FOUNTAIN — When musher Damon Ramaker takes his family’s Alaskan Huskies for a run, he is an unexpected sight on the roads of Fillmore County.

“We get a lot of funny looks from people,” Damon said. “A lot of people pull over, and they’re taking pictures of you as you’re going by just because it’s so peculiar.”

Damon and his family own 13 dogs and participate in at least one 250-300 mile race each year. Four years ago Damon completed the Iditarod, a 1,000-mile dog sled race across Alaska, from Anchorage to Nome.

Back at his residence in Fountain, Ramaker’s home is also an unusual sight. The canvas walls of a yurt form the home he and his wife, Kylie share with their three children, Ruby, Lucy and Walter.

The Ramakers keep their canine athletes in individual dog houses in their large, outdoor kennel area. They also like to bring a few at a time

into their home to keep them h company.

Their yurt is over 700 squarefeetplusapartial

square feet plus a partial loft. Inside, stained wood in a lattice formation supports the outer walls. Above, on the coneshaped ceiling, wooden rafters wing upward, creating a sun-like formation around the peak’s central skylight.

Damon’s first experiences with sled dogs came when he was a child on a vacation in Alaska. Experience with a yurt did not come until later, when he and Kylie stayed in one during an anniversary trip.

The Ramakers, who grew up in southeast Minnesota, moved back to the area more than a decade ago after a stint living in the Twin Cities. They became

connected with musher Cindy Gallea. When Damon was not working at his full-time job at the Mayo Clinic, he worked for Gallea as a handler.

is not currently planning to do another.

connected W a Galleaaas

“We got inundated to the sport of mushing and really started to understand what

“We sport of t

“I would love to do it again,” Damon said. “But, the effort to get even (to the starting point) was tremendous, and there’s a lot of sacrifices made.”

Damon said preparing for

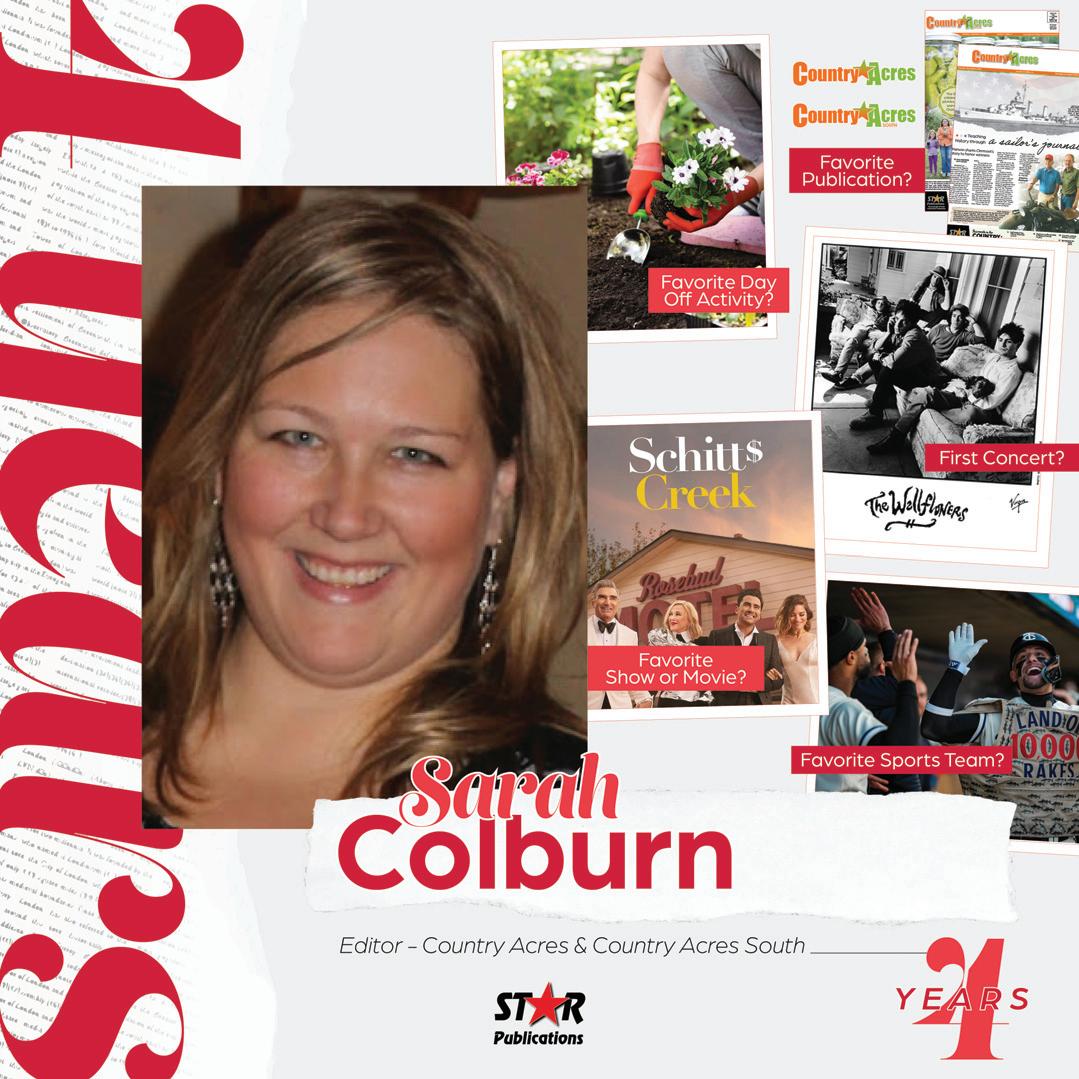

SOUTH NEWS STAFF

Sarah Colburn, Editor, sarah.c@star-pub.com

Amy Kyllo, Assistant Editor, amy.k@star-pub.com

Mark Klaphake, Writer, mark.k@dairystar.com

Tiffany Klaphake, Writer, tiffany.k@dairystar.com

Ben Sonnek, Writer, ben.s@saukherald.com

Hans Lammeman, Writer, hans.l@star-pub.com

Story ideas send to: sarah.c@star-pub.com

SALES STAFF

Laura Seljan, 507-350-2217, laura.s@dairystar.com

Julia Mullenbach, 507-438-7739, julia.m@star-pub.com

Missy Traeger, 320-291-9899, missy@saukherald.com

Robin Brunette, 320-293-5911, robin@star-pub.com

Tim Vos, 320-492-6987, tim.v@star-pub.com

Mike Schafer, 320-894-7825, mike.s@dairystar.com

Jaime Ostendorf, 320-309-1988, jaime@star-pub.com

Bob Leukam, 320-260-1248, bob.l@star-pub.com

Neil Maidl, 320-292-4454, neil.m@star-pub.com

PRODUCTION STAFF

Amanda Thooft | Nancy Powell | Maddy Peterson

Cheyenne Middendorf | Karen Knoblach

Annika Gunderson | Nadiia Zalitach Deadlines:

Country Acres South

be

the first Saturday of each month. The deadline for news and advertising is the Friday a week before publication.

PHOTO

“The amount of support that we had through that was humbling,” he said.

In dog sled racing, formal training starts in September as weather begins to cool. The first races begin in January.

counted, really in the long run. ... There was a lot of sacrifices that were made by everybody.”

Kylie said this hectic schedule for Damon was preparation.

of mileage.”

During the race, Kylie and the children refreshed Damon’s location as they anxiously watched the race from Anchorage, Alaska.

“Sleep deprivation training is really important for the race, ... being able to think while you have no sleep underneath you,” Kylie said.

“I felt such blessing that he was able to accomplish it,” Kylie said.

Besides physical training, the Ramakers also planned their race schedule and shipped bags of supplies to drop points along the race course.

Publications bli ti

“Committed to being the eyes and ears of our communities.”

Runs begin at distances of 1-2 miles. These runs are focused on manners and strength building. Eventually, runs build up to be as much as 50 miles, simulating a race stint.

As training continues and the miles extend, the focus is on speed. During training, dogs run three or four times per week. For the Iditarod, Damon would get up at 3 a.m. to run the dogs before work. He also would go on short trips with Gallea to find snow and trails, all packed into his days between work.

