SRUJANA P

GRADUATE ARCHITECT

HELLO,

AS A FRESH GRADUATE IN ARCHITECTURE, I EMBARK ON A JOURNEY TO BLEND FORM AND FUNCTION, CRAFTING SPACES THAT IGNITE IMAGINATION. READY TO UNLEASH INNOVATIVE DESIGN SOLUTIONS AND LEAVE AN INDELIBLE MARK ON THE ARCHITECTURAL SCENE.

EDUCATION

PRE - UNIVERSITY

JNANASUDHA PU COLLEGE, KARKALA,KARNATAKA

2017 - 2019

BACHELORS

ACHARYA’S NRV SCHOOL OF ARCHITECTURE, BANGALORE

2019 - 2024

INDUSTRY EXPOSURE

SERVED AS A CREW MEMBER ON INDIA’S FIRST LUNAR ANALOG EXPEDITION WITH AAKA SPACE STUDIO, ACTIVELY CONTRIBUTING EXPERTISE IN EXTREME CONDITION ARCHITECTURE. (2023)

INTERNED AT AECOM WITHIN THE TRANSIT ARCHITECTURE DEPARTMENT, WHERE I HAD THE OPPURTUNITY TO CONTRIBUTE TO SIGNIFICANT PROJECTS SUCH AS NHSRCL, MUMBAI STATION, AND BMRCL STATIONS.

TECHNICAL SKILLS

BIM & 3D MODELLING

INTERESTS

PAINTING

GRAPHIC DESIGN

MODEL MAKING

MUSIC (JAZZ, POP ROCK)

