliding Full Lite Doors Smooth White Finish | LoE366 Glass

Precision Engineered

Neuma Doors are complete door systems with components purposely designed to work together for optimal performance with lasting durability. The door panel, frame, hardware and weather-stripping all function cohesively to provide superior protection.

Factory Assembled

Neuma Doors are meticulously assembled in our state of the art factory by craftsmen with an eye for detail. A factory assembled pre-hung Neuma Door reduces the chance of possible errors in assembly that sometimes occur with a field-assembled door.

Tested as a Complete Unit

Neuma Doors undergo extensive testing. We test the integrity of our entire door system, not only the individual components. This comprehensive testing provides assurance that the entire door system performs to expectations.

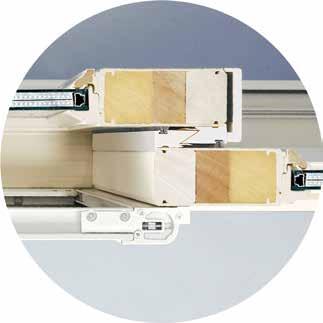

Composite Frame

The composite frame is made of non-porous material that is impervious to penetration by water. The frame will never absorb water, swell, split or rot, minimizing the need for maintenance and extending the life of the door.

Sturdy Hardware

As a complete system, Neuma Doors include hardware components. From the stainless steel rollers and hinges, integrated flush bolts, to the included handle set in your choice of style and color, each component is built to last.

High Quality Fiberglass Door Panels

Thanks to advancements in manufacturing, Neuma fiberglass panels are available in highly realistic woodgrain or smooth texture options that are easy to stain or paint and even easier to maintain.

Constructed from high compression molded fiberglass with full composite stiles and rails, Neuma Door panels are not susceptible to moisture conditions or pest infestations. Unlike doors made from other materials, Neuma Doors will not absorb water, dent or rot; resulting in a reliable option that will look beautiful for years to come.

Energy Efficient

An ENERGY STAR certified Neuma Door is not only a beautiful addition to your home, but helps save money on heating and cooling costs yearround. Standard LoE366 insulated glass with Argon Gas and an insulating CFC-free foam core provides superior energy performance.

Flush Glazed Door Panels

The flush glazed system of a Neuma Door offers a clean finished appearance and additional protection against water intrusion. The integrated glazing bead allows the glass to sit flush within the door without an unsightly screwed on glazing frame. The easily removed glazing bead allows replacement of the door glass if needed.

09 Neuma Benefits

Designed for Energy Efficiency

Environmental Responsibility

As part of our ongoing commitment to environmental conservation, Neuma Doors, backed by Nan Ya Plastics Corp. USA, has developed comprehensive programs focused on recycling, reducing carbon emissions and water and energy conservation.

Neuma Doors are manufactured with recycled materials and do not contain any harmful CFC’s that damage the Earth’s ozone layer.

As the leading manufacturer of energy efficient patio doors, we help reduce home energy use across the country and are a proud partner with the Environmental Protection Agency’s ENERGY STAR Program.

ENERGY STAR is an EPA voluntary program that helps businesses and individuals save money and protect our climate through superior energy efficiency. ENERGY STAR certified doors lower energy bills, reduce greenhouse gas emissions from power plants and help keep the indoor environment consistently comfortable.

Reduce Your Energy Use

Home energy use accounts for about one-quarter of your carbon footprint. As part of an energy efficient home, ENERGY STAR certified doors help reduce your energy use.

Stay Warm in the Winter

With ENERGY STAR certified Neuma Doors, the interior glass stays warmer, so you can stay warm even when the outside temperature is below freezing.

Stay Cool in the Summer

ENERGY STAR certified doors help you stay cool on hot summer days. By reducing the “heat gain” into your home without reducing the visible light, you get a bright space without the extra heat.

Reflects the sun’s heat & damaging UV rays in summer

Keeps the cold weather out and the warm air in during the winter

10 Neuma Benefits

What makes a Neuma Door Energy Efficient?

Neuma Doors meet or exceed the rigorous testing in EPA-recognized laboratories and meet the U-Factor and SHGC (Solar Heat Gain Coefficient) qualifications for Energy Star Certification EVERYWHERE in the United States.

U-Factor measures how well the door prevents heat from escaping the home. The lower the U-Factor, the better the door performs at keeping heat inside.

SHGC measures how much heat from the sun is blocked by the door. The lower the SHGC, the better the protection against solar heat.

1 Insulated energy efficient glass reduces heat flow.

2 Improved CFC-free polyurethane foam core for energy efficient insulation.

3 Precision engineered door system with weather stripping for reduced air leakage.

Neuma Benefits 11

2 3 1

Door

Design The Perfect Door for your space

Let your home’s personality shine through with customizable door options. Neuma Doors provides an array of design options to fit seamlessly with your home’s style. Sidelights next to the door or transom windows above the door expand the visual impact, letting in light and creating a larger viewing area. Create a classic look with a traditional SDL (simulated divided lite) pattern. Craft a contemporary look with a bypass door that allows unobstructed views and the flexibility to open your space and blur the lines between indoor and outdoor living. A variety of stain, paint, and hardware finish options allow you to accent your décor and create the perfect door for you.

Gliding Full Lite Door with Transom Painted Finish | Blinds Between Glass

Gliding Full Lite Door with Transom Painted Finish | Blinds Between Glass

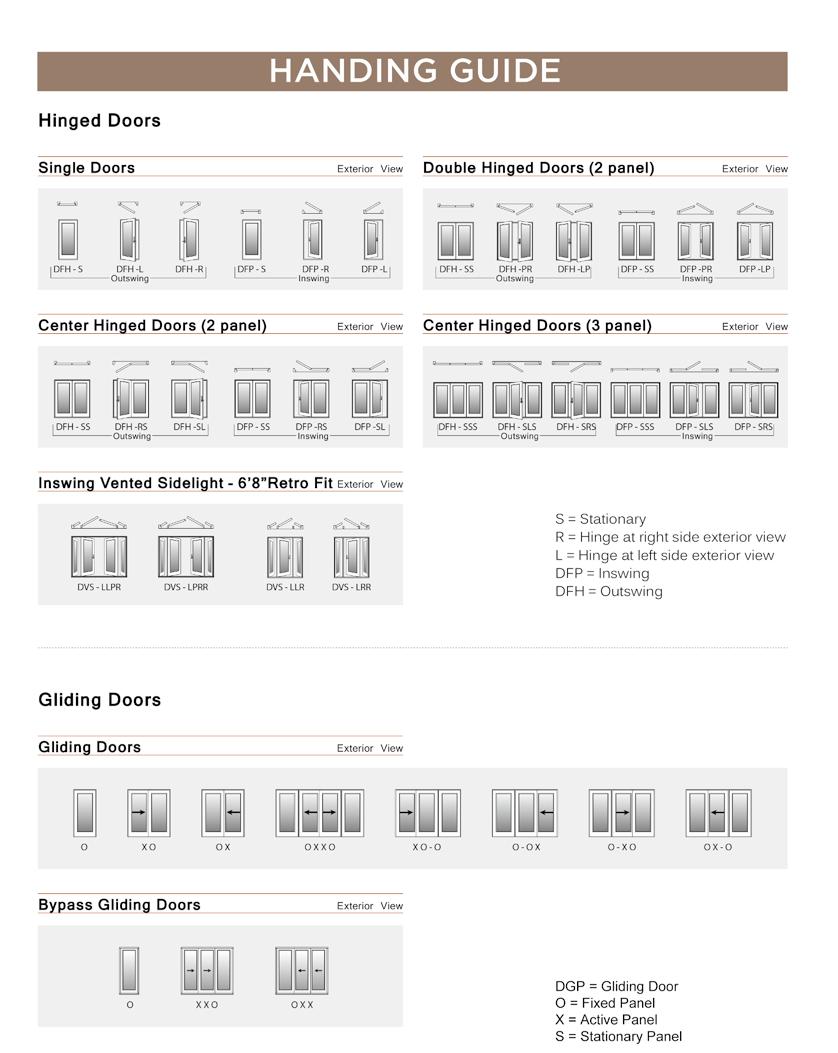

2 Select Your Door Type

Choose from Hinged, Folding, Gliding or Bypass Gliding Doors.

Select our Full Lite door style for maximum views or choose the ¾ Lite door style for added architectural detail.

Select Your Configuration

Select the number of panels. With options from a single door to 4 panel configurations, Neuma offers the best design to fit your space. Our wide range of configurations allows you the flexibility to design your perfect door.

Enhance your door and increase your viewing area with sidelights and transoms.

Select Your Glass

Add a touch of style to your door with our divided lite options, available as simulated divided lites (SDL) or as grilles between the glass (GBG).

When privacy is a concern, select blinds between the glass, now available in an energy efficient LoE option.

*** Colors and finishes in this publication are not actual representations.

Select Your Finishes And Hardware

Handlesets and hardware are included with your Neuma Door system. Select the hardware style and color to compliment your home.

Choose from our smooth white paintable finish or one of our woodgrain options to best suit your space.

Neuma Benefits 13

1 3

4

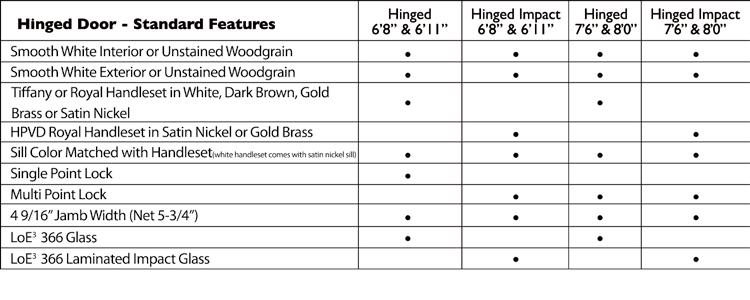

HINGED SERIES

Panels and frames made of fiberglass and composite material, a part of the Weather Guard System for advanced moisture protection and maximum durability

Durable fiberglass skins will not rust, dent, split or rot

Energy Star certified in all 50 States

Durable CFC-free polyurethane foam panel core

Stainless steel hinges

Removable glazing bead for easy glass replacement

Door heights available in 6’-8”, 6’-11”, 7’-6” and 8’-0” sizes

Frames available in 4-9/16” or 6-9/16” sizes, Net jamb dimensions are 5-3/4” or 7-3/4” (See pg. 24 for more details)

Thresholds include drainage systems to channel water away from doors

Paintable smooth surface or unstained woodgrain are standard with pre-finished options available

Doors tested for structural stability, water infiltration, air infiltration, forced entry, sound transmission, and energy efficiency

14 Products

Double Hinged Full Lite Door with Sidelight

Painted Finish | Rain Glass

Double Hinged Full Lite Door with Sidelight

Painted Finish | Rain Glass

FEATURES

The Neuma Door system is ready to install and provides complete protection from the elements. Doors and frames are enginered to work together to withstand use in the harshest environments.

16 Products

Double Hinged 3/4 Lite Door | Mahogany Finish

LoE366 Glass | 6 Lite SDL

Double Hinged 3/4 Lite Door | Mahogany Finish

LoE366 Glass | 6 Lite SDL

SELECT AND BUILD YOUR OWN HINGED UNIT

Full Lite Option

Full Lite unit available in smooth white, and stainable woodgrain finishes.

3/4 Lite Option

3/4 Lite design available in a smooth white finish or a mahogany grain that emulates the beauty of natural hard-wood.

18 Products

Fixed

Center

Double Hinged Single Hinged/

Units

Hinged

Grilles are used to visually divide the glass area of the door for added architectural detail. Grilles Between Glass (GBG) are aluminum grilles sealed between the two layers of glass and offer an attractive low maintenance option. Simulated Divided Lites (SDL) are applied directly to the glass surface and offer a more traditional appearance. Neuma offers standard 10, 12, 15, and 18 grille patterns as well as custom grille patterns available through special order.

Be creative in building a custom large view hinged door design. Build a three panel hinged door unit with a single opening on a center hinged unit or broaden your double hinged into a 2+1 or 2+2 unit.