“We got very intentional about time,” Damon said. “Minutes

“Different dogs eat different things at different times,” Kylie said. “The amount of calories you need for the amount

The Ramakers’ goal was for Damon to finish. He was successful in spite of being stopped by a snow storm for 36 hours with 11 teams at the town of Elim. The race officials helped them to take an old mail trail up and over a mountain so they could complete the race.

Ramaker page 3

Damon brought gifts for each of his children. Salmon for Ruby from the town of Ruby, colored dog booties for Lucy and a raven feather for Walter.

Damon has the support of his family. Mushing has not only given the Ramakers something to rally around and support one another with, so does their lifestyle.

The Ramakers’ yurt living started around 2015-16 after they purchased a property in rural Fountain. The house on the land was beyond fixing, and they needed a home.

They considered moving a trailer, but Damon found a used, fixer-upper yurt online, located in Missouri.

“We bought one moldy house over there to buy another moldy house down in Missouri,” Damon said.

Damon and his dad met the seller and one of his friends, and the four disassembled it, labeling every board.

The yurt needed new canvas, so they used the old material as a guide and sewed the surround themselves. It took several people to hold and feed the canvas into and out of an industrial

sewing machine.

Living in a yurt has challenges, the Ramakers said. Around 10 degrees, their home becomes chilly. Kylie said she is more sensitive to the cold than Damon is.

“Below zero is difficult, but, I mean, it’s livable,” Kylie said.

In the summer, the yurt can be warm with a greenhouse effect. Trips to their local swimming pool help get through the heat.

“You just find a new rhythm of how to deal with life,” Kylie said. “It takes effort and intention.”

Damon said their yurt also has a limited amount of space for the family of five.

“We all have to get along,” Damon said. “It’s not big enough for ... everybody to go to their separate rooms and just not talk to each other for a couple of days.”

Both of the Ramakers credit their yurt lifestyle with many benefits for their family.

Kylie said they have better communication and appreciate each other more.

Damon agreed.

“The struggles are good struggles,” Damon said. “In the moment, it doesn’t always feel so good, but when you get through it, it makes you more resilient. It changes your expectations, and it’s probably improved our relationship.”

I self-sabotage the rest I need in pursuit of significance.

Lately, it feels like my life is an immense giant ambling along the road looking for a snack. This giant always carries along her favorite rag doll — in this analogy, me — on all her giant adventures. I bounce along behind, being dragged by a foot, through sunshiny pastures, mud puddles and a little bit of fresh, pokey gravel.

I know that being a grown up means your commitments order your life; however, there is a difference between the ordering of one’s life versus these selfsame commitments and activities — no matter how fun — dragging me along behind them.

My life is not actually that crazy, but I have been looking for more balance this year. Generally, my unwillingness to change an unhealthy, but easy, routine self-sabotages my efforts.

A pursuit of balance starts with work. This year, I have added a few responsibilities that I am excited about. I know I can balance it all, but finding that balance is taking time as I have been looking to both learn and adjust to the new tasks and to find time for my old work.

Added to the responsibilities has been a tremendous level of success at landing interviews which no reporter can ever truly complain about. Interviews are, and will always will be, feast or famine.

With responsibilities and stories populating on my desk like bunny rabbits in spring, I need to find a routine. I asked my community for prayer, and I have already begun to see change. A recent, very productive day using time blocking gave me hope that I had found my answer to balance at work.

Next has been the weather. I am an overall happy person almost all the time. However, like most Minnesotans, I do not benefit from sitting in the house and getting little exercise or vitamin D because I am barely poking my nose out of the door.

A few random episodes of feeling either wildly happy or oddly and unshakably sad has been a reminder that, even if its winter, I need to prioritize fresh air, moving my body and sunshine to keep the seasonal depression away.

The final area where life has been dragging me is the personal and social side. I am fairly extroverted, and if I don’t spend time with people, I end up having silly, unreasonable thoughts that no one loves me and that I have no friends. Suffice to say, I keep myself hopping to try and keep up with my people both in person and virtually.

Sometimes, all this busyness is in part because I don’t know what to do with myself if my schedule isn’t full. Sure, I regularly take a good nap and accomplish nothing, but I crave having a list of social engagements.

I need to find balance, because though I get excited and crave a full list, conversely, I also can get an unreasonable, trapped feeling as I see commitments stretching into the coming weeks.

As I say this, I am not as busy as most others. With no children, a small apartment to clean and furnish, only a full-time job and just a couple things I volunteer for, I ought not to be busy or stressed at all.

The fact that I am busy and occasionally stressed makes me fear that if I am not wise in controlling my time in the area of work, home, social and rest, I will find myself burned out for literally no good reason whatsoever.

Often, the problem comes from what I fill my time with. At work, it can be productive procrastination: filling my time with little things that need doing but are not that important. At home, it can mean realizing that I need to mentally expect and plan for a certain amount of time daily for household tasks in order to keep on top of everything. For social, it could mean making sure I don’t schedule myself so heavily that I feel exhausted when doing my other responsibilities.

For rest, health might mean prioritizing things that refresh me like a quick walk, taking a short nap or keeping in touch with my upcoming decisions, goals, dreams and faith through journaling.

I know my life may compare apples to oranges to yours, but I hope this column gives you hope that you are not walking alone in the busyness or stress. Sometimes life is tricky or out of balance, but ultimately, there’s always hope for tomorrow to be a little more beautiful than today.

