BY RAE LANZRATH STAFF WRITER

ry and work on the family farm.

CARLOS — Sibling relationships are unique in each family; the Yohnke brothers live, work and play together, literally. From being teammates to roommates to coworkers, they are never far from one another.

Chuck and Sandy Yohnke raised their four sons, Grant, Travis, and twins Preston and Spencer, on a farm near Carlos. The boys have spent their entire lives doing farm work, playing games and competing with one another. From playing baseball in their grandma’s yard to swimming in the river, they have never sat still.

Today, Travis and Preston both attend the University of Sioux Falls and play football. Grant and Spencer both work for Thoennes Mason-

to play together again is one of my favorite football moments,” Travis said. “I never thought that would happen again.”

“That farming mindset of dedication and staying positive when things aren’t looking good has always set me apart from my competition,” Travis said.

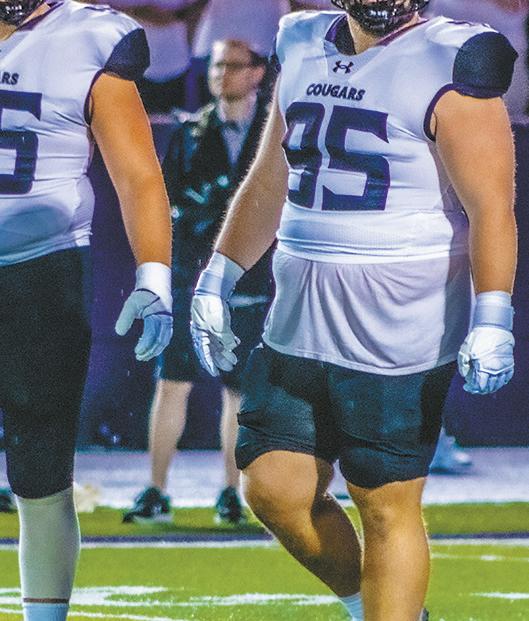

Travis, a graduate student, is working on getting his master’s degree in business administration. Preston is majoring in criminal justice and minoring in psychology. Travis plays as a tight end for USF and Preston is a defensive lineman.

Following high school, Preston went to North Dakota State College of Science, where he played football for two years. When he had completed his time at NDSCS, he wanted to transfer to another school. Travis spoke with the coaches at USF and got his brother a spot on the team.

