123 minute read

Advertiser Index

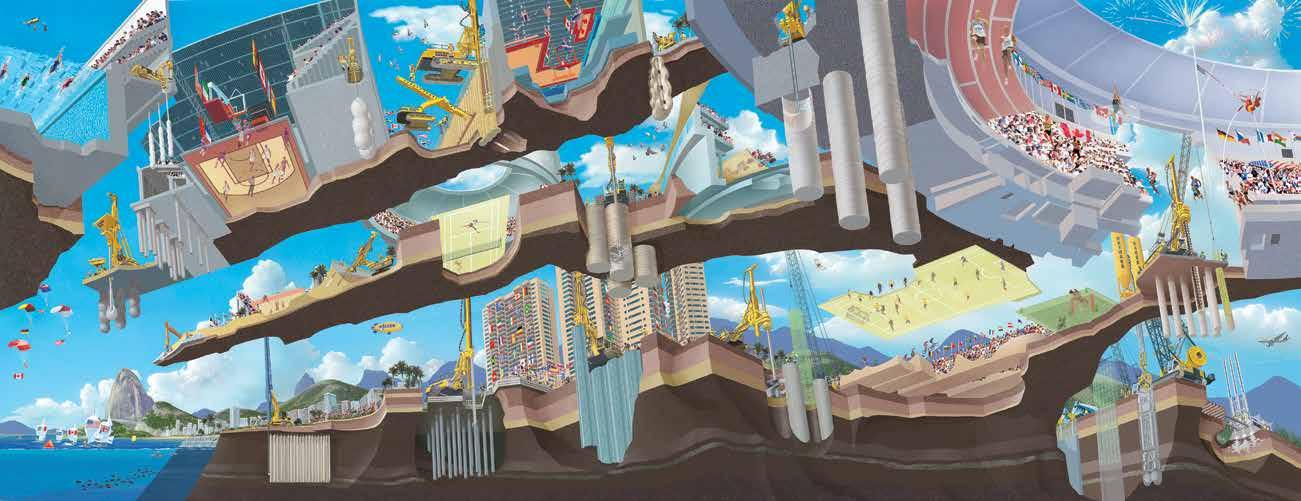

InFocus new trends, new techniques and current industry issues Toward a Bright Future By Barry Arnold, P.E., S.E., SECB

Jon Schmidt, and the past and present editorial board, did an excellent job of building STRUCTURE magazine into a high-quality, sought-after publication. Under Jon’s leadership and the talent and commitment of the editorial board, STRUCTURE magazine has become a widely-read and wellrespected publication. The profession owes Jon, those who served with him, and those who have contributed content to the magazine, our sincere appreciation. STRUCTURE magazine’s Vision Statement clearly defines the magazine’s destiny: STRUCTURE magazine will be the premier resource for practicing structural engineers. Its Mission Statement contains the road map of how the magazine will achieve its destiny: The Editorial Board will engage, enlighten, and empower structural engineers by publishing interesting, informative, and inspirational content in STRUCTURE magazine that is professionally relevant, technically reliable, and intellectually refreshing. To guide the Editorial Board in making decisions regarding magazine content, they adhere to the following, equally important, objectives: First, disseminate useful tips, tools, and techniques that will help structural engineers increase the quality, productivity, and profitability of their work; Second, introduce new and innovative concepts in structural engineering through project descriptions, case studies, lessons learned, and other approaches; and Third, promote structural engineering as a true profession, not merely a technical avocation, and highlight how it is unique from the other design disciplines. The Editorial Board, consisting of three members from ACEC/ CASE, three members from NCSEA, three members from ASCE/ SEI, and three members from industry, has done an excellent job of adhering to these objectives, mission, and vision. The Editorial Board’s work and contribution to the profession have been considerable and commendable. Having proven effective and valuable in the past, these are the objectives that the Editorial Board and I will continue following in pursuit of the magazines’ mission and vision. In addition to the types of articles you are familiar with, the editorial board will continue to seek out articles highlighting unique design approaches and imaginative solutions. STRUCTURE magazine should be a safe place to learn. It should be a place where questions can be asked and discussed freely, as well as a place where structural engineers can express innovative ideas and opinions and receive a respectful critique from their peers. STRUCTURE magazine must be a place where quality education and enlightenment are received without fear or embarrassment. It must be a place where structural engineers can look to re-stock their technical, business, and managerial toolboxes with relevant information. I may be the Editorial Chair, but I serve you and the profession. STRUCTURE magazine is your magazine. The members of the Editorial Board are open to your comments and suggestions, and we will eagerly review any content you submit. I want to provide a magazine you want to read. I want this to be a magazine you look forward to receiving and spending time reading, devouring the ideas it contains and discussing the design approaches presented during inner-office, lessons-learned type meetings. I want to use this medium to inspire structural engineers and instill a vision of what we can accomplish. I want the readers to be inspired to dream big and speak proudly about the profession. I want you to be encouraged to bravely stand up, stand out, and stand for something. My hope is that every structural engineer will be inspired by the articles they read, that they will embrace the people they read about as mentors and find value in the insights they share. I want every structural engineer to wear the title structural engineer proudly as a badge of honor, and be willing to defend it fiercely and fearlessly. I want you to believe in yourself as much as I believe in you. I want STRUCTURE magazine to remain surprising, novel, and interesting by including the work of thought leaders. I want you to see a future with abundant opportunity and ways to express your creative and technical skills and ability. Instead of worrying about changing the code every three years and complaining about having to obtain continuing education credits, we should worry that the value of being a structural engineer will plateau or decline. An engineer friend said that professional licenses were secure, and that the state would never take them away because they are a profitable revenue stream. Although his assessment and conclusion may be correct, it troubles me that, as a profession, we have missed the mark. If the only reason we are allowed to exist as a profession is because the states make money from licensing regulations, then somewhere along the way we have failed to adequately inform the public about the critical role we play in protecting their health, safety and welfare. Have the words professional and engineer become so over-used and so misused that they mean nothing? Have we spent so much time advocating structural engineering to structural engineers that our message hasn’t been heard by the public? Given all the accomplishments of the structural engineering profession, why, when the term engineer is mentioned, does the public only think of Howard Wolowitz? While I am serving you as Editorial Chair of STRUCTURE magazine, I want the Editorial Board to support NCSEA, CASE, and SEI as they take action to strengthen and improve the profession in meaningful ways, so that it will exist in grand splendor in the future.▪

Barry Arnold (barrya@arwengineers.com), is a Vice President at ARW Engineers in Ogden, Utah. He chairs the STRUCTURE magazine Editorial Board, is the Immediate Past President of NCSEA, and a member of the NCSEA Licensure Committee.

Structural DeSign

design issues for structural engineers

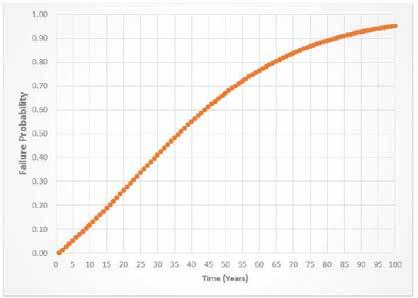

Historically, reinforced concrete has been thought of as very forgiving when it comes to the amount of time the material performs in service. Although there is a lot of truth to this, the environment inevitably can shorten reinforced concrete’s life expectancy, resulting in costly repairs and disruption to everyday life. When we think of durable concrete, the Pantheon in Rome comes to mind. This structure has been in service for well over 2000 years. If Roman concrete can last for centuries, surely current construction materials should be suitable to serve a 50 or 100 year design life. In some ways, assumptions on material durability may have influenced early specifications which fail to address material performance over time. As our understanding of durability increases, we expect increased performance of the materials we put into service. In the instance of landmarks or monuments, we want to build and preserve these structures in perpetuity. As we are constantly striving Durability of Reinforced Concrete to improve material performance, we simultaneously want to be more sustainable in our approach, and be proud of what we build. Like Roman engineering, attaining durable structures By Paul Noyce and Gina Crevello with an extended service life, like the Pantheon, should be our end goal. A vast amount of research was carried out on the durability of concrete from the 1970s to the 1990s and a great deal of technical knowledge was achieved. It is now possible to utilize this information in our designs to provide a level of confidence to owners on the future performance of reinforced concrete structures. To make reinforced concrete more durable, Paul Noyce is a concrete and a design approach has to be considered; the material durability expert. Paul is the Chairman of National Association of Corrosion Engineer’s (NACE) Standard Technical Group 01 for Reinforced Concrete. He may be reached at pnoyce@e2chem.com. Gina Crevello is material conservator. Gina is on the board of the Association for Preservation Technology International. She may be reached at gcrevello@e2chem.com. performance over time should be modeled where various dimensions and material specifications can be reviewed. This type of design is referred to as service life design (SLD), where the engineer can demonstrate performance of the selected structure over time, as seen in Figure 1. The SLD has to demonstrate the performance and degradation of the engineering materials. Both of these are heavily influenced by the environment which, in turn, is affected by local macro and micro climates. In addition to understanding the environment, knowledge of local materials is required, as this too varies greatly. Because of these variations, material performance and service life should be treated stochastically.

