11 minute read

Springmaker Spotlight

David Janowski

Blazing His Own Trail:

David Janowski and AMW Springs

By Gary McCoy, Managing Editor AMW(Austinburg Mechanical Wire) Springs started in 2002 and is relatively new when compared to the stalwarts of the spring industry, who trace their origins back to the mid-1800s. However, the values of hard work, determination and a unique identity that built those companies are evident in David Janowski, the founder and president of AMW Springs.

Each spring company has a one-of-a-kind story, and AMW Springs is no different. As Gary Van Buren, SMI’s technical advisor and a longtime friend and consultant to Janowski, says, “The company was not handed down to him. David built it from scratch. It’s a modern success story.”

Janowski’s introduction to the spring industry came after he graduated from high school in 1992. He set out to pursue an engineering degree at Youngstown (Ohio) State University. After a year, Janowski quickly realized college wasn’t for him.

David Janowski (left) inspects parts produced by AMW Springs with plant manager Phil Oeffner.

Kevin Rose (left) the company’s senior setup technician with Janowski.

He was working at the local McDonald’s as a shift manager, making $5 an hour. “A friend of mine got a job at a spring factory making $7.50 an hour grinding springs,” explained Janowski. “I begged my friend to get me a job there.”

Janowski took a mechanical aptitude and math test and was hired by Sanborn Wire Company in Rock Creek, Ohio. But instead of grinding springs, the company thought he was overqualified for that task and instead had him doing machine setups.

He started out setting up a Torin W125 machine. “It was a total disaster,” said Janowski with a laugh. “I broke more tooling in six months than the previous individual had.”

Janowski admits he was young and extremely cocky at the time, and there was conflict with the person who was training him.

“I would break an arbor here and a cutter there,” said Janowski. “The straw literally broke when I destroyed the power assist on the Torin 125.”

How it happened is a story that Janowski is happy to tell anyone who asks. Suffice it to say that when he told his boss that the machine was broken, “there was a lot of screaming and hollering” and Janowski offered to quit.

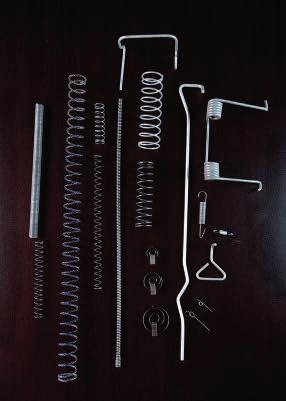

Samples of springs and wireforms manufactured by AMW Springs.

Senior secondary technician Stephanie Potter.

“I told my boss, ‘I will work for a month to pay for this thing, and you can keep my paycheck. You don’t have to swear and yell at me. I’ll go back to flipping hamburgers.’”

Fortunately, cooler heads prevailed and Janowski switched machines, and was trained by Wilburn Summers, a veteran springmaker who was originally from Tennessee.

With his southern drawl, Summers pulled Janowski aside and said, “Come over here, David. You can break all the tools you want.”

Janowski said Summers was a genius on Torin mechanical machines. “He took me under his wings and started training me on the Torin W11’s and the code was cracked.”

Janowski admits that had always been mechanically inclined and “this gentleman put a little faith in me.” That’s all that Janowski needed.

When a co-worker who ran the Torin 10a’s had a heart attack, Janowski was assigned to take over his duties. “I ran the 10a’s for almost a year and I loved it. I liked running those smaller wires from .008” to .028.”

Moving to the World of CNCs

Janowski attended his first CASMI SpringWorld in 1994. He asked his bosses at Sanborn Wire if could go back in 1996 and attend for two days. “Most of the guys were running around grabbing golf balls and coffee cups,” related Janowski. “I came with a pair of calipers, because I wanted to understand how the machines worked at this show.”

At the time there were not many computer numerical control (CNC) machines available for making springs. Janowski saw a CNC machine at the show that was made by a Taiwanese company. He asked the owners of Sanborn Wire if they would buy the machine, and they did.

Janowski started running the CNC machine and became friends with the guys at Moyer Process & Control, who had expertise in this area.

“I remember being alone in the plant at Sanborn Wire on a Friday, and a customer needed a quarter million parts by Monday,” said Janowski. “I called Jeff Duguid at Moyer and asked him how to setup the job. I was on the phone with him for an hour and he helped me wire it in. By the end of the weekend, the job was completed.”

After working at Sanborn Wire, Janowski worked for a Chicago-based company called Horizon Machinery that was selling Taiwanese CNC machines. It was the same company that Sanborn Wire had bought its first 2-axis CNC machine from in 1996.

At Sanborn Wire Janowski felt like he was “a big fish in a small pond.” After a short duration at Horizon, he quickly realized that he had a lot to learn!

During his time at Horizon, Janowski built the relationships that he holds today with his current clientele. As you will discover later in this article, most of AMW’s clients are other spring companies. Along the way Janowski met several people that influenced and helped steer him forward. After working at Horizon for a couple of years, Janowski ended up leaving to start AMW.

eBay to the Rescue

With his background making springs, Janowski decided to venture out and start his own company. “I started AMW Springs with the initial purchase of equipment from eBay and production in my garage,” explained Janowski.

Top: Janowski is a self-described gear head and his current favorite vehicle is a 1980 Pinto race car. Center: An assortment of smaller parts manufactured by AMW Springs. Bottom: Senior setup technician Tim Beck. Amanda and David Janowski are wife and husband, parents to Veronica and Caroline, and business partners.

With a rapid period of sales growth in its initial years, Janowski was able to purchase a larger space. That larger space was the old Sanborn Wire Products building in Rock Creek, where Janowski had started his career in the spring industry.