“That day, two years ago, when I found out Preston and I would get

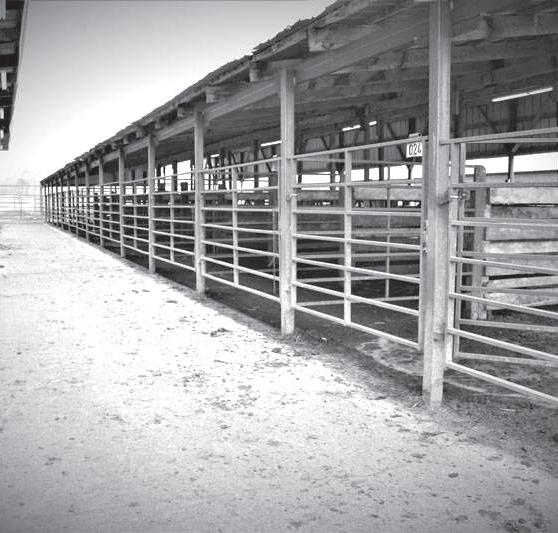

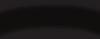

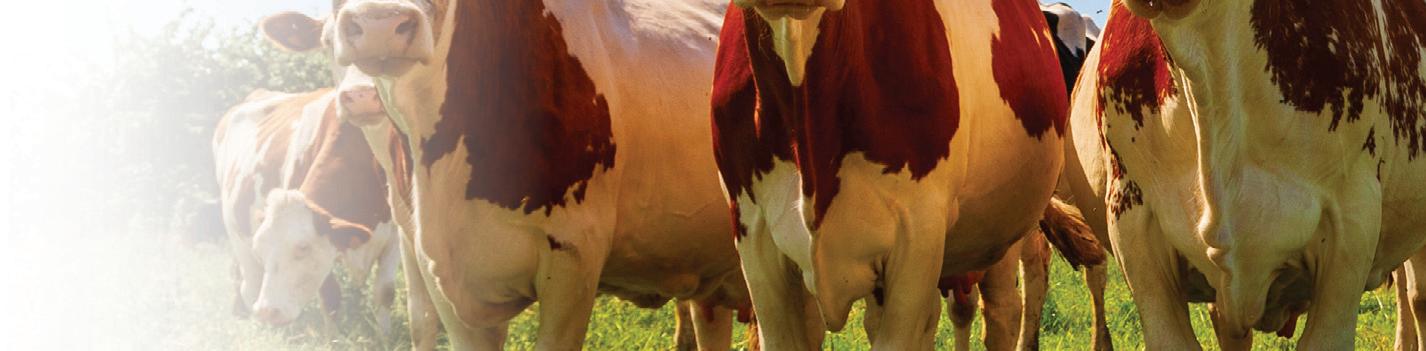

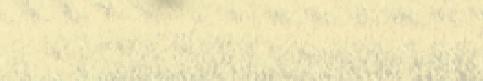

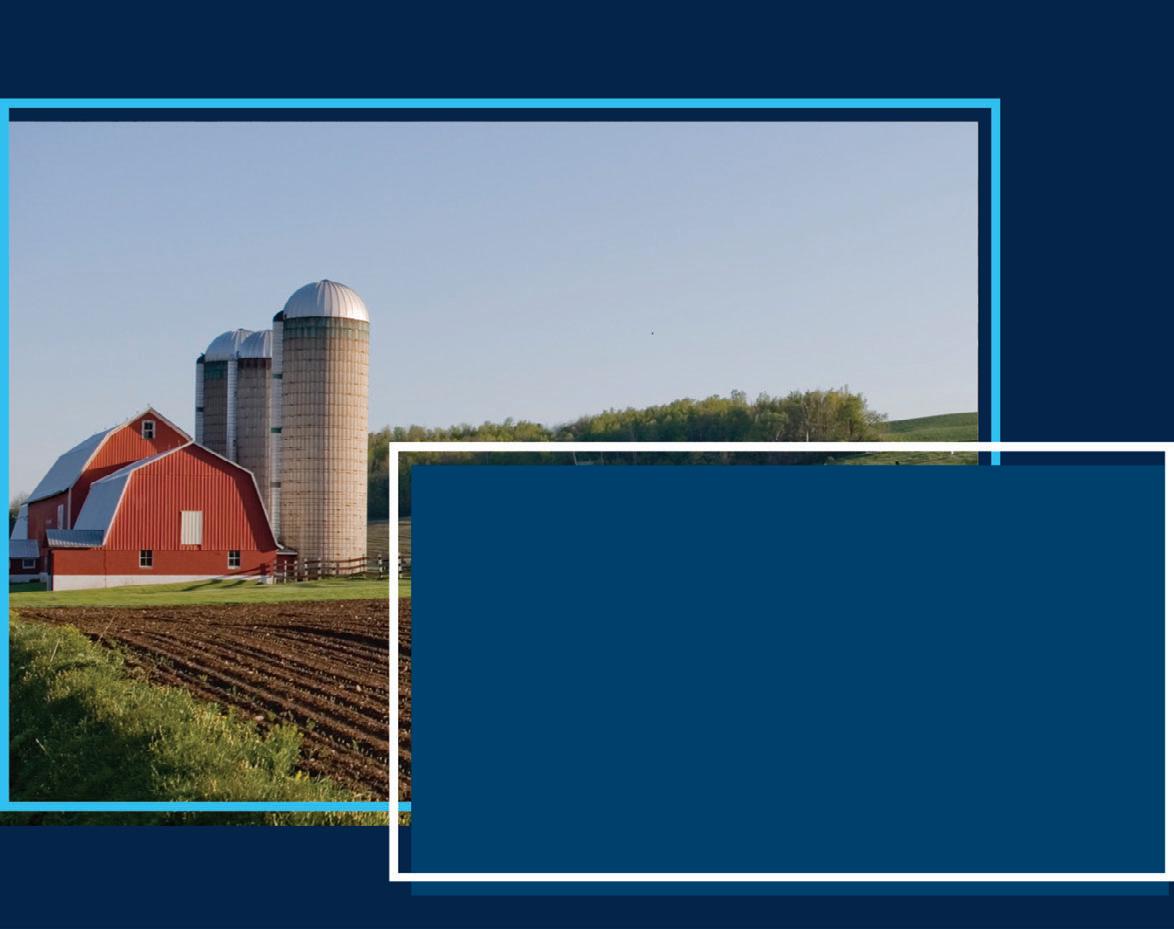

Cattle gather Sept. 16 at the Yohnke farm near Carlos. The Yohnkes manage calves from previous years with their cow-calf pairs.

Travis and Preston are both in Sioux Falls, but the farm is still running without them. The Yohnkes raise around 20 cow-calf pairs as well as calves from the previous year. The total herd typically numbers 60 head.

“We feel guilty being away from the farm,” Preston said. “Our dad and other brothers have had to pick up so much slack from us being gone. We sit in our apartment and just know they’re out there baling hay or doing chores.”

Being raised on a farm shaped the brothers into who they are today, teaching them life lessons they wouldn’t have gotten otherwise.

“We always had to figure

out who was the best at what, what each other’s strengths and weaknesses were,” Travis said.