Performance and Degradation

The performance of a structure is typically seen as how well it is functioning related to its use. This can be further expressed as the performance of key principles like load capacity, stability, safety and visual appearance. Performance is regarded by many as a quantifiable property and is always a function of time. When considering time in evaluating performance, degradation of the structural materials is regarded as the most important factor. This links the structure’s performance directly with the durability of its materials. ASTM E632, Standard Practice for Developing Accelerated Tests to Air Prediction of the Service Life of Building Components and Materials, defines durability as the capability of maintaining the serviceability of a product, component, assembly, or construction over a specified time. Serviceability is viewed as the capacity of the above to perform the function(s) for which they are designed and constructed. Degradation is the reduction or decrease in performance over time and can be understood

as the inverse of performance; therefore, measuring degradation allows one to assess performance related problems. Performance is then measured by a minimum acceptable level, while degradation is set by a maximum acceptable level. These levels are known as durability limit states and can be defined for future performance measurements. The limit state can be set to either an ultimate or serviceability limit, which defines the service life and ultimately the performance requirements of the structure. When looking at degradation problems in reinforced concrete, the two main materials, the concrete and the reinforcing steel, are what impact the durability of the structure. The symbiotic relationship between reinforced concrete and steel ensures that, if defects exist within the original design or material selection and if load factors that enhance corrosion are present, deterioration will ensue. In turn, the environment in which these materials are installed impacts and defines their long term performance and degradation.

Service Life

Service life of materials can be assessed by their expected lifetime, or their acceptable period of use in service. As service life can be expressed in three ways, technical, functional or economic, then different use requirements are needed. In assessing service life as a business policy, financial tools and mathematical calculations can be carried out to develop a maintainability and reliability analysis. The questions regarding service life and maintenance are always related as maintenance routines are carried out during the service life of the structure. Maintenance activities, which influence service life, need due consideration. This changes the overall definition of service life which is stated as “when routinely maintained” as defined in TC 71-PSL Systematic Methodology for Service Life: Prediction of Building Materials and Components (Masters and Brandt, 1989). It is always the requirement of the owner to define the service life requirements and set forth the duration requirements, which sets the target service life.

Probability of Failure

When a target service life is set, a stochastic durability design will involve a definition of the maximum probability of not reaching a certain limit state. These limit states can be either an ultimate limit state (ULS) or a serviceability limit state (SLS). Two distinct types of failure exist, as either a durability failure or mechanical failure. However, in most instances, a material durability failure will be responsible for the mechanical failure. A maximum failure probability has to be set and defined by evaluating the consequences of the risk of failure. The risk is defined as the multiplication of the probability of failure by the amount of damage (Kraker, de Tichler and Vrouwenvelder, 1982). When considering how to set the required probability of failure, social, economic and environmental criteria should be considered. For social criteria, the importance of the structure and the consequences of failure, where human lives are at risk, is essential. Economic criteria should consider the financial consequences of disruption due to failure when these are considerably more than the construction cost. As with environmental and ecological criteria, consideration is due to either an environmental disaster or in line with ecological principles. Probability of failure can be applied during the design phase of new structures or to existing structures, as the principles are the same. The only significant difference is that the margin of safety used for existing structures will be much lower than new construction. continued on next page

ADVERTISEMENT–For Advertiser Information, visit www.STRUCTUREmag.org

Conceptually, a durability design is based around safety, where the structure must resist failure by various hazards it is exposed too. Safety has typically been applied to structural mechanics; however, we should not be so restricted in our design when dealing with the performance of materials. The use of this technique is increasingly advocated for dealing with durability and service life problems (Siemes, Vrouwenvelder and van den Beukel, 1985). By incorporating time into the design, we can now value the degradation of the materials as part of the overall problem. This time-based design has to set performance related requirements to ensure that the structure fulfils its long term service life goals for safety. This then has the effect of forcing the designer to ensure that the material selection will achieve the long-term durability requirement for the service life goals.

Category Class Condition

Freezing and Thawing (F) F0 Concrete not exposed to freezing-and-thawing cycles F1 Concrete exposed to freezing-and-thawing cycles with limited exposure to water F2 Concrete exposed to freezing-and-thawing cycles with frequent exposure to water F3 Concrete exposed to freezing-and-thawing cycles with frequent exposure to water and exposure to deicing chemicals Water-soluble sulfate (SO4 2-) in soil,

percent by mass[1]

Dissolved sulfate (SO4 2-) in water, ppm[2]

Sulfate (S) S0 SO4 2- < 0.10

S1 0.10 < SO4 2- < 0.20 SO4 2- < 150

150 < SO4 2- < 1500 or seawater

S2 0.20 < SO4 2- < 2.00 1500 < SO4 2- < 10,000

S3 SO4 2- > 2.00 SO4 2- < 10,000

The Environment

When considering a durability design, a key understanding of the environment and the exposure of the materials is essential in In Contact with Water (W) W0 W1 Concrete dry in service Concrete in contact with water and low permeability is not required Concrete in contact with water and low permeability is required achieving a good design. The building code requirements for structural concrete, the C0 Concrete dry or protected from moistureAmerican Concrete Institute’s ACI 318-14, defines exposure categories and classes as shown in Table 1. BS EN 206:2013: Concrete Specification, Performance, Production and Corrosion Protection of Reinforcement C1 Concrete exposed to moisture but not to an external source of chlorides Conformity, also provides exposure classes (C) Concrete exposed to moisture and an external source of for concrete durability, as shown in Table 2. C2 chlorides from deicing chemicals, salt, brackish water, seawater, Although both these tables differ overall, or spray from these sources it can be seen that they both consider the 1 Percent sulfate by mass in soil shall be determined by ASTM C1580. degradation of the materials. ACI categories 2 Concentration of dissolved sulfates in water, in ppm, shall be determined by ASTM D512 or ASTM D4130. are broken down by a damage mechanism and then class, with a variation of severity. As with BS EN 206:2013, the class is broken down based on wet and dry cycles, with various corrosion risks associated with a letter in the exposure class. As with most situations, a series of environments and contaminants can coexist on the same structure, so the design engineer must pay attention to this in the durability design. This can be extremely

NEW

engineering manual

STEEL DECK INSTITUTE s ®

DIAPHRAGM DESIGN

EDITION 4

STEEL DECK INSTITUTE s ®

The Fourth Edition of the SDI Diaphragm Design Manual (DDM04) complies with the requirements of the new ANSI/AISI S310-2013 North American Standard for the Design of Profi led Steel Diaphragm Panels. It includes new and expanded design examples and diaphragm strength tables.

NOW AVAILABLE

Figure 2. Holistic approach to durability. Courtesy of NRMCA.

X0 For concrete without reinforcement or embedded metal where there is no significant freeze/thaw, abrasion or chemical attack No risk of corrosion or attack

XC1 Dry or permanently wet XC2 Wet, rarely dry XC3/4 Moderate humidity or cyclic wet and dry XD1 Moderate humidity

Corrosion induced by carbonation

Corrosion induced by chlorides XD2 Wet, rarely dry other than from seawater XD3 Cyclic wet and dry XS1 XS1 Exposed to airborne salt but not in direct contact with sea water Corrosion induced by chlorides XS2 Permanently submerged from seawater XS3 Tidal, splash and spray zones XF1 Moderate water saturation without de-icing agent Freeze/thaw with or without XF2 Moderate water saturation with de-icing agent de-icing agents XF3 High water saturation without de-icing agent XF4 High water saturation with de-icing agent or sea water Chemical attack (ACEC classes) Refer to BS 8500–1 and Special Digest 111

complex on some structures but, if overlooked, can result in a degradation failure in an unacceptable period, which can cost many millions of dollars. As we repair structures today, durability and the environment are not considered enough in their role in leading to premature and costly maintenance repairs. The most deleterious durability failure of concrete is related to corrosion of the embedded reinforcing steel, which subsequently causes damage to the surrounding concrete and results in millions of dollars in damage, repair and associated ‘indirect’ costs.

Summary

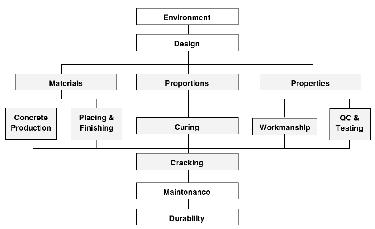

In summary, it is essential that a holistic approach is used for the design of durable concrete structures by considering multi-faceted aspects of the structure, the structure’s relationship to its surroundings, appropriate material selection, the utilization of proper construction methods, adequate quality control and planned maintenance. Figure 2 provides an overall holistic approach to the considerations required to provide durable concrete structures. As we can see from Figure 2, the overall approach to durability goes beyond the design engineer’s work. By reducing QA on a construction project due to cost and budget constraints, the long term performance of a building or a structure can be drastically affected. QA is still, in our opinion, one of the major factors in achieving long term durability of concrete structures. Whether designing new or fixing existing, attention to the installation of the work is paramount to the structure’s long term survival in our ever changing environment.▪

Design Aids and Solutions.

Analysis, design, done.

Use promo code DESIGN-15 and save 15% on our popular design guides at www.crsi-webstore.org.

24/7 continuing education and FREE technical and informational downloads at www.crsi.org!

Structural rehabilitation

renovation and restoration of existing structures

Figure 1.