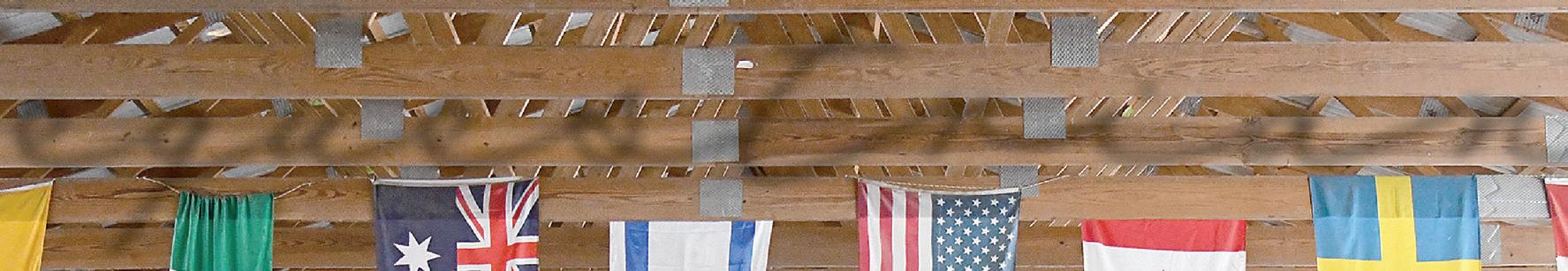

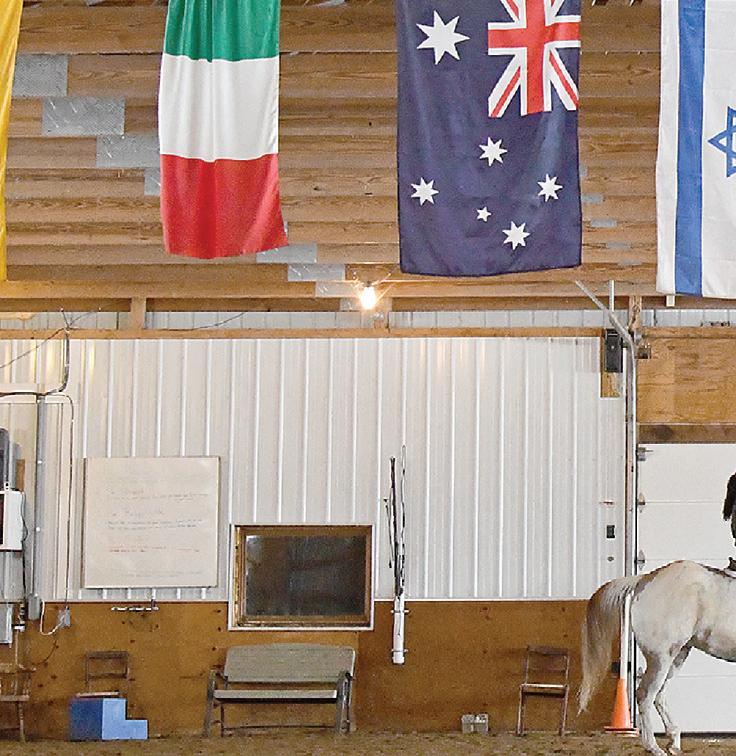

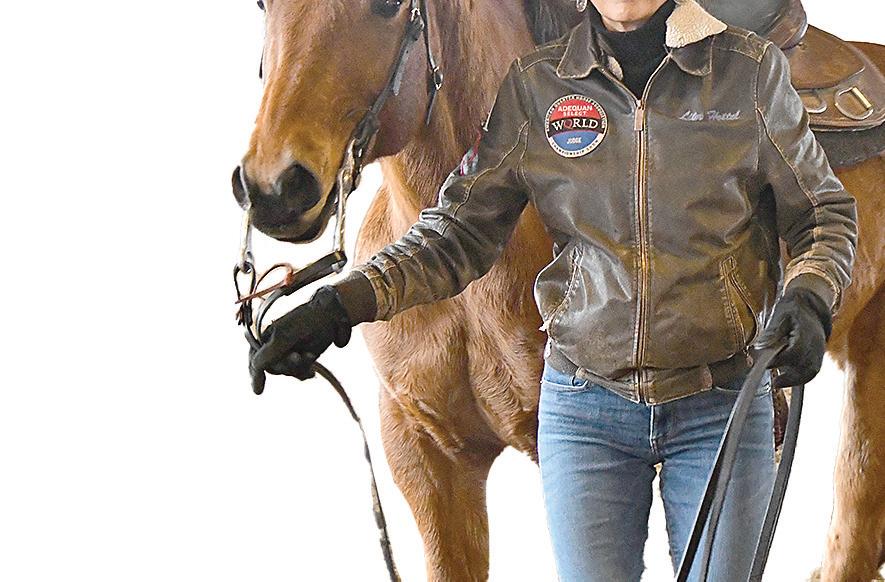

MARION — Thirteen colorful national flags hang across the ceiling of the arena at Lita’s Equitation. Each flag represents a country where Lita Perrin has judged horse shows.

“It’s always been my dream todo what I’m doing,” Perrin said. “I feel pretty blessed to be able to get paid to do what I love to do. It’s hard to tell if I’m working or playing half the time.”

Perrin owns Lita’s Equitation south of Rochester near Marion. There, she boards and trains horses and gives riding lessons.

“To me, it’s like a big puzzle,” Perrin said. “When I train a horse or I train a rider, I have to determine the best way that they learn.”

Perrin holds 18 judges’ cards qualifying her to

judge for numerous equestrian associations and showing disciplines. She judges domestically and internationally throughout the year. She has worked in Australia, Canada, Denmark, France, Germany, Israel, Italy, Japan, Mexico, South Africa, Sweden and the United Kingdom.

The first international show she judged was held in Germany. She said the show was attended by exhibitors from multiple nations who later hired her to judge in their countries.

“It just snowballs,” Perrin said. “It’s a lot of fun for sure.”

In the summer, Perrin attends local horse shows, either as a judge or as a coach for her riders, most weekends. The rest of the year, she travels to shows at least once a month.

Perrin page 7

Perrin started her equine career as a youth taking lessons in dressage and jumping. Her work showing horses sparked her interest in becoming a judge.

“From such an early age, I was driven to do what I’m doing,” Perrin said. “I never expected to do it at this level.”

Perrin trains riders who have never touched a horse and she conversely trains riders preparing for world competitions. She has riders who are 70 years old, and she has young riders with physical disabilities.

disciplines in the horse world and the knowledge of training and judging is very thorough.”

Ronningen said her daughter responds well to Perrin’s demeanor.

“She tends to be very calm in the storm, helping to explain what happened, and why, and things that she can work on better for next time,” Ronningen said.

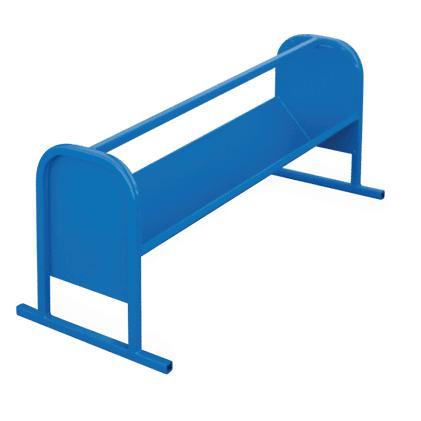

• Constructed of heavy-duty 12ga. Steel. 2” square tube frame

• Feeds round of square bales, grain, silage and TMR

• Adjustable spring-loaded locks for any size cattle

• Entry door & raised center “v” platform

• Adjustable spring-loaded locks on all four sides

• Feeds round or square bales, grain, silage and TMR

• Constructed of heavy-duty 12ga. steel

• Heavy-duty 2” square tube frame

The Fence Line Feeder is built for barnyard or fence line feeding

• Feeds grain, silage and TMR

Perrin’s facilities include an in-

an

door and an outdoor riding arena

“With the riders, sometimes there’s fear; sometimes they have lack of confidence,” Perrin said. “You have to know when to push them and when to encourage them.”

Perrin also teaches riders how judges score patterns. A pattern refers to a predetermined sequence of riding maneuvers that a horse and rider may be asked to perform at a show to exhibit their skills. Perrin said knowing how judges score helps riders learn precision in executing their patterns. Perrin also has riders perform many

Perrin also has many patterns during training

•

• “V” floor for easy feed flow

• Inside double bars 8” apart for minimum feed waste

• Constructed of heavy-duty 12ga. steel.

• Heavy-duty 2” square tube frame

• Heavy-duty multipurpose tub feeder

• Constructed of heavy-duty 12ga. steel.

Colleen Ronningen’s daughters have been taking lesson from Perrin for several years.

whelmed and panicking, ... (they have)

“When the shows come and they are given patterns, it’s easy for them,” Perrin said. “Instead of feeling overconfidence.”

• Heavy-duty 2” square

• 1-1/4” Square tube frame

“She’s probably the most confi

“Sh’bbltht

“She’s the most conent, kind, knowledgeable person that I’ve worked with,” Ronningen said. knows all sorts of different

and where should it saf

To prepare a horse and rider for a show, Perrin helps decide where in a pattern they should try for extra points dhthhldlitf

and where they should play it safe.

Perrin page 8

• 1-1/2 x 1/4” flat hoops spaced 7-1/4”

• Stacks for transport

•

Walk-through for hay and grain

• Basket rod spacing 2-3/4”

• 8” alley through center

• Remove doors to create row feeder

• LCF 48” long, 12” wide, 12” high

• CF 48” long, 8” wide, 8” high

“If we have some errors or problems with the horse or the rider, we have to figure out ways to hide those and to show off the horse and the rider’s best abilities,” Perrin said.

Perrin trains both horses that are starting formal training and horses that are highly skilled and need refinement and finesse.

“It’s important to build a foundation and build trust,” Perrin said. “Help the horses to be able to do their job. ... Instead of forcing them to do it, I try to build a foundation (and) get them physically ready for it, so that when I ask them to do it, it’s an easy choice for them.”

Jennifer Dessner has had her daughter in lessons with Perrin since 2018. Dessner works four days a week at the stable and has been the barn manager for the past three years.

“(Perrin) has a lot of patience with (horses),” Dessner said. “She knows what they’re thinking and what they can give, and she doesn’t expect more than what they can give at the time.”

Perrin has about 18 horses living at her barn. The horses are either being boarded or trained or are personal horses for giving lessons and timeshare horses.

Timeshare horses are available to riders who have reached a baseline level of skills and knowledge. Clients can enter into a timeshare for a horse for a few months, up to a year.

“It’s a great way to (experience) owning a horse without owning a horse,” Perrin said.

If a timeshare client decides to buy a horse later, Perrin said they are better equipped

to know the type of horse they want.

Perrin said one of her proudest memories of her equine career was helping a boy with a disability get a variance with Minnesota 4-H so he could compete in horse shows at the county and state level.