Yohnkes page 2

Published by

Star Publications

Copyright 2024

522 Sinclair Lewis Ave.

Sauk Centre, MN 56378

Phone: 320-352-6577

Fax: 320-352-5647

NEWS STAFF

Mark Klaphake, Editor

Mark.k@dairystar.com

Tiffany Klaphake, Assistant Editor tiffany.k@dairystar.com

Emily Breth, Writer emily.b@star-pub.com

Rae Lanzrath, Writer raeanna.l@star-pub.com

Carol Moorman, Writer carol@melrosebeacon.com

Natasha Barber, Writer natasha@saukherald.com

Ben Sonnek, Writer ben.s@saukherald.com

Hans Lammeman, Writer hans.l@star-pub.com

Story ideas send to: annika@star-pub.com

SALES STAFF

Robin Brunette, 320-293-5911

robin@saukherald.com

Missy Traeger, 320-291-9899 missy@saukherald.com

Tim Vos, 320-845-2700 tim@albanyenterprise.com

Mike Schafer, 320-894-7825 mike.s@dairystar.com

Neil Maidl, 320-292-4454

neil.m@star-pub.com

Jaime Ostendorf, 320-309-1988 jaime@star-pub.com

Bob Leukam, 320-260-1248

bob.l@star-pub.com

PRODUCTION STAFF

Amanda Thooft

Nancy Powell

Maddy Peterson

Cheyenne Middendorf

Karen Knoblach

Annika Gunderson

Nadiia Griepentrog

Deadlines:

Country Acres will be published the first Saturdays of April, May, June, September, October and November, and the third Saturday of every month. Deadline for news and advertising is the Friday a week before publication.

ISSN: Print 2834-6440 Online 2834-6459

front

Growing up, the Yohnkes participated in 4-H, FFA and church activities. They showed pigs, chickens, beef cattle and rabbits in 4-H. They are also avid hunters, spending most of fall hunting deer.

“They never stopped,” Chuck said. “From chores to practices to playing games in the yard, they were always going.”

The brothers have been playing football since they were in fifth grade at Miltona-Union Middle School.

“We started as soon as we were old enough to know how to throw and catch a ball,”

Travis said.

The Yohnkes attended Parkers Prairie High School, where their football careers really started. In his senior year, Travis was able to play on the same team as Preston and Spencer, who were juniors at the time.

“It was such a great experience sharing a field with my brothers,” Travis said. “At the time, we thought it would never happen again.”

Travis graduated high school and went on to play college football at North Dakota State University. The following year, Preston and Spencer graduated, and both headed to Wahpeton, North Dakota, to attend NDSCS. Spencer joined the John Deere tech program.

Grant had attended college

Publications bli ti

“The newspaper of today is the history of tomorrow.”

in Fergus Falls and returned home to work on the farm and start his family. Today, Grant and his wife, Micaela, live locally with their son, Camden, and help on the farm.

Travis attended NDSU for three years, bringing home two national championships.

Yohnkes page 3

Lahrs create high-demand grains using unique process

BY BEN SONNEK STAFF WRITER

SAUK CENTRE —

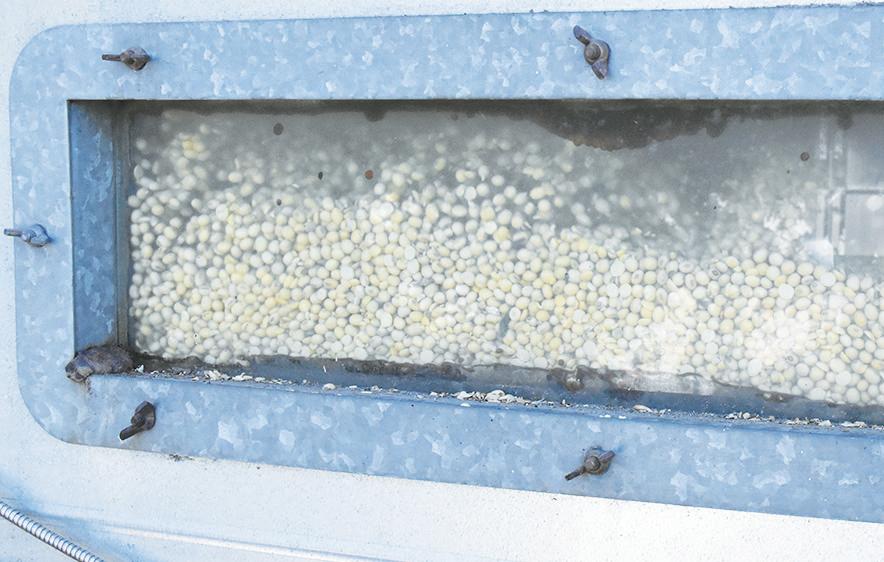

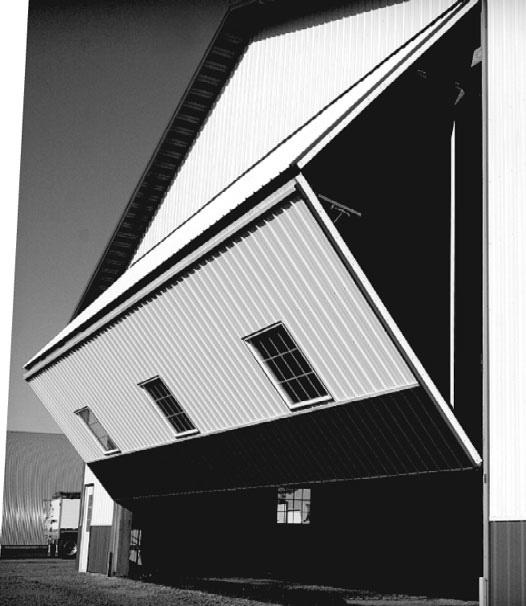

Fall is the busiest time of year at KLC Farms Roasting south of Sauk Centre. Not only is the farm harvesting and making their own feed, but they also take in crops of other area farmers who want to benefit from their hot-air roasting system.