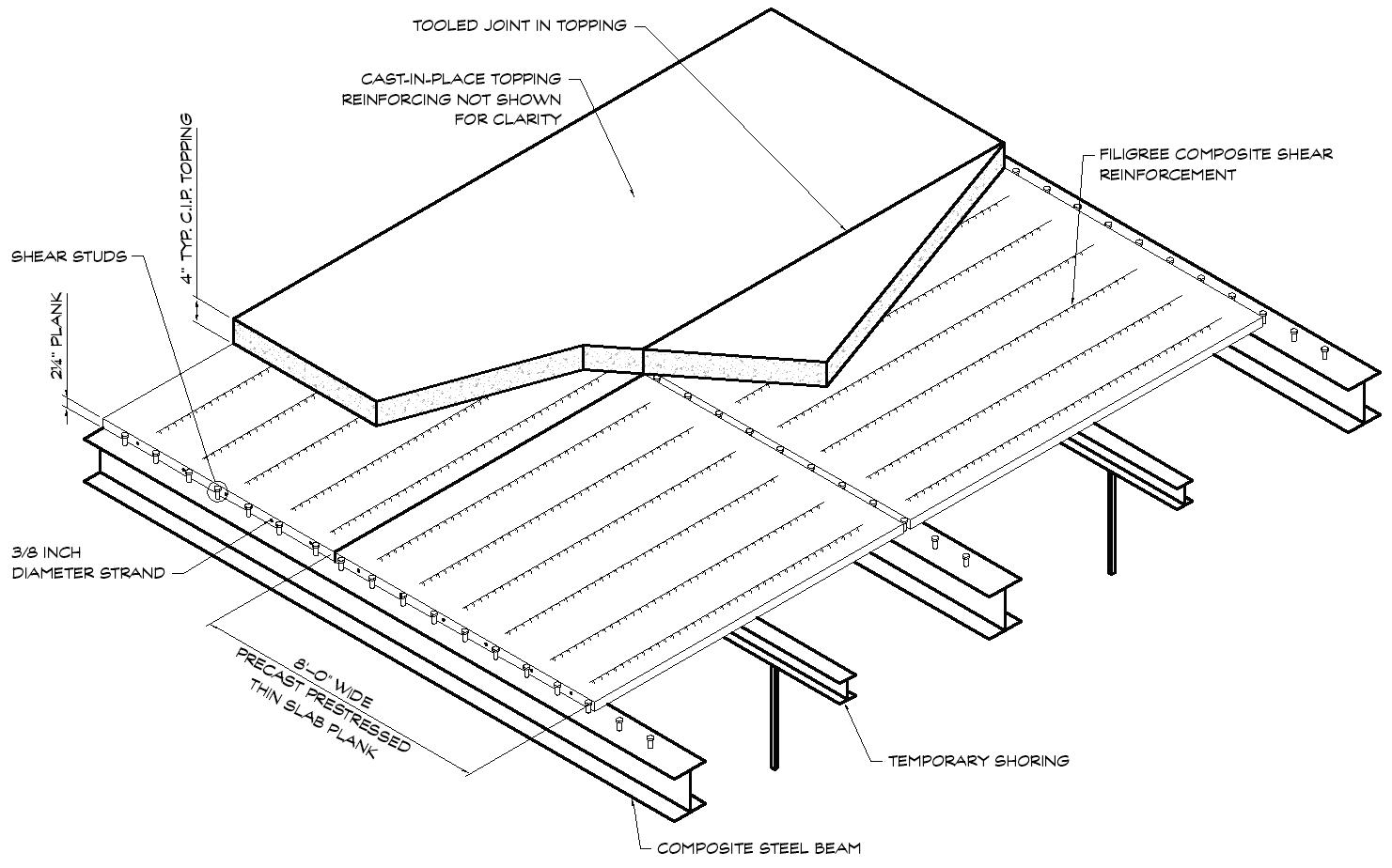

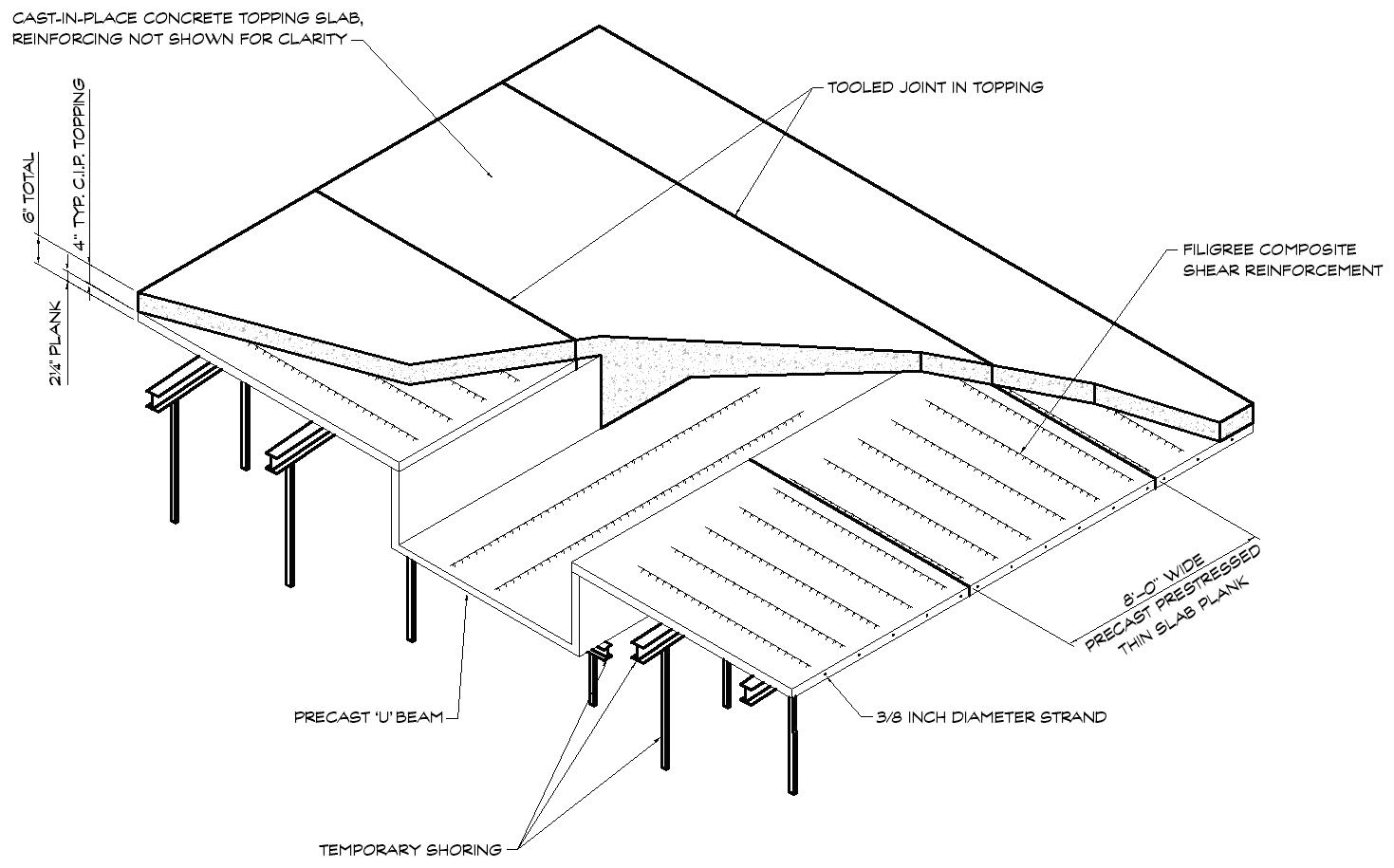

Precast, Prestressed Thin Slabs in Parking R ecently, Pennoni Associates was involved in the investigation and Garage Structures assessment of several existing parking garages constructed with precast, prestressed thin slabs. In this type of structural system, Or, When Thin is a Not precast planks function as stay-in-place formwork a Win-Win and become a part of an overall composite slab once a field-cast topping is placed and the shoring is removed. Although this type of construction is By D. Matthew Stuart, P.E., S.E., P.Eng., F.ASCE, F.SEI, SECB common in bridge decks, it is more unusual in parking garages, except perhaps in the Delaware Valley and surrounding region. In those areas, it is popular in cast-in-place concrete building construction as a voided system and is referred to as D. Matthew Stuart Wideslabs. There appear to be no similar precast, (MStuart@Pennoni.com) is prestressed thin slab products available for comthe Structural Division Manager mercial use in the remainder of U.S. at Pennoni Associates Inc. in Philadelphia, Pennsylvania. The System The cross-section of the thin composite slab typically consists of a 2¼-inch-thick by 8-footwide solid precast, prestressed concrete planks in combination with a minimum 4-inch-thick castin-place concrete topping. The system is capable of clear spans of roughly 20 feet between beams that act compositely with the topping – either structural steel (Figure 1) or precast U-shaped beams that are infilled when the field-cast concrete is placed (Figure 2). The erection of the planks and beams requires the use of temporary shoring that remains in place until the field-cast topping is placed and has achieved adequate compressive strength. The composite capabilities of the combined precast planks and cast-in-pace topping is provided primarily via vertical lattice or “filigree” reinforcing that is cast into the precast planks but protrudes above the top of them in order to engage the topping. The primary positive or bottom flexural reinforcing of the resulting system is provided by the prestressing strands (typically 3/8-inch diameter) in the precast planks, while the top or negative flexural reinforcing is provided via conventional deformed bars in the topping. Temperature and shrinkage reinforcing is also provided transverse to the slab span in both the precast planks and the cast-in-place topping. Unlike similar thin precast components used in parking garage construction, such as double tee flanges, mechanical plank edge connections (e.g., embedded plate weldments) are not employed along the abutting joints of adjacent planks. As a result, the nominal transverse reinforcing in the topping and aggregate interlock of the cast-inplace concrete are the only mechanisms available for transferring moving, concentrated vehicular wheel loads across the open joints below, as well as the tooled joints in the topping that generally align with the plank joints. A search of the available literature indicated that the structural capability of this portion of the thin slab system to function properly in a parking garage appears to be untested.