Products 19

Mull Extension for Optional Extended Jambs 5/8” SA060 SA061 Mull Extension for Optional Extended Jambs 5/8” SA052 SA061 Available Grille Patterns Combo Options Mull Kits Grille Options 8’ Height Hinged Outswing Hinged Inswing 6’8 & 6’11 Height 10-Lite 15-Lite 3 Lite Prairie 4 Lite 4 Lite Tall 12-Lite 18-Lite 3 Lite Prairie 4 Lite 4 Lite Tall

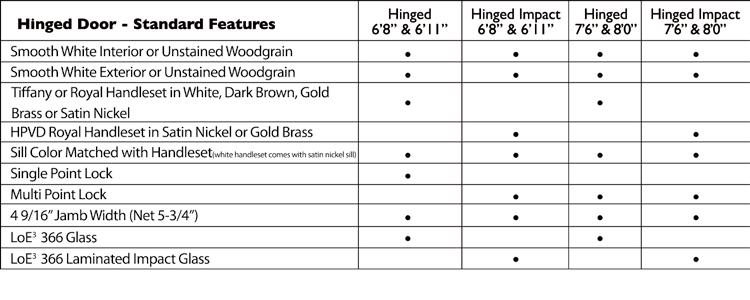

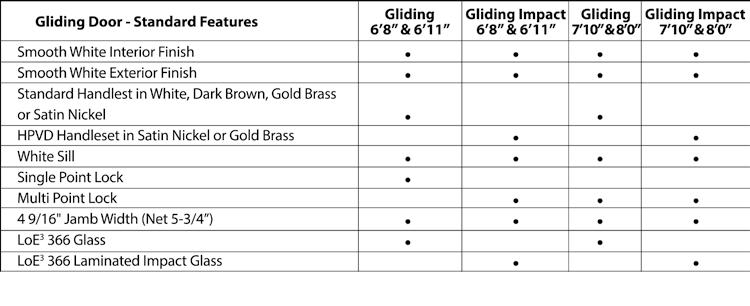

Standard Features Chart

Standard Standard

HINGED UNITS AND DIMENSIONS

Single Panel

Full Lite Handing

20 Products

Lite Fixed Sidelight Single Panel Units Two Panel Units Single Panel Sidelight 1’- 3/4” 1’ 1’-2 3/4” 1’-2 6’-8 ” 6’-1 1” 8’-0 ” 2’-2 13/16” 13 3/8” 2’-2 1/16” 2268 22611 2280 13 3/8” 24 1/2” 3076 7’-6” 7’-5 1/2” 70”

Full

Inswing Outswing 7’-6 7’-5 1/2” 70” 24 1/2” 3076

Sidelight 1’- 3/4” 1’ 1’-2 3/4” 1’-2” 6’-8” 6’-1 1” 8’-0 ” Standard Grille Patterns 2’-2 13/16” 13 3/8” 2’-2 1/16” 2068 20611 2080 13 3/8” Prairie Craftsman Standard Grille Patterns Standard Grille Patterns Prairie Craftsman DFP= Inswing DFH= Outswing 7’-6 7’-5 1/2” 70” 24 1/2” 3076

Single Panel

Sidelight 1’- 3/4” 1’ 1’-2 3/4” 1’-2” 6’-8” 6’-1 1” 8’-0 ” Standard Grille Patterns 2’-2 13/16” 13 3/8” 2’-2 1/16” 2068 20611 2080 13 3/8” Prairie Craftsman Standard Grille Patterns Standard Grille Patterns Prairie Craftsman DFP= Inswing

Handing from exterior view

Doors are not reversible

Retractable screen available as an option

Stationary Hinge at right side exterior view Hinge at left side exterior view

Products 21

Three Panel Units 7’-4 9/16” 7’-3 13/16” 20 9076 LEGEND Handing from exterior view Doors are not reversible Retractable screen available as an option S = Stationary R = Hinge at right side exterior view L = Hinge at left side exterior view DFP= Inswing DFH= Outswing 7’-4 9/16 7’-3 13/16” 20 LEGEND . Handing from exterior view . Doors are not reversible S = Stationary R = Hinge at right side exterior 7’-4 9/16” 7’-3 13/16” 20” LEGEND Handing from exterior view Doors are not reversible Retractable screen available as an option S = Stationary R = Hinge at right side exterior L = Hinge at left side exterior Inswing Outswing Available Grille Patterns 8’ Height

DFP

Full Lite

LEGEND S = R = L =

= Inswing DFH = Outswing

6’8 & 6’11 Height 10-Lite 15-Lite 3 Lite Prairie 4 Lite 4 Lite Tall Standard 12-Lite 18-Lite 3 Lite Prairie 4 Lite 4 Lite Tall Standard

Full Lite Panel Specifications

Sidelights

Fixed Sidelight Panels Hinged Patio Door - Fixed Sidelights 4 7/16” 4 7/16” 4 7/16” 4 7/16” 4 7/16 4 7/16” 62 10 6 ” 6 ” 6” 6” 6” 6” 6” 6” 6” 6” 6” 6” 10”12” 10”12” 10”12” 10”12” 10” 12 7 7/8” 10 7/8” 7 7/8” 7 7/8” 7 7/8” 10 7/8” 79 1/16” 76 1/16” 92 1/16” 79 1/16” 76 1/16” 92 1/16” 12 Sidelights Inswing Outswing 4 7/16” 4 7/16” 4 7/16” 6” 6” 6” 6” 6” 6” 10”12” 10”12” 10 12” Outswing 4 7/16” 4 7/16” 4 7/16” 4 7/16 4 7/16 4 7/16” 62 10” 6 ” 6 ” 6” 6” 6” 6” 6” 6” 6” 6” 6” 6” 10”12” 10”12” 10”12” 12” 10”12” 10” 12 12 7 7/8” 10 7/8” 7 7/8” 7 7/8” 7 7/8” 10 7/8” 6 5/16 ” 5 1/16 ” 79 1/16” 76 1/16” 92 1/16” 79 1/16” 76 1/16” 92 1/16” 5 1/4” 12 47 1/4” 5 1/4” 6 5/16” 77 5/16” 7 1/4” 63 1/4” Inswing Outswing 4 7/16” 4 7/16 62 6” 6” 6” 6” 10”12” 10”12” 12” 7 7/8” 10 7/8” 7 7/8” 7 7/8” 7 7/8” 10 7/8” 5 1/16 ” 6 5/16 ” 5 1/16 ” 79 1/16” 92 1/16” 79 1/16” 79 1/16” 5 1/16 ” 8 1/16 ” 5 1/4” 92 1/16” 92 1/16” 63 1/4” 5 1/4” 5 1/4” 47 1/4” 12” 6 1/4” 7 1/4” 7 1/4” 63 1/4” 4 7/16” 4 7/16” 4 7/16” 4 7/16 4 7/16 4 7/16” 6 6” 6” 6” 6” 6” 6” 6” 6” ”12” ”12” 10”12” 10”12” 10” 12 7 7/8” 10 7/8” 7 7/8” 7 7/8” 7 7/8” 10 7/8” 79 1/16” 76 1/16” 92 1/16” 79 1/16” 76 1/16” 92 1/16” 12”

Inswing Outswing 4 7/16” 4 7/16” 4 7/16” 4 7/16” 4 7/16 4 7/16” 62 10 6 ” 6 ” 6” 6” 6” 6” 6” 6” 6” 6” 6” 6” 10”12” 10”12” 10”12” 12 10”12” 10” 12 12 7 7/8” 10 7/8” 7 7/8” 7 7/8” 7 7/8” 10 7/8” 6 5/16 ” 5 1/16 ” 79 1/16” 76 1/16” 92 1/16” 79 1/16” 76 1/16” 92 1/16” 5 1/4” 12” 47 1/4” 5 1/4” 6 5/16” 77 5/16” 1/4” 63 1/4” Inswing Outswing

Double Hinged Full Lite Door Smooth White Finish | LoE 366 Glass

Full Lite Panel Specifications

Products 23

Inswing & Outswing Patio Doors Hinged Patio Door - Inswing Hinged Patio Door - Outswing 3068 2868 2668 3080 2880 2680 2280 23 3/4” 3076 5 3/8” 11 1/2” 69 1/4” 86 1/16” 5 5/16” 30611 28611 26611 2268 22611 23 3/4” 5 3/8” 12 3/4” 69 1/4” 87 5/16” 5 5/16” 3080 2880 2680 2280 3076 30611 28611 26611 3068 2868 2668 2268 22611

Mull Kits

Hinged Outswing

Hinged Inswing

ADA Handicap Sill

ADA Hinged Outswing Sill-5 5/8" (Endura #ZHCOT5622)

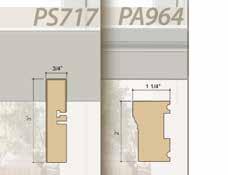

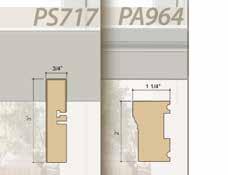

PS Serials-Neuma Outswing Jamb

When creating a custom configuration by combining panels and door units, add 5/8” to the unit dimension to allow for the width of the aluminum mull.

PS Serials-Neuma Outswing Jamb

Hinged Jamb

Outswing Hinged Jamb

PS946 Brickmold (Sold Separately)

PS Serials-Neuma Inswing Jamb

Inswing Hinged Jamb

PS Serials-Neuma Inswing Jamb

PS946 Brickmold (Sold Separately)

ADA Hinged Outswing Sill-7 9/16" (Extension Jamb:Endura #ZHCOT7562*)

ADA Hinged Inswing Sill-4 9/16" (Endura #ZHCIT4562)

PS Serials-Neuma Outswing Extension Jamb

ADA Hinged Inswing Sill-5 5/8" (Extension Jamb:Endura #ZHCIT5622)

PS Serials-Neuma Outswing Extension Jamb

PS946 Brickmold (Sold Separately)

PS Serials-Neuma Inswing Extension Jamb

PS Serials-Neuma Inswing Extension Jamb

PS946 Brickmold (Sold Separately)

24 Products Wall Thickness 4 9/16" [116] Wall Thickness 4 9/16" [116] Overall Jamb Width Wall Thickness 6 9/16" [166.8] Wall Thickness 6 9/16" [166.8] 5 3/4" [146.1] Overall Jamb Width 5 3/4" [146.1] Overall Jamb Width 7 3/4" [196.9] Overall Jamb Width 7 3/4" [196.9]

Shim (by Others)

Shim (by Others) Shim (by Others) Shim (by Others) PS946 Brickmold (Sold Separately)

Brickmold (Sold Separately) Included Nailing Fin Included Nailing Fin Included Nailing Fin Included Nailing Fin

PS946 Brickmold (Sold Separately) PS946 Brickmold (Sold Separately) PS946

Mull Extension fo r Optional Extended Jambs 5/8” SA060 SA061 Mull Extension for Optional Extended Jambs 5/8” SA052 SA061

Wall Thickness 4 9/16" [116] Wall Thickness 4 9/16" [116] Overall Jamb Width Wall Thickness 6 9/16" [166.8] Wall Thickness 6 9/16" [166.8] 5 3/4" [146.1] Overall Jamb Width 5 3/4" [146.1] Overall Jamb Width 7 3/4" [196.9] Overall Jamb Width 7 3/4" [196.9]

Shim (by Others)

Shim (by Others) Shim (by Others) Shim (by Others)

Included Nailing Fin Included Nailing Fin Included Nailing Fin Included Nailing Fin

5 5/8" [143] 7 9/16"

1/2" [12.5] 1/2" [12.5] 4 9/16" [115.6] 1/2" [12.7] 5 5/8" [142.9] 1/2" [12.7]

[192.2]

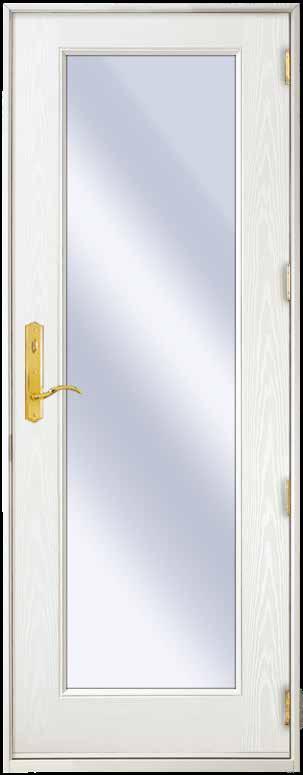

Single Hinged Full Lite Door

Smooth White Finish | LoE 366 Glass

Fixed Sidelight Single Panel Units

Two Panel Units

26 Products

3/4 Lite

6’-8” 6’-1 1” 8’-0 ” 6’-10 1/2” (for Inswing) 6’-9 1/4 (for Outswing) 8“ 7 1’-2 3/4” 1’-2” ” 6’-8” 6’-1 1” 8’-0 ” 6’-10 1/2” (for Inswing) 6’-9 1/4 (for Outswing)

3/4 Lite Handing

Inswing

Outswing

Standard GrilleStandardPatternsGrille Patterns Standard Grille Patterns

Standard GrilleStandardPatternsGrille Patterns Standard Grille Patterns

Handing from exterior view

Doors are not reversible

Retractable screen available as an option

Passive Stationary Hinge at right side exterior view Hinge at left side exterior view