Sometimes, trucks will be backed up to the road, but this is of no concern to Kevin Lahr, co-owner of KLC Farms Roasting. For him, every customer is an opportunity, whether they are bringing in their usual product or have a special or new request.

“You’ve got to treat every opportunity like it could be the one,” Lahr said. “When you call me up and

say, ‘Can you do this?’ the answer is always yes.”

KLC Farms Roasting was founded in 1988 by Lahr’s parents, Larry and Carol, as another revenue stream for KLC Farms. Larry, a longtime farmer, had dairy cattle at the time. He roasted feed for his own cows and soon, neighbors and some grain elevators were asking him to roast feed for them as well. The business grew from there. Larry phased out dairy cows in 1991, making roasting the full-time business.

The majority of KLC Farms’ customers are dairy farms. Lahr enjoys being able to help dairy businesses. Recently, the business was one of the benefactors that brought milk machines to Sauk Centre Public Schools so students could have fresh milk with their meals.

Lahr and his wife, Janet, bought KLC Farms Roasting in 2015.

“I’ve been involved since the beginning,” Lahr said. “I grew up here. … (Larry) let me buy into the business a little bit in the early 2000s, so we partnered in it.”

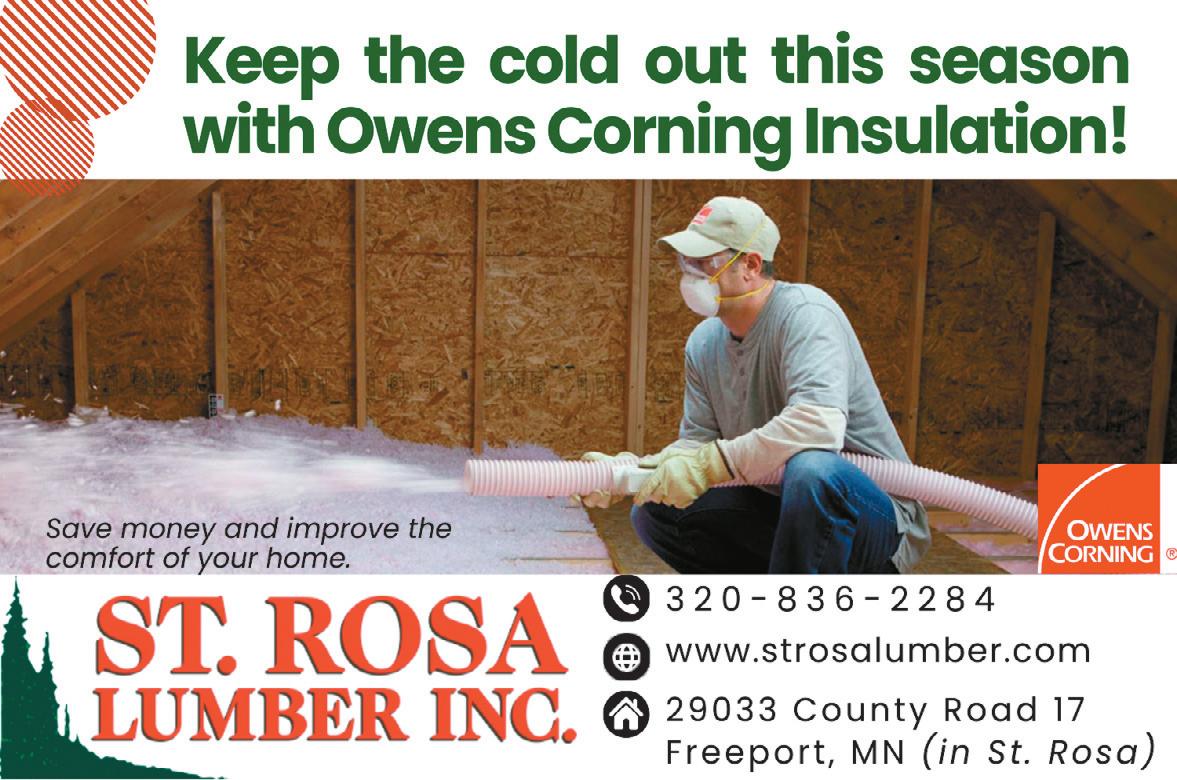

As far as Lahr is aware, KLC Farms Roasting is one of the only private hot-air roasting operations in Minnesota.

“There are numerous people who use flame roasters, but the problem with that is they can’t get to the correct temperature without charring the beans or corn,” Lahr said. “Corn is even worse. They make what we call clinkers

that look like little chunks of coal. We use hot air; if you can imagine a continuous hotair corn popper, that’s the way we heat.”

Because the grain does not come into direct flame contact, the roaster can stay hot enough for long enough to cook the grain all the way through without burning it. For soybeans, it increases bypass proteins and the

Lahrs page 6

bioavailability of fats and oils, especially lysine in soy oil, so animals can more easily digest the feed. Corn is similar, where starches are turned into sugars for easier digestion.