The variance included a family member being able

to walk him through a pattern on a headset because he could not remember a complete pattern, and the pattern could be simplified when he was unable to do it because of his disability.

“He was the first variance for (disability) reasons in Minnesota,” Perrin said. “He was able to be judged equally against the other riders with this variance.”

The boy qualified for the Minnesota State Fair horse show and competed at the state level.

PHOTO SUBMITTED

Oats and peas grow in 2022 at the Bergler farm near Ridgeway. This was part of a triple system of crops, starting with winter rye for stored feed, followed by sorghum for baleage, and oats and peas for grazing.

Besides grazing, Bergler raises almost entirely no-till crops. He also practices double cropping. For his corn crop, he plants 25% to 30% using 60-inch rows inter-seeded with cover crops.

“It’s a lifestyle, not a living,” Bergler said.

Bergler’s beef cows are mostly Limousin or Lim-Flex, which is a Limousin-Red Angus or Limousin-Angus crossbred. Three donkeys live with the cows to deter coyotes.

Bergler has sections of pasture that have not had outside influence in the 17 years he and his family have lived there. Bergler said he wants to access the latent seed bed in his pasture and revive native prairie plants.

“My goal is to have big bluestem or little bluestem show up — the true native prairie in my eyes,” Bergler said.

Bergler’s paddocks are 1-2 acres. His goal is to move the cows every 24 to 48 hours. He grazes 50% of the forage available, with about a 35-day rest period.

“I’ve had two flowers and a forb show up,” Bergler said. “It tells me it’s working, but we have a long ways to go.”

This year, Bergler grazed his cows into the final week of December. He will graze into 10-12 inches of snow.

Bergler said he would like to graze year-round, with minimal supplementation.

“It can be done,” Bergler said. “There’s guys out here doing it (in) worse climates than I’m in. It’s just a matter of getting your rotation right. ... Part of it, in the back of my mind, is maybe (I’ll) graze the whole farm.”

In the fields, Bergler has multiple crops and practices.

One of these practices is to do a double crop. He starts with a plant mix, such as oats, peas, barley, triticale, buckwheat, clover and flax. After harvesting the first crop for baleage, he comes behind with a different way mix, which includes sorghum, millet, Sudangrass and sunflowers. This year the mix grew 6-9 feet tall. Bergler stockpile grazes this in late fall.

MONDAY

8:00 am Overnight market cows/bulls

10:00 am Fed cattle, followed by day-delivered market cows & bulls

1:00 pm Dairy cattle, stock cows & breeding bulls followed by feeder cattle

4:00 pm Baby calves, arena 2

TUESDAY

8:00 am Sheep and goats

11:00 am Feeder pigs

WEDNESDAY

10:00 am Hog/Sow/Boar Auction

alsosaidhemakessureto

To encourage native plant growth, Bergler allows the cows to beat up the pasture by massaging it with their hooves. He said this is similar to what the bison did in the past. He also said he makes sure to never graze a piece of ground

sure to never graze a of feed it again All these are costs.”

“I believe in the profit per acre,” Bergler said. “That’s factored all the way down to grazing the stockpiled sorghum and not cutting and baling it just so I have to haul it back out here to feed it again. ... All these things are compounding costs.”

pg

2:00 pm Fed cattle, followed by market cows and bulls

THURSDAY

10:00 am Special feeder cattle auctions, September - April

feeditagainAllthesethings gpg t the same time as the year fo f re r

Bergler page 12

FRIDAY

Closed Office open 8:00 am – Noon

YARD HOURS

Sunday Noon – 10pm

Monday 6am – 10pm

Tuesday 6am – 10pm

Wednesday 6am – 4pm

(Open until 10pm, preceding special Thursday sales ONLY)

Thursday 6am – 4pm

Friday 6am – Noon

Saturday By Appointment

Over the winter months, Bergler unrolls bales in the pasture. The cows stay outside during winter except for days with hard wind from the north or west when Bergler opens up a shed for shelter. His topography is rolling, which provides natural protection.

“A cow is a lot tougher than we give them credit for,” Bergler said.

During calving season, Bergler brings the cow-calf pairs to the yard after calving for seven to 10 days.

The time spent in the yard results in bedding packs. Bergler allows his pigs to root through these decaying bedding packs. Before his four-legged compost turners, Bergler used to haul 65-70 loads of bedding pack in a box spreader. Now, he said he hauls about 15-20 loads.

“It almost looks like you’re out here spreading potting soil,” Bergler said.

Bergler also raises corn. Part of Bergler’s corn is planted with 60inch rows inter-seeded with 15-25 varieties of cover crops.

Bergler plants corn at the same seed rate per acre as his typical 30-inch rows. Once it is established, he sprays for weed control, then seeds the cover crops as the corn is at the V4 or V5 stage.

Bergler said he has been able to get the same yield per acre on his 60-inch row corn as 30-inch row corn. Once the corn is taken off the field, the cover crop is grazed.

“The neatest thing is we can make 200-bushel corn by coming behind cover crops and coming behind cattle,” Bergler said. “Can I do it as consistently as I like? I’m getting there.”

Bergler puts no more than 100 pounds of nitrogen on per acre, in keeping with his profit per acre philosophy. He also does not take corn stalk bales off or sell forage from his owned land.

“My carbon stays on this farm,” Bergler said.

Bergler’s animals are fed grain that is grown on the farm except for the starter pellets for feeder pigs. Bergler simultaneously grows seven varieties of

Bergler

grain which he swaths and then combines.

Bergler said implementing no till and grass management have been important.

“This is how I picture simplifying life: taking away some of the chore load and not living on a tractor,” he said.

After years of searching for the perfect home that fits their needs or would be excited to renovate, John and Nancy decided to build!

Around that same time, they attended the Eagle Bluff Environmental Learning Center’s presentation about the Passive House movement – an exceptionally rigorous building standard that results in a home which, using the latest technologies, has the smallest carbon footprint currently possible.

The concept hit home. John says he doesn’t consider himself an “environmentalist” per se; he just believes in living within his means.

“We believe in energy conservation. We believe in protecting our valuable non-renewable resources. But we’re also big believers in electricity and living the lifestyle we’ve come to know within reason, but just to do it more efficiently and more economically.”

To see more testimonials visit us at www.solarconnectioninc.com

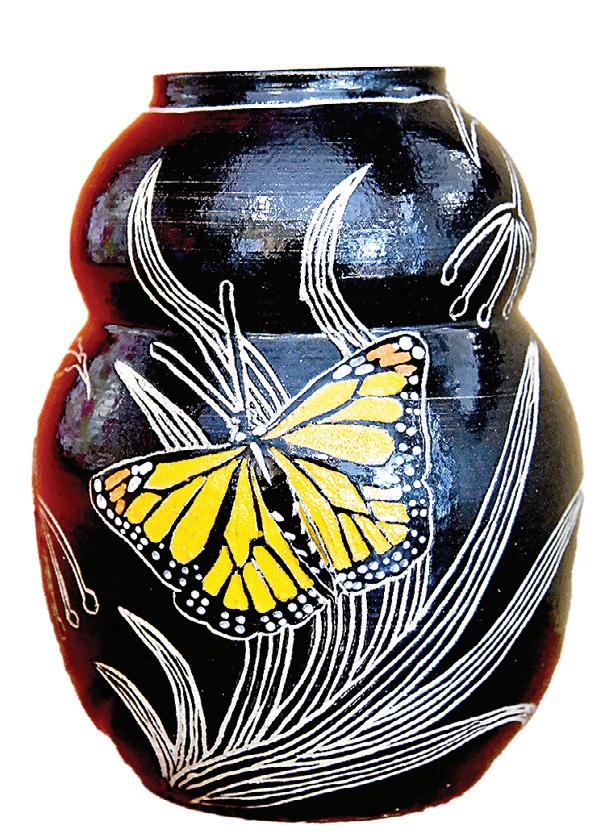

WABASHA — A butterfly alights on foliage, an owl looks serious, flowers bloom and an animal peers out inquisitively; each gracing their own canvas of pottery in Judy Anderson’s studio.

The artist throws, decorates and fires all her own pottery.

“I try to infuse my pottery with joy,” Anderson said. “That’s what I hope (customers) bring home.”

world as my inspiration, it seems I just have endless subject matter available to me.”