The company now employs 12 people and utilizes 27 production machines. As the company states on its website, “AMW Springs is a young, aggressive spring and wireform manufacturer…the company was formed as a venture to implement creative ideas and techniques for spring and wireform manufacturing.”

“We have a reputation for taking on very difficult jobs with long lead times,” said Janowski. “The majority of work we do is very complicated. Fortunately, I’ve surrounded myself with a great staff of employees.”

Janowski jokes that his employees are not always happy that he’s taken on certain jobs and admits, “I can’t do it without them.”

AMW Springs has developed custom equipment and tooling to manufacture extension springs (produced up to 30” lengths), compression springs, extension springs, constant force springs, twisted wire springs, shaped wire springs, magazine springs and various wireforms. AMW does not do any stamping yet, but it is an area that Janowski has considered for the future. Currently, 90 percent of the AMW’s work is for other spring companies.

“We do unique coiling with shaped wire, stranded wire, bizarre alloys, and some of the harder stuff, like wire coated with Teflon,” said Janowski. “We’re not afraid to try. We have failed before, but we will always keep trying.”

A self-described problem solver, Janowski does not have any engineering staff per se. “It’s just the hands-on knowledge of the products and the materials that we have developed over the years.”

Wired For Challenges

Janowski admits that he does not have a whiteboard in his office and does not want to follow a prescribed business philosophy.

“I’m more of a guy who likes to fly by the seat of my pants; I like every challenge that comes across my desk. As a spring company, we try to address every situation we encounter.”

Not trying to come off as cocky or overconfident, Janowski believes that “if we can’t do it, then I know the majority of the spring companies can’t do it either.”

Like most springmakers, Janowski has faced a lack of materials during the past six months, along with the challenge of finding people to work.

Janowski is known for being a straight shooter and not shy about his opinions.

Janowski enjoys the challenges that come along with being a springmaker, he just wishes there was a better way to educate customers about spring products. “A lot of people don’t understand that we’re not just machining a product,” said Janowski. “We are bending and forming wire, and the tolerances have gotten ridiculous.”

He further states, “What we are seeing is that JIT (just in time) inventory doesn’t work during a materials shortage.”

In addition to AMW Springs, Janowski is also the founder of A&D Trading LCC. A&D, which stands for Amanda (Janowski’s wife and business partner) and David, was started in 2004 as a machinery sales company to supply and service equipment, representing many of the same Taiwanese product lines he was familiar with along with several new lines.

A&D is operated completely separately from AMW Springs. Janowski says he has

Janowski would like to be remembered in the spring industry as someone who helps his fellow springmakers make springs and purchase equipment. “A guy that can get it done!”

Stock Springs

To Ship

Your complete source for all your stock and custom spring needs

Ready Compression Springs Extension Springs Die Springs Torsion Springs

www.DiamondWire.com

1-800-424-0500

MADE IN USA

Spring Tooling for All Machines Complete line of carbide and steel tooling for the spring industry.

Machines

• Fenn (TORIN) • Itaya • MEC • Samuel • Sleeper & Hartley • Additional Machines – A.I.M. – ASAHI – Bamatec (Schenker) – Baird – Bobbio – E.N. Machine (Ming) – Simplex – Wafios

Line of carbide and steel tooling include…

• Arbors/Mandrels • Block Guides • Body Tools • Caps • Coiling Tools • Cutting Tools • Feed Rolls • Guides/Liners • Pencil Arbors • Pitch Tools • Quills

naspringtool.com 860-583-1693

169 WHITE OAK DRIVE BERLIN, CT 06037

earned the trust of other springmakers when he comes into their facilities. He represents the Taiwanese manufacturer Primera Precision and is a sales agent for Shinko Machinery out of Japan.

When it comes to technology, Janowski believes he could teach almost anyone how to run a spring machine. “But I can’t teach you how to be a springmaker. I can explain it, but not everyone will understand the ‘how’ behind making springs. You have to understand how it works to be a successful springmaker.”

Away from the Office

David and Amanda Janowski have two daughters, Veronica and Caroline. They live north of the office in the middle of 34 acres in Geneva, Ohio. Janowski travels quite a bit for work and enjoys the time at home, when he can relax and work around the family property.

He enjoys gardening and sometimes just “sitting in the middle of the woods drinking beer and burning sticks.” In addition to fishing for walleye on Lake Erie, Janowski is an avowed “gear head” who likes tinkering with cars.

When I asked Janowski what his favorite car is currently, he said, “you are going to laugh hysterically, but my favorite right now is my “1980 Pinto race car.” Janowski says, “I’m like a dog with a bone, my favorite is what I’m playing with at the time.”

For those who are old enough to remember, the safety reputation of the Pinto generated controversy in the 1970s because of the cars fuel-tank design, especially after several deadly fires related to the tanks rupturing in rearend collisions.

All that aside, Janowski has modified his Pinto with things such as an aftermarket block with a 2.6 liter displacement and a 16-valve Volvo head with a turbocharger. He competes with the Pinto in drag races at a local track in northeast Ohio.

Other cars in Janowski’s collection include a 1966 Ford Galaxie 500 convertible, a 1931 Ford 5 Window Coupe and his “dream car,” a replica of a 1936 Auburn Speedster.

Janowski is a lifetime springmaker and says, “It’s all I have ever done and I love what I do.”

He looks up to many in the spring industry who have helped shape his career, including Dave Morrow of Sanborn Wire Products, who hired Janowski out of high school and gave him his first taste of the business. Others include: Walter, Kevin, Jim, Dennis, Mark, Reb, Ed and Gary, “all of which know who they are.” Janowski says, “I don’t want to get too personal!”

As to the question of how he would like to be remembered in the spring industry, Janowski responded in his Snapshot profile in the Winter 2020 issue of Springs: “Helping my fellow springmakers with making springs and purchasing equipment. A guy that can get it done!” n