LANGUAGES

ENGLISH

KANNADA

HINDI

+916366292903

srujanapgowda1571@gmail.com

EVERYDAY ACTIVITIES OF PEOPLE IN BHOPAL ILLUSTRATED

SEASONAL ACTIVITIES NEAR THE LAKE

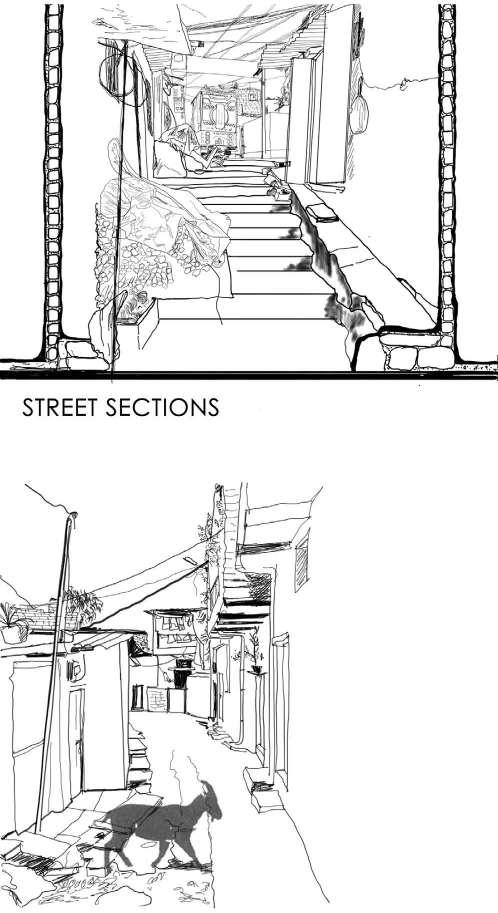

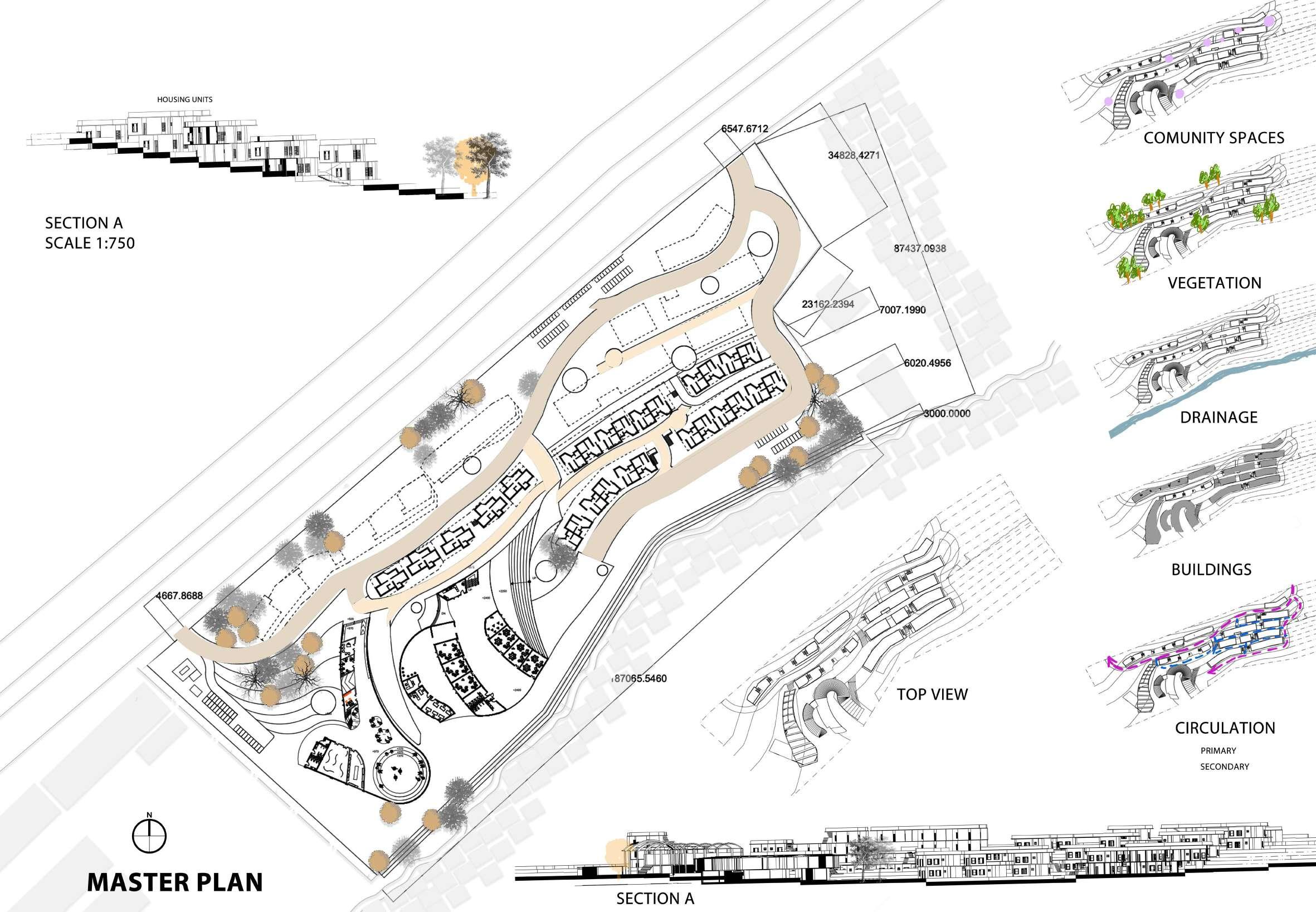

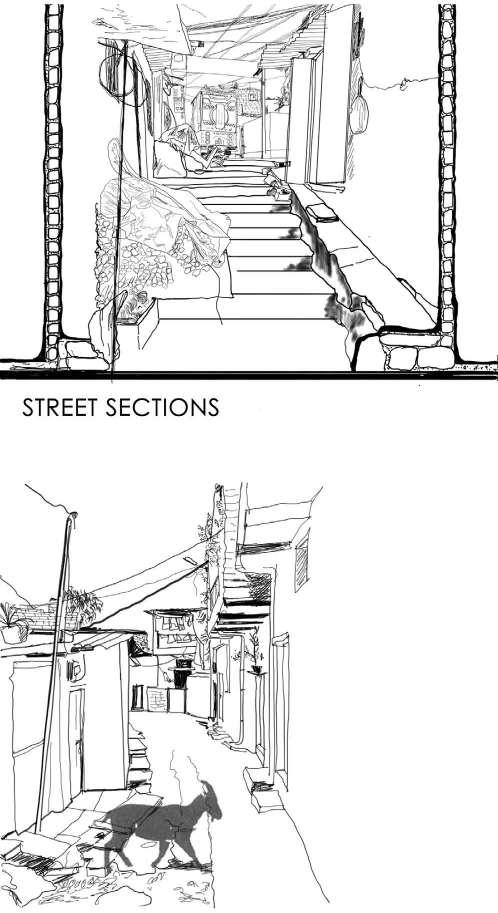

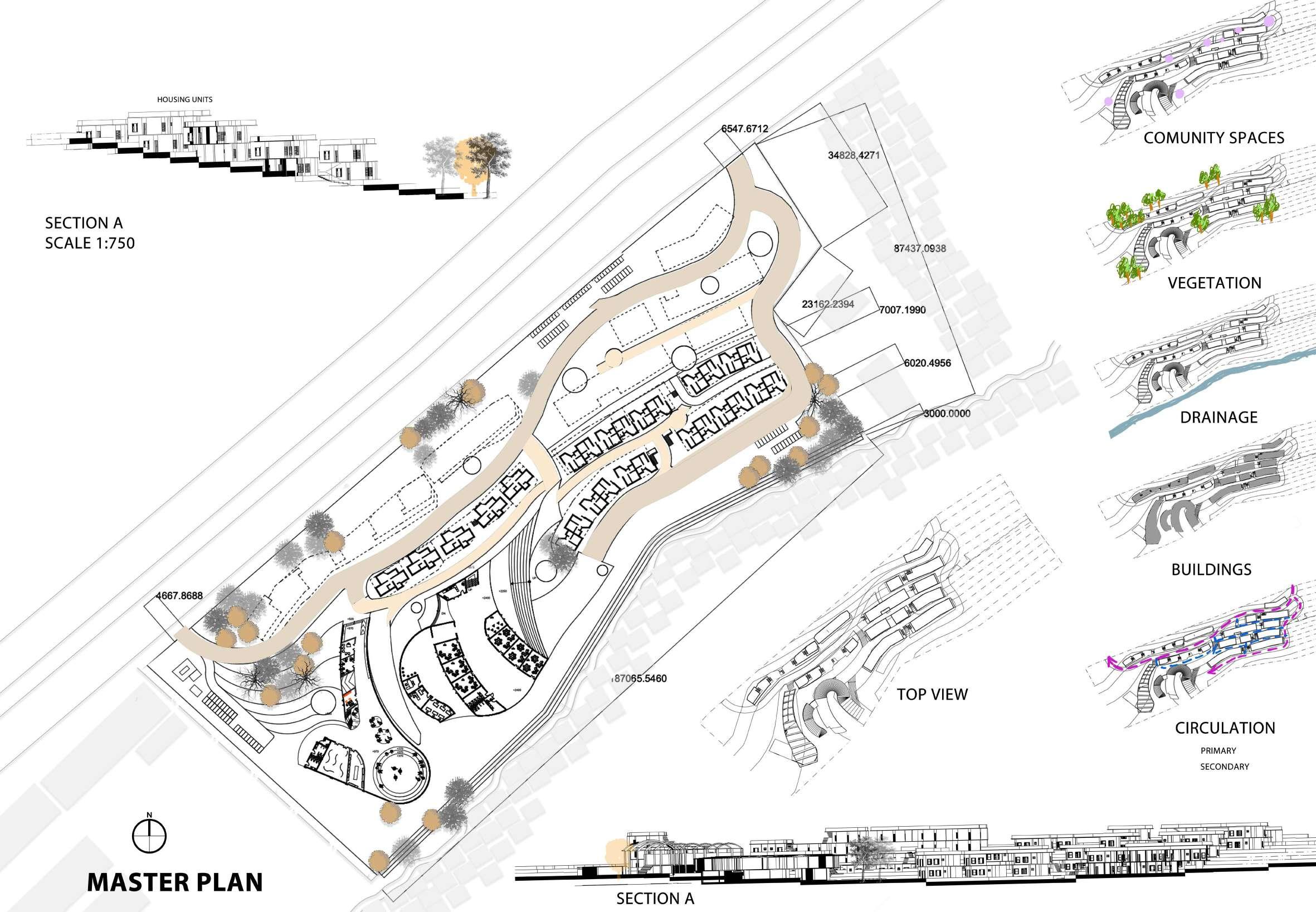

Studying and documenting Bhopal city also known as “The city of Lakes” in India. Understanding and Evaluating rich culture, the daily activities of the people living in the city, the design challenge wasto build an Affordable housing, A skill development centre and a School for the under privilaged children.