Sgraffito, Italian for scratched, refers to a decorating style in which the potter carves designs from an outer layer of partially dried watery clay called slip, which is a different color than the base of the piece.

Anderson has been decorating using sgraffito for approximately seven years. She said that she has been mo-

drawing, paying close attention to capture all the details that make up each animal or depiction. The potter uses pictures from the internet or photographs she has taken to guide her designs.

“I don’t want people to look at my work and go, ‘They don’t really look like that,’” Anderson said. “I just wanted to be as accurate as I can for the people who know.”

tivated to improve her decoat and abs

Anderson’s pottery features animals, birds, flowers and insects, including monarch butterflies. Sometimes, Anderson’s pottery is decorated with swirls and abstract designs.

Anderson’s pottery is sold at Local World Gallery, the business she and her husband, Rob Trussell, own and operate in Wabasha.

Anderson’s pieces are decorated in sgraffito style. She gleans ideas from nature, taking long walks regularly.

“It really seemed to resonate with people,” Anderson said. “Everyone has a favorite animal. Many people have favorite birds.” Using the natural

“When I am at a loss for a subject, I do what I call doodling,” Anderson said. “It helps get my creative juices flowing.”

“W loss for what I And help ativ ing Anderson page 15

A monarch butterfly forms the centerpiece of the decoration of a ceramics piece Jan. 17 at Judy Anderson’s home near Alma, Wisconsin. Anderson uses nature as an inspiration for the decoration on many of her pieces.

from page 14

Anderson’s work area is adjacent to her living room in Alma, Wisconsin. Her workspace is surrounded by windows letting in natural light and views of the countryside.

Potted plants bring the vibrancy of nature inside even in the winter months.

When Anderson finishes throwing her vessels she said she immediately works to clean up so her home does not fill with clay dust or mess.

Anderson began learning ceramics in high school and went on to earn a Bachelor of Arts degree in studio art with a concentration in ceramics from the University of Minnesota – Twin Cities. She paused her work in pottery to raise a family and then in 1998, she returned to the art, working at a local community studio in the Twin Cities where she lived at the time.

In 2006, she began

teaching pottery. In her very first class, she taught two Minnesota Lynx players, who Anderson said were just as competitive off the court as on.

“I had to be very ju-

dicious with my praise and my criticism,” Anderson said. “It was funny.”

Anderson encourages those who want to learn pottery to take a class with a hands-on teacher. She advises against learning from videos on the internet because they can unknowingly learn bad habits. Pottery, she said, is nuanced and even the distance a person sits from the pottery wheel can affect their success.

Anderson page 16

www.hmauction.com

Inspection: March 4 thru March 13 from 8:00-5:00

Reset, Mounted On CIH 9280; (3) Meyers 4118 Forage Chopper Boxes, Rear Unload, 15T Running Gear; Balzer 4800 Tank, Vacuum, Hyd. Drive;

Spread-All TR22-T 20’ Apron Box Spreader, Slop Gate, Poly; Hagedorn 216 Spreader, Poly, Double Beater; JD 955 Discbine, Center Pivot, 14.5’; JD 430 Round Baler, Monitor, 4x5; NH 492 Haybine, 9’ Cut; JD 630A Forage Harvester Hay Head; Vermeer R23A Twin Hay Rake; Automatic Earcorn Mill, w/Blower, Hyd. Drive;

Semi’s, Fertilizer & Straight Trucks, Dump Truck, Trailers ‘89 Peterbilt 379 Day Cab, 400 Cummins, 9sp, 529,000 Miles, Air Ride; ‘04 Freightliner Century, Wilmar 16T Rear Unload Fertilizer Tender, Twin Screw, 10sp; ‘02 Wilson Grain Trl, 42’x66”x96”, Ag Hopper, Spring Ride; ‘05 Freightliner, Small Sleeper, 14L Detroit, 10sp, 671,544 Miles; ‘03 Volvo Sleeper Semi, D12 Motor, 13 Speed, 761,864 Miles; ‘89 Volvo Short Sleeper, 350 Cummins, 9sp, 829,513 Miles; ‘87 Ford 9000 Dump Truck, 3406 Cat, 10Sp LL, 16’ Box & Hoist, 347,341 Miles; ‘99 Sterling Straight Truck, Twin Screw, 3406 Cat, 8sp; ‘91 IH 2574 Straight Truck, Twin Screw, Cummins Dsl, 8sp; ‘88 Transcraft 53’ Double Drop Deck Semi Trailer, Dovetail, Ramps; ‘01 Tow Master Flatbed Trailer TO-20, Dovetail, Tandem Duals; Grain Vac, Augers, Spraying

Rem VRX Grain Vac, 282 Hrs; West eld MK130-71 Plus Swing Hopper Auger; Top Air TA1200, 80’, 46” Rubber, Hyd Pump; L&D 750 Gal. Sprayer, 60’, Hyd. Pump, Raven Controller;

Equinox, 36,750 Miles, Clean; ‘04 Ford F150, 171,111 Miles, 5.4L; ‘04 Ford Expedition, 4WD, 5.4L, 205,000 Miles; ‘26 Ford Model T Roadster; ‘57 Ford Fairlane, 4 Door, Parts Car; 2015 Polaris 90 ATV, Clean; 200+ Lots of Farm Support Equipment, Attachments & Tools Area Farmers

Hrs, 1285 Cutting Hrs, JD Link Ready, Clean; Puck 34’ Manure Bar, Krohne Flow Meter, 12 Shank, 6” Pipe, Dietrich Series 70, Auto

Rushford Office: 219 S Mill St.

MN | (507) 864-7755

Houston Office: 108 E Cedar St.

MN | (507) 896-7755

507-346-2579

17643 121st Avenue Spring Valley, MN

Spring Valley, MN

from page 15

In 2019, Anderson’s husband bought what is now Local World Gallery, and in 2021, she moved to Alma, Wisconsin. Since 2020, Anderson has been working fulltime as a potter and quit teaching. Prior to pottery, Anderson said she cleaned homes for three decades and her most recent resume is on a floppy disk.

Anderson focuses mostly on wheel-thrown pottery, although she will use a slab roller for platters and trays. She said that she likes the speed of working on the wheel.

“I really love wheel throwing,” Anderson said. “I love the process of it. I love the rhythm of it.”

Each week, Anderson throws around 8-10 tumblers and a few other pieces like vases. Tumblers are popular among her customers, but Anderson said her favorite item to make is a vase.

“It’s a bigger canvas for me to fill,” she said.

After the pottery is thrown and has reached the leather-hard stage, Anderson adds the liquid clay or slip. The slip contains colorant so it contrasts with the base clay it it contrasts with the base it is applied to. Once the slip is dry, she carves out the designs. To add color within the design, she applies a colored underglaze

“Everything about pottery is finding

the sweet spot,” Anderson said. “Just the right time, just the right firmness, just the right everything.”

Anderson said she has to be cognizant of her body as she carves, because she can get migraines from holding certain positions for too long.

Once the pieces are completely dry, they undergo bisque firing to 1,830 degrees. She then applies a colored liner glaze to the inside of the piece and a clear glaze to the outside of the piece. The final firing is at 2,285 degrees.

Anderson uses all-electric oxidation firing and she does several firings per month.

This winter, Anderson started teaching pottery classes at Iron Bridge Art and Clay in Wabasha. She said teaching over the winter months is helpful because it is a slower time of year for sales.

“The clay community that I’ve belonged to has always been so generous with their knowledge,” Anderson said. “This is a way for me to pay it forward.”

Anderson said one of the things she likes about teaching is that she can explain to people the reasoning behind her instructions to help students further understand.

“I try to respectfully impart the benefit of my 30-plus years of experience, regardless of a student’s skill level,” Anderson said.

Friday,

Acres Located in Udolpho Township Section 20 in Mower County, MN.

Bidding ends March 5.

Farm Address: 51479 305th St., Blooming Prairie, MN 55917

Wednesday, March 13th (online only)

Thursday, April 4th (online only) Estate Auction for John and Joan Mohoney Ring 1 John Deere tractors and machinery and Ring 2 Household items and collectibles

Bidding Opens: March 25, 8 am

Bidding Starts Closing: April 4, 3 pm

Inspection Dates: March 29, 10 am - 4 pm; April 3, 10 am - 4 pm

Spring Farmers Consignment Auction.