Inswing

Products 27

L

DFP

LEGEND P = S = R =

=

= Inswing DFH = Outswing

Outswing 6’-10 1/2” 6’-9 7/16 6’-10 1/2” 6’-9 7/16 6’-10 1/2” 6’-9 7/16

Three Panel Units

28 Products Outswing Inswing

3/4 Lite

3/4 Lite Inswing & Outswing Patio Doors

Hinged Patio Door - Inswing

Hinged Patio Door - Outswing

Hinged Patio Door Sidelights - Inswing

Hinged Patio Door Sidelights - Outswing

Products 29 3068 3080 2868 2880 2668 2680 3068 30611 3080 2868 28611 2880 2668 26611 2680 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 19 1/4” 19 1/4” 21 1/4” 21 1/4” 21 1/4” 25 1/4” 25 1/4” 25 1/4” 5 1/16” 5 1/16” 5 1/16” 6 5/16” 6 5/16” 6 5/16” 8 1/16” 8 1/16” 8 1/16” 5 1/16” 5 1/16” 5 1/16” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 5 1/4” 5 1/4” 5 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 5 1/4” 5 1/4” 5 1/4” 47 1/4” 47 1/4” 47 1/4” 6 5/16” 6 5/16” 6 5/16” 76 1/16” 5 1/16” 5 1/4” 47 1/4” 12” 6 1/4” 18 17/32” 1268 18 17/32” 1280 79 1/16” 8 1/16” 5 1/4” 47 1/4” 12” 6 1/4” 92 1/16” 5 1/16” 5 1/4” 63 1/4” 12” 7 1/4” 18 17/32” 77 5/16” 6 5/16” 5 1/4” 47 1/4” 12” 6 1/4” 18 17/32” 1268 1280 93 5/16” 6 5/16” 5 1/4” 63 1/4” 12” 7 1/4” 18 17/32” 5 1/4” 5 1/4” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 30611 28611 26611 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 8 1/16” 8 1/16” 8 1/16” 5 1/4” 47 1/4” 47 1/4” 47 1/4” 5 1/4” 5 1/4” 18 17/32” 18 17/32” 18 17/32” 79 1/16” 79 1/16” 79 1/16” 18 17/32” 79 1/16” 8 1/16” 5 1/4” 47 1/4” 12” 6 1/4” 3068 3080 2868 2880 2668 2680 3068 30611 3080 2868 28611 2880 2668 26611 2680 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 19 1/4” 19 1/4” 21 1/4” 21 1/4” 21 1/4” 25 1/4” 25 1/4” 25 1/4” 5 1/16” 5 1/16” 5 1/16” 6 5/16” 6 5/16” 6 5/16” 8 1/16” 8 1/16” 8 1/16” 5 1/16” 5 1/16” 5 1/16” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 5 1/4” 5 1/4” 5 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 5 1/4” 5 1/4” 5 1/4” 47 1/4” 47 1/4” 47 1/4” 6 5/16” 6 5/16” 6 5/16” 76 1/16” 5 1/16” 5 1/4” 47 1/4” 12” 6 1/4” 18 17/32” 1268 18 17/32” 1280 79 1/16” 8 1/16” 5 1/4” 47 1/4” 12” 6 1/4” 92 1/16” 5 1/16” 5 1/4” 63 1/4” 12” 7 1/4” 18 17/32” 77 5/16” 6 5/16” 5 1/4” 47 1/4” 12” 6 1/4” 18 17/32” 1268 1280 93 5/16” 6 5/16” 5 1/4” 63 1/4” 12” 7 1/4” 18 17/32” 5 1/4” 5 1/4” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 30611 28611 26611 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 8 1/16” 8 1/16” 8 1/16” 5 1/4” 47 1/4” 47 1/4” 47 1/4” 5 1/4” 5 1/4” 18 17/32” 18 17/32” 18 17/32” 79 1/16” 79 1/16” 79 1/16” 18 17/32” 79 1/16” 8 1/16” 5 1/4” 47 1/4” 12” 6 1/4” 3068 3080 2868 2880 2668 2680 3068 30611 3080 2868 28611 2880 2668 26611 2680 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 19 1/4” 19 1/4” 21 1/4” 21 1/4” 21 1/4” 25 1/4” 25 1/4” 25 1/4” 5 1/16” 5 1/16” 5 1/16” 6 5/16” 6 5/16” 6 5/16” 8 1/16” 8 1/16” 8 1/16” 5 1/16” 5 1/16” 5 1/16” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 5 1/4” 5 1/4” 5 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 5 1/4” 5 1/4” 5 1/4” 47 1/4” 47 1/4” 47 1/4” 6 5/16” 6 5/16” 6 5/16” 76 1/16” 5 1/16” 5 1/4” 47 1/4” 12” 6 1/4” 18 17/32” 1268 18 17/32” 1280 79 1/16” 8 1/16” 5 1/4” 47 1/4” 12” 6 1/4” 92 1/16” 5 1/16” 5 1/4” 63 1/4” 12” 7 1/4” 18 17/32” 77 5/16” 6 5/16” 5 1/4” 47 1/4” 12” 6 1/4” 18 17/32” 1268 1280 93 5/16” 6 5/16” 5 1/4” 63 1/4” 12” 7 1/4” 18 17/32” 5 1/4” 5 1/4” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 30611 28611 26611 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 8 1/16” 8 1/16” 8 1/16” 5 1/4” 47 1/4” 47 1/4” 47 1/4” 5 1/4” 5 1/4” 18 17/32” 18 17/32” 18 17/32” 79 1/16” 79 1/16” 79 1/16” 18 17/32” 79 1/16” 8 1/16” 5 1/4” 47 1/4” 12” 6 1/4” 3068 3080 2868 2880 2668 2680 3068 30611 3080 2868 28611 2880 2668 26611 2680 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 19 1/4” 19 1/4” 21 1/4” 21 1/4” 21 1/4” 25 1/4” 25 1/4” 25 1/4” 5 1/16” 5 1/16” 5 1/16” 6 5/16” 6 5/16” 6 5/16” 8 1/16” 8 1/16” 8 1/16” 5 1/16” 5 1/16” 5 1/16” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 5 1/4” 5 1/4” 5 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 63 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 5 1/4” 5 1/4” 5 1/4” 47 1/4” 47 1/4” 47 1/4” 6 5/16” 6 5/16” 6 5/16” 76 1/16” 5 1/16” 5 1/4” 47 1/4” 12” 6 1/4” 18 17/32” 1268 18 17/32” 1280 79 1/16” 8 1/16” 5 1/4” 47 1/4” 12” 6 1/4” 92 1/16” 5 1/16” 5 1/4” 63 1/4” 12” 7 1/4” 18 17/32” 77 5/16” 6 5/16” 5 1/4” 47 1/4” 12” 6 1/4” 18 17/32” 1268 1280 93 5/16” 6 5/16” 5 1/4” 63 1/4” 12” 7 1/4” 18 17/32” 5 1/4” 5 1/4” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 18 17/32” 30611 28611 26611 4 5/8” 4 5/8” 4 5/8” 19 1/4” 21 1/4” 25 1/4” 8 1/16” 8 1/16” 8 1/16” 5 1/4” 47 1/4” 47 1/4” 47 1/4” 5 1/4” 5 1/4” 18 17/32” 18 17/32” 18 17/32” 79 1/16” 79 1/16” 79 1/16” 18 17/32” 79 1/16” 8 1/16” 5 1/4” 47 1/4” 12” 6 1/4”

Double Hinged Vented Sidelight Door Smooth White | LoE340 Glass

Double Hinged Vented Sidelight Door Smooth White | LoE340 Glass

VENTED SIDELIGHT OPTIONS

Operable Vented Sidelights

Continuous head and sill, with a mullion system designed to maximize stability and ease of installation.

Sidelights come standard with multipoint locking system for stability and security.

Sidelights come standard with stationary screens for maximum comfort. Screens are removable for cleaning.

No extra assembly required. Vented Sidelight door units are designed and delivered fully assembled.

Fully operable hinged sidelights

Available in woodgrain finish

Optional retractable screens available

Height 6’-8” only

Width 6’-0” and 8’-0”

Fully Operable Hinged Sidelights Shown

Sidelight vents feature a craftsman style thumb-turn.

medium

Products 31

Interior

Exterior

with

oak finish and satin nickel Royal handle set.

Shown with golden oak finish, gold brass Royal handle set.

VENTED SIDELIGHT UNITS AND DIMENSIONS

Vented Sidelight

Inswing Ve nted Sidelig ht 6’8” Retro Fit

Vented Sidelight Panel Specifications

Ve nted Sidelig ht 6’8” Retro Fit

Inswing Ve nted Sidelig ht 6’8” Retro Fit

Inswing Ve nted Sidelig ht 6’8” Retro Fit

Inswing Vented Sidelight 6’8’’Retro Fit

LEGEND

LEGEND

. Handing from exterior view

. Handing from exterior view

Doors are not reversible

Doors are not reversible

Retractable screen available as an option

Retractable screen available as an option

LEGEND

LEGEND

. Handing from exterior view

. Handing from exterior view

P = Passive

P = Passive

S = Stationary

S = Stationary

Stationary Hinge at right side exterior view Hinge at left side exterior view

Stationary at right side exterior view at left side exterior view

LEGEND

DFP= Inswing DFH= Outswing

DFP= Inswing DFH= Outswing

Handing from exterior view

Doors are not reversible

Retractable screen available as an option

LEGEND

LEGEND

P = Passive

. Doors are not reversible

. Doors are not reversible

. Retractable screen available as an option

R = Hinge at right side exterior view

. Retractable screen available as an option

P = Passive

S = Stationary

R = Hinge at right side exterior view

L = Hinge at left side exterior view

DVS = Vented Sidelight

P = Passive

R = Hinge at right side exterior

L = Hinge at left side exterior view

L = Hinge at left side exterior view

DVS= Vented Sidelight

DVS= Vented Sidelight

.

Handing from exterior view

Handing from exterior view

S = Stationary

S = Stationary

Doors are not reversible

Doors are not reversible

Retractable screen available as an option

R = Hinge at right side exterior view

. Retractable screen available as an option

R = Hinge at right side exterior view

L = Hinge at left side exterior view

L = Hinge at left side exterior view

*For all product testing approval numbers and information, please visit http://www.neumadoors. com/resource

DVS= Vented Sidelight

DVS= Vented Sidelight

**For Florida Building Code Approval, please see http://www.floridabuilding.org/pr/pr_app_srch.aspx. For Texas Department of Insurance Approval, see http://www.tdi.state.tx.us/wind/prod/indexdr.html For Dade County Approval, see http://www.miamidade.gov/building/pcsearch_app.asp?

32 Products

Ve nted Sidelig ht 6’8” Retro Fit 9076

Inswing

P = S

R

L = DVS=

=

=

Inswing Ve nted Sidelig ht 6’8” Retro Fit 9076

P = Passive S = Stationary R = Hinge L = Hinge

DVS=

63

63

Product Description: glazing layers / spacer type LoE emissivity (surface) / gap l / gap width / grilles / *New Data Pending SS=stainless steel LoE emissivity 0.057=LoE 340 0.022=LoE 366 ARG = argon N = no grille G = with grille < 1" Product Speci cation STC OITC 6068, LS Gliding (1" Double Laminated Glass) 33 30 6068, LS Gliding (1" Standard Laminated Glass) 32 29

Sound Transmission Class - Non-Impact

HINGED TRANSOM UNITS AND DIMENSIONS

Transoms For Hinged Doors

Single Panel Units

Two Panel Units

LEGEND

For Three Panel Units

For Vented Sidelight

*For

Rough Opening Width = Unit Dim. Width + 3/4”

Rough Opening Height = Unit Dim. Height + 1/2” Glass Option: Clear / Inner Grille / Art Glass

Custom Size Also Available by Special Order

Standard Transom are Equal Size Glass

Special Size or Special Lite Pattern Must be by Special Order

GTI = Inswing

GTO = Outswing

GTV = Vented Sidelight

1. Rough Opening Width=Unit Dim. Width + 3/4”

2. Rough Opening Height = Unit Dim. Height + 1/2”

3. Glass Option: Clear / Inner Grille / Art Glass

4. Custom Size Also Available by Special Order

5. Standard transom are equal size glass

LEGEND

Note: Transom grid patterns may not align with certain doors. Please call for assistance with transom selection.

6. Special size or special Lite pattern must be by special order

7.

8.

LEGEND

1. Rough Opening Width=Unit Dim. Width + 3/4”

2. Rough Opening Height = Unit Dim. Height + 1/2”

3. Glass Option: Clear / Inner Grille / Art Glass

1. Rough Opening Width=Unit Dim. Width + 3/4”

9. GTV = Vented Sidelight

4. Custom Size Also Available by Special Order

2. Rough Opening Height = Unit Dim. Height

5. Standard transom are equal size glass

3. Glass Option: Clear / Inner Grille / Art Glas

6. Special size or special Lite pattern must be by special order

7. GTI = Inswing

*All transoms with divided lites are True Divided Lite (TDL). Grille between glass (GBG) and simulated divided lite (SDL) options are also available.