“Imagine cooking your potato or eating it raw,” Lahr said. “You can (buy regular corn), but for what they’re buying corn for at (retailers), we sell cleaned, roasted corn for that price.”

Grains are roasted for a proprietary temperature and time for maximum nutritional value.

“You can over-roast it,” Lahr said. “There’s no nutritional value in (char). It’s a pretty fine line, and we do testing; we send (product) to labs to make sure we’re within the parameters we want to be.”

After roasting comes steeping in which grains are kept at a set temperature to finish the cooking process.

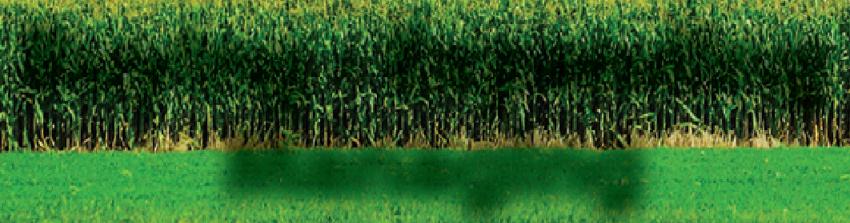

The farm-to-feed

pipeline is completely vertically integrated. KLC Farms Roasting grows, roasts, bags and ships all their product on-site. Area farmers bring corn and soybeans for roasting, which is done on a rotation system instead of a batch system to save space and time. The team is meticulous about checking grain condition, so customers pick up the same, high-quality grains they left.

KLC Farms Roasting is always looking for a new angle to expand its business, and one of the ideas they have tried is popping milo. Lahr was once approached by someone who wanted milo grain popped so horses with bad teeth could chew it.

“Unfortunately, we weren’t able to pop a high enough percentage of it,” Lahr said. “They did use it. We popped a lot of it, but they were

looking for a 90% pop, … We didn’t do it twice, (but) that’s something you couldn’t do in a flame roaster. You’d just fry it.”

Every farm has a farm dog. These faithful companions serve as cattle herders and guards and alert everyone when someone pulls in the driveway. Most farmers do not shell out hundreds of dollars for their precious pup, but most would agree a good farm dog is priceless.

Our dog, Jack, is a German Shepard mix and has finally outgrown his puppy stage of chewing up everything in sight. He is decent as a cattle dog and barks at Jason anytime he gets too close to me or the kids. Jack always tags along when I take the kids for walks in the yard or down the road. I never put him on a leash because my hands are always busy pushing a stroller, and the road we live on is quiet. He wanders around the ditch as we make our merry way, but when a car approaches, he makes his way back to stand next to me.

We got Lovely in the fall, and I remember playing with her in a pile of leaves and building a doghouse from scratch for her, complete with shingles. She did not use it much; I think the door we made was too small. Most of the time, she slept in the straw shed or our detached garage. Lovely had several batches of puppies, which we all were sad to see go when we sold them to other families. In the meantime, until the puppies were old enough to leave, we would have so much fun playing with them and naming them.

By Tiffany Klaphake

Lovely was a great cattle dog and barked when someone other than us drove in the driveway. She would stop barking as soon as the person got out of the car and she had the chance to smell them.

Jack’s favorite thing to do is to go for rides on our side-by-side. If anyone starts walking towards the machine shed where the gator is kept, Jack immediately runs for the shed and once inside, jumps in the side-by-side in hopes the human follows suit. We have taught him to jump into the bed portion instead of the passenger seat. He does not chase things, like the dog we had growing up, Lovely, who would run after anything that moved.

Lovely was my most memorable and favorite dog, as she was our family dog when I was growing up. I do not recall how we got her name, but she was very pretty. Lovely was a light brown border collie mix. I was in first grade when we got her, and she lived for 14 years.

That beautiful dog would chase us on four-wheelers and snowmobiles until we drove off our property. Like a lot of dogs, she was scared of thunder and fireworks. During many a thunderstorm, she would bust through a screen door to get inside the house. I can distinctly remember that, when she did come in, she would never roam about the house, but rather curled up in a ball on the rug on the floor right inside the door. If we were all in the house, we would try to coax her into coming in further to play, but she would not leave her spot. Once the storm passed and as soon as someone went back outside, so would Lovely, all on her own.

While Lovely died over 15 years ago, I still remember her like it was last year. I hope my kids make lasting memories with Jack as I did with our dog, Lovely; I know I am.

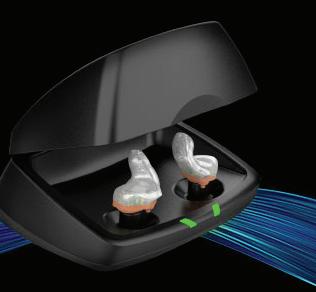

Soybeans pour into a truck Sept. 20 at KLC Farms Roasting near Sauk Centre. The farm roasts grains on a rotating system rather than a batch system.