Bidding Opens: March 4 at 8 am

Bidding Starts Closing: March 13 at 10 am

Inspection Dates: March 4-13, 8 am - 5 pm

Payment & Loading: March 14 & 15, 8 am - 5 pm; March 16, 8 am - 1 pm; March 18-20, 8 am - 5 pm (Maring)

Thursday, March 21st @ 10 am (live and online) Low Houred Farm Retirement Auction for Warren and Lucinda Alleven

Auction Location: 24141 440th Ave., Delevan, MN 56023 watch for signs

Inspection Dates: March 15-21, 9 am - 5 pm

Only a 2 Hour Auction, Be On Time. (Maring)

Tuesday, March 26th (online only)

Spring Area Farmers Consignment Auction (advertising deadline March 1st)

Bidding Opens: March 15, 10 am

Bidding Starts Closing: March 26, 10 am (Hamilton)

Saturday, March 30th @ 9:30 am (live and online) Farm Retirement Auction for Glenn and Deb Johnson

Auction Location: 9368 SE 18th St., Claremont, MN 55924 watch for signs

Inspection Dates: March 23-30, 9 am - 5 pm (Maring)

Removal Times: April 5, 9 am - 5 pm; April 6, 9 am - 1 pm (Maring)

Sunday, April 14th (online only) Estate Auction for David W Olson Estate (Maring)

Sunday, April 14th (No-reserve, online only) Real estate auction on 2 bedroom rambler home on Lindsey Lake, MN.

Monday, April 22nd (online only) Estate and Moving Auction for Harris & Peggy Nelson Estate. Tractors, tools, lawn and garden, household items.

Tuesday, June 4th (online only) Early Summer Area Farmers Consignment Auction (advertising deadline May 1st) (Maring)

Saturday, August 10th @ 8:30 am (live and online) Pre Harvest Area Farmers Consignment Auction (advertising deadline July 9th) (Maring)

ST. CHARLES — LeRoy Schwartz did not have formal training in carpentry. Instead, he learned through doing.

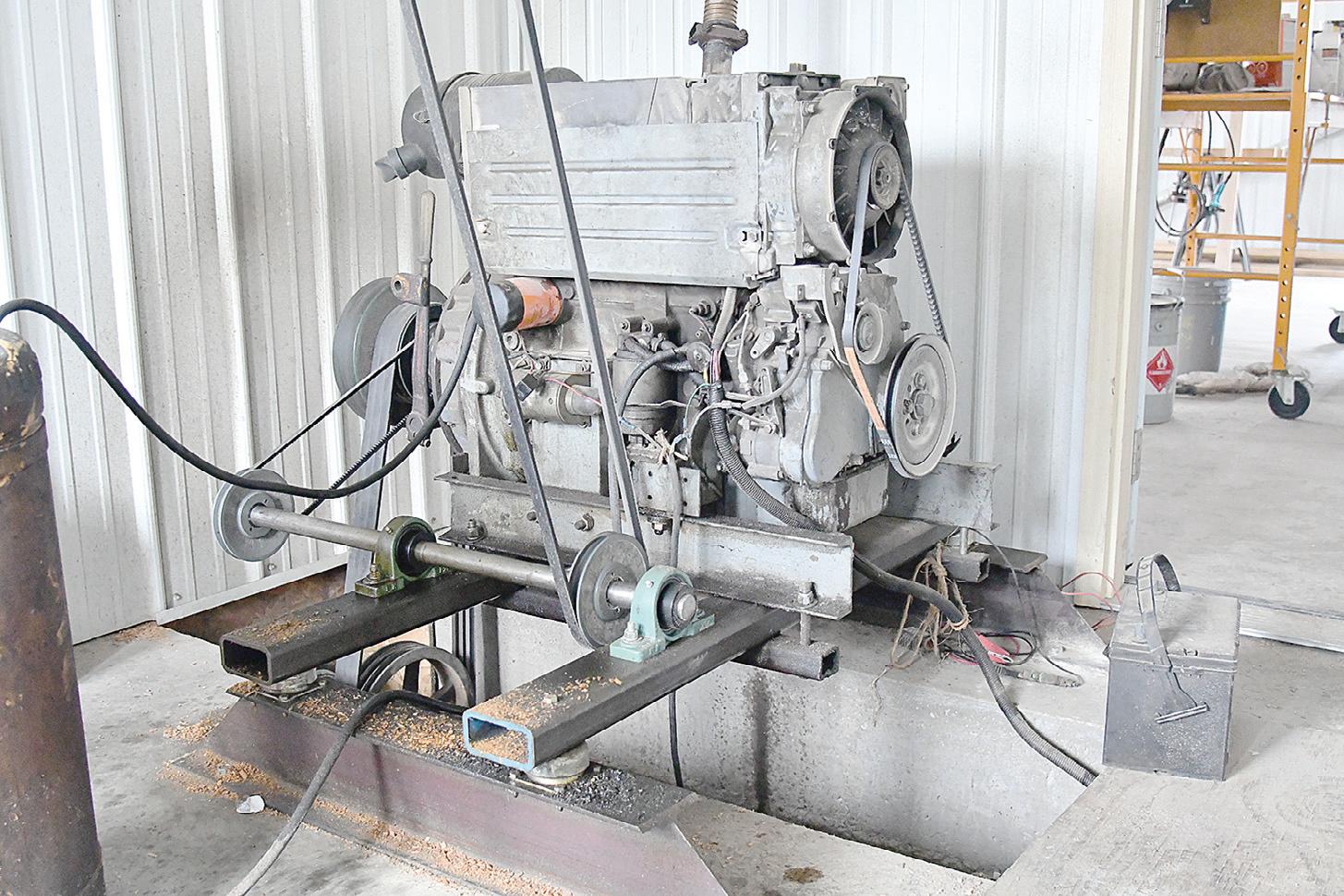

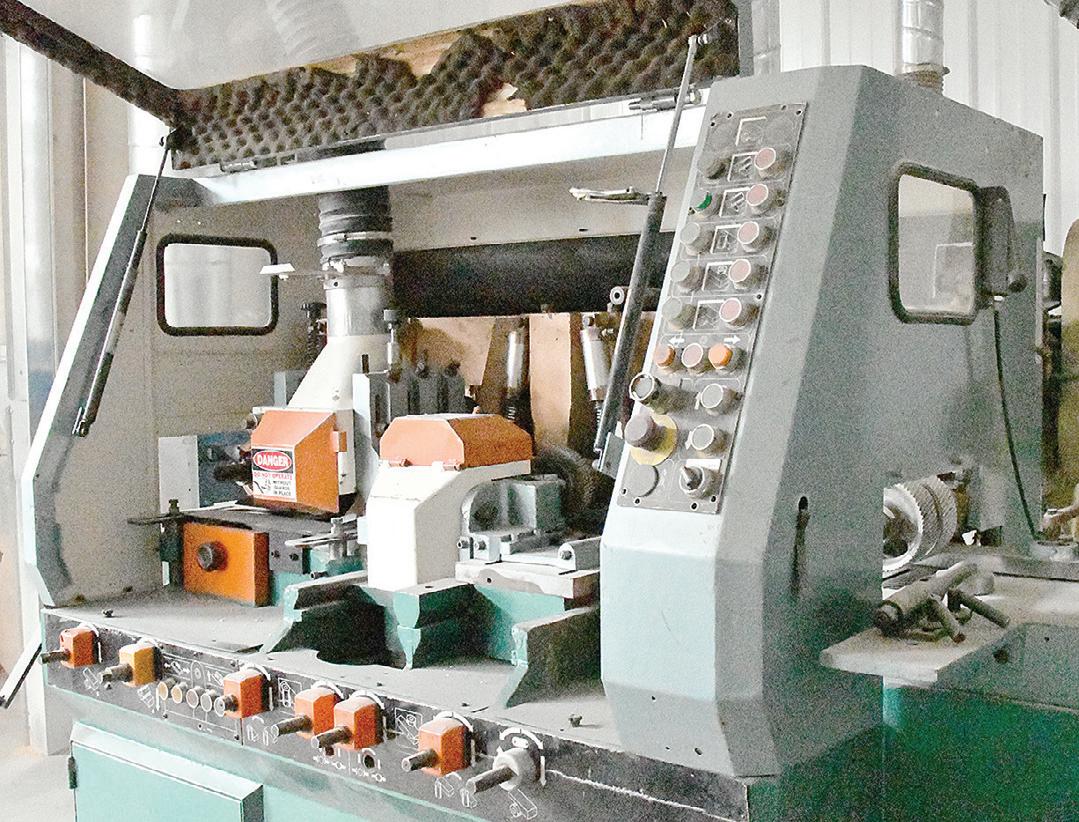

Schwartz owns Highview Millworks, a custom trim business operated out of his shop on his acreage near St. Charles. Schwartz, who is a member of an Old Order Amish community, has equipped his shop with specialized machinery powered by a diesel engine to avoid using electricity.