4. Custom Size Also Available by Special Orde

5. Standard transom are equal size glass

8. GTO = Outswing

9. GTV = Vented Sidelight

6. Special size or special Lite pattern must be by special order

=

Products 33

2‘-7 3/8” 2’-6 5/8” 28 1/2” 2‘-9 3/8” 2’-8 5/8” 30 1/2” 3‘-1 3/8” 3’-0 5/8” 34 1/2” GTI 2610 GTO 2610 GTI 2810 GTO 2810 GTI 3010 GTO 3010 GTI 5010 GTO 5010 GTI 5410 GTO 5410 GTI 6010 GTO 6010 GTI 5010-2 TDL GTO 5010-2 TDL GTI 5410-2 TDL GTO 5410-2 TDL GTI 6010-2 TDL GTO 6010-2 TDL GTI 5014 GTO 5014 GTI 5414 GTO 5414 GTI 6014 GTO 6014 GTI 5014-2 TDL GTO 5014-2 TDL GTI 5414-2 TDL GTO 5414-2 TDL GTI 6014-2 TDL GTO 6014-2 TDL GTI 5020 GTO 5020 GTI 5420 GTO 5420 GTI 6020 GTO 6020 GTI 5020-2 TDL GTO 5020-2 TDL GTI 5420-2 TDL GTO 5420-2 TDL GTI 6020-2 TDL GTO 6020-2 TDL GTI 2614 GTO 2614 GTI 2814 GTO 2814 GTI 3014 GTO 3014 GTI 2620 GTO 2620 GTI 2820 GTO 2820 GTI 3020 GTO 3020 * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * 5‘ 4’-11 1/4” 57 1/8” 5‘-4” 5’-3 1/4” 61 1/8” 6‘ 5’-11 1/4” 69 1/8” 27 3/4” 29 3/4” 33 3/4” 1‘1/2” 1’ 9 7/8” 1‘4 1/2” 1’-4“ 13 7/8” 2‘1/2” 2’ 21 7/8” Rough Opening Unit Dim. Glass Dim. * * * * * * * * * * * * * * * * * * 7‘-4 9/16” 7’-3 13/16” 27 7/16” 7‘-10 9/16” 7’-9 13/16” 29 7/16” 8‘-10 9/16” 8’-9 13/16” 33 7/16” 1‘1/2” 1’ 9 7/8” 1‘4 1/2” 1’-4“ 13 7/8” 2‘1/2” 2’ 21 7/8” GTI 7610-3 TDL GTO 7610-3 TDL GTI 8010-3 TDL GTO 8010-3 TDL GTI 9010-3 TDL GTO 9010-3 TDL GTI 9014-3 TDL GTO 9014-3 TDL GTI 8014-3 TDL GTO 8014-3 TDL GTI 7614-3 TDL GTO 7614-3 TDL GTI 7620-3 TDL GTO 7620-3 TDL GTI 8020-3 TDL GTO 8020-3 TDL GTI 9020-3 TDL GTO 9020-3 TDL Rough Opening Unit Dim. Glass Dim.

** ** ** ** ** ** * * *

*For Vented Sidelight*

LEGEND

TDL TDL TDL TDL TDL TDL TDL TDL TDL

GTI

= Inswing

GTO

= Outswing

* * * * * * * * * * * * * * * * * * * * * * * * * * * 2‘-7 3/8” 2’-6 5/8” 28 1/2” 2‘-9 3/8” 2’-8 5/8” 30 1/2” 3‘-1 3/8” 3’-0 5/8” 34 1/2” GTI 2610 GTO 2610 GTI 2810 GTO 2810 GTI 3010 GTO 3010 GTI 5010 GTO 5010 GTI 5410 GTO 5410 GTI 6010 GTO 6010 GTI 5010-2 TDL GTO 5010-2 TDL GTI 5410-2 TDL GTO 5410-2 TDL GTI 6010-2 TDL GTO 6010-2 TDL GTI 5014 GTO 5014 GTI 5414 GTO 5414 GTI 6014 GTO 6014 GTI 5014-2 TDL GTO 5014-2 TDL GTI 5414-2 TDL GTO 5414-2 TDL GTI 6014-2 TDL GTO 6014-2 TDL GTI 5020 GTO 5020 GTI 5420 GTO 5420 GTI 6020 GTO 6020 GTI 5020-2 TDL GTO 5020-2 TDL GTI 5420-2 TDL GTO 5420-2 TDL GTI 6020-2 TDL GTO 6020-2 TDL GTI 2614 GTO 2614 GTI 2814 GTO 2814 GTI 3014 GTO 3014 GTI 2620 GTO 2620 GTI 2820 GTO 2820 GTI 3020 GTO 3020 * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * 5‘ 4’-11 1/4” 57 1/8” 5‘-4” 5’-3 1/4” 61 1/8” 6‘ 5’-11 1/4” 69 1/8” 27 3/4” 29 3/4” 33 3/4” 1‘1/2” 1’ 9 7/8” 1‘4 1/2” 1’-4“ 13 7/8” 2‘1/2” 2’ 21 7/8” Rough Opening Unit Dim. Glass Dim. * * * * * * * * * * * * * * * * * * 7‘-4 9/16” 7’-3 13/16” 27 7/16” 7‘-10 9/16” 7’-9 13/16” 29 7/16” 8‘-10 9/16” 8’-9 13/16” 33 7/16” 1‘1/2” 1’ 9 7/8” 1‘4 1/2” 1’-4“ 13 7/8” 2‘1/2” 2’ 21 7/8” GTI 7610-3 TDL GTO 7610-3 TDL GTI 8010-3 TDL GTO 8010-3 TDL GTI 9010-3 TDL GTO 9010-3 TDL GTI 9014-3 TDL GTO 9014-3 TDL GTI 8014-3 TDL GTO 8014-3 TDL GTI 7614-3 TDL GTO 7614-3 TDL GTI 7620-3 TDL GTO 7620-3 TDL GTI 8020-3 TDL GTO 8020-3 TDL GTI 9020-3 TDL GTO 9020-3 TDL Rough Opening Unit Dim. Glass Dim.

** ** ** ** ** ** * * *

*For Vented Sidelight*

TDL TDL TDL TDL TDL TDL TDL TDL TDL

GTI

Inswing

GTO

Outswing

GTV

Vented Sidelight * * * * * * * * * * * * * * * * * * * * * * * * * * * 2‘-7 3/8” 2’-6 5/8” 28 1/2” 2‘-9 3/8” 2’-8 5/8” 30 1/2” 3‘-1 3/8” 3’-0 5/8” 34 1/2” GTI 2610 GTO 2610 GTI 2810 GTO 2810 GTI 3010 GTO 3010 GTI 5010 GTO 5010 GTI 5410 GTO 5410 GTI 6010 GTO 6010 GTI 5010-2 TDL GTO 5010-2 TDL GTI 5410-2 TDL GTO 5410-2 TDL GTI 6010-2 TDL GTO 6010-2 TDL GTI 5014 GTO 5014 GTI 5414 GTO 5414 GTI 6014 GTO 6014 GTI 5014-2 TDL GTO 5014-2 TDL GTI 5414-2 TDL GTO 5414-2 TDL GTI 6014-2 TDL GTO 6014-2 TDL GTI 5020 GTO 5020 GTI 5420 GTO 5420 GTI 6020 GTO 6020 GTI 5020-2 TDL GTO 5020-2 TDL GTI 5420-2 TDL GTO 5420-2 TDL GTI 6020-2 TDL GTO 6020-2 TDL GTI 2614 GTO 2614 GTI 2814 GTO 2814 GTI 3014 GTO 3014 GTI 2620 GTO 2620 GTI 2820 GTO 2820 GTI 3020 GTO 3020 * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * 5‘ 4’-11 1/4” 57 1/8” 5‘-4” 5’-3 1/4” 61 1/8” 6‘ 5’-11 1/4” 69 1/8” 27 3/4” 29 3/4” 33 3/4” 1‘1/2” 1’ 9 7/8” 1‘4 1/2” 1’-4“ 13 7/8” 2‘1/2” 2’ 21 7/8” Rough Opening Unit Dim. Glass Dim. * * * * * * * * * * * * * * * * * * 7‘-4 9/16” 7’-3 13/16” 27 7/16” 7‘-10 9/16” 7’-9 13/16” 29 7/16” 8‘-10 9/16” 8’-9 13/16” 33 7/16” 1‘1/2” 1’ 9 7/8” 1‘4 1/2” 1’-4“ 13 7/8” 2‘1/2” 2’ 21 7/8” GTI 7610-3 TDL GTO 7610-3 TDL GTI 8010-3 TDL GTO 8010-3 TDL GTI 9010-3 TDL GTO 9010-3 TDL GTI 9014-3 TDL GTO 9014-3 TDL GTI 8014-3 TDL GTO 8014-3 TDL GTI 7614-3 TDL GTO 7614-3 TDL GTI 7620-3 TDL GTO 7620-3 TDL GTI 8020-3 TDL GTO 8020-3 TDL GTI 9020-3 TDL GTO 9020-3 TDL Rough Opening Unit Dim. Glass Dim.

7.

=

8.

=

9.

** ** ** ** ** ** * * *

Vented Sidelight*

TDL TDL TDL TDL TDL TDL TDL TDL TDL

* * * * * * * * * * * * * * * * * * * * * * * * * * *

1. 2. 3. 4. 5. 6. 7. 8. 9.

Center Hinged Full Lite Door

Painted Finish | LoE366 Glass

Center Hinged Full Lite Door

Painted Finish | LoE366 Glass

HINGED TEST RESULTS

Hinged Non-Impact

Full Lite Inswing Non-Impact AAMA Test Results

Hinged Patio Doors - Non-Impact Inswing AAMA Test Results (Full Lite Panel)

Hinged Patio Doors - Non-Impact Inswing AAMA Test Results (Full Lite Panel)

Hinged Patio Doors - Non-Impact Inswing AAMA Test Results (Full Lite Panel)

3/4 Lite Inswing - Non-Impact AAMA Results

Inswing - Non-Impact AAMA Test Results (3/4 Lite Panel)

Full Lite Outswing - Non-Impact AAMA Test Results

3/4 Lite Outswing - Non-Impact AAMA Test Results

Outswing - Non-Impact AAMA Test Results (3/4 Lite Panel)

Products 35

Product Struc ture Performance (psf ) Water Resistance (psf) 3068, 30611, L/R/S DP40 +90/-906.0 6068, 60611, LP/PR/SL/RS/SS DP40 +90/-90 6.0 FL 14752.5-R FL 14752.7-R dr649 12068, 120611, SLPS/SPRS DP40 +90/-90 6.0 3080, L/R/S DP40 +75/-757.5 6080, LP/PR/SL/RS/SS DP40 +75/-75 7.5 FL 14752.24-R6 dr649 12080, SLPS/SPRS DP40 AAMA 101 Standard F.B.C & Approval Design Pressure Rating +75/-75 7.5 SHD-CLASS R-PG40 144” X 83” SHD-CLASS R-PG50 144” X 96” s Product Water Resistance (psf) DP50 +75/-75 7.5 SHD-class R-PG50 143 1/8"x95 1/2" FL14752.27-R4 12080 SLPS Design Pressure Rating

AAMA 101 Standard F.B.C & T.D.I Approval No. Struc ture Performance (psf )

- Non-Impact AAMA Test Results (Full Lite Panel) Product Struc ture Performance (psf ) Water Resistance (psf) 3068, 30611, L/R/S DP65 +97.5/-97.59.75 6060, 60611, LP/PR/SL/RS/SS DP70 +105/-105 10.5 FL 14752.7 dr65 DP65 +97.5/-97.5 9.75 DP70 +105/-105 10.5 DP65 +97.5/-97.5 9.75 FL 14752.9 dr65 12068, 120611, SLPS/SPRS DP70 AAMA 101 Standard F.B.C & Approval Design Pressure Rating +105/-105 10.5 SHD-CLASS R-PG70 143 1/4” X 82 1/2” s 3080, L/R/S DP65 +97.5/-97.5 9.75 6080, LP/PR/SL/RS/SS DP70 +105/-105 10.5 FL 14752.7 dr65 DP65 +97.5/-97.5 9.75 DP70 +105/-105 10.5 DP65 +97.5/-97.5 9.75 FL 14752.9 dr65 12080, SLPS/SPRS DP70 +105/-105 10.5 SHD-CLASS R-PG70 143 1/4” X 95 3/4” Air In ltration (cfm/ft2) Air In ltration (cfm/ft2) Air In ltration (cfm/ft2) 0.02 0.09 0.006 DP50 +75/-75 7.5 SHD-class R-PG50 143 1/8"x82 1/2" FL14752.30-R4 120611 SLPS 0.1 0.19 0.14

Outswing

Product Struc ture Performance (psf ) Water Resistance (psf) 3068, 30611, L/R/S DP40 +90/-906.0 6068, 60611, LP/PR/SL/RS/SS DP40 +90/-90 6.0 12068, 120611, SLPS/SPRS DP40 +90/-90 6.0 3080, L/R/S DP40 +75/-757.5 6080, LP/PR/SL/RS/SS DP40 +75/-75 7.5 12080, SLPS/SPRS DP40 AAMA 101 Standard Design Pressure Rating +75/-75 7.5 SHD-CLASS R-PG40 144” X 83” SHD-CLASS R-PG50 144” X 96” s Product Water Resistance (psf) DP50 +75/-75 7.5 SHD-class R-PG50 143 1/8"x95 1/2" FL14752.27-R4 12080 SLPS Design Pressure Rating Inswing - Non-Impact AAMA Test Results (3/4 Lite Panel) AAMA 101 Standard F.B.C & Approval Struc ture Performance (psf )