One of KLC Farms’ newer and more successful ventures has been into Rack Roast, a deer feed made of roasted corn and soybeans, which they have offered for about five years. They started creating this at the request of Cody Butler, producer of the Dream Chasers hunting show.

All the beans and corn that go into the Rack Roast are first cleaned with a fanning mill.

“We try to make sure it’s the highest-quality product going out there,” Lahr said. “Everybody who’s tried it has loved it.”

Because of freight costs and the markups retailers typically put on their products, KLC Farms generally markets through their website. They have served customers all across the United States,

including Alaska, and some of their biggest non-Minnesotan customers are located on the Florida-Georgia line and in North Dakota, South Carolina, Kansas and Texas.

“Some of the other industry people say, ‘There’s the deer hunting business in the rest of the country, and then there’s Texas,’” Lahr said. “They’re big into deer hunting in Texas; that’s where they have ranches where people come and pay to hunt.”

Whenever Lahr gets up and goes to work, he enjoys the fact that he never knows what is going to happen in a given day.

“It’s always something new,” Lahr said. “There are lots of challenges, but you make your own opportunities, too. I’ve always enjoyed the challenge.”

They have also explored creating new products. The shave soap — used as an alternative to shaving cream — Adam makes was created from scratch.

“That was his recipe,” Sara said. “He tested some things out, and I think that’s one of my favorite products because it’s unique and works really well.”

Trying new things is always a gamble. Even before making his first bar of soap, Adam said it took a good month or more of learning how and what to do before he could even attempt to give it a go.

“He watched a lot of YouTube videos, read some articles and then found some recipes to try,” Sara said.

Aside from learning to make soap on his own, Adam also decided to design his own tools to make the soap. He made wooden drying racks and a loaf cutter using guitar strings.

“I sat down with a pencil and some cardboard and started coming up with what I wanted,” Adam said. “Once I had a general size I thought would work, I went to

I pretty much just start working, and when it’s done, it’s done.”

After completing the

Adam moved on to making his

soap. Soon after, he started making shampoo bars, activated charcoal facial bars, powdered laundry

balm, mechanics

Schmidts page 13

from page 12

“We are trying out some whipped tallow body butter, and our newest product is dishwashing soap,” Sara said.

“We had a local farmer that wanted to try that, and (we thought) it would be fun.”

All the products the Schmidts make share a similar process with slightly different ingredients and proportions.

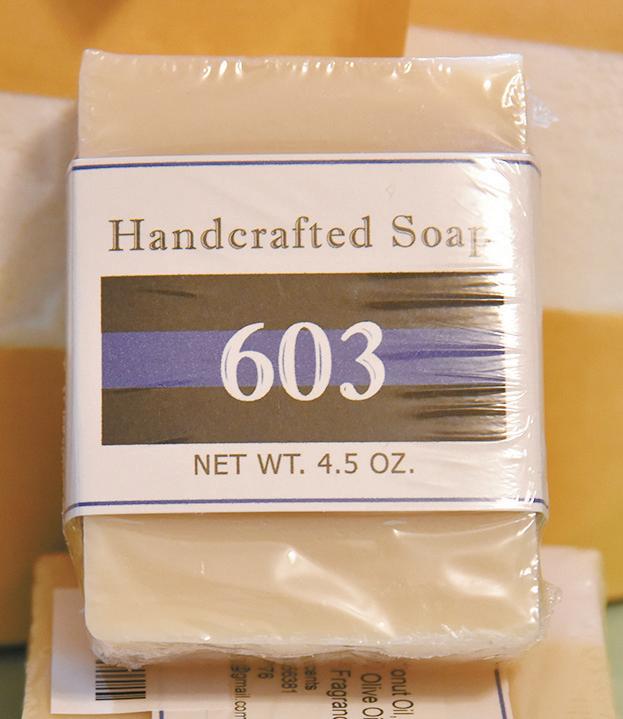

The couple is proud of their progress on the farm. However, being able to support family, friends and community are among the most valuable aspects of the farm. One way the Schmidts accomplished this was by creating a bar of soap to honor Pope County Deputy Sheriff Josh Owen, who died in the line of duty in April 2023.

“Adam used to work with (Josh Owen), so we wanted to do something for the family,” Sara said.

Adam was the master-

mind behind all the detail that went into this bar of soap, from the label design to the scent.

All the profits raised from this soap benefitted Owen’s wife and son.

“We scented it bonfire because Josh always loved being around bonfires and having a good time with family and friends,” Sara said. “We aren’t selling them any longer, but it was a unique and meaningful way to support and honor a guy involved in the community.”

Another focus of the farm is expanding and growing in different ways. Currently, the couple

sells their products online and at farmers markets.

“I have a little dream to wholesale more,” Sara said.

“I think it is a fun way to get people to shop locally while trying our products. We really are striving to grow and be more present (in many areas).”

The Schmidts hope to have a store on their farm in the future. For now, Sara will continue to handle advertising and attend farmers markets while Adam makes all of the products.

“(Our soap) is really beneficial for your skin,” Adam said.

“It is also a way to use more of the animal so we don’t have waste.”

The biggest thing Adam has noticed with the use of their soap is his hands are not as dry in the winter.