The Problem

Similar to an aged and failed, tooled and sealed topping joint in a typical double tee parking garage structure, joints in a thin slab garage structure will allow for moisture intrusion into the joint. The moisture, which is typically contaminated with chlorides from deicing salts either applied to the surface or brought in from the road by vehicles, tends to migrate through the

Figure 2.

joint. The moisture flows horizontally into the interface between the topping and precast via capillary action, and across the bottom surface of the soffit of the precast (Figure 3). As a result, any reinforcing steel that is adjacent to the joint will begin to corrode, causing the surrounding concrete to deteriorate. In a double tee flange edge, this can result in isolated damage to the connectors and mesh reinforcing, which can often be repaired conventionally. In a thin slab plank, however, the proximity of the outside strand to the joint edge can result in the corrosion of a portion of the primary positive flexural reinforcing in the composite slab system. If the two outside strands of a typical 6-strand plank become corroded to a point at which a considerable amount of cross-sectional area is lost, or the strand is completely consumed – which is frequently the case because of the relatively small diameter of the strand (Figure 4) – the associated 8-foot-wide section loses 33% of its positive moment capacity. This vulnerability of the thin slab system is exacerbated by the lack of an adequate vertical load transfer mechanism at the joints. This susceptibility was evident even in garages that were only 5 to 10 years of age in which the condition of the tooled topping joint sealant appeared to be in very good condition. Test results indicated that the same level of contamination existed at both the driving surface above and the plank soffit joint edge below, with water-soluble chloride content as high as 2.63% by mass of cement versus an ACIrecommended limit of 0.06% for prestressed members. Similar planks in bridge decks do not appear to exhibit this phenomenon, primarily because tooled and sealed joints in the topping are not routinely used in such construction. Petrographic testing of thin slab planks revealed additional susceptibilities of the product, including the lack of sufficient airentrainment and concrete cover beneath the strands that was less than the 1-inch minimum recommended by ACI for precast slabs. In addition, laboratory testing revealed significant coarse aggregate segregation due to high-slump concrete and/or over-vibration, as well as carbonation as deep as 1 inch from the bottom of the soffit.

The Solution for Older Garages

The inability of individual deteriorated planks with completely corroded strands to share the support of imposed vertical loads with adjacent intact planks, due to the lack of mechanical connections at the thin slab joints, caused concern for the structural integrity of these planks. Furthermore, it was also not unusual for adjacent strands in adjoining planks to be corroded as well. This led to the development of the following mitigation strategy for the unsafe conditions created in garages, that were approximately 30 years of age, by the loss of one or more strands out of the available six in each plank. Based on the age of these older garages, the original design live load was probably 50 psf. Comparing this with the current minimum garage live load of 40 psf suggested a reserve capacity of 10 psf, or 20% of the assumed original live load capacity of the planks. A loss of only one out of six strands equated to a strength reduction of approximately 17%, which was less than the 20% reserve capacity. Therefore, planks that had only lost one strand were deemed to be still capable of safely supporting the minimum imposed live load. continued on next page

Figure 5.

The loss of two out of six strands, which was the maximum strand loss documented in any of the 30-year-old planks, equated to a strength reduction of approximately 33%, which was greater than the 20% reserve capacity. These planks required the installation of aluminum shoring beams immediately below the location of the corroded strand, which were shimmed tight to the underside of the plank soffit. The shoring beams spanned between, and were supported by, the existing steel beams that provided the original support of the planks (Figure 5). The composite nature of the plank and topping, made possible by the vertical lattice shear reinforcing, also makes it difficult to facilitate conventional repairs to both the precast and cast-in-place components of the slab system. This is because the vertical shear reinforcing is not robust enough to avoid being significantly damaged when subjected to the renovation demolition of the surrounding concrete. Supplanting the existing shear reinforcement with alternate means of providing composite action was also not considered practical or economical. As a result, any repairs from the top surface or bottom soffit that encountered the shear reinforcement would cause a loss of composite action between the planks and topping. This condition meant that practical options for conventional concrete repair were extremely limited. Additional challenges in the older garages included the absence of a chloride extraction or re-alkalization system that would not risk hydrogen embrittlement of the strands, insufficient concrete cover over the reinforcing, and non-uniform air-entrainment and the resulting susceptibility of the concrete to freeze-thaw damage. Because of these impediments, the most practical and cost-effective method of renovating the older garages involved the complete demolition, removal, and replacement of the existing composite slab system. A review of several options led to the selection of a 3¼-inch-thick cast-in-place slab on top of a shored 3-inch-deep composite metal deck, for a total thickness that matched the original slab system.

The Solution for Newer Garages

The mitigation strategy for the newer garages, where the extent of chloride contamination and carbonation had not yet resulted in corrosion of the plank strands, was different. Due to the limited ability of the filigree vertical lattice reinforcing to withstand renovation demolition of the CIP topping and the difficulty of replacing it with an alternate method of ensuring composite action between the prestressed planks and the topping, the success of repairs to the surface delaminations was difficult to predict. This led to the recommendation to conduct a limited test program at one of the deteriorated surface areas in order to assess the potential for successful repair. In order to prevent further moisture intrusion at the plank joints and the subsequent introduction of road salts, the top wearing surface would be coated with a waterproofing membrane after such repair. The presence of significant chloride contamination of the plank soffits at the joint edges, even with the elimination of further chloride-contaminated moisture migration due to the presence of a new surface membrane, would result in the eventual corrosion of the affected strands. This potential existed because of the exposure of the concrete to ambient conditions, which would allow for enough humidity in the concrete to be present to enable corrosion cells to develop. The recommended solution was installation of a surface-applied, metalized cathodic protection system on the plank soffit at the area of chloride contamination. The recommended proprietary system was capable of providing long-term galvanic protection without damaging the prestressing steel via hydrogen embrittlement. The location and extent of the metalized cathodic system was established based on the results of an Electrical Resistivity survey. This allowed for the extent of the potential for corrosion to be mapped in areas not immediately adjacent to the plank joints, to ensure that the protection system did not have to be installed over the entire soffit.

Conclusion

The results of the investigation revealed the susceptibility of precast, prestressed thin slab parking structures to corrosion and resulting loss of strength over the life of this type of construction. It is interesting to note that the International Parking Institute began discouraging the use of this type of product in parking garages in 2004. In addition, a number of reputable consulting engineering firms that specialize in the design of parking structures do not recommend the use of precast, prestressed thin slab members in garages.▪

Technology

information and updates on the impact of technology on structural engineering

Tilt-Up and BIM

The Value Proposition

By Douglas G. Fitzpatrick, P.E. and Joe Steinbicker, P.E., S.E.

Douglas G. Fitzpatrick is President of Fitzpatrick Engineering Group in Cornelius, NC and is an avid BIM advocate. He can be reached at dfitzpatrick@fegstructural.com. Joe Steinbicker is a charter member and past chairman of ACI Committee 551, Tilt-Up Concrete Construction. He is also a founding member of the Tilt-Up Concrete Association and past member of their Board of Directors. He recently co-authored the book, Engineering Tilt-Up. He can be reached at joes@tilt-werks.com. I remember my first day of work as a young engineer like it was yesterday. The firm where I was starting my career was ceremoniously ditching the teletype machine that had provided them with computing power from a timeshared computer in a remote office building, in downtown Charlotte, NC, in favor of a desktop computer – a Wang SVP. It sported 32,000 characters of user memory (yes, characters – this was before MB and GB), a 500,000 character 8-inch diskette drive, and a 4 million character Winchester fixed disk drive. Some of you may have had one of these in your office. The ability to run our little programs from the main frame computer downtown via the teletype punch tape reader had been a significant improvement over hand calculations, although each time you hit the run button there was a charge. “Garbage in = garbage out” had a price tag to it back then. While our new Wang had a not so insignificant price tag, we quickly discovered it gave us much more computing power than we could have imagined and many more opportunities to experiment with programming and our designs. It didn’t take very long before we needed more computing power. We were really seeing benefits of local accessibility of the computer in the office but, more importantly, we were saving a significant amount of time. The computer had easily replaced hand number crunching with the enviable benefit of knowing if the programming was right, the answers would be right – every time – eliminating human error. The mundane repetitive calculations we were doing by hand could be automated and free us to focus other things. Of course, the rest is history. Computing power has grown by leaps and bounds. The sophistication of our analysis and design software has allowed us to economically analyze buildings that would have been unthinkable when I first graduated. The engineering community has been a significant beneficiary of what technology and computing power has to offer. And now, we have BIM – a way to virtually construct a building before anyone lifts a hammer. Architectural and engineering disciplines can perform an electronic mash-up of their work before handing it off to the construction team. For the first time, they have an opportunity to know that all of their systems work and play together well. Similarly, our construction partners have all seen significant improvements due to technology as well. Construction simulations, electronic tracking of materials at a job site, even laser scanning of existing conditions are common technologies at many of today’s construction sites.

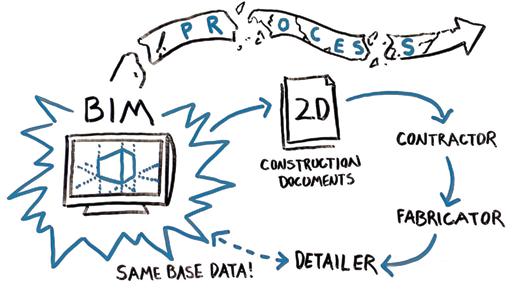

But Some Things Have Not Changed

Sadly, though, that’s where the significant technological improvements end. The way we get from design intent to construction has remained essentially unchanged since that first day as a young engineer (Figure 1). Our use of all of this wonderful 3D rich content dies with a hand-off of 2D paper drawings for construction. Both sides of the equation benefit greatly from technology individually, but the missing link – the gap between our two processes – is hindering the true efficiency improvements technology could really bring to bear on our projects. In 2004, I left my old firm and started out on my own. We adopted BIM in 2006 and quickly recognized its potential. As my new firm expanded our use of BIM, this gap between design and construction became more apparent.

Figure 2. Complete steel and tilt BIM combined together for visual coordination.