AAMA

Product Struc ture Performance (psf ) Water Resistance (psf) 3068, 30611, L/R/S DP65 +97.5/-97.59.75 6060, 60611, LP/PR/SL/RS/SS DP70 +105/-105 10.5 DP65 +97.5/-97.5 9.75 DP70 +105/-105 10.5 DP65 +97.5/-97.5 9.75 12068, 120611, SLPS/SPRS DP70 AAMA 101 Standard Design Pressure Rating +105/-105 10.5 SHD-CLASS R-PG70 143 1/4” X 82 1/2” s 3080, L/R/S DP65 +97.5/-97.5 9.75 6080, LP/PR/SL/RS/SS DP70 +105/-105 10.5 DP65 +97.5/-97.5 9.75 DP70 +105/-105 10.5 DP65 +97.5/-97.5 9.75 12080, SLPS/SPRS DP70 +105/-105 10.5 SHD-CLASS R-PG70 143 1/4” X 95 3/4” Air In ltration (cfm/ft2) Air In ltration (cfm/ft2) Air In ltration (cfm/ft2) 0.02 0.09 0.006 DP50 +75/-75 7.5 SHD-class R-PG50 143 1/8"x82 1/2" FL14752.30-R4 120611 SLPS 0.1 0.19 0.14 6080, LP/PR/SL/RS/SS DP65 +97.5/-97.5 9.75 DP70 +105/-105 10.5 DP65 +97.5/-97.5 9.75 12080, SLPS/SPRS DP70 +105/-105 10.5 Product Water Resistance (psf) Design Pressure Rating Vented Sidelight - Non-Impact AAMA Test Results AAMA Standard Struc ture Performance (psf )

Outswing - Non-Impact

Test Results (Full Lite Panel)

12080 SLPS DP50 +75 / -75 7.5 12068,SLPS DP50 +75 / -75 7.5 SHD-class R-PG50 143 1/8"x95 1/2" SHD-class R-PG50 143 1/8"x79 1/2" Air In ltration (cfm/ft2) 0.14 0.001 0.001 Product Speci cation Design Pressure Rating Structure Performance (psf) Water Resistance (psf) Air In ltration (cfm/ft2) AAMA 101 Standard

Product Struc ture Performance (psf ) Water Resistance (psf) 3068, 30611, L/R/S DP40 +90/-906.0 6068, 60611, LP/PR/SL/RS/SS DP40 +90/-90 6.0 FL 14752.5-R7 FL 14752.7-R7 dr649 12068, 120611, SLPS/SPRS DP40 +90/-90 6.0 3080, L/R/S DP40 +75/-757.5 6080, LP/PR/SL/RS/SS DP40 +75/-75 7.5 FL 14752.24-R7 dr649 12080, SLPS/SPRS DP40 AAMA 101 Standard F.B.C & T.D.I Approval No. Design Pressure Rating +75/-75 7.5 SHD-CLASS R-PG40 144” X 83” SHD-CLASS R-PG50 144” X 96” s Product Water Resistance (psf) DP50 +75/-75 7.5 SHD-class R-PG50 143 1/8"x95 1/2" FL14752.27-R4 12080 SLPS Design Pressure Rating

- Non-Impact

AAMA 101 Standard F.B.C & T.D.I Approval No. Struc ture Performance (psf )

Product Struc ture Performance (psf ) Water Resistance (psf) 3068, 30611, L/R/S DP65 +97.5/-97.59.75 6060, 60611, LP/PR/SL/RS/SS DP70 +105/-105 10.5 FL 14752.7 dr650 DP65 +97.5/-97.5 9.75 DP70 +105/-105 10.5 DP65 +97.5/-97.5 9.75 FL 14752.9 dr650 12068, 120611, SLPS/SPRS DP70 AAMA 101 Standard F.B.C & T.D.I Approval No. Design Pressure Rating +105/-105 10.5 SHD-CLASS R-PG70 143 1/4” X 82 1/2” s 3080, L/R/S DP65 +97.5/-97.5 9.75 6080, LP/PR/SL/RS/SS DP70 +105/-105 10.5 FL 14752.7 dr650 DP65 +97.5/-97.5 9.75 DP70 +105/-105 10.5 DP65 +97.5/-97.5 9.75 FL 14752.9 dr650 12080, SLPS/SPRS DP70 +105/-105 10.5 SHD-CLASS R-PG70 143 1/4” X 95 3/4” SHD-CLASS R-PG70 143 1/4” F.B.C. Approval FL14752.28-R4 Air In ltration (cfm/ft2) Air In ltration (cfm/ft2) Air In ltration (cfm/ft2) 0.02 0.09 0.006 DP50 +75/-75 7.5 SHD-class R-PG50 143 1/8"x82 1/2" FL14752.30-R4 120611 SLPS 0.1 0.19 0.14 FL14752.31-R4

Inswing

AAMA Test Results (3/4 Lite Panel)

Outswing - Non-Impact AAMA Test Results (Full Lite Panel)

Hinged Transoms

Transom Test Results - Non

HINGED TRANSOMS

Transom Test Results - Non Impact

Transom Test Results Impact

Transom Results - Impact

Transom Results - Impact

36 Products

Energy Performacnce Rating - Non-Impact Hinged Transom Test Results - Non Impact

Sound Transmission Class - Non-Impact Hinged Vented Sidelight - Non-Impact AAMA Results Product Water Resistance (psf) DP30 +45/-45 4.5 HGD-LC30 94” X 83” 8068, LLPR Design Pressure Rating Vented Sidelight - Non-Impact AAMA Test Results AAMA 101 Standard Struc ture Performance (psf )

12080 SLPS DP50 +75 / -75 7.5 12068,SLPS DP50 +75 / -75 7.5 SHD-class R-PG50 143 1/8"x95 1/2" SHD-class R-PG50 143 1/8"x79 1/2" Product Speci cation U-Factor (BTU/hrft² F) Visible Light Thansmittance (VT) Solar Heat Gain Coe cient (SHGC) Energy Performance Rating (Full Lite Panel)--For Non-Impact Hinge Patio Doors 2/SS/0.057/ARG/0.444/N 0.27 0.13 0.19 2/SS/0.057/ARG/0.444/G 0.27 0.11 0.16 2/SS/0.057/ARG/0.567/N 0.26 0.13 0.18 2/SS/0.057/ARG/0.567/G 0.26 0.11 0.15 2/SS/0.042/ARG/0.444/N 0.26 0.20 0.34 2/SS/0.042/ARG/0.444/G 0.26 0.18 0.28 2/SS/0.042/ARG/0.567/N 0.26 0.20 0.32 2/SS/0.042/ARG/0.567/G 0.26 0.17 0.27 2/SS/0.022/ARG/0.444/N 0.26 0.14 0.30 2/SS/0.022/ARG/0.444/G 0.26 0.12 0.25 2/SS/0.022/ARG/0.567/N 0.26 0.14 0.29 2/SS/0.022/ARG/0.567/G 0.26 0.12 0.24 Air In ltration (cfm/ft2) 0.001 0.001 0.02 Product Speci cation Design Pressure Rating Structure Performance (psf) Water Resistance (psf) Air In ltration (cfm/ft2) AAMA 101 Standard Sound Transmission Class - Non-Impact Hinged 6068, LP Outswing (0.625" Standard Non-Impact Glass) 29 25 6080 Outswing Pemko ADA Sill (1" Special Non-Impact Glass) 30 27 6080 Inswing Endura ADA Sill (1" Special Non-Impact Glass) 29 24 Product Speci cation OITC STC 3080 Outswing Pemko ADA Sill (1" Special Glass) 35 28 3080 Outswing Extended Pemko ADA Sill (5/8" Standard Glass) 31 27 3080 Inswing Endura ADA Sill (1" Special Glass) 31 26 Product Speci cation OITC STC Product Water Resistance (psf) DP80 +120/-120 12.00 TR-LC80 71 1/4” X 24” Inswing GTI 6020 Design Pressure Rating

Outswing - Non-Impact AAMA Test Results (3/4 Lite Panel)

Impact HINGED TRANSOMS AAMA 101 Standard Type Struc ture Per formance (psf ) Outswing DP75 +120/-120 11.25 TR-R75 145 3/8” X 24” GTI 12020 (with mullion) DP80 +120/-120 12.00 TR-LC80 71 1/4” X 24” GTO 6020 DP75 +120/-120 11.25 TR-R75 145 3/8” X 24” GTO 12020 (with mullion) 0.01 0.01 0.01 0.01 Product Water Resistance (psf) DP80 +120/-120 12.00 TAS 201/202/203 Inswing & Outswing GTI/GTO 6020 Design Pressure Rating

Test Standard Type Struc ture Per formance (psf ) +120/-120 12.00 TAS 201/202/203 GTI/GTO 12020 (with mullion) DP80 0.01 0.01 Transom - Non Impact GLIDING TRANSOMS Product Water Resistance (psf) DP80 +120/-120 12.00 TR-LC80 71 1/4” X 24” Inswing GTI 6020 Design Pressure Rating

AAMA 101 Standard Type Struc ture Per formance (psf ) Outswing DP75 +120/-120 11.25 TR-LC75 145 3/8” X 24” GTI 12020 (with mullion) DP80 +120/-120 12.00 TR-LC80 71 1/4” X 24” GTO 6020 DP75 +120/-120 11.25 TR-LC75 145 3/8” X 24” GTO 12020 (with mullion) (cfm/ft ) 0.01 0.01 0.01 0.02 Product Water Resistance (psf) DP80 +120/-120 12.00 TAS 201/202/203 Inswing & Outswing GTI/GTO 6020 Design Pressure Rating

Test Standard Type Struc ture Per formance (psf ) +120/-120 12.00 TAS 201/202/203 GTI/GTO 12020 (with mullion) DP80 (cfm/ft ) 0.01 0.01 Energy Star Guide Door Style Glass Type North North Central South South Central U-Factor SHGC VT LoE3 366 ** * * 0 25 0 14 0 30 LoE3 340 0 25 0 09 0 18 LoE3 Blinds - - 0.27 0.25 0.28 LoE3 366 0 25 0 09 0 20 Door Style Glass Type North North Central South South Central U-Factor SHGC VT LoE3 366 ** * * 0 24 0 13 0.30 LoE3 340 ** * * 0 24 0 09 0 18 LoE3 366 ** * * 0 29 0 09 0 20 Door Style Glass Type North North Central South South Central U-Factor SHGC VT LoE3 366 ** * * 0.26 0.18 0.40 LoE3 340 ** * * 0 27 0 12 0 24 Door Style Glass Type North North Central South South Central U-Factor SHGC VT LoE3 366 0 26 0 17 0 39 LoE3 340 ** * * 0 26 0 11 0 24 Door Style Glass Type North North Central South South Central U-Factor SHGC VT LoE3 366 ** * * 0 26 0 18 0 40 LoE3 340 ** * * 0 27 0 12 0 24 LoE3 Blinds 0.29 0.36 0.41 Door Type Door Type Door Type Door Type Door Type Hinged Impact Gliding Impact Bypass Gliding Non-Impact Energy Star Climate Zones Hinged Non-Impact Full Lite 3/4 Lite Energy Star Climate Zones Full Lite 3/4 Lite Gliding Non-Impact Full Lite Energy Star Climate Zones Full Lite Energy Star Climate Zones Energy Star Climate Zones Full Lite -* * * * * * * * Sound Transmission Class - Non-Impact Hinged 6068, LP Outswing (0.625" Standard Non-Impact Glass) 29 25 6080 Outswing Pemko ADA Sill (1" Special Non-Impact Glass) 30 27 6080 Inswing Endura ADA Sill (1" Special Non-Impact Glass) 29 24 Product Speci cation OITC STC 3080 Outswing Pemko ADA Sill (1" Special Glass) 35 28 3080 Outswing Extended Pemko ADA Sill (5/8" Standard Glass) 31 27 3080 Inswing Endura ADA Sill (1" Special Glass) 31 26 Product Speci cation OITC STC

Hinged Impact

Hinged Patio Doors

Hinged Patio Doors - Impact & Cycle Testing Performance

Full Lite - Impact & Cycle Testing Performance 3/4 Lite - Impact & Cycle Testing Performance Energy Performance Rating - Impact Hinged Sound Transmission Class - Impact Hinged

Sound Product Speci cation STC OITC 6068, LS Gliding (1" Double Laminated Glass) 33 30

6068, LS Gliding (1" Standard Laminated Glass) 32 29

**For Florida Building Code Approval, please see: http://www.floridabuilding.org/pr/pr_app_srch. aspx.

Products 37

For Texas Department of Insurance Approval, see: http://www.tdi.state.tx.us/wind/prod/indexdr.html . For Dade County Approval, see: http://www.miamidade.gov/building/pc-search_ app.asp? Transmission Class - Non-Impact Product Description: glazing layers / spacer type LoE emissivity (surface) / gap l / gap width / grilles / *New Data Pending SS=stainless steel LoE emissivity 0.057=LoE 340 0.022=LoE 366 ARG = argon N = no grille G = with grille < 1"