“It is being as purposeful with the animal as we can (be) and making more natural products,” Sara said.

We have a variety of other Purina ® products on hand too!

Horse, Dairy, Cattle, Poultry, Swine, Goats & Sheep, also Show Animals

Purina® RangeLand® 30-13 Cattle Tub, 225 lb.

Purina® RangeLand® Protein Tubs are a free choice supplement designed for cattle on forage diets providing less than 8% protein. The low moisture, cooked molasses products in a non-returnable plastic container will enhance intake and utilization of available forages, while reducing labor for producers.

Purina® Wind & Rain® All Season 4 Mineral Tub

Beef cattle minerals in a cooked molasses tub that is designed to correct the mineral deficiencies of the available forage in a highly palatable, weather-resistant form. This line of minerals is designed for cow/calf and seedstock operators that need a free choice mineral supplement to assure that their cattle are getting the proper levels and ratios of all of the 14 essential minerals cattle need for health, growth, and reproduction. Wind and Rain® Mineral Tubs provide these benefits in cooked molasses formulas packaged in a non-returnable plastic tub. This gives the producer a mineral that is the ultimate in weather resistance, palatability and consistent consumption, all in its own mineral feeder.

“We are in the land improvement business. We do farm drainage, ag waste systems, site work for farm buildings and silage pads, plus miscellaneous work. We also do county, township, and watershed work, as well as soil conservation work.”

- MBC Drainage, Sauk Centre

be stored this way because they will spoil. To get sugar beets processed, a farmer must be a shareholder at a cooperative. Each cooperative determines when the sugar beets will be harvested and

when the factories will start processing them. The cooperative works with the farmers and tells them when crops should be harvested.

Sugar beet harvest times are strategically planned by the pro-

cessing factories to ensure the best quality product is delivered to the facility. Because sugar beets can spoil, they need to be stored in cool temperatures to keep them fresher for longer periods of time. Harvest begins when outdoor temperatures are cool enough to keep the sugar beets below 60 degrees when they are being piled. If temperatures are too warm and the beets won’t cool, the cooperatives shut down during the hottest parts of the day.

Gordons page 17

Don’t just thank a farmer...

Thank his wife for cooking, delivering meals, going for parts, or helping in the fields, all while taking care of her usual jobs.

Thank his hired man for working endless hours on sleepless nights caring for the animals and harvesting the crops.

And thank his children who are okay with seeing him if just for a brief moment while he eats his meals in the field.

Farming is a family business and it takes a sacrifice from all... so when you thank a farmer – thank the family team!

• 1 1/3 cups sifted flour

• 2 teaspoons baking powder

• 2 tablespoons sugar

• 1/2 teaspoon salt • 1 egg • 1 cup milk • 2 tablespoons melted shortening

Sift together dry ingredients in mixing bowl. Beat eggs until thick. Add milk and shortening and stir. Heat griddle and cook pancakes.

• 1 package Oreos (or any chocolate creme-filled

Preheat oven to 325 degrees and line a 9- by 13-inch pan with tinfoil; make sure ends of tinfoil extend over sides of pan. Place 30 cookies in a food processor; process until finely ground. Add butter and mix well. Press firmly onto bottom of prepared pan. Beat cream cheese, sugar and vanilla in large bowl with electric mixer on medium speed until well blended. Add sour cream; mix well. Add eggs one at a time, beating just until blended after each. Chop remaining cookies and gently stir 1 1/2 cups of them into mixture. Pour over crust and sprinkle with remaining chopped cookies. Bake for 45 minutes or until center is almost set. Let cool. Refrigerate for three hours or overnight. Lift cheesecake from pan using tinfoil handles and serve. Store in refrigerator.

• 4 cups water

• 1 cup uncooked rice • 1 pound browned hamburger • Onion and celery, to taste

Mix together and bake at 350 degrees for one hour.

1 cup milk

1/2 teaspoon seasoned salt

Preheat oven to 325 degrees. Beat eggs, milk and seasoned salt. Stir in ham and cheese. Pour into buttered 12- by 7-inch pan. Bake uncovered for 45 minutes.

Make yellow cake mix according to directions on box, except reduce water by 1/3 cup. Add bananas and baking soda; mix. Put into greased pan and bake at 350 degrees for 15-20 minutes. Frost with cream cheese frosting.

Heat a large skillet over medium heat. Add the sausage and cook, stirring often to crumble, until cooked through. Do not drain. Add coleslaw mix, garlic, ginger and soy sauce to the skillet with the sausage. Cook for 3-4 minutes or until cabbage has softened a little bit. Remove from heat and top with green onions; drizzle with sesame oil. Serve immediately.

Tell us about your pumpkin patch.

Tell us about your pumpkin patch. We have about five acres of pumpkins; I don’t know how many plants. We have all sizes, from tiny to really large, and both white and orange varieties.

How did you get into raising pumpkins? I started when I was about 12 years old as a way to make money.

How do you care for your pumpkins throughout the year? Our patch is all organic, so we don’t spray or use any non-organic practices.

When you get to the harvest season, what do you do with your pumpkins? We sell them at our three stands in Alexandria.