He creates custom trim work, with personalized styles, woods and stains. Schwartz also does the installation. “That makes me happy ... when I know people like it,” Schwartz said. Schwartz said he

has always been a shop person, albeit he also liked farming. His business, which started a few years ago, emerged through connections to the lumber yard his son used. Additionally, Amish building crews recommended him to the people they

were doing projects for. Schwartz completes every step of the trim process, from start to finish.

“The more I got lined up to go, the more work I get done,” Schwartz said. Schwartz works six days a week from 8 a.m. to 6 p.m. in his shop down the hill from his home.

All the equipment that would traditionally require electronics, is adapted to a line shaft and pulley system. His shop starts with an office. Then, in the large room a table saw, straight line rip saw, a jointer, a planer, a double head sander and the molder create the raw wood product.

In a 40-foot addition is a room for applying finish. The addition is walled off from the rest of shop, helping keep fumes from taking over the

space. There is also an exhaust fan with an air filter.

In the addition is the engine room. A line shaft travels through the cement in a gutter about 1 foot deep that extends across the shop under a wooden cover and runs past each of the woodworking machines.

Each machine is connected to the drive shaft, which spins at about 1,200 rotations per minute. They are powered via a pulley system.

“The machines are

Schwartz page 19

Schwartz from page 18

all set up for the right speed with the pulleys,” Schwartz said.

Each machine has a clutch system to engage the machine with the drive shaft so that all of Schwartz’s machines are not running simultaneously.

Depending on the power the machine would have gotten from the electric motor it came with, the pulleys are different sizes to give the machines more or less power.

Switching a machine from electric to a line shaft pulley system can be expensive. Schwartz said it could cost between $8,000-$10,000 to have a machine converted. In addition to the windows that let sunlight in, Schwartz’s shop is also equipped with several battery powered lights.

The central diesel engine that powers the equipment, also provides heat for the shop. The heat off the exhaust is exchanged. The hot exhaust heats 20 pipes which have fresh air blown through them, and the warmed, fresh air heats the shop.

The tools Schwartz has allow him to do work that is special-

ized. Schwartz can create different trim profiles, including custom profiles if a customer has an etch of what they want. He can have those custom cutting pieces made and he has many cutting pieces already on hand.

Schwartz page 20

Nutrien Ag Solutions

is looking for truck drivers for April, May and June, making deliveries of fertilizer, chemical and seed in

Harmony area. CDL Class A with tanker preferred, Class B or able to obtain seasonal ag permit. Hazmat a plus.

We are flexible on number of days worked per week. Stop at the office for Application or contact Scott at 507.886.4222

13723 US 52 Harmony, MN 55939

Sale opens at 9 am on March 7th

Bidding starts at 9 am

Online bidding starts 10:30 am at zenkeonline.com

11511 State Hwy 44 Caledonia, MN 55921

Selling Trucks, Trailers and Ag Equipment

Questions? Call Hoyt at 507-429-9999 or view complete listings online at zenkeonline.com

LICENSE

| APPRAISERS | REALTORS

WWW.ZENKEAUCTIONREALTY.COM

OFFICE: (507) 895-2090

CZMar2-1B-JM

First Southeast Bank in Harmony and Canton is seeking a detailed oriented individual for a full-time Customer Service Representative/Loan Operations Assistant position.

The qualified candidate will contribute to the success and growth of First Southeast Bank by providing support in both the deposit and loan operations, processing support, file maintenance, teller responsibilities and assistance to lending staff. Applicant must possess excellent organizational and communications skills along with being accountable, self-motivated, and professional, with the ability to adapt. Experience in Banking with strong computer knowledge preferred. First Southeast Bank offers an exceptional benefits package and competitive wage.

Please apply at First Southeast Bank, 3 Main Ave North, PO Box 429, Harmony MN 55939,

Attention: Debra A. Dowe Skaalen, Director of Human Resources.

firstsoutheastbank.com

CZMarch2-1B-JM

Hundreds of guns on hand to choose from, including Ri es, Shotguns and Hand guns plus the accessories you need to make all your hunting trips a success.

Each project has its own timeline depending on the size of the house or building and how many windows it has. However, on average, Schwartz said a project will take about 10 days of shop work and two days of installation to complete.

“I usually don’t leave that house until I know everybody’s happy,” Schwartz said.

Sometimes Schwartz will have the trim installed by someone else, but he does about 80% of the installation work himself.

Schwartz said that if he is both making and installing, he will do his own measurements. For a log cabin Schwartz has been trimming out recently, he said the measurements on the window frame deviated by almost an inch because of the differing size of the logs.

“It’s really precise,” Schwartz said.

he and his family milked goats. More recently, Schwartz made drawers for custom cabinet makers.

In 2016, his son purchased a lumberyard. There, requests for trim birthed Schwartz’s most recent venture. He moved to doing all trim because he liked it better than drawers.

“I have to do something for a living, and I don’t know what else I want to do,” Schwartz said.

Schwartz said he hopes to pass down his business to his family. He has four daughters living at home, and he wants it to continue as a vocation for one of their husbands.

18.4x50 Tires, 80% Block Heater, 3pt w/Top Link, John Deere 8400T Tractor, Large 1,000 PTO & 3pt, Newer Radiator/AC System/Interior, 10,211 Hours,International 560 Tractor, Gas, WF, 3pt w/Adapter, PTO, 2 Hyds., Chalmers B Tractor – Runs, Allis Chalmers B Tractor w/One Row Cultivator –Runs, Allis Chalmers B - Parts Tractor , IH 3444 Industrial Loader Tractor FARM EQUIPMENT: 2011 Meridian Bulk Seed Tender, Model 375RT, Scale, Remote, Shedded ,1993 John Deere 985 59’6” Field Cultivator, 3 Bar Harrow,John Deere 980 Field Cultivator, 28’5”, Knock-Off Sweeps, 4-Bar Harrow, Massey Ferguson 43 Grain Drill, Ferguson 2-14 Plow,New Holland 315 Square Baler, Super Sweep Pickup, Hyd. Controls w/Kicker, Bale Counter, Fertilizer Spreader, Tandem Axle, Hyd. Drive, Electric Controls, DMC Transfer 1700 Grain Air System, 5”, 3 Phase, No Monitor or Pipes, Miller Pro 500-gal Pull-Type Sprayer w/3 Sections, 45ft Boom, Raven Controls & Raven 440 Monitor w/Manual, Simonson 6-Ton Fertilizer Spreader, Tandem, PTO Drive,Degelman Rock Picker, DMI 5 Shank Disc Ripper, Tiger Mate II, Case IH 496 36ft Rock Flex Disc, John Deere Disc, BWF, 14ft, New Holland BR770 Round Baler w/Auto Wrap, Monitor & Manual, All new belts & tires, International 7 Bottom Moldboard Plow, On-Land Pull-Type, John Deere 1770 16-Row 30” Planter w/Liquid Fert.Wil-Rich 357 5-Shank 3pt Ripper, John Deere #37 Pull-Type Sickle Mower, John Deere 845 10ft Side Dress Bar, No Pump, Yetter Coulters , Houle 6000 Liquid Manure Spreader, New Straw Processor, Patz 290 TMR Mixer Wagon, REM 2500 Grain Vac, Speed King Seed Tender ANTIUQUE/HOBBY FARM ITEMS: 2John Deere 290 Planter, Pull-Type, 2 Rows Wide, Plates & Manual, Bushhog 3pt 8ft Chisel Plow,Pull-Type Potato Digger, Hand Corn Planter, Stockland Road Grader, Pull-Type, Model #10, Made in Minneapolis MN,

The trim builder said he likes working on new homes better than remodels for exactly that reason, he said the builds are more precise.