- Impact & Cycle Testing Performance Product Max. Testing Dimension Structure Performance (psf) Inswing SLPS (OXXO) 11’11” X 6’11” DP50 +75/-75 Outswing SLPS (OXXO) 11’11” X 6’11” DP5 0 +75/-75 DP70 +105/-105 Outswing SLP (OXX) 9’1” X 6’11” DP70 +105/-105 Inswing SLPS (OXXO) 11’11” X 8’0” +75/-75 10.5 Inswing SLP (OXX) 9’1” X 8’0” Test Standard Water Resistance (PSF) ASTM E1886/ASTM E1996 ASTM E1886/ASTM E1996 TAS201/202/203 ASTM E1886/ASTM E1996 2.9 10.5 7.5 7.5 Design Pressure Rating +75/-75 s Outswing SLPS (OXXO) 11’11” X 8’0” DP50 DP70 +75/-75 +105/-105 10.5 TAS201/202/203 TAS201/202/203 7.5 3.75 Air 0.003 0.002 0.01 0.03 0.003 0.12 Outswing SLP (OXX) 9’1” X 8’0” DP50 +75/-75 Outswing SLPL (OXXO) 12’1” X 8’0” DP70 +105/-105 ASTM E1886/ASTM E1996 TAS201/202/203 10.5 7.5 0.002 0.01 DP50 Structural Only DP50 Structural Only

Product Max. Testing Dimension Structure Performance (psf) Inswing SLP (OXX) 8’10” X 8’0” +75/-75 Outswing SLP (OXX) 8’10” X 8’0” DP5 0 +75/-75 Outswing SLPS (OXXO) 11’11” X 6’8” DP50 +75/-75 Inswing SLPS (OXXO) 11’11” X 6’11” +75/-75 7.5 Test Standard Water Resistance (PSF) ASTM E1886/ASTM E1996 ASTM E1886/ASTM E1996 ASTM E1886/ASTM E1996 7.5 7.5 3.75 Design Pressure Rating s Outswing SLPS (OXXO) 11’11” X 8’0” DP50 DP70 +75/-75 +105/-105 10.5 TAS201/202/203 7.5 Air 0.001 0.1 0.001 0.003 0.003 Outswing SLP (OXX) 9’1” X 8’0” DP50 +75/-75 Outswing SLPL (OXXO) 12’1” X 8’0” DP70 +105/-105 ASTM E1886/ASTM E1996 TAS201/202/203 10.5 7.5 0.002 0.01 DP50 Structural Only DP50 ASTM E1886/ASTM E1996 Energy Star Guide Door Style Glass Type North North Central South South Central U-Factor SHGC VT LoE3 366 ** * * 0.25 0.14 0.30 LoE3 340 0 25 0 09 0 18 LoE3 Blinds - - 0 27 0 25 0 28 LoE3 366 0 25 0 09 0 20 Door Style Glass Type North North Central South South Central U-Factor SHGC VT LoE3 366 ** * * 0 24 0 13 0.30 LoE3 340 ** * * 0 24 0 09 0 18 LoE3 366 ** * * 0 29 0 09 0 20 Door Style Glass Type North North Central South South Central U-Factor SHGC VT LoE3 366 ** * * 0.26 0.18 0.40 LoE3 340 ** * * 0.27 0.12 0.24 Door Style Glass Type North North Central South South Central U-Factor SHGC VT LoE3 366 0 26 0 17 0 39 LoE3 340 ** * * 0 26 0 11 0 24 Door Type Door Type Door Type Door Type Hinged Impact Gliding Impact Energy Star Climate Zones Hinged Non-Impact Full Lite 3/4 Lite Energy Star Climate Zones Full Lite 3/4 Lite Gliding Non-Impact Full Lite Energy Star Climate Zones Full Lite Energy Star Climate Zones * * * * * * * * Sound Transmission Class - Hinged Impact 3080, L Outswing (1" Double Laminated Glass) 35 30 6068, LP Inswing (1" Standard Impact Glass) 34 30 6068, LP Outswing (1" Standard Impact Glass) 34 30 Product Speci cation OITC STC

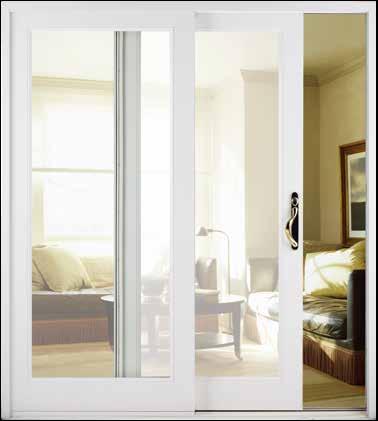

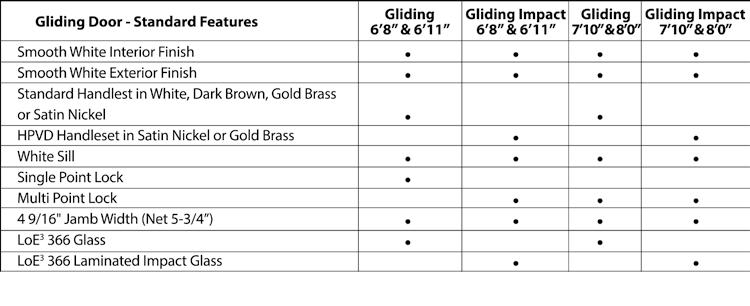

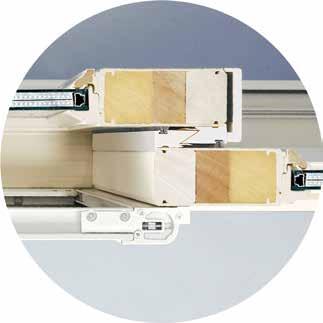

GLIDING SERIES

Panels and frames made of fiberglass and composite material, a part of the Weather Guard System for advanced moisture protection and maximum durability

Durable fiberglass skins will not rust, dent, split or rot

ENERGY STAR certified in all 50 States

Durable CFC-free polyurethane foam panel core

Advanced interlocking seal design

Monorail track for reduced friction

Adjustable stainless steel tandem rollers

Removable glazing bead for easy glass replacement

Door heights available in 6’-8”, 6’-11”, 7’-10” and 8’-0” sizes

Frames available in 4-9/16” or 6-9/16” sizes, Net Jamb dimensions are 5-3/4 or 7-3/4 (See pg. 44 for more details)

Thresholds include drainage systems to channel water away from doors

Paintable smooth surface or unstained woodgrain are standard with pre-finished options available

Doors tested for structural stability, water infiltration, air infiltration, forced entry, sound transmission, and energy efficiency

38 Products

Gliding Full Lite Doors Smooth White Finish | LoE366 Glass

Gliding Full Lite Doors Smooth White Finish | LoE366 Glass

Advanced Interlocking Seal Design Provides superior weather protection.

Optional Retractable Screens

Attractive option that keeps the screen hidden from view when not in use.

Co-extruded Glazing Bead

Designed for easy glass replacement.

Weep Holes

Allow water to drain away from the door while keeping dirt and dust out.

Bottom Wind Stopper

Provides extra weather protection and helps prevent air leakage.

Adjustable Stainless Steel Tandem Rollers

Designed for smooth effortless operation.

1 WeatherGuard waterproof composite Jambs

Advanced Interlocking Seal Design

Waterproof Composite Edging on all Sides

Co-extruded Glazing Bead

Weep Hole

Bottom Wind Stopper

Adjustable Stainless Steel Tandem Rollers

2 4 4 5 5 6 6 2 7 7 3

1

40 Products

FEATURES

Gliding Full Lite Door

Smooth White Finish | LoE366 Glass

Gliding Full Lite Door

Smooth White Finish | LoE366 Glass

42 Products 2 Panel Unit Fixed 4 Panel Gliding Option Full Lite Option 3/4 Lite Option Standard Features Chart SELECT AND BUILD YOUR OWN GLIDING UNIT

Gliding Options

Be creative in building a custom large view gliding unit design. Build a multi-panel gliding unit on your standard double gliding unit with our impact tested mull post system.

Grille Options

Grilles are used to visually divide the glass area of the door for added architectural detail. Grilles Between Glass (GBG) are aluminum grilles sealed between the two layers of glass and offer an attractive low maintenance option. Simulated Divided Lites (SDL) are applied directly to the glass surface and offer a more traditional appearance.

Neuma offers standard 10, 12, 15, and 18 grille patterns as well as custom grille patterns available through special order.

Finish | LoE366 Glass | Prarie SDL Products 43 Mull Extension for Optional Extended Jambs 5/8” SA052 SA061

Gliding Full Lite Door Smooth White

Combo Options Available Grille Pattern Mull Kits Gliding

8’ Height 12-Lite 18-Lite 3 Lite Prairie 4 Lite 4 Lite Tall 6’8 & 6’11 Height 10-Lite 15-Lite 3 Lite Prairie 4 Lite 4 Lite Tall Standard Standard

PS Serials-Neuma Outswing Jamb

Full Lite

Single Panel Units

PS Serials-Neuma Outswing Extension Jamb

GLIDING UNITS AND DIMENSIONS

Two Panel Units

PS946 Brickmold (Sold Separately)

PS Serials-Neuma Inswing Jamb

PS946 Brickmold (Sold Separately)

PS Serials-Neuma Inswing Extension Jamb

PS946 Brickmold (Sold Separately)

PS Serials-Neuma Gliding Jamb

Gliding Jamb

PS946 Brickmold (Sold Separately)

PS Serials-Neuma Gliding Extension Jamb

DGP= Gliding

PS946 Brickmold (Sold Separately)

PS946 Brickmold (Sold Separately)

44 Products DGP 2668 DGP 3068 DGP 4068 DGP 5068 DGP 6068 DGP 8068 DGP 26611 DGP 30611 DGP 40611 DGP 50611 DGP 60611 DGP 80611 3’-2 1/4” 3’-1 1/2” 27 5/16” 2’-8 1/4” 2’-7 1/2” 21 5/16” 4’-2 1/4” 4’-1 1/2” 38” 5’ 4’-11 1/4” 21 5/16” 6’ 5’-11 1/4” 27 5/16” 8’ 7’-11 1/4” 38” ( O ) ( O ) ( O ) ( X O ) ( X O ) ( X O ) ( O ) ( O ) ( O ) ( X O ) ( X O ) ( X O ) Single & Two panel Rough Opening Unit Dim. Glass Dim. 6‘8” 6’-7 1/2” 67” 6‘11” 6’-10 3/8“ 67” 8‘0” 7’-11 1/2“ 80” For 8’ Height Standard Grille Patterns 6’8 & 6’11 Height items 10-Lite 12-Lite 18-Lite 15-Lite DGP 2680 DGP 3080 DGP 4080 DGP 5080 DGP 6080 DGP 8080 ( O ) ( O ) ( O ) ( X O ) ( X O ) ( X O ) 26” 20” 38” 20” 26” 38” Glass Dim. 7‘9 3/4” 7‘9 1/4” 80” DGP 60710 ( X O )

Door

Wall Thickness 4 9/16" [116] Wall Thickness 4 9/16" [116] Overall Jamb Width Wall Thickness 4 9/16" [116] Wall Thickness 6 9/16" [166.8] Wall Thickness 6 9/16" [166.8] Wall Thickness 6 9/16" [166.8] Overall Jamb Width 5 3/4" [146.1] 7 3/4" [196.9] Overall Jamb Width 5 3/4" [146.1] Overall Jamb Width 5 3/4" [146.1] Overall Jamb Width 7 3/4" [196.9] Overall Jamb Width 7 3/4" [196.9]

Shim (by Others)

Shim

Shim (by Others) Shim (by Others) Shim (by Others) Shim (by

(by Others)

Others)

Included Nailing

Included Nailing Fin Included Nailing

Included Nailing

Included Nailing

Included Nailing

Fin

Fin

Fin

Fin

Fin

Full Lite

Three

Four Panel Units

Mull Kits

When creating a custom configuration by combining panels and door units, add 5/8” to the unit dimension to allow for the width of the aluminum mull.