We do our work in BIM and hand off our design via 2D drawings, only to learn later that the contractor has recreated most of the original design models himself. Schedules are generally a driving factor in most of our projects. It seems like everyone needs to get into their building quickly and the current economy has only escalated the need. One of the ways the construction industry has responded is by involving construction trade partners earlier. Identify the tasks on the critical path and get those players involved earlier. On most of our projects, that usually means getting the steel fabricator involved at some point during the design phase. While I think we could agree that schedules have improved, it has been accomplished by taking an old, out dated process and simply making it faster, not more effi cient. Th is is apparent by the increasing amount of RFIs and change orders we engineers have to deal with. Earlier involvement means our drawings are less developed, which translates into lots of clarifi cations. On our projects, early involvement typically means the fabricator is hired based on a GMP before the design is fi nished which has consistently resulted in change orders. Th e constant parade of change orders for our steel buildings is not good for the industry, regardless of whether they’re justifi ed or not. Owners won’t tolerate having to pony up for more cost forever when they think they have been given a GMP.

The Process Needs to Change

In 2012, we set out to change the old outdated process. We fi gured out a way to share our structural data, multiple times during the design phase of the project, with a steel detailing partner to shorten the delivery of steel to our projects by 8 weeks. And, we eliminated the RFIs and change orders in the process by creating the steel fabrication package during design. Problem solved, with case studies to demonstrate the savings. Th e key factor here was leveraging our structural data and sharing it downstream. We could use it both to improve our productivity from analysis to construction documents; and also make downstream processes more effi cient, not just faster, by eliminating the recreation of data. Once we saw the benefi t this new process brought to the construction of our steel buildings, we started looking for other building types that could leverage what we had learned from steel. Our tilt-up projects seemed to be handicapped by many of the same problems. Our analysis is done in 3D, yet the method of communicating our design is 2D. Someone else is typically responsible for coordinating the minutia of details, completing the engineer’s design intent and delivering it to the fi eld in the form of shop drawings. And, much like our steel buildings, all of the construction phase work involves the recreation of data the engineer already has, and is subject to the same RFI and change order hazards.

Leveraging Lessons Learned

In 2014, we started looking for tilt-up design software that would address the following criteria and allow us to really take advantage of BIM: • Working with walls as opposed to individual panels to minimize the bookkeeping while the design was changing, i.e., four walls instead of 100 individual panels • Adding loads globally to walls and the program divides the loads to individual panels

SIGN UP FOR A FREE TRIAL TODAY

TILT-WERKS.COM Tilt-Werks is a Unique & Powerful New Technology

• Developed specifically for the tilt-up industry • Web based — Can be accessed anywhere, anytime Tilt-Werks Automatically Generates:

• Structural design for all walls/panels • Panel design/shop drawings • Panel reinforcing design & placing drawings • Complete panel reinforcing cut list • Material quantities & cost estimates • Dayton Superior product parts list & pricing • Building Information

Models (BIM)

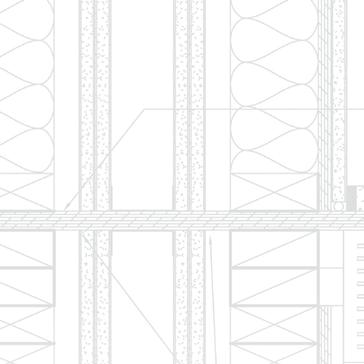

• Adding panel geometry, openings and embeds • Associativity of components – move a support line, and loads and embeds move with it • Automated determination and design of the panel • Automated generation of panel layout drawings and reinforcing drawings • A BIM ready 3D output of the walls – an IFC complete with panel joints and openings • Quantity take-offs that we could share with downstream users. Tilt-Werks® satisfied all of those criteria. So, what can you do with all of this design information to add value to your tilt-up projects with BIM? With some careful planning of modeling and origins, the BIM you get from your steel design program can be attached to the IFC model you get from the tilt-up software. The automated panel layout shop drawings from the tilt-up software – complete with embeds and openings – could be repurposed by attaching each drawing to the inside face of the wall IFC model at its respective panel location. That puts the steel framing, panels, openings and embeds all in the same context. As the design evolves, the steel BIM gets updated from the analysis program, and the exported IFC and panel drawings are refreshed from the tilt-up software. You could end up with something like Figure 2 (page 19). But Doug, you say, this looks like all the other images found on any company’s website on the internet. Where’s the value in another pretty picture? Not only that, this looks really tough to review and coordinate in 3D.

Leveraging BIM

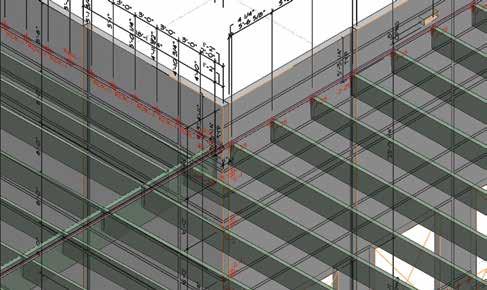

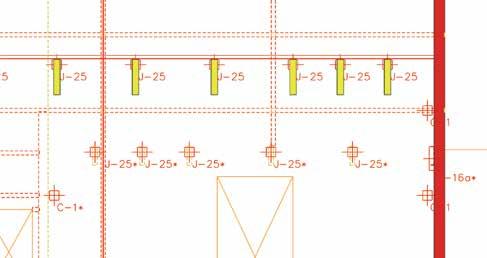

So, let BIM do all the work! By cutting sections at the face of the walls, coordination becomes very easy. The steel and tilt-up elements are all shown in context to one another and errors can be easily uncovered. If you set your view attributes correctly, you can see which members are on the near side of the wall (solid) and which are on the far side (dashed). If you develop an embed naming convention that distinguishes between embeds on the upcast and downcast faces of the panel, you can visually verify that the embed labeling matches the location of the steel members – before the panels get built. In our case, we use an asterisk to identify embeds on the downcast face. For coordination, we scan the extracted elevations (Figure 3) to make sure all embeds with an asterisk

Figure 3. Using BIM to verify embeds and framing in complicated areas.

Figure 4. Using BIM to resolve coordination errors for tilt-up construction.

have a dashed member at their location. If a solid member is found, one of the two is wrong and the correction can be made. Figure 3 is an example of a section cut with framing on both sides of the wall. This composite BIM can also be used to check for errors as well, not just the upcast or downcast location of embeds. Because there are two analysis programs (steel and tilt-up), it’s not unthinkable that a change in one program doesn’t get picked up in the other, particularly while the design is changing. BIM is a perfect environment to do this error checking (Figure 4). This is an example where a new bay was added, the steel framing was modified but the tilt-up embeds had not been adjusted accordingly. So, BIM can do a really great job of coordinating our steel design and tilt-up design. But, what if we take this a step further to add even more value? What if the quantity take-offs from the tilt-up software were shared with the tilt-up sub-contractor? If the take-offs are robust enough and include all of the items that the contractor needs to price the project – length of forming, gross and net square footage of the panels, length and size of reveals, quantities of embeds, tonnage of reinforcing, etc. – they could all be used at any point during the design to help monitor the cost of the structure. What contractor or owner doesn’t want to know where they stand during the design phases instead of waiting until the design is finished? At any point during the design you can provide a take-off that could easily have dollar amounts applied to it.

The Value Proposition

Some of this may seem like a lot of extra work; some of it may not. The first time or two will require some trial and error as you home in on a system that works for your office. But once set up, updating is almost automated. You are getting design information from your steel design program pushed down to your

steel BIM multiple times during design, and as the tilt-up design continues to mature you can generate updated drawings, an IFC and quantity take-offs at any time. Here’s a summary at some of the key valueadd you gain by doing this extra work: • Single source responsibility for the design and detailing. You are the EOR for the project. Your seal is on the building drawings. Who best knows how the building needs to go together.

Why not leverage that knowledge and put it to good use. Do the coordination yourself and know you have everything covered. You have to review the shop drawings anyway. • Better coordination. If you have worked in BIM (3D) before, surely you have discovered something you wouldn’t have caught in 2D until the project was in construction.

Why wait for something to get caught later, regardless of who is

“responsible”, and have to deal with the RFI (or change order) in panic mode during construction.

Coordinate early, save time later.

Leverage BIM to help with all of that work. • Speed to market. If your tilt-up design program is able to generate the panel layout and reinforcing drawings automatically, you can easily generate a complete set of field use drawings when you issue your construction documents.

Think of the time savings you can offer your client by shortening the typical construction schedule. • Quantity take-offs. If your tilt-up software gives you robust quantities (surface areas, embeds, weights, tonnages, reveals, etc.) at any time during design, allow that information to be used downstream.

This can be particularly helpful if you are working with a design/build or fast-tracked project. Everyone has their finger on the pulse of the project cost these days. Anything you could do to help with that would be valuable. lesser fee than you. Even though you know you do a better job than those other guys, trying to sell subjective benefits to a client (“better” engineering, faster response time to questions, always accessible, and just plain nice guys) is difficult at best and generally a waste of time. However, if you can show you can add real value to a project – specifically time and/ or money – now you have their attention. A difference in design fees could pale in comparison to the additional revenue an owner receives by getting in their building

The Bigger Picture

I think we could all agree that the last seven years have been pretty tough on both the design and construction communities. Design fees are under constant pressure and it seems there is always someone willing to take a project for a a month early. Leveraging BIM on your tilt-up projects is a great place to start for adding tangible value your clients will notice immediately. By the way, if you’re doing what everyone else is doing, you’ll get paid what everyone else is getting paid. Find something your firm does better than everyone else, leverage it to the max to differentiate your firm from the rest and figure out how to translate it into real value for your clients. Hopefully, the thoughts presented here give you a decent starting place for your tilt-up projects.▪

This article is a two part series which discusses special inspection provisions for wood construction in the 2015 International Building Code (Part 1) and perspectives from several States (based on the 2012 International Building Code) on suggested handling of special inspections regionally (Part 2).