Schwartz said he would like to move out of the installation aspect of his business and focus on building trim.

“Just be busy at home,” Schwartz said. “It kind of goes together, so I don’t mind going installing.”

Schwartz’s father also was a craftsman. He built buggies and died when Schwartz was 13 years old.

Like his father, Schwartz too built buggies, from 1991 until 2018. Schwartz said he was not the cheapest builder, but he made quality products.

Schwartz has done a variety of trades throughout his career. He was a dairy farmer, working with cows for a few years. Then, from 2006 until 2019,

BY SARAH COLBURN STAFF WRITER

BY SARAH COLBURN STAFF WRITER

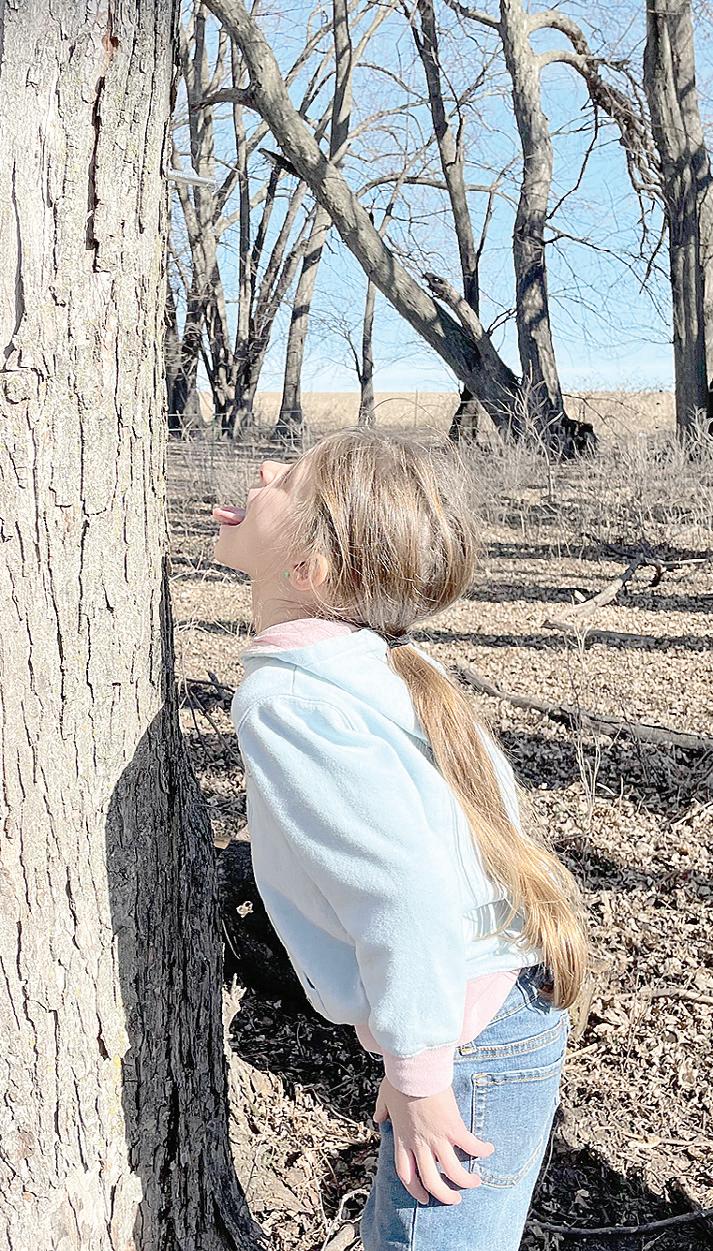

With the help of their children, the couple hangs pails from the row of thick-bodied, mature trees. With dappled shade over head and a layer of crunchy leaves under foot, the sap starts to flow Feb. 25.

“We don’t normally start

until March, I’m the latest person in the area to start tapping here,” Zane said. “I thought for sure the cold weather was going to return.”

This year, the Merrills are getting creative in storing their sap. They usually pour the sap into stainless steel milk jugs and store them in the creek on their land to keep them cool, but it dried up. So, they are harkening back to 1800s-era technology to chill the sap.

Just 2 miles west, Zane’s grandmother owns land, and there

sits a historic spring house at the headwaters of Bear Creek. The land was settled before the Civil War, and the spring house, with its stone foundation, served as refrigeration for perishables before the advent of electricity.

A second level wooden structure above the stone foundation served as living quarters for the Bear family, for which the creek is named, before the farm house was constructed. Over the years, Zane has maintained and repaired the building.

Merrills page 22

Merrills from page 21

“It grew my interest in doing repairs on old barns,” he said. “I’ve patched it up and kept it going.”

The Merrills operate Star M Farm in Eyota where they raise registered Dexter cattle and sell beef. They also create small squares of horse hay and raise laying hens, and Leslie cans goods including homemade salsa, pickles, jams and jellies. She also finishes off the maple syrup.

Zane’s work on the spring house inspired him to launch Merrill Versatile Services LLC, a business where he repairs houses, barns, garages and outbuildings.

“I really enjoy working on my buildings at home,” he said. “The buildings were kept up well, but my buildings needed a lot of maintenance.”

The couple bought the farm in 2017, and from the start, there was not only work to be done but evidence that the silver maples on the land had once been tapped for maple syrup. Two years after buying the farm, the couple decided to tap the trees themselves.

They researched hobbyists on the internet and came up with a plan.

Today, they tap around 20 trees, but they have 50 they could tap covering the east and south sides of their farm. With the trees they tap, they can collect 100 gallons of sap

in a few days which makes roughly 60 pints.

Their biggest limitation is time.

“The time to boil it down is pretty prohibitive,” Zane said. “We try to do it on the weekends.”

Typically, that means boiling the sap collected the previous week all day Saturday and Sunday. They usually plan three boiling weekends a season.

They boil the sap outside in pans over converted 55-gallon drums. Zane preheats the sap over a coal stove he fills with wood. Once the sap is warmed, he transfers it to a second pan to begin the boiling process.

He moves the sap through five pans to keep it from getting burned and to give him the ability to continually add sap to the first pan to keep the process moving. Once the sap hits the fourth pan, it is nearly turned into syrup and is then processed inside the house.

Leslie handles the product once it is brought inside. Typically, the sap is about 95% evaporated at that point. She brings the sap back to a boil, raising its temperature to 7 degrees above the boiling point of water. Then, she checks it with a thermometer or hydrometer, though she said she has better luck confirming its state by dipping a metal spoon and watching the syrup sheet off.

Once the syrup has reached the proper temperature, she runs it through a filter. The filter looks like a thick felt bag and is lined with three layers of paper. The syrup runs through the filter to remove any debris, ash and a sandy-like sediment.

When the syrup is still hot, she said, the filtering process can go fairly quickly, but as it cools, it can take 15 minutes to run through the filter.

She transfers the filtered syrup to a commercial-grade coffee percolator to keep it warm and then uses the spigot to fill the bottles. When filled warm, the process creates a natural seal for the syrup.

“It keeps it fresher longer,” Leslie said.

Right now, the Merrills do the majority of their sap boiling outdoors in the open air, before bringing it inside to finish it, but one day, they hope to build a sugar shack.

While they distribute their syrup to family and friends, their circle keeps growing as people learn of the product through word of mouth. Leslie sells syrup at craft shows along with her jams and jellies, and Zane is hoping to make his way to farmers markets this year.

Zane said maybe someday they will work to distribute the product through local grocery stores.

For Zane, the syrup is an extension of their work on the farm.

“I like making things here on the farm,” he said. “I like eating our own beef. I like eating our own eggs, making our own hay and feeding it to the animals.”

For Leslie, the work is about keeping things natural.

“I like knowing exactly where our food comes from, and I know what goes into it,” she said. “It’s pure.”