SITE LOACTED NEAR THE

BANGANGA SLUM AREA

MAHARASTRA, INDIA

PUPPETRY MAKING OCCUPATION GOAT REARING OCCUPATION

BANGANGA SLUM AREA

MAHARASTRA, INDIA

PUPPETRY MAKING OCCUPATION GOAT REARING OCCUPATION

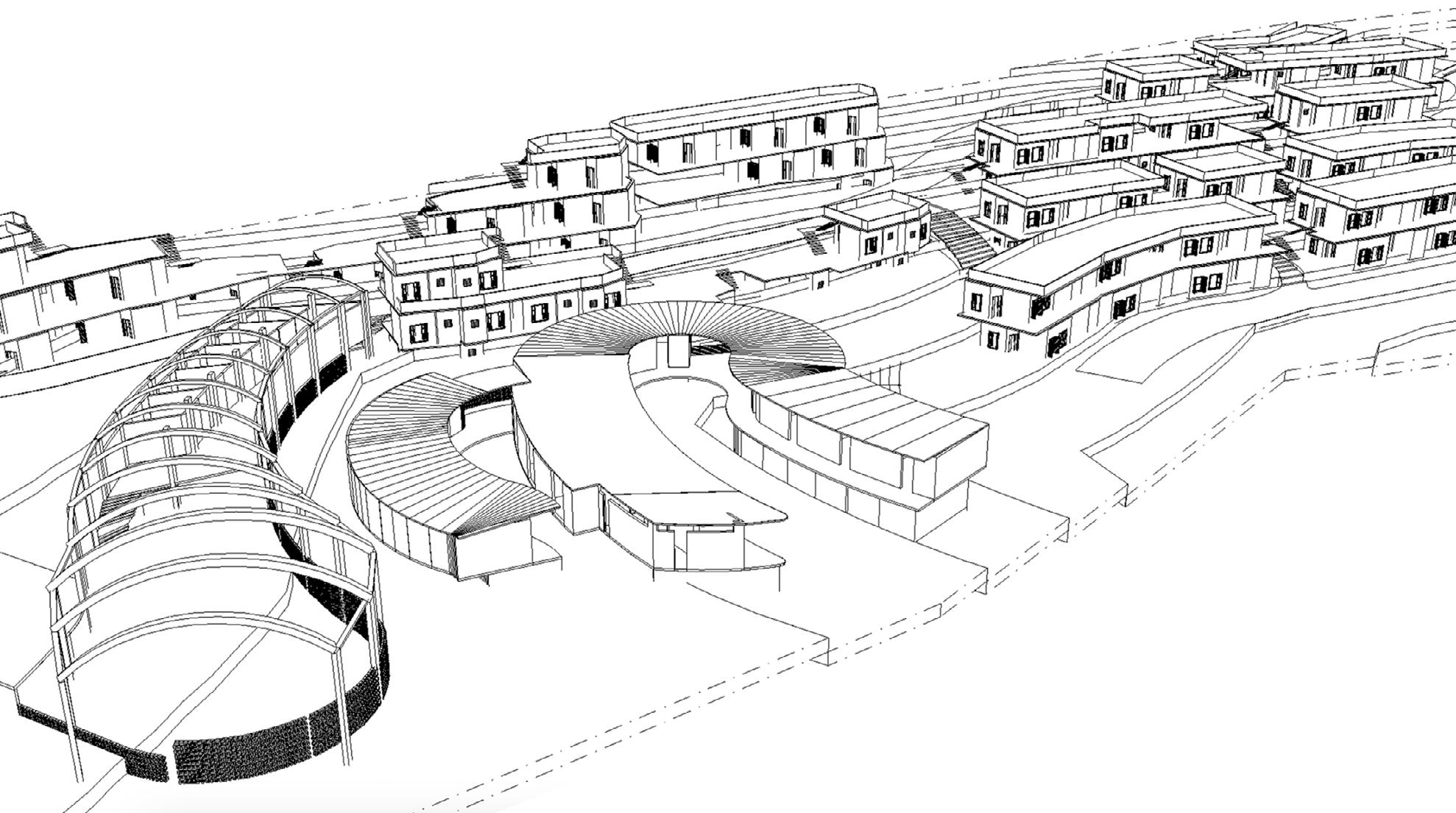

AFFORDABLE HOUSING

SKILL DEVELOPMENT CENTRE

SCHOOL

THE UNDERPRIVILAGED

FOR

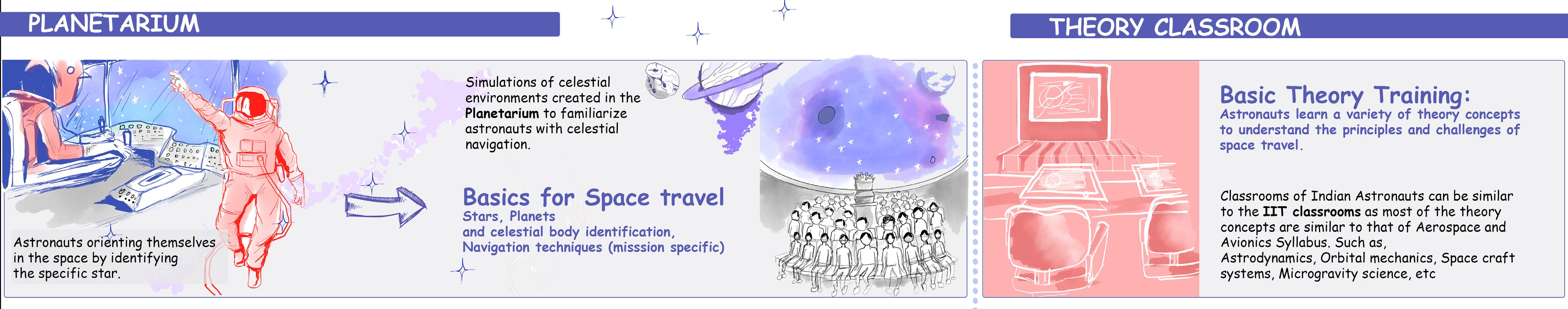

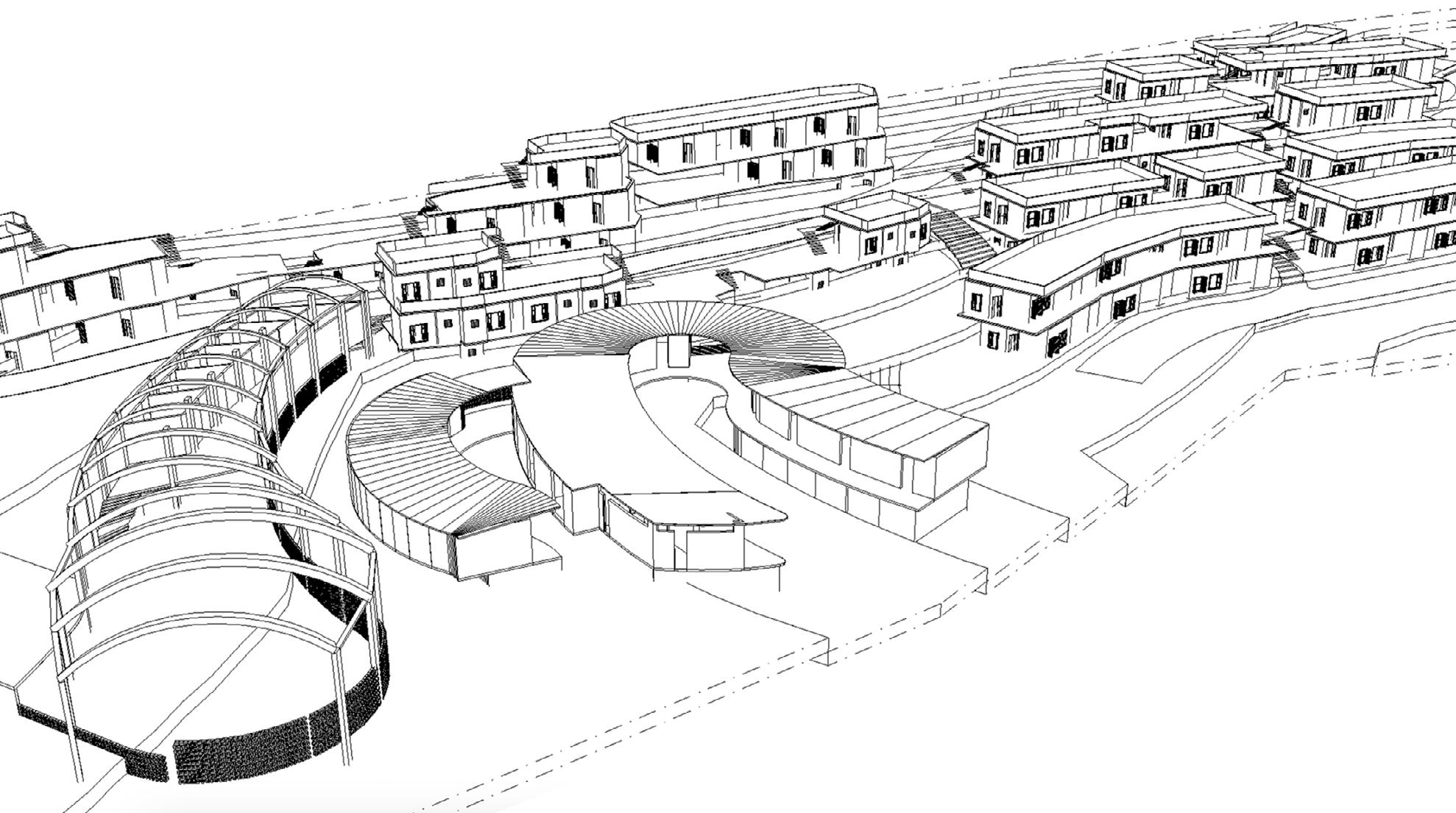

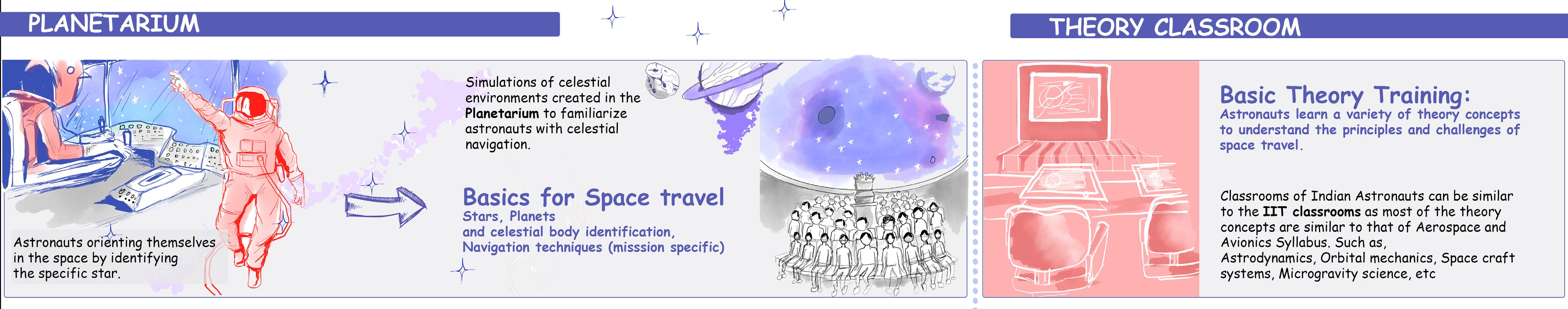

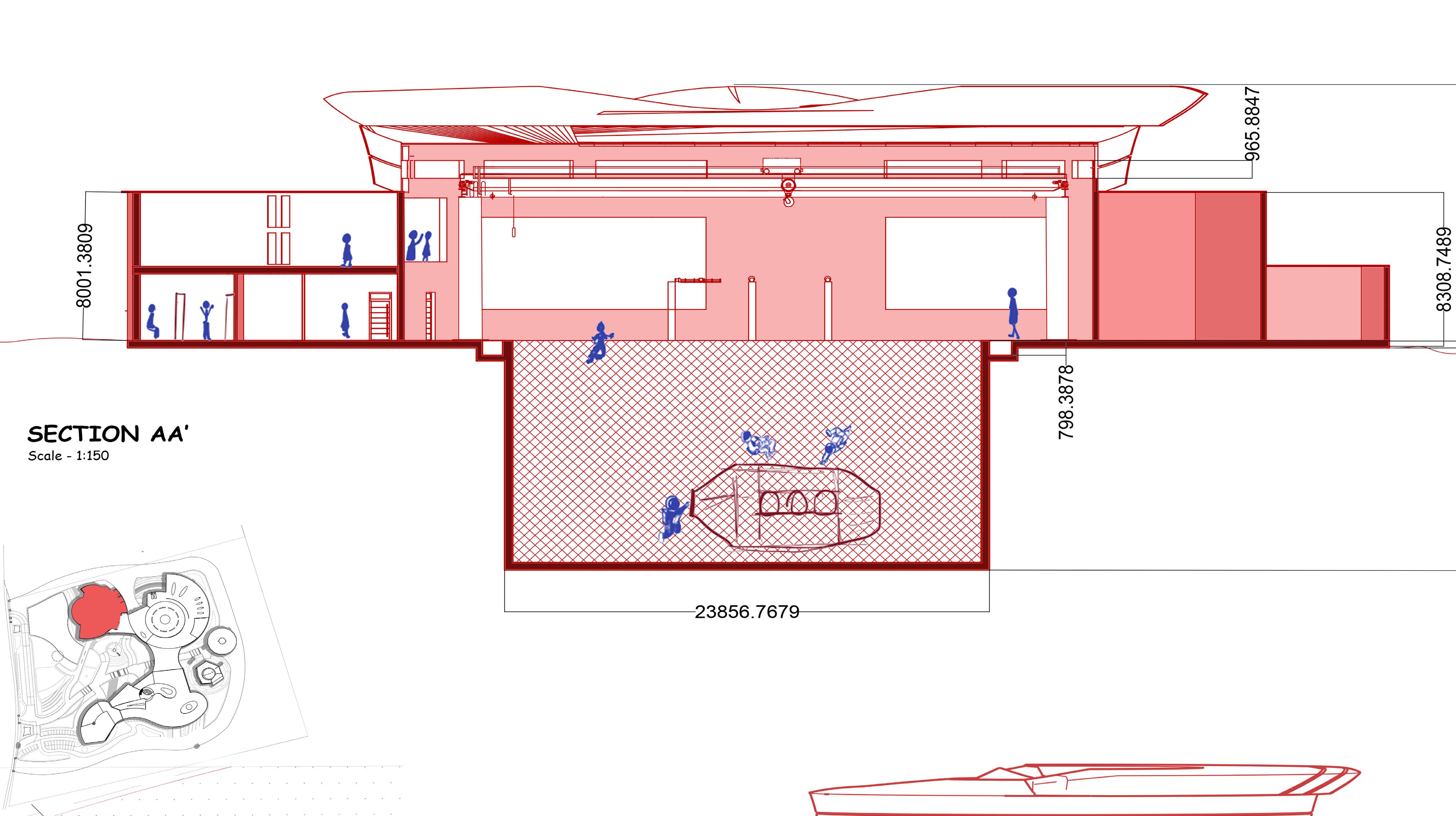

ASTRONAUT TRAINING CENTRE, CHALLAKERE

ASTRONAUT TRAINING CENTRE, CHALLAKERE

Classroom block Planetarium Crew quarters Planetarium Crew quarters

Classroom block Planetarium Crew quarters Classroom block Planetarium Crew quarters

a visionary thesis project that introduces a state-of-the-art Astronaut Training Centre situated in India. This groundbreaking design seamlessly blends cutting-edge technology, architectural innovation, and educational excellence to create a hub where aspiring space explorers can undergo rigorous training, preparing them for the challenges of space missions. stands as a testament to the fusion of science, design, and the pursuit of cosmic exploration on the Indian landscape.

Embark on a journey beyond the stars with

SRUJANA P

“An Astronaut training centre, Challakere,” a visionary thesis project that introduces a state-of-the-art Astronaut Training Centre situated in India. This groundbreaking design seamlessly blends cutting-edge technology, architectural innovation, and educational excellence to create a hub where aspiring space explorers can undergo rigorous training, preparing them for the challenges of space missions. stands as a testament to the fusion of science, design, and the pursuit of cosmic exploration on the Indian landscape.

3.5 PARTICIPANTS

b.

Participants The

Simulation Activities

The expedition attracted a diverse group of participants, including scientists, engineers, researchers, and space enthusiasts from around the world. A stringent selection process ensured that the participants possessed the necessary skills and expertise to contribute to the expedition’s objectives.

3.6 SIMULATION ACTIVITIES

a. Lunar Habitat:

of participants,

engineers, researchers, and space enthusiasts from around the world. A stringent selection process ensured that the participants possessed the necessary skills and expertise to contribute to the expedition's objectives.

AAKA Space Studio constructed a simulated lunar habitat to replicate the living conditions that astronauts would experience on the moon. The habitat incorporated necessary life support systems, communication equipment, and recreational facilities.

a. Lunar Habitat: AAKA Space Studio constructed a simulated lunar habitat to replicate the living conditions that astronauts would experience on

b. Extra-Vehicular Activities (EVAs):

Participants engaged in simulated extravehicular activities, which involved exploring the lunar surface while wearing spacesuits. These activities provided valuable insights into the challenges of conducting research and navigation on the moon.

on the moon.

Embark on a journey beyond the stars with “An Astronaut training centre, Challakere,” a visionary thesis project that introduces a state-of-the-art Astronaut Training Centre situated in India. This groundbreaking design seamlessly blends cutting-edge technology, architectural innovation, and educational excellence to create a hub where aspiring space explorers can undergo rigorous training, preparing them for the challenges of space missions. stands as a testament to the fusion of science, design, and the pursuit of cosmic exploration on the Indian landscape.

3.5 PARTICIPANTS

The expedition attracted a diverse group researchers, and space enthusiasts from ensured that the participants possessed the necessary expedition’s objectives.

Admin block Planetarium

CENTRE,

Lunar Rover Operations: AAKA Space Studio developed a lunar rover prototype for participants to operate during the expedition. This allowed them to gain practical experience in controlling and maneuvering a vehicle in lunarlike conditions.

Communication and Data Analysis: The expedition emphasized the importance of effective communication between the lunar

c.

d.

expedition attracted a diverse group

including scientists,