Special inspection is not a new term to the building code. The International Conference of Building Officials’ (ICBO) Uniform Building Code (UBC) has had special inspection requirements in the code since the 1961 edition. The Building Officials and Code Administrators’ (BOCA) National Building Code first introduced special inspection provisions in 1988. The ICBO and BOCA codes had a slightly different philosophy and emphasis, which resulted in very different special inspection implementation approaches in ICBO jurisdictions from BOCA jurisdictions. When the International Code Council’s (ICC) International Building Code (IBC) was first issued in 2000, it merged the ICBO and BOCA special inspection requirements into its Chapter 17. Today, the IBC continues this practice with criteria included in 2015 IBC Chapter 17, titled Structural Tests and Special Inspections. The Special Inspections in Chapter 17 are in addition to the inspections identified in Chapter 1 Section 110 and although Chapter 1 will not be covered in this article, Section 110.3.4 Frame Inspection is specific to wood construction elements.

Background

Special inspection is a quality control measure intended to ensure that certain critical – mostly structural – features incorporated into a structure are constructed properly. This requires inspection by professionals (usually registered design professionals) with specialized skills and experience to verify that the material and workmanship comply with approved plans, specifications, and industry standards. Some aspects of construction may only need periodic inspection, while other aspects of construction require continuous inspection. In Codes and most cases, wood construction is only required to have periodic inspections. The authority to standards enforce provisions contained in the building code for special inspections rests solely with the local building official. Since a building official certainly cannot be expected to be an expert on all technical updates and discussions related to codes and standards building systems contained in a modern structure, inspectors are necessary who have special expertise to evaluate critical building components. The purpose of special inspections is to provide additional evaluation and inspections above and beyond inspections which are normally performed by the building department, particularity in areas of construction where strength, safety, and construction practices have been determined by the building code, registered design professional, or building official to be sufficiently critical to warrant a special inspector. Ensuring competence of the special inspector has always been and continues to be Special Inspections for Wood Construction – Part 1 the responsibility of the building official. The registered design professional in responsible charge and engineer of record involved in the By David P. Tyree, P.E., C.B.O., design of the project are permitted to act as the James B. Smith, P.E. and Michelle approved agency, and their personnel are permit- Kam-Biron P.E, S.E., SECB ted to act as the special inspector for the work designed by them, provided those personnel are qualified to perform the inspection and are approved by the building official.

Pre-fabricated Wood Members

The definition of a pre-fabricated item is located in Section 202 of the IBC. The definition notes that any item that is manufactured in accordance David P. Tyree is the Central Regional Manager, James B. Smith is the Midwest Regional Manager, and Michelle KamBiron is the Director of Education at the American Wood Council, Washington, DC.

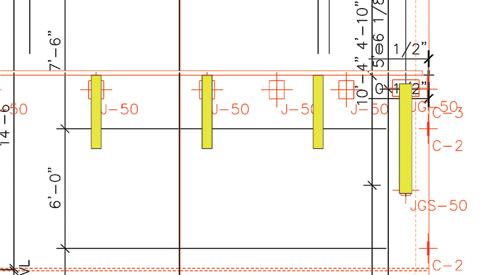

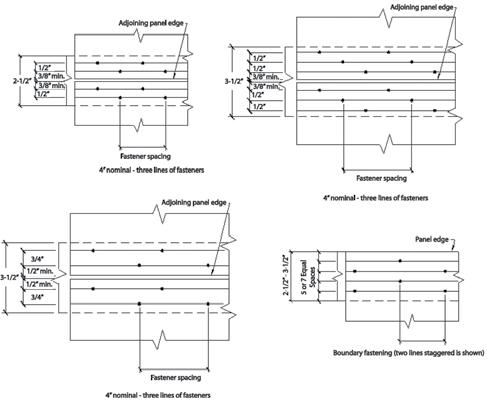

Figure 2. Special design provisions for wind and seismic – high load diaphragm nailing details.

with one of the standards referenced in the code (Chapter 35) is not to be considered a fabricated item and thus is not subject to the special inspection requirements of Section 1704. However, this exception is only permitted if the fabricator maintains approved detailed fabrication and quality control procedures that provide a basis for control of the workmanship and the fabricator’s ability to conform to approved construction documents and the code. As an example, most metal plate connected wood trusses, glued laminated timbers (glulam), and I-joists are manufactured to a referenced standard (such as ANSI A190.1 for glulam). Therefore, unless there is an unusual situation where a reference standard is not being used, special inspection of these items is not required by the IBC. Chapter 23 of the IBC specifies requirements for wood design and construction. Section 2303 specifies the minimum standards and quality control procedures for various wood products. Quality control certification programs such as those implemented by APA–The Engineered Wood Association, Truss Plate Institute, International Accreditation Service (IAS), etc., are covered under provisions specified in IBC Section 1704.2.5.1 for “fabricator approval.” These requirements include a comprehensive audit to stringent industry-specific performance criteria by trained auditors and industry professionals. IBC Section 1704 outlines requirements for special inspections and tests, contractor responsibility and structural observation. Since the 2000 IBC was published, this section of the code has changed several times and provides much more guidance for the building official.

Special Inspection and Tests

Where application is made to the building official for construction as specified in Section 105, the owner or the owner’s authorized agent, other than the contractor, shall employ one or more approved agencies to provide special inspections and tests during construction on the types of work listed under Section 1705. Per Section 1704.2, there are exceptions as to where special inspections are required including: construction of a minor nature or in situations where the building official does not feel special inspection is necessary; portions of structures designed and constructed in accordance with Section 2211.7 for cold-formed steel light frame construction or conventional light-frame construction in accordance with Section 2308; and, a Group U occupancy which is accessory to a residential occupancy including but not limited to those uses listed in Section 312.1. Additionally, it is noted in this section that the contractor is permitted to employ the approved special inspection agency where the contractor is also the owner. Prior to the start of construction, the approved special inspection agency is required to provide written documentation to the building official demonstrating that the special inspectors are qualified individuals who demonstrate competence, and relevant experience and training, for the inspection of the particular type of construction or operation requiring special inspection or testing. Generally, it is the opinion of most building officials that the increased involvement by the registered design professional in responsible charge during the construction process of a project will help facilitate early detection of code and structural problems, which can be resolved much more easily when caught at an earlier stage of construction. The building codes do not specifically state how a special inspector is to be considered qualified. Minimum qualifications are somewhat clarified in IAS Accreditation Criteria for Special Inspection Agencies (AC291), but additional assistance can be found in other documents concerning special inspection as well and can be of help to the building official.

Special Inspection for Wood Construction

Sections 1705.5.1, 1705.11 and 1705.12.2 of the IBC specify special inspection requirements for wood construction, and these are in addition to basic requirements of the frame inspection in Section 110.3.4. The IBC does not contain special inspection requirements for conventional wood frame construction per Section 2308, which is specifically exempted from special inspection as noted previously. The IBC specifies generally that all wood special inspections be “periodic” as opposed to “continuous”, except in Sections 1705.11.1 and 1705.12.2 where continuous special inspection is required during field gluing operations of the main wind force-resisting system in certain high wind areas and of the seismic force-resisting system in seismic areas. Therefore, the special inspection frequency is usually left to the special inspector’s discretion unless the structural engineer specifies a specific frequency of inspections in the Statement of Special Inspections.

Statement of Special Inspections

IBC Section 1704.2.3 requires a “Statement of Special Inspections.” The extent and duration of special inspections, as well as their frequency, should be clearly stated. Not all buildings are created equal; therefore, when considering the statement of special inspections, the required number of inspections for specific elements should take a number of factors into

consideration such as complexity of construction details, the general contractor’s wood construction skill and experience, building size, and staffing of the building department.

High-Load Diaphragms

Under the 2015 IBC, section 1705.5.1 requires special inspection of high-load diaphragms designed and constructed in accordance with Section 2306.2. Per Section 1705.5.1, the special inspector is required to complete the following when inspecting high-load diaphragms: • inspect the wood structural panel sheathing to determine whether it is the grade and thickness shown on the approved construction documents • verify the nominal size of framing members at adjoining panel edges • verify the nail or staple diameter and length (Figure 1, page 23) • determine the number of fastener lines • verify that the spacing between fasteners in each line and at edge margins agrees with the approved construction documents (Figure 2) Additional special inspection requirements for high wind and high seismic areas are listed in

Metal-Plate-Connected Wood Trusses Spanning 60 Feet or Greater

The 2015 IBC section 1705.5.2 requires special inspection when a metal-plate connected wood truss has a clear span of 60 feet or greater. The special inspector is required to verify that the temporary installation restraint/ bracing, and the permanent individual truss member restraint/bracing, are installed in accordance with the approved truss submittal package. This section specifically requires that the owner or his/her authorized agent employ one or more approved agencies to perform inspections on the temporary and permanent truss bracing during construction to verify installation is in accordance with the truss submittal package.

Section 1705.11 requires special inspections for wood buildings in Exposure B areas where design wind speed, Vasd, as determined in accordance with Section 1609.3.1, is equal to or greater than 120 miles per hour; and in Exposures C & D areas where Vasd is equal to or greater than 110 miles per hour. Continuous special inspection is required during field gluing operations of elements of the main wind force-resisting system, and periodic special inspection is required for nailing, bolting, anchoring and other fastening of elements of the main wind force-resisting system, including wood shear walls, wood diaphragms, drag struts, braces and hold-downs. Section 1705.11.3 goes further to state that special inspections should include periodic inspection for fastening of the following systems and components: roof covering, roof deck, roof framing connections, exterior wall coverings, wall connections to the roof, and floor diaphragms and framing (Figure 3b, page 26). Section 1705.12.2 requires special inspections for wood buildings when the building is located in Seismic Design Categories C, D, E or F. In these Seismic Design Categories, continuous special inspection is required during field gluing operations of elements of the seismic force-resisting system and periodic inspection is required for: nailing, bolting,

ADVERTISEMENT–For Advertiser Information, visit www.STRUCTUREmag.org

RFEM 5

Dlubal Software, Inc. Philadelphia, Pennsylvania (267) 702-2815 info-us@dlubal.com www.dlubal.com Join us:

Structural Analysis and Design Software

Structural Congress February 14-16, 2016 German Engineering Precision. NASCC April 13-15, 2016 DOWNLOAD FREE TRIAL www.dlubal.com Designed for American Innovation.