Products 45

Panels

Units

Gliding DGP 7668 DGP 9068 DGP 12068 26” 20” 38” 7’-8 1/8” 7’-7 3/8” 21 5/16” 9’-2 1/8” 9’-1 3/8” 27 5/16” 12’-2 1/8” 12’-1 3/8” 38” DGP 76611 DGP 90611 DGP 120611 DGP 7680 DGP 9080 DGP 12080 ( X O O ) ( X O O ) ( X O O ) ( X O O ) ( X O O ) ( X O O ) ( X O O ) ( X O O ) ( X O O ) Three & Four panel 6‘8” 6’-7 1/2“ 67” 6‘11” 6’-10 3/8“ 67” 8‘-0” 7’-11 1/2“ 80” Rough Opening Unit Dim. Glass Dim. Glass Dim. DGP 10068 DGP 12068 26” 20” 9’-10” 9’-9 1/4” 21 5/16” 11’-9 7/8” 11’-9 1/8” 27 5/16” DGP 100611 DGP 120611 DGP 10080 DGP 12080 ( O X X O ) ( O X X O ) ( O X X O ) ( O X X O ) ( O X X O ) ( O X X O ) For 8’ Height 12-Lite 18-Lite 15-Lite 10-Lite Standard Grille Patterns 6’8 & 6’11 Height items LEGEND Handing from exterior view Doors are not reversible O = Fixed Panel X = Active Panel S = Stationary Panel DGP = Gliding Door Mull Extension for Optional Extended Jambs 5/8” SA052 SA061

12068 1/8” 3/8” 120611 12080 O ) O ) O ) DGP 10068 DGP 12068 26” 20” 9’-10” 9’-9 1/4” 21 5/16” 11’-9 7/8” 11’-9 1/8” 27 5/16” DGP 100611 DGP 120611 DGP 10080 DGP 12080 ( O X X O ) ( O X X O ) ( O X X O ) ( O X X O ) ( O X X O ) ( O X X O ) For 8’ Height 15-Lite 10-Lite Standard Grille Patterns 6’8 & 6’11 Height items

Handing from exterior view Doors are not reversible . O = Fixed Panel X = Active Panel

= Stationary Panel DGP = Gliding Door Reference Handing Call-out Reference Code LSS SSR Reference Handing Call-out Reference Code SRS SLS Three Panels Three Panels O-OX XO-O O-XO OX-O Reference Handing Call-out Reference Code Four Panels OXXO SPLS Reference Handing Call-out Reference Code Two Panels O S One Panel OX SR XO LS Reference Handing Call-out Reference Code LSS SSR Reference Handing Call-out Reference Code SRS SLS Three Panels Three Panels O-OX XO-O O-XO OX-O Reference Handing Call-out Reference Code Four Panels OXXO SPLS Reference Handing Call-out Reference Code Two Panels O S One Panel OX SR XO LS Reference Handing Call-out Reference Code LSS SSR Reference Handing Call-out Reference Code SRS SLS Three Panels Three Panels O-OX XO-O O-XO OX-O Reference Handing Call-out Reference Code Four Panels OXXO SPLS Reference Handing Call-out Reference Code Two Panels O S One Panel OX SR XO LS Reference Handing Call-out Reference Code LSS SSR Reference Handing Call-out Reference Code SRS SLS Three Panels Three Panels O-OX XO-O O-XO OX-O Reference Handing Call-out Reference Code Four Panels OXXO SPLS Reference Handing Call-out Reference Code Two Panels O S One Panel OX SR XO LS

LEGEND .

S

Gliding Panel Specifications

Gliding Patio Doors - Full Lite Gliding

46 Products GLIDING PATIO DOORSFULL LITE GLIDING PATIO DOORSFULL LITE GLIDING PATIO DOORSFULL LITE GLIDING PATIO DOORS

Patio Doors - 3/4 Lite 3068 30611 3080 2668 26611 2680 5 1/4” 5 1/4” 5 1/4” 5 1/4” 19 1/4” 19 1/4” 19 1/4” 25 1/4” 25 1/4” 25 1/4” 5 7/16” 5 7/16” 8 1/4” 8 1/4” 3/8” 3/8” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 63 1/4” 63 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 29 3/4” 76 7/16” 18 17/32” 29 3/4” 79 1/4” 18 17/32” 29 3/4” 5 1/4” 18 17/32” 92 3/8” 92 3/8” 18 17/32” 35 3/4” 18 17/32” 79 1/4” 5 1/4” 35 3/4” 18 17/32” 76 7/16” 35 3/4” 5 1/4” 3068 30611 2668 26611 5 1/4” 5 1/4” 5 1/4” 5 1/4” 19 1/4” 19 1/4” 19 1/4” 25 1/4” 25 1/4” 25 1/4” 5 7/16” 5 7/16” 8 1/4” 8 1/4” 3/8” 3/8” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 63 1/4” 63 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 29 3/4” 76 7/16” 18 17/32” 29 3/4” 79 1/4” 18 17/32” 29 3/4” 5 1/4” 18 17/32” 92 3/8” 92 3/8” 18 17/32” 35 3/4” 18 17/32” 79 1/4” 5 1/4” 35 3/4” 18 17/32” 76 7/16” 35 3/4” 5 1/4” 3068 30611 3080 2668 26611 2680 5 1/4” 5 1/4” 5 1/4” 5 1/4” 19 1/4” 19 1/4” 19 1/4” 25 1/4” 25 1/4” 25 1/4” 5 7/16” 5 7/16” 8 1/4” 8 1/4” 5 3/8” 5 3/8” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 63 1/4” 63 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 29 3/4” 76 7/16” 18 17/32” 29 3/4” 79 1/4” 18 17/32” 29 3/4” 5 1/4” 18 17/32” 92 3/8” 92 3/8” 18 17/32” 35 3/4” 18 17/32” 79 1/4” 5 1/4” 35 3/4” 18 17/32” 76 7/16” 35 3/4” 5 1/4” 3068 30611 3080 2668 26611 2680 5 1/4” 5 1/4” 5 1/4” 5 1/4” 19 1/4” 19 1/4” 19 1/4” 25 1/4” 25 1/4” 25 1/4” 5 7/16” 5 7/16” 8 1/4” 8 1/4” 3/8” 3/8” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 63 1/4” 63 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 29 3/4” 76 7/16” 18 17/32” 29 3/4” 79 1/4” 18 17/32” 29 3/4” 5 1/4” 18 17/32” 92 3/8” 92 3/8” 18 17/32” 35 3/4” 18 17/32” 79 1/4” 5 1/4” 35 3/4” 18 17/32” 76 7/16” 35 3/4” 5 1/4” 3068 30611 3080 2668 26611 2680 5 1/4” 5 1/4” 5 1/4” 5 1/4” 19 1/4” 19 1/4” 19 1/4” 25 1/4” 25 1/4” 25 1/4” 5 7/16” 5 7/16” 8 1/4” 8 1/4” 5 3/8” 5 3/8” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 63 1/4” 63 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 29 3/4” 76 7/16” 18 17/32” 29 3/4” 79 1/4” 18 17/32” 29 3/4” 5 1/4” 18 17/32” 92 3/8” 92 3/8” 18 17/32” 35 3/4” 18 17/32” 79 1/4” 5 1/4” 35 3/4” 18 17/32” 76 7/16” 35 3/4” 5 1/4” 3068 30611 2668 26611 5 1/4” 5 1/4” 5 1/4” 5 1/4” 19 1/4” 19 1/4” 19 1/4” 25 1/4” 25 1/4” 25 1/4” 5 7/16” 5 7/16” 8 1/4” 8 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 5 1/4” 63 1/4” 63 1/4” 47 1/4” 47 1/4” 47 1/4” 47 1/4” 29 3/4” 76 7/16” 18 17/32” 29 3/4” 79 1/4” 18 17/32” 29 3/4” 5 1/4” 18 17/32” 92 3/8” 92 3/8” 18 17/32” 35 3/4” 18 17/32” 79 1/4” 5 1/4” 35 3/4” 18 17/32” 76 7/16” 35 3/4” 5 1/4”

Gliding Full Lite Door

Smooth White Finish | LoE366 Glass

Gliding Full Lite Door

Smooth White Finish | LoE366 Glass

3/4 Lite Gliding Handing

Single Panel Units

Two Panel Units

LEGEND

Handing from exterior view

Doors are not reversible Retractable screen available as an option O X S DGP

= = = =

Fixed Panel Active Panel Stationary Panel Gliding Door

Three Panel Units

Four Panel Units

* Testing not available

48 Products 3’-2 1/4” 3’-1 1/2” 26” 2’-8 1/4” 2’-7 1/2” 20” 5’ 4’-11 1/4” 20” 6’ 5’-11 1/4” 26” Rough Opening Unit Dim. Glass Dim. 6‘8” 6’-7 1/2” 48” 6‘11” 6’-10 3/8“ 48” 8‘0” 7’-11 1/2“ 64” 26” 20” 20” 26” Glass Dim. DGP 2680 ( O ) DGP 6080 ( X O ) DGP 5080 ( X O ) DGP 3080 ( O ) DGP 60611 ( X O ) DGP 50611 ( X O ) DGP 30611 ( O ) DGP 26611 ( O ) DGP 2668 ( O ) DGP 3068 ( O ) DGP 5068 ( X O ) DGP 6068 ( X O ) Rough Opening Unit Dim. Glass Dim. 6‘8” 6’-7 1/2” 48” 6‘11” 6’-10 3/8“ 48” 8‘0” 7’-11 1/2“ 64” Glass Dim. 11’-9 7/8” 11’-9 1/8” 26” ( O X X O ) DGP 10080 ( O X X O ) DGP 100611 DGP 10068 ( O X X O ) DGP 120611 ( O X X O ) DGP 12080 ( O X X O ) 26” 9’-2 1/8” 9’-1 3/8” 26” 20” 7’-8 1/8” 7’-7 3/8” 20” DGP 12068 ( O X X O ) ( X O - O ) DGP 9068 ( X O - O ) DGP 90611 ( X O - O ) DGP 7680 ( X O - O ) DGP 9080 9’-10” 9’-9 1/4” 20” 20” 26” DGP 7668 ( X O - O ) DGP 76611 ( X O - O )

Transoms For Gliding Doors

For Single Panel Units

For Two Panel Units

For Three Panel Units

For 3 Panel

For 3 Panel

For 3 Panel

HINGED TRANSOMS

Transom Test Results - Non Impact

For Four Panel Units

For 4 Panel

For 4 Panel

For 4 Panel

Transom Results - Impact

*For all product testing approval numbers and information, please visit : http://www.neumadoors.com/resource

*For Florida Building Code Approval, please see : http://www.floridabuilding.org/pr/pr_app_srch.aspx.

*For Texas Department of Insurance Approval, see : http://www.tdi.state.tx.us/wind/prod/indexdr.html .

*For Dade County Approval, see : http://www.miamidade.gov/building/pc-search_app.asp?

LEGEND

LEGEND

Gliding Transoms Test Results

GLIDING TRANSOMS

1. Rough Opening Width=Unit Dim. Width + 3/4”

1. Rough Opening Width=Unit Dim. Width + 3/4”

2. Rough Opening Height = Unit Dim. Height + 1/2”

Transom - Non Impact

2. Rough Opening Height = Unit Dim. Height + 1/2”

3. Glass Option: Clear / Inner Grille / Art Glass

3. Glass Option: Clear / Inner Grille / Art Glass

4. Custom Size Also Available by Special Order

4. Custom Size Also Available by Special Order

5. Standard transom are equal size glass

5. Standard transom are equal size glass

6. Special size or special Lite pattern must be by special order

7. GTG = Gliding

Transom - Impact

6. Special size or special Lite pattern must be by special order

7. GTG = Gliding

Products 49

Product Description: glazing layers / spacer type LoE emissivity (surface) / gap l / gap width / grilles / *New Data Pending SS=stainless steel LoE emissivity 0.057=LoE 340 0.022=LoE 366 ARG = argon N = no grille G = with grille < 1" LEGEND 1. Rough Opening Width=Unit Dim. Width + 3/4” 2. Rough Opening Height = Unit Dim. Height + 1/2” 3. Glass Option: Clear / Inner Grille / Art Glass 4. Custom Size Also Available by Special Order 5. Standard transom are equal size glass 6. Special size or special Lite pattern must be by special order 7. GTG = Gliding GTG 2610 GTG 3010 GTG 4010 GTG 5010 GTG 6010 GTG 5010-2 TDL GTG 6010-2 TDL GTG 8010-2 TDL GTG 2614 GTG 3014 GTG 4014 GTG 5014 GTG 6014 GTG 5014-2 TDL GTG 6014-2 TDL GTG 8014-2 TDL GTG 2620 GTG 3020 GTG 4020 GTG 5020 GTG 6020 GTG 5020-2 TDL GTG 6020-2 TDL GTG 8020-2 TDL * * * * * * * * * Rough Opening Unit Dim. Glass Dim. 2‘-8 1/4” 2’-7 1/2” 29 7/16” 3‘-2 1/4” 3’-1 1/2” 35 7/16” 4‘-2 1/4” 4’-1 1/2” 47 7/16” 5‘ 4’-11 1/4” 57 1/8” 6‘ 5’-11 1/4” 69 1/8” 8‘ 7’-11 1/4” 27 3/4” 33 3/4” 45 3/4” 2‘1/2” 2’ 21 7/8” 1‘-4 1/2” 1’-4” 13 7/8” 1‘1/2” 1’ 9 7/8” GTG 7610-3 TDLGTG 9010-3 TDL GTG 12010-3 TDL GTG 7614-3 TDLGTG 9014-3 TDL GTG 12014-3 TDL GTG 7620-3 TDL GTG 9020-3 TDL GTG 12020-3 TDL * * * * * * * * * 2‘1/2” 2’ 21 7/8” 1‘-4 1/2” 1’-4” 13 7/8” 1‘1/2” 1’ 9 7/8” Rough Opening Unit Dim. Glass Dim. 7‘-8 1/8” 7’-7 3/8” 28 5/8” 9‘-2 1/8” 9’-1 3/8” 34 5/8” 12‘-2 1/8” 12’-1 3/8” 46 5/8” GTG 10010-4 TDL GTG 12010-4 TDL GTG 10014-4 TDL GTG 12014-4 TDL GTG 10020-4 TDL GTG 12020-4 TDL 9‘-10” 9’- 9 1/4” 27 1/2” 11‘-9 7/8” 11’-9 1/8” 33 1/2” * * * * * * 2‘1/2” 2’ 21 7/8” 1‘-4 1/2” 1’-4” 13 7/8” 1‘1/2” 1’ 9 7/8” Rough Opening Unit Dim. Glass Dim.