the moon. The habitat incorporated necessary life support systems, communication equipment, and recreational facilities.

which involved exploring the lunar surface while wearing spacesuits. These activities provided valuable insights into the challenges of conducting research and navigation

extra-vehicular activity - II partial gravity walk c. Lunar Rover Operations: AAKA Space Studio developed a lunar rover prototype for participants to operate during the expedition This allowed them to gain practical experience in controlling and maneuvering a vehicle in lunarParticipants The expedition attracted diverse group of participants, including scientists, engineers, researchers, and space enthusiasts from around the world. A stringent selection process ensured that the participants possessed the necessary skills and expertise to contribute to the expedition's objectives. Simulation Activities a. Lunar Habitat: AAKA Space Studio constructed simulated lunar habitat to replicate the living conditions that astronauts would experience on the moon. The habitat incorporated necessary life support systems, communication equipment, and recreational facilities. b. Extra-Vehicular Activities (EVAs): Participants engaged in simulated extravehicular activities, which involved exploring the lunar surface while wearing spacesuits. These activities provided valuable insights into the challenges of conducting research and navigation on the moon. extra-vehicular activity extra-vehicular activity II partial gravity walk c. Lunar Rover Operations: AAKA Space Studio developed lunar rover prototype for participants to operate during the expedition This allowed them to gain practical experience in controlling and maneuvering vehicle in lunarlike conditions. d. Communication and Data Analysis: The expedition emphasized the importance of effective communication between the lunar habitat and mission control. Participants utilized advanced communication systems to relay data, conduct experiments, and analyze the gathered information. Fig 3.6.1:Simulation of zero gravity walk Fig 3.6.2: hunting for samples in the surroundings (EVA)

Extra-Vehicular Activities (EVAs): Participants engaged in simulated extravehicular activities,