BIM Integration Non-linear Analysis Dynamic Analysis

Figures 3a and 3b. Periodic special inspection is required for nailing, bolting, anchoring and other fastening of elements of the seismic and main wind forceresisting systems, including wood shear walls, wood diaphragms, drag struts, braces and hold-downs.

anchoring and other fastening of the elements of the seismic force-resisting system, including wood shear walls (Figures 3a and 4), wood diaphragms (Figure 3b), drag struts, braces, shear panels, and hold downs. Sections 1705.11.1 and 1705.12.2 further provide for an exemption from special inspection for wood shear walls, shear panels, and diaphragms, including nailing bolting, anchoring, and other fastening to other elements of the main wind force-resisting system where the diaphragm fastener spacing is greater than 4 inches. This exception is intended to exempt less highly-stressed lateral force resisting systems from special inspection. Additionally, a general exception to special inspection for seismic force resistance is provided in Section 1705.12 for buildings of light-frame construction not exceeding a building height of 35 feet and located in areas where SDS does not exceed 0.5. The purpose of special inspection requirements in these areas is to provide additional public safety in higher wind and seismic zones, and to provide assurance for the structural engineer of record and the building department that the structure is being built in accordance with the proper design and performance specifications. with all of the requirements of the approved construction documents. Structural observation does not waive nor is it an alternative to the inspections in Section 110 or the special inspection requirements in Section 1705. Typically, observation occurs during significant construction stages and at the completion of the structural system. The objective of the structural observation is to become familiar with the progress and quality of the contractor’s work, and then determine if the work is being completed in general conformance with approved plans and specifications. Observation is a contract-negotiated activity which is usually performed by the structural engineer as a part of the normal scope of services. Structural observations are mandated for certain high wind or high seismic areas, Risk Category III or IV buildings, and in other circumstances in accordance with IBC Section 1704.6. At the conclusion of the work included in the permit, the structural observer is required to submit to the building official a written statement that the site visits have been made and identify any reported deficiencies that, to the best of the structural observer’s knowledge, have not been resolved.

Conclusion

Requirement for special inspections in the model building codes have been mandated since 1961; however, special inspections pertaining to wood construction have only been required for the past twenty-five years. Structural provisions in the building codes, including those for special inspection, have evolved based on experience following natural and manmade disasters. Certain types of wood construction require special inspections per IBC Chapter 17. Most commonly specified wood products have quality control and third-party auditing procedures in place that exempt the manufacturer from these additional requirements. High capacity (blocked) diaphragms and applications for certain high wind and high seismic zones, however, are the most common examples where special inspections for wood construction are required. Part 2 of this article will provide perspectives from several States (based on the 2012 IBC) on suggested handling of special inspections regionally.▪

Structural Observations

When required by Sections 1704.6.1 for those structures assigned to Seismic Design Category D, E or F or Section 1704.2 for those structures sited where Vasd , as determined in accordance with Section 1609.3.1 exceeds 110 mph, structural observations are to be provided on a project. Structural Observation is the visual observation of structural systems by a Registered Design Professional (i.e., licensed engineer or architect) for general conformance with approved construction documents. Structural Observation is intended to assist and supplement the work of the Building Official. Structural Observation by itself does not certify, guarantee, or ensure conformance

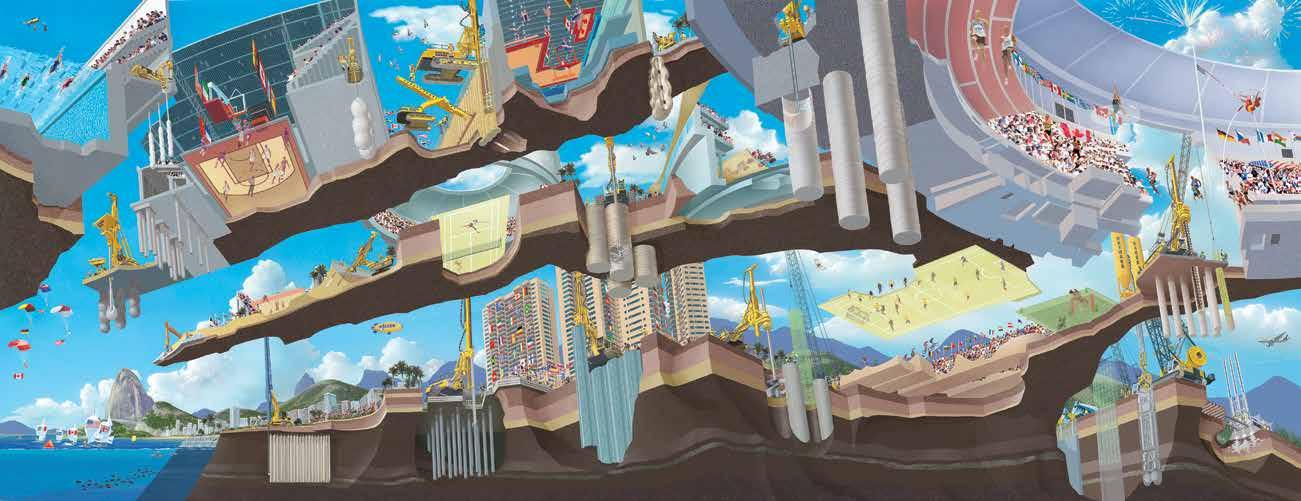

Foundation Companies Had A GOOD 2015 and Look Ahead to

A STRONG 2016

STRONG DOLLAR MAY IMPACT OVERSEAS PROJECTS

By Larry Kahaner

In a solid market for foundation services, companies are ramp- At Geopier Foundation Company (www.geopier.com), President ing up new products and services to keep pace with demand. Kord Wissmann says that the ground improvement industry as a “Because foundations are the first step in construction, this whole is changing rapidly and interfacing with the structure engiindustry tends to experience trends a little bit before the rest of neering community in lots of ways. “It seems that this part of the the construction market. By analyzing economic trends, I suspect we’ll whole ground-support-for-structures segment is expanding rapidly. continue to see the American market recover and yield good results for Within our company we have two new things that SEs might like the foundation industry,” says Gina Beim, Senior Consulting Engineer to know about. One is within the rigid inclusion realm of things. and Marketing Director at Pile Dynamics, Inc. (www.pile.com). For We have developed something called a GeoConcrete Column that her own company, she notes: “Business has been good, but the strong is being used to support fairly heavy loads on very, very soft soil. dollar is affecting sales in some international markets, particularly in Most of that work is being done on the East coast, New England Asia. In the United States, however, sales increased in 2015 when compared to the previous year.” For 2016, Pile Dynamics will launch a Thermal Integrity Profiler (TIP) new product called SQUID. Beim says, The Heat Is On. “SQUID is a large device that attaches to the end of the Kelly bar used in foundation drilling, and assesses the quality of the bottom surface of the bored pile Shape, quality, cage alignment and concrete cover of drilled shafts. or drilled shaft hole. It is a disruptive New TIP Reporter Assesses the entire cross section, technology, in that this assessment is shows soil profi le and reinforcing cage. no blind zones. currently made qualitatively only – visually, by means of a video camera lowered down the hole. The SQUID instead measures stuff – it’s a quantitative assessment, Testing with the TIP is fast and is done soon after casting, so construction can move on. which, of course, engineers prefer. The Complies with ASTM D7949. device measures the thickness of any soft material or debris still to be cleaned from the bottom of the hole. It can also take some measurements that evaluate the strength of the bearing layer, which is the layer at the bottom of the hole where www.foundations.cc www.pile.com/tip the shaft is supposed to rest.” engineering@foundations.cc sales@pile.com

and the mid-Atlantic regions,” Wissmann says. “GeoConcrete Columns are a form of rigid inclusions which are becoming quite popular to support structures. These are foundation, systems that are neither deep foundations nor are they shallow foundations, but something in between. Sometimes, when traditional forms of ground improvement don’t quite do the trick, then rigid inclusion is being used, a ground improvement element that’s constructed with cement.” He adds: “The second item is improvements to our Rammed Aggregate Pier systems. We have a hybrid called the X1 system. It’s a way of constructing a Rammed Aggregate Pier where we can partially drill a hole and then use our tool to displace the remainder of the hole. This particular type of compaction device does a good job of compacting the Rammed Aggregate Pier in place. The advantage to SEs is that it’s a more efficient way of building Rammed Aggregate Piers, saving time and money on projects.”