* * * * * * * * * * * * * * * * * * * * * * * *

Rough Opening Width=Unit Dim. Width + 3/4”

Rough Opening Height = Unit Dim. Height + 1/2”

Glass Option: Clear / Inner Grille / Art Glass

Custom Size Also Available by Special Order

Standard transom are equal size glass

Special size or special Lite pattern must be by special order

GTG = Gliding GTG 2610 GTG 3010 GTG 4010 GTG 5010 GTG 6010 GTG 5010-2 TDL GTG 6010-2 TDL GTG 8010-2 TDL GTG 2614 GTG 3014 GTG 4014 GTG 5014 GTG 6014 GTG 5014-2 TDL GTG 6014-2 TDL GTG 8014-2 TDL GTG 2620 GTG 3020 GTG 4020 GTG 5020 GTG 6020 GTG 5020-2 TDL GTG 6020-2 TDL GTG 8020-2 TDL * * * * * * * * * Rough Opening Unit Dim. Glass Dim. 2‘-8 1/4” 2’-7 1/2” 29 7/16” 3‘-2 1/4” 3’-1 1/2” 35 7/16” 4‘-2 1/4” 4’-1 1/2” 47 7/16” 5‘ 4’-11 1/4” 57 1/8” 6‘ 5’-11 1/4” 69 1/8” 8‘ 7’-11 1/4” 27 3/4” 33 3/4” 45 3/4” 2‘1/2” 2’ 21 7/8” 1‘-4 1/2” 1’-4” 13 7/8” 1‘1/2” 1’ 9 7/8” GTG 7610-3 TDLGTG 9010-3 TDL GTG 12010-3 TDL GTG 7614-3 TDLGTG 9014-3 TDL GTG 12014-3 TDL GTG 7620-3 TDL GTG 9020-3 TDL GTG 12020-3 TDL * * * * * * * * * 2‘1/2” 2’ 21 7/8” 1‘-4 1/2” 1’-4” 13 7/8” 1‘1/2” 1’ 9 7/8” Rough Opening Unit Dim. Glass Dim. 7‘-8 1/8” 7’-7 3/8” 28 5/8” 9‘-2 1/8” 9’-1 3/8” 34 5/8” 12‘-2 1/8” 12’-1 3/8” 46 5/8” GTG 10010-4 TDL GTG 12010-4 TDL GTG 10014-4 TDL GTG 12014-4 TDL GTG 10020-4 TDL GTG 12020-4 TDL 9‘-10” 9’- 9 1/4” 27 1/2” 11‘-9 7/8” 11’-9 1/8” 33 1/2” * * * * * * 2‘1/2” 2’ 21 7/8” 1‘-4 1/2” 1’-4” 13 7/8” 1‘1/2” 1’ 9 7/8” Rough Opening Unit Dim. Glass Dim.

LEGEND 1.

2.

3.

4.

5.

6.

7.

* * * * * * * * * * * * * * * * * * * * * * * *

2610 GTG 3010 GTG 4010 GTG 5010 GTG 6010 GTG 5010-2 TDL GTG 6010-2 TDL GTG 8010-2 TDL 2614 GTG 3014 GTG 4014 GTG 5014 GTG 6014 GTG 5014-2 TDL GTG 6014-2 TDL GTG 8014-2 TDL 2620 GTG 3020 GTG 4020 GTG 5020 GTG 6020 GTG 5020-2 TDL GTG 6020-2 TDL GTG 8020-2 TDL * * * * * * 1/4” 1/2” 7/16” 3‘-2 1/4” 3’-1 1/2” 35 7/16” 4‘-2 1/4” 4’-1 1/2” 47 7/16” 5‘ 4’-11 1/4” 57 1/8” 6‘ 5’-11 1/4” 69 1/8” 8‘ 7’-11 1/4” 27 3/4” 33 3/4” 45 3/4” GTG 7610-3 TDLGTG 9010-3 TDL GTG 12010-3 TDL GTG 7614-3 TDLGTG 9014-3 TDL GTG 12014-3 TDL GTG 7620-3 TDL GTG 9020-3 TDL GTG 12020-3 TDL * * * * * * 7‘-8 1/8” 7’-7 3/8” 28 5/8” 9‘-2 1/8” 9’-1 3/8” 34 5/8” 12‘-2 1/8” 12’-1 3/8” 46 5/8” GTG 10010-4 TDL GTG 12010-4 TDL GTG 10014-4 TDL GTG 12014-4 TDL GTG 10020-4 TDL GTG 12020-4 TDL 9‘-10” 9’- 9 1/4” 27 1/2” 11‘-9 7/8” 11’-9 1/8” 33 1/2” * * * * * * Panel Panel * * * * * * * * * * * * * * * * * * * * *

GTG 2610 GTG 3010 GTG 4010 GTG 5010 GTG 6010 GTG 5010-2 TDL GTG 6010-2 TDL GTG 8010-2 TDL GTG 2614 GTG 3014 GTG 4014 GTG 5014 GTG 6014 GTG 5014-2 TDL GTG 6014-2 TDL GTG 8014-2 TDL GTG 2620 GTG 3020 GTG 4020 GTG 5020 GTG 6020 GTG 5020-2 TDL GTG 6020-2 TDL GTG 8020-2 TDL * * * * * * * * * Rough Opening Unit Dim. Glass Dim. 2‘-8 1/4” 2’-7 1/2” 29 7/16” 3‘-2 1/4” 3’-1 1/2” 35 7/16” 4‘-2 1/4” 4’-1 1/2” 47 7/16” 5‘ 4’-11 1/4” 57 1/8” 6‘ 5’-11 1/4” 69 1/8” 8‘ 7’-11 1/4” 27 3/4” 33 3/4” 45 3/4” 2‘1/2” 2’ 21 7/8” 1‘-4 1/2” 1’-4” 13 7/8” 1‘1/2” 1’ 9 7/8” GTG 7610-3 TDLGTG 9010-3 TDL GTG 12010-3 TDL GTG 7614-3 TDLGTG 9014-3 TDL GTG 12014-3 TDL GTG 7620-3 TDL GTG 9020-3 TDL GTG 12020-3 TDL * * * * * * * * * 2‘1/2” 2’ 21 7/8” 1‘-4 1/2” 1’-4” 13 7/8” 1‘1/2” 1’ 9 7/8” Rough Opening Unit Dim. Glass Dim. 7‘-8 1/8” 7’-7 3/8” 28 5/8” 9‘-2 1/8” 9’-1 3/8” 34 5/8” 12‘-2 1/8” 12’-1 3/8” 46 5/8” GTG 10010-4 TDL GTG 12010-4 TDL GTG 10014-4 TDL GTG 12014-4 TDL GTG 10020-4 TDL GTG 12020-4 TDL 9‘-10” 9’- 9 1/4” 27 1/2” 11‘-9 7/8” 11’-9 1/8” 33 1/2” * * * * * * 2‘1/2” 2’ 21 7/8” 1‘-4 1/2” 1’-4” 13 7/8” 1‘1/2” 1’ 9 7/8” Rough Opening Unit Dim. Glass Dim.

* * * * * * * * * * * * * * * * * * * * * * * * Product Water Resistance (psf) DP80 +120/-120 12.00 TR-LC80 71 1/4” X 24” Inswing GTI 6020 Design Pressure Rating

AAMA 101 Standard Type Struc ture Per formance (psf ) Outswing DP75 +120/-120 11.25 TR-R75 145 3/8” X 24” GTI 12020 (with mullion) DP80 +120/-120 12.00 TR-LC80 71 1/4” X 24” GTO 6020 DP75 +120/-120 11.25 TR-R75 145 3/8” X 24” GTO 12020 (with mullion) 0.01 0.01 0.01 0.01 Product Water Resistance (psf) DP80 +120/-120 12.00 TAS 201/202/203 Inswing & Outswing GTI/GTO 6020 Design Pressure Rating

Test Standard Type Struc ture Per formance (psf ) +120/-120 12.00 TAS 201/202/203 GTI/GTO 12020 (with mullion) DP80 0.01 0.01 Product Water Resistance (psf) DP80 +120/-120 12.00 TR-LC80 71 1/4” X 24” Gliding GTG 6020 Design Pressure Rating

AAMA 101 Standard Type Struc ture Per formance (psf ) DP75 +120/-120 11.25 TR-R75 145 3/8” X 24” GTG 12020 (with mullion) 0.01 0.01 Product Water Resistance (psf) DP80 +120/-120 12.00 TAS 201/202/203 Gliding GTG 6020 Design Pressure Rating

Test Standard Type Struc ture Per formance (psf ) +120/-120 12.00 TAS 201/202/203 GTG 12020 (with mullion) DP80 0.01 0.01

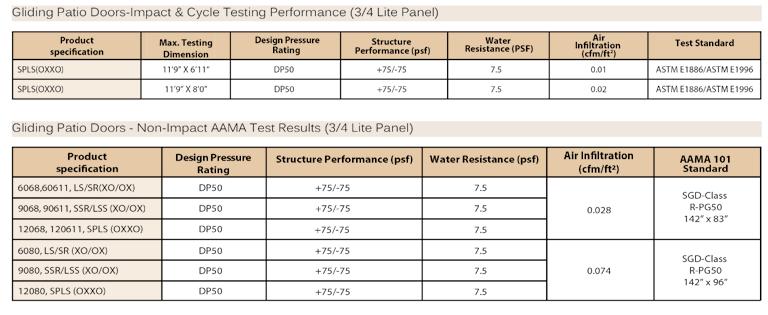

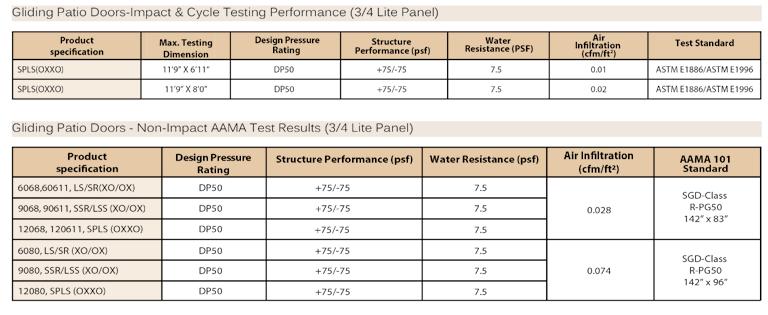

GLIDING TEST RESULTS

Gliding Non-Impact

Full Lite Gliding - Non-Impact AAMA Test Result

Gliding Patio Doors - Non-Impact AAMA Test Result (Full Lite Panel)

Energy Performance Rating - Gliding Non-impact

Gliding Impact

Full Lite - Impact & Cycle Testing Performance

Gliding Patio Doors -

& Cycle Testing Performance

Sound

Full Lite - Impact & Cycle Testing Performance

50 Products

Sound Transmission Class - Impact Gliding Sound Transmission Class - Non-impact

Product Design Pressure Rating Structure Performance (psf) 6068,60611, LS/SR(XO/OX) DP50 +75/-75 9068, 90611, SSR/LSS (OOX/XOO) DP50 +75/-75 12068, 120611, SPLS (OXXO) DP50 +75/-75 8068, 80611, LS/SR (XO/OX) DP50 +75/-75 12068, 120611, SRS (OXO) DP50 +75/-75 6080, LS/SR (XO/OX) DP50 Water Resistance (psf) 7.5 7.5 7.5 7.5 7.5 +75/-75 s 9080, SSR/LSS (OOX/XOO) 12080, SPLS (OXXO) DP50 DP50 +75/-75 +75/-75 7.5 7.5 7.5 8080, LS/SR (XO/OX) 12080, SRS (OXO) DP50 DP50 +75/-75 +75/-75 7.5 7.5 AAMA 101 Standard SGD-Class R-PG50 142” x 83” SGD-Class R-PG50 146” x 83” SGD-Class R-PG50 142” x 96” SGD-Class R-PG50 146” x 96” Air In ltration (cfm/ft2) 0.028 0.007 0.074 0.028

Impact