Planetarium PAGE

Classroom block

3.6 SIMULATION ACTIVITIES Participants

Admin

Classroom block

block

Crew quarters Lake Hydrolaboratory

Classroom block Admin block

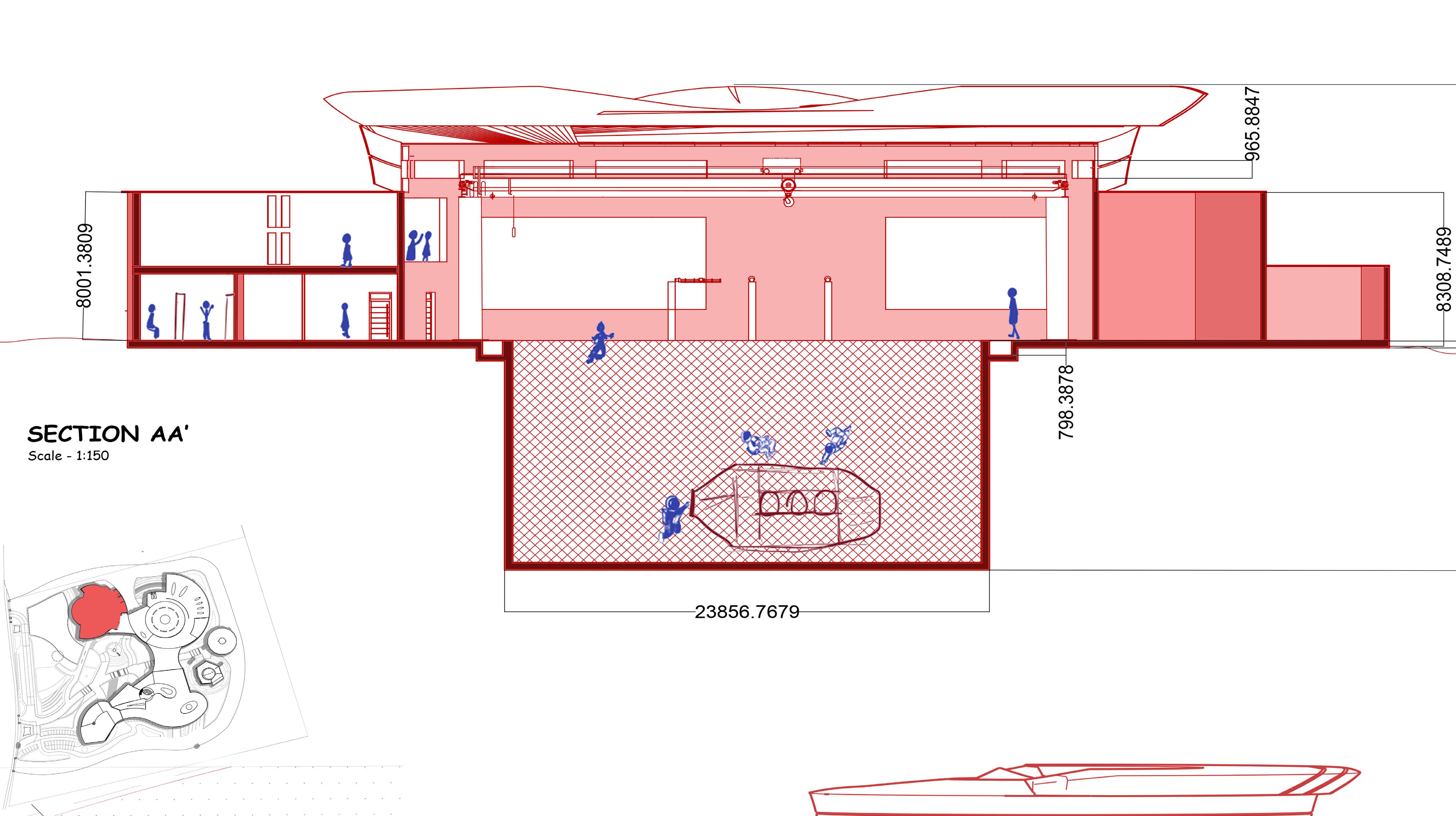

Fig 6.3.1: Massing

Fig 6.3.2: Table showing area of the blocks

Fig 6.3.1: Massing

Fig 6.3.2: Table showing area of the blocks

Planetarium

46

Simulator building

Astronaut training centre, Challakere

Fig 6.3.1: Massing

Fig 6.3.2: Table showing area of the blocks

Classroom block Admin block

Planetarium Crew quarters Lake Hydrolaboratory

PAGE

Simulator building

PAGE PAGE PAGE PAGE

TRAINING CHALLAKERE

vital for mastering tasks like spacewalks and handling equipment in space. Buoyancy pools for astronauts incorporate specialized tools like harness systems, buoyancy aids, and underwater cameras. These elements enable astronauts to simulate weightlessness on Earth missions.

Conducted in large water tanks, buoyancy training allows astronauts to experience weightlessness akin to microgravity. Astronauts practice extravehicular activities (EVAs) underwater, refining their movements and coordination in a simulated weightless environment. This training is vital for mastering tasks like spacewalks and handling equipment in space. Buoyancy pools for astronauts incorporate specialized tools like harness systems, buoyancy aids, and underwater cameras. These elements enable astronauts to simulate weightlessness on Earth missions.

ASTRONAUT TRAINING

CENTRE, CHALLAKERE

Conducted in large water tanks, buoyancy training allows astronauts to experience weightlessness akin to microgravity. Astronauts practice extravehicular activities (EVAs) underwater, refining their movements and coordination in a simulated weightless environment. This training is vital for mastering tasks like spacewalks and handling equipment in space. Buoyancy pools for astronauts incorporate specialized tools like harness systems, buoyancy aids, and underwater cameras. These elements enable astronauts to simulate weightlessness on Earth missions.

CENTRE, CHALLAKERE and coordination in a simulated weightless environment. This training is