What is the most challenging aspect about the pumpkin growing season? Weeds and water. Deer will eat some of them, but not so much that it becomes an issue.

Tell us about your pumpkin patch. I have 12 different plants that I planted with seeds from last year’s pumpkins.

How did you get into raising pumpkins? I was spending a lot of money buying pumpkins for decor, so I just decided to grow them myself.

How do you care for your pumpkins throughout the year? I plant the seeds and hope for the best.

When you get to the harvest season, what do you do with your pumpkins? I use most of them to decorate my home, and I’ll sell a couple. I also feed them to my pigs.

What is the most challenging aspect about the pumpkin growing season? Making sure they’re getting enough water if it’s dry.

we care about your community. because it’s our community too.

Tell us about your pumpkin patch. The garden is 75-by-40 feet. We planted seeds, and we have pie, mini, white, large and jack-o’-lantern pumpkins growing.

How did you get into raising pumpkins? My grandma already had a garden, so we just started planting pumpkins in it. This is our second year doing it.

How do you care for your pumpkins throughout the year? Before the vines get too long, we roto-till between the rows. We use a “Critter Ridder,” which is a motion-activated animal repellent and sprinkler. It keeps the deer away, and my grandma and grandpa press the water button on it every day to water the pumpkins.

When you get to the harvest season, what do you do with your pumpkins? We sell them on a trailer and keep some for ourselves.

What is the most challenging aspect about the pumpkin growing season? Trying to keep the deer away from them, because they will take big bites out of them

BY EMILY BRETH | STAFF WRITER

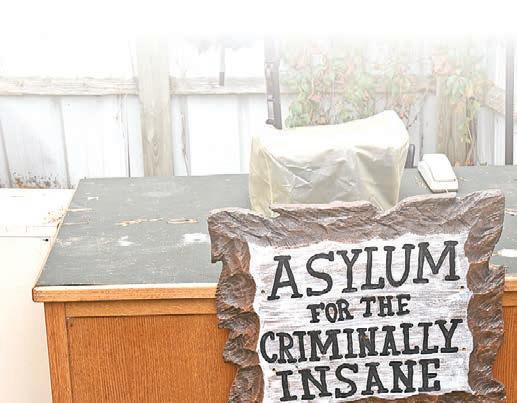

ROYALTON — Hearing screams is nothing shy of normal for Randy and Nancy Winscher, owners of Wicked Woods, an outdoor trail full of surprises.

“We want everyone to have a great time, but we want them to get scared,” Randy said. “That’s the bottom line. When they are screaming and yelling, I know they are having a good time.”

Last year was the first year for Wicked Woods, which took about 30 employees, including family, to pull off. When the Winschers said they were opening, most of the workers reached out, wanting to work and bring along their ideas.

“They are real Halloween enthusiasts,” Nancy said. “They are so full of energy — it’s amazing.”

As visitors ventures through the trail, they will find a range of different themes and fears. This year, 50 actors perform skits at various locations and are given the freedom to set up and design their area as they desire.

“We try to get each person to take charge,” Randy said. “It’s their zone. We don’t say much about it.”

The excitement around Halloween and getting to craft their own area is what motivates the workers to do as much as they can and strive to bring their best.

“We have some actors that will come and demand new lights when they have one that is burnt out,” Nancy said. “I like that, because it shows that they want their spot to be the best.”

However, not all the events at Wicked Woods are meant to be extremely spooky. The couple also hosts what they call “Little Monsters.” This part of the day is dedicated to younger kids so they can enjoy the holiday festivities as well.

“For Little Monsters, we have everything lit even though it’s not dark,” Nancy said. “(The kids) love that ambiance and so do the parents.”

During this time, there will be more friendly decorations displayed and no big sounds. The idea

behind Wicked Woods and all its parts came from Randy’s childhood.

“(My siblings and I) used to scare each other all the time,” Randy said. “Over the past years, we did our own little decorations for Halloween, and finally, one of (our) kids said, ‘Why don’t you guys start your own haunt?’ and ding, ding, ding, here we are.”

Winschers page 26

from page 25

Nancy also recalled playing outside in the dark with her siblings and having fun scaring each other. Having a house an ideal distance from the road is another aspect that made the haunted woods a possibility.

“It would be different if we could showcase everything we had off the road, but nobody could see it,” Nancy said. “It came down to, we wanted to show everybody what we had.”

The family started working on the land to prepare for the hosting of the event. The list of to-dos included making trails, removing trees and getting structures ready to make the haunted trail.

“We had to blaze these (trails) through last year, and it is a lot of work,” Nancy said. “One of the hardest things for us was clearing out our buildings. They were packed with stuff — it was exhausting.”

To help with safety and organization, Randy installed solar lights in their parking areas and surrounded each lot with lights.

“Safety is a big thing for us,” Nancy said. “The parking area lights are so people feel safer, and by the time they leave here, some of them are really spooked.”

There are also lights throughout the trail to help people stay on the right track and find their way. Sometimes animals wreak havoc by knocking down the lights. The wind also plays a factor and can cause props to be knocked

Winschers page 27