ADVERTISEMENT–For Advertiser Information, visit www.STRUCTUREmag.org

Wissmann sees a trend towards increased use of ground improvement and more methods for SEs to choose from. “Business is up this year versus last year. Last year was a tremendous year for us, and this year is still better.” (See ad on page 32.) Eric Droof, President of Hayward Baker (www.haywardbaker.com) says that some engineers are still not familiar with all the ground improvement services that are available. “I think these things are still not well understood by consulting geotechnical engineers. Consulting geotechnical engineers typically don’t have the knowledge or skills to design these solutions. Some of the solutions include products like soil mixing, earthquake drains, jet grouting, aggregate piers and rigid inclusions.” He says these methods are typically replacements for deep foundations, or solutions for very soft or difficult soil conditions. “They offer lower cost, reduced time for construction, reduced cost for foundation construction, and they also offer seismic mitigation in conjunction with foundation support.” continued on next page

ADVERTISEMENT–For Advertiser Information, visit www.STRUCTUREmag.org

GROUTING Cement Grouting (High Mobility Grouting) • Chemical Grouting • Jet Grouting Compaction Grouting (Low Mobility Grouting) • Fracture Grouting • Polyurethane Grouting GROUND IMPROVEMENT Dry Soil Mixing • Dynamic Compaction • Injection Systems for Expansive Soils • Rapid Impact Compaction • Rigid Inclusions (Controlled Stiffness Columns) Vibro Compaction • Vibro Concrete Columns • Vibro Piers® (Aggregate Piers) Vibro Replacement (Stone Columns) • Wet Soil Mixing STRUCTURAL SUPPORT Augercast Piles Drilled Shafts • Driven Piles • Franki Piles (PIFs) • Helical Piles • Jacked Piers • Macropiles® Micropiles • Pit Underpinning EARTH RETENTION Anchors • Anchor Block Slope Stabilization Gabion Systems • Micropile Slide Stabilization System (MS3) • Secant or Tangent Piles Sheet Piles • Soil Nailing • Soldier Piles and Lagging ADDITIONAL SERVICES Earthquake Drains Sculpted Shotcrete • Slab Jacking • Slurry Walls • TRD Soil Mix Walls • Wick Drains

DESIGN-CONSTRUCT SERVICES

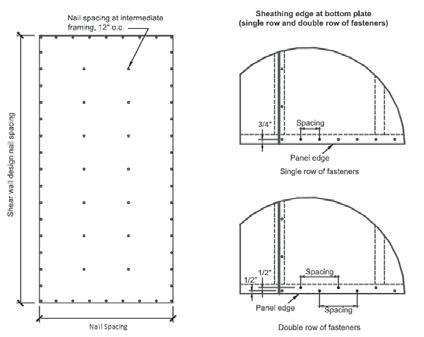

Says Droof: “Business is pretty good. Th e commercial markets in major urban areas have come back nicely. Places like New York, Miami, Atlanta and Los Angeles are all busy with the commercial sort of residential construction, as well as educational and hospital.” He says that the company is excited about a new project in lower Manhattan. “It’s a 55-story residential tower. We’ve just completed the jet grouting for it.” He says that the alternative would have been 190-foot deep drift shafts. “We believe it will be the fi rst high rise building in lower Manhattan that is not supported by a deep foundation.” At Adapt Corporation (www.adaptsoft.com), President Florian Aalami says: “We have made major advancements in our ADAPTBuilder software platform for integrated design of concrete buildings, in particular for the design of foundations using the ADAPT-MAT module. Structural engineers can now model a complete building, including all details of the foundation system. Global gravity and lateral analysis results are available for detailed foundation design, all within the same model, without requiring the need to fi rst export/import the solution between programs. Th is saves time and reduces errors often introduced when translating global building analysis results into separate foundation design programs. ADAPT-MAT can be used to design any type of foundation system.” Aalami notes that he sees a continuing trend towards BIM even though many practitioners are not completely clear about their BIM requirements. “We also continuously hear complaints about how it is much more effi cient to design and detail steel buildings, compared to what is possible for concrete structures. Th e potential to deliver ever more effi cient, complete

Geopier Ground improvement concrete design solutions is what keeps us motivated.” controls structure settlement As for business, Aalami says, “Th e U.S. market has been very strong this year, but we are seeing some softening in international markets. We largely attribute this to the slowdown in their economies and the weakening of many international currencies against the U.S. Dollar.” (See ad on page 28.) Th e company Subsurface Constructors (www.subsurfaceconstructors.com) has had a busy year, according to Lyle Simonton, Director of Business Development. “In addition to it just being an extremely busy year, Subsurface Constructors has had some exciting new experiences in 2015,” he says. “We completed Aggregate Pier ground improvement projects in several new states, including Washington, Alabama, and New Hampshire. We had some huge news with the opening of our New England offi ce, just outside of Boston. Having a physical presence in this region will help us to remain competitive Give your structure stability on bid day and provide better support to the engineering community.” Simonton adds: “More than ever before, Work with Geopier’s geotechnical engineers to solve your ground we are working directly with structural improvement challenges. Submit your project specifications to engineers during the design phase of receive a customized feasibility assessment and preliminary cost projects to help develop the optimum estimate at geopier.com/feasibilityrequest. foundation plan using Aggregate Pier ground improvement. We are providing 800-371-7470 them with specifi c project information regarding bearing pressures, which can be geopier.com achieved with Aggregate Piers.” info@geopier.com He says that Subsurface Constructors was fortunate to have been involved with several high profi le St. Louis area projects in 2015, including a large earth retention ©2016 Geopier Foundation Company, Inc. The Geopier® technology and brand names are protected under U.S. patents and trademarks listed at www.geopier.com/patents and other trademark applications and patents pending. Other project at the Gateway Arch foreign patents, patent applications, trademark registrations, and trademark applications also exist. and completing the ground improvement work for the St. Louis IKEA store.▪

A New Era of Women’s Health for Central Florida

By Kevin Casey, P.E., S.E., Bill Mitzo, P.E. and Nathan Morrow, P.E.

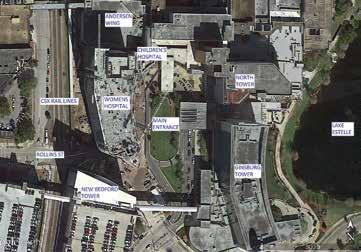

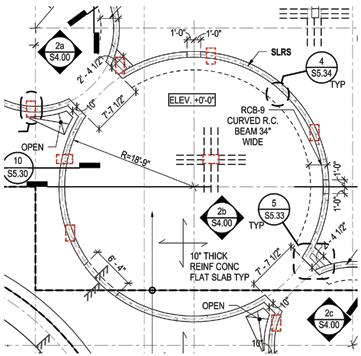

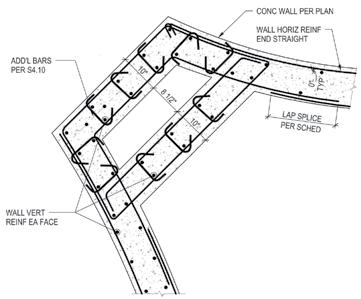

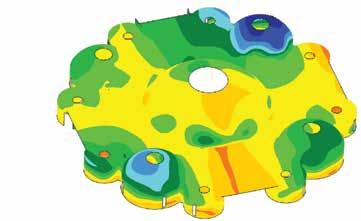

The Florida Hospital for Women is located on the main campus of Florida Hospital South in Orlando, FL. It is a 12-story, 430,000 square-foot facility dedicated to the health and well-being of women and new born children, with a 322-bed tower. Opened in December 2015, the facility includes 14 labor and delivery suites, 13 operating rooms for obstetric and women’s services, 72 postpartum care beds, mother-baby beds, high-risk beds and 80 neonatal intensive beds. The operating rooms accommodate robotic surgeries for obstetrics, including the da Vinci Surgical System for robotic minimally invasive surgery. The building is situated on a tight urban site bordered by CSX rail lines on the west, the 3-story Andersen Wing, an existing 40 year old hospital building, on the north, the 10 year old 7-story Walt Disney Pavilion for Children on the northeast corner, Rollins Street, a public street on the south and the main hospital entrance on the east.

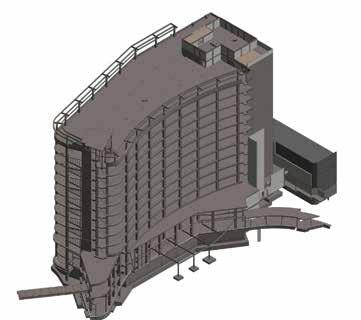

Structural Frame

A cast-in-place concrete building was the preference of the hospital, based on their previous success with concrete construction. The benefits to the hospital include: • Inherent fire protection • Accommodates future modifications and changes of use, with minimal disruption to ongoing operations in a sterile environment • Inherent ability to dampen vibrations The project team evaluated two framing systems during the schematic design phase. Preliminary designs were prepared by Paul J. Ford & Company (PJF) for a conventionally reinforced 27-inch deep module joist and beam system (5-inch slab + 22-inch pans) and a 12-inch conventionally reinforced concrete flat plate. Post-tensioning was not considered as conventional reinforcing is more easily modified for future floor penetrations and openings required for healthcare

Figure 1. Campus plan. facilities. The designs were evaluated by the team and the flat plate was selected based on the following benefits: • Accommodated an irregular column layout dictated by the building’s unique curvilinear shape • Minimized the structural floor depth allowing increased interstitial space for high demand MEP systems necessary for a hospital • Reduced the overall height of the building by 12 feet, reducing the cost of the building envelope • Simplified the form work and reinforcing steel placement • Increased the speed of construction Columns are typically 30 x 30 inches from foundation to roof. Interior columns from the foundation to Level 7 are 30 x 36 inches. Concrete strengths varied from 7000 psi to 5000 psi. Concrete reinforcing steel was specified to be Grade 60 for bars up to No. 9 and Grade 75 steel for No. 10 and No. 11 bars. Specifying the higher strength steel for the larger bars eased congestion by reducing the required number of bars, and saved placement costs. The material cost for the Grade 75 bars was 4% greater than the Grade 60 bars. The primary lateral load resisting system is an ordinary concrete shear wall system. A “blade” shear wall was required at the south end of the building to supplement the stair and elevator cores, in order to maintain torsional rotation within allowable limits.

Figure 2. Isometric view of Revit model. Figure 3. Progress as of September, 2015.

An elevated pedestrian bridge located between the second and third levels connects the new hospital to the New Bedford Tower on the south end of the hospital. Escalators connecting the bridge lobby to the main lobby on Level 1 dictated the need for a transfer girder over the escalators. A one-story connector was included along the north east corner that connects to the existing Children’s Hospital.

Vibration Study and Design