PAGE

CENTRE, CHALLAKERE

PAGE

1/15 RAMP AUTOMATIC FLOOD BARRIER +5.50 m FFL +6.50 m FFL UP UP UP UP AUTOMATIC FLOOD BARRIER ST-10 LEVEL-B1F TO GF RISER- 150.00 mm TREAD- 300.0 mm STEPS- 83 WIDTH-2400.00 mm AUTOMATIC FLOOD BARRIER 10000 1500 10000 1600 1800 10000 1500 10000 1600 1800 ST-12 LEVEL-B1F TO GF RISER- 150.00 mm TREAD- 300.0 mm STEPS- 83 WIDTH-2400.00 mm ST-11 LEVEL-B1F TO GF RISER- 150.00 mm TREAD- 300.0 mm STEPS- 83 WIDTH-2400.00 mm ES-05 LEVEL-PLINTH STEPS RISER- 142.86 mm TREAD- 300.0 mm STEPS- 7 WIDTH-85750.00 mm ST-09 LEVEL-B1F TO GF RISER- 150.00 mm TREAD- 300.0 mm STEPS- 83 WIDTH-2400.00 mm SEC AA +6.50 m FFL +5.50 m FFL +5.50 m FFL +5.50 m FFL AUTOMATIC FLOOD BARRIER 1/15 RAMP 1/15 RAMP 1/15 RAMP X21 X22 X20 X19 X18 X17 X16 Y1 Y2 Y3 Y5 Y6 Y7 12500 12500 12500 12500 12500 12500 Y4 10660 10260 10260 10260 10260 10660 62360 57680 46840 X21 X22 X20 X19 X18 X17 X16 B1F (FFL) -5.950 M B2F (FFL) -12.600 M URF (TOC) +3.000 M GF (FFL) +6.500 M GL +5.500 M GREENERY GREENERY HARD PAVEMENT SKYLIGHT SKYLIGHT 12500 12500 12500 12500 12500 12500 6650 57680 4000 3590 1480 4000 4000 EMERGENCY STAIRCASE EMERGENCY STAIRCASE 900 ALUMINIUM DECORATIVE PANEL ALUMINIUM DECORATIVE PANEL 3100 2100 46665 1850 19205 SKYLIGHT GLASS GREEN 1 (PLANT MIX) GREEN 2 (PLANT MIX) PAVEMENT X21 X22 X20 X19 X18 X17 X16 Y1 Y2 Y3 Y5 Y6 Y7 12500 12500 12500 12500 12500 12500 Y4 10660 10260 10260 10260 10260 10660 62360 57680 46840 ST-09 ST-11 ST-10 ST-12 ALUMINIUM DECORATIVE PANEL ALUMINIUM DECORATIVE PANEL STRUCTURAL BEAM SKYLIGHT GLASS SPACE FRAME TRUSS2 Scale 1:500 GROUND LEVEL PLAN1 Scale 1:500 SECTION AA3 Scale (A1) 1:500 REFLECTED CEILING PLAN 12 11 10 9 8 7 6 5 4 3 2 1 H H G G F F E E D D C C TECHNICAL DESIGN B KEY PLAN B REVISIONS QUALITY ASSURANCE The responsibility of control, check and verification of accuracy, correctness, completeness, integration, interfacing with other disciplines and full compliance of contract provisions in respect of design analysis and drawings rests with the contractor. A REV DATE DESCRIPTION 12 DRAWN DSGN CHKD APR 11 DRAWN BY DESIGNED BY CHECKED BY APPROVED BY NAME 10 SIGN DATE 9 PROJECT TITLE Design and Construction of Civil and Building Works including Testing and Commissioning on Design Build Lump Sum Price Basis for Double Line High Speed Railway for Mumbai Underground Station, Cut & Cover Tunnel and Shaft-1 from MAHSR Km. -0.255 to Km. 0.775 at Bandra-Kurla Complex in the State of Maharashtra for the Project for Construction of Mumbai-Ahmedabad High Speed Rail. 8 7 6 5 4 LEGEND 200 MM THK BLOCKWORK WALL 1 00000-00 SEC/ELE NAME DRAWING NUMBER STRUCTURAL WALL COLUMNS (THK. AS/STR. Dwg.) PARTITION WALL WALL LEGEND +00.00m TITLE ELEVATION WITH RESPECT TO MEAN SEA LEVEL MUMBAI HSR STATION CENTRAL SKYLIGHT PLAN AND SECTION DRAWING NO TD-NHS-MEH-C01-S01-STA-B01- 50000 SHEET 1 OF 1 SCALE PRELIMINARY 3 INFORMATION 2 APPROVAL CONSTRUCTION As indicated 1 REV 002 SIZE A3 A PROJECT MUMBAI - AHMEDABAD HIGH SPEED RAIL PROJECT Package No. MAHSR C - 1 (Km. -0.255 Km. 0.775) ISOA1 594x841 CH: 774.669 CH: 0+239.669 CH: 0+706.669 (START OF SHAFT 1) C & C TUNNEL END OF STATION CENTER OF STATION END OF PLATFORM CH: 0+209.669 OF CH. -0.205.331

700 200 1400 3300 (11 TREADS @ 300 MM) 1800 (12 RISERS @ 150 MM) CAPPING: SUS SUS LAMINATED FLOAT GLASS (TRANSPARENT) SUS-PIPE RLG-03 FLR-01 DETAIL - A 500 150 300 80 30 10 80 30 10 50 50 50 50 25 FLR-01 30 MM THK ANTI SKID FINISH STONE STRIP WITH CONTRAST FINISH (GRANITE) R10 MORTAR 150 DETAIL B FLR-01 30 MM THK ANTI SKID FINISH STONE STRIP WITH CONTRAST FINISH (GRANITE) 80 30 R10 5 5 5 5 30 10 25 30 5 5 25 25 25 25 20 FLR-01 30 MM THK ANTI SKID FINISH STONE STRIP WITH CONTRAST FINISH (GRANITE) ANTISKID STRIP 5MM×5MM MORTAR FLR-01 2 mm GAP FILLED WITH SEALANT RLG-14 700 200 250 1150 38 mm Ø HOT DIP GALVANIZED STEEL PIPE PAINTED FINISH 20 MM Ø HOT DIP GALVANIZED STEEL PIPE PAINTED FINISH 50 x 50 x 2 MM THK HOT DIP GALVANIZED STEEL PIPE PAINTED FINISH DETAIL - C 2700 (9 TREADS @ 300 MM) 1450 (10 RISERS @ 140-150 MM) 25 x 25 x 1.5 MM THK HOT DIP GALVANIZED STEEL PIPE PAINTED FINISH 140-150 15 300 140-150 FLR-03 15 50 50 50 R10 25 25 MORTAR DETAIL D 15 25 50 25 25 25 25 R10 FLR-03 MORTAR FLR-03 2 2 mm GAP FILLED WITH SEALANT 20 5 5 5 ANTISKID GROOVES 5 51 SCALE-1:50 TYPICAL SECTION - PUBLIC STAIRCASE GLASS PANEL SS RAILING STAIRCASE RLG-03 SIDE MOUNTED MS RAILING (WITH GRAB RAIL) RLG-142 SCALE-1:10 DETAIL - A3 SCALE-1:5 DETAIL - B4 SCALE-1:50 TYPICAL SECTION - EMERGENCY & MAINTENANCE STAIRCASES5 SCALE-1:10 DETAIL - C6 SCALE-1:5 DETAIL - D GRANITE STONE-1 (LEATHER FINISH) FLR-01 KOTA STONE FLR-03 12 11 10 9 8 7 6 5 4 3 2 1 H H G G F F E E D D C C TECHNICAL DESIGN B KEY PLAN B REVISIONS QUALITY ASSURANCE The responsibility of control, check and verification of accuracy, correctness, completeness, integration, interfacing with other disciplines and full compliance of contract provisions in respect of design analysis and drawings rests with the contractor. A REV DATE DESCRIPTION 12 DRAWN DSGN CHKD APR 11 DRAWN BY DESIGNED BY CHECKED BY APPROVED BY NAME Koteswararao Sushil Verma Divya Gosain 10 SIGN DATE 9 PROJECT TITLE Design and Construction of Civil and Building Works including Testing and Commissioning on Design Build Lump Sum Price Basis fo Double Line High Speed Railway for Mumbai Underground Station, Cut & Cover Tunnel and Shaft-1 from MAHSR Km. -0.255 to Km. 0.775 at Bandra-Kurla Complex in the State of Maharashtra for the Project for Construction of Mumbai-Ahmedabad High Speed Rail. 8 7 6 5 4 LEGEND 200 MM THK BLOCKWORK WALL 1 00000-00 SEC/ELE NAME DRAWING NUMBER STRUCTURAL WALL COLUMNS (THK. AS/STR. Dwg.) PARTITION WALL WALL LEGEND +00.00m TITLE ELEVATION WITH RESPECT TO MEAN SEA LEVEL MUMBAI HSR STATION TYPICAL DETAILS OF STEPS DRAWING NO TD-NHS-MEH-C01-S01-STA-B01-18020-000 SHEET 1 OF 1 SCALE PRELIMINARY 3 INFORMATION 2 APPROVAL CONSTRUCTION As indicated 1 REV 000 SIZE A3 A PROJECT MUMBAI - AHMEDABAD HIGH SPEED RAIL PROJECT Package No. MAHSR C 1 (Km. -0.255 - Km. 0.775) ISOA1 594x841 CH: 774.669 C1 PACKAGE END CH: 0+239.669 END OF C & C TUNNEL (START OF SHAFT 1) C & C TUNNEL END OF STATION CENTER OF STATION END OF PLATFORM OF CH. -0.205.331 START OF STATION CH. -0.255.331 000 28/03/24 TECHNICAL DESIGN 1 DG SV UG Unmesh Galgale 28/03/24 KK 28/03/24 28/03/24 28/03/24

VARIES CAST IN ANCHOR GALVANIZED ROLL SHAPED CHANNEL AS PER TECHNICAL SPECIFICATION I-BEAM AS PER STRUCTURAL REQUIREMENT MS SHS AS PER STRUCTURAL REQUIREMENT FALSE CEILING 12 MM THK TEMPERED GLASS SMOKE DOWN STAND 750 1200 1200 1200 DETAIL - A CAST IN ANCHORGALVANIZED ROLL SHAPED CHANNEL AS PER TECHNICAL SPECIFICATION I-BEAM AS PER STRUCTURAL REQUIREMENT MS SHS AS PER STRUCTURAL REQUIREMENT FALSE CEILING 12 MM THK TEMPERED GLASS SMOKE DOWN STAND MS SHS AS PER STRUCTURAL REQUIREMENT 750 50 VARIES DETAIL - B DETAIL - C CAST IN ANCHORGALVANIZED ROLL SHAPED CHANNEL AS PER TECHNICAL SPECIFICATION I-BEAM AS PER STRUCTURAL REQUIREMENT MS SHS AS PER STRUCTURAL REQUIREMENT WELD WELD WELD FALSE CEILING 12 MM THK TEMPERED GLASS SMOKE DOWN STAND MS SHS AS PER STRUCTURAL REQUIREMENT SS GLASS FIXING FRAME AS PER VENDOR MS SHS AS PER STRUCTURAL REQUIREMENT FALSE CEILING 12 MM THK TEMPERED GLASS SMOKE DOWN STAND SS GLASS FIXING FRAME AS PER VENDOR1 Scale - 1:50 SMOKE DOWN STAND TYPICAL ELEVATION2 Scale - 1:20 DETAIL - A3 Scale - 1:20 SECTION - 14 Scale - 1:10 DETAIL - B5 Scale - 1:10 DETAIL - C 12 11 10 9 8 7 6 5 4 3 2 1 H H G G F F E E D D C C TECHNICAL DESIGN B KEY PLAN B REVISIONS QUALITY ASSURANCE The responsibility of control, check and verification of accuracy, correctness, completeness, integration, interfacing with other disciplines and full compliance of contract provisions in respect of design analysis and drawings rests with the contractor. A REV DATE DESCRIPTION 12 DRAWN DSGN CHKD APR 11 DRAWN BY DESIGNED BY CHECKED BY APPROVED BY NAME Koteswararao Sushil Verma Divya Gosain 10 SIGN DATE 9 PROJECT TITLE Design and Construction of Civil and Building Works including Testing and Commissioning on Design Build Lump Sum Price Basis fo Double Line High Speed Railway for Mumbai Underground Station, Cut & Cover Tunnel and Shaft-1 from MAHSR Km. -0.255 to Km. 0.775 at Bandra-Kurla Complex in the State of Maharashtra for the Project for Construction of Mumbai-Ahmedabad High Speed Rail. 8 7 6 5 4 LEGEND 200 MM THK BLOCKWORK WALL 1 00000-00 SEC/ELE NAME DRAWING NUMBER STRUCTURAL WALL COLUMNS (THK. AS/STR. Dwg.) PARTITION WALL WALL LEGEND +00.00m TITLE ELEVATION WITH RESPECT TO MEAN SEA LEVEL MUMBAI HSR STATION TYPICAL DETAILS OF SMOKE DOWN STAND DRAWING NO TD-NHS-MEH-C01-S01-STA-B01-18022-000 SHEET 1 OF 1 SCALE PRELIMINARY 3 INFORMATION 2 APPROVAL CONSTRUCTION As indicated 1 REV 000 SIZE A3 A PROJECT MUMBAI - AHMEDABAD HIGH SPEED RAIL PROJECT Package No. MAHSR C 1 (Km. -0.255 - Km. 0.775) ISOA1 594x841 C1 PACKAGE END CH: 0+239.669 END OF C & C TUNNEL CH: 0+706.669 (START OF SHAFT 1) C & C TUNNEL END OF STATION CENTER OF STATION END OF PLATFORM OF CH. -0.205.331 000 28/03/24 TECHNICAL DESIGN 1 DG SV UG Unmesh Galgale 28/03/24 KK 28/03/24 28/03/24 28/03/24

BANGANGA SLUM AREA

MAHARASTRA, INDIA

PUPPETRY MAKING OCCUPATION GOAT REARING OCCUPATION

BANGANGA SLUM AREA

MAHARASTRA, INDIA

PUPPETRY MAKING OCCUPATION GOAT REARING OCCUPATION

Fig 6.3.1: Massing

Fig 6.3.2: Table showing area of the blocks

Fig 6.3.1: Massing

Fig 6.3.2: Table showing area of the blocks